The Definitive Guide to Hottub One Way Vaule: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for hottub one way vaule

In the competitive landscape of the hot tub industry, sourcing reliable one-way valves can pose significant challenges for international B2B buyers. Whether you’re operating in emerging markets across Africa, South America, the Middle East, or established regions in Europe, the need for high-quality check valves is paramount to ensure the integrity and efficiency of spa systems. This comprehensive guide delves into the intricacies of the hot tub one-way valve market, addressing various types, applications, and the critical factors involved in supplier vetting.

By exploring the diverse functionalities of check valves, including their role in preventing backflow and maintaining water quality, you will gain a nuanced understanding of their importance in hot tub operations. Additionally, we will cover cost considerations, helping you make informed purchasing decisions that align with your business objectives.

This guide is designed to empower B2B buyers by equipping them with actionable insights and best practices for sourcing high-quality hot tub one-way valves. With a focus on practical applications and supplier assessment, you can navigate the complexities of the global market with confidence, ensuring that your hot tub systems operate smoothly and efficiently in any region.

Understanding hottub one way vaule Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Swing Check Valve | Uses a swinging mechanism to prevent backflow | Spa systems, pool integration | Pros: Simple design, reliable; Cons: Limited pressure rating. |

| Spring Check Valve | Utilizes a spring to maintain closure | Ozone systems, water heaters | Pros: Effective sealing, versatile; Cons: Potential for wear over time. |

| Ball Check Valve | Features a ball that blocks reverse flow | High-pressure applications, industrial | Pros: High durability, excellent sealing; Cons: More complex installation. |

| Diaphragm Check Valve | Operates with a flexible diaphragm | Chemical dosing systems, spas | Pros: Good for varying pressures, efficient; Cons: Sensitive to debris. |

| Ozone Check Valve | Designed specifically for ozone systems | Ozone sanitation in spas | Pros: Ensures ozone effectiveness; Cons: Requires careful sizing for optimal performance. |

What Are the Key Characteristics of Swing Check Valves?

Swing check valves are characterized by their simple design, featuring a swinging disc that opens with forward flow and closes to prevent backflow. They are predominantly used in spa systems and pool integrations, making them ideal for B2B buyers looking for reliable components in water management systems. While they are known for their ease of use and effectiveness, they may have limitations regarding pressure ratings, which should be considered in high-pressure applications.

How Do Spring Check Valves Function in Spa Applications?

Spring check valves utilize a spring mechanism to maintain a tight seal, preventing backflow in various applications, including ozone systems and water heaters. Their versatility makes them suitable for B2B buyers who require reliable performance across different setups. However, it’s essential to note that the springs can wear out over time, necessitating regular maintenance or replacement to ensure continued functionality.

Why Choose Ball Check Valves for High-Pressure Needs?

Ball check valves are designed with a spherical ball that effectively blocks reverse flow, making them ideal for high-pressure applications, including industrial environments. They are favored for their durability and excellent sealing capabilities. B2B buyers should consider the complexity of installation and potential costs associated with maintenance when opting for ball check valves, as they may require specialized knowledge to install correctly.

What Are the Advantages of Diaphragm Check Valves?

Diaphragm check valves operate using a flexible diaphragm, allowing them to handle varying pressures efficiently. They are particularly suited for chemical dosing systems and spas, providing reliable performance in fluctuating conditions. B2B purchasers should be aware of their sensitivity to debris, which can affect operation, thus necessitating regular inspections and maintenance to ensure optimal performance.

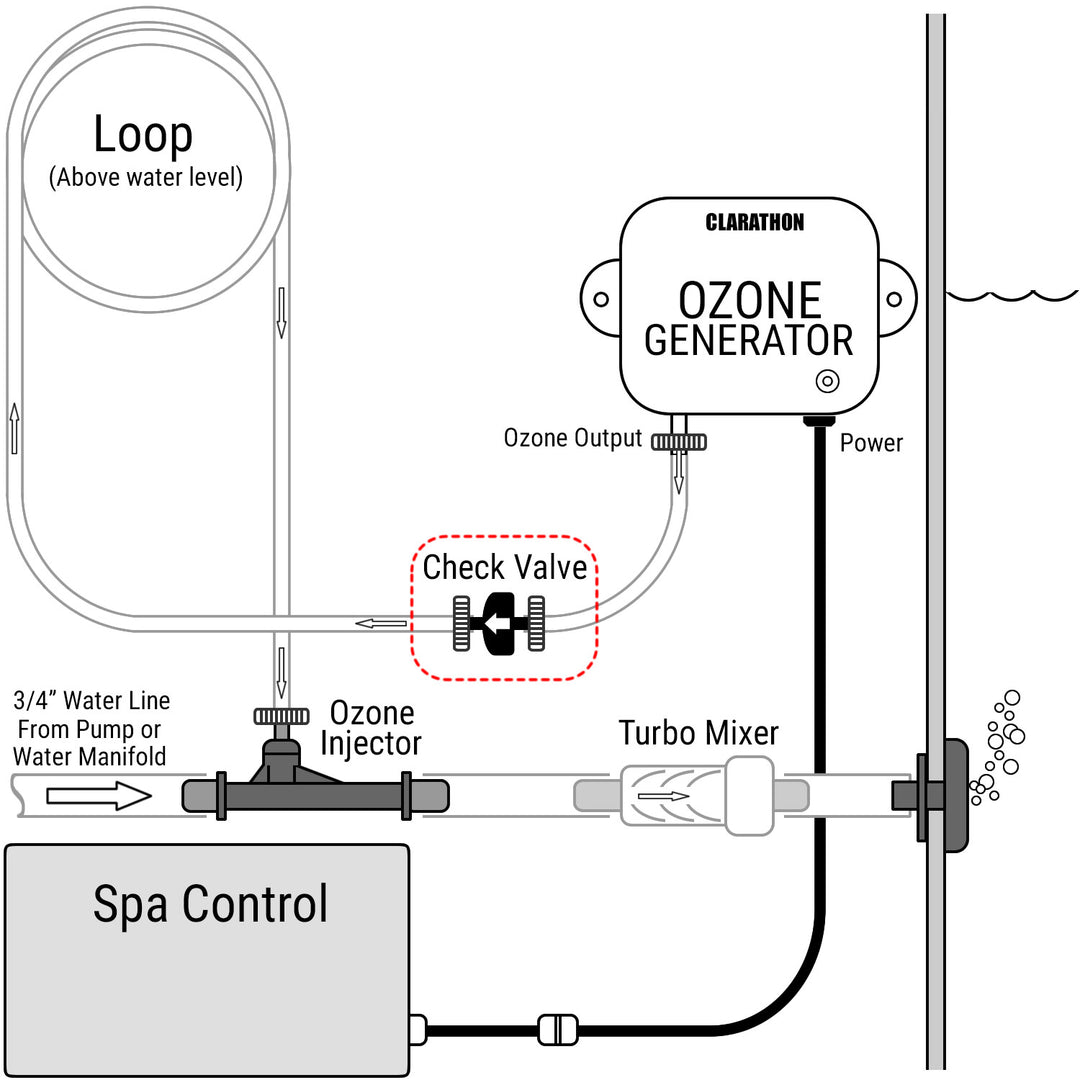

How Do Ozone Check Valves Enhance Spa Systems?

Ozone check valves are specifically designed for use in ozone systems, ensuring that the ozone remains effective in sanitizing spa water. These valves are crucial for maintaining water quality, making them an essential component for businesses in the spa industry. Buyers should ensure proper sizing for optimal performance, as incorrect sizing can lead to inefficiencies and potential system failures.

Key Industrial Applications of hottub one way vaule

| Industry/Sector | Specific Application of hottub one way vaule | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Spa and wellness facilities in hotels and resorts | Enhances guest experience by maintaining water levels and hygiene | Quality assurance, compatibility with existing systems, availability of technical support |

| Construction | Residential and commercial pool installations | Ensures efficient water management and prevents backflow issues | Compliance with local regulations, material durability, installation expertise |

| Water Treatment | Ozone water purification systems | Improves water quality and reduces chemical usage | Sizing for specific systems, resistance to corrosion, reliability of seals |

| Recreational Facilities | Public pools and spas | Maintains operational efficiency and safety standards | Bulk purchasing options, warranty terms, service agreements |

| Agriculture | Aquaculture systems for fish farming | Prevents water loss and maintains optimal conditions for aquatic life | Environmental compliance, adaptability to varying conditions, long-term reliability |

How is ‘hottub one way valve’ utilized in hospitality settings?

In the hospitality industry, particularly in hotels and resorts, the hottub one way valve is crucial for spa and wellness facilities. These valves help maintain water levels, preventing backflow that can compromise hygiene and guest experience. For B2B buyers in this sector, sourcing high-quality valves that ensure reliability and compatibility with existing spa systems is essential. Moreover, considering local regulations regarding water safety and maintenance will be crucial to avoid operational disruptions.

What role does the ‘hottub one way valve’ play in construction projects?

In construction, particularly for residential and commercial pool installations, the hottub one way valve plays a vital role in efficient water management. It prevents backflow, ensuring that water remains where it is intended, thus avoiding costly repairs and maintenance. Buyers in this sector need to focus on compliance with local building codes, the durability of materials used in the valves, and the expertise required for installation to ensure a successful project outcome.

How does the ‘hottub one way valve’ enhance water treatment processes?

In water treatment applications, especially those involving ozone purification systems, the hottub one way valve is essential. It ensures that treated water does not flow back into untreated sources, thus maintaining high water quality and reducing the need for excessive chemicals. For international buyers, factors such as the valve’s resistance to corrosion and its compatibility with specific treatment systems are critical for ensuring long-term functionality and compliance with environmental standards.

Illustrative image related to hottub one way vaule

Why is the ‘hottub one way valve’ important for recreational facilities?

Public pools and spas rely on the hottub one way valve to maintain operational efficiency and adhere to safety standards. These valves prevent water from draining back into the system, which is crucial for maintaining proper water levels and ensuring safety during use. When sourcing valves for recreational facilities, businesses should consider bulk purchasing options, warranty terms, and service agreements to ensure they can maintain their facilities effectively without incurring excessive costs.

How does the ‘hottub one way valve’ benefit agricultural practices?

In agriculture, particularly in aquaculture systems for fish farming, the hottub one way valve is instrumental in preventing water loss and maintaining optimal conditions for aquatic life. This application is critical for ensuring the health of fish and other aquatic organisms. Buyers in this sector must consider environmental compliance, the valve’s adaptability to varying conditions, and its long-term reliability to ensure sustainable farming practices.

3 Common User Pain Points for ‘hottub one way vaule’ & Their Solutions

Scenario 1: Inconsistent Water Levels Leading to Increased Maintenance Costs

The Problem: Many B2B buyers, especially those managing resort facilities or spas, encounter the frustrating issue of inconsistent water levels in their hot tubs. This problem often arises due to a failure in the check valve system, which allows water to drain back into the pool or plumbing system. This not only leads to frequent refilling of the hot tub but also increases chemical usage and maintenance costs, thereby reducing overall operational efficiency. Facilities may find themselves spending extra time and resources to maintain water quality and balance.

The Solution: To address this issue, it’s crucial to implement high-quality one-way check valves designed specifically for hot tub applications. Buyers should source valves that provide a positive seal, preventing backflow effectively. When specifying these valves, look for options that feature durable materials resistant to corrosion and chemical damage, such as PVC or stainless steel. Proper installation is equally important; ensure that the check valves are installed in the correct orientation and location in the plumbing system to minimize the risk of water backflow. Regular inspections and maintenance of these valves can help identify wear and tear early, ensuring optimal performance and consistent water levels.

Scenario 2: Complications with Spa Integration in Multi-Pool Systems

The Problem: In facilities that integrate hot tubs with larger swimming pool systems, such as hotels or community centers, B2B buyers often face the challenge of ensuring seamless functionality across multiple components. A common issue is the inability of the spa’s plumbing system to prevent water backflow from the pool, leading to contamination and imbalance in chemical levels. This not only complicates maintenance but can also pose health risks to users.

The Solution: To mitigate this risk, buyers should consider investing in specialized check valves that are designed for high-flow applications typically seen in multi-pool systems. These valves should be able to handle pressure fluctuations and provide a reliable seal. Implementing a comprehensive plumbing strategy that includes multiple check valves at critical junctures can prevent backflow effectively. Additionally, utilizing a professional plumbing service for the installation can ensure that the system is configured correctly, reducing the likelihood of future complications. Regular training for maintenance staff on the importance of these valves can also improve system longevity and user safety.

Scenario 3: Difficulty in Sourcing Replacement Parts for Hot Tub Systems

The Problem: B2B buyers often struggle with sourcing replacement parts for hot tub systems, particularly when it comes to specific components like one-way check valves. This challenge is exacerbated by a lack of standardization across manufacturers, leading to compatibility issues and extended downtimes during repairs. Such delays can disrupt service delivery in hospitality settings and negatively affect customer satisfaction.

The Solution: To overcome sourcing challenges, B2B buyers should establish relationships with multiple suppliers that specialize in hot tub components. It is advisable to create a detailed inventory of the specific parts used in each hot tub model, including the make and model of the check valves. By doing so, buyers can streamline the ordering process and reduce lead times. Additionally, consider investing in bulk purchasing agreements with reliable suppliers to ensure consistent availability of replacement parts. This proactive approach can minimize downtime and enhance service reliability, ultimately leading to improved customer satisfaction and loyalty.

Strategic Material Selection Guide for hottub one way vaule

What Are the Key Materials for Hot Tub One Way Valves?

When selecting materials for hot tub one way valves, it is essential to consider their properties, advantages, disadvantages, and how they align with the specific needs of international B2B buyers. Here, we analyze four common materials used in the manufacturing of these valves: PVC, brass, stainless steel, and EPDM rubber.

How Does PVC Perform in Hot Tub One Way Valves?

PVC (Polyvinyl Chloride) is widely used in plumbing applications, including hot tub one way valves. It has excellent corrosion resistance and can withstand temperatures up to 140°F (60°C). PVC is lightweight and easy to work with, making it a popular choice for manufacturers.

Pros: PVC is cost-effective, durable, and resistant to chemicals, which is crucial for hot tub environments where sanitizing agents are used. Its manufacturing process is relatively straightforward, leading to lower production costs.

Cons: However, PVC can become brittle over time when exposed to UV light, which may limit its longevity in outdoor applications. Additionally, it has a lower pressure rating compared to metals, which could be a drawback in high-pressure systems.

Impact on Application: PVC is compatible with various media, including water and chemicals commonly used in hot tubs. However, it may not be suitable for high-temperature applications beyond its rating.

Considerations for International Buyers: Compliance with ASTM standards is crucial when sourcing PVC components. Buyers from regions like Africa and South America should ensure that the materials meet local regulations regarding safety and environmental impact.

What Are the Benefits of Brass in Hot Tub One Way Valves?

Brass is another popular material for hot tub one way valves, known for its excellent strength and durability. It can handle high temperatures and pressures, making it suitable for more demanding applications.

Pros: Brass has superior corrosion resistance compared to other metals, particularly in chlorinated environments. It also provides a reliable seal, which is essential for preventing leaks.

Cons: The primary downside of brass is its higher cost compared to PVC. Additionally, brass can be susceptible to dezincification in certain water conditions, which may compromise its integrity over time.

Impact on Application: Brass is compatible with a variety of media, including hot water and chemicals used in spas. Its robustness makes it ideal for high-performance applications.

Considerations for International Buyers: Buyers should be aware of the specific standards applicable in their regions, such as DIN or JIS, to ensure compliance with quality and safety requirements.

Illustrative image related to hottub one way vaule

How Does Stainless Steel Compare for Hot Tub One Way Valves?

Stainless steel is favored for its exceptional strength and resistance to corrosion, particularly in harsh environments. It can withstand high pressures and temperatures, making it a reliable choice for hot tub applications.

Pros: Stainless steel is highly durable and has a long lifespan, which can reduce replacement costs over time. Its resistance to rust and corrosion makes it suitable for both indoor and outdoor installations.

Cons: The main drawback of stainless steel is its higher cost compared to PVC and brass. Additionally, it may require more complex manufacturing processes, which can increase production times.

Impact on Application: Stainless steel can handle a wide range of media, including hot water and various chemicals. Its robust nature makes it ideal for high-performance applications.

Illustrative image related to hottub one way vaule

Considerations for International Buyers: Compliance with international standards such as ASTM and EN is crucial for stainless steel components. Buyers should also consider the availability of stainless steel grades that meet local regulations.

What Role Does EPDM Rubber Play in Hot Tub One Way Valves?

EPDM (Ethylene Propylene Diene Monomer) rubber is often used for seals and gaskets in hot tub one way valves. It is known for its excellent elasticity and resistance to heat, ozone, and weathering.

Pros: EPDM rubber provides a reliable seal, preventing leaks and ensuring optimal performance. It is also cost-effective and easy to manufacture.

Cons: While EPDM is durable, it may not be suitable for high-pressure applications. Additionally, its compatibility with certain chemicals should be evaluated to avoid degradation.

Impact on Application: EPDM rubber is compatible with water and many common spa chemicals, making it a versatile choice for sealing applications.

Illustrative image related to hottub one way vaule

Considerations for International Buyers: Buyers should ensure that the EPDM rubber used complies with relevant standards, particularly in regions with strict regulations regarding material safety and environmental impact.

Summary of Material Selection for Hot Tub One Way Valves

| Material | Typical Use Case for hottub one way vaule | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Plumbing applications in hot tubs | Cost-effective and durable | Brittle over time, lower pressure | Low |

| Brass | High-performance valves | Excellent corrosion resistance | Higher cost, dezincification risk | Med |

| Stainless Steel | High-pressure and temperature applications | Exceptional durability | Higher cost, complex manufacturing | High |

| EPDM Rubber | Seals and gaskets in valves | Reliable sealing properties | Not suitable for high pressure | Low |

This guide provides essential insights into the strategic selection of materials for hot tub one way valves, helping international B2B buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hottub one way vaule

What Are the Main Stages in the Manufacturing Process of Hot Tub One Way Valves?

The manufacturing process for hot tub one way valves typically involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial phase involves selecting high-quality materials, often plastic or metal, that can withstand the corrosive nature of spa chemicals and high temperatures. Suppliers must ensure that the materials meet specific industry standards for durability and safety. This may involve sourcing raw materials from certified suppliers who can provide material safety data sheets (MSDS) to verify compliance.

-

Forming: The forming stage encompasses various techniques such as injection molding for plastic components or machining for metal parts. Injection molding allows for high precision and repeatability, crucial for ensuring that the one way valve functions correctly under pressure. During this stage, manufacturers also consider the design aspects, ensuring that the valve can maintain a proper seal and prevent backflow effectively.

-

Assembly: Once the components are formed, they are assembled into the final product. This process may involve automated machinery for efficiency, but manual assembly is also common to ensure quality control. Key components, such as seals and springs, must be integrated meticulously to guarantee that the valve operates smoothly and reliably.

-

Finishing: The finishing stage includes surface treatments, painting, or coating to enhance durability and aesthetics. This may involve applying anti-corrosive coatings or UV-resistant finishes, especially important for products intended for outdoor use. Manufacturers often conduct visual inspections at this stage to catch any defects before the product is finalized.

How is Quality Assurance Implemented in the Manufacturing of Hot Tub One Way Valves?

Quality assurance is critical in the manufacturing of hot tub one way valves to ensure that they meet both international and industry-specific standards.

-

International Standards and Certifications: Compliance with standards such as ISO 9001 is essential for manufacturers targeting international markets. ISO 9001 provides a framework for quality management systems, ensuring consistent product quality and continuous improvement. Other relevant certifications may include CE marking for products sold in Europe and API standards for those focusing on safety and reliability in industrial applications.

-

Quality Control Checkpoints: Manufacturers typically establish several quality control checkpoints throughout the production process:

– Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon receipt to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): During manufacturing, samples may be taken at various stages to verify that processes are yielding products within tolerance levels.

– Final Quality Control (FQC): After assembly, the finished products are subjected to rigorous testing. This may include pressure testing, leak detection, and functional testing to ensure that the valves perform as intended. -

Common Testing Methods: Testing methods can include hydrostatic pressure testing to verify that the valve can withstand operational pressures, and flow tests to ensure proper functionality. Some manufacturers also employ non-destructive testing methods to identify potential weaknesses in the material without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of their suppliers, which is particularly important when sourcing from international markets.

-

Conducting Supplier Audits: Buyers should consider performing on-site audits of potential suppliers. This allows them to assess manufacturing capabilities, quality control processes, and overall compliance with industry standards firsthand. An audit can reveal insights into the supplier’s commitment to quality and reliability.

-

Requesting Quality Control Reports: Suppliers should be able to provide detailed QC reports that outline their processes, testing results, and compliance with relevant standards. Buyers should not hesitate to ask for these documents as part of their due diligence.

-

Utilizing Third-Party Inspection Services: Engaging third-party inspection services can provide an additional layer of assurance. These organizations can conduct random inspections and testing to verify that products meet specified quality standards before shipment. This is particularly useful for buyers in regions with stringent import regulations.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances to ensure that they receive products that meet their expectations and regulatory requirements.

-

Understanding Regional Standards: Different regions may have specific compliance requirements. For instance, European buyers may require CE certification, while buyers in the Middle East may need to adhere to local regulations that govern product safety and quality.

-

Language Barriers and Documentation: Language differences can pose challenges in understanding technical documentation and quality reports. Buyers should ensure that they have access to translated materials or engage interpreters when necessary to avoid misunderstandings.

-

Cultural Differences in Quality Perception: Quality expectations can vary significantly across cultures. Buyers should take the time to communicate their specific quality requirements clearly to suppliers and ensure that they understand the importance of these standards.

-

Logistical Considerations: Finally, B2B buyers must consider the logistics of importing goods, including potential delays in customs due to incomplete documentation or non-compliance with local regulations. Establishing a clear line of communication with suppliers about shipping and handling can mitigate these issues.

By understanding the manufacturing processes and quality assurance practices associated with hot tub one way valves, B2B buyers can make informed decisions that enhance their supply chain and ensure product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hottub one way vaule’

Introduction

Navigating the procurement of hot tub one-way valves requires a systematic approach to ensure you select the right components for your business needs. This guide serves as a practical checklist for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. By following these steps, you can effectively streamline your sourcing process and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing hot tub one-way valves. Consider the size, material, and pressure ratings that align with your application. This will help ensure compatibility with existing systems and prevent operational issues.

- Material Considerations: Look for durable materials such as PVC or stainless steel, which resist corrosion and wear.

- Size Requirements: Ensure that the valve dimensions match the plumbing specifications of your hot tub system.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in hot tub components. A supplier’s experience and industry reputation can significantly impact the quality of the products you receive.

- Supplier Background: Investigate the history and market presence of potential suppliers.

- Client Testimonials: Seek reviews and case studies from existing clients to gauge reliability and service quality.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that your chosen suppliers hold relevant industry certifications. Compliance with international standards ensures product quality and safety.

- Certification Types: Look for ISO certifications or other industry-specific credentials that demonstrate adherence to quality control practices.

- Regulatory Compliance: Ensure that the products meet local regulations in your target markets.

Step 4: Request Samples for Testing

Always request samples of the hot tub one-way valves before placing a bulk order. Testing samples allows you to assess their functionality and compatibility with your systems.

- Functionality Testing: Check for proper flow direction and ensure the valves operate as intended under different conditions.

- Durability Assessment: Evaluate the materials for resistance to chemicals and temperature variations commonly found in hot tubs.

Step 5: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare their pricing structures and terms of sale. This step is critical for budget management and overall cost-effectiveness.

- Pricing Transparency: Look for detailed quotations that include shipping costs, taxes, and any potential additional fees.

- Payment Terms: Review payment options and terms of credit to ensure they align with your financial policies.

Step 6: Negotiate Contracts Wisely

Engage in negotiations with your chosen supplier to finalize the terms of purchase. A well-negotiated contract can lead to better pricing and service agreements.

- Volume Discounts: Discuss bulk order discounts if you plan to make large purchases.

- Return Policies: Ensure clear return and warranty policies are outlined to protect your investment.

Step 7: Establish a Long-Term Relationship

After successful procurement, aim to build a long-term relationship with your supplier. A reliable partnership can enhance your supply chain efficiency and provide ongoing support for your hot tub components.

- Regular Communication: Maintain open lines of communication for timely updates on new products or potential issues.

- Feedback Loop: Provide feedback on product performance to help suppliers improve their offerings and service.

By adhering to these steps, B2B buyers can successfully navigate the sourcing process for hot tub one-way valves, ensuring they select the best products for their needs while fostering reliable supplier relationships.

Comprehensive Cost and Pricing Analysis for hottub one way vaule Sourcing

Analyzing the cost structure and pricing strategies for sourcing hot tub one-way valves involves understanding several key components and influencers. This knowledge is essential for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Illustrative image related to hottub one way vaule

What Are the Key Cost Components for Hot Tub One-Way Valve Sourcing?

When sourcing hot tub one-way valves, buyers should consider the following cost components:

-

Materials: The primary material for these valves often includes high-quality plastics or stainless steel, which influence durability and functionality. Prices can fluctuate based on the raw material market and quality specifications.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as certain South American nations, manufacturers may offer competitive pricing. However, higher labor costs in Europe can affect overall pricing structures.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and indirect labor. Efficient manufacturing processes can lower these overheads, impacting the final pricing.

-

Tooling: Custom tooling for specific valve designs can require a substantial initial investment, which is often amortized over the production volume. This cost is particularly relevant for customized valves.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards. Higher QC costs may lead to increased prices but can enhance the product’s value proposition.

-

Logistics: Shipping costs are a critical factor, especially for international buyers. Factors like distance, shipping method, and import duties significantly affect the total landed cost.

-

Margin: Supplier margins can vary widely based on market competition, brand reputation, and the perceived value of the product. Understanding the margin expectations of suppliers can aid in negotiation.

How Do Price Influencers Impact Hot Tub One-Way Valve Pricing?

Several factors can influence the pricing of hot tub one-way valves, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to better pricing. Buyers should negotiate MOQs to ensure they can take advantage of volume discounts.

-

Specifications and Customization: Customized valves tailored to specific requirements may incur higher costs. Buyers should assess whether the customization justifies the additional expense.

-

Material Quality and Certifications: Valves that meet international quality standards and certifications may be priced higher but offer better reliability and longevity. Buyers should weigh the cost against potential long-term savings.

-

Supplier Factors: Supplier reliability, reputation, and service levels can affect pricing. Established suppliers with proven track records may charge a premium but provide peace of mind regarding quality and delivery.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities regarding shipping, insurance, and tariffs, which can significantly impact overall costs.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiate Effectively: Leverage your purchasing power, especially for larger volumes. Don’t hesitate to request better pricing or terms based on your order size.

-

Focus on Total Cost of Ownership (TCO): Assess not only the initial purchase price but also factors like durability, maintenance costs, and potential downtime. A higher upfront cost may lead to lower TCO over time.

-

Understand Pricing Nuances: Be aware of regional pricing variations and currency fluctuations. This understanding can help in budgeting and financial planning for purchases.

-

Seek Multiple Quotes: Obtaining quotes from multiple suppliers can provide insights into market pricing and help identify the best value for your investment.

-

Evaluate Supplier Relationships: Building strong relationships with suppliers can lead to better service, priority treatment, and potential discounts on future orders.

Disclaimer

The prices and cost components discussed are indicative and may vary based on market conditions, supplier agreements, and specific buyer requirements. Always conduct thorough due diligence when sourcing products.

Alternatives Analysis: Comparing hottub one way vaule With Other Solutions

Exploring Alternatives to Hottub One Way Value

In the competitive landscape of spa and hot tub solutions, understanding alternatives to the Hottub One Way Value is essential for B2B buyers. This section provides a comparative analysis of the Hottub One Way Value against other viable solutions, helping businesses make informed decisions tailored to their specific operational needs.

Illustrative image related to hottub one way vaule

| Comparison Aspect | Hottub One Way Value | Alternative 1: Check Valves | Alternative 2: Diverter Valves |

|---|---|---|---|

| Performance | High efficiency in preventing backflow | Effective for controlling flow, but may require regular checks | Versatile in directing water flow, but can be prone to wear |

| Cost | Moderate initial investment | Lower cost options available, $5-$60 depending on size | Generally higher cost, $20-$100 depending on complexity |

| Ease of Implementation | Simple installation with standard fittings | Easy to install, often DIY-friendly | Installation may require professional assistance |

| Maintenance | Low maintenance needs, durable design | Requires periodic inspection and potential replacement | Moderate maintenance, parts may need replacement over time |

| Best Use Case | Ideal for spas requiring a reliable, one-directional flow | Suitable for pools and spas needing flow control | Best for systems needing to switch water flow between multiple outlets |

In-Depth Analysis of Alternatives

Alternative 1: Check Valves

Check valves are a popular solution for preventing backflow in spa and pool systems. Their primary function is to allow fluid to flow in one direction while blocking reverse flow. The advantages of check valves include cost-effectiveness and ease of installation, making them suitable for businesses operating on a budget. However, they may require regular maintenance to ensure optimal performance, especially in environments with varying water levels or pressure. Additionally, the effectiveness of check valves can be influenced by their positioning and the specific system design.

Alternative 2: Diverter Valves

Diverter valves offer a versatile approach to managing water flow in spa systems. They allow operators to direct water to different outlets, which can enhance the functionality of a spa. While diverter valves can be more expensive and complex than check valves, their ability to control flow direction makes them a valuable investment for systems that require flexibility. However, diverter valves may be prone to wear and require more frequent maintenance, particularly in high-use environments. Thus, they are best suited for businesses that prioritize adaptability and are prepared for potential upkeep costs.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the right solution for hot tub and spa systems, B2B buyers should consider the specific operational requirements of their facilities. The Hottub One Way Value excels in providing a reliable and efficient one-directional flow, making it a strong candidate for businesses focused on maintaining consistent water levels. However, for those with varying needs, check valves and diverter valves present viable alternatives, each with distinct advantages and considerations. By evaluating performance, cost, ease of implementation, maintenance, and specific use cases, businesses can make informed decisions that align with their operational goals and customer satisfaction.

Essential Technical Properties and Trade Terminology for hottub one way vaule

What Are the Key Technical Properties of a Hot Tub One-Way Valve?

Understanding the essential technical properties of a hot tub one-way valve is crucial for B2B buyers looking to make informed decisions. Here are some critical specifications to consider:

-

Material Grade

– One-way valves are commonly made from materials like PVC, CPVC, or stainless steel. The choice of material affects durability, corrosion resistance, and compatibility with various water types, including chlorinated water. For international buyers, selecting the right material is crucial to ensure longevity and performance, especially in varying climates. -

Pressure Rating

– This specification indicates the maximum pressure the valve can withstand. For instance, a valve rated for 50 PSI is suitable for typical residential hot tub applications, whereas industrial setups might require valves rated for 150 PSI or more. Understanding pressure ratings helps buyers ensure the valve will function correctly under their specific conditions, reducing the risk of failure. -

Flow Rate

– Measured in gallons per minute (GPM), the flow rate indicates how much water can pass through the valve in a given time. A higher flow rate ensures efficient operation, particularly in larger hot tubs or spas. Buyers need to match the flow rate with their system’s requirements to maintain optimal performance and energy efficiency. -

Size and Connection Type

– One-way valves come in various sizes, typically ranging from 1 inch to 3 inches in diameter. The connection type (threaded, slip, or flanged) also matters, as it impacts installation compatibility. International buyers must consider local plumbing standards and ensure that the valve fits seamlessly into existing systems. -

Seal Type

– The effectiveness of a one-way valve often depends on its sealing mechanism, which can be a rubber diaphragm, a spring-loaded disc, or a ball. Each type has its advantages and disadvantages, influencing how effectively the valve prevents backflow. Understanding these differences is vital for selecting a valve that minimizes maintenance and operational issues.

Which Trade Terminology Should B2B Buyers Understand?

Familiarity with industry jargon helps streamline communication and negotiations. Here are some common terms relevant to hot tub one-way valves:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products that are sold under another company’s brand. Understanding OEM relationships can help buyers assess quality and reliability, as established brands often work with reputable manufacturers. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For international buyers, being aware of MOQs is essential for budgeting and inventory management, especially when importing goods. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request pricing and availability from suppliers. Crafting a clear RFQ can help buyers receive accurate quotations and make competitive comparisons among different suppliers. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is critical for managing shipping costs and responsibilities effectively. -

Lead Time

– This term refers to the time it takes from placing an order to receiving the goods. Knowing the lead time is vital for planning inventory and ensuring timely product availability, especially in seasonal markets. -

Warranty Period

– The warranty period defines the timeframe during which the manufacturer guarantees the product against defects. Understanding warranty terms can help buyers evaluate the long-term reliability of a valve and the potential costs of future repairs or replacements.

In summary, grasping these technical properties and trade terms equips B2B buyers with the knowledge necessary to make informed purchasing decisions regarding hot tub one-way valves, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the hottub one way vaule Sector

What Are the Current Market Dynamics and Key Trends in the Hot Tub One Way Valve Sector?

The hot tub one way valve sector is experiencing significant growth driven by the increasing popularity of wellness and relaxation products globally. As urbanization rises, particularly in regions like Africa, South America, and the Middle East, consumers are increasingly investing in home spa experiences. This trend is supported by a growing middle class with disposable income, particularly in emerging markets such as Brazil and Vietnam.

Technological advancements are reshaping sourcing trends within the industry. Automation in manufacturing processes and the integration of smart technology in hot tub systems are becoming common, enhancing user experiences and efficiency. For B2B buyers, this means sourcing suppliers that not only provide high-quality one way valves but also offer innovative, tech-driven solutions. Additionally, the demand for custom and modular designs is on the rise, allowing businesses to cater to specific consumer preferences.

International B2B buyers should also be aware of the impact of global supply chain dynamics. Geopolitical tensions and trade tariffs can affect sourcing strategies, necessitating the exploration of local suppliers to mitigate risks. Understanding local regulations and certifications is essential for smooth market entry, particularly for buyers in regions with strict compliance requirements.

How Can Sustainability and Ethical Sourcing Impact the Hot Tub One Way Valve Sector?

Sustainability is becoming a critical consideration for B2B buyers in the hot tub one way valve sector. The environmental impact of manufacturing processes, particularly in the use of plastics and chemicals, has prompted businesses to seek eco-friendly alternatives. Sourcing materials that are recyclable or made from sustainable sources is increasingly important.

Illustrative image related to hottub one way vaule

Ethical supply chains are also gaining traction, with buyers looking for suppliers who adhere to fair labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and other green certifications can help buyers identify responsible suppliers. By prioritizing ethical sourcing, businesses can enhance their brand reputation and appeal to eco-conscious consumers, which is particularly pertinent in markets like Europe, where sustainability is a key purchasing factor.

Moreover, incorporating sustainable practices can lead to cost savings over time through reduced waste and energy consumption. B2B buyers should look for partners that invest in sustainable technologies, such as energy-efficient manufacturing processes, which not only align with global sustainability goals but also offer competitive advantages in the marketplace.

What is the Evolution of the Hot Tub One Way Valve Market and Its Significance for B2B Buyers?

The hot tub one way valve market has evolved significantly over the past few decades. Initially, these components were primarily viewed as functional necessities in spa systems. However, as consumer preferences shifted towards enhanced user experience and wellness, the role of one way valves has expanded. Modern designs incorporate advanced materials and technologies that improve efficiency and performance, catering to a more discerning consumer base.

This evolution signifies an opportunity for B2B buyers to engage with suppliers who are at the forefront of innovation. Understanding the historical context of these products can inform purchasing decisions and foster partnerships with manufacturers that prioritize quality and reliability. As the market continues to mature, buyers must stay informed about emerging trends and technologies to maintain a competitive edge in their offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of hottub one way vaule

-

How do I solve water drainage issues in a hot tub?

To address water drainage issues in a hot tub, consider installing a check valve. This device prevents backflow, ensuring that water does not drain from the hot tub into the pool when not in use. It’s essential to choose a valve compatible with your system’s specifications, including size and pressure ratings. Additionally, regularly inspect and maintain the valve to ensure optimal performance, as wear and tear can lead to leaks. Engaging with a qualified technician for installation can provide peace of mind and ensure proper setup. -

What is the best check valve for preventing backflow in hot tubs?

The best check valve for preventing backflow in hot tubs is typically a swing or spring-loaded valve, as these designs offer reliable sealing against reverse flow. When selecting a valve, ensure it matches the pipe diameter and material used in your hot tub system. It’s also crucial to consider the operating pressure and temperature ratings of the valve to ensure durability and performance. Consulting with suppliers who specialize in spa components can help you identify the most suitable options for your specific needs. -

What are the key factors to consider when sourcing hot tub components internationally?

When sourcing hot tub components internationally, consider factors such as supplier reliability, product quality, and compliance with local regulations. Verify the supplier’s credentials and reputation by reviewing customer testimonials and industry certifications. Additionally, assess the logistics capabilities of the supplier to ensure timely delivery and efficient handling of customs processes. Understanding the terms of trade, including payment methods and currency fluctuations, will also help mitigate risks associated with international transactions. -

How can I ensure quality assurance for hot tub parts from overseas suppliers?

To ensure quality assurance for hot tub parts sourced from overseas suppliers, implement a robust vetting process. This includes requesting samples, conducting factory audits, and reviewing quality certifications such as ISO standards. Establish clear quality benchmarks and specifications in your purchase agreements to hold suppliers accountable. Consider using third-party inspection services to verify product quality before shipment. Building strong relationships with suppliers can also facilitate better communication regarding quality expectations and potential issues. -

What customization options are available for hot tub one-way valves?

Customization options for hot tub one-way valves can include size, material, and design features tailored to specific operational needs. Suppliers may offer valves in various materials, such as PVC or stainless steel, to suit different environments and applications. Additionally, you can request modifications to the valve’s internal mechanisms to enhance flow control or pressure ratings. Discussing your unique requirements with the supplier will help identify suitable customization options that meet your operational standards. -

What is the minimum order quantity (MOQ) for hot tub components?

The minimum order quantity (MOQ) for hot tub components can vary significantly between suppliers and product types. Generally, it is advisable to inquire directly with potential suppliers to understand their MOQ policies. Some manufacturers may have flexible MOQs for smaller businesses, while others may require larger orders for cost efficiency. If you’re concerned about meeting MOQ requirements, consider collaborating with other businesses to consolidate orders, which can also help reduce shipping costs. -

What payment terms should I expect when sourcing hot tub products internationally?

Payment terms when sourcing hot tub products internationally can vary widely depending on the supplier and your negotiation. Common terms include upfront payments, deposits, or payment upon delivery. Some suppliers may offer credit terms for established buyers, allowing for payment after the goods have been received. It’s crucial to clarify payment methods, such as wire transfers or letters of credit, and to ensure that terms are documented in the purchase agreement to protect both parties. -

How can I streamline logistics when importing hot tub components?

To streamline logistics when importing hot tub components, start by selecting suppliers with established shipping capabilities and experience in international trade. Work with freight forwarders who understand the intricacies of customs clearance and can manage shipping logistics effectively. Plan for potential delays by allowing sufficient time for shipping and customs processing. Maintaining clear communication with suppliers regarding shipping timelines and tracking information will also help ensure a smooth delivery process.

Top 3 Hottub One Way Vaule Manufacturers & Suppliers List

1. Hot Tub Warehouse – Check Valves & Spa Parts

Domain: hottubwarehouse.com

Registered: 2001 (24 years)

Introduction: Hot Tub & Spa Check Valves, Ozonator, Air Blower and Standard Check Valves. Free Shipping on orders $50+. Various parts available including plumbing, pumps, jets, and more.

2. Jandy – Check Valve with Spring Loaded Swing

Domain: troublefreepool.com

Registered: 2007 (18 years)

Introduction: Jandy check valve (with spring loaded swing)

3. Bulkley Capital – Ozone Resistant One Way Valve

Domain: bulkleycapital.com

Registered: 1999 (26 years)

Introduction: Valve Ozone Resistant One Way Valve for Hot Tubs Water Systems

Strategic Sourcing Conclusion and Outlook for hottub one way vaule

In the rapidly evolving landscape of hot tub and spa components, strategic sourcing emerges as a pivotal strategy for B2B buyers. By leveraging insights into the specific needs of markets across Africa, South America, the Middle East, and Europe, businesses can optimize their supply chains, ensuring the procurement of high-quality components such as check valves, diverter valves, and ozone systems. This not only enhances operational efficiency but also significantly reduces costs associated with maintenance and potential downtime.

Investing in reliable suppliers who prioritize quality and innovation is essential for staying competitive. As buyers navigate the complexities of international trade, understanding regional regulations and market trends becomes paramount. This knowledge allows companies to make informed sourcing decisions that align with their long-term business objectives.

Looking ahead, the demand for advanced hot tub solutions will continue to grow, driven by rising consumer interest in wellness and leisure products. Now is the time for international B2B buyers to seize opportunities in this dynamic market. By adopting a strategic approach to sourcing, businesses can position themselves as leaders in the hot tub industry, capitalizing on emerging trends and meeting the evolving needs of their customers. Embrace the future—invest in strategic sourcing today to unlock your business’s full potential.

Illustrative image related to hottub one way vaule

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.