The Definitive Guide to Iron For Casting: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for iron for casting

In the competitive landscape of metal casting, sourcing high-quality iron for casting presents a significant challenge for international B2B buyers. With diverse applications ranging from automotive components to intricate machinery parts, the demand for reliable iron sources is ever-increasing. This guide aims to equip buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Saudi Arabia—with the insights necessary to navigate the complexities of sourcing iron for casting.

Understanding the various types of iron, such as gray iron, ductile iron, and white iron, is crucial for making informed purchasing decisions. Each type has unique properties and applications, affecting everything from cost to performance in final products. Additionally, we will delve into the critical aspects of supplier vetting, ensuring that buyers can identify reputable partners capable of meeting their specific needs.

This comprehensive resource will also cover cost factors, market trends, and best practices for establishing long-term supplier relationships. By leveraging the insights and strategies outlined in this guide, B2B buyers will be empowered to make informed decisions that enhance their operational efficiency and product quality, ultimately driving success in the global market for iron in casting.

Understanding iron for casting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gray Iron | High carbon content, excellent castability, good machinability | Automotive, machinery components | Pros: Cost-effective, good wear resistance. Cons: Brittle; may not be suitable for high-stress applications. |

| Ductile Iron | Enhanced ductility and toughness, spherical graphite structure | Pipelines, automotive parts | Pros: High strength, good fatigue resistance. Cons: More expensive than gray iron; requires careful processing. |

| White Iron | High carbon and silicon content, very hard and wear-resistant | Abrasive applications, grinding media | Pros: Excellent hardness, wear resistance. Cons: Difficult to machine; brittle nature limits applications. |

| Malleable Iron | Heat-treated gray iron, improved ductility and strength | Agricultural equipment, fittings | Pros: Good ductility, easier to weld. Cons: More complex production process; higher costs. |

| Cast Iron Alloys | Combinations of various elements, tailored properties | Specialized machinery, heavy-duty applications | Pros: Customizable properties for specific needs. Cons: May require extensive testing and validation. |

What Are the Characteristics of Gray Iron for Casting?

Gray iron is characterized by its high carbon content and the presence of graphite flakes, which provide excellent castability and machinability. This type of iron is widely used in the automotive industry for engine blocks and transmission cases due to its good wear resistance and ability to dampen vibrations. For B2B buyers, gray iron is often the most cost-effective option, although its brittleness can pose risks in high-stress applications.

How Does Ductile Iron Differ from Other Types?

Ductile iron, or nodular iron, is recognized for its spherical graphite structure, which enhances its ductility and toughness compared to gray iron. This makes it suitable for applications such as pipelines and automotive components that require high strength and fatigue resistance. While ductile iron offers superior performance, buyers should consider its higher costs and the necessity for careful processing to maintain its beneficial properties.

Why Choose White Iron for High-Durability Needs?

White iron is distinguished by its high carbon and silicon content, resulting in exceptional hardness and wear resistance. It is primarily used in abrasive applications, such as grinding media and wear plates. However, its brittle nature and difficulty in machining limit its versatility. B2B buyers should evaluate their specific application requirements against these trade-offs when considering white iron.

What Advantages Does Malleable Iron Offer?

Malleable iron is produced by heat-treating gray iron, which improves its ductility and strength. It is commonly used in agricultural equipment and fittings, where flexibility and ease of welding are essential. Although the production process is more complex and costly, the benefits of malleable iron make it an attractive option for applications requiring durable and robust components.

How Do Cast Iron Alloys Meet Specialized Requirements?

Cast iron alloys are formulated by combining various elements to achieve tailored properties for specific applications. This customization allows for enhanced performance in specialized machinery and heavy-duty environments. While the ability to design alloys can address unique challenges, B2B buyers must be prepared for extensive testing and validation to ensure the materials meet their operational standards.

Key Industrial Applications of iron for casting

| Industry/Sector | Specific Application of iron for casting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine Blocks and Cylinder Heads | Enhanced durability and thermal efficiency | Quality of iron, compliance with automotive standards |

| Construction | Structural Components (Beams, Columns) | High strength-to-weight ratio, cost-effectiveness | Sourcing from local suppliers to reduce logistics |

| Machinery Manufacturing | Machine Tool Frames and Bases | Stability and precision in machining operations | Specific alloy requirements, machining capabilities |

| Agricultural Equipment | Tractor and Harvester Parts | Resistance to wear and tear, improved longevity | Availability of specific grades of cast iron |

| Energy Sector | Turbine Housings and Pipeline Components | High-temperature resilience and corrosion resistance | Certifications for high-pressure applications |

How is Iron for Casting Used in the Automotive Industry?

In the automotive sector, iron for casting is primarily used for manufacturing engine blocks and cylinder heads. These components require high durability and thermal efficiency, which cast iron provides due to its excellent heat retention and distribution properties. International buyers need to ensure that the sourced iron meets stringent automotive industry standards, including specific alloy compositions that enhance strength and reduce weight. Furthermore, local sourcing can facilitate faster delivery and cost savings, particularly in regions like Africa and South America where logistics can be challenging.

What Role Does Iron for Casting Play in Construction?

In construction, cast iron is pivotal for producing structural components such as beams and columns. Its high strength-to-weight ratio allows for the creation of robust frameworks that can support significant loads while being cost-effective. Buyers in this sector should focus on sourcing from suppliers who can provide iron with the necessary certifications for construction applications. Additionally, understanding local building codes and regulations is crucial for compliance, especially in regions like the Middle East and Europe, where safety standards are stringent.

How is Iron for Casting Utilized in Machinery Manufacturing?

Machinery manufacturing relies heavily on iron for casting in the production of machine tool frames and bases. These components must offer stability and precision to ensure accurate machining operations. Buyers should consider the specific alloy requirements that can enhance the machinability of cast iron. Additionally, sourcing from manufacturers with advanced machining capabilities can ensure that the final products meet the high standards of the industry, particularly in competitive markets across Europe and South America.

What Benefits Does Iron for Casting Provide in Agricultural Equipment?

In the agricultural sector, cast iron is commonly used in parts for tractors and harvesters. Its resistance to wear and tear significantly enhances the longevity of these components, which are subjected to harsh working conditions. Buyers should prioritize sourcing cast iron that meets the specific performance requirements of agricultural machinery, as this can lead to reduced downtime and maintenance costs. Local suppliers in regions like Africa can provide tailored solutions that address unique agricultural challenges.

How is Iron for Casting Essential in the Energy Sector?

The energy sector utilizes iron for casting in critical components such as turbine housings and pipeline fittings. These applications require materials that can withstand high temperatures and resist corrosion. For international buyers, it is essential to ensure that the sourced iron complies with relevant certifications for high-pressure applications, particularly in the Middle East where energy projects are prevalent. Establishing relationships with reliable suppliers who understand the specific demands of the energy sector can lead to successful project outcomes.

3 Common User Pain Points for ‘iron for casting’ & Their Solutions

Scenario 1: Sourcing High-Quality Cast Iron for Consistent Production

The Problem: Many B2B buyers encounter challenges when sourcing cast iron that meets their specific quality and consistency standards. Fluctuations in material quality can lead to production delays, defective products, and increased scrap rates. This is particularly problematic for companies that rely on precise specifications for their cast iron components, as inconsistency can jeopardize the integrity of the final product.

The Solution: To mitigate these issues, buyers should establish strong relationships with reputable suppliers who offer transparent material specifications and quality control measures. Request detailed documentation on the chemical composition and mechanical properties of the iron, as well as certifications from third-party testing labs. Additionally, consider implementing a vendor qualification process where potential suppliers are evaluated based on their ability to provide consistent quality. Engaging in long-term contracts can also help secure favorable pricing and ensure a reliable supply of high-quality cast iron.

Scenario 2: Managing the Risks of Melting and Casting Iron Safely

The Problem: The process of melting and casting iron can be fraught with safety hazards, including burns, explosions, and inhalation of toxic fumes. B2B buyers, especially those in foundry operations, often struggle with ensuring the safety of their workforce while maintaining efficient production processes. Incidents can lead to severe injuries, legal ramifications, and operational downtime, ultimately affecting profitability.

The Solution: Implementing robust safety protocols is crucial. Buyers should invest in comprehensive training programs for employees that cover the risks associated with melting and casting processes. This includes proper handling of molten iron, emergency response procedures, and the use of personal protective equipment (PPE). Moreover, integrating advanced technology, such as automated pouring systems and remote monitoring of furnaces, can significantly reduce human exposure to dangerous conditions. Regular safety audits and updates to safety equipment should be part of the operational routine to ensure compliance and worker safety.

Scenario 3: Overcoming Environmental Compliance Challenges in Iron Casting

The Problem: Environmental regulations around emissions and waste disposal are becoming increasingly stringent, posing significant challenges for B2B buyers in the iron casting industry. Non-compliance can lead to hefty fines, operational shutdowns, and damage to the company’s reputation. Companies often find it difficult to adapt their processes to meet these regulations while also maintaining cost-efficiency.

Illustrative image related to iron for casting

The Solution: To navigate these challenges, buyers should proactively invest in environmentally friendly technologies and practices. This includes adopting closed-loop systems for waste management, utilizing more efficient furnaces that reduce emissions, and exploring alternative materials that minimize environmental impact. Collaborating with environmental consultants can provide insights into compliance requirements and potential improvements. Additionally, participating in industry groups focused on sustainable practices can help companies stay informed about regulatory changes and innovative solutions that can enhance both compliance and operational efficiency. Regularly reviewing and updating environmental strategies will ensure long-term sustainability and competitiveness in the market.

Strategic Material Selection Guide for iron for casting

What Are the Key Materials Used for Iron Casting?

When selecting materials for iron casting, several types of iron are commonly utilized, each with unique properties and applications. Understanding these materials is crucial for B2B buyers looking to optimize their casting processes, especially in diverse international markets.

What Are the Key Properties of Gray Iron for Casting?

Gray iron is one of the most widely used materials in casting due to its excellent castability and machinability. It has a high carbon content, which gives it good fluidity when molten, allowing for intricate designs. Its thermal conductivity is also noteworthy, making it suitable for applications requiring heat dissipation, such as engine blocks and cylinder heads. However, gray iron is relatively brittle, which can limit its use in high-stress applications.

Pros:

– Excellent castability and machinability.

– Good thermal conductivity.

– Cost-effective for mass production.

Cons:

– Brittle nature limits its use under high stress.

– Susceptible to corrosion if not properly treated.

Impact on Application:

Gray iron is compatible with various media, including water and oil, but may not perform well in highly corrosive environments without protective coatings.

How Does Ductile Iron Compare for Casting Applications?

Ductile iron, also known as nodular cast iron, is characterized by its high strength and ductility. This material is produced by adding small amounts of magnesium to molten gray iron, which alters the graphite structure. Ductile iron is ideal for applications requiring high tensile strength, such as automotive components and heavy machinery.

Pros:

– High strength and ductility.

– Good wear resistance.

– Versatile for various applications.

Cons:

– More expensive than gray iron.

– Requires more complex manufacturing processes.

Impact on Application:

Ductile iron is suitable for applications exposed to dynamic loads or impacts, such as suspension components in vehicles. It is less prone to cracking under stress compared to gray iron.

What Are the Benefits of Malleable Iron in Casting?

Malleable iron is produced by heat-treating white iron, which improves its ductility and toughness. This material is often used in applications requiring high impact resistance, such as pipe fittings and agricultural machinery. Malleable iron can also be easily machined, making it a preferred choice for complex parts.

Illustrative image related to iron for casting

Pros:

– Excellent impact resistance and toughness.

– Good machinability.

– Versatile in applications.

Cons:

– Higher production costs due to heat treatment.

– Limited availability compared to gray and ductile iron.

Impact on Application:

Malleable iron is compatible with various media but may require protective coatings in corrosive environments to enhance longevity.

How Does White Iron Fit into the Casting Landscape?

White iron is characterized by its high hardness and wear resistance, making it suitable for applications like grinding mills and wear plates. However, its brittleness limits its versatility compared to other types of iron. White iron is typically used in applications where abrasion resistance is critical.

Pros:

– Exceptional hardness and wear resistance.

– Suitable for high-abrasion environments.

Cons:

– Brittle and difficult to machine.

– Limited application scope due to its properties.

Impact on Application:

White iron is best suited for applications where high wear resistance is essential, but it may not be appropriate for components that experience significant impact or stress.

Illustrative image related to iron for casting

Summary Table of Iron Casting Materials

| Material | Typical Use Case for iron for casting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Gray Iron | Engine blocks, cylinder heads | Excellent castability and cost-effective | Brittle under high stress | Low |

| Ductile Iron | Automotive components, heavy machinery | High strength and ductility | More expensive and complex to manufacture | Medium |

| Malleable Iron | Pipe fittings, agricultural machinery | Excellent impact resistance | Higher production costs | Medium |

| White Iron | Grinding mills, wear plates | Exceptional hardness | Brittle and difficult to machine | High |

This strategic material selection guide provides a comprehensive overview of the key types of iron used in casting, highlighting their properties, advantages, and limitations. For international B2B buyers, understanding these factors is essential for making informed purchasing decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for iron for casting

What Are the Key Manufacturing Processes for Iron Used in Casting?

The manufacturing processes for iron intended for casting involve several critical stages that ensure the final product meets the required specifications and performance standards. Understanding these stages is essential for B2B buyers seeking quality materials.

Material Preparation: How Is Raw Iron Processed?

The first step in the manufacturing process is material preparation. Raw iron, often sourced from iron ore or recycled scrap, undergoes several treatments to remove impurities and enhance its properties. This typically involves:

Illustrative image related to iron for casting

-

Melting: The iron is melted in a furnace, which can use various fuel types, including coke or natural gas. This stage requires precise temperature control to achieve the desired molten state.

-

Alloying: At this stage, alloying elements such as silicon, manganese, or chromium may be added to enhance specific characteristics of the iron, such as its strength or corrosion resistance.

-

Refining: After melting and alloying, the molten iron is refined to remove any remaining impurities. This is often achieved through processes like desulfurization and degassing.

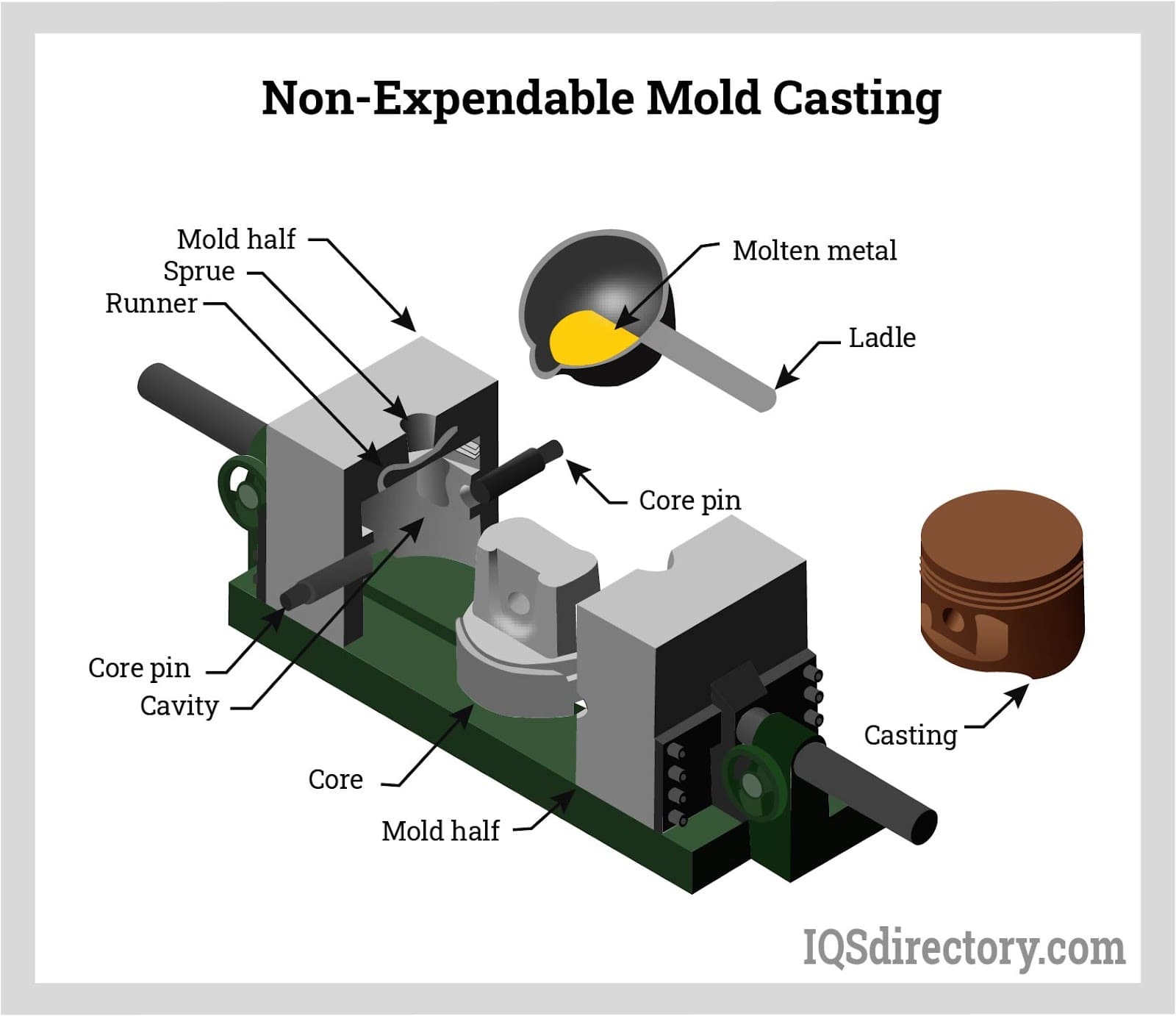

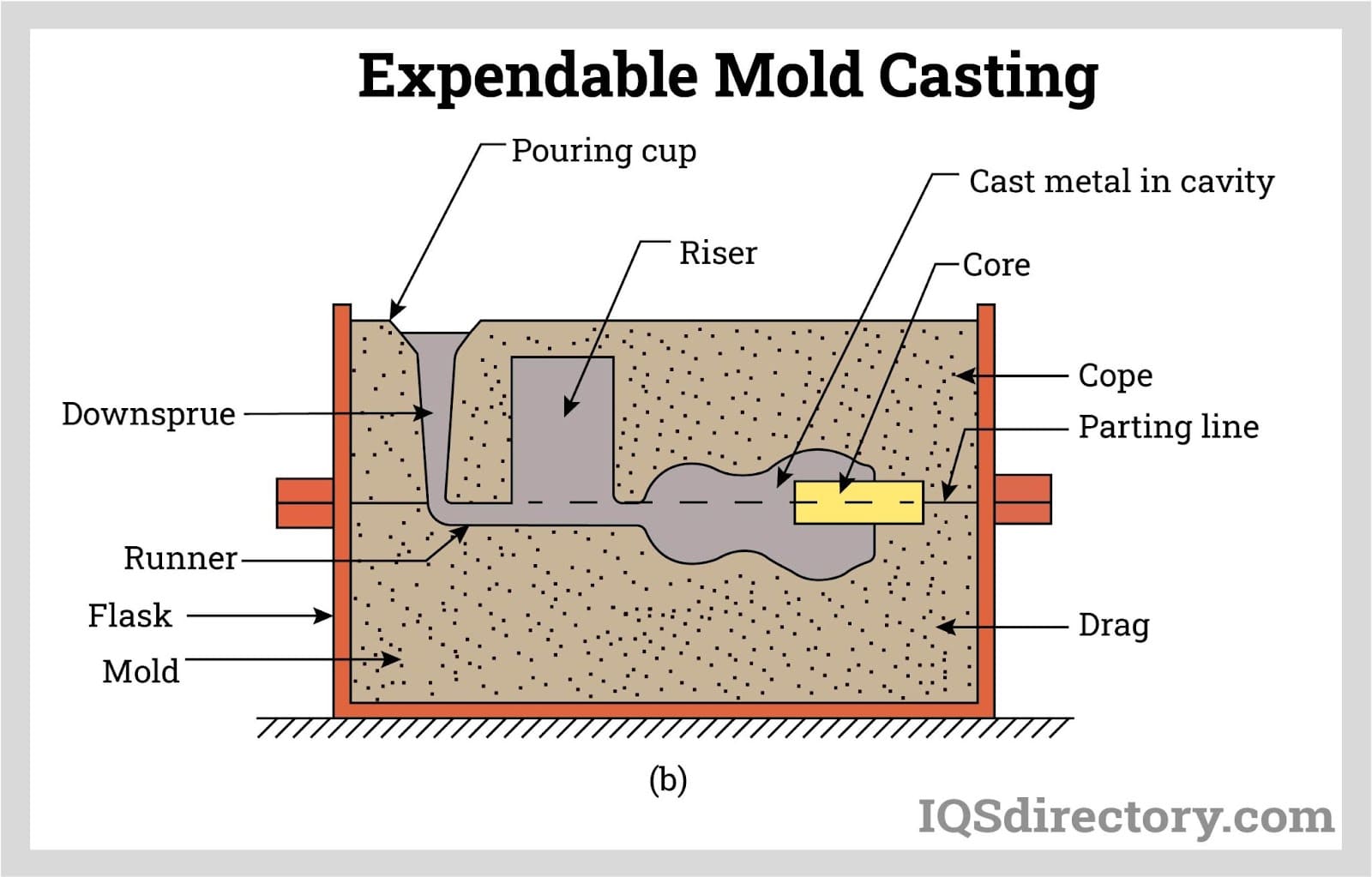

Forming: What Techniques Are Used to Shape Iron for Casting?

Once the raw material is prepared, the next stage is forming, where the molten iron is shaped into the desired form. Key techniques include:

-

Sand Casting: This is one of the most common methods, where the molten iron is poured into a sand mold that has been shaped to the specifications of the final product. This method is cost-effective and allows for intricate designs.

-

Investment Casting: Also known as lost-wax casting, this method is used for creating complex shapes with high precision. A wax pattern is coated with a ceramic shell, which is then heated to melt away the wax, leaving a mold for the molten iron.

-

Die Casting: This technique involves forcing molten iron into a mold under high pressure. It is ideal for high-volume production and yields a smooth surface finish.

Assembly: How Are Components Joined in Iron Casting?

After the forming process, components may require assembly, especially in cases where multiple parts are involved. Common methods include:

-

Welding: This is frequently used to join iron components, particularly for larger castings that need to be assembled into a final product.

-

Mechanical Fastening: Bolts, screws, and other fasteners may be used to assemble parts, ensuring that they are securely attached and can withstand operational stresses.

Finishing: What Processes Enhance the Quality of Cast Iron Products?

Finishing processes are crucial for enhancing the quality and appearance of the final iron casting. Key finishing techniques include:

Illustrative image related to iron for casting

-

Machining: This involves cutting or grinding the iron to achieve precise dimensions and a smooth surface finish. It is essential for parts that require tight tolerances.

-

Surface Treatment: Techniques such as shot blasting, painting, or coating may be applied to improve corrosion resistance and aesthetics.

-

Heat Treatment: This process alters the microstructure of the iron to enhance its mechanical properties. Common methods include annealing, quenching, and tempering.

What Are the Quality Assurance Practices for Iron Casting?

Quality assurance (QA) is vital in ensuring that iron castings meet international standards and customer specifications. B2B buyers should be familiar with the QA processes their suppliers employ.

Which International Standards Should B2B Buyers Be Aware Of?

Several international standards govern the quality of iron for casting, including:

-

ISO 9001: This standard focuses on quality management systems and is applicable to manufacturers of all sizes. It ensures that suppliers have consistent processes to meet customer requirements.

-

CE Marking: Particularly relevant in Europe, CE marking indicates that products meet EU safety, health, and environmental protection standards.

-

API Standards: For industries such as oil and gas, adherence to American Petroleum Institute (API) standards is crucial. These standards cover specifications for materials used in critical applications.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integrated at various stages of the manufacturing process, often categorized as follows:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements. Buyers should request IQC reports to verify compliance.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor processes and identify any deviations from standards. This stage is critical for maintaining product integrity.

-

Final Quality Control (FQC): Before products are shipped, a final inspection is performed to ensure that the castings meet all specifications and quality standards. FQC reports should be made available to buyers.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several proactive steps:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and QC practices. This helps buyers identify any potential risks and ensure compliance with standards.

-

Request Reports: Suppliers should provide documentation of their QA processes, including IQC, IPQC, and FQC results. These reports can help verify that the supplier adheres to international standards.

-

Utilize Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality practices. This is particularly important for international transactions, where local regulations may differ.

What Unique Quality Control Considerations Exist for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance:

-

Cultural Differences: Understanding and navigating cultural differences in business practices and expectations can be crucial for effective communication with suppliers.

-

Regulatory Compliance: Different regions may have varying regulations regarding materials used in casting. Buyers should ensure that their suppliers are compliant with local laws.

-

Logistical Challenges: Transporting iron castings across borders can introduce risks related to damage and quality degradation. Proper packaging and shipping procedures are essential to mitigate these risks.

By understanding the manufacturing processes and quality assurance practices for iron used in casting, B2B buyers can make informed decisions, ensuring that they source high-quality materials that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘iron for casting’

To assist international B2B buyers in sourcing iron for casting effectively, this practical guide provides a structured checklist. By following these steps, you can ensure that your procurement process is efficient, cost-effective, and aligned with your technical needs.

Step 1: Define Your Technical Specifications

Clearly outline the specifications required for your iron casting projects. This includes the grade of iron, the desired mechanical properties, and any specific chemical composition needed for your applications. Defining these parameters will help you communicate effectively with suppliers and ensure that the materials you receive meet your production standards.

Illustrative image related to iron for casting

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of iron for casting. Look for suppliers with a solid track record in the industry, focusing on those who specialize in the specific types of iron you require. Utilize online directories, industry associations, and trade shows to compile a list of candidates.

- Check for Regional Availability: Ensure that the suppliers you consider can reliably deliver to your location in Africa, South America, the Middle East, or Europe.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with international standards. This is crucial as it assures you of the quality and safety of the materials. Look for certifications such as ISO 9001 for quality management systems and ISO 14001 for environmental management.

- Request Documentation: Ask for copies of certifications and any relevant quality assurance documentation to review their compliance.

Step 4: Request Sample Materials

Once you have shortlisted potential suppliers, request samples of the iron they offer. This step is essential to evaluate the quality and suitability of the material for your specific casting processes. Pay attention to the physical characteristics and any certifications associated with the sample.

- Conduct Tests: Perform tests on the samples to ensure they meet your technical specifications and quality requirements.

Step 5: Assess Pricing and Terms

Negotiate pricing and terms with your selected suppliers. Ensure you understand the total cost, including shipping, taxes, and potential tariffs that may apply. Consider the supplier’s payment terms and delivery timelines, as these can impact your overall project budget and schedule.

- Compare Offers: Don’t just settle for the first quote; compare offers from multiple suppliers to find the best value without compromising quality.

Step 6: Review Customer References

Ask potential suppliers for references from other businesses that have used their iron for casting. This will give you insights into their reliability, customer service, and the quality of their products. Contact these references to gain firsthand feedback about their experiences.

- Look for Industry-Specific References: Prioritize references from companies in your industry or similar sectors to ensure relevant feedback.

Step 7: Finalize the Contract

Once you are satisfied with the supplier’s quality, pricing, and references, finalize the contract. Ensure that all terms are clearly outlined, including delivery schedules, payment terms, and quality guarantees. This formal agreement will protect both parties and set clear expectations.

By following this checklist, B2B buyers can streamline their sourcing process for iron for casting, ensuring they secure high-quality materials that meet their specific needs while building strong relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for iron for casting Sourcing

When sourcing iron for casting, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers. This analysis provides insights into the various cost components, price influencers, and practical tips for negotiation, specifically tailored for international buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Iron for Casting?

The cost structure for iron for casting typically encompasses several components:

-

Materials: The primary cost driver is the raw material itself. The price of iron can fluctuate based on global market conditions, demand, and the quality of the iron sourced (e.g., scrap vs. virgin material).

-

Labor: Labor costs vary significantly depending on the region. For instance, countries with lower labor costs may offer a competitive edge. However, skilled labor for handling and processing iron can be more expensive, affecting overall pricing.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overheads, thus lowering the final price.

-

Tooling: The investment in tooling for casting molds and patterns is essential. Custom tooling can incur significant upfront costs but may offer savings in the long run through improved efficiencies.

-

Quality Control (QC): Ensuring the quality of cast iron products is paramount. QC processes add to the cost but are essential for meeting industry standards and customer specifications.

-

Logistics: Transporting raw materials and finished goods introduces additional costs. Factors such as distance, transportation modes, and local infrastructure impact logistics expenses.

-

Margin: Suppliers will typically add a margin to cover their costs and achieve profit. Understanding the market rates can help buyers gauge if the offered price is competitive.

What Influences the Pricing of Iron for Casting?

Several factors can affect the pricing of iron for casting:

-

Volume/MOQ: Bulk purchases often attract discounts. Understanding the minimum order quantities (MOQs) can help buyers negotiate better prices.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized processes or materials. It’s essential to balance quality requirements with budget constraints.

-

Materials Quality and Certifications: Higher quality iron, or those meeting specific certifications, may come at a premium. Buyers should assess the trade-off between cost and quality.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding Incoterms is vital for international transactions. The chosen terms can significantly affect the total landed cost, including shipping, insurance, and customs duties.

How Can Buyers Negotiate Effectively for Iron for Casting?

-

Research and Benchmarking: Conduct thorough market research to understand current pricing trends. Comparing quotes from multiple suppliers can provide leverage in negotiations.

-

Cost-Efficiency Focus: Emphasize total cost of ownership (TCO) rather than just the purchase price. Consider logistics, quality, and potential rework costs when evaluating offers.

-

Volume Commitments: If feasible, commit to larger volumes for better pricing. Suppliers are often willing to negotiate lower prices for guaranteed long-term contracts.

-

Flexibility in Specifications: If possible, be open to adjusting specifications to align with available products, which can result in cost savings.

-

Utilizing Incoterms: Clearly define shipping responsibilities and costs in negotiations to avoid unexpected expenses later in the procurement process.

Conclusion: What Should International Buyers Keep in Mind?

Buyers from Africa, South America, the Middle East, and Europe should approach the procurement of iron for casting with a comprehensive understanding of the cost structure and pricing dynamics. While indicative prices can provide a baseline, actual costs may vary based on the factors discussed. By employing effective negotiation strategies and focusing on total cost efficiency, buyers can secure favorable terms that align with their operational needs.

Alternatives Analysis: Comparing iron for casting With Other Solutions

Exploring Alternatives to Iron for Casting: A Comparative Analysis

When evaluating materials for casting, iron remains a popular choice due to its strength, durability, and casting properties. However, various alternatives can offer unique benefits depending on specific project requirements. This analysis compares iron for casting with aluminum and steel casting, providing insights into their respective advantages and disadvantages to help B2B buyers make informed decisions.

| Comparison Aspect | Iron For Casting | Aluminum Casting | Steel Casting |

|---|---|---|---|

| Performance | High strength, good wear resistance, excellent machinability | Lightweight, good corrosion resistance, lower melting point | Very high strength, excellent toughness and ductility |

| Cost | Moderate initial cost, but can be economical in large quantities | Generally higher due to raw material and processing costs | Higher than iron and aluminum, influenced by alloying elements |

| Ease of Implementation | Requires specialized furnaces and handling | Easier to work with due to lower melting point | More complex due to higher melting temperatures and equipment needs |

| Maintenance | Requires regular maintenance of molds and furnaces | Generally lower maintenance, molds can be reused | High maintenance due to wear from high temperatures |

| Best Use Case | Heavy machinery, automotive parts, and construction | Aerospace, automotive, and consumer products | Structural components, heavy machinery, and high-stress applications |

Aluminum Casting: Pros and Cons

Aluminum casting offers several advantages, particularly in applications where weight reduction is critical. Its low density makes it ideal for industries like aerospace and automotive, where every gram counts. Additionally, aluminum has excellent corrosion resistance, making it suitable for outdoor and marine applications. However, the initial cost of aluminum is typically higher than that of iron, and its lower melting point can limit its use in high-temperature applications.

Steel Casting: Pros and Cons

Steel casting is renowned for its high strength and versatility, making it a go-to choice for structural components and heavy machinery. Its toughness and ductility allow it to withstand significant stress, which is essential in industries such as construction and manufacturing. However, the production process for steel casting is more complex and costly compared to iron and aluminum. Additionally, the higher melting temperatures require specialized equipment, which can increase operational costs and maintenance requirements.

Conclusion: How to Choose the Right Casting Material for Your Needs

When deciding between iron for casting and its alternatives, B2B buyers should carefully consider their specific project requirements, including the intended application, performance needs, and budget constraints. Iron remains a solid choice for heavy-duty applications due to its strength and cost-effectiveness, while aluminum may be preferable for lightweight designs. Steel, though typically more expensive, offers unmatched strength for high-stress applications. Ultimately, the right decision will depend on a thorough assessment of these factors, ensuring the chosen material aligns with both immediate and long-term business goals.

Essential Technical Properties and Trade Terminology for iron for casting

What Are the Key Technical Properties of Iron for Casting?

When sourcing iron for casting, understanding its technical properties is crucial for ensuring that the material meets the specific needs of your production processes. Below are some essential specifications that B2B buyers should consider:

-

Material Grade

Material grades for cast iron can vary significantly, influencing properties such as strength, ductility, and machinability. Common grades include Gray Iron (e.g., ASTM A48) and Ductile Iron (e.g., ASTM A536). Each grade has specific applications; for instance, Gray Iron is often used for engine blocks, while Ductile Iron is favored for components requiring higher tensile strength. Knowing the right grade ensures optimal performance and longevity in your products. -

Tensile Strength

Tensile strength measures a material’s resistance to being pulled apart and is critical for determining how well the iron will perform under load. High tensile strength is essential for components subjected to high stress, such as machinery parts. Buyers should request tensile strength specifications to ensure that the iron can withstand operational demands. -

Hardness

Hardness indicates a material’s resistance to deformation and wear. It is measured using scales such as Brinell or Rockwell. For casting applications, hardness affects wear resistance and machinability. A harder iron may be more durable but could pose challenges during machining, so balancing these factors is vital for production efficiency. -

Ductility

Ductility reflects how much a material can deform before fracturing, which is crucial for applications that require bending or shaping without breaking. Ductile Iron, for example, has superior ductility compared to traditional Gray Iron, making it suitable for components that need to absorb shocks. Buyers should consider ductility to avoid brittle failures in critical applications. -

Chemical Composition

The chemical composition of iron for casting can significantly affect its properties and performance. Key elements include carbon, silicon, and manganese, which influence the iron’s mechanical characteristics. Buyers must review the chemical composition specifications to ensure compatibility with their applications and to avoid unexpected performance issues.

What Are Common Trade Terminology and Jargon in Iron Casting?

Navigating the world of iron for casting involves understanding specific trade terms that facilitate effective communication and transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of casting, knowing whether a supplier is an OEM can indicate the quality and reliability of the iron products you are considering. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management. Buyers should inquire about MOQ to ensure it aligns with their production needs without incurring unnecessary costs. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing for specific quantities of products. It is essential for obtaining competitive pricing and ensuring that all suppliers are evaluated on the same basis. Including detailed specifications in your RFQ can lead to more accurate and tailored responses. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international transactions, as it helps clarify who is responsible for shipping costs, risks, and logistics. -

Casting Tolerance

Casting tolerance defines the allowable deviation from specified dimensions in a casting. Understanding tolerances is essential for ensuring that cast parts fit and function correctly within assemblies. Buyers should communicate their tolerance requirements clearly to avoid costly rework or delays.

By familiarizing yourself with these technical properties and trade terminologies, you can make informed decisions when sourcing iron for casting, ultimately enhancing the efficiency and quality of your production processes.

Navigating Market Dynamics and Sourcing Trends in the iron for casting Sector

What Are the Current Market Dynamics and Key Trends in the Iron for Casting Sector?

The global iron for casting market is undergoing significant transformations influenced by a range of factors. One of the primary drivers is the increasing demand for cast iron components in automotive, construction, and machinery sectors. As industries pivot towards sustainability, there’s a growing preference for recycled cast iron, sourced from scrap materials like used brake rotors. This shift not only reduces production costs but also aligns with circular economy principles.

Emerging technologies are reshaping sourcing practices as well. The adoption of Industry 4.0 technologies, such as IoT and AI, enhances supply chain transparency, enabling buyers to monitor material quality and provenance in real time. Advanced data analytics are also being leveraged to optimize procurement strategies, facilitating better inventory management and reducing lead times. Buyers from regions like Africa and South America are particularly benefiting from these advancements, as they seek reliable suppliers amidst fluctuating market conditions.

Illustrative image related to iron for casting

Furthermore, geopolitical factors, such as trade tariffs and regulations, are impacting sourcing strategies. For instance, buyers in the Middle East and Europe must navigate complex import regulations, which can affect supply chain dynamics. To remain competitive, international buyers are encouraged to diversify their supplier base and consider partnerships with local foundries that can provide not just materials, but also added value through processing and logistics support.

How Can Sustainability and Ethical Sourcing Be Integrated into B2B Practices for Iron for Casting?

Sustainability is becoming a non-negotiable aspect of sourcing strategies in the iron for casting sector. The environmental impact of traditional iron production, which is often carbon-intensive, is prompting buyers to prioritize suppliers who adopt sustainable practices. This includes the use of recycled materials, which significantly reduces the carbon footprint associated with sourcing new iron.

Ethical sourcing is equally crucial. Buyers are increasingly scrutinizing their supply chains to ensure compliance with labor standards and environmental regulations. This is particularly important in regions like Africa and South America, where labor practices can vary widely. By choosing suppliers with recognized sustainability certifications—such as ISO 14001 or LEED—businesses can bolster their reputation and appeal to environmentally conscious customers.

Illustrative image related to iron for casting

Moreover, the market is seeing a rise in ‘green’ iron products, which are produced using lower emissions technologies. These products not only meet the growing demand for sustainable materials but also offer a competitive edge in procurement processes. For B2B buyers, integrating sustainability into sourcing strategies is not just a regulatory requirement; it is a pathway to long-term profitability and resilience in an ever-evolving market landscape.

What Is the Historical Context of Iron for Casting in B2B Transactions?

The use of iron for casting dates back thousands of years, with its applications evolving alongside technological advancements. Historically, cast iron was primarily utilized in the production of cookware and structural components due to its durability and excellent casting properties.

As industrialization gained momentum in the 19th century, the demand for cast iron surged, particularly in the automotive and construction sectors. The introduction of mass production techniques allowed for more efficient manufacturing processes, significantly lowering costs and increasing availability. Today, the market is characterized by a blend of traditional practices and modern technological innovations, such as 3D printing and advanced metallurgy, which continue to shape the landscape of iron for casting.

Understanding this historical context can provide valuable insights for B2B buyers, highlighting the importance of adaptability and innovation in sourcing strategies. As the market continues to evolve, recognizing the legacy of iron casting can empower businesses to make informed decisions that align with both current trends and future opportunities.

Illustrative image related to iron for casting

Frequently Asked Questions (FAQs) for B2B Buyers of iron for casting

-

How do I ensure the quality of iron for casting?

To ensure the quality of iron for casting, request certifications and test reports from your supplier. Look for materials that meet international standards, such as ASTM or ISO certifications. Conduct periodic audits and quality checks during production and before shipment. Establish a clear quality assurance process that includes visual inspections and mechanical testing of the iron to confirm its properties, ensuring it meets your specific casting requirements. -

What is the best type of iron for casting applications?

The best type of iron for casting applications typically depends on the specific requirements of your project. Gray cast iron is favored for its excellent machinability and wear resistance, making it ideal for engine blocks and machine bases. Ductile iron, known for its strength and ductility, is preferred for parts subject to high stress. Evaluate the mechanical properties and performance characteristics needed for your application to make an informed choice. -

How can I vet potential suppliers of iron for casting?

Vetting potential suppliers involves assessing their reputation, production capabilities, and compliance with international standards. Start by researching their history and client testimonials. Request samples and conduct quality assessments. Verify their certifications and check for any industry-specific compliance. Building relationships through direct communication can help you gauge their responsiveness and reliability in meeting your needs. -

What are the typical minimum order quantities (MOQs) for iron casting materials?

Minimum order quantities (MOQs) for iron casting materials can vary widely depending on the supplier and the type of iron. Typically, MOQs range from a few tons to several dozen tons. It’s essential to discuss your requirements with potential suppliers and negotiate terms that suit your production needs. Some suppliers may offer flexibility for first-time orders or smaller projects, so clarify these details upfront. -

What payment terms should I expect when sourcing iron for casting?

Payment terms for sourcing iron for casting can differ based on the supplier’s policies and your negotiation. Common terms include a deposit upon order confirmation (often 30% to 50%) with the balance due before shipment. Some suppliers may offer credit terms for long-term clients. Ensure you clarify payment methods accepted, such as letters of credit, wire transfers, or payment through platforms like PayPal, to avoid any misunderstandings. -

How do I handle logistics when importing iron for casting?

Handling logistics for importing iron involves coordinating shipping methods, customs clearance, and delivery timelines. Work with a freight forwarder experienced in international shipping to navigate regulations and tariffs. Ensure that your supplier provides necessary shipping documents, such as bills of lading and certificates of origin. Plan for potential delays by allowing ample time for customs processing and arranging storage if necessary upon arrival. -

What customization options are available for iron casting?

Customization options for iron casting can include variations in alloy composition, surface treatments, and specific dimensions to meet your project requirements. Many suppliers offer tailored solutions based on your technical specifications, including the addition of elements like silicon or nickel for enhanced properties. Discuss your needs with the supplier to explore available customization options and any associated costs or lead times. -

What are the key quality assurance practices for iron casting suppliers?

Key quality assurance practices for iron casting suppliers include implementing strict material inspections, conducting mechanical property tests, and maintaining comprehensive documentation of production processes. Suppliers should follow standardized procedures for testing chemical composition and physical properties of the iron. Regular audits and adherence to industry certifications ensure that the supplier consistently meets quality standards, reducing the risk of defects in the final product.

Top 7 Iron For Casting Manufacturers & Suppliers List

1. Reddit – Cast Iron Production Techniques

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: To make cast iron, you can use scrap cast iron from a scrapyard, which can be smashed into manageable pieces and melted down in a foundry furnace. The process involves pouring the molten iron into a sand mold. Alternatively, you can purchase round-bar cast iron stock from metal suppliers, although this may be more expensive. For larger scale production, a cupola furnace can be used, which requires…

2. Hackaday – Recycling Cast Iron for Home Foundries

Domain: hackaday.com

Registered: 2004 (21 years)

Introduction: The article discusses the use of cast iron in home foundries, highlighting its advantages over aluminum. It features a user named luckygen1001 who recycles cast iron from car disc brake rotors, which are often available for free at local brake shops. The process involves scoring the rotors with an angle grinder and breaking them into smaller pieces. The furnace used for melting operates on a mixtu…

3. Instructables – Iron Melting Project

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Iron melting and casting project involving the creation of an iron plaque. Key details include:

– Melting point: 1500 °C (2732 °F)

– Material used: Iron pipe, crushed into small pieces

– Fuel used: Hell fuel

– Final product: Channel iron plaque, with a note that more iron could be added for improvement.

4. iForgeIron – Metal Casting Essentials

Domain: iforgeiron.com

Registered: 2001 (24 years)

Introduction: Overview of metal casting for beginners, including smelting, melting, foundry, and casting techniques. Key points include: 1. Safety precautions: Use goggles, faceshield, thick leather jacket, welding gloves, jeans, and heavy leather boots. Keep dry sand and a shovel on hand for spills. 2. Crucibles: Recommended not to use homemade crucibles for metals hotter than aluminum. Proper crucibles are es…

5. Engineering – Permanent Casting Molds for Cast Iron

Domain: engineering.stackexchange.com

Registered: 2009 (16 years)

Introduction: Materials commonly used for permanent casting molds for cast iron include: 1. Cast Iron – Often used for small ingots in artisan foundries. 2. Steel – More difficult to manufacture but also suitable. 3. Solid Graphite – Used for simple shapes, but brittle and requires careful design to avoid fractures due to shrinkage.

6. Quaker City Castings – High-Quality Iron Castings

Domain: quakercitycastings.com

Registered: 2016 (9 years)

Introduction: Quaker City Castings produces high-quality iron castings in the USA, specializing in no-bake sand casting for gray iron and ductile iron. The iron castings are designed for demanding industrial applications, offering superior dimensional accuracy, excellent surface finish, and enhanced structural integrity. Key advantages include cost-effectiveness for high volumes, versatility in alloys, and high…

7. Taylor & Fenn – Gray and Ductile Iron Casting

Domain: taylorfenn.com

Registered: 1996 (29 years)

Introduction: The Taylor & Fenn Company is a cast iron foundry specializing in gray iron and ductile iron casting. They handle component casting complexities and sizes from one pound to 6,000-pound molds. Customers can provide their own patterns or use in-house designs. The foundry works with over 100 grades of iron and steel, including high-chrome irons. Gray iron has a composition of 2.5 – 4% carbon and 1 – 3…

Strategic Sourcing Conclusion and Outlook for iron for casting

In summary, strategic sourcing of iron for casting is pivotal for manufacturers seeking to enhance product quality, reduce costs, and ensure supply chain resilience. By exploring diverse sourcing options, including recycled materials like cast iron from automotive components, businesses can capitalize on both economic and environmental benefits. The global demand for high-quality cast iron continues to rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe, making it essential for buyers to establish robust supplier relationships.

Investing in strategic sourcing not only mitigates risks associated with market volatility but also opens doors to innovative practices that can improve production efficiency. As international B2B buyers navigate this landscape, staying informed about evolving technologies and market trends will empower them to make well-informed decisions.

Looking ahead, it’s crucial for buyers to actively engage with suppliers, leverage new materials, and adopt sustainable practices. By doing so, they will not only enhance their competitive edge but also contribute to a more sustainable future in the casting industry. Embrace the opportunity to refine your sourcing strategy today and position your business for long-term success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to iron for casting

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.