The Definitive Guide to Heat Exchanger Systems: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for heat exchanger systems

Navigating the intricate landscape of the global market for heat exchanger systems can present a significant challenge for international B2B buyers. With diverse applications ranging from power generation to food processing, understanding the nuances of heat exchanger technology is crucial for making informed purchasing decisions. This comprehensive guide delves into the various types of heat exchangers, including shell and tube, plate, and air-cooled systems, and highlights their specific applications across different industries.

Additionally, we provide insights into the critical aspects of supplier vetting, ensuring that buyers can identify reliable manufacturers who meet their operational needs. Cost considerations are also explored, equipping businesses with the knowledge to budget effectively while maximizing efficiency and safety.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Nigeria—this guide serves as a valuable resource. By empowering decision-makers with actionable insights and expert recommendations, we aim to streamline the sourcing process, enhance procurement strategies, and ultimately foster more sustainable and efficient operations in their respective industries.

Understanding heat exchanger systems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Shell and Tube | Comprises a series of tubes, one inside another, allowing for efficient heat transfer. | Oil refineries, chemical processing, HVAC | Pros: High durability, versatile; Cons: Larger footprint, potential for leaks. |

| Plate | Made of thin plates stacked together to create channels for fluid flow, maximizing surface area. | Food processing, pharmaceuticals, HVAC | Pros: Compact design, efficient heat transfer; Cons: Limited temperature range, potential for fouling. |

| Finned Tube | Incorporates fins to increase surface area, enhancing heat transfer efficiency. | Power generation, gas cooling | Pros: Effective for low thermal conductivity fluids; Cons: More complex maintenance due to fin design. |

| Air-Cooled | Utilizes air as the cooling medium, often with fans to enhance airflow. | Refrigeration, HVAC systems | Pros: No water usage, energy efficient; Cons: Performance can be affected by ambient temperature. |

| Double Pipe | Simple design with one pipe inside another, where one fluid flows through the inner pipe and another through the outer. | Heating systems, small-scale applications | Pros: Easy to maintain, cost-effective; Cons: Limited heat transfer efficiency compared to other types. |

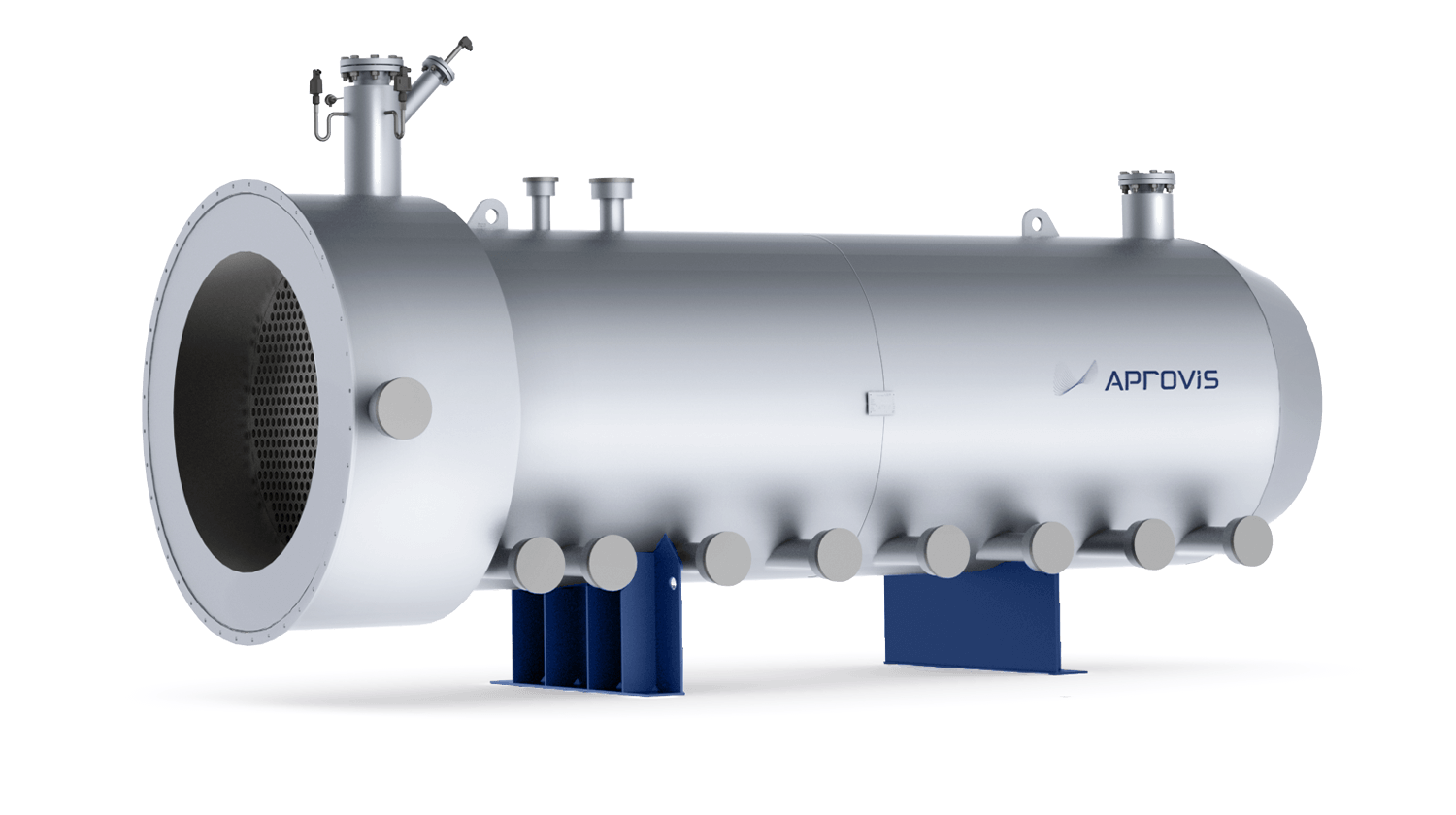

What Are the Characteristics of Shell and Tube Heat Exchangers?

Shell and tube heat exchangers are characterized by their robust construction, featuring a series of tubes housed within a larger shell. This design allows for high-pressure applications and is suitable for a variety of fluids, making it a popular choice in industries such as oil refining and chemical processing. When purchasing, buyers should consider the materials used, as these can affect durability and resistance to corrosion, especially in aggressive environments.

How Do Plate Heat Exchangers Maximize Efficiency?

Plate heat exchangers consist of multiple thin plates that create a large surface area for heat transfer. This design is particularly effective for applications in the food and pharmaceutical sectors, where hygiene and compactness are crucial. Buyers should evaluate the plate material and gasket options to ensure they meet specific temperature and pressure requirements, as well as the potential for fouling, which can impact performance.

What Advantages Do Finned Tube Heat Exchangers Offer?

Finned tube heat exchangers are designed with extended surfaces (fins) that significantly enhance heat transfer efficiency, particularly in applications involving air or other low thermal conductivity fluids. They are widely used in power generation and gas cooling systems. When considering a purchase, buyers should assess the complexity of maintenance due to the fin design, as well as the specific operational conditions to ensure optimal performance.

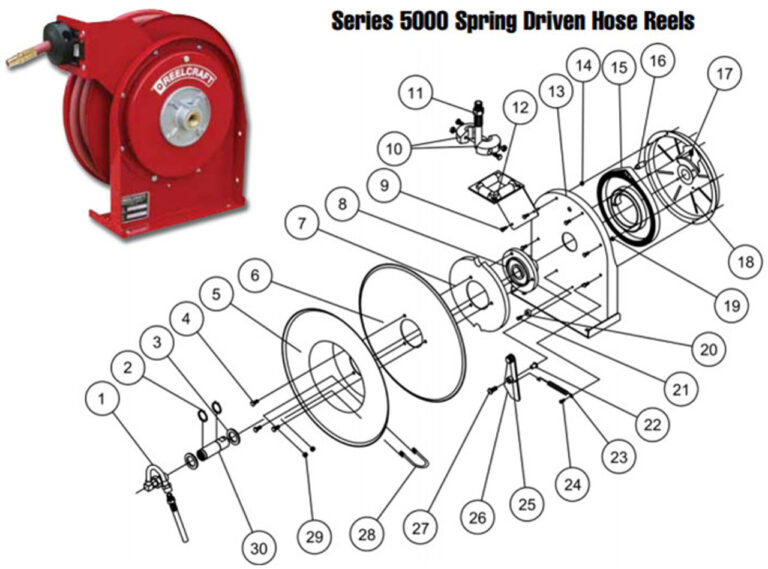

Illustrative image related to heat exchanger systems

Why Choose Air-Cooled Heat Exchangers?

Air-cooled heat exchangers utilize ambient air for cooling, often enhanced by fans. This design is advantageous in applications like refrigeration and HVAC, where water usage is a concern. Buyers should consider the local climate, as performance can vary with ambient temperatures. Additionally, the initial investment might be lower, but operational efficiency can fluctuate based on environmental conditions.

What Are the Key Features of Double Pipe Heat Exchangers?

Double pipe heat exchangers are straightforward in design, featuring one pipe inside another. This simplicity makes them easy to maintain and cost-effective for small-scale applications, such as heating systems. However, their heat transfer efficiency is generally lower compared to more complex designs. Buyers should evaluate the specific application requirements, including flow rates and temperature differentials, to determine if this type meets their needs effectively.

Key Industrial Applications of heat exchanger systems

| Industry/Sector | Specific Application of heat exchanger systems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Cooling systems in thermal and nuclear power plants | Enhanced efficiency and safety in energy production | Compliance with international safety standards, materials that withstand high temperatures and pressures |

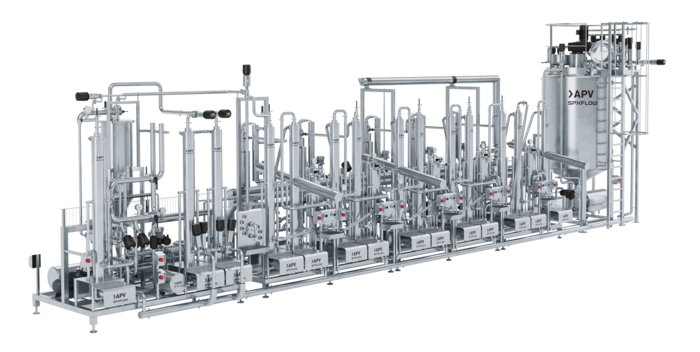

| Food Processing | Pasteurization and refrigeration processes | Improved product safety and extended shelf life | Hygiene standards, material compatibility with food, energy efficiency ratings |

| Chemical Manufacturing | Heat recovery in chemical reactors | Cost reduction through energy efficiency | Resistance to corrosive chemicals, custom designs for specific processes |

| HVAC Systems | Heating and cooling in commercial buildings | Optimized energy use and climate control | Size and efficiency ratings, compatibility with existing systems, maintenance support options |

| Marine Engineering | Cooling systems for ship engines and nuclear submarines | Increased operational reliability and safety | Durability against marine conditions, compact design for space constraints |

How Are Heat Exchanger Systems Used in Power Generation?

In power generation, heat exchanger systems are critical for cooling processes in thermal and nuclear power plants. They ensure that excess heat is effectively removed from equipment, enhancing operational efficiency and safety. For international buyers, especially in regions like Africa and the Middle East, sourcing heat exchangers that meet stringent safety standards is paramount. Additionally, materials must be selected for their ability to withstand high temperatures and pressures, ensuring longevity and reliability in harsh operational conditions.

What Role Do Heat Exchangers Play in Food Processing?

In the food processing industry, heat exchangers are essential for pasteurization and refrigeration processes. They help maintain product safety by effectively controlling temperatures, which is crucial for extending shelf life and meeting health regulations. Buyers in South America and Africa should prioritize suppliers that comply with food safety standards and offer heat exchangers made from materials compatible with food products. Energy efficiency ratings are also vital, as they contribute to cost savings in large-scale operations.

How Are Heat Exchangers Applied in Chemical Manufacturing?

Heat exchangers in chemical manufacturing facilitate heat recovery in reactors, optimizing energy use and minimizing operational costs. They help maintain precise temperature control, which is critical for safe and efficient chemical reactions. For B2B buyers in Europe and South America, sourcing heat exchangers that resist corrosive chemicals is essential. Custom designs may be required to fit specific processes, necessitating collaboration with manufacturers who can tailor solutions to unique operational needs.

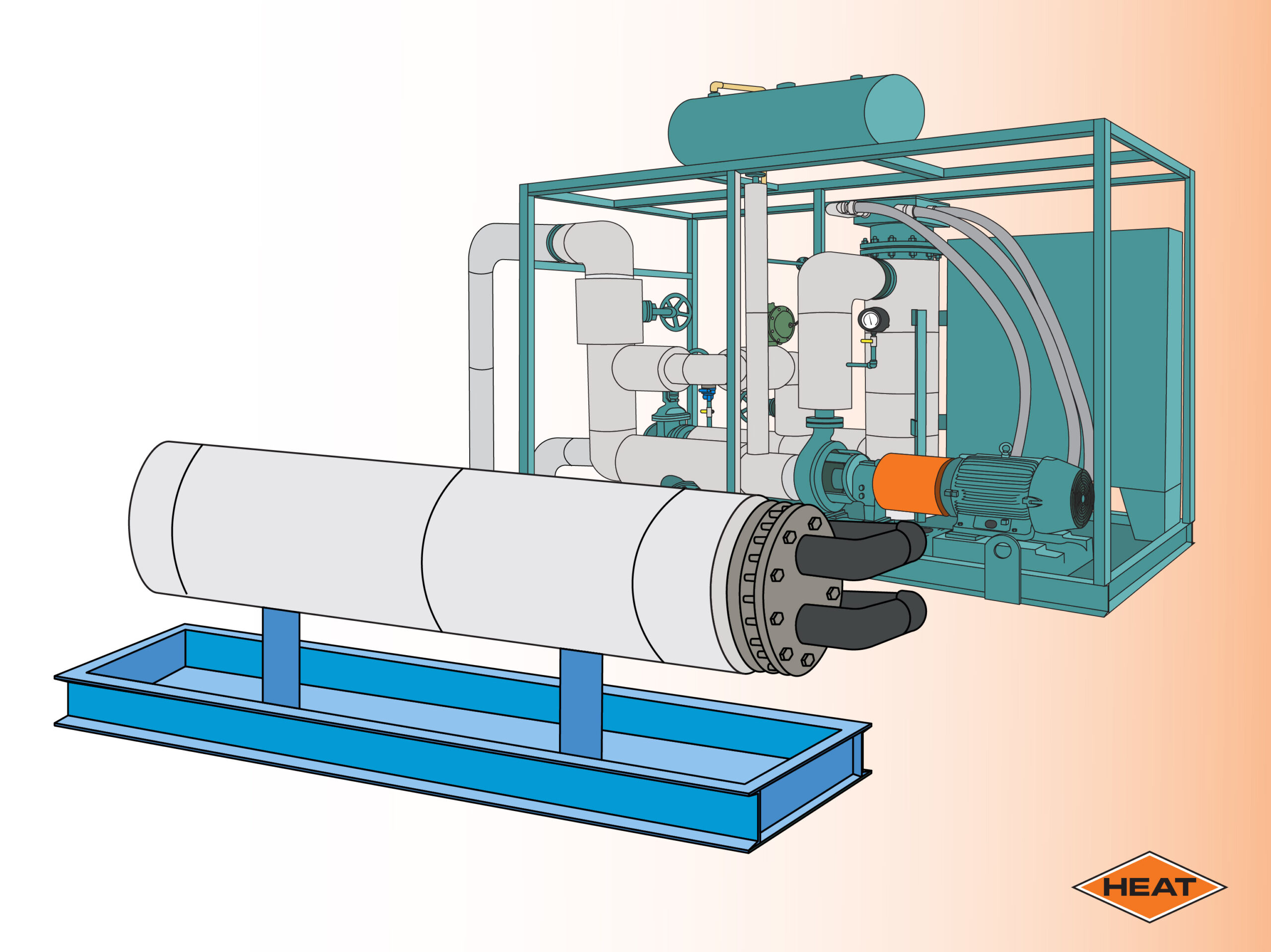

Illustrative image related to heat exchanger systems

Why Are Heat Exchanger Systems Important for HVAC Applications?

In HVAC systems, heat exchangers play a vital role in heating and cooling commercial buildings. They optimize energy use, ensuring comfortable climates while reducing operational costs. Buyers in the Middle East and Africa should consider the size and efficiency ratings of heat exchangers to ensure they meet the demands of larger facilities. Compatibility with existing systems and the availability of maintenance support are also crucial factors in the sourcing process.

What Are the Benefits of Heat Exchangers in Marine Engineering?

In marine engineering, heat exchangers are used to cool ship engines and nuclear submarines, enhancing operational reliability and safety. They must be designed to withstand harsh marine environments, which presents unique sourcing challenges. Buyers should look for durable materials and compact designs that fit within limited space constraints. Additionally, ensuring that suppliers understand the specific requirements of marine applications can lead to better performance and reliability in critical operations.

3 Common User Pain Points for ‘heat exchanger systems’ & Their Solutions

Scenario 1: Inefficiency in Heat Transfer Process

The Problem: One of the most common challenges faced by B2B buyers in industries like manufacturing and chemical processing is the inefficiency in heat transfer due to suboptimal heat exchanger systems. This inefficiency can lead to increased energy costs, longer processing times, and reduced overall equipment effectiveness. For instance, if a heat exchanger is not appropriately sized for the application or if it utilizes outdated technology, it may not effectively transfer heat, causing the system to work harder than necessary. This can also lead to overheating and potential damage to sensitive equipment.

The Solution: To overcome this challenge, it’s crucial for buyers to conduct a thorough analysis of their heat transfer requirements before sourcing a heat exchanger. Begin by assessing the specific operational parameters, including the temperature ranges, flow rates, and fluid characteristics involved in your processes. Collaborate with manufacturers who specialize in bespoke heat exchangers, ensuring they understand your unique application needs. This collaboration can lead to the development of custom solutions that maximize efficiency. Additionally, consider investing in modern technologies such as enhanced finned tube or plate heat exchangers that offer superior heat transfer capabilities due to their design. Regular monitoring and maintenance of your heat exchanger systems will also ensure they operate at peak efficiency over time.

Illustrative image related to heat exchanger systems

Scenario 2: High Maintenance Costs and Downtime

The Problem: B2B buyers often encounter high maintenance costs associated with heat exchanger systems, particularly in industries where continuous operation is critical. Frequent maintenance not only incurs direct costs but can also lead to unexpected downtime, disrupting production schedules and affecting overall productivity. Factors contributing to high maintenance needs include corrosion, fouling, and improper installation, which can complicate upkeep and increase the likelihood of system failures.

The Solution: To mitigate maintenance costs and reduce downtime, buyers should prioritize selecting heat exchangers designed with longevity and easy maintenance in mind. Invest in materials that resist corrosion and fouling, such as stainless steel or specialized alloys, especially if your applications involve aggressive fluids. Additionally, consider heat exchangers with accessible designs that facilitate routine inspections and cleaning. Implementing a proactive maintenance schedule is vital. This schedule should include regular inspections and cleaning protocols to prevent buildup and prolong the lifespan of the equipment. Engaging with service providers who offer comprehensive maintenance support can also ensure that any potential issues are identified and addressed before they escalate into costly repairs or downtime.

Scenario 3: Inadequate Heat Exchanger Sizing

The Problem: Another prevalent issue faced by B2B buyers is the inadequacy in the sizing of heat exchangers for their specific applications. Sizing issues can stem from a lack of precise calculations during the design phase or from using generic solutions that do not consider the unique thermal loads of the operational environment. An undersized heat exchanger can lead to overheating and equipment failure, while an oversized unit can result in unnecessary capital expenditure and inefficient operation.

The Solution: To effectively address sizing concerns, buyers should engage in detailed thermal analysis during the procurement process. This involves calculating the precise heat transfer requirements based on the specific processes and fluid characteristics involved. Work closely with manufacturers who provide tailored solutions, ensuring they have the expertise to recommend the correct heat exchanger type and size. Utilize advanced simulation tools that can model the thermal dynamics of your system to make informed decisions. By investing in properly sized heat exchangers, you not only enhance system performance but also improve energy efficiency and reduce operational costs. Additionally, incorporating flexibility in design can allow for future scalability, accommodating potential increases in production or changes in operational parameters.

Strategic Material Selection Guide for heat exchanger systems

What Are the Key Properties of Common Materials Used in Heat Exchanger Systems?

When selecting materials for heat exchanger systems, it’s crucial to consider their properties, performance under various conditions, and compatibility with the media they will encounter. Here, we analyze four common materials: copper, stainless steel, carbon steel, and titanium.

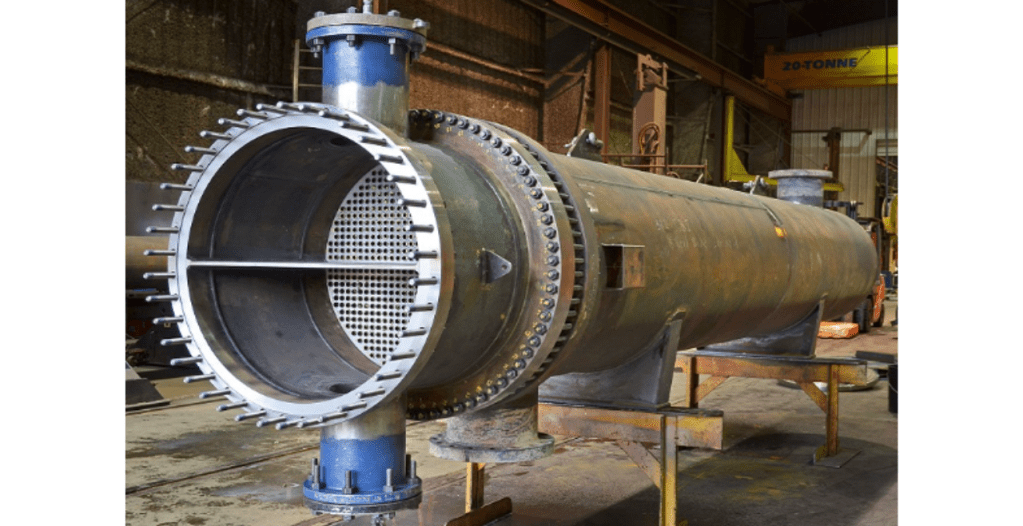

Illustrative image related to heat exchanger systems

How Does Copper Perform in Heat Exchanger Applications?

Copper is renowned for its excellent thermal conductivity, making it a preferred choice in applications requiring efficient heat transfer. It typically operates effectively at temperatures up to 200°C and can withstand moderate pressures. However, copper’s susceptibility to corrosion, especially in aggressive environments, can limit its use.

Pros: Copper’s high thermal conductivity ensures efficient heat exchange, and its antimicrobial properties make it suitable for food and beverage applications.

Cons: The cost of copper can be high, and its corrosion resistance is inadequate in certain environments, necessitating protective coatings or treatments.

Impact on Application: Copper is ideal for applications involving water or non-corrosive fluids but may not be suitable for chemical processing involving acids or chlorides.

Considerations for International Buyers: Compliance with standards like ASTM B280 (for copper tubing) is essential. Buyers in regions such as Africa and South America should also consider local corrosion risks, which may necessitate additional protective measures.

Why Choose Stainless Steel for Heat Exchanger Systems?

Stainless steel is widely used in heat exchangers due to its excellent corrosion resistance and ability to withstand high temperatures and pressures. It typically operates well in environments up to 300°C and is compatible with a wide range of fluids.

Pros: Its durability and resistance to oxidation make stainless steel a long-lasting choice, suitable for various applications, including food processing and petrochemical industries.

Cons: The initial cost of stainless steel can be higher than that of other materials, and its manufacturing process may require more complex fabrication techniques.

Impact on Application: Stainless steel is versatile, suitable for both clean and corrosive media, including water, oils, and chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM A312 for stainless steel pipes is crucial. Buyers should also be aware of local market preferences for specific grades, such as 304 or 316 stainless steel, which may vary by region.

What Are the Advantages of Carbon Steel in Heat Exchanger Systems?

Carbon steel is a cost-effective material commonly used in heat exchangers, particularly for applications involving water or steam. It typically operates effectively at temperatures up to 400°C and can handle high pressures.

Pros: Carbon steel’s affordability and strength make it an attractive choice for large-scale industrial applications.

Cons: Its susceptibility to corrosion limits its use in environments where aggressive fluids are present, often requiring protective coatings or regular maintenance.

Illustrative image related to heat exchanger systems

Impact on Application: Carbon steel is suitable for applications involving water or steam but may not perform well with corrosive chemicals.

Considerations for International Buyers: Buyers should consider compliance with standards like ASTM A106 for carbon steel pipes. In regions with high humidity or corrosive conditions, additional protective measures may be necessary.

Why Is Titanium a Preferred Material for Specialized Heat Exchanger Systems?

Titanium is increasingly used in heat exchangers for its outstanding corrosion resistance and strength-to-weight ratio. It can operate effectively in extreme environments, with temperature capabilities exceeding 600°C.

Pros: Titanium’s resistance to corrosion makes it suitable for aggressive media, including seawater and acidic fluids.

Cons: The high cost and complexity of manufacturing titanium heat exchangers can be prohibitive for some applications.

Illustrative image related to heat exchanger systems

Impact on Application: Titanium is ideal for specialized applications in the chemical and marine industries, where corrosion resistance is paramount.

Considerations for International Buyers: Compliance with standards such as ASTM B338 for titanium tubing is essential. Buyers should also consider the availability and cost implications of titanium in their specific regions.

Summary Table of Material Selection for Heat Exchanger Systems

| Material | Typical Use Case for heat exchanger systems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Domestic heating, refrigeration systems | Excellent thermal conductivity | Susceptible to corrosion | High |

| Stainless Steel | Food processing, petrochemical applications | High corrosion resistance | Higher initial cost | Med |

| Carbon Steel | Water and steam applications | Cost-effective and strong | Prone to corrosion | Low |

| Titanium | Chemical processing, marine applications | Outstanding corrosion resistance | High cost and complex manufacturing | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in heat exchanger systems, aiding informed decision-making for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for heat exchanger systems

What Are the Main Stages of Manufacturing Heat Exchanger Systems?

The manufacturing process for heat exchangers involves several critical stages that ensure the final product meets rigorous performance and safety standards. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Heat Exchanger Manufacturing?

Material preparation is the first step in the manufacturing process. It involves selecting the appropriate raw materials, typically conductive metals such as stainless steel, copper, or aluminum, depending on the specific application and operating conditions. The materials must be free from defects and impurities, as these can affect the heat exchanger’s efficiency and durability.

Once selected, the materials undergo cutting and shaping to create components like tubes, plates, or shells. Advanced techniques such as laser cutting or water jet cutting are often employed to ensure precision. This stage is critical, as the quality of the raw materials and their preparation directly influences the heat exchanger’s performance.

What Forming Techniques Are Used in Heat Exchanger Production?

Forming is the next stage, where the prepared materials are shaped into the necessary components of the heat exchanger. Common forming techniques include bending, rolling, and stamping. For instance, tubes may be bent to specific angles to fit within a shell, while plates are often stamped to create grooves that enhance surface area for heat transfer.

Innovative techniques such as extrusion are also utilized, particularly for creating complex geometries that optimize heat transfer efficiency. The choice of forming technique is guided by the design requirements and the intended application, ensuring that the heat exchanger performs optimally under various operational conditions.

How Are Heat Exchanger Components Assembled?

After forming, the components are assembled to create the complete heat exchanger. This stage often involves welding, brazing, or bolting, depending on the design and material compatibility. For example, shell and tube heat exchangers typically use welding to join the tubes to the shell, ensuring a robust and leak-proof structure.

Quality control is paramount during assembly. Each joint must be inspected to prevent leaks and ensure structural integrity. Automated welding techniques, such as TIG or MIG welding, can enhance precision and reduce human error, which is crucial for maintaining high-quality standards.

Illustrative image related to heat exchanger systems

What Finishing Processes Are Applied to Heat Exchangers?

Finishing processes enhance the durability and efficiency of heat exchangers. Common finishing techniques include surface treatment, coating, and cleaning. Surface treatments like passivation remove impurities and enhance corrosion resistance, critical for applications in harsh environments such as chemical processing.

Coatings, such as epoxy or polyurethane, are often applied to protect against corrosion and improve thermal efficiency. Finally, thorough cleaning is conducted to eliminate any residues from manufacturing, ensuring that the heat exchanger operates at peak efficiency from the outset.

How Is Quality Assurance Managed in Heat Exchanger Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for heat exchangers. It ensures that the products meet international standards and specific industry requirements.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems, emphasizing consistent product quality and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are essential, especially for heat exchangers used in critical applications like oil and gas.

B2B buyers should verify that suppliers adhere to these standards, as compliance indicates a commitment to quality and reliability. Understanding these certifications is crucial for buyers from regions like Africa and South America, where local standards may differ significantly from international norms.

What Are the Key Quality Control Checkpoints in Heat Exchanger Manufacturing?

Quality control checkpoints are established throughout the manufacturing process to ensure that each component and the final product meet predefined standards. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specifications before they enter the production line.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing process help identify and rectify any issues early on, minimizing waste and rework.

- Final Quality Control (FQC): The finished heat exchanger undergoes comprehensive testing, including pressure tests and thermal performance evaluations, to ensure it meets operational requirements.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers can take several steps to verify a supplier’s quality control measures. Conducting supplier audits is a proactive approach, allowing buyers to assess the manufacturing processes, quality management systems, and compliance with international standards firsthand.

Illustrative image related to heat exchanger systems

Additionally, requesting quality control reports and certifications can provide insights into the supplier’s commitment to quality. Engaging third-party inspection services can also add an extra layer of assurance, especially for high-stakes projects where failure is not an option.

What Are the Unique Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like the Middle East and Europe, must navigate varying quality control expectations and regulations. Understanding local market requirements, including customs regulations and certification needs, is critical for successful procurement.

Moreover, language barriers and cultural differences can impact communication regarding quality standards. Buyers should establish clear channels of communication with suppliers, ensuring that quality expectations are understood and met. Regular follow-ups and engagement can help bridge any gaps, fostering a productive partnership that prioritizes quality.

Conclusion

The manufacturing processes and quality assurance measures for heat exchanger systems are complex and multifaceted. B2B buyers must understand these processes to make informed purchasing decisions. By considering the stages of manufacturing, relevant quality standards, and verification methods, buyers can ensure they partner with reliable suppliers who prioritize quality and efficiency in their heat exchanger systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heat exchanger systems’

This guide is designed to assist B2B buyers in the effective sourcing of heat exchanger systems. By following this checklist, you can ensure that your procurement process is thorough, efficient, and tailored to meet your specific operational needs.

Illustrative image related to heat exchanger systems

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for your heat exchanger systems. This includes understanding the types of fluids involved, the temperature and pressure conditions, and the required heat transfer efficiency. Proper specifications will help you communicate your needs effectively to potential suppliers, ensuring they can provide suitable solutions.

Step 2: Research Different Types of Heat Exchangers

Familiarize yourself with various heat exchanger types, such as shell and tube, finned tube, and plate heat exchangers. Each type has unique characteristics that make it suitable for different applications. Understanding these differences allows you to make informed decisions and select a system that best fits your operational demands.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it is essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record of delivering high-quality heat exchangers and exceptional customer service.

Illustrative image related to heat exchanger systems

- Check for certifications such as ISO or ASME, which indicate adherence to industry standards.

- Review customer testimonials to gauge satisfaction and performance reliability.

Step 4: Assess Customization Capabilities

Determine if the supplier can provide customized heat exchanger solutions tailored to your specific processes. Customization may involve adjustments in design, materials, or size to meet unique operational requirements. Suppliers that offer bespoke solutions can better align their products with your business needs, leading to improved efficiency and performance.

Step 5: Inquire About Material Selection

Discuss the materials used in the heat exchangers with potential suppliers. The choice of materials is crucial as it affects durability, corrosion resistance, and thermal conductivity. Ensure that the materials are suitable for the fluids involved and can withstand the operational conditions they will face.

- Common materials include copper and steel, but also consider alternatives like specialized plastics or ceramics for specific applications.

Step 6: Understand Installation and Maintenance Requirements

Inquire about the installation process and maintenance support offered by the supplier. Proper installation is vital for optimal performance, while a robust maintenance plan can extend the lifespan of the heat exchanger. Ask for details on recommended maintenance schedules and any training that may be available for your team.

Step 7: Evaluate After-Sales Support and Warranty

Finally, assess the after-sales support and warranty options provided by the supplier. A strong warranty and responsive customer service can greatly enhance your purchasing experience and provide peace of mind. Ensure that the supplier is willing to assist with troubleshooting and repairs, should issues arise post-installation.

By following this checklist, you can streamline your procurement process and ensure that you select the most suitable heat exchanger systems for your business needs.

Comprehensive Cost and Pricing Analysis for heat exchanger systems Sourcing

What Are the Key Cost Components in Heat Exchanger Systems?

When sourcing heat exchanger systems, understanding the cost structure is paramount. The primary cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials constitute a significant portion of the costs, with conductive metals like copper and steel being the most common choices. The specific materials used can greatly influence both performance and pricing, especially when corrosive fluids are involved, necessitating more expensive alloys or coatings.

Illustrative image related to heat exchanger systems

Labor costs encompass not just the assembly of the heat exchangers, but also the skilled engineering required for design and installation. This is particularly relevant for customized systems where specific application requirements must be met.

Manufacturing overhead includes expenses related to facility operations, utilities, and maintenance of equipment. This often fluctuates based on production volume and operational efficiency.

Tooling costs arise from the need for specialized equipment to manufacture certain types of heat exchangers, such as those with unique designs or materials.

Quality Control (QC) is crucial, especially for industries with stringent safety regulations. Effective QC processes can add to the overall cost but are essential for ensuring reliability and compliance.

Illustrative image related to heat exchanger systems

Logistics costs involve the transportation of materials and finished products, which can vary significantly based on the geographic location of the buyer and supplier.

Finally, the margin for manufacturers and suppliers is influenced by market competition and demand, often leading to variations in pricing strategies.

How Do Price Influencers Affect Heat Exchanger Costs?

Several factors can influence the pricing of heat exchanger systems, impacting both the initial purchase price and the Total Cost of Ownership (TCO).

Volume and Minimum Order Quantity (MOQ) play a critical role; larger orders typically reduce the per-unit cost due to economies of scale.

Specifications and customization can also affect pricing. Tailored solutions often come with higher costs due to the additional design and engineering required.

Material selection significantly impacts cost, especially when high-performance or corrosion-resistant materials are necessary.

Quality certifications can add to the price, as products that meet international standards often require more rigorous testing and quality assurance processes.

Supplier factors such as reputation, reliability, and geographical location can also dictate pricing. For example, sourcing from a reputable supplier may incur higher costs but offers reliability and support.

Incoterms play an essential role in logistics and pricing. Understanding who is responsible for shipping, insurance, and tariffs can help buyers negotiate better deals and avoid unexpected costs.

What Are Effective Buyer Tips for Sourcing Heat Exchanger Systems?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, being strategic in sourcing heat exchanger systems can lead to significant savings.

Negotiation is key. Buyers should leverage competitive bids from multiple suppliers to drive down prices. Understanding the cost structure can also provide leverage during negotiations.

Cost-efficiency should be a primary focus. Buyers should consider not only the purchase price but also the TCO, which includes installation, maintenance, and operational costs over the product’s lifespan.

Pricing nuances in international markets can vary significantly. Buyers must account for currency fluctuations, tariffs, and shipping costs, which can impact overall pricing.

Finally, maintaining a clear line of communication with suppliers about expectations, timelines, and quality requirements can foster better relationships and potentially lead to more favorable pricing agreements.

Disclaimer on Indicative Prices

Prices for heat exchanger systems can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and obtain multiple quotes to understand the range of pricing in their specific context. Always consider the long-term value and reliability of the heat exchanger system in addition to the upfront costs.

Alternatives Analysis: Comparing heat exchanger systems With Other Solutions

Exploring Alternatives to Heat Exchanger Systems: What Are Your Options?

In the realm of industrial heat management, heat exchanger systems are a popular choice for transferring heat between two fluids without mixing them. However, other technologies and methods can also achieve similar outcomes. Understanding these alternatives is crucial for B2B buyers aiming to optimize their operations, particularly in diverse markets like Africa, South America, the Middle East, and Europe.

Comparison of Heat Exchanger Systems and Alternative Solutions

| Comparison Aspect | Heat Exchanger Systems | Direct Contact Heat Exchangers | Cooling Towers |

|---|---|---|---|

| Performance | Highly efficient, suitable for various applications | High thermal efficiency in specific scenarios | Effective for large-scale cooling |

| Cost | Moderate to high initial investment, depending on type | Generally lower initial cost, but may have higher operational costs | Lower capital cost but can require significant water and energy |

| Ease of Implementation | Requires skilled installation and ongoing maintenance | Simpler to install, but may need careful monitoring | Relatively straightforward installation, but dependent on water source |

| Maintenance | Regular maintenance needed to ensure efficiency | Lower maintenance but requires monitoring of fluid quality | Requires regular cleaning and water treatment |

| Best Use Case | Industrial processes, HVAC, power generation | Applications with high-temperature fluids | Large industrial plants needing cooling |

Understanding Direct Contact Heat Exchangers: Pros and Cons

Direct contact heat exchangers (DCHE) operate by allowing two fluids to come into direct contact, enabling efficient heat transfer. Their primary advantage lies in their simplicity and lower initial costs compared to traditional heat exchangers. They are particularly effective in applications involving high-temperature fluids and can achieve high thermal efficiency. However, they require careful monitoring of the fluids’ quality and can lead to contamination, making them less ideal for processes needing stringent cleanliness standards.

Illustrative image related to heat exchanger systems

Analyzing Cooling Towers: Benefits and Limitations

Cooling towers are an effective alternative for large-scale cooling applications, especially in industrial settings. They work by transferring heat from water to the atmosphere, making them suitable for power plants, manufacturing facilities, and HVAC systems. The initial investment for cooling towers is typically lower than that of heat exchangers, and they can handle significant cooling loads. However, they depend heavily on water availability and require ongoing maintenance to prevent issues like algae growth and scale buildup, which can affect efficiency.

How Should B2B Buyers Choose the Right Solution?

When considering heat exchanger systems versus alternatives like direct contact heat exchangers or cooling towers, B2B buyers must evaluate their specific operational needs, budget constraints, and maintenance capabilities. Factors such as the required thermal efficiency, the nature of the fluids involved, and site-specific conditions, like water availability, should guide the decision-making process. Ultimately, selecting the right technology involves balancing performance, cost, and ease of implementation to ensure optimal efficiency and safety in heat management processes.

Essential Technical Properties and Trade Terminology for heat exchanger systems

What Are the Key Technical Properties of Heat Exchanger Systems?

Understanding the critical specifications of heat exchanger systems is essential for B2B buyers looking to make informed purchasing decisions. Here are several key properties to consider:

Illustrative image related to heat exchanger systems

1. Material Grade

Heat exchangers are typically constructed from materials like stainless steel, copper, or specialized alloys. The material grade affects thermal conductivity, corrosion resistance, and overall durability. For instance, stainless steel offers excellent corrosion resistance and is suitable for a wide range of applications, while copper is often used for its superior thermal conductivity. Selecting the right material can influence the longevity and efficiency of the heat exchanger, directly impacting operational costs and maintenance schedules.

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions and is crucial in the manufacturing of heat exchangers. Precise tolerances ensure proper fit and function within a system, minimizing the risk of leaks or inefficiencies. In B2B contexts, understanding tolerance levels can help buyers evaluate manufacturer capabilities and ensure that components will integrate seamlessly into existing systems, thereby reducing installation complications.

3. Heat Transfer Efficiency

This specification measures how effectively a heat exchanger can transfer heat between mediums. It is typically quantified by the overall heat transfer coefficient (U-value), which is influenced by design, material, and flow arrangement. High heat transfer efficiency leads to better energy savings and improved process performance. Buyers should prioritize vendors who provide detailed performance data to assess how a specific model will meet their operational needs.

4. Pressure Rating

The pressure rating indicates the maximum pressure a heat exchanger can withstand during operation. This specification is critical for applications in high-pressure environments, such as chemical processing or power generation. Selecting a heat exchanger with an appropriate pressure rating ensures safety and reliability, preventing potential failures that could result in costly downtime or hazardous situations.

5. Surface Area

The surface area of a heat exchanger directly affects its heat transfer capacity. Larger surface areas facilitate better heat exchange, which can lead to improved efficiency. B2B buyers should consider the specific requirements of their applications to determine the optimal surface area needed for effective heat transfer, balancing performance with space constraints and cost.

6. Flow Configuration

Flow configuration defines how fluids move through the heat exchanger—common types include counterflow, parallel flow, and crossflow. Each configuration has its advantages and disadvantages in terms of heat transfer efficiency and pressure drop. Understanding these configurations helps buyers choose the right type for their specific application, optimizing performance and energy use.

Illustrative image related to heat exchanger systems

What Are the Common Trade Terms in Heat Exchanger Systems?

Familiarity with industry jargon is essential for navigating the procurement process effectively. Here are several common terms used in the heat exchanger industry:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the heat exchanger industry, working with an OEM can ensure that buyers receive high-quality, reliable components that meet specific standards and certifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure they can meet their procurement needs without overcommitting financially. It can also influence negotiation strategies and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products or services. In the context of heat exchangers, an RFQ helps buyers compare options and negotiate better deals, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms is vital for B2B buyers to understand shipping costs, delivery timelines, and liability during transportation, ultimately affecting total cost calculations.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For heat exchanger systems, understanding lead times can help businesses plan their projects and manage workflow efficiently, avoiding delays in production or operation.

By grasping these essential properties and terminologies, B2B buyers can make more informed decisions, optimizing their procurement processes and enhancing overall operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the heat exchanger systems Sector

What Are the Current Market Dynamics and Key Trends in the Heat Exchanger Systems Sector?

The global heat exchanger systems market is experiencing substantial growth driven by several factors, including increased demand for energy-efficient solutions, rapid industrialization, and the need for advanced thermal management systems across various sectors. The rise in energy costs and the pressing need for sustainability are prompting businesses to seek innovative heat transfer solutions that optimize energy consumption. In regions like Africa and South America, where industrial growth is accelerating, the demand for heat exchangers is expected to surge as industries such as oil and gas, power generation, and manufacturing expand.

Emerging technologies such as digital twins and IoT-enabled heat exchangers are reshaping how businesses approach sourcing. These technologies allow for real-time monitoring and predictive maintenance, leading to enhanced operational efficiency and reduced downtime. As international B2B buyers look to invest in heat exchanger systems, understanding the capabilities of these technologies will be critical. In Europe and the Middle East, regulatory frameworks are increasingly favoring systems that demonstrate energy efficiency and reduced environmental impact, further influencing sourcing decisions.

Moreover, the shift towards modular and customizable heat exchanger designs is gaining traction, allowing businesses to tailor solutions to their specific needs. This adaptability is particularly vital in regions facing unique climatic and operational challenges, such as Brazil and Nigeria, where extreme temperatures can affect system performance. By aligning sourcing strategies with these trends, international buyers can enhance their competitive edge in the marketplace.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Heat Exchanger Market?

Sustainability is becoming a cornerstone of procurement strategies in the heat exchanger systems sector. The environmental impact of manufacturing processes and the use of materials in heat exchangers is under scrutiny. As international regulations become stricter, buyers are increasingly prioritizing products that adhere to sustainable practices, such as reduced carbon emissions and lower energy consumption.

Ethical supply chains are crucial in meeting these sustainability goals. B2B buyers are now more inclined to partner with manufacturers that demonstrate a commitment to ethical sourcing, including fair labor practices and responsible resource management. Certifications such as ISO 14001 (Environmental Management) and Energy Star can serve as benchmarks for identifying suppliers that align with these values.

Furthermore, the adoption of ‘green’ materials—such as recyclable metals and eco-friendly coatings—can enhance the sustainability profile of heat exchangers. By sourcing systems that utilize these materials, companies not only reduce their ecological footprint but also appeal to environmentally conscious consumers and stakeholders.

What Is the Brief Evolution and History of Heat Exchanger Systems Relevant to B2B Buyers?

The history of heat exchangers dates back to the early 19th century, with significant advancements occurring during the industrial revolution. Initially, these systems were rudimentary, primarily serving to transfer heat in steam engines and basic heating applications. However, as industries evolved, so did the technology. The introduction of materials like stainless steel and innovations in design, such as the shell and tube configuration, significantly enhanced efficiency and durability.

In the latter half of the 20th century, the focus shifted towards energy conservation and environmental protection, leading to the development of more sophisticated heat exchangers that could operate under diverse conditions and handle various fluids. Today, the evolution continues with the integration of digital technologies and a strong emphasis on sustainability. For B2B buyers, understanding this evolution is essential, as it highlights the importance of selecting heat exchangers that not only meet current operational needs but also align with future trends in sustainability and efficiency.

Frequently Asked Questions (FAQs) for B2B Buyers of heat exchanger systems

-

How do I solve issues related to heat exchanger efficiency?

To address efficiency issues with heat exchangers, first, conduct a thorough analysis of the system’s design and application. Common problems include fouling, improper flow rates, or incorrect material selection. Regular maintenance, such as cleaning and inspections, can also prevent efficiency losses. If issues persist, consider consulting with a heat exchanger specialist to evaluate your system and recommend upgrades or replacements tailored to your specific operational needs. -

What is the best type of heat exchanger for industrial applications?

The best type of heat exchanger for industrial applications often depends on the specific process and fluids involved. Shell and tube heat exchangers are commonly favored for their robustness and versatility, especially in high-pressure situations. For applications requiring compact designs, plate heat exchangers offer excellent heat transfer efficiency. Consider factors such as fluid properties, temperature ranges, and space constraints when selecting the most suitable option. -

How can I vet a supplier of heat exchanger systems?

To vet a supplier effectively, start by assessing their industry experience and technical expertise. Request references and case studies to evaluate their past performance in similar applications. Check for certifications and compliance with international standards, such as ISO 9001, which indicate a commitment to quality. Additionally, engage in discussions about their manufacturing processes and after-sales support to ensure they align with your operational requirements. -

What customization options are available for heat exchanger systems?

Customization options for heat exchangers vary widely and can include alterations in size, materials, and configurations to meet specific process requirements. Suppliers can adapt designs based on fluid types, temperature ranges, and space constraints. Discuss your operational goals and challenges with potential suppliers to explore tailored solutions that maximize efficiency and performance for your unique application. -

What are the typical minimum order quantities (MOQs) for heat exchangers?

Minimum order quantities (MOQs) for heat exchangers can vary significantly depending on the supplier and the complexity of the design. For standard models, MOQs may be lower, while custom designs often require higher quantities to justify production costs. Engage with suppliers to understand their MOQ policies and negotiate terms that align with your project needs, especially if you’re entering new markets. -

What payment terms should I expect when purchasing heat exchanger systems?

Payment terms for heat exchanger systems typically vary by supplier and can include options like upfront deposits, progress payments, or net payment terms (e.g., 30, 60, or 90 days post-delivery). It is crucial to clarify these terms during negotiations to ensure they align with your financial planning. Additionally, consider discussing payment options that may offer discounts for early payments or bulk orders. -

How do I ensure quality assurance (QA) for my heat exchanger purchase?

To ensure quality assurance in your heat exchanger purchase, select suppliers with robust QA processes and certifications. Inquire about their testing procedures, including performance evaluations and material inspections. Request documentation such as compliance certificates and test reports. Establish clear acceptance criteria and consider on-site inspections or third-party audits to confirm that the heat exchangers meet your specifications and quality standards. -

What logistics considerations should I keep in mind for international shipments of heat exchangers?

When planning for international shipments of heat exchangers, consider factors such as shipping methods, customs regulations, and potential tariffs. Collaborate with suppliers to ensure proper packaging and labeling to prevent damage during transit. Additionally, assess lead times and coordinate delivery schedules to align with your operational timelines. Engaging a logistics partner experienced in international trade can facilitate smoother transactions and compliance with local regulations.

Top 5 Heat Exchanger Systems Manufacturers & Suppliers List

1. Danfoss – Heat Exchangers

Domain: theengineeringmindset.com

Registered: 2015 (10 years)

Introduction: Danfoss heat exchangers increase efficiency, reduce refrigerant charge, and save space in HVAC systems. Types of heat exchangers include coil and plate designs, with common applications such as finned tube coils in air handling units, duct plate heat exchangers for thermal energy exchange without moisture transfer, trench heaters for perimeter heating, duct electric heaters using open coil element…

2. CORE – Heat Exchangers

Domain: core.life

Introduction: CORE heat exchangers are designed for energy-efficient heating and ventilation systems, ensuring effective heating of room air with optimum energy efficiency. They transfer heat from one medium to another, typically air or water, and are essential for improving the energy efficiency of heating and ventilation systems. CORE offers a wide range of products, including counterflow and crossflow heat e…

3. Bryant – Heat Exchangers

Domain: bryant.com

Registered: 1996 (29 years)

Introduction: A heat exchanger is a vital component in HVAC systems designed to transfer heat between two or more fluids without mixing them. Its primary function is to efficiently transfer thermal energy, ensuring optimal temperature regulation in residential and commercial spaces. Heat exchangers operate on thermodynamic principles, transferring heat from a hotter fluid to a cooler one through conduction, con…

4. Neural Concept – Heat Exchangers

Domain: neuralconcept.com

Registered: 2018 (7 years)

Introduction: Heat exchangers are devices that facilitate efficient heat transfer between fluids without mixing them. They are crucial in various industries, including HVAC, automotive, and chemical production, enhancing energy efficiency and reducing waste. Key types include: 1. Double Pipe Heat Exchangers: Versatile for various fluids, easy maintenance, economical for small-scale uses, and used in chemical pr…

5. Emerson – Heat Exchanger Monitoring Solutions

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Heat Exchanger Monitoring Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for heat exchanger systems

In summary, the strategic sourcing of heat exchanger systems is pivotal for businesses aiming to enhance operational efficiency and safety. By understanding the diverse types of heat exchangers, their applications, and the importance of tailored designs, international B2B buyers can make informed decisions that align with their specific industrial needs. Prioritizing high-quality materials and effective maintenance strategies not only prolongs the lifespan of heat exchangers but also ensures optimal performance and cost savings in the long run.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable and efficient heat exchanger systems is set to rise. Businesses must leverage strategic sourcing to identify reputable suppliers who can offer customized solutions that cater to local conditions and regulations.

Now is the time for B2B buyers to act. By investing in advanced heat exchanger technologies and establishing strong supplier partnerships, companies can position themselves for success in a competitive global landscape. Embrace this opportunity to enhance your operations and drive sustainable growth in your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.