The Definitive Guide to Ice Making Vending Machines: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for ice making vending machines

In today’s fast-paced global marketplace, sourcing ice making vending machines presents unique challenges for B2B buyers. With varying demands across regions, from the bustling streets of Nigeria to the vibrant markets of Germany, understanding the nuances of these machines is crucial for successful investments. This guide serves as a comprehensive resource, exploring different types of ice making vending machines, their applications, and the factors influencing their performance in diverse environments.

We delve into supplier vetting processes, highlighting key considerations such as durability, maintenance, and revenue potential. Additionally, we provide insights into cost structures, helping you make informed financial decisions that align with your business goals. By addressing common pain points, such as machine reliability and customer satisfaction, this guide empowers international buyers to navigate the complexities of the ice vending market with confidence.

Whether you’re looking to establish a new venture or expand an existing business, understanding the intricacies of ice making vending machines will enhance your purchasing strategy. Our aim is to equip you with actionable insights that foster successful partnerships and drive profitability across Africa, South America, the Middle East, and Europe. Embrace the opportunity to revolutionize your ice supply strategy and elevate your business’s competitive edge.

Understanding ice making vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ice House | Large capacity (up to 6,500 lbs), built-in filtration, high traffic suitability | Convenience stores, gas stations, events | Pros: High revenue potential; minimal maintenance. Cons: Higher initial investment. |

| Ice Kiosk | Mid-capacity (2,400-3,000 lbs), compact design, customizable | Retail locations, parks, festivals | Pros: Suitable for medium traffic; good for smaller budgets. Cons: Limited storage compared to larger models. |

| Ice Merchant | Compact size, on-the-spot ice production, minimal maintenance | Convenience stores, campgrounds, car washes | Pros: Space-efficient; eliminates delivery costs. Cons: Lower ice capacity than larger models. |

| Inline Merchant | Built for wall installation, similar to ATMs, space-saving | Urban retail environments, small shops | Pros: Ideal for tight spaces; easy access. Cons: Requires specific installation considerations. |

| Auto-Bagging Machine | Automated bagging system, advanced technology, eco-friendly | Large venues, high-demand areas | Pros: Reduces labor costs; efficient for bulk sales. Cons: Higher complexity may require more maintenance. |

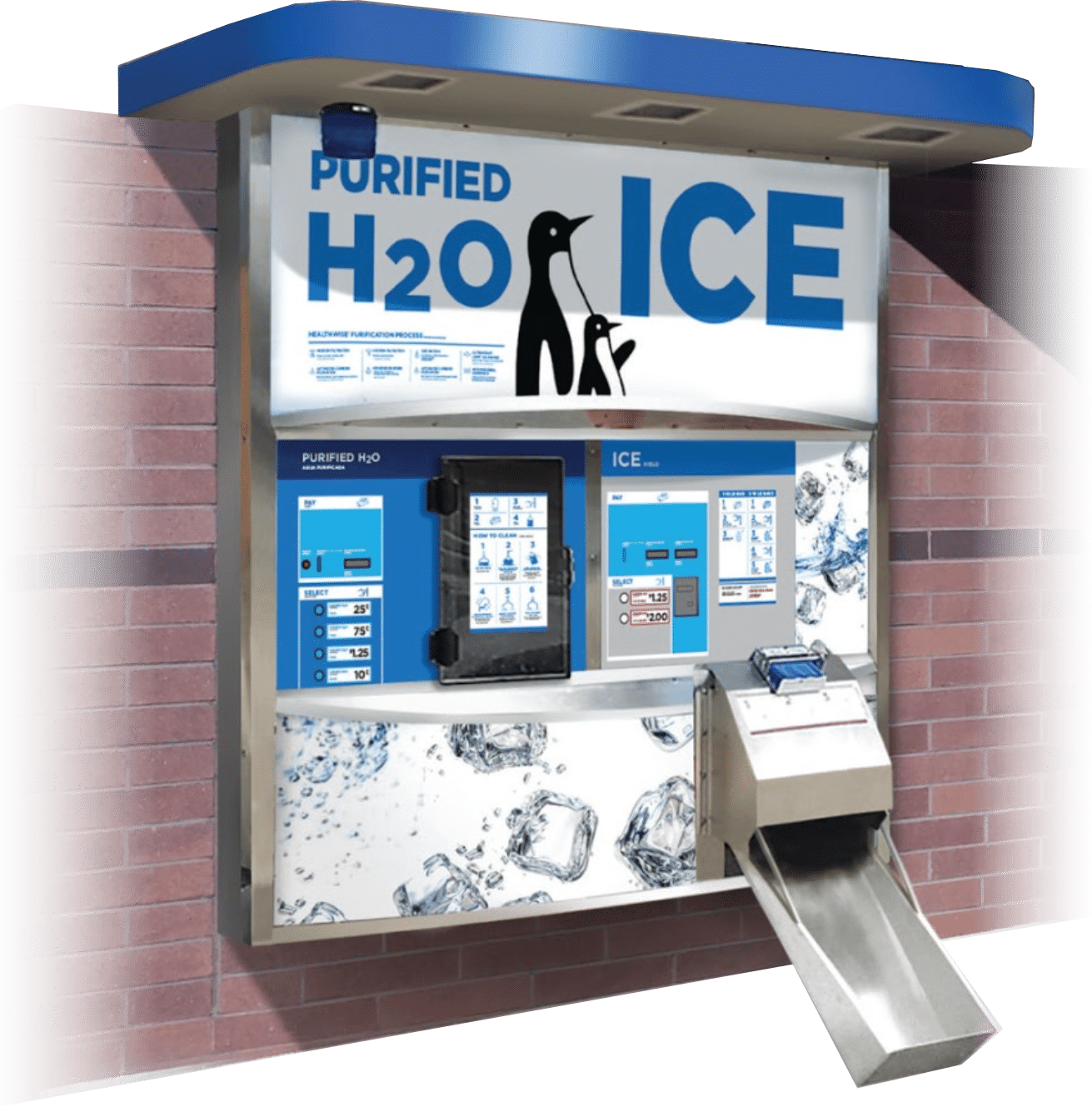

What Are the Key Characteristics of Ice House Vending Machines?

Ice House vending machines are recognized for their substantial ice storage capacity, reaching up to 6,500 lbs. This model features built-in filtration systems and is designed for high-traffic locations, making it ideal for convenience stores and gas stations. B2B buyers should consider the potential for high revenue generation, especially in busy areas. However, the initial investment is relatively high, requiring careful location selection to maximize profitability.

How Does the Ice Kiosk Differ from Other Models?

The Ice Kiosk offers a mid-range capacity between the larger Ice House and smaller models, storing between 2,400 and 3,000 lbs of ice. Its compact design makes it suitable for retail locations, parks, and festivals where space is limited. This model is particularly appealing for businesses with smaller budgets and moderate traffic. While it provides a good balance of capacity and cost, buyers must be aware that its ice storage is less than that of larger machines.

Why Choose an Ice Merchant for Smaller Locations?

The Ice Merchant is designed for versatility and efficiency in smaller spaces. It produces ice on-demand, eliminating the need for delivery, which can significantly enhance profit margins. Ideal for convenience stores and campgrounds, this model requires minimal maintenance and can be installed both indoors and outdoors. However, buyers should consider its lower storage capacity, which may limit operations during peak demand periods.

What Are the Benefits of Inline Merchant Machines?

Inline Merchant machines are engineered for installation directly into walls, akin to ATMs, making them perfect for urban retail environments where space is at a premium. Their compact design allows for easy access while maximizing available floor space. B2B buyers should note that while they save on space, installation may require specific considerations, which could add to initial setup costs.

How Do Auto-Bagging Machines Enhance Ice Vending Operations?

Auto-bagging machines feature automated systems that streamline the bagging process, making them particularly efficient for large venues or areas with high ice demand. These machines are eco-friendly due to their on-demand production capabilities, which reduce waste. While they offer significant operational efficiencies, buyers should be prepared for potentially higher maintenance needs and initial complexity in setup, which may require additional training or support.

Key Industrial Applications of ice making vending machines

| Industry/Sector | Specific Application of ice making vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Ice vending at hotels and resorts | Provides guests with convenient access to ice 24/7, enhancing guest satisfaction and reducing operational costs associated with ice delivery. | Ensure machine size matches guest traffic; consider payment options and energy efficiency. |

| Food and Beverage | Ice supply for restaurants and bars | Reduces dependency on traditional ice delivery, ensuring a steady supply of fresh ice for beverages, thereby improving service quality and operational efficiency. | Evaluate machine capacity based on peak hours; consider filtration systems to ensure ice quality. |

| Event Management | Ice vending at festivals and outdoor events | Offers a reliable source of ice for catering services, minimizing waste and ensuring guests have access to ice for drinks. | Assess location logistics; consider weatherproof features and mobility of machines. |

| Construction | Ice supply for concrete cooling | Provides a consistent supply of ice for cooling concrete mixtures, ensuring structural integrity and compliance with building standards. | Evaluate machine capacity for project scale; consider local regulations for ice usage in construction. |

| Retail | Ice vending in convenience stores | Attracts customers by offering a quick and easy way to purchase ice, enhancing foot traffic and increasing sales of other products. | Consider machine placement for visibility; evaluate payment options and size relative to store layout. |

How Are Ice Making Vending Machines Used in the Hospitality Industry?

In the hospitality sector, ice making vending machines serve as a vital amenity for hotels and resorts, providing guests with 24/7 access to ice. This self-service model not only enhances guest satisfaction but also significantly reduces operational costs related to ice delivery and storage. Buyers should consider the machine’s size based on expected guest traffic, as well as energy efficiency and diverse payment options to meet varying customer preferences.

What Role Do Ice Vending Machines Play in Food and Beverage Businesses?

Restaurants and bars utilize ice making vending machines to ensure a continuous supply of fresh ice for drinks, which is essential for maintaining service quality. By reducing reliance on traditional ice delivery services, businesses can streamline operations and minimize waste. Buyers in this sector should evaluate the machine’s capacity during peak hours and prioritize high-quality filtration systems to guarantee ice purity.

How Do Ice Vending Machines Benefit Event Management?

Ice making vending machines are particularly beneficial for event management companies, especially during festivals and outdoor events. They provide a reliable source of ice for catering services, allowing for quick replenishment and minimizing waste. When sourcing machines for this application, it’s important to assess logistics related to machine placement and consider features like weatherproofing and mobility to adapt to various event environments.

In What Ways Are Ice Vending Machines Used in Construction?

In the construction industry, ice making vending machines are crucial for providing ice to cool concrete mixtures, a process essential for maintaining the structural integrity of builds. A steady supply of ice helps ensure compliance with industry standards. Buyers must assess the machine’s capacity based on the scale of projects and consider local regulations governing the use of ice in construction activities.

How Can Ice Vending Machines Enhance Retail Opportunities?

Convenience stores can leverage ice making vending machines to attract customers looking for quick access to ice, thereby increasing foot traffic and boosting sales of related products. The placement of these machines should be strategic for visibility, and it’s essential to evaluate payment options to accommodate a diverse customer base. Proper sizing relative to the store layout will further enhance customer experience and operational efficiency.

3 Common User Pain Points for ‘ice making vending machines’ & Their Solutions

Scenario 1: Insufficient Ice Production During Peak Demand

The Problem: B2B buyers often encounter the challenge of ice vending machines running out of stock during peak usage times, especially in busy locations such as beaches, festivals, or sporting events. This not only frustrates customers but also leads to lost revenue opportunities. For instance, a convenience store owner in Nigeria might invest in a vending machine expecting it to meet high demand during the hot season, only to find it unable to keep up, resulting in customer dissatisfaction and a tarnished reputation.

The Solution: To mitigate this issue, buyers should prioritize high-capacity ice making vending machines designed for high traffic areas. Opt for models like the Ice House, which boasts a storage capacity of up to 6,500 lbs and can vend thousands of pounds of ice daily. Additionally, implement a SmartIce™ Remote Management System that monitors ice levels in real-time, allowing operators to proactively manage stock and avoid shortages. Buyers should also consider location analysis services provided by vendors to determine the optimal placement of machines in high-demand zones, ensuring maximum profitability.

Scenario 2: Maintenance Costs and Downtime

The Problem: Maintenance issues and associated costs can be a significant pain point for B2B buyers of ice making vending machines. For instance, a business owner in South America might face unexpected repair costs or prolonged downtimes due to faulty components, leading to lost sales and customer trust. The complexity of some vending machines can also deter new entrepreneurs who lack technical expertise, making them hesitant to invest in this business model.

The Solution: To address maintenance concerns, buyers should look for machines with minimal maintenance requirements and robust support from the manufacturer. Models equipped with advanced technology, like Everest’s Cold Fusion technology that recycles water and the patented VersaVend system that prevents jams, can significantly reduce maintenance needs. Additionally, opting for machines that come with comprehensive warranties and support services can provide peace of mind. New buyers should also seek out training programs offered by manufacturers to familiarize themselves with machine operation and troubleshooting, empowering them to manage minor issues efficiently.

Scenario 3: Limited Payment Options Impacting Sales

The Problem: Many ice vending machines come with outdated payment systems, limiting customers’ ability to purchase ice conveniently. This can be particularly detrimental in regions where cash transactions are declining, such as in parts of Europe. A vending machine that only accepts cash may deter potential customers who prefer credit or mobile payment options, directly impacting the machine’s profitability.

The Solution: When sourcing ice making vending machines, buyers should prioritize models that offer multiple payment methods, including credit cards, mobile wallets like Apple Pay and Google Wallet, and even tokens or coupons. This flexibility not only enhances the customer experience but also expands the potential customer base. For instance, the Ice Kiosk model provides a variety of payment options, making it easier for customers to make purchases, which can lead to increased sales. Additionally, businesses should stay updated on the latest payment technologies and consider integrating contactless payment systems to cater to evolving consumer preferences, ensuring that their vending machines remain competitive and accessible.

Strategic Material Selection Guide for ice making vending machines

What Are the Key Materials Used in Ice Making Vending Machines?

When selecting materials for ice making vending machines, it is essential to consider their properties, advantages, and limitations. The choice of materials can significantly influence the machine’s performance, durability, and overall cost-effectiveness. Below, we analyze four common materials used in the construction of these machines, focusing on their relevance to international B2B buyers.

How Does Stainless Steel Perform in Ice Making Vending Machines?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 1,200°F (650°C) and a pressure rating that varies based on the specific grade used.

Pros & Cons: The durability of stainless steel makes it ideal for outdoor environments, where exposure to moisture and varying temperatures can lead to rust in inferior materials. However, it is relatively expensive compared to alternatives like aluminum or plastic. Manufacturing complexity can also be higher due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with various media, including water and ice, ensuring that the product remains uncontaminated. Its smooth surface is easy to clean, which is vital for hygiene in food-related applications.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of local regulations regarding food safety and material compliance. Standards such as ASTM and DIN may apply, particularly for food-grade materials.

What Role Does Aluminum Play in Ice Making Vending Machines?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can handle temperatures up to 1,200°F (650°C) and is often used in components that require efficient heat dissipation.

Pros & Cons: The primary advantage of aluminum is its low cost and ease of manufacturing, which makes it an attractive option for budget-conscious buyers. However, it is less durable than stainless steel and can deform under high pressure or impact, making it less suitable for high-traffic environments.

Impact on Application: Aluminum’s compatibility with water and ice makes it a viable option for internal components. However, its lower strength may limit its use in structural applications.

Considerations for International Buyers: In regions like the Middle East, where high temperatures can affect material performance, buyers should ensure that aluminum components are treated to enhance their durability. Compliance with local standards is also crucial.

How Does Plastic Compare in Ice Making Vending Machines?

Key Properties: Various types of plastics, such as polyethylene and polypropylene, are commonly used in vending machines. They offer good chemical resistance and can handle temperatures up to 200°F (93°C).

Pros & Cons: Plastics are lightweight and cost-effective, making them suitable for non-structural components. However, they can be less durable than metals and may degrade over time, especially under UV exposure or extreme temperatures.

Impact on Application: Plastic is often used for water reservoirs and internal components, where corrosion resistance is essential. However, its lower strength limits its use in structural applications.

Considerations for International Buyers: Buyers should verify that the plastics used comply with food safety standards and are suitable for local climates. In Europe, for example, compliance with EU regulations on food contact materials is essential.

What About Copper in Ice Making Vending Machines?

Key Properties: Copper is known for its excellent thermal conductivity and antimicrobial properties. It can withstand high temperatures and has a melting point of about 1,984°F (1,085°C).

Pros & Cons: The antimicrobial nature of copper makes it a great choice for components that come into contact with water and ice, helping to maintain hygiene. However, it is more expensive than aluminum and can be prone to corrosion if not properly coated.

Impact on Application: Copper is primarily used in piping and heat exchangers due to its thermal efficiency. Its compatibility with water makes it a valuable material for ensuring clean ice production.

Considerations for International Buyers: Buyers in regions with high humidity, such as parts of Africa and South America, should consider the potential for corrosion and ensure that copper components are adequately treated or coated.

Summary Table of Material Selection for Ice Making Vending Machines

| Material | Typical Use Case for Ice Making Vending Machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, exterior casing | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Internal components, heat exchangers | Lightweight and cost-effective | Less durable under high pressure | Medium |

| Plastic | Water reservoirs, non-structural components | Cost-effective and lightweight | Limited durability and UV degradation | Low |

| Copper | Piping and heat exchangers | Excellent thermal conductivity and antimicrobial | Higher cost and potential for corrosion | Medium to High |

This strategic material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ice making vending machines

What Are the Key Stages in the Manufacturing Process of Ice Making Vending Machines?

The manufacturing process of ice making vending machines involves several critical stages that ensure the machines are reliable, efficient, and meet the high standards expected by international B2B buyers.

1. Material Preparation

The first stage in manufacturing begins with the selection of high-quality materials. Stainless steel is commonly used for the machine’s exterior due to its durability and resistance to corrosion. Components such as compressors, evaporators, and electronic systems are sourced from reputable suppliers to ensure reliability. Quality checks on these materials are crucial to prevent defects that could impact the machine’s performance.

2. Forming

In this stage, materials are shaped into the necessary components using techniques such as laser cutting, CNC machining, and bending. These processes allow for precision and consistency, which are essential for the machine’s functionality. Advanced technologies like robotic welding are often employed to enhance the strength of joints and ensure uniformity.

3. Assembly

The assembly stage involves integrating all components into a cohesive unit. Skilled technicians utilize assembly lines equipped with specialized tools to ensure each part is correctly installed. This stage often includes the installation of the ice-making unit, water filtration systems, and payment processing modules. A focus on ergonomics and ease of access during maintenance is also prioritized to facilitate long-term operation.

4. Finishing

After assembly, the machines undergo a finishing process that includes painting or coating to enhance aesthetics and protect against environmental factors. Quality assurance checks are conducted to ensure that all components are correctly installed and functioning as intended.

How Is Quality Assurance Integrated into the Manufacturing of Ice Making Vending Machines?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final product meets both international standards and customer expectations.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with various international quality standards that manufacturers of ice making vending machines may adhere to:

- ISO 9001: This standard outlines criteria for a quality management system, ensuring consistent quality and customer satisfaction.

- CE Marking: In Europe, products must meet specific health, safety, and environmental protection standards to obtain CE marking.

- API Standards: The American Petroleum Institute provides standards that may be relevant for machines used in oil and gas industries.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integral to the manufacturing process and typically involves several checkpoints:

1. Incoming Quality Control (IQC)

This initial checkpoint assesses the quality of raw materials and components before they enter the production line. Suppliers must provide certification that materials meet specified standards.

2. In-Process Quality Control (IPQC)

During the manufacturing process, ongoing inspections are conducted to ensure that each component is produced according to the established quality parameters. This includes monitoring the forming and assembly processes, ensuring that any deviations are addressed immediately.

3. Final Quality Control (FQC)

Once the machines are assembled, a comprehensive inspection is performed. This includes functionality testing, safety checks, and performance assessments to ensure that each unit operates as intended.

What Common Testing Methods Are Utilized in Quality Assurance?

Various testing methods are employed to verify the quality and performance of ice making vending machines:

- Functional Testing: This involves running the machines through their operational cycles to ensure they produce ice correctly and efficiently.

- Pressure Testing: Ensures that water and refrigeration systems are leak-proof and can withstand operational pressures.

- Safety Testing: Checks for electrical safety and compliance with local regulations, ensuring that machines pose no risk to users.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are some strategies to ensure supplier reliability:

- Supplier Audits: Conduct on-site audits to evaluate the manufacturing processes and quality control systems in place. This firsthand observation can provide insights into operational practices.

- Quality Reports: Request documentation of quality assurance processes, including IQC, IPQC, and FQC procedures, as well as results from recent tests.

- Third-Party Inspections: Engage independent third-party inspection services to validate the supplier’s claims regarding quality assurance and product reliability.

What Are the Quality Control Considerations for International Buyers from Diverse Regions?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should consider several factors in the context of quality control:

- Regulatory Compliance: Different regions have specific regulations regarding product safety and environmental impact. Understanding these requirements is crucial for compliance.

- Cultural Expectations: Quality perceptions may vary across cultures. Engaging with local representatives can help navigate these differences and align product offerings with regional expectations.

- Supply Chain Logistics: Consider the implications of logistics on quality assurance, such as transportation conditions and storage facilities, which can impact the final product.

Conclusion

Understanding the manufacturing processes and quality assurance measures for ice making vending machines is vital for B2B buyers seeking reliable suppliers. By focusing on the key stages of manufacturing, international standards, and effective quality control practices, buyers can make informed decisions that enhance their business operations and minimize risks. Engaging with reputable suppliers who demonstrate strong quality assurance practices will ultimately lead to better product performance and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ice making vending machines’

Introduction

This sourcing guide is designed to assist B2B buyers in making informed decisions when procuring ice making vending machines. By following this step-by-step checklist, you can ensure that you choose the right equipment tailored to your business needs, budget, and operational requirements.

1. Define Your Business Requirements

Before you start shopping, clearly outline what your business needs. Consider factors such as the expected customer volume, types of ice to be sold (e.g., bagged or bulk), and whether you’ll also offer water. This step ensures that you select a machine with the appropriate capacity and features to meet your operational demands.

2. Research Different Models

Investigate various ice making vending machine models available in the market. Each model may offer different capacities, functionalities, and technological advancements. Pay attention to aspects like energy efficiency, maintenance requirements, and payment options to find a model that aligns with your business strategy.

3. Evaluate Supplier Reputation

Thoroughly vet potential suppliers to ensure reliability and quality. Look for suppliers with a proven track record in the vending industry and positive reviews from other businesses, particularly those in your region. Request case studies or references to gauge their reliability and customer support.

4. Assess Technical Specifications

Evaluate the technical specifications of the machines you are considering. Focus on features such as ice production capacity, filtration systems, and energy consumption. Understanding these specifications will help you select a machine that not only meets your needs but also operates efficiently, minimizing operational costs.

5. Verify Warranty and Support Services

Check the warranty terms and ongoing support services provided by the supplier. A robust warranty can protect your investment, while strong customer support ensures that any operational issues can be resolved quickly. Look for suppliers that offer training and remote management tools for seamless operation.

6. Request Quotes and Compare Pricing

Once you have shortlisted potential machines and suppliers, request detailed quotes that include all costs—such as shipping, installation, and ongoing maintenance. Comparing these quotes will help you identify the best value for your investment, ensuring you remain within budget while securing quality equipment.

7. Plan for Installation and Maintenance

Finally, develop a plan for the installation and ongoing maintenance of the vending machines. Consider logistical aspects such as location setup, utility connections, and maintenance schedules. Proper planning will facilitate a smooth launch and ensure the longevity of your machines, ultimately maximizing your return on investment.

By following these steps, B2B buyers can effectively navigate the procurement process for ice making vending machines, ensuring a successful investment that meets their business needs and enhances customer satisfaction.

Comprehensive Cost and Pricing Analysis for ice making vending machines Sourcing

What Are the Key Cost Components of Ice Making Vending Machines?

When sourcing ice making vending machines, understanding the cost structure is crucial. The primary components include:

-

Materials: The quality and type of materials used significantly affect the cost. High-grade stainless steel, advanced filtration systems, and energy-efficient components typically increase upfront costs but can lead to lower maintenance and operational expenses.

-

Labor: Labor costs encompass both manufacturing and assembly. Skilled labor for installation and maintenance is also a consideration, particularly in regions where technical expertise may be limited.

-

Manufacturing Overhead: This includes factory costs such as utilities, rent, and administrative expenses. Manufacturers with streamlined operations may offer competitive pricing due to lower overhead.

-

Tooling: Initial tooling costs for specialized components can be substantial, particularly for customized machines. However, these costs may be amortized over larger production runs.

-

Quality Control (QC): Investing in rigorous QC processes ensures high-quality outputs but can increase production costs. Machines that meet international certifications (like ISO) may carry a premium.

-

Logistics: Transportation and shipping costs, including duties and tariffs, can add significant expenses, especially for international buyers. The distance from the manufacturing facility to the buyer’s location plays a vital role in logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on competition, demand, and the uniqueness of the product.

How Do Price Influencers Impact the Cost of Ice Making Vending Machines?

Several factors can influence the pricing of ice making vending machines:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing due to economies of scale. Understanding the MOQ can help buyers negotiate better terms.

-

Specifications and Customization: Custom features or specific design requirements can significantly impact costs. While customization allows for tailored solutions, it often comes at a premium.

-

Material Quality and Certifications: High-quality materials and certifications that ensure safety and efficiency can increase initial costs but may reduce total cost of ownership through durability and lower maintenance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more for their expertise and support, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect shipping costs and responsibilities. Buyers should be aware of which party is responsible for shipping, insurance, and tariffs to accurately calculate total costs.

What Buyer Tips Can Help Achieve Cost Efficiency in Ice Making Vending Machines?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Effectively: Leverage the supplier’s need for business by negotiating terms, especially for bulk purchases. Establishing a long-term relationship can also lead to better pricing over time.

-

Consider Total Cost of Ownership (TCO): Analyze not just the purchase price but also operational costs, maintenance, and potential downtime. Investing in higher-quality machines may yield better long-term savings.

-

Understand Pricing Nuances for International Markets: Be mindful of currency fluctuations, import duties, and local market conditions that can affect pricing. Engaging local distributors may mitigate some of these challenges.

-

Explore Financing Options: Many manufacturers offer financing solutions to ease the initial investment burden. Evaluating such options can provide flexibility and aid in cash flow management.

Disclaimer on Indicative Prices

Prices for ice making vending machines can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing ice making vending machines With Other Solutions

Exploring Alternatives to Ice Making Vending Machines

In the competitive landscape of ice distribution, businesses are increasingly evaluating various solutions for ice delivery and sales. Ice making vending machines offer a unique blend of convenience and efficiency, but there are alternative solutions that may better suit specific business needs. Below, we compare ice making vending machines with two viable alternatives: traditional ice delivery services and ice production facilities.

Comparison Table

| Comparison Aspect | Ice Making Vending Machines | Traditional Ice Delivery Services | Ice Production Facilities |

|---|---|---|---|

| Performance | High output, consistent quality | Variable output, dependent on logistics | High output, tailored production |

| Cost | Initial investment, low operating costs | Recurring costs, delivery fees | High initial setup costs, variable operating costs |

| Ease of Implementation | Quick installation, location-dependent | Requires ongoing logistics planning | Complex setup, regulatory compliance needed |

| Maintenance | Low maintenance, remote monitoring | No maintenance but dependent on supplier reliability | Regular maintenance required |

| Best Use Case | High-traffic areas, remote locations | Areas with established customer base needing regular supply | Large-scale operations, high demand environments |

Detailed Breakdown of Alternatives

1. Traditional Ice Delivery Services

Traditional ice delivery involves purchasing ice from a supplier who delivers it to your business location. This solution is beneficial for businesses that require a steady supply of ice without the upfront investment in machinery. However, the reliance on delivery schedules can lead to inconsistencies in supply, especially during peak seasons. Additionally, ongoing costs can accumulate, potentially leading to higher long-term expenses compared to owning an ice vending machine.

2. Ice Production Facilities

Operating an ice production facility allows businesses to produce ice in bulk, catering to high demand. This solution is ideal for enterprises that have significant ice needs, such as large restaurants, event venues, or recreational facilities. While this method ensures a consistent supply and can be tailored to specific requirements, it comes with substantial initial costs and regulatory hurdles. Furthermore, maintenance of production equipment can be labor-intensive, which may not be feasible for smaller operations.

Conclusion: How to Choose the Right Ice Solution for Your Business

When considering the best solution for your ice distribution needs, it’s essential to evaluate the specific requirements of your business environment. Ice making vending machines provide an excellent option for high-traffic locations where immediate access to ice is crucial, offering low maintenance and operational costs. Conversely, traditional ice delivery services may suit businesses that prefer to avoid equipment investments and can rely on regular supply. Lastly, ice production facilities are optimal for large-scale operations that demand a significant and consistent ice output. By assessing factors such as cost, maintenance, and performance, B2B buyers can make informed decisions that align with their operational goals and customer needs.

Essential Technical Properties and Trade Terminology for ice making vending machines

What Are the Essential Technical Properties of Ice Making Vending Machines?

Understanding the technical specifications of ice making vending machines is vital for B2B buyers, especially when evaluating options for investment. Here are some critical specifications to consider:

1. Ice Storage Capacity

The ice storage capacity refers to the amount of ice the machine can hold, typically measured in pounds. Machines can range from compact models with under 1,000 lbs to larger units capable of storing 6,500 lbs or more. A higher capacity is crucial for high-traffic locations, as it minimizes the risk of running out of ice during peak demand, thereby maximizing revenue potential.

2. Filtration System

A robust filtration system is essential for ensuring the quality of the ice produced. Many machines include multi-stage filtration processes, such as sediment filters, water softeners, and reverse osmosis capabilities. This not only enhances the quality of the ice but also prolongs the machine’s lifespan by preventing mineral buildup, thus reducing maintenance costs.

3. Power Consumption

Ice vending machines vary in energy efficiency, often denoted by their power consumption ratings. Machines utilizing advanced technologies, like energy-efficient compressors and Cold Fusion systems, can significantly lower operational costs. For businesses in regions with high energy prices, selecting a machine with low power consumption can lead to substantial long-term savings.

4. Payment Options

Modern ice vending machines offer diverse payment options including cash, credit/debit cards, mobile payments, and tokens. This flexibility is vital for catering to a wider customer base, especially in diverse markets. Businesses should assess the payment systems that align with local consumer preferences and ensure they can accommodate various payment methods.

5. Dimensions and Footprint

The physical size and footprint of the machine are critical, particularly for locations with space constraints. Compact models are designed to fit in smaller areas while still offering substantial ice production. Understanding the dimensions allows buyers to optimize site layout and ensure compliance with local zoning regulations.

6. Remote Management Capability

Many contemporary ice vending machines come equipped with remote management software, enabling operators to monitor machine performance in real time. This feature is essential for maintaining optimal operations, allowing for proactive maintenance and quick responses to any issues, which is particularly beneficial for businesses managing multiple machines across various locations.

What Common Trade Terms Should B2B Buyers Know About Ice Making Vending Machines?

Familiarity with industry jargon can significantly enhance communication and negotiation processes. Here are some common terms used in the ice vending machine market:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of ice machines, understanding OEM relationships can help buyers evaluate the quality and reliability of machine components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management, especially for businesses looking to scale operations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Crafting a detailed RFQ can ensure that buyers receive competitive pricing and accurate information about machine specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is essential for mitigating risks and ensuring smooth transactions across borders.

5. Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. For ice vending machines, shorter lead times can enhance business agility, allowing companies to respond quickly to market demands.

6. Warranty Period

This term outlines the duration for which the manufacturer guarantees the machine against defects. A comprehensive warranty is an important consideration for buyers, as it reflects the manufacturer’s confidence in their product and can significantly affect long-term maintenance costs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions and navigate the complex landscape of ice making vending machines more effectively.

Navigating Market Dynamics and Sourcing Trends in the ice making vending machines Sector

What are the Current Market Dynamics and Key Trends in Ice Making Vending Machines?

The global ice making vending machine market is experiencing significant growth, driven by urbanization, rising demand for convenience, and the expansion of outdoor recreational activities. In regions like Africa, South America, and the Middle East, increasing temperatures and changing lifestyles are propelling the need for accessible ice and water solutions. Furthermore, as urban areas become denser, the demand for compact, efficient machines that can serve high foot traffic locations is rising.

Emerging technologies are reshaping the sector, with advanced features such as remote management systems, energy-efficient designs, and eco-friendly materials becoming essential for international B2B buyers. For instance, systems like SmartIce™ enable operators to monitor machine performance and sales remotely, improving operational efficiency. Additionally, innovations such as auto-bagging and integrated filtration systems not only enhance product quality but also address the growing consumer preference for sustainable and clean ice.

International buyers are also increasingly aware of the importance of location strategy. In regions like Germany and Nigeria, the right placement of vending machines can significantly influence profitability. Buyers should consider factors such as local competition, accessibility, and customer demographics when sourcing machines. This strategic approach to market dynamics ensures that businesses remain agile and responsive to changing consumer needs.

How is Sustainability and Ethical Sourcing Impacting the Ice Making Vending Machines Industry?

Sustainability has become a pivotal consideration for B2B buyers in the ice making vending machines sector. The environmental impact of traditional ice delivery methods—characterized by significant carbon footprints—has prompted a shift towards on-demand ice vending solutions. These machines minimize waste by producing ice at the source, thereby reducing the need for transportation and storage.

Ethical sourcing is gaining traction as businesses look to align with suppliers that prioritize eco-friendly practices. This includes utilizing green certifications and materials in manufacturing processes. For example, machines that incorporate energy-efficient technologies, such as Cold Fusion technology, not only lower operational costs but also appeal to environmentally conscious consumers.

B2B buyers should prioritize partnerships with manufacturers who demonstrate a commitment to sustainability. This includes evaluating the supply chain for certifications such as ISO 14001, which indicates a commitment to environmental management. By investing in sustainable solutions, businesses can enhance their brand reputation while meeting the growing consumer demand for ethical practices.

What is the Brief Evolution and History of Ice Making Vending Machines?

The evolution of ice making vending machines can be traced back to traditional ice delivery services, which were often inefficient and costly. The shift towards vending machines began in the late 20th century, driven by the need for more convenient and cost-effective solutions. Early models were basic, often requiring manual restocking and maintenance, limiting their effectiveness.

As technology progressed, so did the design and functionality of these machines. The introduction of automatic ice production and advanced filtration systems marked a significant turning point. By the early 21st century, features such as remote monitoring and eco-friendly operations became standard, aligning with the broader trends of convenience and sustainability.

Today, manufacturers are focusing on customization and scalability, allowing businesses to choose machines that fit their specific operational needs. This evolution reflects a broader trend towards enhancing user experience and operational efficiency, ultimately making ice making vending machines a viable business model for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of ice making vending machines

-

How do I choose the right ice making vending machine for my location?

Selecting the appropriate ice vending machine involves evaluating the expected foot traffic and customer demand in your chosen location. High-traffic areas, such as near beaches, parks, or event venues, may benefit from larger capacity machines, like the Ice House, which can store up to 6,500 lbs of ice. Conversely, for smaller retail settings or less busy locations, a mid-capacity option like the Ice Kiosk might suffice. Consulting with suppliers who offer location vetting services can also provide insights into the best machine type for your needs. -

What are the key features to look for in an ice making vending machine?

When sourcing ice vending machines, prioritize durability, ease of maintenance, and advanced filtration systems. Look for machines equipped with sediment filtration and reverse osmosis capabilities to ensure high-quality ice. Additionally, consider payment options; machines that accept multiple payment methods (credit/debit cards, mobile wallets) can enhance customer convenience. Finally, features like remote management systems can assist in monitoring sales and inventory, improving operational efficiency. -

What customization options are available for ice making vending machines?

Many manufacturers offer customization options, allowing you to tailor the machine’s branding, size, and functionality to fit your business model. Custom branding can enhance visibility and attract customers in competitive environments. Additionally, inquire about features like auto-bagging or integrated payment systems to optimize user experience. Discussing your specific needs with the supplier can help identify the best options available for your machine. -

What is the minimum order quantity (MOQ) for ice making vending machines?

MOQs can vary significantly between suppliers and may depend on the machine type and customization level. Some manufacturers may allow single-unit purchases, while others might require bulk orders to access better pricing. When engaging with suppliers, clarify their MOQ policies and explore potential discounts for larger orders. This can be particularly beneficial for businesses looking to establish a network of machines across multiple locations. -

What are the payment terms typically offered by suppliers for ice making vending machines?

Payment terms can vary widely, but many suppliers offer flexible options, including upfront payments, installment plans, or financing arrangements. It’s essential to discuss these terms early in the negotiation process to ensure they align with your budget and cash flow. Additionally, some suppliers may accept different currencies or payment methods, which can be crucial for international transactions, especially in regions like Africa or South America. -

How can I ensure quality assurance (QA) when purchasing ice making vending machines?

To guarantee the quality of your ice vending machines, choose reputable suppliers with a proven track record in the industry. Request documentation such as warranties, certifications, and customer testimonials. Additionally, inquire about the machine’s testing procedures and quality control measures. Establishing a clear line of communication with your supplier can also facilitate ongoing support and maintenance, ensuring your machines operate at peak efficiency. -

What logistics considerations should I keep in mind when importing ice making vending machines?

When importing machines, consider shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling machinery to navigate the complexities of international shipping. Additionally, familiarize yourself with import duties and taxes applicable in your region, as these can impact overall costs. Ensuring that your supplier provides all necessary shipping documents will also streamline the import process. -

How can I assess the reliability of a supplier for ice making vending machines?

To evaluate a supplier’s reliability, research their reputation through industry reviews, case studies, and customer feedback. Look for suppliers who offer comprehensive support, including installation and ongoing maintenance services. Engaging with existing customers can provide insights into the supplier’s performance and service quality. Additionally, consider their experience in your target market, as regional expertise can significantly impact your success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Ice Making Vending Machines Manufacturers & Suppliers List

1. Ice House – Ice Vending Solutions

Domain: icehouseamerica.com

Registered: 2004 (21 years)

Introduction: Ice House: Largest ice capacity with 6,500 lbs storage, optimal for high traffic locations, minimal maintenance, sediment filtration, payment options include cash, credit, Apple Pay, SmartIce™ Remote Management System. Ice Kiosk: Mid-capacity with 2,400-3,000 lbs storage, suitable for medium to high traffic, standard ice and water vending, similar features to Ice House, SmartIce™ Remote Management…

2. Ice Vending Machines – Profitable Business Opportunity

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Ice vending machine business opportunity; ice does not spoil; requires periodic maintenance; costs to fill machine from empty to full is less than $100; sells two sizes of ice (15-16 lbs for $3, 30-32 lbs for $5.75); annual profits estimated at $25k; initial cost of machine was approximately $45k; requires health department tests costing $50; bags cost about $0.18 each.

Strategic Sourcing Conclusion and Outlook for ice making vending machines

The strategic sourcing of ice making vending machines presents a compelling opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The insights gleaned from current market offerings highlight the importance of selecting machines that maximize revenue potential while minimizing operational complexities. By leveraging advanced technologies, such as remote management systems and eco-friendly production methods, businesses can ensure consistent performance and customer satisfaction.

Moreover, understanding the diverse machine capacities—ranging from compact models ideal for lower traffic areas to high-capacity units designed for bustling locales—allows buyers to tailor their investments to specific market demands. This strategic approach not only enhances profitability but also positions businesses to adapt to evolving consumer needs.

As the demand for convenient, on-demand ice solutions continues to rise, now is the time to invest in ice making vending machines. Buyers are encouraged to explore partnerships with reputable suppliers that offer comprehensive support and customization options. By doing so, they can establish a foothold in this lucrative market and contribute to the growing trend of automated retail solutions. Embrace the future of vending and position your business for success in this dynamic industry.