The Definitive Guide to Hose Reel Components: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for hose reel components

In today’s global marketplace, sourcing high-quality hose reel components can pose significant challenges for international B2B buyers. Variability in product quality, compliance with local regulations, and the need for reliable suppliers can complicate the purchasing process. This guide aims to alleviate these concerns by providing a comprehensive overview of hose reel components, including various types, applications, and essential considerations for selecting the right parts for your business needs.

From electric reels to manual options, understanding the different types of hose reel components is crucial for ensuring efficiency and safety in operations. Buyers will find insights on the specific applications of each component, helping them make informed decisions that enhance productivity. Additionally, this guide covers critical aspects of supplier vetting, cost analysis, and the importance of after-sales service—vital factors for businesses operating in regions like Africa, South America, the Middle East, and Europe, including key markets such as Brazil and Nigeria.

By equipping B2B buyers with actionable insights and a clear framework for evaluating potential suppliers, this guide empowers businesses to navigate the complexities of the hose reel components market confidently. With the right knowledge, organizations can optimize their purchasing strategies, ensuring they invest in durable, efficient products that meet their operational demands.

Understanding hose reel components Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| A-Frame Hose Reels | Sturdy frame design, often portable, high capacity | Agriculture, construction, firefighting | Pros: Durable, easy to transport; Cons: May require more space. |

| Electric Hose Reels | Motorized winding, automatic hose retrieval | Industrial cleaning, manufacturing | Pros: Reduces manual labor, efficient; Cons: Higher initial investment. |

| Wall-Mounted Hose Reels | Space-saving design, typically allows for 180° rotation | Commercial landscaping, maintenance | Pros: Saves floor space, easy access; Cons: Limited mobility. |

| Hose Reel Carts | Mobile, often with 2-4 wheels, can hold large hoses | Event management, outdoor services | Pros: High mobility, versatile; Cons: Requires storage space when not in use. |

| Swivel Hose Reels | 360° rotation capability for easy hose access | Vehicle servicing, agricultural use | Pros: Flexible reach; Cons: May be more complex to install. |

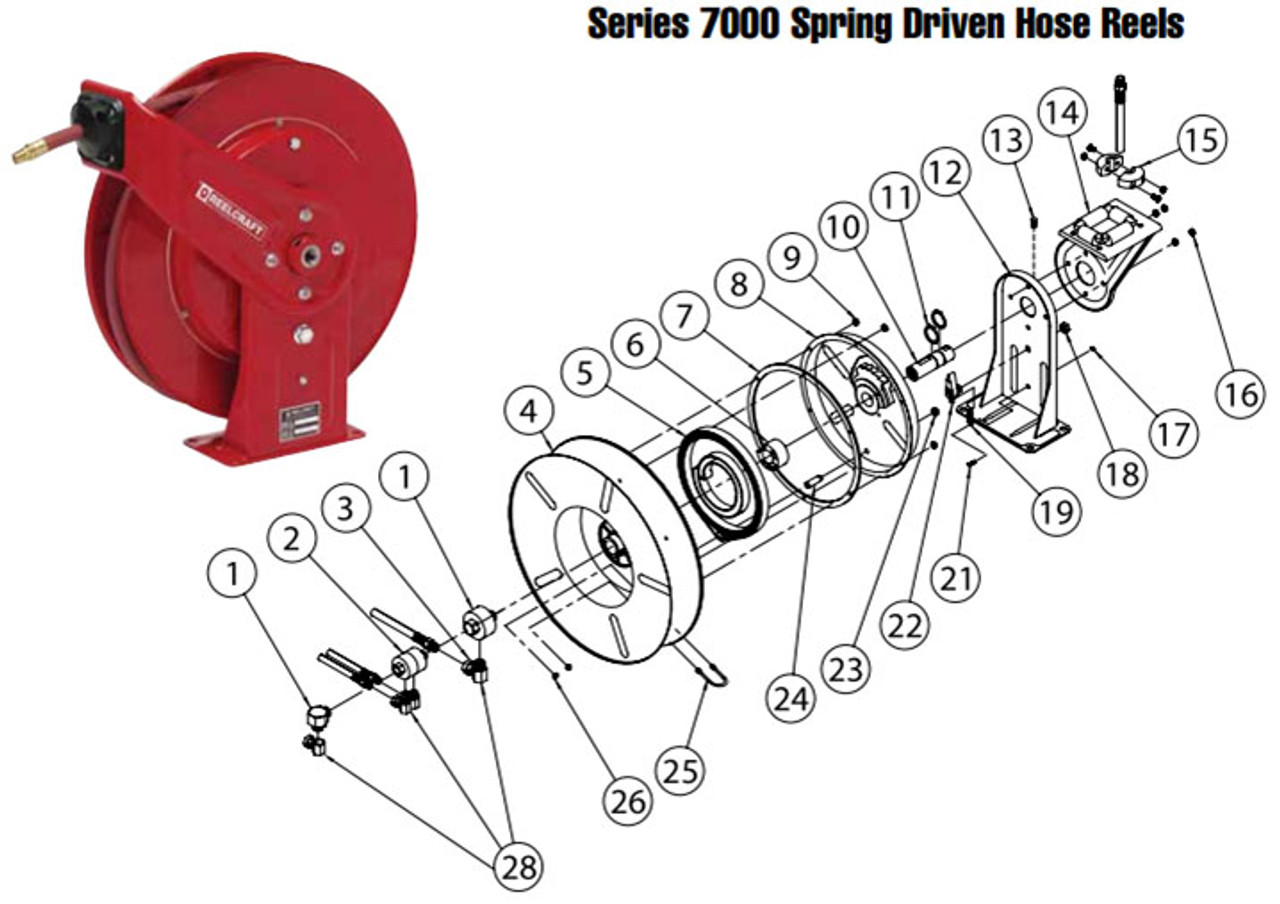

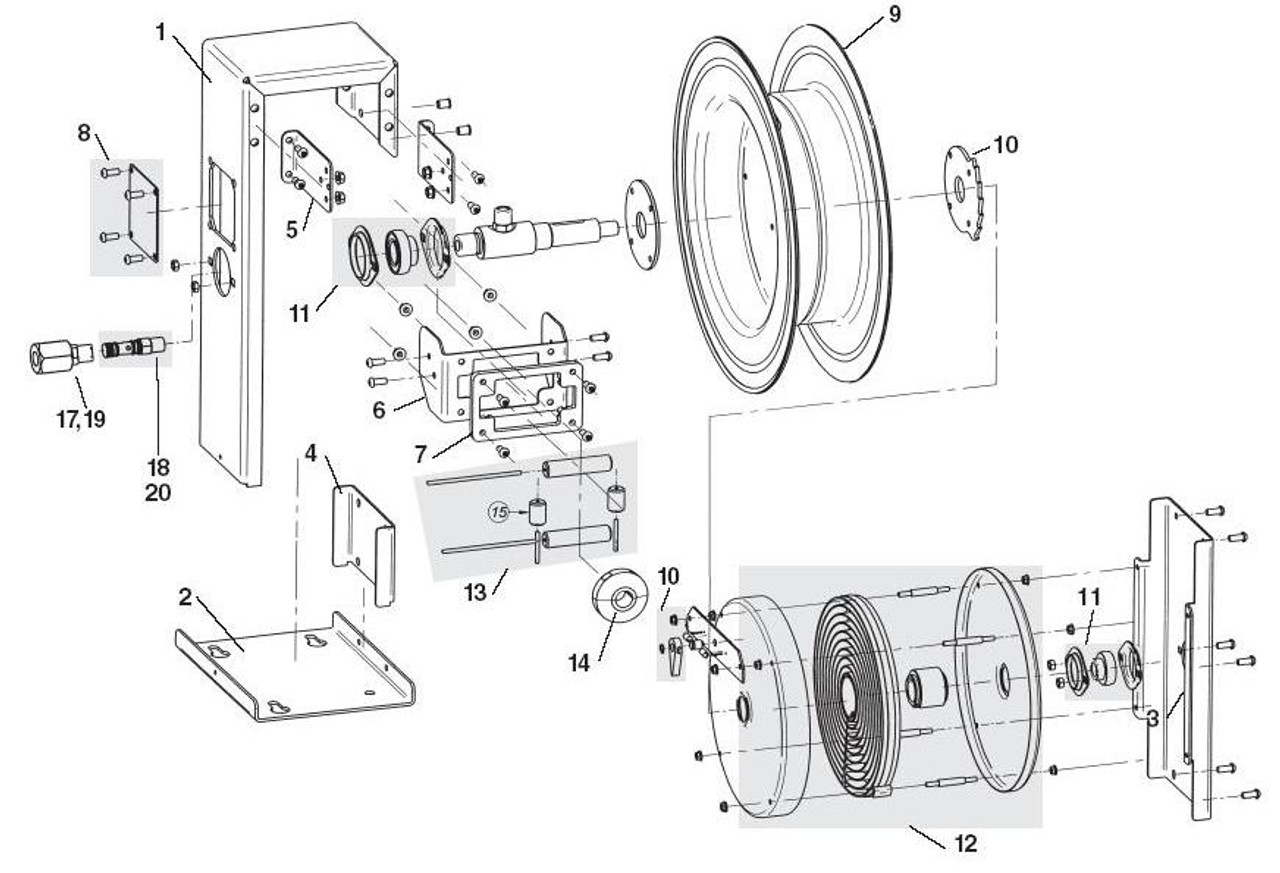

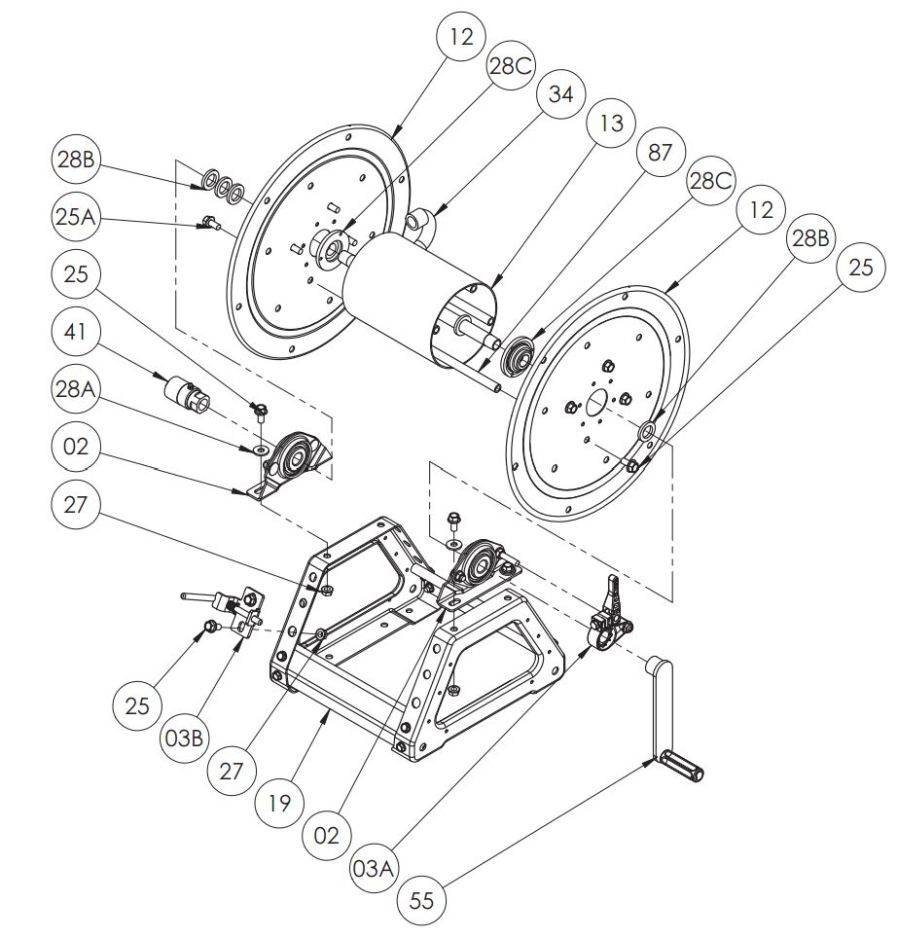

What Are A-Frame Hose Reels and Their Benefits for B2B Buyers?

A-Frame hose reels are characterized by their robust frame design, which typically allows for a higher capacity of hose storage. These reels are often portable, making them suitable for various applications in agriculture, construction, and firefighting. When considering an A-Frame hose reel, buyers should evaluate the weight capacity, ease of transport, and the material used in construction to ensure durability in rugged environments.

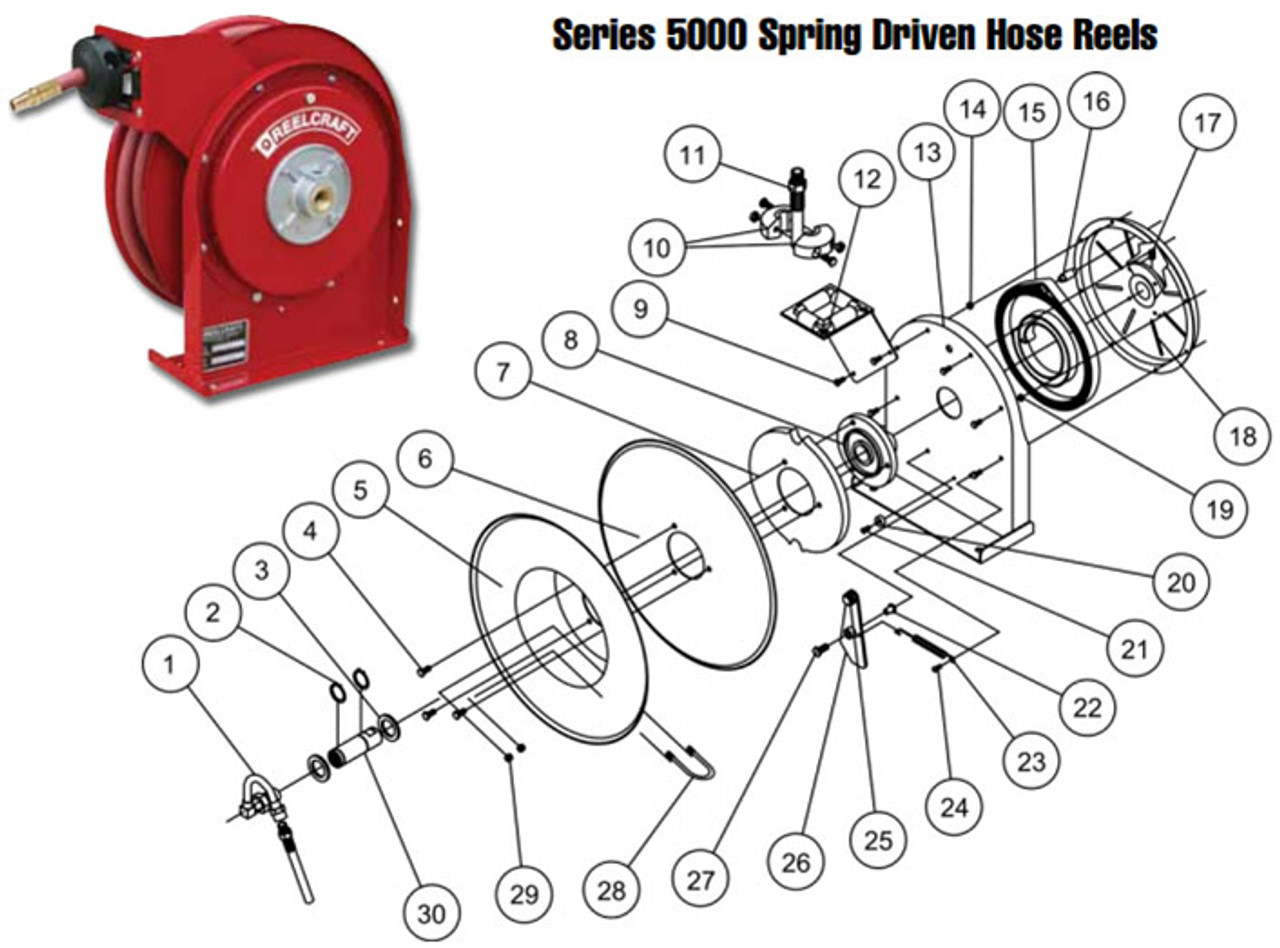

Illustrative image related to hose reel components

How Do Electric Hose Reels Enhance Operational Efficiency?

Electric hose reels feature motorized systems that automate the winding and unwinding of hoses, significantly reducing the physical effort required for hose management. These reels are particularly beneficial in industrial cleaning and manufacturing settings where efficiency is paramount. Buyers should consider the power requirements, hose compatibility, and maintenance needs when investing in electric hose reels to maximize operational efficiency.

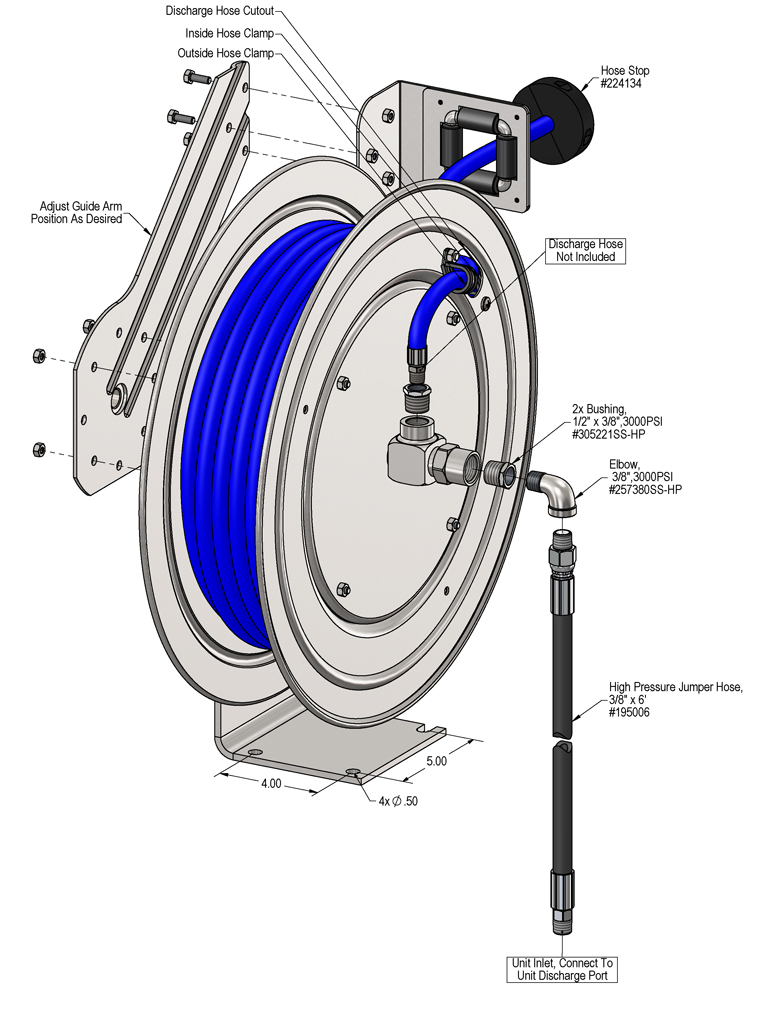

Why Choose Wall-Mounted Hose Reels for Limited Spaces?

Wall-mounted hose reels are designed to save valuable floor space while providing easy access to hoses. With the ability to rotate up to 180 degrees, they are ideal for commercial landscaping and maintenance tasks. Buyers should assess the installation requirements, load capacity, and hose length compatibility to ensure the chosen model meets their operational needs without compromising on accessibility.

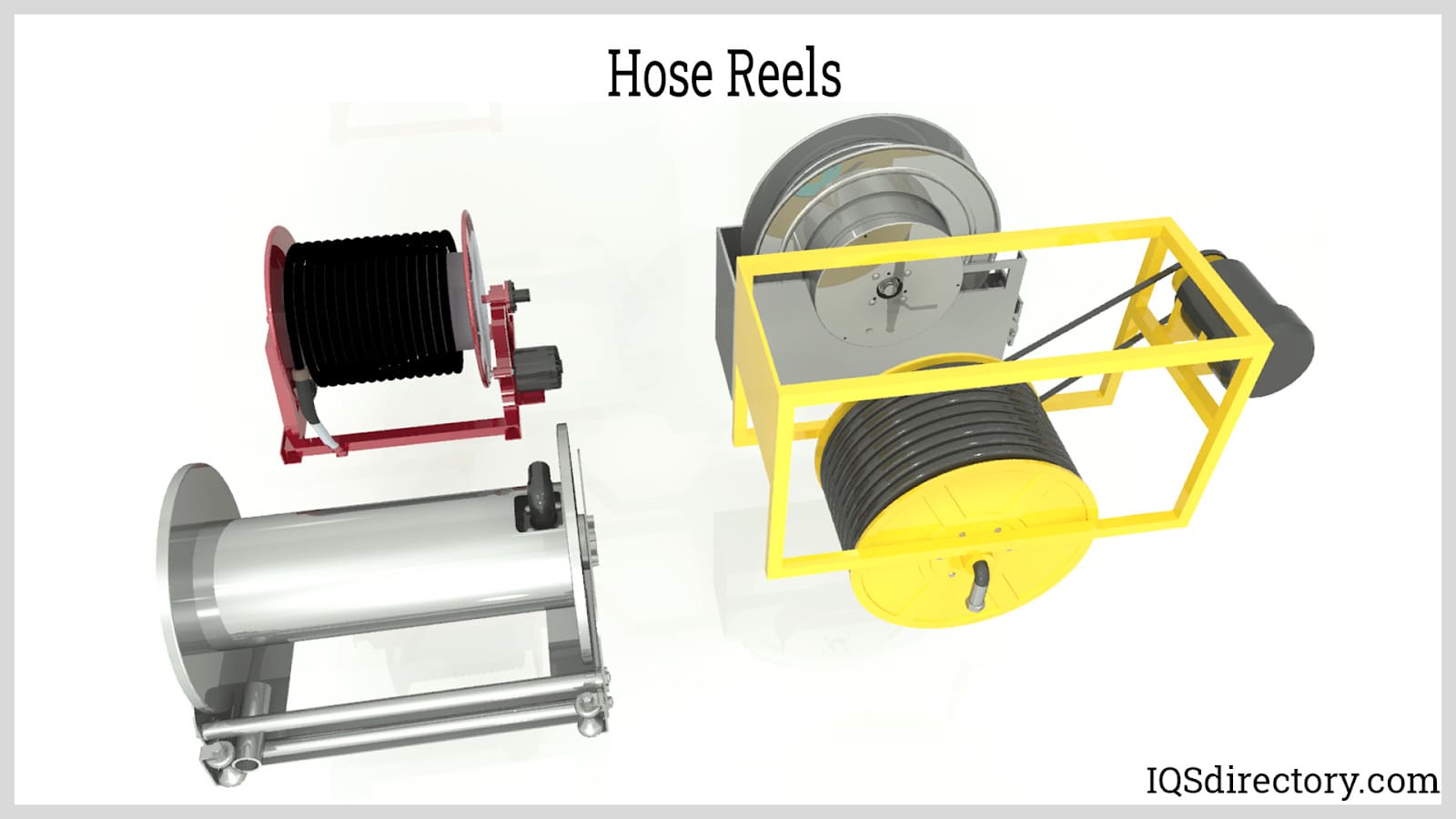

What Are the Advantages of Using Hose Reel Carts?

Hose reel carts offer mobility with their wheel designs, making them perfect for outdoor services and event management. These carts can hold large hoses and can be easily transported across various terrains. When selecting a hose reel cart, buyers should consider the wheel durability, overall weight, and storage capabilities to ensure the cart can withstand frequent use in different environments.

What Makes Swivel Hose Reels a Versatile Option?

Swivel hose reels provide 360-degree rotation, allowing users to easily access hoses from multiple angles. This feature is particularly useful in vehicle servicing and agricultural applications where flexibility is required. Buyers should focus on the installation complexity, the swivel mechanism’s durability, and the reel’s overall stability to ensure it meets their operational demands effectively.

Key Industrial Applications of hose reel components

| Industry/Sector | Specific Application of hose reel components | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation systems for crop management | Efficient water distribution, reducing waste and labor costs | Durability against weather, compatibility with various hoses |

| Construction | Water supply for site cleaning and dust control | Ensures consistent water access, improving site safety | Mobility features and ease of transport |

| Automotive | Car wash facilities and maintenance shops | Streamlined operations, reducing time spent on vehicle cleaning | Resistance to chemicals and wear, ease of installation |

| Oil & Gas | Fluid transfer in drilling operations | Enhances safety by preventing spills and leaks | High-pressure ratings and corrosion resistance |

| Firefighting | Hose management in emergency response vehicles | Quick deployment and retraction, critical for fast response | Reliability under high-stress conditions |

How Are Hose Reel Components Used in Agriculture for Irrigation Systems?

In the agriculture sector, hose reel components are integral to efficient irrigation systems. They enable the easy winding and unwinding of hoses, facilitating precise water distribution across vast fields. This efficiency reduces water waste and labor costs, crucial for farmers operating in regions with limited water resources, such as parts of Africa and South America. Buyers in this sector must consider the durability of materials to withstand harsh weather conditions and ensure compatibility with various types of hoses and fittings.

Illustrative image related to hose reel components

What Role Do Hose Reel Components Play in Construction Sites?

Construction sites utilize hose reel components for effective water supply during cleaning and dust control operations. These reels allow for quick access to water, ensuring that sites remain safe and clean, thereby improving overall productivity. For international buyers, especially in regions with varying infrastructure, sourcing hose reels that offer mobility features and are easy to transport is essential. This ensures that equipment can be easily moved to different locations on-site as needed.

How Are Hose Reel Components Essential in Automotive Applications?

In automotive settings, hose reel components are pivotal for car wash facilities and maintenance shops. They streamline operations by allowing quick access to water for washing vehicles, thus reducing the time spent on cleaning. For B2B buyers in this sector, sourcing hose reels that are resistant to chemicals and wear is critical, as these components will often be exposed to harsh cleaning agents. Additionally, ease of installation and maintenance can significantly impact operational efficiency.

Why Are Hose Reel Components Important in the Oil & Gas Industry?

In the oil and gas sector, hose reel components are vital for the safe transfer of fluids during drilling operations. These reels help manage hoses, preventing spills and leaks that could lead to environmental hazards. Buyers in this industry must prioritize high-pressure ratings and corrosion resistance when sourcing these components, especially in regions like the Middle East where operational conditions can be extreme. Ensuring reliability under high-stress conditions is essential for maintaining safety standards.

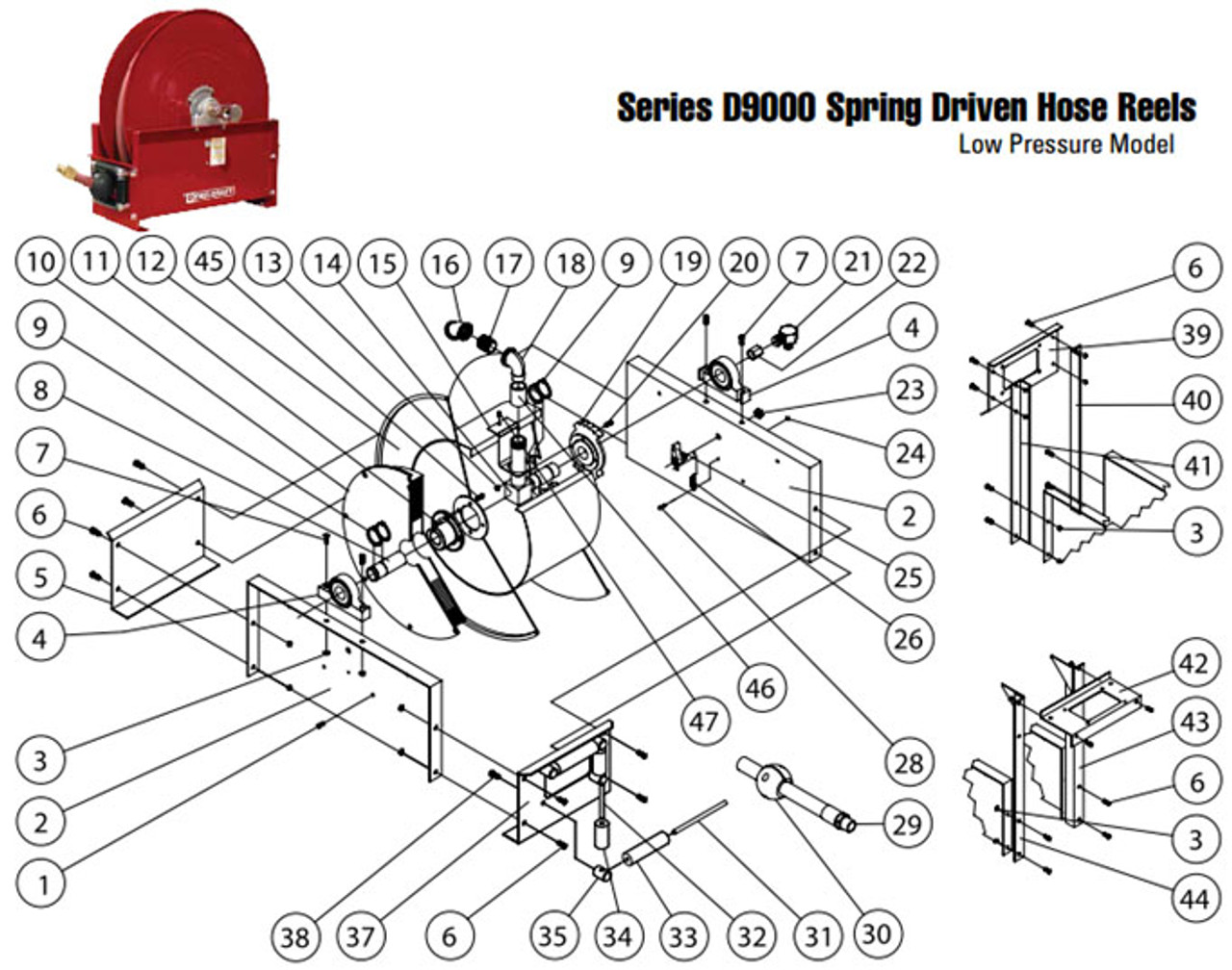

How Do Hose Reel Components Benefit Firefighting Operations?

Hose reel components are crucial in firefighting, where quick deployment and retraction of hoses can save lives and property. These components facilitate efficient hose management in emergency response vehicles, allowing firefighters to act swiftly in critical situations. For international buyers, reliability under high-stress conditions and the ability to withstand extreme temperatures are key considerations when sourcing these essential components. Ensuring that the reels are easily operable in emergency scenarios can significantly enhance response effectiveness.

3 Common User Pain Points for ‘hose reel components’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Hose Reel Components

The Problem:

Many B2B buyers face challenges in sourcing high-quality hose reel components due to a saturated market filled with varying quality standards. This is especially true for buyers from regions like Africa and South America, where access to reliable suppliers may be limited. These buyers often encounter subpar components that lead to frequent breakdowns, increased maintenance costs, and unplanned downtime in their operations. The lack of clear product specifications and inadequate supplier support further complicates the procurement process, leaving buyers frustrated and unsure of their options.

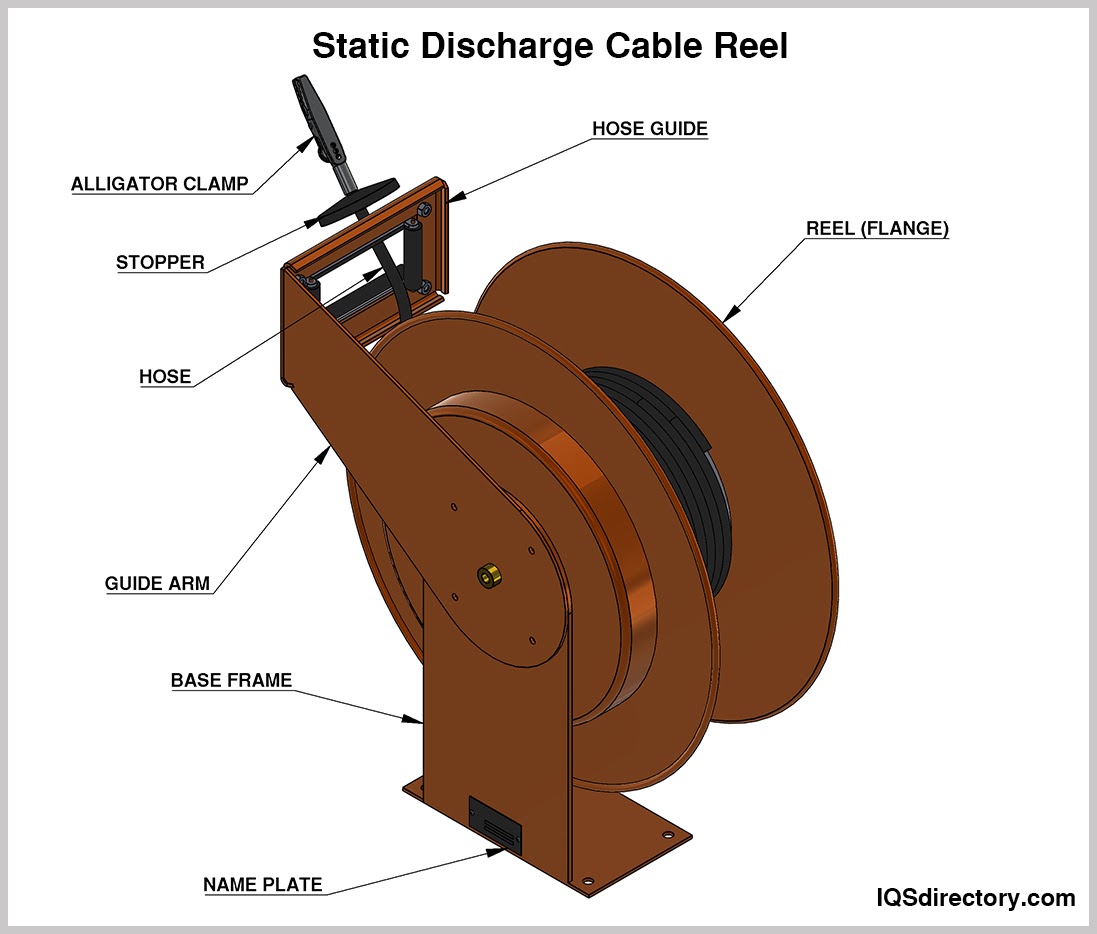

Illustrative image related to hose reel components

The Solution:

To overcome these sourcing challenges, buyers should prioritize establishing relationships with reputable manufacturers and distributors that specialize in hose reel components. Conduct thorough research by checking online reviews, industry certifications, and case studies. Request samples or detailed product specifications to assess quality before making bulk purchases. Consider attending industry trade shows or networking events to connect directly with suppliers, allowing for face-to-face discussions about product durability and support services. Additionally, leveraging platforms that consolidate supplier options can streamline the procurement process, ensuring that buyers have access to reliable parts that meet their operational needs.

Scenario 2: Incompatibility Issues with Existing Equipment

The Problem:

Incompatibility between hose reel components and existing machinery or systems is a common pain point for B2B buyers. For instance, a construction company in the Middle East may find that the hose reel they purchased does not fit with their water truck’s specifications, leading to inefficiencies and wasted resources. This issue can arise from a lack of standardized measurements across different manufacturers or insufficient product information, resulting in costly delays and the need for further adjustments or replacements.

The Solution:

To mitigate compatibility issues, buyers should conduct a thorough needs assessment prior to purchasing hose reel components. This includes measuring existing equipment and understanding the specific requirements for hose reel integration. Communicating directly with suppliers about these specifications can provide clarity on compatibility. Additionally, buyers should look for suppliers that offer customization options or a comprehensive range of fittings and adapters. Utilizing a structured specification sheet that outlines all necessary dimensions and requirements can also help ensure that the selected components will integrate seamlessly with existing systems.

Scenario 3: High Maintenance Costs Due to Poor Quality

The Problem:

High maintenance costs stemming from the use of low-quality hose reel components can severely impact a company’s bottom line. For example, an agricultural business in Brazil may invest in inexpensive hose reels that fail prematurely, leading to constant repairs and replacements. This not only disrupts operations but also strains budgets, especially for businesses that rely on consistent performance to meet production goals. The frustration of dealing with frequent breakdowns can lead to decreased productivity and employee morale.

The Solution:

Investing in high-quality hose reel components is crucial for reducing long-term maintenance costs. Buyers should be encouraged to evaluate the total cost of ownership rather than just the initial purchase price. Opting for components made from durable materials and backed by robust warranties can lead to significant savings over time. Furthermore, establishing a routine maintenance schedule and training staff on proper usage can help extend the lifespan of hose reels. Suppliers that provide comprehensive maintenance guides or support can be invaluable in this regard. By prioritizing quality and implementing preventive maintenance practices, buyers can minimize disruptions and optimize their operational efficiency.

Strategic Material Selection Guide for hose reel components

When selecting materials for hose reel components, it is essential to consider the specific properties and performance characteristics that will impact durability, functionality, and overall cost. Below, we analyze four common materials used in hose reel components, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Steel for Hose Reel Components?

Steel is a widely used material in hose reel components due to its strength and durability. It typically has a high tensile strength, making it suitable for applications that require resistance to deformation under load. Steel components can withstand high temperatures and pressures, making them ideal for heavy-duty applications.

Pros: Steel is exceptionally durable and can handle harsh environmental conditions. It is also relatively cost-effective compared to other materials, making it a popular choice for manufacturers.

Cons: Steel is prone to corrosion if not properly treated or coated, which can lead to reduced lifespan in humid or corrosive environments. Additionally, the manufacturing process can be complex, requiring specialized equipment for cutting and welding.

Illustrative image related to hose reel components

Impact on Application: Steel is compatible with a wide range of media, including water, oil, and chemicals, depending on the specific type of steel used. However, buyers must consider the environmental conditions in which the hose reel will operate.

How Does Aluminum Compare as a Material for Hose Reel Components?

Aluminum is another common material used in hose reel components, particularly for applications where weight is a critical factor. Aluminum is lightweight yet strong, offering good resistance to corrosion due to its natural oxide layer.

Pros: The lightweight nature of aluminum makes it easy to transport and install. It also exhibits excellent corrosion resistance, making it suitable for outdoor applications.

Illustrative image related to hose reel components

Cons: Aluminum is generally less durable than steel and may not withstand high-pressure applications as effectively. It is also more expensive than steel, which can impact overall project budgets.

Impact on Application: Aluminum is compatible with various media, including water and some chemicals, but may not be suitable for high-temperature applications. Buyers should assess the specific media and environmental conditions when selecting aluminum components.

What Are the Benefits of Plastic in Hose Reel Components?

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are increasingly used in hose reel components due to their lightweight and corrosion-resistant properties.

Pros: Plastics are resistant to many chemicals and do not corrode, making them suitable for various applications. They are also lightweight, reducing shipping costs and making installation easier.

Cons: While plastics are resistant to corrosion, they may not withstand high temperatures or pressures as effectively as metals. They can also be more susceptible to physical damage.

Illustrative image related to hose reel components

Impact on Application: Plastic components are ideal for applications involving water and certain chemicals but may not be suitable for heavy-duty or high-pressure environments. Buyers should evaluate the specific requirements of their application to determine the suitability of plastic components.

Why Is Stainless Steel a Preferred Material for Certain Hose Reel Components?

Stainless steel is often used for hose reel components that require both strength and corrosion resistance. It combines the durability of steel with the anti-corrosive properties of chromium.

Pros: Stainless steel is highly resistant to corrosion, making it suitable for outdoor and marine applications. It also maintains its strength at high temperatures.

Illustrative image related to hose reel components

Cons: The cost of stainless steel is generally higher than that of regular steel and plastic, which may affect budget considerations. Additionally, it can be more challenging to work with due to its hardness.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it a versatile choice for various applications. International buyers should ensure compliance with relevant standards for stainless steel grades.

Summary Table of Material Selection for Hose Reel Components

| Material | Typical Use Case for hose reel components | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial hose reels | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Lightweight portable hose reels | Lightweight and corrosion-resistant | Less durable under high pressure | High |

| Plastic | Residential and light-duty hose reels | Corrosion-resistant and lightweight | Susceptible to physical damage | Low |

| Stainless Steel | Marine and corrosive environment hose reels | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

This analysis provides a comprehensive overview of material options for hose reel components, helping international B2B buyers make informed decisions that align with their specific needs and operational environments.

In-depth Look: Manufacturing Processes and Quality Assurance for hose reel components

What Are the Main Stages of Manufacturing Hose Reel Components?

The manufacturing process of hose reel components involves several critical stages, each designed to ensure the final product meets quality standards and operational efficiency. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Hose Reel Component Manufacturing?

The first step in manufacturing hose reel components is material preparation. High-quality materials such as steel, aluminum, and plastic are selected based on the specific requirements of the hose reel design. The materials are then processed to remove impurities, which can include cleaning, cutting, and sometimes heat treatment.

For instance, steel components may undergo a galvanization process to enhance corrosion resistance, while aluminum parts might be anodized. This stage is crucial as it directly affects the durability and performance of the final product.

What Forming Techniques Are Used in Hose Reel Component Production?

Once the materials are prepared, they are subjected to various forming techniques to shape them into usable components. Common techniques include:

- Stamping: Used for creating flat components like side plates and drum covers. Stamping machines apply high pressure to cut and shape metal sheets into desired forms.

- Machining: Precision machining processes, such as turning and milling, are employed to create parts with tight tolerances, such as axles and bearings.

- Injection Molding: For plastic components, injection molding is a preferred method. This involves injecting molten plastic into a mold to form parts like handles and adapters.

These techniques ensure that each component is manufactured to exact specifications, contributing to the overall reliability of the hose reel.

What Is the Assembly Process for Hose Reel Components?

The assembly stage combines the various formed components into a complete hose reel. This process typically involves:

- Component Inspection: Before assembly, each part is inspected for defects or deviations from specifications. This may include visual inspections and measurements.

- Assembly Line Setup: Components are organized in a systematic manner to facilitate efficient assembly. Workers or automated systems assemble parts such as the frame, drum, and wheels.

- Fastening and Securing: Components are joined using methods like welding, bolting, or riveting, depending on the design requirements. Quality fastening ensures the structural integrity of the hose reel.

Effective assembly techniques are crucial for ensuring that the hose reel operates smoothly and has a long service life.

How Are Hose Reel Components Finished?

The finishing stage involves applying protective coatings and conducting final inspections. Common finishing processes include:

- Powder Coating: A durable finish is applied to metal parts to enhance corrosion resistance and aesthetics. This process involves applying a dry powder that is then cured under heat.

- Plating: Components may be plated with materials such as zinc or nickel to provide additional protection against wear and corrosion.

- Final Quality Check: After finishing, each hose reel undergoes a final quality check to ensure it meets all specifications and standards.

This stage is vital as it not only improves the appearance of the hose reel but also extends its lifespan in various environmental conditions.

What Quality Assurance Measures Are Essential for Hose Reel Manufacturing?

Quality assurance (QA) in the manufacturing of hose reel components is critical to ensure that the products are safe, reliable, and compliant with international standards.

Which International Standards Apply to Hose Reel Components?

Compliance with international quality standards is essential for B2B buyers. The most relevant standards include:

- ISO 9001: This standard sets out the criteria for a quality management system (QMS) and is based on principles such as strong customer focus and continuous improvement. Certification can enhance supplier credibility.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For hose reels used in the oil and gas industry, compliance with American Petroleum Institute (API) standards is often required.

These certifications not only assure quality but also help in navigating regulatory requirements in different markets.

What Are the Key Quality Control Checkpoints in Hose Reel Manufacturing?

Quality control (QC) is integrated at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are performed to monitor the production process and detect any deviations.

- Final Quality Control (FQC): Before shipping, a comprehensive inspection is conducted to verify that the finished products meet all specifications and standards.

These checkpoints help identify issues early in the process, reducing waste and ensuring product reliability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some methods:

- Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control measures, and adherence to standards.

- Quality Assurance Reports: Requesting detailed reports from suppliers that outline their QA processes, results of inspections, and any certifications can provide insights into their quality management.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control practices.

By leveraging these verification methods, B2B buyers can mitigate risks and ensure they are partnering with reliable suppliers.

Illustrative image related to hose reel components

What Are the Specific Quality Control Considerations for International Buyers?

International buyers must be aware of certain nuances when it comes to quality control:

- Cultural and Regulatory Differences: Understanding the local manufacturing culture and regulations in the supplier’s country can help buyers navigate potential quality issues.

- Shipping and Handling Risks: Ensuring that quality is maintained during shipping and handling is essential, especially for components that may be sensitive to damage.

- Customs and Compliance Issues: Buyers should ensure that the products comply with their local import regulations and standards to avoid delays or penalties.

By considering these factors, international B2B buyers can enhance their procurement strategies and ensure a successful sourcing experience for hose reel components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hose reel components’

When sourcing hose reel components, international B2B buyers must navigate a complex landscape of specifications, suppliers, and regulations. This practical checklist serves as a roadmap to ensure that your procurement process is efficient, effective, and tailored to your unique operational needs.

Step 1: Define Your Technical Specifications

Before diving into the market, clearly outline the technical specifications required for your hose reel components. Consider factors such as hose size, material durability, and compatibility with existing systems. This clarity will guide your sourcing efforts and help eliminate unsuitable options early in the process.

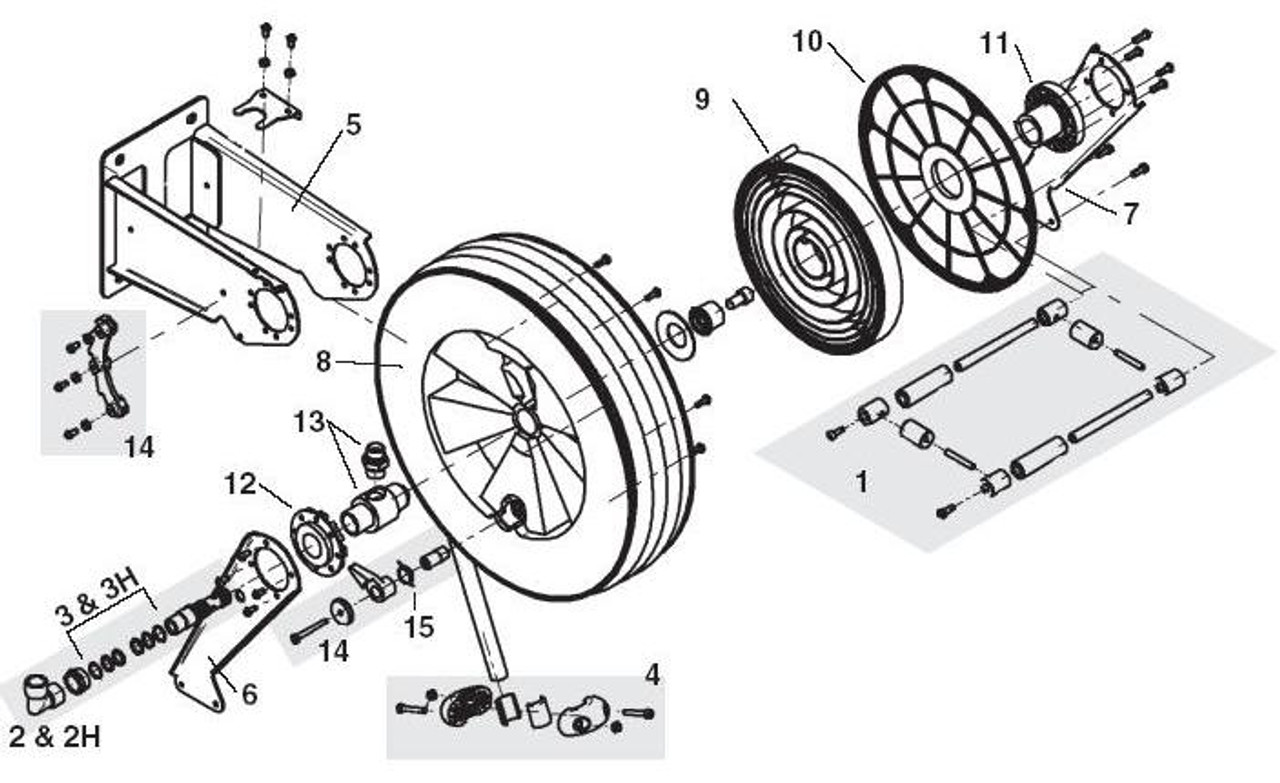

Illustrative image related to hose reel components

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers specializing in hose reel components. Look for companies with a strong reputation, positive customer reviews, and experience in your target market regions, such as Africa, South America, the Middle East, and Europe. Building a list of potential suppliers will streamline your evaluation process.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that potential suppliers meet relevant industry standards and certifications. This step is crucial for maintaining quality and safety in your operations. Check for ISO certifications or other relevant local certifications to confirm that the supplier adheres to recognized quality management standards.

Step 4: Request Samples and Product Specifications

Before making a bulk purchase, request samples of the components you are interested in. This allows you to assess the quality and compatibility of the parts with your existing systems. Additionally, ask for detailed product specifications, including material composition, dimensions, and maintenance requirements.

Step 5: Compare Pricing and Terms of Service

Once you have gathered product samples and specifications, compare pricing among the shortlisted suppliers. Look beyond the initial cost; consider factors such as bulk purchase discounts, shipping fees, and payment terms. A supplier offering competitive pricing with favorable terms can significantly impact your overall procurement budget.

Step 6: Assess Delivery and Lead Times

Timely delivery is essential to maintain operational efficiency. Inquire about the lead times for orders and the supplier’s ability to meet your timeline. Assessing their logistics capabilities can prevent potential delays in your production schedule.

Step 7: Establish a Communication Plan

Effective communication is key to a successful supplier relationship. Establish a clear communication plan outlining how you will interact with your supplier throughout the procurement process. This includes setting expectations for updates on order status, response times for inquiries, and methods for addressing potential issues.

By following these steps, B2B buyers can navigate the complexities of sourcing hose reel components, ensuring that they make informed decisions that align with their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for hose reel components Sourcing

What Are the Key Cost Components in Hose Reel Components Sourcing?

When sourcing hose reel components, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

Illustrative image related to hose reel components

-

Materials: The choice of materials significantly impacts the cost. Steel, aluminum, and high-density plastics are common materials used in hose reels. High-quality materials enhance durability but can increase upfront costs.

-

Labor: Labor costs vary by region and the complexity of the components being manufactured. Skilled labor is typically more expensive but essential for producing high-quality parts.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, rent, and equipment maintenance. A well-optimized manufacturing process can help reduce these costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom components. Buyers should consider whether the supplier has the necessary tooling already or if new molds will need to be created.

-

Quality Control (QC): Implementing stringent QC measures is vital for ensuring product reliability. This may involve additional testing and inspection costs, which should be factored into the overall pricing.

-

Logistics: Shipping and handling costs can vary significantly depending on the destination and shipping method. Buyers must be aware of potential tariffs and customs fees when importing components from different countries.

-

Margin: Suppliers will add their profit margin to cover costs and ensure sustainability. Understanding the typical margin in your industry can provide leverage during negotiations.

How Do Price Influencers Affect Hose Reel Components?

Several factors influence the pricing of hose reel components, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts. Understanding the supplier’s MOQ can help buyers plan their purchases more effectively.

-

Specifications and Customization: Custom parts tailored to specific needs typically come at a premium. It is essential to clarify requirements upfront to avoid unexpected costs.

-

Material Quality and Certifications: Components that require specific certifications or higher material standards will generally be more expensive. Buyers should assess the necessity of these certifications based on their application.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often provide better quality assurance and customer service.

-

Incoterms: Understanding the Incoterms agreed upon in the contract can affect overall costs. Different terms can shift responsibilities for shipping costs, insurance, and risks between buyer and seller.

What Are the Best Buyer Tips for Cost-Efficiency in Hose Reel Components Sourcing?

To maximize cost-efficiency when sourcing hose reel components, consider the following tips:

-

Negotiate Wisely: Leverage your understanding of cost components and price influencers during negotiations. Being informed about market rates can empower you to negotiate better terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider the TCO, which includes maintenance, operation, and potential replacement costs. A higher initial investment may lead to lower long-term costs if the components are more durable.

-

Understand Pricing Nuances for International Markets: For buyers in Africa, South America, the Middle East, and Europe, it’s important to consider local market conditions, currency fluctuations, and varying logistics costs. Engaging local suppliers can sometimes reduce shipping costs and lead times.

-

Request Samples: Before committing to a large order, request samples to assess quality. This can prevent costly mistakes associated with inferior components.

-

Monitor Market Trends: Stay updated on industry trends and pricing movements. Being informed can help you time your purchases better, potentially saving money.

Conclusion

Understanding the cost structure, price influencers, and effective negotiation strategies is essential for international B2B buyers sourcing hose reel components. By taking a comprehensive approach to cost analysis and being mindful of the unique challenges posed by global sourcing, buyers can optimize their purchasing decisions and enhance overall efficiency.

Alternatives Analysis: Comparing hose reel components With Other Solutions

In the competitive landscape of industrial solutions, B2B buyers often seek alternatives that provide similar functionalities to hose reel components. This analysis aims to compare hose reel components with two viable alternatives: hose storage systems and retractable hose systems. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, buyers can make informed decisions tailored to their operational needs.

| Comparison Aspect | Hose Reel Components | Hose Storage Systems | Retractable Hose Systems |

|---|---|---|---|

| Performance | Efficiently organizes hoses for easy access | Varies by design; can be bulky | Automatically retracts hose, minimizing tangles |

| Cost | Moderate, depending on components | Often higher due to structural design | Higher upfront cost for installation and equipment |

| Ease of Implementation | Simple setup; requires minimal tools | May require additional space and tools | Requires professional installation for optimal performance |

| Maintenance | Low maintenance; occasional part replacement | Moderate; depends on material quality | Low maintenance; may require periodic checks |

| Best Use Case | Ideal for workshops and gardens | Best for larger properties with ample space | Perfect for commercial applications needing quick access |

How Do Hose Storage Systems Compare to Hose Reel Components?

Hose storage systems, such as racks or bins, offer a practical solution for organizing hoses. They can accommodate various hose lengths and sizes, making them versatile for different applications. However, they often require more space and may not be as efficient in protecting hoses from wear and tear compared to reel systems. While the initial investment may be higher due to structural components, they can provide a tidy and organized workspace.

What Are the Benefits of Retractable Hose Systems Over Hose Reel Components?

Retractable hose systems present a modern solution by automatically winding hoses after use, which minimizes tangling and storage issues. These systems are particularly beneficial in environments where quick access to hoses is necessary, such as in commercial landscaping or industrial cleaning. While they do come with a higher upfront cost and may require professional installation, their ease of use and low maintenance needs make them an attractive option. However, their reliance on mechanical components can lead to higher repair costs if the system fails.

Illustrative image related to hose reel components

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between hose reel components and alternative solutions, B2B buyers should consider their specific operational requirements, budget constraints, and available space. Hose reel components offer a reliable, cost-effective choice for those needing straightforward organization and low maintenance. In contrast, hose storage systems and retractable hose systems might be more suitable for larger operations requiring flexibility and efficiency. By weighing these factors, buyers can make informed decisions that enhance productivity and ensure long-term satisfaction with their chosen solution.

Essential Technical Properties and Trade Terminology for hose reel components

What Are the Key Technical Properties of Hose Reel Components?

Understanding the essential technical properties of hose reel components is crucial for B2B buyers who aim to ensure quality and reliability in their purchases. Here are some of the critical specifications to consider:

-

Material Grade

Hose reel components are typically made from materials like steel, aluminum, or high-grade plastics. The material grade impacts durability, weight, and corrosion resistance. For instance, stainless steel components offer enhanced resistance to rust and degradation, making them suitable for harsh environments. -

Load Capacity

This specification refers to the maximum weight or pressure a hose reel can handle safely. It is vital for buyers to match the load capacity with their operational needs. An inadequate load capacity could lead to equipment failure, safety hazards, and costly downtime. -

Tolerance Levels

Tolerance indicates the allowable variation in dimensions and weight of components. High tolerance levels ensure that parts fit together perfectly, promoting efficient operation and longevity. Poor tolerance can lead to mechanical issues, affecting the hose reel’s performance. -

Swivel Mechanism Specifications

The swivel mechanism allows for smooth rotation during operation. Key specifications include the type of bearings used and the lubrication system in place. A high-quality swivel mechanism reduces friction and wear, ensuring that the hose can be deployed and retracted easily. -

Brake System Design

A reliable brake system is crucial for safety, especially in mobile hose reels. Specifications to consider include the type of brake (mechanical or hydraulic) and its responsiveness. A well-designed brake system prevents accidental hose unwinding and enhances user safety. -

Dimensions and Weight

The size and weight of hose reel components affect installation and mobility. Buyers should consider the space available for installation and whether the weight aligns with operational handling capabilities.

What Are Common Trade Terms Used in Hose Reel Component Procurement?

Familiarity with industry terminology can facilitate smoother transactions and better communication with suppliers. Here are some common terms:

Illustrative image related to hose reel components

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that may be marketed by another manufacturer. In the hose reel industry, OEM components are often perceived as higher quality because they meet original specifications. -

MOQ (Minimum Order Quantity)

This is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs effectively and ensure they can meet demand without overstocking. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific components. It allows buyers to compare costs and terms before making purchasing decisions, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international trade. Knowing Incoterms can help buyers understand shipping costs, insurance, and risk management. -

Lead Time

Lead time refers to the amount of time from placing an order to delivery. It is crucial for planning inventory and ensuring that projects remain on schedule. Shorter lead times can improve operational efficiency. -

Warranty Period

This term denotes the duration for which a product is guaranteed against defects. Understanding warranty terms is vital for risk assessment and cost management, as it can affect the total cost of ownership.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure long-term satisfaction with hose reel components.

Navigating Market Dynamics and Sourcing Trends in the hose reel components Sector

What Are the Current Market Dynamics and Key Trends in Hose Reel Components?

The hose reel components market is witnessing significant growth, driven by various global factors including industrialization, urbanization, and the increasing need for efficient fluid management solutions across multiple sectors. Notably, the construction, agriculture, and automotive industries are major consumers of hose reels, which are essential for managing hoses used in watering, cleaning, and transportation of liquids. In regions such as Africa, South America, and the Middle East, the rising demand for agricultural productivity is propelling the adoption of hose reel systems, especially in irrigation practices.

Emerging technologies are also reshaping the sourcing landscape. The integration of IoT devices in hose reel systems facilitates real-time monitoring of fluid usage and maintenance needs, leading to better operational efficiency. Furthermore, e-commerce platforms are enabling international buyers to access a broader range of suppliers and components, streamlining the procurement process. The trend towards automation in industries is boosting the demand for electric hose reels, which offer enhanced convenience and efficiency.

Illustrative image related to hose reel components

International B2B buyers must navigate these market dynamics by understanding regional preferences and compliance requirements. For instance, Brazilian buyers may prioritize durable materials to withstand harsh weather conditions, while European buyers might focus on energy efficiency and eco-friendliness in their purchasing decisions. Additionally, leveraging local suppliers can mitigate logistical challenges and reduce lead times, making it crucial for buyers to build strong relationships with regional distributors.

How Does Sustainability and Ethical Sourcing Impact the Hose Reel Components Market?

Sustainability is becoming a cornerstone in the hose reel components sector, driven by increasing environmental awareness among consumers and regulatory pressures. The environmental impact of manufacturing processes and materials used in hose reel components is under scrutiny, prompting businesses to adopt more sustainable practices. International buyers are increasingly seeking suppliers that demonstrate a commitment to reducing their carbon footprint and using eco-friendly materials.

Ethical sourcing has gained traction, with buyers prioritizing suppliers who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade certification can provide buyers with assurance that their suppliers operate responsibly. Moreover, the use of recycled materials in the production of hose reel components is gaining popularity, aligning with the global push towards circular economy principles.

Buyers should evaluate suppliers based on their sustainability initiatives and ethical practices. Engaging with vendors who prioritize green certifications and sustainable materials not only helps in meeting regulatory requirements but also enhances brand reputation among environmentally conscious consumers.

Illustrative image related to hose reel components

What Is the Brief Evolution of Hose Reel Components and Their Importance?

The evolution of hose reel components can be traced back to the early 20th century when manual reels were predominantly used for irrigation and fire safety purposes. Over the decades, advancements in materials science and engineering have led to the development of more durable and efficient hose reels. The introduction of electric and automatic hose reels in the late 20th century transformed the market, allowing for increased convenience and reduced labor costs in various applications.

Today, hose reels are integral to numerous industries, from agriculture to manufacturing, providing solutions for fluid management and storage. Their design has evolved to incorporate features such as swivel mechanisms for ease of use, enhanced durability to withstand harsh environments, and compatibility with various hose types. This historical context underscores the importance of hose reel components in facilitating efficient operations across diverse sectors, highlighting their role as essential tools for modern businesses.

Frequently Asked Questions (FAQs) for B2B Buyers of hose reel components

-

How do I solve compatibility issues with hose reel components?

Compatibility issues often arise from variations in specifications between different manufacturers. To solve this, ensure you have detailed measurements and specifications for your existing hose reel before sourcing components. Cross-reference these details with the product descriptions from potential suppliers. Request samples or detailed technical drawings to confirm fitment. Additionally, communicating directly with suppliers can clarify compatibility and help you avoid costly mistakes. -

What is the best type of hose reel for industrial applications?

For industrial applications, heavy-duty hose reels designed for high-pressure environments are typically the best choice. Look for models made from durable materials like stainless steel or aluminum that can withstand harsh conditions. Electric hose reels are also advantageous for ease of use, especially in large areas. Always consider the hose capacity and length required for your specific application to ensure efficiency and reliability. -

How can I ensure the quality of hose reel components when sourcing internationally?

To ensure quality when sourcing hose reel components from international suppliers, conduct thorough vetting. Request certifications such as ISO or CE to verify compliance with international standards. Additionally, consider conducting factory audits or utilizing third-party inspection services to assess the manufacturing process. Establishing a clear communication channel with your supplier will also help clarify quality expectations and maintain standards throughout the production process. -

What are the typical minimum order quantities (MOQs) for hose reel components?

Minimum order quantities (MOQs) for hose reel components can vary significantly based on the supplier and the type of component. Generally, MOQs can range from 50 to 500 units. It’s advisable to inquire about MOQs early in discussions with suppliers, especially if you are a smaller buyer. Some suppliers may offer flexibility for first-time customers or provide options for mixed orders to meet MOQ requirements. -

What payment terms should I expect when sourcing hose reel components internationally?

Payment terms for international sourcing typically vary by supplier and region. Common arrangements include advance payments, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that protect both parties. Be aware of currency fluctuations and potential international transaction fees. Always review the payment terms in your purchase agreement and consider using escrow services for large orders to mitigate risk. -

How can I customize hose reel components to meet specific requirements?

Customization of hose reel components is often available through many suppliers. Begin by discussing your specific needs, such as size, material, or additional features, with potential manufacturers. Many suppliers can offer tailored solutions based on your specifications. Be prepared to provide technical drawings or prototypes to facilitate the customization process. Ensure to discuss timelines and any additional costs associated with custom orders. -

What logistics considerations should I keep in mind when importing hose reel components?

When importing hose reel components, consider logistics aspects such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with your destination’s import laws. Assess whether air freight or sea freight is more cost-effective based on your timeline and budget. Also, account for potential delays at customs and ensure you have all necessary documentation to expedite the process. -

What warranty or return policies are typical for hose reel components?

Warranty and return policies for hose reel components can vary widely among suppliers. Typically, reputable manufacturers offer warranties ranging from one to several years, covering defects in materials or workmanship. Always request this information upfront to avoid surprises. Understand the return policy, including conditions under which returns are accepted and whether restocking fees apply. Having clear policies in writing can protect your investment and ensure satisfaction with your purchase.

Top 4 Hose Reel Components Manufacturers & Suppliers List

1. Steeleagle – Hose Reel Parts

Domain: steeleagle.com

Registered: 1997 (28 years)

Introduction: Hose Reel Parts Menu includes categories such as A-Frame, Electric Reel, Mini Reels, Non-Swivel, Steel Frame, and Swivel. Specific parts include Electric Reel Motors (1/2 HP, 1 1/3 HP, 1 1/5 HP), Axles (various sizes), Handle Assemblies, Repair Kits (Super Swivel), and various bearings. Prices range from $1.00 for carriage bolts to $165.00 for swivel reel axles. Other parts include spray arms, whe…

2. UnitedBuilt Equipment – Hose Reel Parts

Domain: watertrucks.com

Registered: 1997 (28 years)

Introduction: Hose Reel Parts – UnitedBuilt Equipment. In Stock, Top Quality, Ships in 1 Day! Order by 2PM MST. Product categories include: Adapter Plug, Air Fitting, Air Switch, Airline Anode, Axle Assembly, Ball Bearing, Ball Valve, Bearing Assembly, Bearing Cap, Blind Flange, Brake Knob, Brake Spring, Brass Fitting, Bulkhead Fitting, Butterfly Valve, Camlock, Check Valve, Circuit Breaker, Compression Insert,…

3. Hose Reel Parts – Reelcraft & Underhill

Domain: precisionusa.com

Registered: 1997 (28 years)

Introduction: This company, Hose Reel Parts – Reelcraft & Underhill, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. T&S Brass – Hose Reel Parts

Domain: tsbrass.com

Registered: 1996 (29 years)

Introduction: Hose Reel Parts from T&S Brass include various components designed for washdown solutions. Key features include durable construction, compatibility with T&S hose reels, and a range of replacement parts to ensure optimal performance and longevity. Specific parts may include hoses, reels, and fittings tailored for industrial applications.

Strategic Sourcing Conclusion and Outlook for hose reel components

In conclusion, effective strategic sourcing of hose reel components is essential for international B2B buyers aiming to optimize their operational efficiency and reduce costs. By understanding the diverse types of hose reels and their components, buyers can make informed decisions that meet their specific needs. Key takeaways include the importance of selecting high-quality parts that enhance durability and performance, as well as the potential for cost savings through bulk purchasing and supplier partnerships.

Illustrative image related to hose reel components

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable hose reel components is expected to rise. Buyers should leverage this opportunity to explore innovative sourcing strategies that prioritize quality and sustainability. Engaging with reputable suppliers who offer comprehensive product ranges and exceptional customer support will be crucial in ensuring long-term success.

Looking ahead, now is the time for international B2B buyers to take proactive steps in their sourcing strategies. By investing in quality components and fostering strong supplier relationships, businesses can not only enhance their operational capabilities but also position themselves competitively in the global market. Embrace the future of hose reel components sourcing to drive growth and innovation in your organization.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.