The Definitive Guide to Is Alumina Ceramic Durable: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for is alumina ceramic durable

Navigating the complexities of sourcing durable materials can be a daunting task for international B2B buyers, particularly when it comes to evaluating the longevity of products like alumina ceramics. As industries worldwide increasingly prioritize durability and performance, understanding whether alumina ceramic is durable enough for your specific applications becomes crucial. This guide aims to illuminate the essential characteristics that contribute to the durability of alumina ceramics, including their wear resistance, crack resistance, and electrical insulation properties.

In this comprehensive resource, we will explore various types of alumina ceramics, their diverse applications across multiple industries, and the key factors to consider when vetting suppliers. We will also address cost implications, helping you make budget-conscious decisions while ensuring quality and reliability. By providing actionable insights tailored to the unique needs of B2B buyers from Africa, South America, the Middle East, and Europe—such as those in Nigeria and Saudi Arabia—this guide empowers you to make informed purchasing decisions.

Ultimately, understanding the durability of alumina ceramics not only aids in selecting the right materials for your projects but also enhances operational efficiency and longevity, driving value for your business in a competitive global market.

Understanding is alumina ceramic durable Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Purity Alumina Ceramics | Contains over 99.5% alumina; exceptional chemical resistance | Aerospace, Electronics, Medical Devices | Pros: High performance; Cons: Higher cost than standard variants. |

| Zirconia Toughened Alumina (ZTA) | Combines alumina with zirconia for enhanced toughness | Cutting Tools, Wear Parts | Pros: Excellent fracture toughness; Cons: More complex manufacturing process. |

| Alumina Composites | Incorporates other materials for tailored properties | Automotive, Oil & Gas | Pros: Customizable; Cons: May compromise some inherent alumina benefits. |

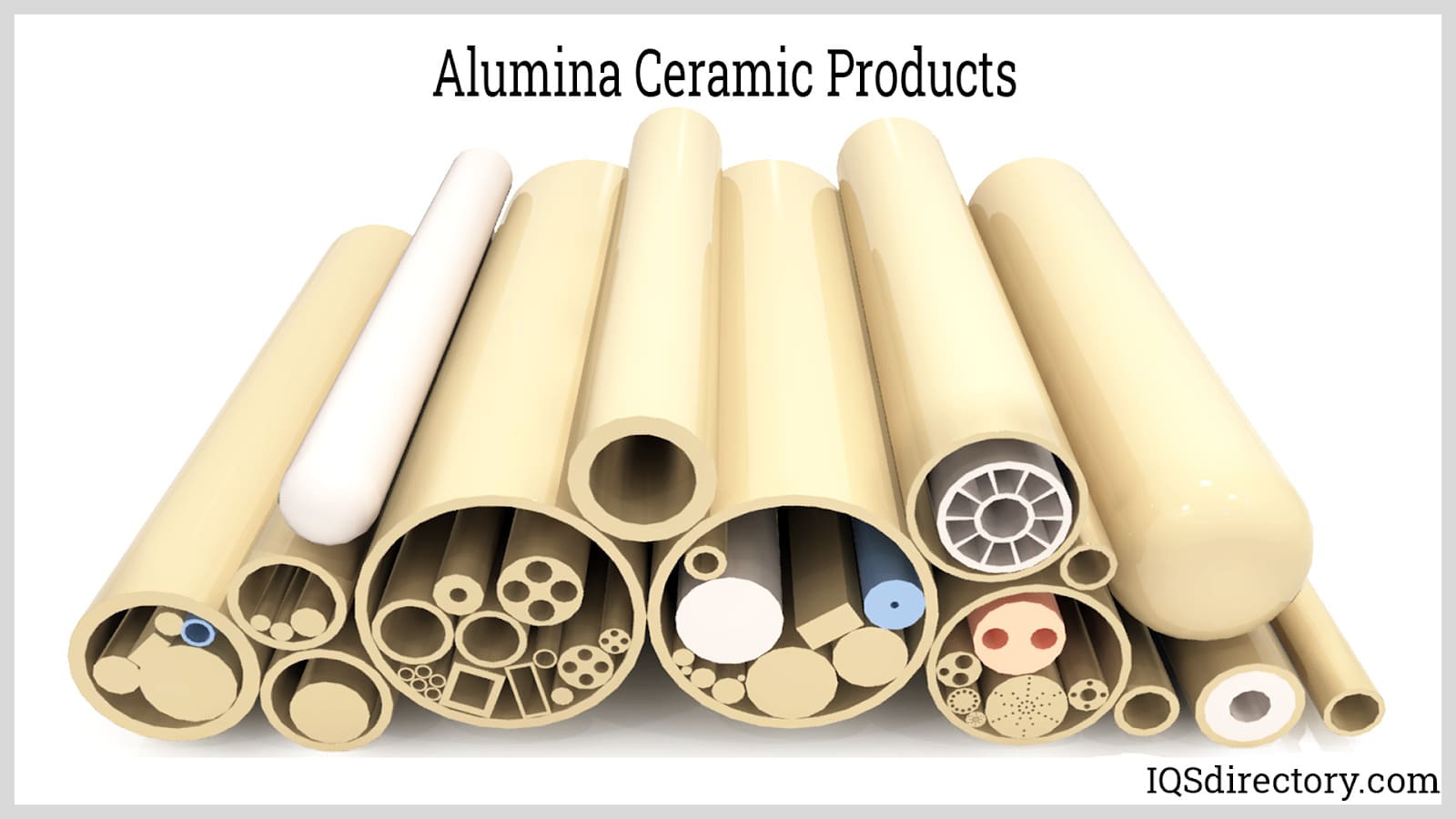

| Alumina Ceramic Tubes | High thermal stability and electrical insulation | Thermal Insulation, Laboratory Equipment | Pros: Versatile applications; Cons: Limited size options may restrict use. |

| Alumina Ceramics with Self-Lubrication | Low friction coefficient for reduced wear | Conveyance Systems, Mechanical Components | Pros: Reduces maintenance costs; Cons: May not suit all environments. |

What Are the Characteristics of High-Purity Alumina Ceramics?

High-purity alumina ceramics are characterized by their exceptional purity levels, typically exceeding 99.5% aluminum oxide content. This purity translates to superior chemical resistance and mechanical strength, making them ideal for demanding applications in aerospace, electronics, and medical devices. B2B buyers should consider the specific performance requirements and potential cost implications, as these ceramics tend to be more expensive than standard variants.

How Do Zirconia Toughened Alumina (ZTA) Ceramics Enhance Durability?

Zirconia toughened alumina combines alumina with zirconia to enhance toughness and resistance to fracture. This type of ceramic is particularly suitable for cutting tools and wear parts, where durability under stress is critical. When purchasing ZTA ceramics, businesses should evaluate the trade-off between enhanced toughness and the complexities involved in the manufacturing process, which may affect lead times and costs.

Why Consider Alumina Composites for Custom Applications?

Alumina composites incorporate various materials to create tailored properties that meet specific industrial needs. These composites are popular in the automotive and oil & gas industries due to their customizable nature. However, buyers should be aware that while these materials can provide enhanced performance characteristics, they may also compromise some of the inherent benefits of pure alumina ceramics, such as thermal stability.

What Are the Benefits of Using Alumina Ceramic Tubes?

Alumina ceramic tubes are known for their high thermal stability and excellent electrical insulation properties. They are widely used in thermal insulation and laboratory equipment, providing reliable performance in extreme conditions. B2B buyers should assess the range of available sizes and specifications, as limited options might restrict their application in certain projects.

How Do Self-Lubricating Alumina Ceramics Reduce Maintenance Costs?

Alumina ceramics with self-lubricating properties feature a low friction coefficient, which minimizes wear and tear in mechanical applications. These ceramics are ideal for use in conveyance systems and mechanical components, as they can significantly reduce maintenance costs over time. However, businesses should ensure that these materials are suitable for their specific operational environments, as not all applications may benefit from their unique properties.

Key Industrial Applications of is alumina ceramic durable

| Industry/Sector | Specific Application of is alumina ceramic durable | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Thermal insulation components | Enhanced safety and performance in extreme temperatures | Certifications for aerospace standards and performance data |

| Oil & Gas | Corrosion-resistant piping systems | Long service life and reduced maintenance costs | Material specifications and resistance ratings |

| Electronics | Insulating substrates for electronic components | Improved reliability and efficiency in electrical systems | Electrical insulation properties and compatibility |

| Mining & Minerals | Wear-resistant liners and parts | Reduced downtime and operational costs due to durability | Sourcing from manufacturers with proven wear resistance |

| Automotive | Engine components and brake systems | Increased performance and longevity of automotive parts | Compliance with industry standards and testing certifications |

How is Alumina Ceramic Durable Used in Aerospace Applications?

In the aerospace sector, alumina ceramics are utilized for thermal insulation components that protect sensitive equipment from extreme temperatures encountered during flight. Their durability ensures that these components can withstand high thermal stress without cracking or degrading, which is crucial for safety and performance. For international buyers, especially in regions like Europe and the Middle East, sourcing from certified manufacturers who can guarantee compliance with aerospace standards is essential to ensure reliability and safety in aviation applications.

What Role Does Alumina Ceramic Play in Oil & Gas Industries?

Alumina ceramics serve as corrosion-resistant piping systems in the oil and gas industry, where exposure to harsh chemicals and extreme conditions is common. The durability of alumina ceramics significantly extends the lifespan of these systems, resulting in lower maintenance costs and reduced downtime. Buyers from Africa and South America should consider manufacturers who provide comprehensive material specifications and performance ratings to ensure that the products meet the rigorous demands of this sector.

Why are Alumina Ceramics Essential in Electronics?

In the electronics industry, alumina ceramics are used as insulating substrates for various components, including capacitors and circuit boards. Their exceptional electrical insulation properties enhance the reliability and efficiency of electronic systems, making them indispensable in high-performance applications. B2B buyers in Europe and the Middle East must prioritize sourcing materials that meet specific electrical resistance standards and compatibility requirements to ensure optimal performance in their products.

How Do Mining & Minerals Benefit from Alumina Ceramics?

Alumina ceramics are employed as wear-resistant liners and parts in mining and minerals processing equipment. Their durability helps to minimize wear and tear, leading to reduced operational costs and extended equipment lifespan. For buyers in South America and Africa, it is vital to partner with manufacturers that have a proven track record in producing high-quality, wear-resistant products to maximize operational efficiency and minimize downtime.

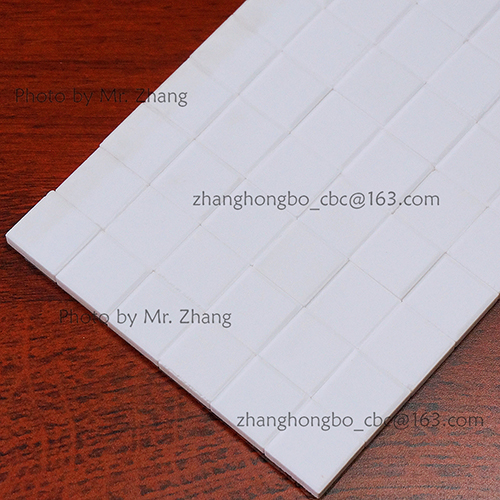

Illustrative image related to is alumina ceramic durable

What Advantages Do Automotive Applications Gain from Alumina Ceramics?

In the automotive industry, alumina ceramics are integrated into engine components and brake systems due to their strength and heat resistance. This durability translates into improved performance and longevity of automotive parts, which is critical in a competitive market. International buyers should focus on sourcing materials that comply with industry standards and have undergone rigorous testing to ensure reliability and performance in automotive applications.

3 Common User Pain Points for ‘is alumina ceramic durable’ & Their Solutions

Scenario 1: Concerns About Wear Resistance in Harsh Environments

The Problem: B2B buyers often face challenges when sourcing materials that can withstand extreme wear conditions, especially in industries like mining, oil and gas, or heavy manufacturing. They may have experienced premature failure of components made from less durable materials, resulting in costly downtime and repairs. This raises significant concerns about whether alumina ceramics can truly deliver the wear resistance required for their specific applications.

The Solution: To ensure that alumina ceramics meet the wear resistance needs, buyers should focus on obtaining detailed technical specifications from suppliers. Look for products that have been tested for wear resistance in conditions similar to those in your operations. It is advisable to request case studies or performance data from manufacturers showcasing how their alumina ceramics have performed in high-wear applications. Additionally, engaging in discussions with technical support teams from suppliers can provide insights into optimizing the material’s use, such as proper installation techniques or recommended operational parameters that prolong the lifespan of alumina components.

Scenario 2: Uncertainty Over Thermal Stability in High-Temperature Processes

The Problem: In industries where high temperatures are the norm, such as ceramics manufacturing or metal processing, buyers often worry about the thermal stability of the materials they are considering. They may have encountered issues with materials that warp or crack under intense heat, leading to production delays and increased costs. As a result, they seek assurance that alumina ceramics can withstand the thermal stresses they will face in real-world applications.

Illustrative image related to is alumina ceramic durable

The Solution: To address these concerns, buyers should prioritize sourcing alumina ceramics that are specifically formulated for high-temperature environments. When evaluating potential suppliers, inquire about the material’s thermal shock resistance and maximum service temperature. It’s beneficial to request samples for preliminary testing in your specific application environment. Buyers should also consider collaborating with suppliers on pilot projects to assess performance before full-scale implementation. Ensuring that the ceramics are properly treated and finished can further enhance their thermal stability, so buyers should discuss these options with their suppliers.

Scenario 3: Electrical Insulation Needs in Specialized Applications

The Problem: For companies in the electronics or electrical sectors, the insulation properties of materials are critical. Buyers might struggle with sourcing alumina ceramics that not only provide the necessary electrical insulation but also maintain performance under operational stresses like vibration and thermal cycling. This can lead to safety concerns and potential failures in electrical systems, affecting overall operational integrity.

The Solution: To navigate these challenges, buyers should conduct thorough research into the electrical insulation properties of alumina ceramics. Seek out products that meet relevant international standards for electrical resistance, such as GB1843. Engaging with suppliers who specialize in electrical applications can yield better insights into which formulations provide superior insulation. Buyers should also consider the geometry and design of the components, as this can impact their insulating capabilities. Implementing a rigorous testing protocol for newly sourced materials can help in validating their performance under the specific conditions they will encounter, thus ensuring reliability and safety in electrical applications.

Strategic Material Selection Guide for is alumina ceramic durable

What Are the Key Properties of Alumina Ceramics That Contribute to Their Durability?

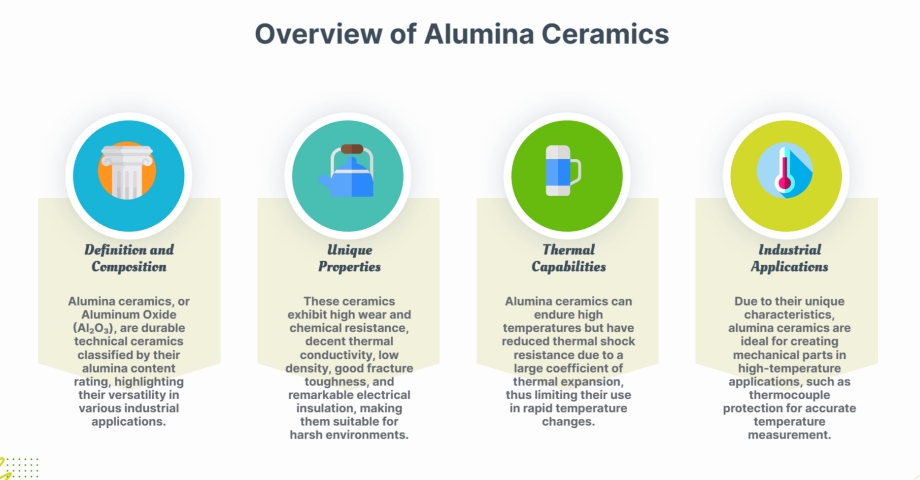

Alumina ceramics are primarily composed of aluminum oxide, which is known for its exceptional durability. The key properties of alumina ceramics include high wear resistance, outstanding crack resistance, excellent electrical insulation, and effective self-lubrication. These characteristics make alumina ceramics suitable for various industrial applications, particularly in environments that demand high performance under extreme conditions.

What Are the Pros and Cons of Using Alumina Ceramics?

When considering alumina ceramics for industrial applications, it’s essential to weigh their advantages against potential drawbacks.

Pros:

– Durability: Alumina ceramics exhibit superior wear and crack resistance, making them ideal for high-stress environments.

– Corrosion Resistance: They are highly resistant to corrosive agents, extending the lifespan of components made from this material.

– Electrical Insulation: Their excellent electrical insulation properties make them suitable for applications in electrical and electronic industries.

– Self-Lubrication: The low friction coefficient allows for smoother operation in moving parts, reducing wear and maintenance needs.

Illustrative image related to is alumina ceramic durable

Cons:

– Cost: Alumina ceramics can be more expensive than alternative materials, which may impact budget considerations for some projects.

– Manufacturing Complexity: The production process can be intricate, requiring specialized equipment and techniques.

– Brittleness: While they are durable, alumina ceramics can be brittle, which necessitates careful handling during installation and use.

How Does Alumina Ceramic Impact Specific Applications?

Alumina ceramics are versatile and can be used in various applications, including aerospace, automotive, and chemical processing. Their compatibility with different media, such as corrosive chemicals and high-temperature gases, makes them valuable in industries that require reliable performance under extreme conditions. For international B2B buyers, understanding the specific requirements of their applications is crucial for selecting the right alumina ceramic products.

What Should International Buyers Consider When Selecting Alumina Ceramics?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, several factors should be considered when selecting alumina ceramics:

Illustrative image related to is alumina ceramic durable

- Compliance with Standards: Ensure that the materials meet international standards such as ASTM, DIN, or JIS, which can vary by region.

- Local Preferences: Different markets may have preferences for specific grades or formulations of alumina ceramics based on local industrial practices.

- Supply Chain Reliability: Consider the logistics of sourcing materials, including lead times and availability, particularly in regions with less established supply chains.

Summary Table of Material Analysis

| Material | Typical Use Case for is alumina ceramic durable | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina Ceramics | Aerospace components, chemical processing | Exceptional wear and crack resistance | Higher cost compared to other materials | High |

| Zirconia Ceramics | Cutting tools, dental applications | Superior toughness and thermal stability | More expensive and complex to manufacture | High |

| Silicon Carbide | High-performance bearings, automotive parts | Excellent hardness and thermal conductivity | Brittle and can be challenging to process | Medium |

| Boron Nitride | High-temperature applications, crucibles | Outstanding thermal and chemical stability | Limited availability and higher costs | High |

This analysis provides a comprehensive overview of alumina ceramics and their alternatives, equipping international B2B buyers with the insights necessary for informed decision-making.

In-depth Look: Manufacturing Processes and Quality Assurance for is alumina ceramic durable

What Are the Main Stages in the Manufacturing Process of Durable Alumina Ceramics?

The manufacturing process of alumina ceramics involves several critical stages that ensure the final product meets high durability standards.

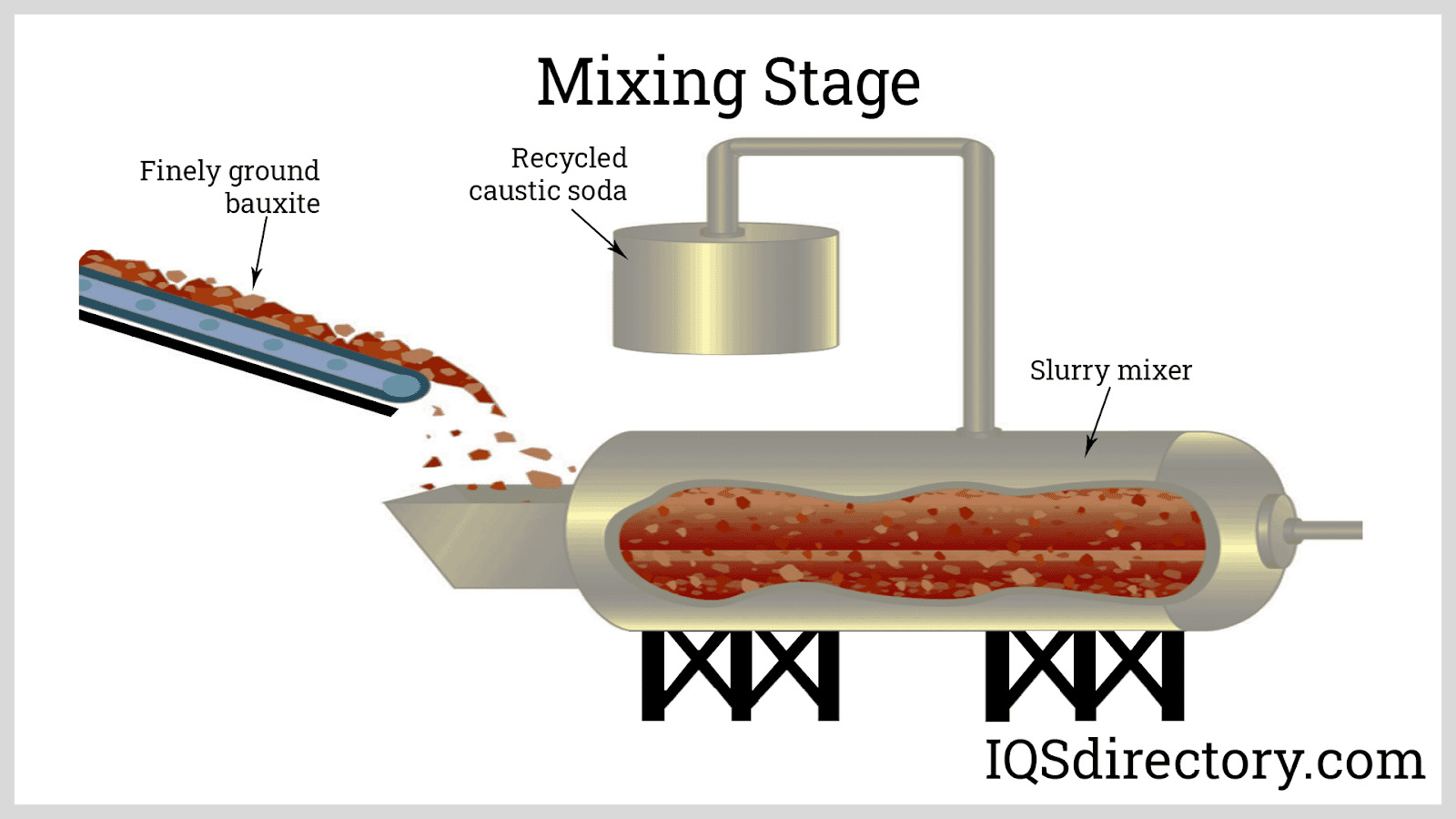

Material Preparation

The first step is material preparation, which involves sourcing high-purity aluminum oxide (Al₂O₃) powder. The quality of this raw material is paramount, as impurities can significantly affect the mechanical and thermal properties of the final product. The aluminum oxide powder is often blended with additives to enhance specific characteristics, such as sintering aids that promote better densification during the firing process.

Illustrative image related to is alumina ceramic durable

Forming Techniques

Once the materials are prepared, the next stage is forming. This can be achieved through various methods, including:

-

Dry Pressing: Involves compressing the powder in a mold to form a compact shape. This method is commonly used for producing large quantities of uniform parts.

-

Isostatic Pressing: Utilizes equal pressure applied from all directions, resulting in a denser and more uniform product.

-

Injection Molding: This technique allows for complex geometries and is often used for small to medium-sized components.

Assembly and Sintering

After forming, the components may require assembly, especially if they are part of a larger system. The assembled parts then undergo sintering, where they are heated to a temperature below their melting point. This process facilitates particle bonding and densification, enhancing the ceramic’s strength and durability. The sintering temperature and time are carefully controlled to optimize properties such as hardness and wear resistance.

Finishing Processes

The final stage involves finishing processes, which may include grinding, polishing, or coating. These processes are essential for achieving precise dimensions and surface finishes, which can affect performance in applications. For instance, a smoother surface can enhance wear resistance and reduce friction in applications where alumina ceramics serve as bearings or insulators.

What Quality Assurance Measures Are Essential for Durable Alumina Ceramics?

Quality assurance is a critical aspect of the manufacturing process for alumina ceramics, ensuring that the final products meet international standards and customer specifications.

Illustrative image related to is alumina ceramic durable

What International Standards Should B2B Buyers Consider?

Several international standards govern the quality of ceramics, with ISO 9001 being the most recognized. This standard outlines requirements for a quality management system, ensuring consistent product quality and customer satisfaction. Other relevant standards may include:

-

CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

-

API Standards: Particularly relevant for industries such as oil and gas, ensuring that materials meet specific performance criteria.

These certifications provide B2B buyers with confidence in the durability and reliability of alumina ceramics.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected for purity and consistency before production begins. This initial checkpoint is crucial as it can prevent defects in the final product.

-

In-Process Quality Control (IPQC): Monitoring during the manufacturing process, including temperature controls during sintering and dimensional checks post-forming, ensures that any deviations are addressed promptly.

-

Final Quality Control (FQC): Once the products are completed, they undergo rigorous testing. Common testing methods include:

-

Mechanical Testing: Evaluating properties such as tensile strength, hardness, and wear resistance.

-

Thermal Testing: Assessing thermal shock resistance and thermal conductivity.

-

Electrical Testing: For applications requiring electrical insulation, ensuring compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to verify the quality control processes of suppliers can take several steps:

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes, equipment used, and adherence to quality standards. This firsthand assessment helps buyers gauge the reliability of their suppliers.

-

Reviewing Quality Reports: Suppliers should provide regular quality reports detailing the results of their QC checks. These reports can include data on defect rates, compliance with standards, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct their assessments and provide unbiased reports on product quality.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may face unique challenges when sourcing alumina ceramics:

-

Regulatory Compliance: Understanding the local regulations regarding product safety and quality is vital. Different regions may have varying standards that products must meet to be sold.

-

Logistics and Transportation: The durability of alumina ceramics can be compromised during transportation. Ensuring that suppliers have robust packaging and handling procedures can mitigate risks associated with damage.

-

Cultural and Language Barriers: Effective communication with suppliers is essential. Buyers should seek suppliers who can provide comprehensive documentation and support in a language they understand.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing durable alumina ceramics, ensuring they meet their specific application needs while maintaining compliance with international standards.

Illustrative image related to is alumina ceramic durable

Practical Sourcing Guide: A Step-by-Step Checklist for ‘is alumina ceramic durable’

Introduction

This practical sourcing guide aims to equip B2B buyers with a comprehensive checklist for evaluating the durability of alumina ceramics. Understanding the key aspects of durability is essential for making informed procurement decisions, especially for industries that rely on high-performance materials. This checklist will help you navigate through the critical steps to ensure you select the right alumina ceramic products that meet your operational needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your application. This includes factors such as temperature resistance, wear and crack resistance, and electrical insulation properties. Clearly defined specifications will help you communicate effectively with suppliers and ensure that the alumina ceramics you procure meet your performance expectations.

Step 2: Research Material Properties

Investigate the inherent properties of alumina ceramics, particularly their durability aspects. Look for information regarding their wear resistance, crack resistance, and thermal stability. Understanding these properties will enable you to compare different products and select those that provide the best long-term performance for your applications.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thoroughly vet their capabilities and reputation. Request detailed company profiles, product catalogs, and case studies relevant to your industry. Additionally, seek references from other companies that have successfully used their products, as this will give you insight into the supplier’s reliability and product quality.

Illustrative image related to is alumina ceramic durable

Step 4: Check Certifications and Compliance

Ensure that the suppliers you consider adhere to international quality standards and have the necessary certifications. Look for compliance with ISO standards or industry-specific regulations that pertain to the durability of ceramic materials. This step is crucial to guarantee that the products you receive meet both safety and performance requirements.

Step 5: Request Sample Testing

Always request samples of the alumina ceramics you are considering. Conduct your own testing to evaluate their performance under conditions similar to your operational environment. This hands-on approach allows you to assess the durability and suitability of the materials before making a bulk purchase.

Step 6: Analyze Cost vs. Value

While cost is a significant factor, it should not be the only consideration. Analyze the long-term value of the alumina ceramics in relation to their durability and performance. Investing in higher-quality materials may yield better returns through reduced maintenance and longer service life, especially in demanding applications.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, carefully negotiate the terms of purchase, including pricing, delivery schedules, and warranty conditions. Ensure that the agreement includes provisions for addressing any potential issues related to product durability. Clear terms will help protect your investment and ensure accountability from the supplier.

By following this checklist, you will be better positioned to procure durable alumina ceramics that meet your specific needs, ultimately enhancing the efficiency and reliability of your operations.

Comprehensive Cost and Pricing Analysis for is alumina ceramic durable Sourcing

What Are the Key Cost Components in Sourcing Durable Alumina Ceramics?

When analyzing the costs associated with sourcing durable alumina ceramics, several components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary material used in alumina ceramics is aluminum oxide, which varies in purity and cost. Higher purity alumina often leads to increased durability and performance but comes at a premium. Pricing can fluctuate based on global supply and demand, particularly if sourcing from regions with limited availability.

-

Labor: Labor costs will differ based on the region of production. In regions with lower wage standards, such as parts of Africa and South America, labor costs can be significantly lower than in Europe or the Middle East. However, it’s essential to consider the skill level required for handling advanced manufacturing processes, which can impact overall labor costs.

-

Manufacturing Overhead: This includes expenses related to production facilities, equipment maintenance, and utilities. Advanced manufacturing processes for alumina ceramics often require specialized equipment, which can elevate overhead costs.

-

Tooling: Custom tooling may be necessary for specific applications or designs, adding to the initial investment. The cost of tooling is often amortized over production runs, impacting pricing based on order volume.

-

Quality Control (QC): Given the critical applications of alumina ceramics, rigorous QC is essential. The costs associated with testing and certification for quality assurance can vary based on the required standards and certifications, which are crucial for international markets.

-

Logistics: Shipping costs can be significant, especially for international buyers. Factors such as freight charges, insurance, and customs duties should be factored into the total cost. Incoterms will also influence the final pricing, as they dictate the responsibilities of buyers and sellers in shipping arrangements.

-

Margin: Suppliers typically add a profit margin on top of the total costs, which can vary widely depending on market conditions and competition.

How Do Price Influencers Impact the Cost of Alumina Ceramics?

Several factors can influence the pricing of alumina ceramics, particularly in international B2B transactions:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can significantly reduce per-unit costs due to economies of scale. Negotiating lower prices for higher volumes can be advantageous for buyers.

-

Specifications and Customization: Custom specifications or specialized applications may lead to increased costs due to additional tooling and production requirements. Buyers should assess whether standard products can meet their needs to optimize costs.

-

Material Quality and Certifications: Higher quality materials and certifications from recognized bodies often come at a premium. Buyers must evaluate the necessity of such certifications based on their industry standards and application requirements.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge more, but they often provide better quality assurance and reliability.

-

Incoterms: Understanding the implications of Incoterms is crucial for international transactions. Different terms can affect the overall cost structure, especially regarding who bears the risk and cost of transportation.

What Are the Best Practices for Negotiating Costs in Alumina Ceramic Procurement?

B2B buyers should adopt strategic approaches to negotiate favorable pricing for alumina ceramics:

-

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with alumina ceramics, including maintenance, durability, and potential replacements. This comprehensive view can justify higher upfront costs if they lead to lower overall expenses.

-

Leverage Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Frequent and consistent orders may qualify buyers for loyalty discounts.

-

Market Research: Conduct thorough market research to understand prevailing prices and trends in alumina ceramics. This information can empower buyers during negotiations.

-

Consider Local Sourcing: For buyers in Africa or South America, exploring local suppliers can reduce logistics costs and import duties, making procurement more cost-effective.

-

Disclaimer on Pricing: Be aware that prices can fluctuate based on market conditions, and it’s wise to request indicative pricing rather than fixed quotes. This ensures that buyers remain informed about potential changes in cost structures.

By understanding these cost components, price influencers, and negotiation strategies, international B2B buyers can make informed decisions when sourcing durable alumina ceramics, ensuring they receive the best value for their investment.

Illustrative image related to is alumina ceramic durable

Alternatives Analysis: Comparing is alumina ceramic durable With Other Solutions

Introduction: Evaluating Alternatives to Alumina Ceramic Durability

When considering materials for industrial applications, durability is a critical factor. Alumina ceramics are known for their impressive durability, but several alternatives exist, each with unique characteristics that may better suit specific needs. This analysis compares the durability of alumina ceramics with two prominent alternatives: Silicon Carbide (SiC) and Zirconia (ZrO₂). By understanding their performance, costs, and use cases, B2B buyers can make informed decisions that align with their operational requirements.

| Comparison Aspect | Is Alumina Ceramic Durable | Silicon Carbide (SiC) | Zirconia (ZrO₂) |

|---|---|---|---|

| Performance | Excellent wear and crack resistance; high thermal stability | Superior hardness and thermal conductivity; excellent wear resistance | High toughness and fracture resistance; good thermal insulation |

| Cost | Moderate | Higher than alumina | Generally lower than SiC |

| Ease of Implementation | Easily machined and shaped | Requires specialized tooling for shaping | Moderate; can be processed with standard equipment |

| Maintenance | Low maintenance required | Low maintenance required | Moderate maintenance; can be susceptible to chipping |

| Best Use Case | Industrial applications requiring wear resistance and electrical insulation | High-performance applications like aerospace and automotive | Dental applications and thermal barriers in high-stress environments |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Silicon Carbide (SiC)?

Silicon Carbide is renowned for its exceptional hardness and thermal conductivity. Its superior wear resistance makes it ideal for high-performance applications, including aerospace and automotive components. However, the cost of SiC is generally higher than that of alumina ceramics, which can be a limiting factor for some businesses. Additionally, the specialized tooling required for machining SiC can increase overall project expenses and complexity.

How Does Zirconia (ZrO₂) Compare in Terms of Durability?

Zirconia is another viable alternative known for its high toughness and fracture resistance. It is often used in dental applications and as a thermal barrier in high-stress environments. While it tends to be more affordable than Silicon Carbide, it does require moderate maintenance and can be prone to chipping if not handled carefully. Its processing is generally straightforward, making it a practical choice for many manufacturers.

Illustrative image related to is alumina ceramic durable

Conclusion: How Should B2B Buyers Select the Right Durable Solution?

Selecting the appropriate material for industrial applications is crucial for operational efficiency and cost-effectiveness. When deciding between alumina ceramics, Silicon Carbide, and Zirconia, B2B buyers should consider not only the performance and durability of each material but also their specific application needs, budget constraints, and long-term maintenance requirements. By thoroughly evaluating these factors, businesses can ensure they choose the best solution that aligns with their production goals and enhances their overall competitiveness in the market.

Essential Technical Properties and Trade Terminology for is alumina ceramic durable

What Are the Key Technical Properties That Make Alumina Ceramic Durable?

Alumina ceramics are renowned for their exceptional durability, which is crucial for various industrial applications. Here are several key technical properties that define their durability:

-

Wear Resistance

Alumina ceramics exhibit outstanding wear resistance, significantly surpassing conventional steel alloys. This property is vital for industries such as mining, manufacturing, and materials processing, where components are subject to high abrasion. The enhanced wear resistance translates into longer service life, reducing the frequency of replacements and maintenance costs. -

Thermal Stability

These ceramics can endure extreme temperatures, often exceeding 1,600°C, without deforming or cracking. This thermal stability is essential for applications in industries like aerospace, automotive, and energy, where materials are exposed to high heat. It ensures reliability and safety in high-temperature environments, minimizing the risk of failure. -

Chemical Resistance

Alumina ceramics resist corrosion from various chemical agents, including acids and alkalis. This property is crucial for industries dealing with harsh chemicals, such as pharmaceuticals and petrochemicals. The ability to withstand corrosive environments enhances the longevity of equipment and components, leading to lower operational costs. -

Electrical Insulation

With excellent electrical insulating properties, alumina ceramics are widely used in electrical applications. They offer high dielectric strength and low electrical conductivity, making them ideal for insulators, substrates, and components in electrical circuits. This property ensures the safe and efficient operation of electrical systems, particularly in high-voltage environments. -

Impact Toughness

Alumina ceramics possess impressive impact toughness, allowing them to withstand sudden forces and stresses without cracking. This characteristic is particularly beneficial in industries like construction and automotive, where materials may face unexpected impacts. High impact resistance contributes to the durability and reliability of critical components.

What Trade Terms Should B2B Buyers Understand When Sourcing Alumina Ceramics?

Understanding trade terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms relevant to alumina ceramics:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of alumina ceramics, OEMs often supply custom solutions tailored to specific industry needs, enhancing product compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For alumina ceramics, understanding MOQ is crucial for budgeting and inventory management, as it can influence purchasing decisions and overall project costs. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. In the context of alumina ceramics, submitting an RFQ helps buyers obtain competitive pricing and understand the available options, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and risk management. Familiarity with Incoterms is essential for B2B buyers of alumina ceramics to ensure smooth logistics and compliance with international trade regulations. -

Lead Time

Lead time refers to the duration from placing an order to receiving the product. Understanding lead time is critical for B2B buyers, as it affects project timelines and inventory management. Buyers should inquire about lead times when sourcing alumina ceramics to plan accordingly. -

Technical Data Sheet (TDS)

A TDS provides detailed information about a product’s specifications, applications, and performance characteristics. For alumina ceramics, reviewing the TDS is vital for buyers to ensure that the materials meet their specific requirements and industry standards.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alumina ceramics, ensuring they select the right materials for their industrial applications.

Navigating Market Dynamics and Sourcing Trends in the is alumina ceramic durable Sector

What Are the Current Market Dynamics and Key Trends in the Alumina Ceramic Sector?

The global market for alumina ceramics is driven by several factors, including increasing demand for high-performance materials in industries such as aerospace, automotive, electronics, and healthcare. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigate this evolving landscape, they must remain aware of key trends shaping the sector.

Illustrative image related to is alumina ceramic durable

One prominent trend is the shift toward advanced manufacturing techniques, such as additive manufacturing and precision machining, which enhance the quality and performance of alumina ceramic products. These techniques facilitate the production of complex geometries and tailored solutions, meeting the specific needs of diverse industries. Additionally, the emergence of smart materials that integrate with IoT technologies is gaining traction, offering enhanced functionality and efficiency.

Moreover, sustainability is becoming increasingly important, with companies focusing on reducing their environmental footprint. This includes the adoption of energy-efficient manufacturing processes and sustainable sourcing of raw materials. Understanding these dynamics allows B2B buyers to make informed decisions that align with both market demand and sustainability goals.

How Does Sustainability and Ethical Sourcing Impact the Durability of Alumina Ceramics?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the alumina ceramic sector. The environmental impact of sourcing raw materials, particularly aluminum oxide, has led to a heightened focus on responsible practices. Buyers are increasingly seeking suppliers who can demonstrate a commitment to sustainable operations, from mining practices to manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers should prioritize suppliers who adhere to international standards and certifications, such as ISO 14001 for environmental management and responsible sourcing certifications. These certifications not only ensure compliance with regulations but also enhance the reputation of buyers in their respective markets.

Furthermore, the use of ‘green’ materials and technologies in the production of alumina ceramics contributes to their durability. Sustainable practices can improve the lifecycle of these materials, resulting in lower wear and tear and extending their usability in demanding applications. Therefore, buyers who prioritize sustainability and ethical sourcing will not only contribute to environmental conservation but also enhance the long-term value of their investments in alumina ceramics.

Illustrative image related to is alumina ceramic durable

What Is the Historical Evolution of Alumina Ceramics in the B2B Market?

The evolution of alumina ceramics dates back to the early 20th century when they were primarily utilized in electrical insulation and structural applications. As industries expanded and technological advancements were made, the properties of alumina ceramics were further enhanced through innovative manufacturing techniques. The introduction of high-purity alumina and advanced sintering methods significantly improved their mechanical strength, wear resistance, and thermal stability.

By the late 20th century, alumina ceramics gained prominence in various sectors, including aerospace and automotive, due to their exceptional durability and performance under extreme conditions. Today, they are widely recognized as critical materials for high-tech applications, thanks to ongoing research and development efforts aimed at enhancing their properties further.

Understanding this historical context helps B2B buyers appreciate the long-standing reliability and ongoing innovation within the alumina ceramic sector, guiding them in making informed purchasing decisions that meet their operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of is alumina ceramic durable

-

How do I determine the durability of alumina ceramics for my application?

To assess the durability of alumina ceramics, consider factors such as wear resistance, crack resistance, and thermal stability. Evaluate the specific conditions of your application, including temperature, pressure, and exposure to corrosive materials. Request technical data sheets and performance reports from suppliers, which should detail these properties. Additionally, inquire about any third-party testing or certifications to validate their claims regarding durability. -

What is the best grade of alumina ceramic for industrial applications?

The best grade of alumina ceramic for industrial applications typically ranges from 90% to 99.9% purity, with higher purity offering better mechanical and thermal properties. For applications requiring high wear resistance, consider using alumina with a higher percentage of aluminum oxide. Consult with suppliers to identify the optimal grade based on your specific operational conditions and performance requirements. -

How can I ensure the quality of alumina ceramics from my supplier?

To ensure quality, verify that your supplier follows stringent manufacturing processes and quality control measures. Request certifications such as ISO 9001, which indicates adherence to international quality standards. Additionally, ask for samples to conduct your own testing or for third-party lab testing results to confirm durability and performance specifications. Regular audits of your supplier’s facilities can also enhance quality assurance. -

What customization options are available for alumina ceramics?

Many suppliers offer customization options for alumina ceramics, including specific shapes, sizes, and compositions tailored to your application needs. Discuss your requirements with the supplier to determine the feasibility of custom designs. Some manufacturers may also provide engineering support to optimize the performance of the ceramic components in your specific application, ensuring enhanced durability and efficiency. -

What are the typical minimum order quantities (MOQ) for alumina ceramics?

Minimum order quantities for alumina ceramics can vary significantly based on the supplier and the complexity of the product. Typically, MOQs range from 100 to 1,000 pieces, depending on the item. Discuss your project requirements with the supplier to negotiate MOQs, especially if you need a smaller quantity for a pilot project or trial run. -

What payment terms should I expect when sourcing alumina ceramics internationally?

Payment terms for international orders of alumina ceramics can vary by supplier and region. Common terms include 30% upfront payment with the balance due prior to shipment, or net 30 to 60 days after delivery. It’s essential to clarify payment terms early in negotiations and consider using secure payment methods such as letters of credit for larger orders to mitigate risks. -

How do I manage logistics when importing alumina ceramics?

When importing alumina ceramics, work closely with your supplier to understand shipping options and costs. Consider partnering with a logistics provider experienced in international freight to handle customs clearance, documentation, and delivery. Ensure that you have a clear understanding of import regulations in your country to avoid delays. Tracking shipments and maintaining open communication with your supplier can also help manage logistics effectively. -

What should I do if I encounter issues with the durability of alumina ceramics after purchase?

If you encounter durability issues, first review the specifications and performance data provided by the supplier to confirm compliance with your application requirements. Document any failures and contact the supplier immediately to discuss the problem. Most reputable suppliers will have a warranty or return policy in place. Work collaboratively with them to resolve the issue, which may include replacement, refunds, or technical support for proper installation and use.

Top 5 Is Alumina Ceramic Durable Manufacturers & Suppliers List

1. CS Ceramic – Alumina Ceramics

Domain: csceramic.com

Registered: 2012 (13 years)

Introduction: Alumina ceramics are primarily composed of aluminum oxide and are formed through high-temperature sintering and specialized processes. They are known for their remarkable durability. Key product details include:

– Alumina Ceramic Crucibles

– Combustion Boats

– Alumina Ceramic Tubes & Rods

– Alumina Substrates/Plates/Sheets

– Alumina Balls and Ball Mill Jar

– Alumina Industrial Parts

– Applications…

2. Ceramic Solutions – Alumina Ceramics

Domain: ceramic-solutions.com

Registered: 2020 (5 years)

Introduction: Alumina ceramics are durable ceramic products primarily composed of sintered alumina at high temperatures. Key aspects of their durability include: 1. Strong wear resistance, with a wear resistance that is double that of ordinary steel alloys, significantly extending the life of piping. 2. Excellent crack resistance, capable of withstanding high temperatures and pressures, with resistance to envir…

3. Better Ceramic – Alumina Ceramics

Domain: betterceramic.com

Registered: 2018 (7 years)

Introduction: Alumina ceramics are primarily composed of aluminum oxide and undergo high-temperature sintering. Key characteristics include: 1. Strong Wear Resistance: Exceptional wear resistance with an ultra-high molecular weight, extending the lifespan of pipelines. 2. High Electrical Resistivity: Effective in electrical applications, capable of withstanding considerable impact forces. 3. Excellent Self-Lubr…

4. GGSCeramic – Alumina Ceramics

Domain: ggsceramic.com

Registered: 2019 (6 years)

Introduction: Alumina ceramics are made from raw materials that undergo precision machining. They are known for their high hardness, wear resistance, and excellent electrical insulation properties. These ceramics are used in various applications, including electronics, medical devices, and industrial components.

5. Digital Fire – Alumina Solutions

Domain: digitalfire.com

Registered: 1996 (29 years)

Introduction: Alumina, also known as Aluminum Oxide (Al2O3), is a high-tech ceramic material with a formula weight of 102.00. It can be found in three general types: Hydrated, Calcined, and Tabular, each with various grades. Alumina is characterized by its white granular or fine silky powder form and is widely used in ceramics due to its exceptional properties. It has high melting temperatures, mechanical stren…

Strategic Sourcing Conclusion and Outlook for is alumina ceramic durable

How Does Alumina Ceramic’s Durability Impact Strategic Sourcing?

In conclusion, the durability of alumina ceramics is a critical factor for international B2B buyers, especially in sectors demanding high-performance materials. Their exceptional wear and crack resistance, combined with superior electrical insulation properties, make them invaluable in various applications, from industrial machinery to electronic components. This inherent durability not only reduces maintenance costs but also enhances the overall efficiency of operations.

Illustrative image related to is alumina ceramic durable

Strategic sourcing becomes paramount as companies look to partner with reliable suppliers who can provide high-quality alumina ceramics tailored to their specific needs. By understanding the key aspects of durability, buyers can make informed decisions that align with their operational goals and budget considerations.

Looking ahead, businesses in Africa, South America, the Middle East, and Europe should seize the opportunity to invest in alumina ceramics. As industries evolve and demand for advanced materials increases, establishing strong partnerships with reputable manufacturers will be essential. Engage with suppliers today to secure a competitive edge and ensure your operations are equipped with the best materials available.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.