The Definitive Guide to Hinge 654.375.53: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for hinge 654.375.53

In the ever-evolving landscape of global commerce, sourcing the right components—such as hinge 654.375.53—poses significant challenges for international B2B buyers. Ensuring that these essential components meet quality standards while also being cost-effective is critical, particularly in competitive markets across Africa, South America, the Middle East, and Europe, including countries like Germany and Nigeria. This guide aims to equip decision-makers with the insights necessary for informed purchasing decisions, addressing key considerations such as product types, applications, supplier vetting processes, and cost implications.

As you navigate the complexities of sourcing hinge 654.375.53, you’ll discover a wealth of knowledge tailored to your specific needs. From understanding the various applications of this hinge in different industries to exploring effective supplier evaluation techniques, this guide serves as a comprehensive resource. We delve into the nuances of pricing structures and offer strategies for negotiating favorable terms, ensuring that you secure the best value for your investment.

Furthermore, this guide emphasizes the importance of establishing reliable partnerships with suppliers who can deliver quality products on time and within budget. By leveraging the information presented here, B2B buyers will be empowered to make strategic decisions that enhance operational efficiency and drive business success in their respective markets.

Understanding hinge 654.375.53 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Hinge | Basic design, typically made of steel, offers 180-degree rotation | Doors, cabinets, and furniture | Pros: Cost-effective, widely available. Cons: Limited load capacity. |

| Heavy-Duty Hinge | Reinforced construction, suitable for high-load applications | Industrial machinery, gates | Pros: High durability, suitable for heavy loads. Cons: More expensive. |

| Concealed Hinge | Hidden installation, provides a clean aesthetic | High-end cabinetry, furniture | Pros: Enhanced aesthetics, minimal visibility. Cons: More complex installation. |

| Adjustable Hinge | Allows for fine-tuning of door alignment | Office partitions, cabinetry | Pros: Flexibility in alignment, easy adjustments. Cons: More moving parts may lead to wear. |

| Self-Closing Hinge | Automatically closes doors after being opened | Commercial doors, cabinets | Pros: Convenience, enhances security. Cons: Can be more expensive than standard types. |

What Are the Characteristics of Standard Hinges?

Standard hinges are the most common type, typically made from steel or stainless steel, and are designed to provide a simple pivot mechanism for doors and cabinets. They rotate up to 180 degrees, making them suitable for various applications in both residential and commercial settings. When purchasing standard hinges, consider the material and finish to ensure compatibility with your existing fixtures. These hinges are cost-effective and widely available, making them a go-to choice for many businesses, although they may not support heavy loads.

How Do Heavy-Duty Hinges Differ from Standard Options?

Heavy-duty hinges are designed for applications requiring greater strength and durability, often made from thicker materials or reinforced designs. They are ideal for industrial machinery, large gates, and other high-load environments. Buyers should assess the load capacity and environmental factors, such as exposure to moisture or chemicals, when choosing heavy-duty hinges. While they come at a higher price point, their longevity and reliability in demanding situations often justify the investment.

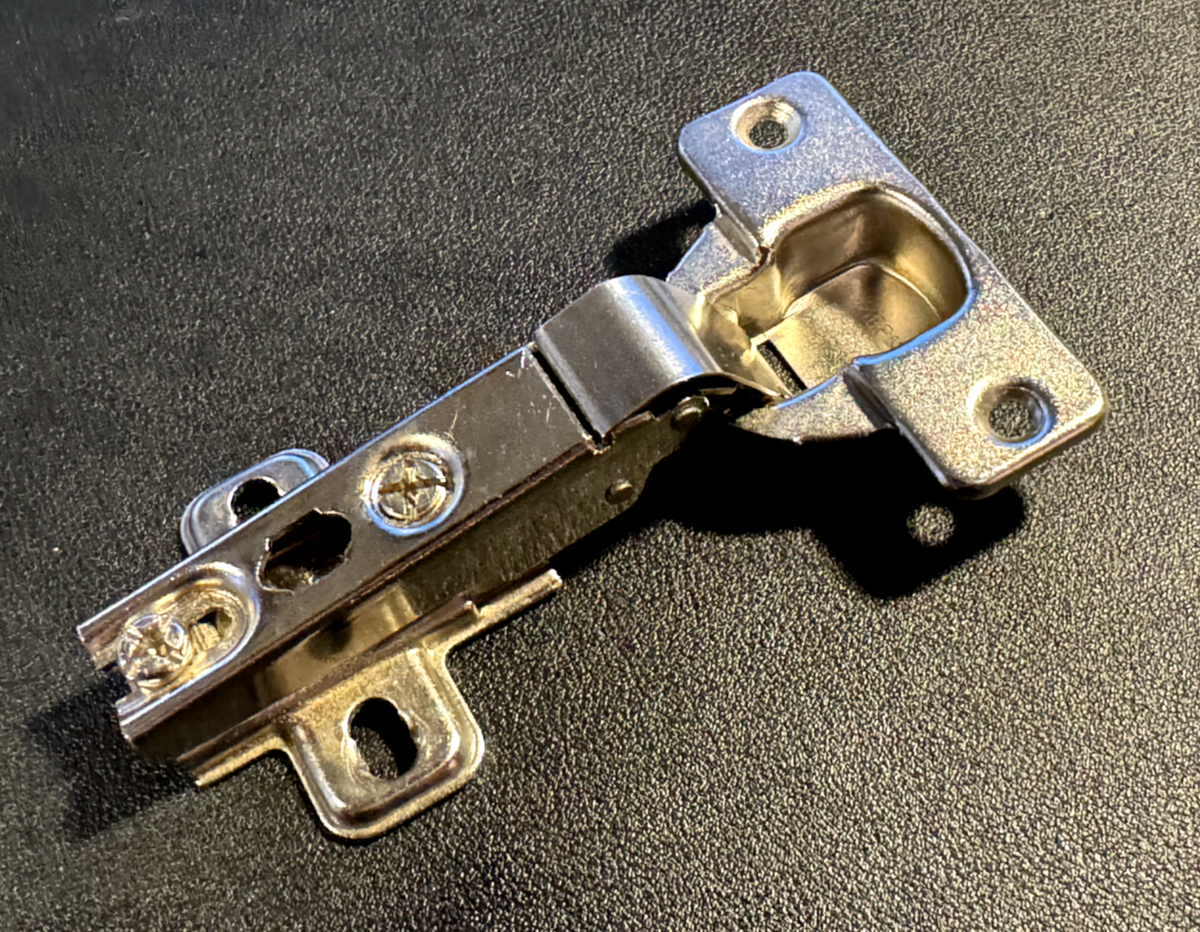

Illustrative image related to hinge 654.375.53

What Advantages Do Concealed Hinges Offer for Businesses?

Concealed hinges are installed within the cabinet or door frame, offering a clean and modern aesthetic that is particularly appealing in high-end cabinetry and furniture. These hinges allow doors to close flush with the cabinet, eliminating visible hardware. Businesses should consider the complexity of installation and the need for specialized tools or skills. While concealed hinges enhance the overall appearance of a product, they may require more maintenance over time due to their intricate mechanisms.

Why Are Adjustable Hinges Beneficial for Specific Applications?

Adjustable hinges provide the flexibility to fine-tune door alignment after installation, making them particularly useful for office partitions and cabinetry where precise fit is crucial. They allow for easy adjustments over time, accommodating shifts in building structures or settling. When purchasing adjustable hinges, businesses should evaluate the mechanism’s durability, as the increased number of moving parts can lead to wear. Their adaptability can save time and costs in maintenance, making them a valuable addition to any project.

What Is the Functionality of Self-Closing Hinges in Commercial Settings?

Self-closing hinges are designed to automatically close a door after it has been opened, which is particularly useful in commercial settings where security and energy efficiency are priorities. These hinges can be found in applications ranging from cabinet doors to entryways in businesses. Buyers should consider the force required for the self-closing mechanism and the potential for wear over time. While they may come at a higher cost than standard hinges, the convenience and security they provide can be a worthwhile investment for many businesses.

Key Industrial Applications of hinge 654.375.53

| Industry/Sector | Specific Application of hinge 654.375.53 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Used in industrial machinery for doors and covers | Enhances operational efficiency and safety | Durability, load capacity, and corrosion resistance |

| Construction | Applied in commercial building access points | Provides security and ease of access | Compliance with local building codes and standards |

| Automotive | Incorporated in vehicle assembly for hoods and doors | Improves vehicle functionality and aesthetics | Weight, strength, and material compatibility |

| Retail | Utilized in display cases and storage units | Facilitates customer interaction and product visibility | Design versatility and locking mechanisms |

| Aerospace | Essential in aircraft cabin access doors | Ensures safety and reliability in high-stakes environments | Weight reduction and high-performance materials |

How is hinge 654.375.53 Used in Manufacturing Applications?

In the manufacturing sector, hinge 654.375.53 is crucial for enabling smooth operation of industrial machinery, particularly for equipment doors and access panels. This hinge type is designed to withstand heavy loads and frequent use, ensuring that machinery remains operational and safe for workers. Buyers in this sector should prioritize sourcing hinges that meet specific durability standards and offer corrosion resistance, especially in regions with harsh environmental conditions, such as parts of Africa and South America.

What Role Does Hinge 654.375.53 Play in Construction?

In construction, hinge 654.375.53 is commonly used in commercial buildings for access points, including doors and gates. Its robust design contributes to enhanced security and ease of access, which are critical for both employees and visitors. Buyers must ensure that the hinges comply with local building codes and standards, particularly in Europe, where regulations can be stringent. Additionally, sourcing hinges that are easy to install and maintain can significantly reduce project timelines.

How Does Hinge 654.375.53 Benefit the Automotive Industry?

Within the automotive industry, hinge 654.375.53 is utilized in the assembly of vehicle components such as hoods and doors. This hinge type enhances both functionality and aesthetics, contributing to the overall user experience. For international buyers, especially from regions like the Middle East, it is essential to consider the weight and strength of the hinges to ensure they meet vehicle performance standards while also optimizing fuel efficiency.

In What Ways is Hinge 654.375.53 Used in Retail Settings?

In retail, hinge 654.375.53 is employed in the design of display cases and storage units, facilitating customer interaction and product visibility. This application is critical for creating an inviting shopping environment. Buyers should look for hinges that offer design versatility and effective locking mechanisms, as these features enhance both functionality and security. Understanding regional preferences and trends can also guide sourcing decisions, particularly in diverse markets like South America.

Why is Hinge 654.375.53 Important in Aerospace Applications?

In the aerospace sector, hinge 654.375.53 is essential for aircraft cabin access doors, where safety and reliability are paramount. This hinge type must meet rigorous performance standards to ensure operational safety in high-stakes environments. Buyers in this industry should focus on sourcing hinges that prioritize weight reduction and are made from high-performance materials, as these factors significantly influence aircraft efficiency and performance.

3 Common User Pain Points for ‘hinge 654.375.53’ & Their Solutions

Scenario 1: Limited Availability and Sourcing Issues

The Problem: B2B buyers often face challenges in sourcing the hinge 654.375.53 due to limited availability from suppliers or manufacturers. This can be especially frustrating for companies operating in regions like Africa or South America, where logistics and supply chain disruptions are common. Buyers may find that they have to deal with delays in delivery, leading to project hold-ups and increased operational costs. Furthermore, not all suppliers provide transparent information about stock levels or lead times, leaving buyers in the dark and unable to plan effectively.

The Solution: To overcome sourcing challenges, B2B buyers should establish relationships with multiple suppliers, ensuring that they have a backup option in case of delays. It is beneficial to create a comprehensive list of vetted suppliers who specialize in the hinge 654.375.53 and regularly communicate with them to stay updated on stock levels. Additionally, leveraging technology such as supply chain management software can help buyers track orders and inventory in real-time. This proactive approach not only reduces the risk of delays but also allows buyers to negotiate better terms based on their purchasing volume.

Illustrative image related to hinge 654.375.53

Scenario 2: Compatibility and Specification Concerns

The Problem: Another common pain point for B2B buyers is the difficulty in ensuring that the hinge 654.375.53 is compatible with existing products or systems. Buyers may struggle to find clear specifications and compatibility information, leading to potential mismatches that can cause delays and additional costs. This is particularly critical for companies in construction or manufacturing, where precise specifications are vital for product performance and safety.

The Solution: To address compatibility concerns, buyers should invest time in thoroughly reviewing the technical specifications and compatibility guidelines provided by manufacturers. Engaging with technical support teams from suppliers can also provide insights into potential issues before making a purchase. Furthermore, conducting a pilot test or a small-scale implementation of the hinge 654.375.53 with existing systems can help identify any compatibility issues early on. This hands-on approach will ensure that the buyer is confident in their purchase and can avoid costly mistakes.

Scenario 3: Quality Assurance and Performance Reliability

The Problem: Quality assurance is a significant concern for B2B buyers when dealing with components like the hinge 654.375.53. Buyers may find themselves in situations where the hinges do not meet the expected quality standards, resulting in performance issues, product failures, and customer dissatisfaction. This risk is heightened in markets where regulatory standards are stringent, making quality even more critical for compliance.

The Solution: To mitigate quality-related risks, buyers should prioritize sourcing hinges from reputable manufacturers known for their rigorous quality control processes. Requesting certifications and compliance documentation can help buyers ensure that the products meet necessary industry standards. Additionally, implementing a thorough inspection process upon receiving the hinges can help identify any defects before they are integrated into larger assemblies. Establishing a feedback loop with end-users can also provide valuable insights into performance, allowing buyers to make informed decisions for future purchases. Regularly reviewing supplier performance and quality metrics will further enhance reliability in sourcing high-quality hinges.

Strategic Material Selection Guide for hinge 654.375.53

When selecting materials for hinge 654.375.53, it is crucial to consider various properties that will affect performance, durability, and suitability for specific applications. Below is an analysis of four common materials used in manufacturing this hinge, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

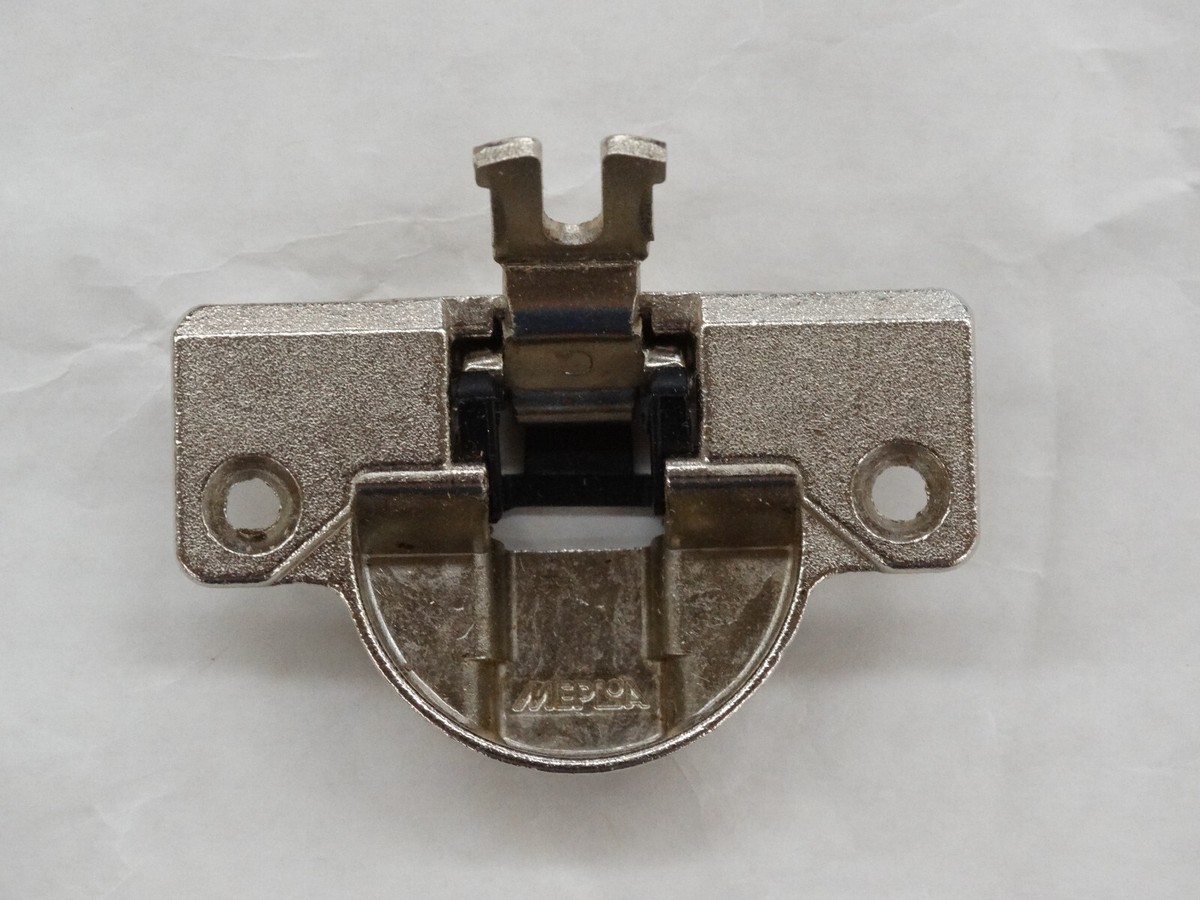

Illustrative image related to hinge 654.375.53

What Are the Key Properties of Stainless Steel for Hinge 654.375.53?

Stainless steel is a popular choice for hinge 654.375.53 due to its excellent corrosion resistance and strength. It can withstand high temperatures and pressures, making it suitable for various environments. The most commonly used grades for hinges are 304 and 316, with the latter offering superior resistance to chlorides and marine environments.

Pros: Stainless steel is highly durable, resistant to rust, and requires minimal maintenance. It also has a polished finish, enhancing aesthetic appeal.

Cons: The cost of stainless steel is relatively high compared to other materials. Additionally, it can be challenging to machine, leading to increased manufacturing complexity.

Impact on Application: Stainless steel is compatible with a wide range of media, including water and chemicals, making it ideal for both indoor and outdoor applications.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with ASTM and DIN standards for stainless steel grades. In Africa and South America, local sourcing of stainless steel may affect cost and availability.

How Does Aluminum Compare for Hinge 654.375.53?

Aluminum is another viable option for hinge 654.375.53, known for its lightweight and corrosion-resistant properties. It is particularly advantageous in applications where weight reduction is critical, such as in aerospace and automotive industries.

Pros: Aluminum is less expensive than stainless steel and is easier to machine, which can reduce production costs and lead times.

Cons: While aluminum is corrosion-resistant, it is not as durable as stainless steel and may not perform well under high-stress conditions. Its lower melting point also limits its use in high-temperature environments.

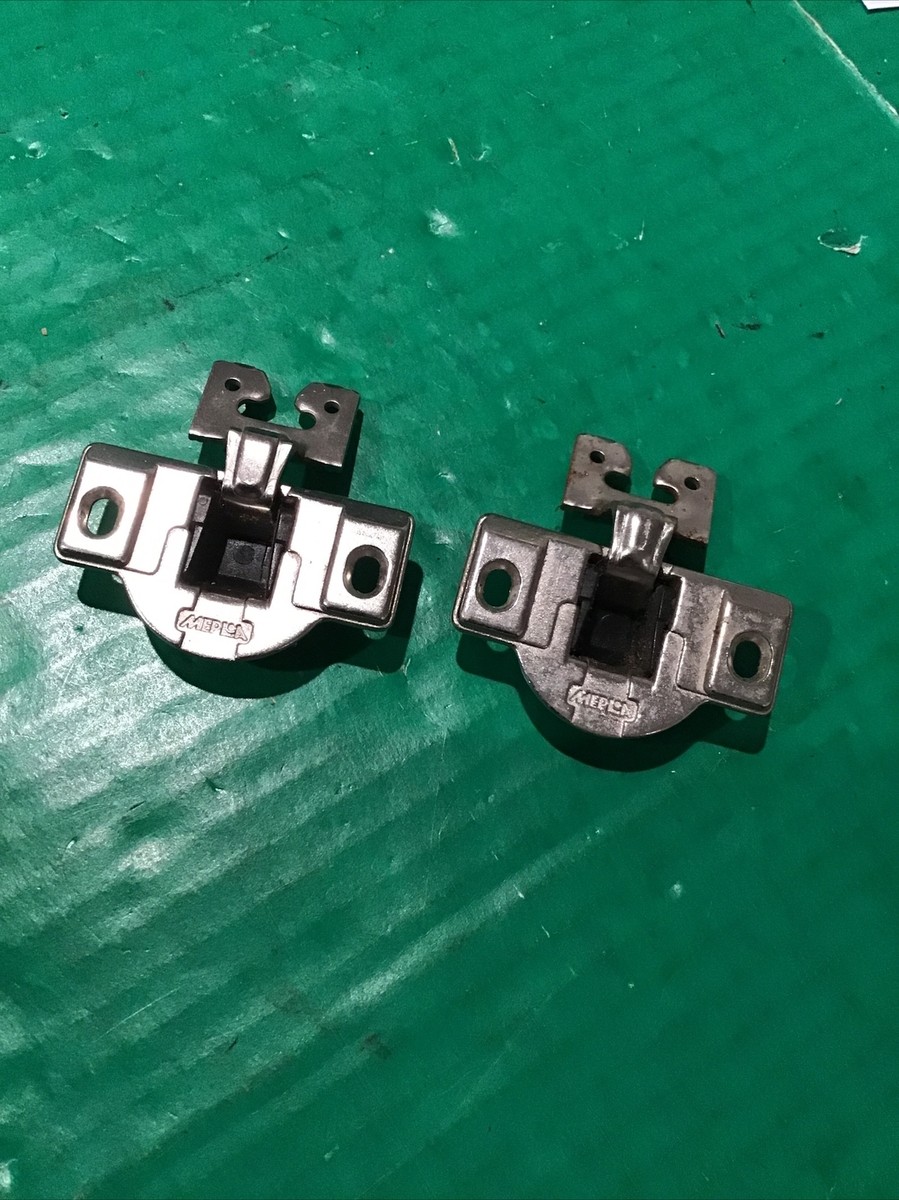

Illustrative image related to hinge 654.375.53

Impact on Application: Aluminum is suitable for applications involving moderate loads and exposure to moisture but may not be ideal for harsh chemical environments.

Considerations for International Buyers: Compliance with JIS and ASTM standards is essential, particularly for buyers in Japan and the U.S. Additionally, buyers in Africa and South America should consider local availability and the potential for corrosion in humid climates.

What Are the Benefits of Plastic Materials for Hinge 654.375.53?

Plastic materials, such as polyamide (nylon) or polypropylene, are increasingly being used for hinge 654.375.53 due to their lightweight and non-corrosive properties. These materials can be particularly beneficial in applications where electrical insulation is required.

Pros: Plastic is generally low-cost and easy to mold, allowing for complex designs and rapid production.

Cons: The mechanical strength of plastic is lower than that of metals, which may limit its use in high-load applications. Additionally, plastics can degrade under UV exposure unless treated.

Impact on Application: Plastic hinges are ideal for indoor applications or environments where moisture is present but not extreme conditions.

Considerations for International Buyers: Buyers should ensure that the selected plastic complies with relevant safety and environmental standards, particularly in Europe, where regulations are stringent.

What Role Does Brass Play in Hinge 654.375.53 Applications?

Brass is often used for decorative hinges due to its aesthetic appeal and corrosion resistance. It offers a good balance of strength and weight, making it suitable for various applications.

Illustrative image related to hinge 654.375.53

Pros: Brass has excellent machinability and can be easily cast into complex shapes. It also has antimicrobial properties, making it suitable for sanitary applications.

Cons: Brass can be more expensive than aluminum and may tarnish over time, requiring maintenance.

Impact on Application: Brass is suitable for low to moderate load applications and is often used in furniture and cabinetry.

Considerations for International Buyers: Compliance with ASTM and DIN standards is important, and buyers should be aware of the potential for price fluctuations based on copper market conditions.

Summary Table of Material Selection for Hinge 654.375.53

| Material | Typical Use Case for hinge 654.375.53 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor and industrial applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace and automotive applications | Lightweight and cost-effective | Lower strength and temperature limits | Medium |

| Plastic | Indoor applications | Low-cost and easy to mold | Limited mechanical strength | Low |

| Brass | Decorative and sanitary applications | Aesthetic appeal and machinability | Higher cost and tarnishing | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for hinge 654.375.53

What Are the Main Stages in the Manufacturing Process of Hinge 654.375.53?

The manufacturing process of hinge 654.375.53 involves several critical stages designed to ensure precision, durability, and functionality. These stages typically include:

Illustrative image related to hinge 654.375.53

-

Material Preparation: The first step is sourcing high-quality raw materials, often steel or aluminum, known for their strength and resistance to corrosion. Materials undergo inspection to confirm they meet specified standards. This may involve chemical analysis to ensure the right alloy composition and physical inspections for defects.

-

Forming: Once materials are prepared, they are subjected to forming processes, which may include stamping, bending, or machining. Stamping involves pressing the material into shape, while bending shapes the hinge components through mechanical force. Precision machining is employed for fine-tuning dimensions, ensuring that each hinge meets exact specifications.

-

Assembly: After forming, the various components of the hinge are assembled. This stage requires precision to ensure smooth functionality. Techniques such as welding, riveting, or using screws can be employed, depending on the design specifications. Automated assembly lines may be used to enhance efficiency while maintaining quality.

-

Finishing: The final stage involves surface treatment to enhance durability and aesthetic appeal. Common finishing processes include powder coating, anodizing, or plating. These treatments not only protect the hinge from environmental factors but also provide a visually appealing finish that can be tailored to customer specifications.

Which Key Techniques Are Used in Hinge Manufacturing?

Several techniques are integral to the production of hinge 654.375.53, each contributing to the overall quality and performance of the final product:

-

CNC Machining: Computer Numerical Control (CNC) machining allows for high precision in cutting and shaping hinge components. This technique minimizes human error and maximizes repeatability, making it ideal for high-volume production.

-

Hydraulic Pressing: This technique is often utilized in the forming stage to achieve complex shapes with high precision. Hydraulic presses apply uniform pressure, ensuring consistent results across batches.

-

Robotic Assembly: Automation through robotics can enhance the assembly process, reducing labor costs while improving consistency and speed. Robots can perform repetitive tasks with high accuracy, which is essential for maintaining quality in large-scale production.

What International Standards and Quality Control Measures Are Relevant?

Quality assurance is paramount in the manufacturing of hinge 654.375.53, particularly given the international market’s demands. Compliance with recognized standards ensures that products meet safety and performance criteria. Key standards include:

-

ISO 9001: This internationally recognized standard outlines quality management principles that ensure consistent quality in products and services. Manufacturers adhering to ISO 9001 are typically required to demonstrate effective processes and continual improvement.

-

CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards. This mark is essential for gaining access to European markets.

-

API Standards: If hinges are intended for use in the oil and gas industry, compliance with American Petroleum Institute (API) standards is crucial. These standards ensure that products can withstand the demanding conditions often found in these environments.

How Are Quality Control Checkpoints Established in Hinge Manufacturing?

Quality control is integrated into various stages of the manufacturing process through specific checkpoints. These checkpoints include:

Illustrative image related to hinge 654.375.53

-

Incoming Quality Control (IQC): Before production begins, materials are inspected to ensure they meet predetermined specifications. This step helps prevent defective materials from entering the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are taken to verify that production parameters are being met. This may involve checking dimensions, surface quality, and mechanical properties.

-

Final Quality Control (FQC): After assembly and finishing, each hinge undergoes a final inspection to ensure it meets all specifications and standards. This may involve functional testing, such as opening and closing cycles, to ensure smooth operation.

What Common Testing Methods Are Used in Quality Assurance for Hinges?

To ensure the hinges meet quality and performance standards, various testing methods may be employed:

-

Visual Inspection: A thorough visual inspection checks for surface defects, dimensional accuracy, and overall appearance. This method is often the first line of defense in quality assurance.

-

Mechanical Testing: This includes tensile strength tests, hardness tests, and fatigue tests to ensure the hinge can withstand operational stresses. These tests help identify potential weaknesses in the material or design.

-

Corrosion Resistance Testing: Especially important for hinges exposed to harsh environments, corrosion resistance testing ensures that the finish can withstand environmental factors without degrading.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers can take several steps to verify the quality control practices of their suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s processes and quality control measures firsthand. This includes reviewing documentation related to compliance with international standards.

-

Quality Assurance Reports: Requesting detailed reports on quality assurance practices and results can provide insights into the supplier’s commitment to quality. This documentation may include records of testing results and compliance certifications.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. These independent evaluations can help ensure that the supplier meets the necessary standards.

What Are the Quality Control Nuances for International Buyers from Different Regions?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe may encounter specific nuances in quality control:

-

Regional Standards Compliance: Different regions may have varying standards and regulations. For instance, European buyers will require CE marking, while buyers in the Middle East may prioritize compliance with local regulations.

-

Cultural Considerations: Understanding cultural differences in business practices can affect how quality control is perceived and implemented. Building strong relationships with suppliers can enhance transparency and trust.

-

Logistical Challenges: International shipping may introduce risks such as damage during transit. Buyers should ensure that suppliers have measures in place to mitigate these risks, such as robust packaging and insurance options.

In conclusion, the manufacturing processes and quality assurance for hinge 654.375.53 are critical in ensuring that these components meet the high standards required by international B2B buyers. By understanding the manufacturing stages, quality control measures, and testing methods, buyers can make informed decisions when selecting suppliers in a global marketplace.

Illustrative image related to hinge 654.375.53

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hinge 654.375.53’

The following guide provides B2B buyers with a comprehensive checklist for procuring the hinge 654.375.53. This systematic approach ensures that you make informed decisions while sourcing high-quality hinges that meet your project requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for hinge 654.375.53. This includes dimensions, load capacity, material, and any specific industry standards that must be met. Having detailed specifications ensures that you communicate effectively with suppliers and prevents costly errors in procurement.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in hinges, particularly the 654.375.53 model. Utilize industry directories, trade shows, and online marketplaces to compile a list of candidates. Look for suppliers with a proven track record in quality and reliability, as these attributes are crucial for long-term partnerships.

Step 3: Evaluate Supplier Certifications

Before engaging further, verify that your shortlisted suppliers hold relevant certifications. This may include ISO 9001 for quality management or other industry-specific certifications. Certifications can serve as indicators of a supplier’s commitment to quality and regulatory compliance, which is especially important for international transactions.

Step 4: Request Product Samples

Once you have narrowed down your supplier options, request product samples of hinge 654.375.53. Evaluating samples allows you to assess the quality and performance of the product firsthand. Pay attention to details such as finish, durability, and functionality to ensure they align with your project needs.

Step 5: Inquire About Lead Times and Pricing

Engage with suppliers to understand their lead times and pricing structures. It’s essential to evaluate not only the cost of the hinges but also any additional fees such as shipping, handling, or bulk purchase discounts. Knowing these details will help you gauge the overall value and plan your budget accordingly.

Step 6: Assess Customer Support and Communication

Effective communication is vital in any B2B relationship. Evaluate how responsive and supportive suppliers are during your inquiries. A supplier that provides clear information and timely responses can significantly enhance your purchasing experience, especially when unforeseen issues arise.

Step 7: Finalize Contracts and Terms

After selecting a supplier, carefully review and finalize contracts. Ensure that all terms related to payment, delivery schedules, and return policies are clearly defined. A well-structured contract protects your interests and establishes a professional relationship with the supplier.

By following this checklist, B2B buyers can navigate the sourcing process for hinge 654.375.53 effectively, ensuring quality procurement while minimizing risks associated with international purchasing.

Comprehensive Cost and Pricing Analysis for hinge 654.375.53 Sourcing

What Are the Key Cost Components for Sourcing Hinge 654.375.53?

When sourcing the hinge 654.375.53, understanding the cost structure is essential for B2B buyers aiming to optimize their procurement strategies. The primary cost components include:

-

Materials: The quality and type of materials directly influence the pricing. High-grade metals or corrosion-resistant materials tend to be more expensive but offer longevity and performance benefits.

-

Labor: Labor costs vary significantly depending on the manufacturing location. Regions with lower wage standards can reduce overall costs, but this might impact quality if not managed properly.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help lower these overheads.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should inquire about these costs upfront, as they can affect the overall pricing structure.

-

Quality Control (QC): Implementing stringent QC processes ensures that the hinges meet required specifications and certifications. While this adds to the cost, it can prevent expensive returns and replacements in the long run.

-

Logistics: Shipping and handling costs can vary based on the location of the supplier and the buyer. Understanding the logistics involved, including freight charges and import duties, is crucial for an accurate total cost assessment.

-

Margin: Suppliers will typically include a profit margin in their pricing. Buyers should consider negotiating this margin, especially when placing bulk orders.

How Do Price Influencers Affect Hinge 654.375.53 Pricing?

Several factors can influence the pricing of hinge 654.375.53:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate the pricing structure. Higher order volumes can lead to discounts, so buyers should assess their needs carefully.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Materials and Quality Certifications: The materials used and any relevant quality certifications (like ISO or CE) can significantly impact pricing. Buyers should weigh the benefits of higher-quality materials against budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can also affect pricing. Established suppliers may charge a premium for their services but offer better quality assurance.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) dictate who bears the transportation costs and risks. Understanding these terms is vital for calculating the total landed cost of the product.

What Buyer Tips Can Help Optimize Costs for Hinge 654.375.53?

To navigate the complexities of sourcing hinge 654.375.53, consider these actionable tips:

-

Negotiate Wisely: Don’t hesitate to negotiate on price, especially for larger orders. Suppliers often have room for discounts, particularly for long-term partnerships.

-

Focus on Cost Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, operational costs, and potential downtime.

-

Understand Pricing Nuances: Pricing can vary by region, so international buyers should be aware of local market conditions and currency fluctuations. For instance, buyers in Germany might encounter different pricing structures compared to those in Nigeria.

-

Seek Multiple Quotes: Always obtain quotes from multiple suppliers to ensure competitive pricing. This practice also provides leverage during negotiations.

-

Evaluate Total Landed Costs: Consider all costs associated with bringing the product to your location, including shipping, customs duties, and handling fees, to avoid surprises.

Disclaimer on Indicative Prices

Prices for hinge 654.375.53 can vary widely based on the factors discussed above. The figures provided in this analysis are indicative and should not be considered final. It is recommended that buyers conduct thorough market research and consult directly with suppliers for accurate pricing based on their specific requirements.

Alternatives Analysis: Comparing hinge 654.375.53 With Other Solutions

Introduction to Alternative Solutions for Hinge 654.375.53

In the dynamic landscape of B2B solutions, understanding the alternatives to a specific product like hinge 654.375.53 is crucial for making informed purchasing decisions. This section examines various alternatives that offer similar functionalities or benefits, empowering international buyers from diverse regions, including Africa, South America, the Middle East, and Europe, to evaluate their options effectively.

| Comparison Aspect | Hinge 654.375.53 | Alternative 1: Hinge 654.375.54 | Alternative 2: Hinge 654.375.55 |

|---|---|---|---|

| Performance | High durability and reliability for heavy doors | Similar performance with minor improvements in load capacity | Comparable durability with enhanced corrosion resistance |

| Cost | Moderate price point, competitive in the market | Slightly higher cost due to advanced features | Lower initial cost but higher long-term maintenance |

| Ease of Implementation | User-friendly installation with standard tools | Simple installation, but requires additional hardware | More complex installation requiring specialized tools |

| Maintenance | Low maintenance, occasional lubrication needed | Minimal maintenance, recommended inspection every 6 months | Higher maintenance due to more moving parts |

| Best Use Case | Ideal for commercial settings with high foot traffic | Suitable for residential and light commercial applications | Best for outdoor settings needing corrosion resistance |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Hinge 654.375.54?

Hinge 654.375.54 offers similar performance to hinge 654.375.53 but incorporates slight enhancements in load capacity, making it an excellent option for businesses needing to support heavier doors. Its price point is slightly higher, which may deter budget-conscious buyers. However, its straightforward installation process makes it accessible for most users without specialized training. This alternative is particularly well-suited for residential properties or light commercial applications where aesthetics and functionality are equally important.

Illustrative image related to hinge 654.375.53

How Does Hinge 654.375.55 Compare in Terms of Durability?

Hinge 654.375.55 is designed with enhanced corrosion resistance, making it a robust choice for outdoor applications or environments exposed to moisture. While it has a lower initial purchase cost, the long-term maintenance can be higher due to more intricate moving parts that may require frequent inspections. This alternative is ideal for international buyers operating in humid or coastal regions where rust and corrosion are significant concerns, ensuring longevity despite environmental challenges.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the right hinge solution depends on specific operational needs, environmental conditions, and budget constraints. B2B buyers should carefully assess the performance, cost-effectiveness, ease of implementation, and maintenance requirements of each alternative. By evaluating these factors in relation to their unique applications—whether for commercial, residential, or outdoor use—buyers can make informed decisions that align with their operational goals and financial strategies. Engaging with suppliers and requesting samples or demos can further aid in understanding the practical applications of each hinge solution, ensuring optimal performance in their respective settings.

Essential Technical Properties and Trade Terminology for hinge 654.375.53

What Are the Essential Technical Properties of Hinge 654.375.53?

Understanding the technical specifications of hinge 654.375.53 is crucial for B2B buyers to ensure compatibility and performance in various applications. Below are key properties that define this hinge:

1. Material Grade

The hinge 654.375.53 is typically manufactured from high-grade steel or stainless steel. The choice of material affects strength, corrosion resistance, and durability. For instance, stainless steel offers superior resistance to environmental factors, making it ideal for outdoor or industrial applications. Selecting the right material can influence the lifespan of the hinge and its maintenance requirements, impacting overall operational costs.

2. Load Capacity

This specification defines the maximum weight the hinge can support without compromising functionality. Load capacity is critical in applications such as doors, gates, and cabinets. Understanding the load requirements helps in selecting a hinge that ensures safety and reliability, preventing premature failure that could lead to costly repairs or replacements.

3. Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. For hinge 654.375.53, maintaining strict tolerance levels ensures smooth operation and proper alignment. In B2B settings, precise tolerances are essential for manufacturing and assembly processes, as they minimize the risk of malfunction due to misalignment or excessive wear.

4. Finish Type

The finish of hinge 654.375.53 can vary, including options like powder coating, plating, or anodizing. The finish impacts both aesthetic appeal and functional properties, such as corrosion resistance and wear resistance. B2B buyers should consider the environment in which the hinge will be used to select an appropriate finish that aligns with their operational requirements.

Illustrative image related to hinge 654.375.53

5. Pin Type

The hinge may feature different pin types, such as removable or fixed pins. Removable pins allow for easy disassembly, which can be advantageous for maintenance or replacement. Understanding the pin type is essential for ensuring that the hinge meets the specific needs of the application, particularly in sectors where frequent adjustments are necessary.

What Are Common Trade Terms Relevant to Hinge 654.375.53?

Familiarity with industry terminology can facilitate smoother transactions and communications among B2B buyers. Here are several critical terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For hinge 654.375.53, knowing the OEM can help buyers ensure they are sourcing quality products that meet industry standards, which is essential for maintaining brand integrity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for budget-conscious buyers who need to balance inventory costs with demand. Understanding MOQ helps in planning purchases and managing stock levels effectively.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to suppliers to request pricing and terms for specific products. Submitting an RFQ for hinge 654.375.53 can help buyers compare offers and negotiate better deals, ensuring they secure competitive pricing and favorable terms.

Illustrative image related to hinge 654.375.53

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers for the delivery of goods. Familiarity with Incoterms is crucial for international transactions involving hinge 654.375.53, as they clarify shipping costs, risks, and liability, thus preventing misunderstandings.

5. Lead Time

Lead time refers to the amount of time it takes for an order to be fulfilled. For hinge 654.375.53, understanding lead times is essential for inventory management and project planning. This information allows buyers to align their procurement processes with production schedules and customer demands.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operational efficiency and product reliability.

Illustrative image related to hinge 654.375.53

Navigating Market Dynamics and Sourcing Trends in the hinge 654.375.53 Sector

What Are the Key Market Dynamics and Trends Affecting the Hinge 654.375.53 Sector?

The hinge 654.375.53 sector is experiencing significant transformation driven by global market dynamics and technological advancements. A notable trend is the increasing demand for customizable and multifunctional hinges, particularly in manufacturing and construction industries across Africa, South America, the Middle East, and Europe. The rise of smart technology integration into traditional hardware has led to an increase in demand for hinges that can accommodate electronic components, enhancing the functionality of doors, cabinets, and machinery.

Furthermore, international buyers are increasingly prioritizing suppliers who can offer quick turnaround times and flexible sourcing options. This is particularly relevant in regions like Germany, where precision engineering is critical, and in Nigeria, where rapid urbanization is driving infrastructure development. Emerging markets are witnessing a rise in e-commerce platforms that facilitate direct sourcing, providing buyers with access to a wider range of suppliers and competitive pricing.

In addition, sustainability is becoming a key consideration in purchasing decisions, with buyers looking for products that align with their corporate social responsibility (CSR) goals. As a result, manufacturers are innovating to create eco-friendly hinges made from recycled materials or with minimal environmental impact during production. This shift not only meets buyer expectations but also enhances brand reputation in an increasingly environmentally conscious market.

How Important Is Sustainability and Ethical Sourcing for the Hinge 654.375.53 Sector?

Sustainability and ethical sourcing are no longer optional but essential components in the hinge 654.375.53 sector. The environmental impact of manufacturing processes has come under scrutiny, and companies that prioritize sustainable practices are better positioned to meet regulatory requirements and consumer expectations. B2B buyers are actively seeking suppliers who demonstrate commitment to reducing carbon footprints and who utilize sustainable materials in their products.

This demand has led to the rise of certifications such as ISO 14001 for environmental management systems and the use of green materials like recycled metals and plastics. Buyers from regions such as Europe, where regulations around sustainability are stringent, are particularly vigilant in ensuring their supply chains are compliant with these standards. By engaging with ethically sourced materials, companies not only contribute to environmental preservation but also enhance their marketability, appealing to a growing demographic of eco-conscious consumers.

Moreover, ethical sourcing practices foster transparency and accountability in the supply chain, mitigating risks associated with labor exploitation and environmental degradation. B2B buyers are encouraged to establish partnerships with manufacturers who prioritize ethical practices, as this can lead to long-term business relationships built on trust and shared values.

What Is the Evolution of the Hinge 654.375.53 Sector?

The hinge 654.375.53 sector has evolved significantly over the past few decades, transitioning from basic mechanical functions to sophisticated, multifunctional components integral to modern engineering and design. Initially, hinges were purely functional, designed to facilitate the opening and closing of doors and cabinets. However, advancements in technology have transformed them into complex systems that can incorporate smart features, such as sensors and automation.

This evolution has been driven by the growing demand for enhanced user experience in various applications, including residential, commercial, and industrial settings. The integration of smart technology has led to the development of hinges that not only perform traditional functions but also contribute to energy efficiency and security in buildings. As the market continues to evolve, B2B buyers must stay informed about these advancements to make informed sourcing decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of hinge 654.375.53

-

How do I ensure the quality of hinge 654.375.53 before purchasing?

To ensure quality, request samples from potential suppliers to evaluate the hinge’s durability and functionality. Additionally, inquire about the manufacturing process and materials used. Look for certifications that meet international standards, such as ISO or ANSI. Consider conducting third-party inspections or audits of the supplier’s facility to validate their quality assurance processes. Establishing clear quality expectations in your purchase agreement can also help mitigate risks. -

What are the key specifications to consider for hinge 654.375.53?

When sourcing hinge 654.375.53, focus on its load capacity, material type (e.g., stainless steel vs. carbon steel), corrosion resistance, and finish options. Ensure the hinge dimensions match your application requirements, including hole spacing and pin diameter. Additionally, confirm whether the hinge supports the necessary rotation angle and features like self-closing or adjustable mechanisms. These specifications are crucial for ensuring compatibility with your products. -

What is the typical minimum order quantity (MOQ) for hinge 654.375.53?

Minimum order quantities can vary significantly by supplier and region. Generally, MOQs for hinge 654.375.53 range from 100 to 1,000 units. Smaller manufacturers may offer lower MOQs, while larger suppliers might set higher limits to optimize production efficiency. When negotiating, consider discussing flexible MOQs if you require a smaller initial order for testing purposes or phased procurement strategies. -

How can I verify a supplier’s credibility for hinge 654.375.53?

To verify a supplier’s credibility, conduct thorough research by checking their business licenses, customer reviews, and industry reputation. Utilize platforms like Alibaba or ThomasNet to find verified suppliers and read feedback from other buyers. Request references from previous clients, and consider visiting the supplier’s facility if possible. Additionally, assess their financial stability by reviewing their credit history and payment terms. -

What payment terms are commonly accepted for international B2B transactions?

Common payment terms for international B2B transactions include Letter of Credit (LC), advance payment, and payment upon delivery. Many suppliers prefer partial upfront payment (30-50%) with the balance due upon shipment. Ensure that the terms are clearly outlined in the contract, including currency, payment methods (bank transfer, PayPal), and any applicable fees. This helps protect both parties and facilitates smoother transactions. -

How do I handle customs and logistics for importing hinge 654.375.53?

To manage customs and logistics effectively, engage a reliable freight forwarder experienced in your destination country. They can assist with shipping documentation, customs clearance, and import regulations. Research tariffs and taxes applicable to hinge 654.375.53 in your region to budget accordingly. Ensure that your supplier provides accurate shipping information, including the Harmonized System (HS) code for the product, to facilitate the import process. -

Can hinge 654.375.53 be customized to meet specific requirements?

Yes, many manufacturers offer customization options for hinge 654.375.53, including size, material, finish, and special features like locking mechanisms. When discussing customization, provide detailed specifications and intended applications to ensure the final product meets your needs. Be aware that custom orders may have longer lead times and higher costs, so factor this into your procurement planning. -

What are the best practices for quality assurance when sourcing hinge 654.375.53?

Implementing best practices for quality assurance includes establishing clear specifications and performance standards upfront. Conduct regular inspections during production and prior to shipment to identify any defects. Utilize third-party quality control services to ensure adherence to international standards. Additionally, maintain open communication with your supplier to address any concerns promptly and ensure continuous improvement in quality management.

A Look at Hinge 654.375.53 Manufacturers & Suppliers

Could not verify enough suppliers for hinge 654.375.53 to create a list at this time.

Strategic Sourcing Conclusion and Outlook for hinge 654.375.53

In the rapidly evolving landscape of hinge 654.375.53, strategic sourcing emerges as a vital component for international B2B buyers looking to enhance their procurement processes. The insights gathered throughout this guide illustrate that leveraging robust supplier relationships and understanding market dynamics can significantly improve operational efficiencies and cost-effectiveness.

As businesses across Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, it is essential to prioritize not only price but also quality, reliability, and supplier capabilities. Engaging in strategic sourcing allows companies to align their purchasing strategies with long-term business goals, fostering innovation and competitive advantage.

Looking ahead, we encourage B2B buyers to remain proactive in their sourcing initiatives. By embracing data-driven decision-making and fostering collaborative partnerships, businesses can position themselves to adapt to market changes swiftly. The future of sourcing hinges on agility and responsiveness—qualities that will define successful businesses in the global marketplace. Connect with reliable suppliers today to drive your business forward and unlock new opportunities in hinge 654.375.53.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to hinge 654.375.53