The Definitive Guide to Inflatable Paint Booth: Cost, Materials & Top Vendors

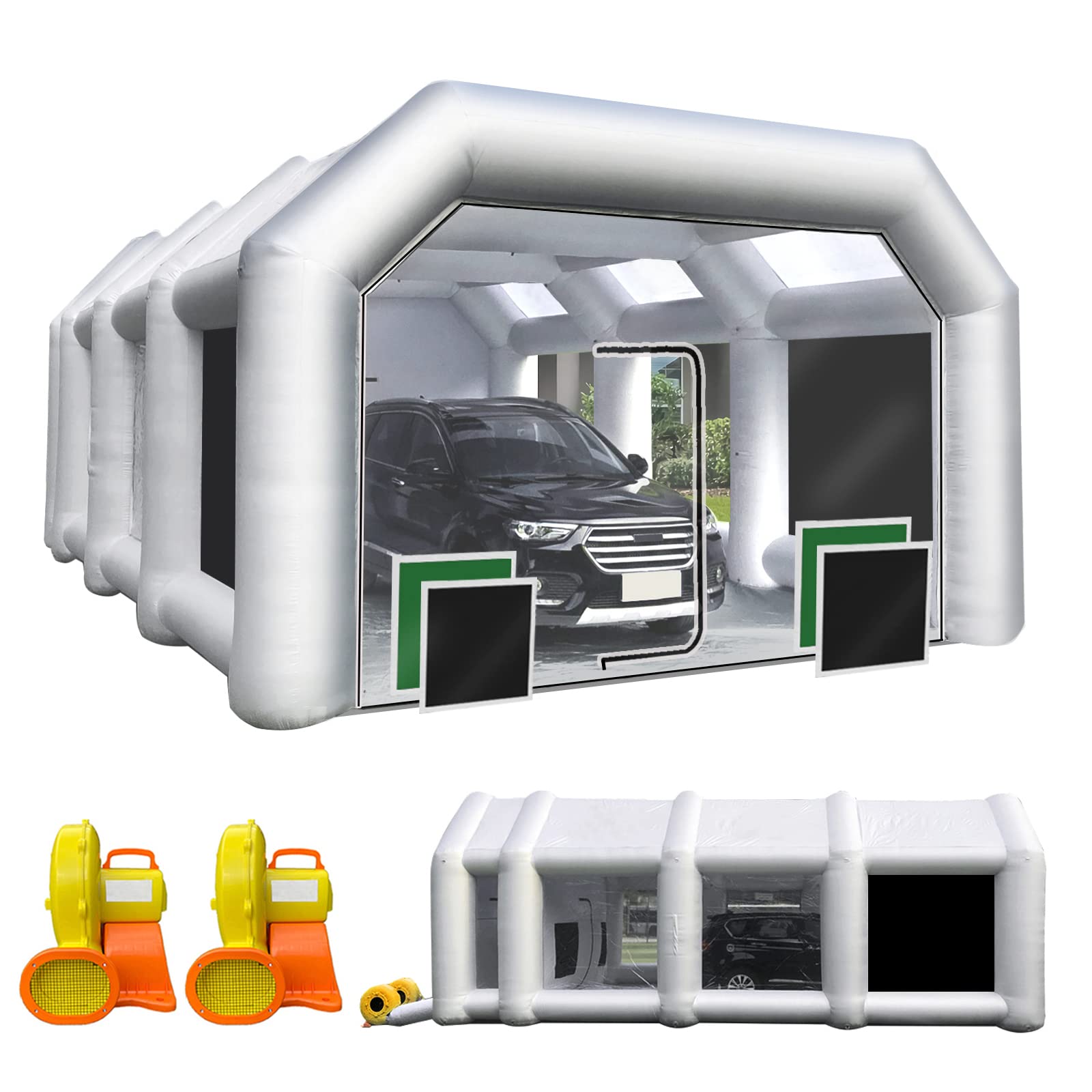

Introduction: Navigating the Global Market for inflatable paint booth

In today’s rapidly evolving automotive and manufacturing landscapes, sourcing an inflatable paint booth presents unique challenges for B2B buyers across diverse markets. These portable, versatile solutions not only facilitate efficient painting processes but also ensure compliance with environmental regulations—a critical consideration for businesses in regions such as Africa, South America, the Middle East, and Europe. As international buyers navigate the complexities of selecting the right inflatable paint booth, understanding the myriad options available is essential to making informed purchasing decisions.

This comprehensive guide delves into the various types of inflatable paint booths, their specific applications, and the factors influencing their costs. It provides insights into supplier vetting processes, ensuring that buyers can identify reputable manufacturers who meet their unique needs. From small-scale workshops requiring compact booths to large-scale operations needing expansive setups, this guide equips decision-makers with the knowledge to match their operational requirements with the right equipment.

By addressing key considerations such as durability, air filtration systems, and ease of setup, this resource empowers B2B buyers to confidently invest in inflatable paint booths that enhance productivity and comply with industry standards. Whether you’re operating in Nigeria, Vietnam, or beyond, understanding these essential elements will enable you to streamline your operations and achieve superior results in your painting projects.

Understanding inflatable paint booth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compact Inflatable Paint Booth | Smaller size, typically under 10 ft in height | Automotive repair shops, small furniture painting | Pros: Easy to transport, cost-effective. Cons: Limited space for larger items. |

| Medium-Sized Inflatable Booth | Dimensions around 20 ft x 10 ft, suitable for mid-sized vehicles | Workshops, body shops, and general painting tasks | Pros: Versatile for various applications. Cons: May require more setup space. |

| Large Inflatable Paint Booth | Over 30 ft in length, designed for large machinery | Commercial vehicle painting, RVs, and industrial use | Pros: Accommodates large projects. Cons: Higher investment and requires substantial space. |

| Heavy-Duty Inflatable Booth | Reinforced materials, designed for rugged environments | Military equipment, heavy machinery maintenance | Pros: Durable and robust. Cons: Heavier and less portable. |

| Customizable Inflatable Booth | Tailored sizes and features based on specific needs | Specialized projects, unique vehicle sizes | Pros: Meets specific business requirements. Cons: Potentially longer lead times and higher costs. |

What are the Characteristics of Compact Inflatable Paint Booths?

Compact inflatable paint booths are typically under 10 feet in height, making them ideal for small-scale operations. They are lightweight and easy to transport, allowing for quick setup in various locations. These booths are particularly suited for automotive repair shops and small furniture painting tasks. When considering a purchase, buyers should evaluate the size of the items they intend to paint, as the limited space may not accommodate larger vehicles or equipment.

How Do Medium-Sized Inflatable Booths Serve B2B Needs?

Medium-sized inflatable booths generally measure around 20 ft x 10 ft, providing a balance between space and portability. These booths are versatile and can handle mid-sized vehicles, making them popular in workshops and body shops. Buyers should consider the booth’s airflow and filtration systems, as effective air management is crucial for achieving high-quality finishes. While they offer more space than compact models, they may require a larger setup area.

Why Choose Large Inflatable Paint Booths for Industrial Use?

Large inflatable paint booths exceed 30 ft in length and are designed for commercial applications, such as painting large machinery and vehicles like RVs. Their expansive interior allows for multiple projects simultaneously, making them an efficient choice for busy operations. Buyers should weigh the benefits of increased productivity against the higher investment costs and the need for significant space. Additionally, ensuring adequate ventilation and climate control is essential for optimal performance.

What Makes Heavy-Duty Inflatable Booths Unique?

Heavy-duty inflatable booths are constructed from reinforced materials to withstand rigorous environments, making them suitable for military equipment and heavy machinery maintenance. Their durability ensures longevity and reliability in demanding applications. Buyers must consider their specific needs for ruggedness and how often they will use the booth in harsh conditions. While they may be less portable due to their weight, their robustness can justify the investment for businesses needing reliable solutions.

How Do Customizable Inflatable Booths Meet Unique Business Needs?

Customizable inflatable paint booths can be tailored to meet specific business requirements, whether in size, features, or design. This adaptability makes them ideal for specialized projects or unique vehicle sizes. Buyers should anticipate longer lead times and potentially higher costs associated with customization but can benefit from a booth that perfectly fits their operational needs. It’s crucial to communicate clearly with manufacturers to ensure that all specifications are met for optimal performance.

Key Industrial Applications of inflatable paint booth

| Industry/Sector | Specific Application of Inflatable Paint Booth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Vehicle refinishing and touch-up painting | Enhances paint quality and reduces contamination risks | Size and air filtration capacity; portability for on-site jobs |

| Aerospace Maintenance | Painting and coating of aircraft components | Ensures compliance with strict aviation standards | Material durability; UV resistance; ability to accommodate larger aircraft |

| Furniture Manufacturing | Finishing and coating of furniture pieces | Improves finish quality and reduces rework costs | Size options for different furniture; compatibility with various paint types |

| Heavy Machinery | Painting of large industrial equipment and vehicles | Protects against corrosion and extends equipment lifespan | Capacity for large items; strong airflow and filtration systems |

| Military Applications | Coating and maintenance of military vehicles and equipment | Meets stringent military specifications and durability | Customization options; ease of deployment in diverse environments |

How are Inflatable Paint Booths Used in Automotive Repair?

In the automotive repair industry, inflatable paint booths are essential for vehicle refinishing and touch-up painting. These booths create a controlled environment that minimizes the risk of dust and debris contaminating the paintwork. For international buyers, especially in regions like Africa and South America, sourcing booths that are portable and easy to set up can enhance service delivery. Key considerations include the booth’s size to accommodate various vehicle types and the effectiveness of its air filtration system to meet local environmental regulations.

What Role Do Inflatable Paint Booths Play in Aerospace Maintenance?

In aerospace maintenance, inflatable paint booths are used for the painting and coating of aircraft components, ensuring compliance with rigorous aviation safety standards. These booths provide a clean, isolated space to perform high-quality finishes that are crucial for both aesthetics and functionality. Buyers in regions like the Middle East and Europe should prioritize booths made from durable, UV-resistant materials that can withstand the specific environmental conditions of their locations. Additionally, the ability to accommodate larger aircraft is a significant factor for sourcing.

How Are Inflatable Paint Booths Beneficial for Furniture Manufacturing?

Furniture manufacturers utilize inflatable paint booths for finishing and coating furniture pieces, allowing for a controlled environment that enhances the quality of the finish. This application helps in reducing the chances of imperfections, leading to lower rework costs and higher customer satisfaction. For buyers in emerging markets, such as Nigeria and Vietnam, it is essential to consider the booth’s size options to accommodate various furniture dimensions and the compatibility with different paint types, ensuring versatility in production.

Why Are Inflatable Paint Booths Important for Heavy Machinery?

Heavy machinery industries benefit from inflatable paint booths for the painting of large industrial equipment and vehicles, providing protection against corrosion and extending the lifespan of machinery. The ability to create a controlled environment allows for high-quality finishes that are crucial in this sector. Buyers must consider the booth’s capacity to handle oversized items and the strength of its airflow and filtration systems to ensure that the paint application meets industry standards, particularly in regions with diverse climates.

How Do Inflatable Paint Booths Serve Military Applications?

In military applications, inflatable paint booths are used for the coating and maintenance of military vehicles and equipment, adhering to stringent military specifications for durability and performance. These booths can be customized for various operational environments, making them invaluable for defense contractors and military maintenance teams. When sourcing, international buyers should focus on customization options that cater to specific military requirements and the ease of deployment in diverse settings, ensuring readiness and efficiency in operations.

3 Common User Pain Points for ‘inflatable paint booth’ & Their Solutions

Scenario 1: Limited Space for Operations

The Problem: Many businesses, particularly in urban areas or smaller workshops, face constraints in available workspace. This limitation can hinder their ability to perform necessary painting tasks, particularly for larger vehicles or equipment. Traditional paint booths are often too large and immobile, making them impractical for companies that need flexibility or have limited storage. As a result, businesses may lose potential clients or suffer delays due to inadequate facilities.

The Solution: An inflatable paint booth is an ideal solution for businesses with limited space. These booths are designed to be portable and can be set up in a matter of minutes, allowing users to convert any open area into a fully functional spray booth. When sourcing an inflatable paint booth, buyers should prioritize models that are easy to inflate and deflate, ensuring quick setup and takedown. Additionally, selecting a booth with adequate dimensions for the vehicles or equipment being painted is crucial. Buyers should also consider features like built-in air filtration systems to maintain a clean environment, which is essential for high-quality finishes. For ongoing operations, investing in a compact inflatable booth that can be stored easily when not in use is a smart strategy.

Scenario 2: Inconsistent Paint Quality Due to Environmental Factors

The Problem: B2B buyers often struggle with maintaining consistent paint quality due to environmental variables such as dust, temperature fluctuations, and humidity levels. These factors can lead to defects in the paint job, requiring costly rework or resulting in unsatisfied customers. Businesses need to ensure a controlled environment to achieve high-quality finishes, but many lack the facilities to manage these conditions effectively.

The Solution: Inflatable paint booths provide an excellent solution by creating a controlled environment for painting tasks. When selecting a booth, buyers should focus on models equipped with efficient air filtration systems that can eliminate dust and other contaminants from the air, thereby reducing the risk of imperfections in the paint job. Additionally, consider inflatable booths with temperature control capabilities to maintain optimal conditions for painting regardless of external weather. Investing in a booth with adjustable ventilation can also help regulate humidity levels, further enhancing paint adhesion and curing. By utilizing these features, businesses can significantly improve their paint quality and customer satisfaction.

Scenario 3: Compliance with Local Regulations and Safety Standards

The Problem: In many regions, businesses involved in automotive refinishing must comply with strict environmental regulations and safety standards. Failure to meet these regulations can result in hefty fines or even the closure of operations. B2B buyers often find it challenging to navigate these regulations, especially when it comes to creating safe and compliant workspaces for painting.

The Solution: A well-designed inflatable paint booth can assist businesses in adhering to safety and environmental regulations. When purchasing a booth, buyers should ensure that it is compliant with local air quality standards and equipped with appropriate filtration systems to capture hazardous fumes and particles. It’s advisable to consult with local regulatory bodies to understand specific requirements that must be met. Additionally, choosing booths made from materials that are fire-resistant and easy to clean can enhance safety and compliance. Regular maintenance of the booth and its systems will further ensure that it remains compliant over time. By taking these proactive measures, businesses can operate confidently within legal parameters, safeguarding their reputation and financial stability.

Strategic Material Selection Guide for inflatable paint booth

When selecting materials for inflatable paint booths, it is crucial to consider their properties, advantages, and limitations to ensure optimal performance and suitability for various applications. Here, we analyze four common materials used in the construction of inflatable paint booths: PVC, Oxford fabric, Polyurethane, and Nylon.

What are the Key Properties of PVC for Inflatable Paint Booths?

PVC (Polyvinyl Chloride) is a widely used material in inflatable paint booths due to its excellent durability and resistance to various environmental factors. It typically has a temperature rating of up to 60°C and can withstand moderate pressure. PVC is also resistant to corrosion and UV light, making it suitable for outdoor use.

Pros: PVC is cost-effective and readily available, which makes it a popular choice for manufacturers. Its durability ensures a longer lifespan for inflatable booths, reducing the need for frequent replacements.

Cons: However, PVC can be less flexible than other materials, which may affect the booth’s portability. Additionally, it can become brittle over time, especially in extreme temperatures, potentially leading to tear issues.

How Does Oxford Fabric Perform in Inflatable Paint Booth Applications?

Oxford fabric is another common choice for inflatable paint booths. This synthetic material is lightweight and has a good balance of strength and flexibility. It generally offers a temperature resistance up to 70°C and is moderately resistant to water and UV rays.

Pros: The lightweight nature of Oxford fabric makes it easy to transport and set up, which is beneficial for mobile operations. Its flexibility allows for easy packing and storage.

Cons: On the downside, Oxford fabric may not be as durable as PVC, leading to a shorter lifespan. It can also be more susceptible to wear and tear from sharp objects or rough handling.

What Advantages Does Polyurethane Offer for Inflatable Paint Booths?

Polyurethane is a high-performance material known for its superior abrasion resistance and flexibility. It can handle temperature variations from -30°C to 80°C, making it suitable for diverse climates. Polyurethane is also resistant to chemicals, which is particularly important for paint applications.

Pros: The chemical resistance of polyurethane makes it an excellent choice for environments where exposure to solvents and other chemicals is common. Its flexibility also allows it to maintain its shape under pressure.

Cons: However, polyurethane can be more expensive than PVC and Oxford fabric, which may deter budget-conscious buyers. Additionally, its manufacturing process can be more complex, potentially leading to longer lead times.

Why is Nylon a Viable Option for Inflatable Paint Booths?

Nylon is a strong, lightweight synthetic fabric that offers excellent tensile strength and elasticity. It can withstand temperatures ranging from -40°C to 90°C and has good resistance to abrasion and UV light.

Pros: The high tensile strength of nylon makes it ideal for inflatable structures, as it can handle significant stress without tearing. Its elasticity allows for easy inflation and deflation, enhancing portability.

Cons: The primary drawback of nylon is its higher cost compared to PVC and Oxford fabric. Additionally, it can absorb moisture, which may lead to mold and mildew growth if not properly maintained.

Considerations for International B2B Buyers

When selecting materials for inflatable paint booths, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local standards such as ASTM, DIN, or JIS. Additionally, understanding the climate conditions in their region is essential, as it can affect material performance. Buyers should also evaluate the availability of materials and local suppliers to ensure timely procurement and support.

| Material | Typical Use Case for inflatable paint booth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General automotive painting | Cost-effective and durable | Can become brittle over time | Low |

| Oxford Fabric | Mobile paint operations | Lightweight and portable | Less durable than PVC | Medium |

| Polyurethane | Chemical exposure environments | Superior abrasion and chemical resistance | Higher cost and complex manufacturing | High |

| Nylon | High-stress inflatable structures | High tensile strength and elasticity | Higher cost and moisture absorption | Medium |

This strategic material selection guide provides insights into the properties and considerations of various materials used in inflatable paint booths, aiding international B2B buyers in making informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for inflatable paint booth

What Are the Main Stages of Manufacturing Inflatable Paint Booths?

The manufacturing process for inflatable paint booths typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring that the final product meets the required quality standards and performs efficiently in various environments.

-

Material Preparation

The first step involves sourcing high-quality materials, often PVC or nylon, known for their durability and resistance to chemicals and environmental conditions. These materials are inspected for defects, ensuring they meet the specifications required for inflatable structures. Suppliers must adhere to international standards, which can impact the selection process. -

Forming

Once the materials are prepared, they undergo a forming process, where they are cut into specific shapes and sizes. This is typically achieved using automated cutting machines that enhance precision and reduce waste. The cut pieces are then subjected to heat welding or sewing techniques to create seams that are strong and airtight, which is critical for the booth’s functionality. -

Assembly

The assembly stage involves bringing together the formed pieces to create the inflatable structure. This is where components like zippers, windows, and ventilation systems are integrated. The assembly process requires skilled labor to ensure that all parts fit together correctly and function as intended. Quality checks at this stage are crucial to identify any assembly defects that could affect performance. -

Finishing

The final stage is finishing, where the inflatable paint booth is cleaned, inspected, and prepared for packaging. This may include applying protective coatings, ensuring that all features operate correctly, and conducting final tests for air retention. The finishing touches ensure that the booth is ready for use and meets aesthetic standards.

How Is Quality Assurance Implemented in Inflatable Paint Booth Manufacturing?

Quality assurance (QA) in the manufacturing of inflatable paint booths is essential to maintain high standards and ensure customer satisfaction. Various international and industry-specific standards guide these processes.

-

Relevant International Standards

Compliance with international standards such as ISO 9001 is crucial for manufacturers targeting global markets. ISO 9001 provides a framework for consistent quality management practices, focusing on customer satisfaction and continuous improvement. Additionally, certifications like CE mark and American Petroleum Institute (API) standards may be relevant, depending on the specific applications of the inflatable booths. -

Quality Control Checkpoints

Effective quality control includes several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Regular checks during manufacturing help to identify issues early, allowing for immediate corrective actions.

– Final Quality Control (FQC): A thorough inspection of the finished product ensures that it meets all quality and safety standards before shipping. -

Common Testing Methods

Manufacturers employ various testing methods to verify the quality of inflatable paint booths:

– Air Retention Tests: To ensure that the booth can hold air without leaks over time.

– Material Strength Tests: Assessing the durability and tensile strength of the materials used.

– Functional Testing: Checking that all components, such as blowers and ventilation systems, operate effectively.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure they receive high-quality products. Here are several strategies to effectively assess supplier quality:

-

Conducting Audits

Regular audits of suppliers can provide in-depth insights into their manufacturing processes and quality assurance practices. Buyers should request audits performed by recognized third parties to ensure impartiality. This can help identify any weaknesses in the supplier’s quality control systems. -

Requesting Quality Reports

Suppliers should be able to provide detailed quality reports, including metrics related to defect rates, returns, and customer feedback. Analyzing these reports can help buyers understand the supplier’s commitment to quality and areas where improvements may be needed. -

Third-Party Inspections

Utilizing third-party inspection services before shipment can provide an additional layer of assurance. These inspections can verify that the inflatable paint booths meet specified standards and contractual requirements. Buyers can request inspection reports as part of their procurement process.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate specific nuances when it comes to quality control in the procurement of inflatable paint booths. These include:

-

Understanding Regional Regulations

Different regions may have specific regulations and standards that affect the quality of products. For instance, European buyers must ensure compliance with CE marking, while buyers in the Middle East may face different certification requirements. Understanding these regulations is essential for ensuring compliance and avoiding potential legal issues. -

Cultural Differences in Quality Expectations

Expectations regarding quality can vary significantly across cultures. Buyers should engage in clear communication with suppliers to align on quality standards and expectations. This includes discussing acceptable defect rates, testing protocols, and documentation requirements. -

Logistical Considerations

Shipping inflatable paint booths internationally can pose challenges related to quality assurance. Buyers should consider factors such as packaging, transportation conditions, and handling processes to ensure that the products arrive in excellent condition. Collaborating with suppliers to establish robust logistics practices is vital.

In conclusion, understanding the manufacturing processes and quality assurance practices for inflatable paint booths is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with implementing rigorous quality control measures, manufacturers can deliver high-quality products that meet the diverse needs of international clients. Buyers can further safeguard their investments by conducting audits, reviewing quality reports, and understanding regional quality control nuances.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘inflatable paint booth’

This guide serves as a comprehensive checklist for B2B buyers in the market for inflatable paint booths, offering practical steps to ensure a successful procurement process. Whether you are a small workshop or a larger manufacturing facility, following these steps will help you make informed decisions, minimize risks, and maximize your investment.

Step 1: Define Your Technical Specifications

Before exploring suppliers, it’s vital to articulate your specific needs. Consider the dimensions, weight capacity, and airflow requirements of the inflatable paint booth.

– Size Requirements: Determine the maximum vehicle size or equipment that will be painted to select an appropriately sized booth.

– Power Specifications: Identify the necessary blower power (in watts) to ensure adequate ventilation and air quality.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify potential suppliers with a strong market presence. Look for companies with a proven track record in the inflatable booth industry.

– Online Reviews: Check customer feedback and ratings on platforms like Trustpilot or industry-specific forums.

– Industry Associations: Verify if the supplier is a member of relevant associations, which often indicates adherence to industry standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Quality Certifications: Ensure the supplier complies with international quality standards, such as ISO certifications, which can be indicative of product reliability.

– Warranty and Support: Inquire about warranty terms and the availability of customer support post-purchase to address any issues that may arise.

Step 4: Request Samples and Demonstrations

Whenever possible, request samples or arrange for demonstrations of the inflatable paint booths. This step allows you to assess the product’s quality and functionality firsthand.

– Material Quality: Inspect the fabric for durability and resistance to chemicals and punctures.

– Operational Testing: Observe the setup process and blower operation to evaluate ease of use.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. This step ensures you get the best value for your investment.

– Bulk Discounts: Inquire about discounts for bulk purchases or long-term contracts, which can significantly reduce overall costs.

– Payment Flexibility: Discuss payment options, including any financing arrangements that may be available.

Step 6: Review Delivery and Installation Services

Understanding the logistics of delivery and installation is crucial to avoid unexpected delays. Confirm the supplier’s ability to deliver and install the booth efficiently.

– Lead Times: Ask about estimated delivery times to plan your operations accordingly.

– Installation Support: Verify if the supplier offers on-site installation services or guidance for your team.

Step 7: Finalize Your Purchase Agreement

Once you’ve selected a supplier, ensure that all terms are clearly outlined in a purchase agreement. This document should detail the specifications, pricing, delivery schedule, and after-sales support.

– Legal Review: Consider having your legal team review the agreement to safeguard your interests.

– Payment Milestones: Establish clear payment milestones tied to delivery and installation phases to ensure accountability.

By following this checklist, B2B buyers can navigate the procurement process for inflatable paint booths with confidence, ensuring that they make well-informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for inflatable paint booth Sourcing

What Are the Key Cost Components in Sourcing Inflatable Paint Booths?

When sourcing inflatable paint booths, understanding the cost structure is essential for B2B buyers. The primary cost components typically include:

- Materials: The fabric quality, such as PVC or nylon, significantly influences the cost. Higher-quality materials enhance durability and performance, impacting the overall price.

- Labor: Skilled labor is required for assembly and quality control. Labor costs can vary by region, affecting total pricing.

- Manufacturing Overhead: This encompasses utilities, rent, and other operational expenses incurred during production. Manufacturers with higher overhead may pass these costs onto buyers.

- Tooling: Custom designs may require specific tooling, which adds to initial costs. For standard sizes, tooling costs can be amortized over larger production runs.

- Quality Control (QC): Rigorous QC processes ensure that the inflatable booths meet safety and performance standards, potentially increasing costs.

- Logistics: Shipping costs are influenced by the booth’s size, weight, and destination. International shipping may incur additional tariffs or fees.

- Margin: Suppliers typically add a margin to cover their costs and profit. The margin can vary based on competition and market demand.

How Do Price Influencers Affect Inflatable Paint Booth Costs?

Several factors can influence the price of inflatable paint booths:

- Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Establishing a minimum order quantity (MOQ) can help negotiate better pricing.

- Specifications/Customization: Custom sizes or features (e.g., integrated lighting, additional ventilation) can significantly increase costs. Standard models are generally more economical.

- Materials: The choice of fabric and additional components (like air filters) affects the overall price. High-performance materials may result in higher upfront costs but offer better longevity.

- Quality/Certifications: Certifications like ISO or CE can add to costs but ensure compliance with safety and environmental standards, which is vital for international markets.

- Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge a premium for their experience and warranty offerings.

- Incoterms: Understanding shipping terms (e.g., FOB, CIF) is critical. These terms determine who is responsible for shipping costs and risks, impacting total costs.

What Buyer Tips Can Help Optimize Costs When Sourcing Inflatable Paint Booths?

To effectively manage costs in sourcing inflatable paint booths, consider the following strategies:

- Negotiation: Engage in negotiations with suppliers to secure better pricing, especially if you can commit to larger orders or long-term contracts.

- Cost Efficiency: Evaluate the total cost of ownership (TCO), which includes purchase price, maintenance, and operational costs over the booth’s lifecycle. Cheaper upfront costs may lead to higher long-term expenses if the product lacks durability.

- Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, be aware of local market conditions and currency fluctuations. Consider logistics and import duties that may increase overall costs.

- Supplier Relationships: Building strong relationships with suppliers can lead to better terms, priority service, and access to exclusive products or discounts.

- Research and Compare: Conduct thorough market research to compare prices and features across different suppliers. This can reveal opportunities for cost savings or better product offerings.

Disclaimer on Indicative Prices

Prices for inflatable paint booths can vary widely based on the factors discussed above. The prices listed in various sources range from approximately $182.99 for smaller models to over $1,100 for larger, more specialized booths. Always consult with suppliers for the most accurate and current pricing tailored to your specific needs.

Alternatives Analysis: Comparing inflatable paint booth With Other Solutions

Exploring Alternatives to Inflatable Paint Booths for B2B Buyers

When considering painting solutions for automotive or industrial applications, inflatable paint booths stand out due to their portability and efficiency. However, it’s essential to explore alternatives that may offer unique advantages depending on specific business needs. This analysis will compare inflatable paint booths with traditional spray booths and mobile paint trailers, providing insights for B2B buyers to make informed decisions.

| Comparison Aspect | Inflatable Paint Booth | Traditional Spray Booth | Mobile Paint Trailer |

|---|---|---|---|

| Performance | High airflow and filtration; portable | High-quality finishes; stationary | Versatile; can handle large jobs |

| Cost | Generally lower initial investment | Higher installation and maintenance costs | Moderate to high depending on customization |

| Ease of Implementation | Quick setup; requires minimal space | Requires more time for installation | More complex setup; needs a vehicle |

| Maintenance | Low maintenance; easy to clean | Higher maintenance; more components | Moderate maintenance; depends on usage |

| Best Use Case | Small to medium jobs, mobile applications | Large, permanent setups for high volume | Large projects requiring mobility |

Understanding the Alternatives: Pros and Cons

Traditional Spray Booths

Traditional spray booths are enclosed structures designed to contain overspray and improve air quality during painting. They typically deliver superior finish quality due to better control over environmental conditions. However, the high initial cost and extensive installation requirements can be a barrier for smaller businesses. Moreover, they are not portable, which limits their use to fixed locations.

Mobile Paint Trailers

Mobile paint trailers are custom-built units that can be towed to various job sites. They offer versatility and the capability to handle larger projects, such as commercial vehicle painting. The main advantage is their mobility, allowing businesses to cater to different locations without significant logistics. However, they can be expensive to purchase and maintain, and their setup may require more time compared to inflatable booths. Additionally, they may not be as efficient in terms of air filtration compared to inflatable options.

Making the Right Choice: Factors for B2B Buyers

When choosing between an inflatable paint booth and its alternatives, B2B buyers should consider several key factors. Assess the specific needs of your projects, including the size and type of items being painted, the volume of work, and the available space for installation.

For businesses focused on mobility and quick turnaround for smaller jobs, inflatable paint booths may offer the best balance of cost and performance. Conversely, companies handling larger projects with a need for high-quality finishes might find traditional spray booths more suitable. Mobile paint trailers serve as a middle ground, providing flexibility for larger jobs but at a higher cost.

Ultimately, the right solution will depend on your operational requirements, budget constraints, and the specific demands of your target market. By evaluating these factors, B2B buyers can select the most effective painting solution tailored to their business model.

Essential Technical Properties and Trade Terminology for inflatable paint booth

What Are the Key Technical Properties of Inflatable Paint Booths?

When considering the procurement of inflatable paint booths, understanding their technical specifications is essential for ensuring optimal performance and suitability for your specific application. Here are some critical properties to evaluate:

1. Material Grade

The material used in inflatable paint booths typically ranges from high-density PVC to Oxford fabric. High-density PVC is preferred for its durability and resistance to chemicals, while Oxford fabric is lightweight and easy to transport. The choice of material impacts the booth’s longevity and ability to withstand various environmental conditions, which is crucial for businesses operating in diverse climates.

2. Size and Dimensions

Inflatable paint booths come in various sizes, often measured in feet or meters. Common dimensions include models that accommodate small vehicles (e.g., 9.8 x 8.2 ft) to larger units capable of housing trucks and RVs (e.g., 50 x 19 x 17 ft). Selecting the right size is vital to ensure it meets the demands of your specific projects, facilitating efficient workflow and maximizing workspace.

3. Airflow and Filtration System

An effective paint booth should have a powerful blower system and an integrated air filtration mechanism. The airflow rate, often measured in cubic feet per minute (CFM), is critical for maintaining optimal painting conditions and minimizing overspray. A robust filtration system helps in capturing paint particles and ensuring a clean environment, which is essential for high-quality finishes.

4. Weight Capacity and Stability

The weight capacity of an inflatable paint booth is crucial, particularly for commercial applications. This specification determines the maximum load the booth can safely accommodate, impacting its stability during operation. Additionally, the booth’s anchoring system should be assessed to ensure it remains securely in place, especially in windy conditions.

5. Setup and Take-Down Time

The ease of setup and disassembly is a significant factor for businesses that require mobility. Most inflatable booths can be set up within minutes, thanks to their portable design and included blowers. This quick turnaround time enhances operational efficiency, making it easier to move from one job site to another.

What Are Common Trade Terms in the Inflatable Paint Booth Industry?

Understanding industry jargon is crucial for effective communication and negotiation. Here are some common terms you may encounter:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of inflatable paint booths, sourcing from an OEM can ensure higher quality and better compatibility with existing equipment.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For inflatable paint booths, understanding the MOQ is essential for budgeting and inventory management, particularly if you plan to purchase multiple units for different locations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price bids for specific products or services. When seeking inflatable paint booths, issuing an RFQ can help you compare prices, features, and terms from multiple suppliers, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers. Familiarity with Incoterms is vital for international transactions, as they clarify shipping obligations, risk management, and payment responsibilities.

5. CE Marking

For inflatable paint booths sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards. Understanding this certification is essential for ensuring that the products meet local regulations, which can impact your purchasing decisions.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring that they select the right inflatable paint booth for their needs and navigate the procurement process efficiently.

Navigating Market Dynamics and Sourcing Trends in the inflatable paint booth Sector

What Are the Current Trends Shaping the Inflatable Paint Booth Market?

The inflatable paint booth sector is witnessing significant growth driven by the increasing demand for portable painting solutions across various industries, including automotive, furniture, and manufacturing. Global expansion in the automotive industry, particularly in emerging markets such as Africa and South America, is a primary catalyst for this growth. B2B buyers in these regions are increasingly seeking cost-effective, efficient, and flexible solutions to meet their operational needs.

Technological advancements have also transformed the landscape of inflatable paint booths. Newer models are equipped with enhanced air filtration systems and powerful blowers, ensuring a cleaner and safer painting environment. Additionally, the rise of e-commerce platforms has simplified the sourcing process, allowing international buyers to compare products, prices, and specifications from multiple suppliers quickly. These platforms often offer bulk purchasing options, which are particularly advantageous for businesses looking to scale operations.

Moreover, trends in customization are becoming prominent, with suppliers offering tailored solutions to meet specific operational requirements. For instance, businesses can now request inflatable paint booths in various sizes and configurations to accommodate different types of vehicles or equipment. This flexibility is crucial for B2B buyers aiming to optimize their workflows and reduce downtime.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in Inflatable Paint Booth Procurement?

Sustainability is increasingly a focal point for businesses across all sectors, including those involved in the inflatable paint booth market. The environmental impact of manufacturing processes and materials used in these booths is under scrutiny, prompting buyers to seek out eco-friendly options. Materials that are recyclable or made from sustainable sources are gaining traction, aligning with global efforts to reduce waste and minimize carbon footprints.

B2B buyers should prioritize suppliers who demonstrate a commitment to ethical sourcing and sustainability. This includes transparency in their supply chains and adherence to international environmental standards. Certifications such as ISO 14001 (Environmental Management) and the use of ‘green’ materials can serve as indicators of a supplier’s dedication to sustainable practices.

Additionally, integrating sustainability into procurement strategies can enhance brand reputation and appeal to environmentally-conscious consumers. By choosing inflatable paint booths that prioritize sustainability, businesses can not only comply with regulations but also contribute positively to their communities and the environment.

What Is the Evolution of Inflatable Paint Booths and Its Impact on B2B Sourcing?

The inflatable paint booth has evolved significantly since its inception. Originally designed for small-scale applications, the technology has advanced to accommodate larger vehicles and more complex operations. The introduction of high-efficiency blowers and advanced filtration systems has enhanced the functionality and safety of these booths, making them suitable for various industrial applications.

This evolution has had a profound impact on B2B sourcing strategies. As inflatable paint booths become more sophisticated, buyers are now faced with a wider array of options, requiring them to evaluate not only the price but also the performance, durability, and features of different models. This increased complexity in sourcing necessitates a more strategic approach, where businesses must assess their specific needs and align them with the capabilities of available products.

Overall, understanding the evolution of inflatable paint booths provides B2B buyers with valuable insights into market dynamics, enabling them to make informed purchasing decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of inflatable paint booth

-

How do I ensure the quality of an inflatable paint booth before purchasing?

To ensure the quality of an inflatable paint booth, request samples or detailed specifications from the supplier. Check for certifications that indicate compliance with industry standards, such as ISO or CE certifications. Additionally, read customer reviews and testimonials, and consider visiting the supplier’s facility if possible. Establishing a quality assurance protocol, including inspections during production and before shipment, can further safeguard your investment. -

What is the best size inflatable paint booth for my business needs?

Choosing the best size inflatable paint booth depends on the types of vehicles or items you plan to paint. For small to medium vehicles, a booth measuring around 20×10 feet is typically sufficient. However, for larger vehicles or equipment, such as trucks or RVs, consider booths that exceed 30 feet in length. Assess your workspace and workflow to determine the most efficient size that accommodates your operations while allowing for easy movement and access. -

What customization options are available for inflatable paint booths?

Many suppliers offer customization options for inflatable paint booths, including size, color, branding, and additional features like built-in lighting or ventilation systems. To ensure that your specific requirements are met, communicate your needs directly with the supplier. Customization can enhance your branding and improve functionality, so consider discussing these options during your initial inquiry. -

What are the typical minimum order quantities (MOQs) for inflatable paint booths?

Minimum order quantities for inflatable paint booths can vary significantly depending on the manufacturer and the complexity of customization. Typically, MOQs range from one unit for standard models to several units for customized designs. It’s advisable to inquire directly with suppliers about their MOQs, as some may offer flexibility, especially for first-time buyers or larger contracts. -

What payment terms should I expect when sourcing inflatable paint booths internationally?

Payment terms for international orders of inflatable paint booths usually include options like advance payment, partial payment upon order confirmation, and the balance before shipment. Common methods of payment include bank transfers, letters of credit, or payment platforms. Discuss your preferred payment terms with the supplier, and ensure that they are clearly outlined in the purchase agreement to avoid misunderstandings. -

How can I effectively vet suppliers of inflatable paint booths?

To vet suppliers, conduct thorough research, checking for their reputation in the industry through reviews and ratings. Request references from previous clients and assess their responsiveness and customer service. Verify their business licenses and certifications to ensure legitimacy. Consider using third-party inspection services to evaluate their manufacturing capabilities and product quality before placing a significant order. -

What logistics considerations should I keep in mind when importing inflatable paint booths?

When importing inflatable paint booths, consider shipping methods, customs regulations, and potential tariffs. Work with a reliable freight forwarder who understands the specific needs of your cargo. Ensure that all shipping documentation is accurate and complete to avoid delays at customs. Additionally, factor in lead times for production and shipping to align with your project timelines. -

What maintenance is required for inflatable paint booths to ensure longevity?

Regular maintenance is essential for the longevity of inflatable paint booths. This includes cleaning the interior and exterior surfaces to prevent paint buildup and checking for leaks or damage regularly. Store the booth properly when not in use, ideally in a cool, dry place, to avoid wear and tear. Following the manufacturer’s guidelines for maintenance and repairs will also help extend the lifespan of your investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Inflatable Paint Booth Manufacturers & Suppliers List

1. VEVOR – Inflatable Paint Booths

Domain: vevor.com

Registered: 2009 (16 years)

Introduction: VEVOR Inflatable Paint Booths:

1. 9.8 x 8.2 x 8.2 ft – 550W Blower, Air Filter System, $182.99 (was $243.99)

2. 21 x 13.5 x 9.8 ft – 1100W Blower, Air Filter System, $464.90

3. 26 x 15 x 11 ft – 750W+950W Blowers, Air Filter System, $692.90 (was $799.99)

4. 13 x 10 x 9 ft – 950W Blower, Air Filter System, $267.90 (was $273.99)

5. 23 x 13 x 8.5 ft – 480W+750W Blowers, Air Filter System, $575.9…

2. Inflatable Paint Booth – Versatile Vehicle Painting Solution

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Inflatable paint booth, suitable for painting sections of vehicles, can accommodate a crew cab truck, priced around $1000, intended for use in a large shop without dedicating space to a permanent booth.

3. Sewinfla – Inflatable Paint Booth

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Sewinfla Inflatable Paint Booth Car Paint Tent, available in 17 sizes with filters and blowers. Condition: New. Price: $83.00. Free shipping. Estimated delivery: Sat, Sep 6 – Wed, Sep 10. Sizes include: 3.8×3.5×3.5m/12.5×11.2×11.2Ft, 4×2.5×2.5m+/13×8.2×8.2Ft, 6x3x2.75m+/20x10x9Ft, 7x4x2.5m/23x13x8.5Ft, 8x4x3m/26x13x10Ft, 10x5x3.5m/33×16.5×11.5Ft, and more.

4. Bearhawk Forums – Inflatable Paint Booths

Domain: bearhawkforums.com

Registered: 2013 (12 years)

Introduction: Inflatable paint booths are used for painting projects, with users reporting that they work well, especially indoors where they catch about 85% of overspray. One user mentioned using a booth purchased from Amazon for $1200, while another utilized a $80 party tent with internal filtration. Users suggested using cheap furnace filters to protect the booth’s filters and emphasized the importance of ve…

5. mgexp – Inflatable Paint Booth

Domain: mgexp.com

Registered: 2011 (14 years)

Introduction: Inflatable Paint Booth, dimensions: 26x13x10 ft, available on eBay, price: $1000, features: inflatable, portable, easy to store, includes a car filtration system.

6. FLAPKWAN – Inflatable Paint Booths

Domain: flapkwan.net

Registered: 2021 (4 years)

Introduction: Portable Inflatable Paint Booths available in various sizes and configurations. Key products include: 1. FLAPKWAN 28X15X10FT Inflatable Spray Paint Booth – $999.00, 4.75/5.0 rating. 2. FLAPKWAN 28X15X11.5FT Inflatable Paint Booth – $1,059.00, 4.0/5.0 rating. 3. FLAPKWAN 33X16.5X13FT Inflatable Paint Booth for Trucks – $1,299.99, 5.0/5.0 rating. 4. FLAPKWAN 30X20X13FT Inflatable Spray Paint Booth -…

7. VEVOR – Inflatable Paint Booth 20x10x8ft

Domain: tractorbynet.com

Registered: 1999 (26 years)

Introduction: VEVOR Inflatable Paint Booth, 20x10x8ft, High Powerful 480W+750W Blowers, Spray Booth Tent, Air Filter System for Car Parking Tent Workstation Motorcycle Garage.

8. Amazon – Inflatable Paint Booth

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Amazon inflatable paint booth used for painting Lexus IS300 and Mazda Miata.

Strategic Sourcing Conclusion and Outlook for inflatable paint booth

As the demand for inflatable paint booths continues to rise across various international markets, strategic sourcing becomes essential for B2B buyers looking to capitalize on this trend. The versatility, portability, and cost-effectiveness of inflatable paint booths make them ideal for diverse applications—from automotive refinishing to furniture painting. Buyers should consider quality, supplier reliability, and after-sales support when sourcing these products, ensuring they partner with manufacturers that offer robust solutions tailored to their specific needs.

Investing in inflatable paint booths not only enhances operational efficiency but also aligns with sustainable practices by minimizing emissions and waste associated with traditional paint booths. As businesses in Africa, South America, the Middle East, and Europe seek to improve their service offerings, the inflatable paint booth market presents a valuable opportunity to innovate and expand.

Looking forward, we encourage international buyers to explore the latest technological advancements and product options available in this sector. By embracing strategic sourcing, you can position your business for growth and stay ahead in a competitive landscape. Engage with reputable suppliers today to discover how inflatable paint booths can transform your operations and meet your evolving business needs.