The Definitive Guide to Invisible Induction Cooktop: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for invisible induction cooktop

In an era where culinary innovation meets modern design, the invisible induction cooktop emerges as a game-changer for the global market. As international B2B buyers seek advanced kitchen solutions that combine safety, efficiency, and aesthetics, the challenge of sourcing reliable and cutting-edge products becomes paramount. This comprehensive guide delves into the multifaceted world of invisible induction cooktops, exploring various types, applications, and the latest technological advancements that cater to diverse markets, including Africa, South America, the Middle East, and Europe—specifically Germany and Saudi Arabia.

Buyers will gain invaluable insights into the intricacies of supplier vetting processes, ensuring that they partner with reputable manufacturers who uphold quality and safety standards. Additionally, we will address cost considerations, helping businesses make informed financial decisions while investing in these innovative cooking solutions. By equipping B2B stakeholders with the necessary knowledge and tools, this guide empowers them to confidently navigate the complexities of the invisible induction cooktop market, enhancing their product offerings and ultimately meeting the evolving demands of consumers.

Whether you are aiming to elevate kitchen designs in residential spaces or enhance culinary experiences in commercial settings, this guide serves as your essential resource for making strategic purchasing decisions in the dynamic landscape of modern cooking technology.

Understanding invisible induction cooktop Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flush-Mount Induction Cooktop | Installed directly beneath the countertop, seamless design | Residential kitchens, luxury homes | Pros: Aesthetic appeal, space-saving. Cons: Higher installation costs, requires specific materials. |

| Portable Induction Cooktop | Standalone units, easy to move and store | Restaurants, catering, outdoor events | Pros: Flexibility, easy to clean. Cons: Limited cooking surface area, may lack power. |

| Integrated Induction Countertop | Combines cooking surface with countertop for a unified look | High-end residential, commercial kitchens | Pros: Elegant design, efficient cooking. Cons: Complex installation, potential compatibility issues. |

| Multi-Burner Induction System | Multiple cooking zones with independent controls | Commercial kitchens, large-scale events | Pros: High capacity, versatile cooking options. Cons: Requires significant space, higher energy consumption. |

| Smart Induction Cooktop | Wi-Fi enabled, app-controlled for remote operation | Modern homes, tech-savvy environments | Pros: Convenience, precise control. Cons: Dependence on technology, potential connectivity issues. |

What are the Characteristics of Flush-Mount Induction Cooktops?

Flush-mount induction cooktops are designed to be installed directly beneath the kitchen countertop, creating a seamless and modern aesthetic. This type is particularly suitable for high-end residential applications, where the emphasis is on design and functionality. B2B buyers should consider the installation requirements, as it often necessitates specific countertop materials like ultra-compact porcelain. While they offer significant aesthetic benefits and save counter space, the initial installation costs can be higher compared to traditional cooktops.

Why Choose Portable Induction Cooktops for Catering Needs?

Portable induction cooktops are standalone units that offer flexibility and ease of use, making them ideal for catering services, outdoor events, and restaurants. They are lightweight and easy to store, allowing for quick setup and breakdown. B2B buyers in the food service industry appreciate their portability, but should be aware of their limited cooking surface area and power output, which may restrict their use in high-demand scenarios.

What Makes Integrated Induction Countertops Ideal for Commercial Kitchens?

Integrated induction countertops merge cooking surfaces with the countertop material, providing an elegant and functional cooking area. This type is favored in luxury residential and commercial kitchens, where aesthetics and efficiency are paramount. B2B purchasers should evaluate the installation complexity and compatibility with existing kitchen designs. While these systems enhance the cooking experience and streamline cleaning, they may require more extensive installation efforts compared to standalone units.

How Do Multi-Burner Induction Systems Benefit Large-Scale Operations?

Multi-burner induction systems feature several cooking zones, allowing multiple dishes to be prepared simultaneously. This capability is essential for commercial kitchens and large-scale events, where efficiency and capacity are critical. B2B buyers should consider the space requirements and energy consumption associated with these systems. While they provide versatility and high cooking capacity, they also demand a larger footprint and may lead to increased operational costs.

What Advantages Do Smart Induction Cooktops Offer for Modern Homes?

Smart induction cooktops come equipped with Wi-Fi capabilities and app controls, enabling users to manage cooking from remote locations. This type is particularly appealing to tech-savvy consumers and modern homes that prioritize convenience and innovation. B2B buyers should assess the technological requirements and potential connectivity issues. While these cooktops enhance user experience and offer precise cooking control, their reliance on technology may pose challenges in less tech-friendly environments.

Key Industrial Applications of invisible induction cooktop

| Industry/Sector | Specific Application of Invisible Induction Cooktop | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | High-end restaurant kitchens where aesthetics are paramount | Enhances the dining experience with a sleek, modern look | Durability, ease of cleaning, and compliance with safety standards |

| Residential Development | Luxury apartments and homes with integrated kitchen solutions | Maximizes space and adds value to properties | Compatibility with various countertop materials and installation requirements |

| Catering Services | Mobile catering units and food trucks | Provides a versatile cooking solution in compact spaces | Energy efficiency and portability features |

| Education | Culinary schools and training kitchens | Offers a safe and modern cooking environment for students | Robustness and ease of use for diverse cooking techniques |

| Healthcare | Hospital kitchens and patient meal preparation areas | Ensures safety and efficiency in food preparation | Hygiene standards and energy consumption considerations |

How is the Invisible Induction Cooktop Used in Hospitality Settings?

In high-end restaurants, the invisible induction cooktop is often utilized in open kitchen designs, allowing chefs to cook directly on the countertop. This innovative technology not only elevates the visual appeal of the kitchen but also enhances safety, as the surface remains cool to the touch. The ability to seamlessly integrate cooking into the dining environment fosters an engaging atmosphere for guests. Buyers in the hospitality sector must prioritize durability and ease of cleaning, as well as compliance with local food safety regulations, to ensure a successful integration into their kitchen operations.

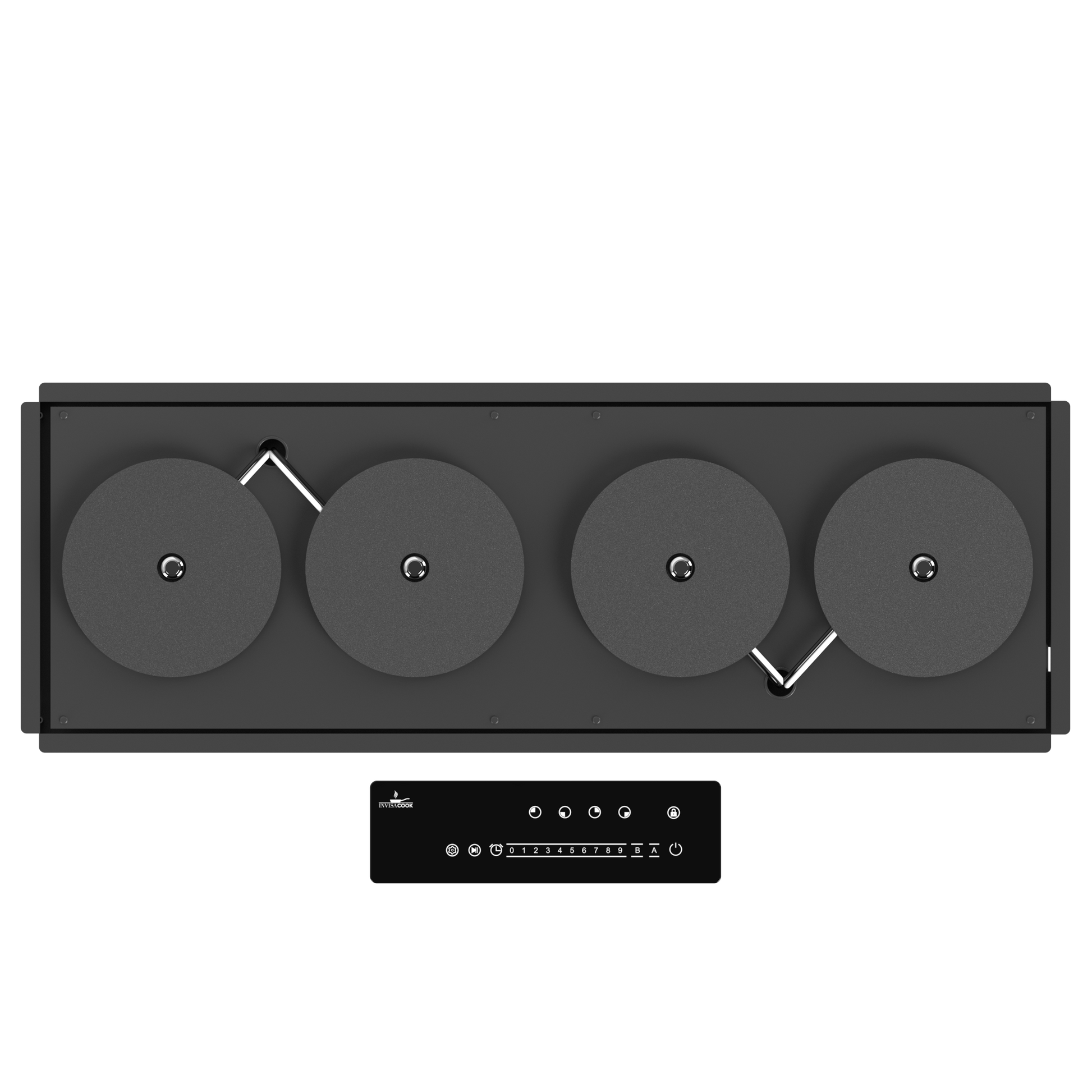

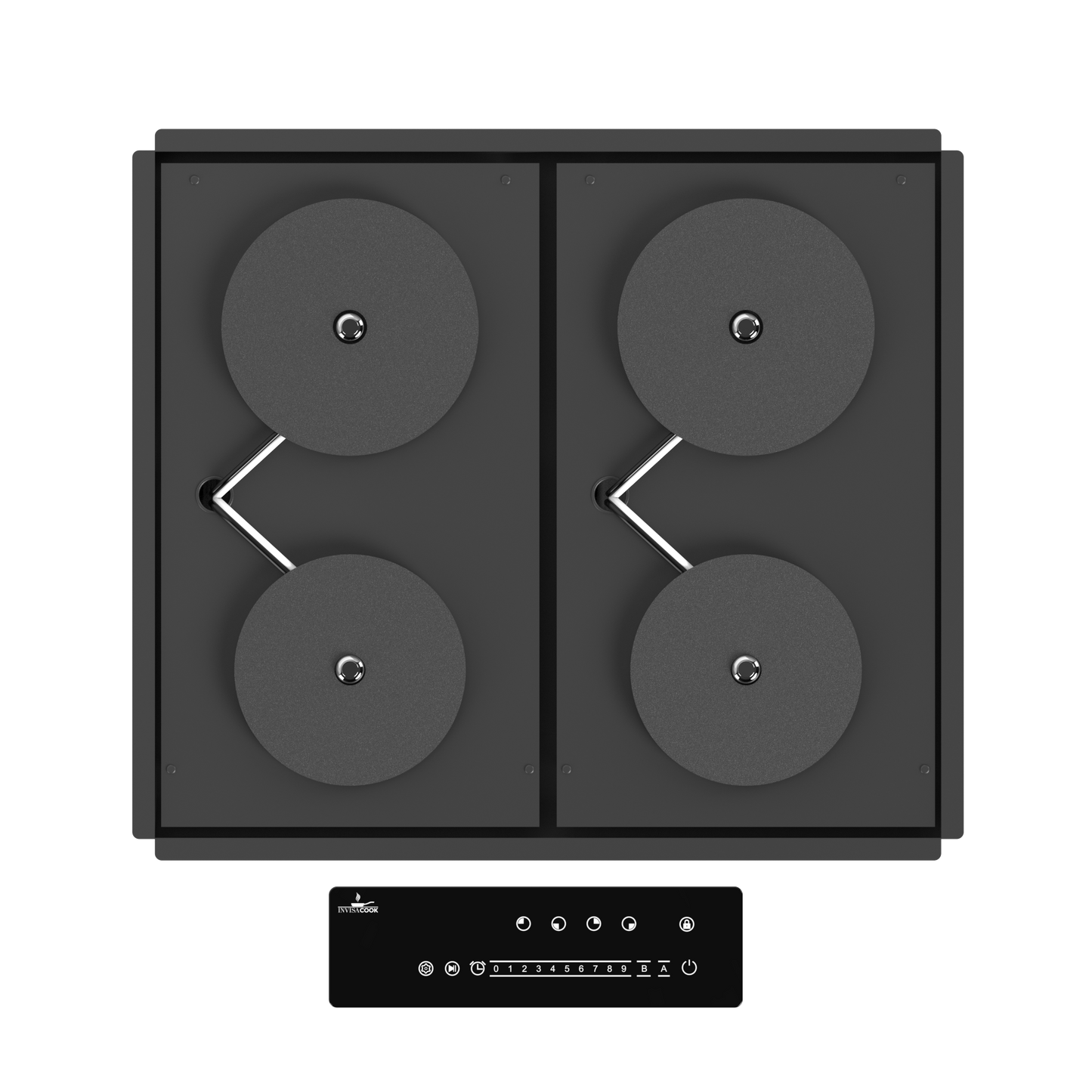

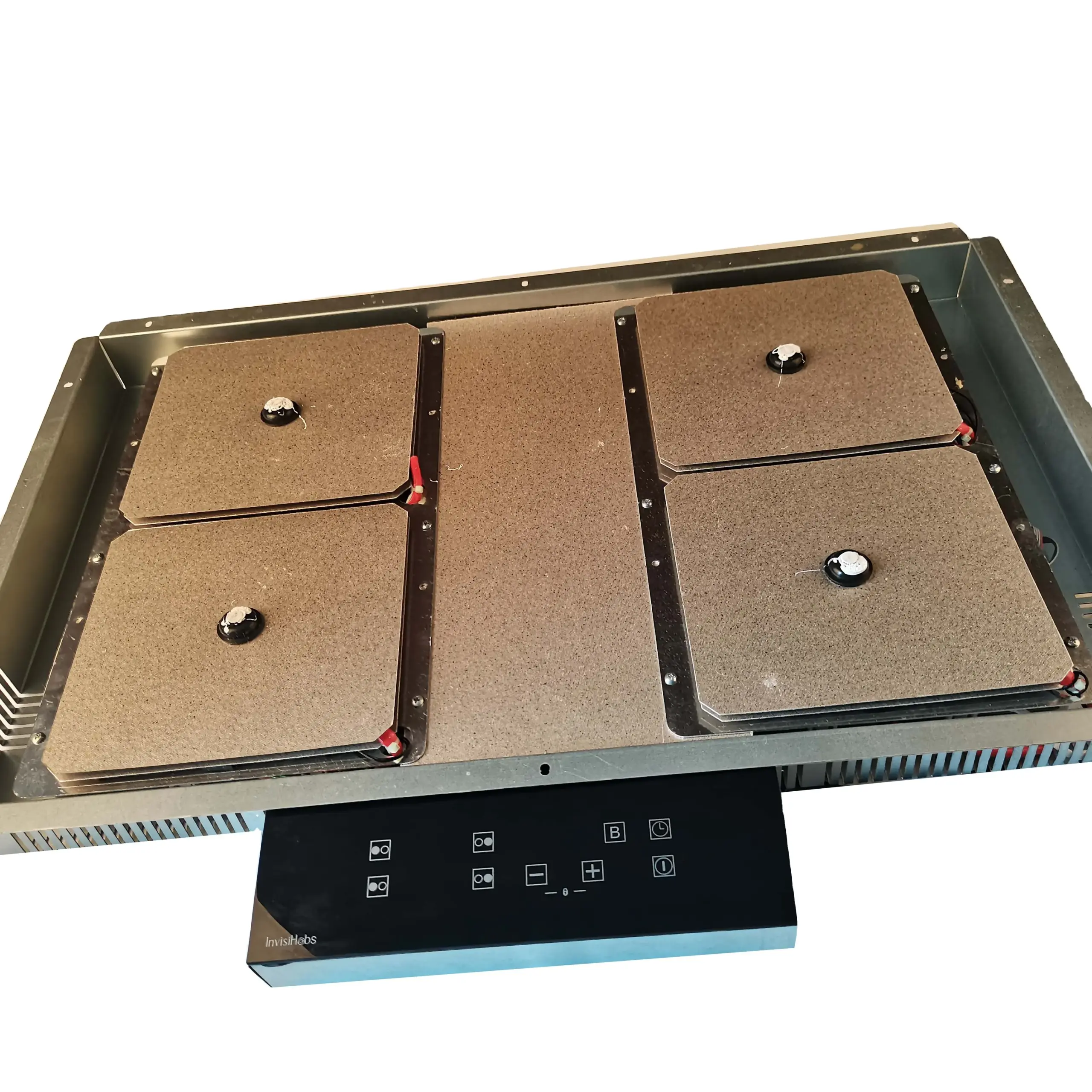

Illustrative image related to invisible induction cooktop

What Role Does the Invisible Induction Cooktop Play in Residential Development?

For luxury apartments and homes, invisible induction cooktops represent a modern solution that maximizes kitchen space while providing an elegant cooking surface. These cooktops can be installed under various countertop materials, allowing architects and developers to design kitchens that are both functional and aesthetically pleasing. The value added to properties equipped with such innovative cooking solutions can be significant, appealing to high-end buyers. International buyers should consider the compatibility of these cooktops with local building codes and the specific countertop materials available in their regions.

How Do Catering Services Benefit from Invisible Induction Cooktops?

Mobile catering units and food trucks benefit greatly from the compact and efficient design of invisible induction cooktops. These cooktops allow caterers to prepare meals in limited spaces while maintaining high safety standards. The ability to control cooking temperatures precisely ensures food quality, while the cooktops’ energy efficiency can reduce operational costs. When sourcing for this application, catering businesses should focus on the portability of the cooktop and its power requirements to ensure it meets the demands of various event settings.

Why are Invisible Induction Cooktops Ideal for Culinary Education?

Culinary schools utilize invisible induction cooktops to create a safe and modern cooking environment for their students. The lack of visible burners reduces the risk of burns, allowing students to focus on mastering cooking techniques without safety concerns. Additionally, the efficiency of induction cooking aligns with the fast-paced nature of culinary training. Institutions should consider the robustness of the cooktops and their ability to withstand heavy use, as well as the ease of use for students at various skill levels.

Illustrative image related to invisible induction cooktop

How is the Invisible Induction Cooktop Used in Healthcare Facilities?

In healthcare settings, invisible induction cooktops are ideal for hospital kitchens and patient meal preparation areas. Their safety features, such as minimal residual heat, help prevent burns in busy environments where staff may be multitasking. Additionally, the efficiency of induction cooking allows for quicker meal preparation, which is crucial in healthcare settings. Buyers in this sector should ensure that the cooktops comply with stringent hygiene standards and consider energy consumption to align with sustainability goals.

3 Common User Pain Points for ‘invisible induction cooktop’ & Their Solutions

Scenario 1: Compatibility Concerns with Countertop Materials

The Problem: B2B buyers often face challenges when selecting the right countertop materials for invisible induction cooktops. Many surfaces, such as common quartz or marble, may not be compatible with induction technology due to their heat resistance and thermal conductivity. This can lead to potential project delays, increased costs, and dissatisfaction among clients who expect seamless integration of high-end appliances with their kitchen design.

The Solution: To overcome this challenge, it is crucial for buyers to thoroughly research and specify countertop materials that are recommended for use with invisible induction cooktops. Opt for ultra-compact porcelain materials, which not only provide the necessary durability but also ensure optimal heat distribution. When sourcing materials, consult manufacturers’ guidelines and reach out to suppliers who specialize in induction-compatible surfaces. Additionally, consider creating a sample board that includes various countertop options alongside the induction cooktop to help clients visualize the final design. This proactive approach not only mitigates compatibility issues but also enhances customer satisfaction by providing a cohesive and aesthetically pleasing kitchen solution.

Scenario 2: Installation Challenges and Technical Support

The Problem: The installation of invisible induction cooktops can be technically demanding, requiring specialized knowledge and skills. B2B buyers may encounter issues related to improper installation, which can lead to functionality problems, safety hazards, and costly repairs. This becomes particularly problematic in regions where access to qualified technicians is limited, resulting in frustration for buyers and end-users alike.

The Solution: To address installation challenges, buyers should prioritize partnerships with reputable suppliers who offer comprehensive installation support and training. Ensure that your supply chain includes manufacturers that provide detailed installation manuals, video tutorials, and access to technical support teams. Additionally, consider organizing training sessions or workshops for local technicians to familiarize them with the installation process of invisible induction cooktops. By investing in proper training and support, B2B buyers can minimize installation errors and enhance the overall reliability of the product, leading to increased customer trust and satisfaction.

Scenario 3: Educating End-Users on Usage and Safety

The Problem: A common pain point for B2B buyers is the need to educate end-users about the functionality and safety of invisible induction cooktops. Many consumers are unfamiliar with how induction cooking works, leading to misconceptions about safety and usability. This lack of knowledge can result in poor user experiences, negative reviews, and ultimately, lower sales for buyers.

Illustrative image related to invisible induction cooktop

The Solution: To effectively educate end-users, B2B buyers should create comprehensive user guides and instructional materials that clearly outline how to operate and maintain invisible induction cooktops. Incorporate visual aids such as infographics and videos that demonstrate the cooking process, safety features, and cleaning techniques. Additionally, consider hosting cooking demonstrations or webinars to showcase the benefits and ease of use of induction cooking. This not only helps demystify the technology for consumers but also fosters a positive relationship between buyers and their customers, ultimately driving sales and enhancing brand loyalty.

Strategic Material Selection Guide for invisible induction cooktop

What Materials Are Best for Invisible Induction Cooktops?

When selecting materials for invisible induction cooktops, it is essential to consider their properties, advantages, disadvantages, and how they align with the needs of international B2B buyers. Here, we analyze four common materials: ultra-compact porcelain, quartzite, granite, and composite materials.

How Does Ultra-Compact Porcelain Perform in Invisible Induction Cooktops?

Ultra-compact porcelain is a popular choice for invisible induction cooktops due to its excellent thermal resistance and durability. This material can withstand high temperatures without warping or cracking, making it ideal for direct cooking applications. Its non-porous surface also provides resistance to stains and scratches, ensuring longevity.

Pros: Ultra-compact porcelain is highly durable, easy to clean, and aesthetically versatile, allowing for various finishes and colors. It is also relatively lightweight, which can simplify installation.

Cons: The primary drawback is its cost, which can be higher than traditional materials. Additionally, while it is robust, it can be fragile during manufacturing and installation, requiring careful handling.

Impact on Application: Ultra-compact porcelain is suitable for high-temperature cooking and is compatible with various cookware materials. However, it may not be ideal in environments where extreme impacts are common.

Illustrative image related to invisible induction cooktop

Considerations for International Buyers: Buyers in regions such as Europe and the Middle East should ensure compliance with local safety and quality standards, such as ASTM or DIN. The demand for high-quality materials is particularly strong in these markets.

What About Quartzite for Invisible Induction Cooktops?

Quartzite is a natural stone known for its strength and heat resistance. It can endure high temperatures, making it suitable for induction cooktops. Its unique veining and patterns also add an aesthetic appeal that many buyers find attractive.

Pros: Quartzite is incredibly durable and resistant to scratching and heat, providing a long-lasting surface. Its natural beauty can enhance kitchen designs significantly.

Illustrative image related to invisible induction cooktop

Cons: The main limitation is its weight, which can complicate installation. Additionally, quartzite can be more expensive than other materials, and its availability may vary by region.

Impact on Application: Quartzite is well-suited for environments requiring high durability and heat resistance. However, its porous nature means it may require sealing to prevent staining, particularly in kitchens.

Considerations for International Buyers: Buyers should verify the sourcing of quartzite to ensure compliance with environmental and safety standards. In regions like Africa and South America, the availability of high-quality quartzite can vary, impacting procurement strategies.

How Does Granite Compare for Invisible Induction Cooktops?

Granite is another natural stone option that offers durability and aesthetic appeal. It is resistant to heat and scratching, making it a viable choice for induction cooktops.

Illustrative image related to invisible induction cooktop

Pros: Granite is widely available and offers a classic look that many consumers prefer. It is also relatively easy to maintain and clean.

Cons: Like quartzite, granite is heavy, which can complicate installation. It is also more prone to chipping than other materials, which may affect its longevity.

Impact on Application: Granite can handle high temperatures but may not be as effective as ultra-compact porcelain in terms of even heat distribution.

Considerations for International Buyers: Buyers should consider local stone availability and compliance with international standards. Countries like Germany have strict regulations regarding stone sourcing and processing.

Illustrative image related to invisible induction cooktop

What Are the Advantages of Composite Materials for Invisible Induction Cooktops?

Composite materials, often made from a blend of natural and synthetic components, provide a versatile option for invisible induction cooktops. They can be engineered for specific performance characteristics, including heat resistance and aesthetics.

Pros: Composite materials are customizable, allowing for a wide range of colors and finishes. They are also lighter than natural stones, making installation easier.

Cons: The durability of composite materials can vary significantly based on the specific formulation. Some may not withstand high temperatures as effectively as natural stones.

Impact on Application: Composite materials can be designed for specific cooking needs, but buyers should ensure they meet the required heat resistance for induction cooking.

Considerations for International Buyers: Buyers should check for compliance with international safety standards, as the quality of composite materials can vary widely. Regions like the Middle East may have specific preferences for composite surfaces due to their modern aesthetic.

Illustrative image related to invisible induction cooktop

Summary Table of Material Selection for Invisible Induction Cooktops

| Material | Typical Use Case for invisible induction cooktop | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ultra-Compact Porcelain | High-end residential kitchens | Excellent thermal resistance | Higher cost, fragile during install | High |

| Quartzite | Luxury residential and commercial kitchens | Natural beauty, durable | Heavy, may require sealing | High |

| Granite | Residential kitchens, traditional settings | Widely available, easy maintenance | Heavy, prone to chipping | Medium |

| Composite Materials | Modern residential and commercial kitchens | Customizable aesthetics | Variable durability | Medium |

This guide provides actionable insights for B2B buyers considering materials for invisible induction cooktops, emphasizing the importance of material properties, regional compliance, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for invisible induction cooktop

What Are the Main Stages of Manufacturing Invisible Induction Cooktops?

The manufacturing process of invisible induction cooktops involves several critical stages, each crucial for ensuring the final product meets safety, performance, and aesthetic standards.

Material Preparation: What Materials Are Used in Invisible Induction Cooktops?

The first stage involves selecting high-quality materials that can withstand the demands of cooking while maintaining aesthetic appeal. The primary components include ultra-compact surfaces, typically made of porcelain or composite materials, which are known for their durability and heat resistance. These materials are processed to achieve specific thicknesses and finishes that contribute to both functionality and style.

Additionally, the induction heating elements are sourced from specialized manufacturers, ensuring they meet stringent performance specifications. This careful selection of materials is vital, as it directly impacts the cooktop’s efficiency, safety, and overall user experience.

How Is the Forming Process Conducted for Cooktops?

Once materials are prepared, the forming process begins. This typically involves precision cutting of the ultra-compact surfaces to fit the designated dimensions for different cooktop models. Advanced machinery, such as CNC (Computer Numerical Control) routers, is employed to achieve high accuracy and repeatability, which is essential for the seamless integration of the induction elements beneath the surface.

Simultaneously, the induction coils are manufactured, often utilizing copper for its excellent conductivity. These coils are then arranged in a specific pattern that maximizes efficiency and ensures even heat distribution across the cooking surface.

What Steps Are Involved in the Assembly of Induction Cooktops?

Following the forming stage, assembly takes place. This phase involves integrating the induction coils with the ultra-compact surface. The coils are securely fixed beneath the surface using high-temperature adhesives, ensuring that they remain in place during operation.

Next, control systems, including touch panels and Wi-Fi connectivity modules, are incorporated. This integration not only enhances user experience but also aligns with modern cooking trends that favor smart technology. Each assembly line is designed to minimize human error and ensure that every unit is constructed to meet the same high standards.

How Is the Finishing Process Conducted for Aesthetic Appeal?

The final assembly stage includes the finishing processes that enhance both the durability and appearance of the cooktop. This may involve polishing the surface to achieve a sleek finish, applying protective coatings, and conducting aesthetic inspections to ensure that the product is free from defects.

Manufacturers may also apply branding and product labeling at this stage, ensuring compliance with international standards. The finishing process is critical, as it not only impacts the product’s look but also its longevity and ability to withstand daily use.

What Quality Assurance Measures Are Implemented in the Manufacturing Process?

Quality assurance (QA) is a critical component of manufacturing invisible induction cooktops, ensuring that each unit meets international standards and customer expectations.

Which International Standards Are Relevant for Invisible Induction Cooktops?

Manufacturers typically adhere to various international standards, such as ISO 9001, which focuses on quality management systems, and CE marking, which indicates conformity with health, safety, and environmental protection standards within the European Economic Area. Additionally, industry-specific standards like API may be relevant depending on the intended application of the cooktops.

These certifications not only enhance product credibility but also facilitate smoother entry into various markets, particularly for B2B buyers looking for reliability and safety assurance.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Before production begins, raw materials undergo inspection to ensure they meet predefined specifications. This step is crucial in preventing defects caused by substandard materials.

-

In-Process Quality Control (IPQC): During the assembly process, random sampling and inspections are conducted to identify any defects or deviations from standards. This real-time monitoring helps in addressing issues promptly and maintaining production quality.

-

Final Quality Control (FQC): Once assembly is complete, each cooktop is subjected to rigorous testing, including functional tests to ensure all features operate correctly and safety tests to confirm compliance with relevant standards.

What Common Testing Methods Are Used for Invisible Induction Cooktops?

Testing methods include thermal efficiency assessments, where the cooktops are evaluated for heat distribution and cooking performance. Electrical safety tests ensure that the units comply with electrical safety regulations, while durability tests assess the resistance of surfaces to scratches and heat.

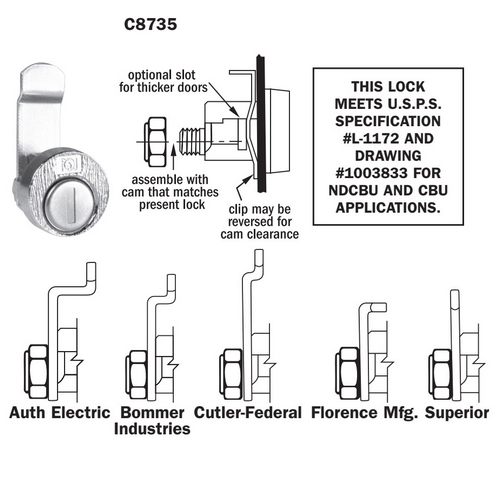

Illustrative image related to invisible induction cooktop

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

-

Audits: Requesting audits of the manufacturing facilities can provide insight into the QC processes in place. This may include reviewing their adherence to ISO standards and other certifications.

-

Quality Reports: Suppliers should be able to provide documentation of their quality assurance processes, including test results and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and product quality, ensuring that the supplier meets the necessary standards.

What Are the Specific Quality Control Nuances for International B2B Buyers?

For buyers in regions such as Africa, South America, the Middle East, and Europe, it is essential to understand the specific regulatory requirements and market expectations. Each region may have unique standards that affect product acceptance. For instance, European buyers may prioritize CE certification, while buyers in the Middle East might require compliance with local safety regulations.

Understanding these nuances allows B2B buyers to make informed decisions and select suppliers who can meet their specific quality and compliance needs.

Conclusion

The manufacturing and quality assurance processes for invisible induction cooktops are complex and multifaceted, requiring a thorough understanding of materials, assembly techniques, and quality control measures. By recognizing the critical stages of production and the relevant quality standards, B2B buyers can better evaluate suppliers and ensure they invest in products that meet their expectations for performance, safety, and design.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘invisible induction cooktop’

In the rapidly evolving kitchen technology landscape, the invisible induction cooktop represents a blend of safety, efficiency, and modern design. This practical sourcing guide is designed for B2B buyers, particularly those engaged in the kitchen appliance industry or involved in the design of modern culinary spaces. Here, we outline the essential steps to consider when procuring invisible induction cooktops for your business.

Step 1: Define Your Technical Specifications

Before approaching suppliers, it’s vital to establish clear technical specifications for the cooktops you intend to purchase. Consider factors such as the power requirements (e.g., 220V vs. 110V), the number of burners, and compatible materials for countertop integration. Defining these parameters helps ensure that the products align with your operational needs and the expectations of your clients.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in kitchen technology and design, particularly for invisible induction cooktops. This includes understanding new materials, energy efficiency standards, and consumer preferences. Researching these trends will enable you to make informed decisions and ensure that your offerings remain competitive in the market.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, conduct thorough evaluations. Look for suppliers with proven track records in the industry, and request their company profiles, case studies, and references from clients in similar markets. Pay attention to their manufacturing capabilities and any certifications that validate their product quality and safety standards.

Illustrative image related to invisible induction cooktop

- Certifications to Consider:

- CE (Conformité Européenne) for European markets

- IEC60950-1 for international safety standards

Step 4: Assess Product Quality and Performance

Request samples or demonstrations of the invisible induction cooktops to evaluate their quality and performance firsthand. Consider factors like cooking efficiency, heat distribution, and ease of cleaning. Ensure that the cooktops you select can withstand the demands of both residential and commercial use, depending on your target market.

Step 5: Understand Warranty and Support Terms

Review the warranty and support options offered by the supplier. A robust warranty can indicate confidence in the product’s durability and reliability. Inquire about customer service availability, technical support, and any training resources for installation and maintenance.

Step 6: Negotiate Pricing and Payment Terms

Once you have identified suitable suppliers and products, engage in negotiations regarding pricing and payment terms. Consider the total cost of ownership, which includes not just the purchase price but also shipping, installation, and potential maintenance costs. Establishing favorable payment terms can enhance your cash flow management.

Step 7: Plan for After-Sales Support and Feedback

Finally, consider how you will provide after-sales support to your customers. Develop a system for collecting feedback on the cooktops’ performance and customer satisfaction. This information can be invaluable for future purchasing decisions and can help strengthen your relationship with suppliers.

By following this checklist, you will be well-equipped to source invisible induction cooktops that meet your business needs while providing cutting-edge solutions to your customers.

Comprehensive Cost and Pricing Analysis for invisible induction cooktop Sourcing

What Are the Key Cost Components for Sourcing Invisible Induction Cooktops?

When sourcing invisible induction cooktops, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The core materials for invisible induction cooktops often include ultra-compact porcelain or other heat-resistant surfaces. High-quality materials are vital for durability and performance, influencing overall costs. Suppliers may offer various grades of materials, which can significantly affect pricing.

-

Labor: Skilled labor is necessary for manufacturing these technologically advanced cooktops. The complexity of the induction technology and the need for precise assembly contribute to labor costs. Regions with higher labor costs, such as Western Europe, may see higher prices compared to countries in Africa or South America where labor might be less expensive.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, equipment maintenance, and factory space. Efficient manufacturing processes can help reduce these overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom tooling may be required for specific designs or functionalities of the cooktops. This upfront investment can be significant but is essential for producing high-quality products. Buyers should consider whether they can share tooling costs with other orders to lower individual expenses.

-

Quality Control (QC): Ensuring that each unit meets international safety and performance standards is crucial. QC processes add to the cost but are necessary to maintain product reliability and customer satisfaction. Certifications that comply with international standards can also influence pricing.

-

Logistics: Transportation costs, including shipping, insurance, and customs duties, can vary significantly based on the destination. Buyers should evaluate potential logistics partners and their capabilities to optimize shipping costs.

-

Margin: Suppliers will typically add a profit margin to their costs, which can vary based on market demand and competition. Understanding the expected margin can help buyers negotiate better pricing.

How Do Price Influencers Impact the Cost of Invisible Induction Cooktops?

Several factors can influence the pricing of invisible induction cooktops beyond the basic cost structure:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often results in lower per-unit costs. Suppliers may have MOQs that can affect pricing, so negotiating these terms can lead to cost savings.

-

Specifications and Customization: Customized features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses. Simple designs may be more cost-effective than complex, tailored solutions.

-

Quality and Certifications: Higher quality products typically come with a premium price tag. Certifications that comply with international safety and performance standards add to the cost but may also be necessary to meet regulatory requirements in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers may charge more for their products due to perceived quality and service levels.

-

Incoterms: Understanding Incoterms is vital for determining who bears the costs and risks during shipping. Different terms can significantly affect the total landed cost of the product.

What Tips Can B2B Buyers Use to Negotiate Better Prices for Invisible Induction Cooktops?

Negotiation strategies can be crucial for securing favorable terms:

-

Do Your Research: Understand the market rates and supplier offerings to ensure you’re negotiating from an informed position. Competitive analysis can reveal opportunities for better pricing.

-

Total Cost of Ownership (TCO): Consider the TCO when evaluating bids. Lower upfront costs may lead to higher operational expenses over time. Assessing energy efficiency, maintenance, and lifespan can provide a clearer picture of the overall value.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield benefits such as discounts, priority service, and access to new products.

-

Be Open to Alternatives: If a specific supplier’s pricing is too high, consider exploring other suppliers or alternative materials that may offer similar performance at a lower cost.

-

Understand Regional Nuances: Pricing may vary based on regional factors, including tariffs, local competition, and economic conditions. Being aware of these nuances can aid in more effective negotiation.

Disclaimer

Prices for invisible induction cooktops can vary widely based on specifications, supplier relationships, and market conditions. The figures mentioned in this analysis are indicative and should be validated with current supplier quotes.

Illustrative image related to invisible induction cooktop

Alternatives Analysis: Comparing invisible induction cooktop With Other Solutions

When considering kitchen technology, the invisible induction cooktop stands out for its innovative design and enhanced safety features. However, it is essential for B2B buyers to explore alternative cooking solutions to make informed purchasing decisions. This section compares the invisible induction cooktop with two viable alternatives: traditional gas cooktops and electric ceramic cooktops.

| Comparison Aspect | Invisible Induction Cooktop | Traditional Gas Cooktop | Electric Ceramic Cooktop |

|---|---|---|---|

| Performance | Rapid heating, precise control, and minimal residual heat | Immediate heat, but less precise; longer cooling time | Moderate heating, slower than induction; consistent heat |

| Cost | Higher upfront investment ($3,500+) | Generally lower initial cost, but variable operating costs | Mid-range initial cost ($500-$1,500) |

| Ease of Implementation | Requires professional installation; compatible with specific countertops | Simple installation; can fit most kitchen designs | Easy installation; can be placed on various surfaces |

| Maintenance | Low maintenance; easy to clean due to seamless design | Requires regular cleaning and maintenance of burners | Requires regular cleaning; can scratch easily |

| Best Use Case | High-end residential and commercial kitchens prioritizing aesthetics and safety | Traditional homes and restaurants focusing on cost-effectiveness | Versatile kitchens requiring a balance of performance and budget |

What are the advantages and disadvantages of traditional gas cooktops?

Traditional gas cooktops are favored for their immediate heat response and the visual feedback they provide during cooking. They allow for a high level of control over cooking temperatures, making them ideal for chefs who rely on precise heat adjustments. However, they come with drawbacks such as higher safety risks (open flames), increased energy costs, and the need for regular maintenance to ensure the burners function correctly. Additionally, gas cooktops can create excess heat in the kitchen and require proper ventilation.

How do electric ceramic cooktops compare in functionality?

Electric ceramic cooktops offer a balance between performance and cost. They provide a flat cooking surface that is easy to clean, which can be a significant advantage in busy kitchens. However, their heating times are slower compared to induction cooktops, and they can retain heat longer, posing a burn risk after cooking. While generally more affordable than invisible induction cooktops, they can require more frequent maintenance due to potential scratches or wear on the ceramic surface.

How can B2B buyers choose the right cooking solution for their needs?

When selecting a cooking solution, B2B buyers should consider their specific operational needs, budget constraints, and desired kitchen aesthetics. The invisible induction cooktop is an excellent choice for those looking to invest in modern, safe, and efficient cooking technology, particularly in high-end residential or commercial settings. In contrast, traditional gas cooktops may appeal to those prioritizing cost and immediate heating capabilities, while electric ceramic cooktops serve as a versatile middle-ground option. Ultimately, understanding the unique advantages and limitations of each solution will enable buyers to make informed decisions that align with their operational goals and customer expectations.

Illustrative image related to invisible induction cooktop

Essential Technical Properties and Trade Terminology for invisible induction cooktop

What Are the Key Technical Properties of Invisible Induction Cooktops?

Invisible induction cooktops represent a significant advancement in kitchen technology, blending aesthetics with functionality. Here are some critical specifications that B2B buyers should consider:

-

Material Grade

The most common materials used for invisible induction cooktops include ultra-compact porcelain, quartzite, and high-quality composites. Porcelain is often preferred for its durability and heat resistance. The choice of material directly impacts the cooktop’s longevity, ease of cleaning, and overall kitchen design. For buyers, selecting the right material ensures a balance between aesthetic appeal and practical performance. -

Power Output

Invisible induction cooktops typically feature varying power outputs across their burners, measured in watts. For instance, a 5-burner model might have a total power capacity of 5,600 watts, distributed among individual burners. This specification is crucial as it influences cooking speed and efficiency. Higher wattage can reduce cooking times, making the product more appealing to commercial buyers who prioritize efficiency. -

Installation Dimensions

The dimensions of the cooktop, including its thickness and the required cutout size in the countertop, are essential for compatibility with different kitchen designs. A typical thickness range is between 12mm and 20mm for the surface material. B2B buyers must ensure that their kitchen layouts can accommodate the specific dimensions to avoid installation issues. -

Temperature Range

The operating temperature range for invisible induction cooktops usually spans from a minimum of 97°F (36°C) to a maximum of 400°F (205°C). This range is essential for various cooking techniques, from simmering to searing. Understanding the temperature capabilities helps buyers assess whether the cooktop meets their culinary needs, especially in professional kitchens. -

Safety Features

Safety is a paramount concern in kitchen environments. Invisible induction cooktops often come equipped with features like low residual heat, automatic shut-off, and child safety locks. These attributes are particularly appealing to B2B buyers in the hospitality sector, where customer safety is critical. Ensuring that the cooktop adheres to international safety standards can also influence purchasing decisions. -

Energy Efficiency

Energy consumption is an important consideration, especially for businesses looking to minimize operational costs. Many invisible induction cooktops are designed to operate at high efficiency, consuming less energy compared to traditional gas or electric cooktops. Highlighting energy efficiency can attract eco-conscious buyers and those aiming to reduce utility costs.

Which Trade Terminology Should B2B Buyers Understand?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B space. Here are some common terms related to invisible induction cooktops:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of invisible induction cooktops, buyers may work directly with OEMs to customize features or branding, ensuring that the product meets specific market demands. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is critical for budgeting and inventory planning. High MOQs may require larger upfront investments, while lower MOQs can provide flexibility for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and other relevant information from suppliers. When purchasing invisible induction cooktops, B2B buyers should prepare detailed RFQs to ensure they receive accurate and comparable quotes from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. Familiarity with these terms is vital for B2B buyers, as they dictate shipping responsibilities, risk management, and cost allocations. Understanding Incoterms helps buyers negotiate better shipping terms and avoid potential disputes. -

Lead Time

Lead time is the amount of time from the placement of an order until its delivery. Knowing the lead time for invisible induction cooktops allows buyers to plan their inventory and project timelines effectively. Short lead times can be a competitive advantage in fast-paced markets. -

Warranty

A warranty is a promise from the manufacturer regarding the quality and longevity of a product. Buyers should carefully evaluate warranty terms for invisible induction cooktops, as they provide assurance of product reliability and can impact long-term maintenance costs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when purchasing invisible induction cooktops, ensuring that they meet both operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the invisible induction cooktop Sector

What Are the Key Trends and Dynamics in the Invisible Induction Cooktop Market?

The invisible induction cooktop sector is experiencing significant growth driven by technological advancements, consumer demand for aesthetics, and a shift towards energy-efficient cooking solutions. The global kitchen appliance market is witnessing a surge in interest from international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. In these markets, buyers are increasingly prioritizing safety, efficiency, and space-saving designs. Innovations such as Wi-Fi connectivity and smartphone applications, enabling remote cooking control, are becoming essential features that resonate with tech-savvy consumers.

Emerging trends indicate a growing preference for multifunctional appliances that not only serve as cooking surfaces but also enhance the overall kitchen experience. The seamless integration of invisible induction cooktops into countertop materials is appealing to interior designers and architects looking for modern, luxurious finishes. In Europe, particularly in Germany, there is a strong push for high-quality, durable materials that meet stringent safety and performance standards. In contrast, markets in the Middle East are leaning towards high-end, luxury installations that blend functionality with opulent design.

Furthermore, B2B buyers are increasingly looking for suppliers who can provide not just products but also comprehensive solutions, including installation support and after-sales service. This demand for full-service offerings is reshaping sourcing strategies, making it crucial for manufacturers and suppliers to adapt to these evolving market dynamics.

How Is Sustainability and Ethical Sourcing Addressed in the Invisible Induction Cooktop Industry?

Sustainability is becoming a critical focus for B2B buyers in the invisible induction cooktop sector. As environmental concerns gain traction, manufacturers are urged to adopt eco-friendly practices and materials. The production of invisible induction cooktops often involves the use of high-quality, durable materials like porcelain and composite surfaces that minimize waste and offer longevity. These materials not only enhance the aesthetic appeal of kitchens but also ensure energy efficiency during cooking, aligning with global sustainability goals.

Ethical sourcing is equally important, as buyers are increasingly scrutinizing supply chains for transparency and responsibility. This includes ensuring that raw materials are sourced from suppliers who adhere to ethical labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and other green certifications can serve as indicators of a company’s commitment to sustainability. Buyers are encouraged to partner with manufacturers who prioritize sustainable practices, as this can significantly enhance their brand reputation and appeal to eco-conscious consumers.

Moreover, the invisible induction cooktop’s energy-efficient technology reduces energy consumption compared to traditional cooking methods, further contributing to a smaller carbon footprint. This dual focus on sustainability and ethical sourcing is not just a trend but a necessity for B2B buyers looking to align their purchasing decisions with broader environmental and social responsibilities.

What Is the Brief Evolution of Invisible Induction Cooktops?

The evolution of invisible induction cooktops can be traced back to the broader development of induction cooking technology. Initially, induction cooktops were bulky, visible appliances that required specific cookware. However, advancements in engineering and materials science led to the creation of sleek, integrated designs that allow for cooking directly on the countertop. This innovation enhances aesthetic appeal while maintaining high safety standards, as the surface remains cool to the touch.

As consumer preferences shifted towards minimalist design and multifunctionality, manufacturers began developing invisible induction cooktops that seamlessly blend into kitchen environments. Today, these cooktops are not only a symbol of modern luxury but also represent a technological leap that prioritizes efficiency and safety. With ongoing innovations in smart technology and material durability, the future of invisible induction cooktops promises even greater versatility and appeal, positioning them as a must-have for contemporary kitchens.

Frequently Asked Questions (FAQs) for B2B Buyers of invisible induction cooktop

-

How do I ensure the quality of invisible induction cooktops from suppliers?

To ensure product quality, conduct thorough due diligence on potential suppliers. Request product samples to assess quality firsthand, and check for certifications that meet international standards (e.g., IEC60950-1). Additionally, inquire about their manufacturing processes and quality control measures. Engaging third-party inspection services can provide an unbiased evaluation before shipment. Establishing a clear communication line for ongoing quality assurance can help maintain standards throughout your partnership. -

What is the best invisible induction cooktop for commercial kitchens?

The best invisible induction cooktop for commercial kitchens combines high efficiency, durability, and safety features. Look for models with multiple burner options to accommodate various cooking needs and those that provide precise temperature control. Brands like Invisacook and TPB Tech offer advanced technology that ensures fast cooking and easy cleaning. Evaluate the cooktop’s power output and compatibility with your kitchen’s infrastructure to maximize performance and reliability. -

What are the typical payment terms when sourcing invisible induction cooktops internationally?

Payment terms can vary significantly between suppliers, but common practices include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer flexible terms such as letter of credit or escrow services for added security. It’s crucial to clarify payment methods, including acceptable currencies and transaction fees, during negotiations to ensure a smooth procurement process. -

What are the minimum order quantities (MOQ) for invisible induction cooktops?

Minimum order quantities can differ based on the manufacturer and product specifications. Typically, MOQs for invisible induction cooktops range from 10 to 50 units. However, some suppliers may accommodate smaller orders for initial trials or special projects. Always discuss your requirements upfront, as negotiating MOQs can be possible, especially for long-term partnerships or bulk orders. -

How can I customize invisible induction cooktops for my brand?

Customization options for invisible induction cooktops may include branding, specific design elements, and tailored features. To initiate the process, communicate your requirements with potential suppliers, including desired colors, finishes, and functionality. Some manufacturers may offer OEM services, allowing you to create a product that aligns with your brand identity. Ensure that you have a clear agreement on timelines and costs associated with customizations. -

What logistics considerations should I keep in mind when importing invisible induction cooktops?

When importing invisible induction cooktops, consider shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder experienced in handling kitchen appliances. Be aware of import duties and taxes in your country, as these can impact overall costs. It’s also advisable to track shipments closely and maintain communication with suppliers to address any potential delays or issues promptly. -

How do I evaluate the reliability of suppliers for invisible induction cooktops?

Evaluating supplier reliability involves checking their track record, customer reviews, and industry certifications. Request references from previous clients and assess their responsiveness and willingness to engage in open communication. Visit their manufacturing facilities if possible, or conduct virtual audits. Additionally, consider their financial stability, production capacity, and adherence to international quality standards as indicators of long-term reliability. -

What after-sales support should I expect when purchasing invisible induction cooktops?

After-sales support varies by supplier but typically includes warranty coverage, installation guidance, and customer service assistance. Confirm the warranty duration and what it covers, such as parts and labor. A reputable supplier will provide training resources or manuals for installation and operation. Ensure that you have access to technical support for troubleshooting and maintenance, as this can significantly affect your customer satisfaction and operational efficiency.

Top 4 Invisible Induction Cooktop Manufacturers & Suppliers List

1. Invisacook – 5 Burner Flush-Mount Invisible Induction Cooktop

Domain: invisacookcalifornia.com

Registered: 2023 (2 years)

Introduction: {“product_name”: “Invisacook 5 Burner 220V – Flush-Mount Invisible Induction Cooktop”, “price”: “$3,500.00 USD”, “features”: [“5 separate burning unit elements”, “Power Boost option for faster speed”, “Wi-Fi capable with the Invisacook App”, “Designed for Under-mount installation”, “50 amp needed for 220v”], “burner_sizes”: [“3 x 8.25\””, “2 x 7\””], “power”: [“3 x 2000 Watt”, “2 x 1600 Watt”], “d…

2. TPB Tech – Invisible Induction Cooking Surface

Domain: tpbtech.com

Registered: 2017 (8 years)

Introduction: TPB Tech offers an innovative invisible induction cooking surface that integrates seamlessly into countertops, allowing for cooking without visible burners or glass. Key features include easy cleaning, low energy consumption, and safety due to low residual temperatures. The product is designed for both domestic and professional use, providing a modern aesthetic and efficient cooking experience. Th…

3. Invisacook – Induction Cooktops

Domain: cabinetsalescenter.com

Registered: 2018 (7 years)

Introduction: Invisacook Cooktops are designed to blend seamlessly into kitchen countertops, providing a sleek cooking surface. They utilize electromagnetic induction for efficient cooking, ensuring even heat distribution and precise temperature control. The cooktops feature easy-to-use touch controls and a glass surface that is easy to clean. They are energy-efficient, helping to reduce electricity bills. Avai…

4. Invisacook – Invisible Induction Hobs

Domain: invisacook-deutschland.de

Introduction: Invisacook offers invisible induction hobs in four sizes: 2 Burner, 3 Burner, 4 Burner, and 5 Burner. The 3 Burner model is designed to be mounted in line for easier access, while the 5 Burner features a larger and stronger middle burner suitable for big roasters. The units utilize magnetic coils to generate heat, providing advantages such as fast cooling, low energy consumption, and short boiling…

Strategic Sourcing Conclusion and Outlook for invisible induction cooktop

In conclusion, the invisible induction cooktop represents a significant advancement in kitchen technology, merging aesthetics with functionality. For B2B buyers across Africa, South America, the Middle East, and Europe, the strategic sourcing of these innovative cooktops provides multiple advantages, including enhanced safety, efficient space utilization, and modern design that appeals to both residential and commercial markets. By integrating invisible induction cooktops into product offerings, businesses can cater to the growing consumer demand for stylish and safe cooking solutions.

Strategic sourcing is crucial in navigating the competitive landscape of kitchen appliances. It allows buyers to identify reliable suppliers, negotiate favorable terms, and ensure product quality, ultimately enhancing their market positioning. As the global trend towards sustainable and high-tech solutions continues to rise, investing in invisible induction cooktops is not just a choice but a forward-thinking strategy.

Looking ahead, international B2B buyers are encouraged to explore partnerships with leading manufacturers in this field. Embrace the future of cooking technology by incorporating invisible induction cooktops into your product lines, positioning your business at the forefront of kitchen innovation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to invisible induction cooktop

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.