The Definitive Guide to Frosted Plexiglass 4 X 8 Sheet: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for frosted plexiglass 4 x 8 sheet

In today’s competitive landscape, sourcing high-quality frosted plexiglass 4 x 8 sheets poses a significant challenge for international B2B buyers. With the increasing demand for versatile materials in various industries—ranging from construction and design to signage and retail—making informed purchasing decisions is crucial. This guide serves as a comprehensive resource, addressing not only the diverse types and applications of frosted plexiglass but also the essential aspects of supplier vetting, pricing strategies, and logistics considerations.

By delving into the unique properties of frosted plexiglass, including its lightweight durability and aesthetic appeal, buyers can better understand how to leverage this material for their specific needs. Additionally, we will explore key factors that influence cost, helping businesses from regions such as Africa, South America, the Middle East, and Europe—including Brazil and Nigeria—navigate the complexities of international procurement.

With detailed insights and actionable strategies, this guide empowers B2B buyers to make confident and informed decisions, ensuring they secure the best products for their projects while optimizing their supply chain efficiencies. Whether you are looking to enhance your product offerings or streamline your operations, understanding the nuances of frosted plexiglass is essential for maintaining a competitive edge in the global market.

Understanding frosted plexiglass 4 x 8 sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Frosted Cast Acrylic | Smooth surface, high clarity, customizable thicknesses | Signage, displays, furniture | Pros: Excellent light diffusion, easy to shape. Cons: More expensive than extruded options. |

| Frosted Extruded Acrylic | Uniform thickness, lower cost, good impact resistance | Retail displays, protective barriers, windows | Pros: Cost-effective, lightweight. Cons: Less clarity than cast acrylic, may warp under heat. |

| Frosted Polycarbonate | Superior impact resistance, UV resistant | Safety shields, industrial applications | Pros: Extremely durable, shatterproof. Cons: Higher weight and cost compared to acrylic. |

| Textured Frosted Acrylic | Unique surface texture, enhances light diffusion | Decorative panels, architectural features | Pros: Aesthetic appeal, customizable designs. Cons: Can be more challenging to clean. |

| Frosted Colored Acrylic | Available in various colors, retains frosted finish | Creative projects, artistic installations | Pros: Versatile color options, good light transmission. Cons: Color may fade over time, less clarity than clear options. |

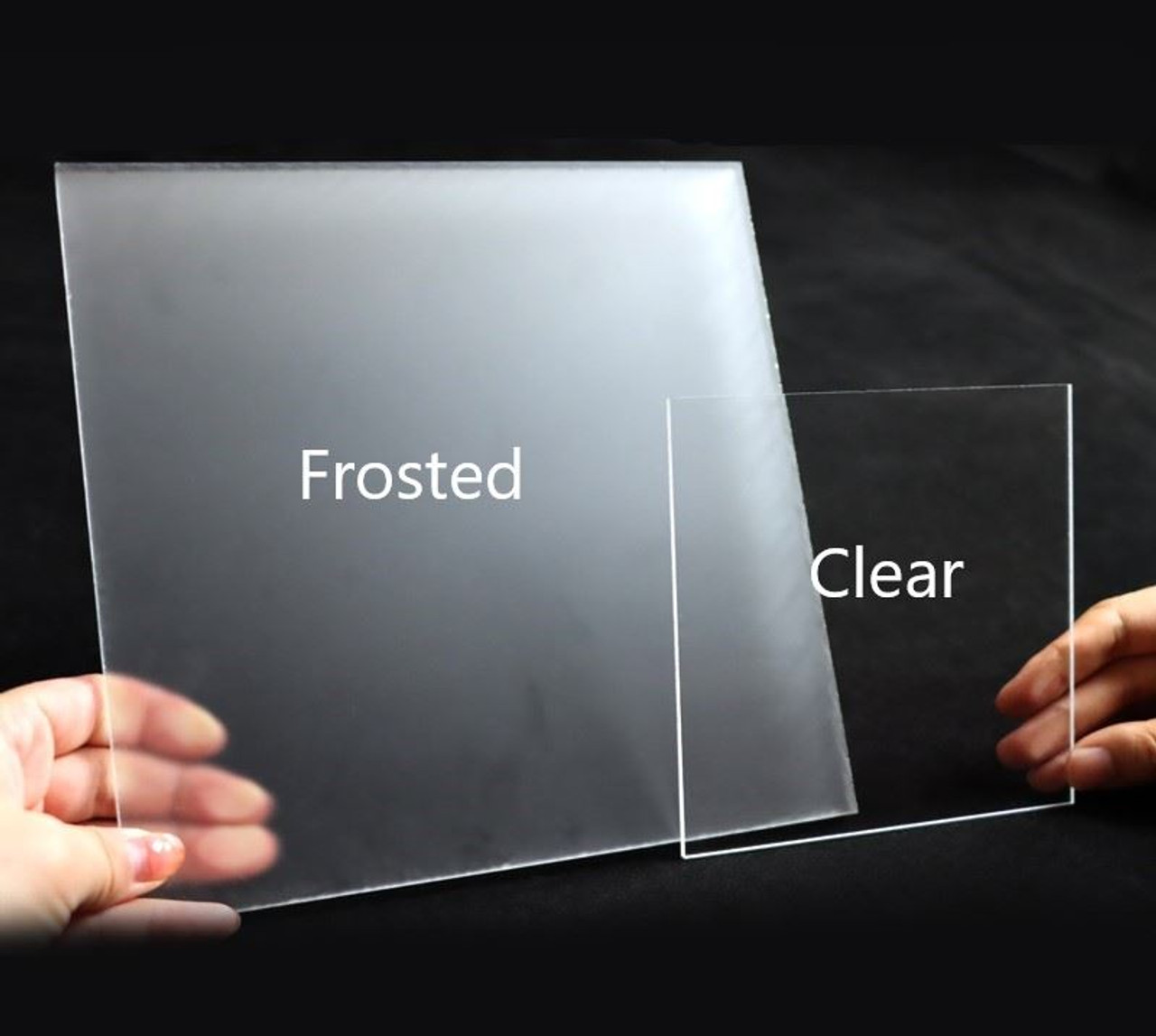

What are the Characteristics of Frosted Cast Acrylic Sheets?

Frosted cast acrylic sheets are known for their smooth surface and high clarity, making them an ideal choice for applications requiring excellent light diffusion. They are available in various thicknesses, allowing for customization based on specific project needs. These sheets are particularly well-suited for signage, displays, and furniture designs, where aesthetics and durability are paramount. When purchasing, buyers should consider the higher cost relative to extruded options, but the superior quality often justifies the investment.

Illustrative image related to frosted plexiglass 4 x 8 sheet

How do Frosted Extruded Acrylic Sheets Compare?

Frosted extruded acrylic sheets offer a more budget-friendly alternative to cast acrylic while maintaining good impact resistance. They are manufactured to provide uniform thickness, making them ideal for retail displays and protective barriers. However, they may not achieve the same level of clarity as cast acrylic and can warp under heat. Buyers looking for cost-effective solutions without compromising on basic performance will find extruded sheets appealing, especially in high-volume applications.

What Makes Frosted Polycarbonate Unique?

Frosted polycarbonate sheets stand out due to their exceptional impact resistance and UV protection. This makes them suitable for industrial applications where safety is a priority, such as safety shields and protective barriers. While they are heavier and generally more expensive than acrylic sheets, their durability makes them a worthwhile investment for businesses prioritizing long-term performance. Buyers should evaluate the trade-off between weight and durability when selecting materials for specific applications.

Why Choose Textured Frosted Acrylic Sheets?

Textured frosted acrylic sheets offer a unique aesthetic, enhancing light diffusion while providing an artistic touch to various projects. They are commonly used in decorative panels and architectural features, allowing for creative design possibilities. However, the textured surface can pose cleaning challenges, which buyers should consider. For projects that prioritize visual appeal alongside functionality, these sheets can provide a distinctive advantage.

What are the Benefits of Frosted Colored Acrylic Sheets?

Frosted colored acrylic sheets are available in an array of colors while maintaining the frosted finish that diffuses light effectively. These sheets are popular in creative projects and artistic installations, allowing businesses to customize their designs. However, buyers should be aware that colored sheets may fade over time and typically offer less clarity than clear options. When selecting frosted colored acrylic, consider the long-term visual impact and potential color stability to ensure it meets project requirements.

Key Industrial Applications of frosted plexiglass 4 x 8 sheet

| Industry/Sector | Specific Application of frosted plexiglass 4 x 8 sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Point of Purchase (POP) Displays | Enhances product visibility while maintaining privacy. | Consider thickness for durability and custom cut options for fit. |

| Architecture | Interior Partitions | Provides aesthetic appeal and light diffusion in spaces. | Ensure UV resistance and weather durability for long-term use. |

| Signage | Backlit Signage | Offers a soft glow effect, attracting customer attention. | Look for options with minimal scratching and easy customization. |

| Transportation | Window Screens in Vehicles | Reduces glare while maintaining visibility and safety. | Assess weight specifications and shatter-resistance for safety. |

| Hospitality | Decorative Room Dividers | Adds elegance and privacy in restaurants and hotels. | Evaluate thickness and finish options for desired light diffusion. |

How is Frosted Plexiglass Used in Retail POP Displays?

Frosted plexiglass sheets are commonly used in retail environments for point-of-purchase (POP) displays. Their frosted finish enhances product visibility while providing a level of privacy, making them ideal for showcasing items without detracting from the overall aesthetic. Retailers benefit from the lightweight nature of the material, which allows for easy installation and rearrangement. International buyers should consider sourcing options that allow for custom cutting and thickness to ensure the displays meet specific design requirements.

What Role Does Frosted Plexiglass Play in Architectural Applications?

In architecture, frosted plexiglass sheets serve as effective interior partitions, offering both functionality and style. They diffuse light, creating a soft ambiance while maintaining privacy in open-plan spaces. This material is particularly advantageous in regions with varying climates, as it is resistant to moisture and UV rays. Buyers in Africa, South America, and the Middle East should prioritize sourcing sheets that meet local building codes and can withstand environmental factors unique to their regions.

How Does Frosted Plexiglass Enhance Signage?

Frosted plexiglass is frequently utilized in backlit signage applications, where its ability to diffuse light creates an inviting glow. This characteristic is particularly beneficial for businesses looking to attract customers through effective visual communication. The material’s shatter-resistant properties also enhance safety, making it suitable for high-traffic areas. B2B buyers should focus on acquiring sheets that offer minimal scratching and customization options to align with branding needs.

What are the Benefits of Using Frosted Plexiglass in Vehicle Window Screens?

In the transportation sector, frosted plexiglass sheets are used as window screens in vehicles, providing glare reduction while maintaining visibility. This application is essential for enhancing driver and passenger comfort. The lightweight nature of plexiglass contributes to fuel efficiency, a key consideration for fleet operators. Buyers should evaluate the material’s shatter-resistance and weight specifications to ensure compliance with safety regulations and performance standards.

How is Frosted Plexiglass Used in the Hospitality Industry?

In the hospitality sector, frosted plexiglass sheets are increasingly used for decorative room dividers, adding an element of elegance and privacy in spaces such as restaurants and hotels. The ability to diffuse light creates a warm atmosphere while delineating areas without completely obstructing views. For international buyers, it’s crucial to assess the thickness and finish options available, as these factors will influence both the aesthetic appeal and functionality in diverse environments.

3 Common User Pain Points for ‘frosted plexiglass 4 x 8 sheet’ & Their Solutions

Scenario 1: Difficulty in Accurate Sizing and Cutting

The Problem:

B2B buyers often face challenges when it comes to sizing and cutting frosted plexiglass sheets to meet specific project requirements. In many cases, the standard 4 x 8 sheets may not fit the exact dimensions needed for installations, leading to wasted material and increased costs. Additionally, improper cutting techniques can lead to jagged edges or cracks, making the final product unappealing or unusable. This issue is particularly critical for businesses in industries such as signage, interior design, and construction, where precise measurements are crucial.

The Solution:

To address sizing and cutting challenges, buyers should invest in professional cutting services offered by suppliers who specialize in frosted plexiglass. Many distributors provide custom cutting options, allowing businesses to specify exact dimensions, thereby reducing waste. If buyers prefer to cut the sheets themselves, they should utilize specialized tools such as a table saw with a fine-toothed blade or a laser cutter, which can provide clean edges. Additionally, it is advisable to measure multiple times before cutting to ensure accuracy. Implementing these practices not only saves material costs but also enhances the quality of the finished product.

Scenario 2: Concerns About Durability and Scratch Resistance

The Problem:

Many B2B buyers are concerned about the durability and scratch resistance of frosted plexiglass, especially in high-traffic or industrial environments. While plexiglass is generally more shatter-resistant than glass, it is still susceptible to scratches that can diminish its appearance and functionality. This concern is particularly relevant for businesses in sectors like retail displays, where aesthetics and clarity are paramount.

The Solution:

To enhance the durability of frosted plexiglass sheets, businesses should consider applying a protective coating designed specifically for acrylic materials. These coatings can significantly improve scratch resistance and UV protection, extending the lifespan of the sheets. Furthermore, buyers should ensure that the plexiglass is regularly cleaned with non-abrasive cleaners to prevent scratches from dirt and grime accumulation. Choosing higher-quality acrylic sheets with superior impact resistance can also mitigate durability concerns, providing a long-term solution for businesses reliant on these materials for their operations.

Scenario 3: Challenges with Light Diffusion and Aesthetics

The Problem:

A common issue faced by B2B buyers is ensuring that the frosted plexiglass provides the desired level of light diffusion without compromising aesthetics. In applications such as office partitions, lighting fixtures, or decorative displays, achieving the right balance of opacity and clarity is essential. Buyers may struggle to find the right product that meets their design specifications while also delivering effective light diffusion.

The Solution:

To achieve optimal light diffusion while maintaining aesthetic appeal, buyers should explore different grades and finishes of frosted plexiglass available in the market. Suppliers often provide samples or small sections that can be tested in situ to evaluate how well they diffuse light. It’s also beneficial to consult with manufacturers about the specific light transmission properties of their products. By combining different thicknesses or layering sheets, buyers can customize the light diffusion effect to fit their unique applications. Furthermore, considering the overall design context, such as the color palette and surrounding materials, can help in selecting the most appropriate frosted plexiglass for a cohesive look.

Strategic Material Selection Guide for frosted plexiglass 4 x 8 sheet

When selecting materials for frosted plexiglass 4 x 8 sheets, it’s essential to consider various types of acrylic and their unique properties. This guide will analyze four common materials: extruded acrylic, cast acrylic, polycarbonate, and glass, focusing on their performance, suitability for specific applications, and considerations for international B2B buyers.

What are the Key Properties of Extruded Acrylic for Frosted Plexiglass Sheets?

Extruded acrylic is known for its lightweight nature and ease of fabrication. It typically has a lower molecular weight compared to cast acrylic, making it less expensive and simpler to manufacture. However, it is also less durable, with a lower impact resistance. Extruded acrylic sheets are available in various thicknesses and can be easily cut and shaped, making them suitable for applications like signage and displays.

Pros: Cost-effective, easy to work with, lightweight.

Cons: Lower impact resistance, less clarity compared to cast acrylic.

Impact on Application: Suitable for indoor applications where high durability is not critical.

Considerations for Buyers: Ensure compliance with local standards, as extruded acrylic may not meet the same performance specifications as cast acrylic in some regions.

How Does Cast Acrylic Compare for Frosted Plexiglass Applications?

Cast acrylic is produced by pouring liquid acrylic into molds, resulting in a denser and more durable product. It offers superior optical clarity and UV resistance, making it ideal for high-end applications such as decorative panels and high-visibility signage. Cast acrylic is also more resistant to scratching than extruded acrylic.

Pros: Higher durability, better optical clarity, and UV resistance.

Cons: More expensive and complex to manufacture.

Impact on Application: Ideal for outdoor use and applications requiring high visibility.

Considerations for Buyers: Verify compliance with international standards like ASTM or DIN, especially for outdoor applications.

What are the Benefits and Limitations of Polycarbonate Sheets?

Polycarbonate is a robust thermoplastic that is shatter-resistant and offers high impact resistance, making it suitable for applications requiring durability, such as safety barriers and protective screens. However, it is more prone to scratching than acrylic and can be more expensive.

Pros: Extremely durable, high impact resistance.

Cons: Susceptible to scratching, potential for yellowing over time.

Impact on Application: Best for environments where safety and durability are paramount.

Considerations for Buyers: Ensure that polycarbonate sheets meet local safety standards, particularly in industrial applications.

How Does Glass Compare to Frosted Plexiglass for Applications?

Glass is a traditional material known for its clarity and aesthetic appeal. While it is heavier and more fragile than acrylic or polycarbonate, it offers excellent scratch resistance and UV protection. Glass is suitable for applications where aesthetics are crucial, such as in high-end retail displays.

Pros: Excellent clarity and scratch resistance, aesthetically pleasing.

Cons: Heavier, more fragile, and more expensive to transport.

Impact on Application: Suitable for upscale applications but requires careful handling.

Considerations for Buyers: Glass must comply with safety standards in many regions, and shipping costs can be higher due to its weight.

Summary of Material Properties and Considerations

| Material | Typical Use Case for frosted plexiglass 4 x 8 sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Extruded Acrylic | Indoor signage and displays | Cost-effective and easy to fabricate | Lower impact resistance | Low |

| Cast Acrylic | High-end decorative panels | Superior clarity and UV resistance | More expensive and complex to manufacture | High |

| Polycarbonate | Safety barriers and protective screens | Extremely durable and shatter-resistant | Susceptible to scratching | Medium |

| Glass | High-end retail displays | Excellent clarity and scratch resistance | Heavy and fragile | High |

This strategic material selection guide provides essential insights for B2B buyers in Africa, South America, the Middle East, and Europe, ensuring informed decisions that align with regional compliance and application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for frosted plexiglass 4 x 8 sheet

What are the Key Stages in the Manufacturing Process of Frosted Plexiglass 4 x 8 Sheets?

The manufacturing process of frosted plexiglass, particularly for 4 x 8 sheets, consists of several critical stages that ensure the final product meets the required specifications and quality standards.

-

Material Preparation: The process begins with sourcing high-quality polymethyl methacrylate (PMMA) resin, the primary material used in acrylic sheet production. This resin is either cast or extruded, with cast acrylic typically providing superior optical clarity and stability. The raw materials undergo rigorous quality checks to ensure they are free from impurities and meet the desired specifications for color, clarity, and consistency.

-

Forming Techniques: Depending on the desired properties, manufacturers may opt for either casting or extrusion methods. In casting, the PMMA is poured into molds and allowed to cure, resulting in a thicker, more durable sheet with a smoother finish. Extrusion, on the other hand, involves melting the resin and forcing it through a die to create sheets of varying thicknesses. The frosted finish is typically achieved during this stage, either through a surface treatment process or by mixing a frosted material into the resin before forming.

-

Assembly and Cutting: Once the sheets are formed, they are cut to size. For 4 x 8 sheets, precision cutting techniques such as laser cutting or CNC machining are employed to ensure accuracy and clean edges. This stage may also include additional processes such as drilling or routing, depending on the specific applications for which the sheets are intended.

-

Finishing Processes: After cutting, the sheets undergo finishing processes to enhance their aesthetic appeal and performance. This may include polishing edges, applying protective coatings, or additional texturing for improved grip or light diffusion. The frosted effect can be enhanced through treatments that create micro-patterns on the surface, ensuring that the material disperses light effectively while maintaining privacy.

What Quality Assurance Measures are Essential for Frosted Plexiglass Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing of frosted plexiglass sheets, ensuring that products meet international standards and customer expectations.

Illustrative image related to frosted plexiglass 4 x 8 sheet

-

International Standards Compliance: Manufacturers should adhere to internationally recognized standards such as ISO 9001, which focuses on quality management systems, and CE marking for products sold in the European Economic Area. These certifications demonstrate a commitment to quality and continuous improvement in manufacturing processes.

-

Quality Control Checkpoints: Key checkpoints in the quality control process include:

– Incoming Quality Control (IQC): Inspecting raw materials for conformity to specifications before production begins.

– In-Process Quality Control (IPQC): Monitoring production processes to detect any deviations in real-time, allowing for immediate corrective actions.

– Final Quality Control (FQC): Conducting thorough inspections of finished products, including dimensional checks, surface quality assessments, and testing for clarity and strength. -

Common Testing Methods: Various testing methods are employed to ensure the integrity of frosted plexiglass sheets, including:

– Impact Resistance Testing: Evaluating the shatter resistance of the material.

– UV Resistance Testing: Assessing the durability of the frosted finish under UV exposure.

– Clarity and Light Transmission Tests: Measuring how much light passes through the sheet and the uniformity of the frosted effect.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential to ensure product reliability.

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes, quality control measures, and adherence to international standards. Buyers should look for suppliers who welcome audits and provide transparency about their operations.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the frequency and outcomes of quality checks throughout the production process. These reports should include data from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These organizations can perform independent assessments of manufacturing processes and product quality, providing unbiased evaluations of a supplier’s capabilities.

What Nuances Should International Buyers Consider Regarding QC for Frosted Plexiglass?

International buyers should be aware of several nuances when it comes to quality control in the procurement of frosted plexiglass.

-

Regional Standards and Regulations: Different regions may have specific regulations and standards that affect product quality and safety. For example, the European Union has strict guidelines for materials used in construction and signage, which may differ from those in African or South American markets.

-

Cultural and Economic Factors: Understanding the cultural and economic landscape of a supplier’s country can provide context for their quality practices. For instance, suppliers in emerging markets may have different approaches to quality assurance due to varying levels of technology and resources.

-

Supply Chain Transparency: Buyers should seek suppliers who maintain transparency throughout their supply chains. This includes providing information about the sourcing of raw materials, manufacturing processes, and any third-party certifications.

In conclusion, the manufacturing and quality assurance processes for frosted plexiglass 4 x 8 sheets are complex and require meticulous attention to detail. By understanding these processes and actively verifying supplier practices, B2B buyers can ensure that they receive high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘frosted plexiglass 4 x 8 sheet’

To assist B2B buyers in procuring frosted plexiglass 4 x 8 sheets, this guide provides a systematic checklist to ensure a smooth and informed purchasing process. Frosted plexiglass, known for its aesthetic appeal and functional versatility, is ideal for various applications including signage, partitions, and decorative elements. Follow these steps to ensure you make a well-informed decision.

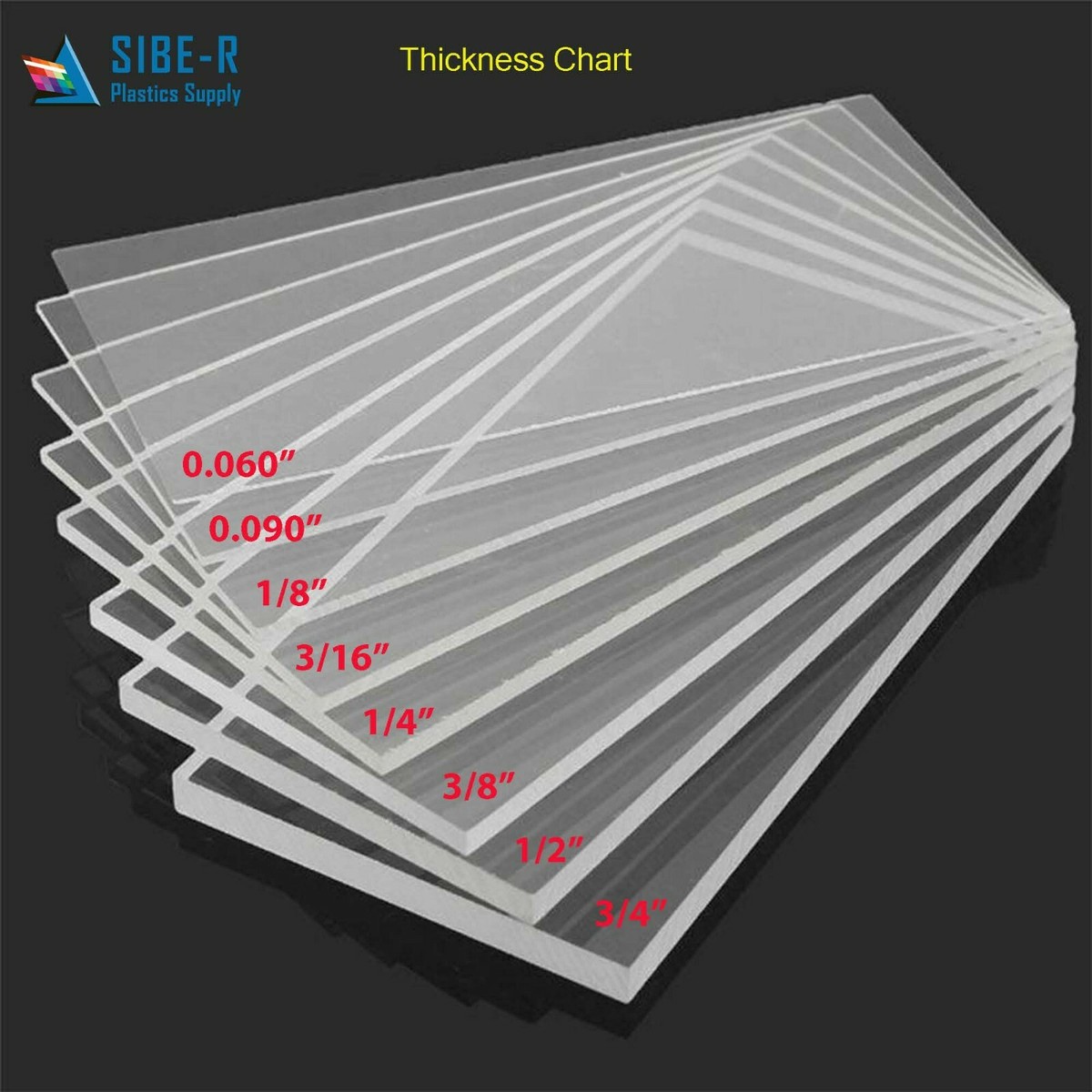

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before sourcing frosted plexiglass. Consider factors such as thickness, dimensions, and UV resistance. Understanding these requirements will help you communicate effectively with suppliers and ensure that the products meet your project’s needs.

- Thickness Options: Common thicknesses range from 1/8″ to 1/2″. Determine the right thickness based on your application.

- Surface Finish: Frosted sheets can vary in texture; decide if you need a smooth or more textured finish based on the aesthetic and functional requirements.

Step 2: Determine Your Budget

Creating a realistic budget is crucial for effective procurement. Frosted plexiglass sheets can vary significantly in price depending on factors such as quality, thickness, and supplier.

- Cost Analysis: Compare prices from different suppliers, considering shipping costs and potential tariffs for international purchases.

- Quality vs. Price: Balance your budget against the quality of the materials. Cheaper options may compromise durability and performance.

Step 3: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers. Look for manufacturers or distributors with a solid reputation in the industry.

- Supplier Credentials: Verify their certifications, such as ISO or other industry-specific standards.

- Customer Reviews: Check testimonials and case studies from previous clients to gauge reliability and product quality.

Step 4: Request Samples

Before making a large order, request samples of the frosted plexiglass sheets. This step allows you to assess the quality, texture, and color firsthand.

- Evaluate Samples: Inspect samples for clarity, finish, and overall quality. This will help you avoid surprises in your bulk order.

- Application Testing: If possible, test the samples in your intended application to ensure they meet performance expectations.

Step 5: Negotiate Terms and Conditions

Once you have selected a supplier, it’s important to negotiate favorable terms. This includes price, payment terms, delivery schedules, and warranties.

- Contractual Clarity: Ensure all terms are clearly stated in the contract to avoid misunderstandings.

- Delivery and Lead Times: Discuss the expected lead times for production and shipping to align with your project timelines.

Step 6: Verify Compliance and Quality Assurance

Confirm that the supplier adheres to international standards and regulations relevant to your region. This step is particularly important for international shipments.

- Quality Assurance Procedures: Inquire about their quality control processes to ensure that the products meet your specifications consistently.

- Compliance with Local Regulations: Ensure that the materials comply with any local building codes or environmental regulations.

Step 7: Plan for Logistics and Delivery

Lastly, finalize the logistics of your order. Understanding the delivery process will help you avoid delays.

- Shipping Options: Choose a shipping method that balances cost and delivery time.

- Customs and Import Duties: Familiarize yourself with any customs regulations and potential import duties to prevent unexpected expenses.

By following this checklist, B2B buyers can navigate the procurement of frosted plexiglass 4 x 8 sheets with confidence, ensuring they select the right product for their needs while establishing a solid relationship with reliable suppliers.

Comprehensive Cost and Pricing Analysis for frosted plexiglass 4 x 8 sheet Sourcing

Understanding the cost structure and pricing for frosted plexiglass 4 x 8 sheets is crucial for international B2B buyers aiming to optimize their procurement strategies. This analysis encompasses key cost components, price influencers, and practical buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Frosted Plexiglass Pricing?

-

Materials: The primary cost driver in frosted plexiglass sheets is the raw material, polymethyl methacrylate (PMMA). Prices can fluctuate based on global supply and demand dynamics, impacting the overall cost. High-quality PMMA generally commands a higher price but offers better durability and clarity.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process, which can vary significantly depending on the region. For instance, labor costs may be lower in countries like Nigeria compared to Europe, impacting the final pricing.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize overhead and reduce the overall cost of production.

-

Tooling: The initial investment in molds and cutting tools can be substantial, particularly for custom specifications. These costs are typically amortized over large production runs, so higher order volumes can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring that the product meets industry standards and customer specifications incurs additional costs. Investing in robust QC processes can enhance product reliability but may increase initial costs.

-

Logistics: Shipping costs depend on the distance to the buyer, the mode of transport, and the packaging requirements. For international shipments, factors like tariffs, insurance, and local handling can add significant costs.

-

Margin: Suppliers will incorporate a profit margin into their pricing. This margin can vary based on market conditions, competition, and the supplier’s positioning strategy.

What Factors Influence Pricing for Frosted Plexiglass Sheets?

-

Volume and Minimum Order Quantity (MOQ): Suppliers often set lower prices for larger orders due to economies of scale. Buyers should consider negotiating for bulk discounts, especially when sourcing from manufacturers.

-

Specifications and Customization: Custom sizes, thicknesses, or colors can significantly increase costs. Standard products typically have lower pricing, so buyers should assess whether customization is necessary.

-

Quality and Certifications: Higher quality products or those with specific certifications (e.g., UV resistance, fire safety) may command premium prices. Buyers should evaluate the importance of these certifications based on their application needs.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence costs. Established suppliers may charge more due to perceived value, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the agreed-upon Incoterms (International Commercial Terms) is vital, as they dictate responsibility for shipping costs and risks. Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact total landed costs.

What Are Effective Buyer Tips for Sourcing Frosted Plexiglass?

-

Negotiation Strategies: Engaging in open discussions about pricing can yield discounts. Consider exploring long-term contracts or repeat orders for better pricing terms.

-

Focus on Cost-Efficiency: Calculate the Total Cost of Ownership (TCO) by factoring in not just the purchase price, but also logistics, installation, and maintenance costs over the product’s lifecycle.

-

Understand Pricing Nuances for International Buyers: Currency fluctuations, import duties, and local market conditions can affect pricing. Buyers should conduct thorough market research to anticipate these variables.

-

Build Relationships with Suppliers: Establishing a strong rapport with suppliers can lead to better pricing, priority in production, and improved service levels.

Disclaimer on Pricing

Prices for frosted plexiglass sheets can vary widely based on the factors discussed above. It is advisable for buyers to obtain quotes from multiple suppliers to ensure competitive pricing and to verify that all specifications meet their project requirements.

Alternatives Analysis: Comparing frosted plexiglass 4 x 8 sheet With Other Solutions

When considering the use of a frosted plexiglass 4 x 8 sheet, it’s essential to evaluate alternative materials that can fulfill similar requirements. This analysis will highlight how these alternatives stack up against frosted plexiglass, providing B2B buyers with the necessary insights to make informed decisions based on their specific needs.

| Comparison Aspect | Frosted Plexiglass 4 X 8 Sheet | Acrylic Sheet (Clear) | Polycarbonate Sheet |

|---|---|---|---|

| Performance | Shatter-resistant, lightweight | Stronger than glass, UV resistant | Extremely durable, impact-resistant |

| Cost | Moderate cost, varies by thickness | Generally lower cost | Higher cost, premium durability |

| Ease of Implementation | Easy to cut and shape | Easy to cut, versatile | More challenging to cut, requires special tools |

| Maintenance | Susceptible to scratching | Scratches less, UV resistant | Highly resistant to scratches |

| Best Use Case | Decorative applications, privacy screens | Display cases, signage | Safety barriers, high-impact applications |

What Are the Pros and Cons of Using Acrylic Sheets as an Alternative?

Acrylic sheets, particularly in clear formats, provide a versatile and cost-effective alternative to frosted plexiglass. They are known for their clarity and UV resistance, making them ideal for applications such as display cases and signage. However, while they are less expensive, they can be more prone to scratching compared to frosted plexiglass. Thus, they may not offer the same aesthetic appeal for decorative or privacy applications.

How Does Polycarbonate Sheet Compare as a Durable Alternative?

Polycarbonate sheets stand out for their exceptional strength and impact resistance, making them suitable for applications requiring high durability, such as safety barriers and protective equipment. However, they come at a higher price point and can be more challenging to work with, requiring specialized tools for cutting and shaping. While they offer excellent performance in demanding environments, their application may be limited for decorative uses compared to frosted plexiglass.

What Factors Should Buyers Consider When Choosing Between These Options?

When selecting between frosted plexiglass, acrylic sheets, and polycarbonate, buyers should assess their specific use case requirements. For decorative applications where aesthetics and moderate durability are prioritized, frosted plexiglass is likely the best option. On the other hand, if the project demands high impact resistance and durability, polycarbonate may be more suitable. For general applications that do not require frosting, acrylic sheets provide a cost-effective solution with good clarity and UV resistance.

In conclusion, B2B buyers should carefully consider performance, cost, ease of implementation, and maintenance when choosing between frosted plexiglass and its alternatives. Evaluating these aspects against project requirements will ensure the selection of the most suitable material for their needs, ultimately leading to better outcomes in their applications.

Essential Technical Properties and Trade Terminology for frosted plexiglass 4 x 8 sheet

What are the Key Technical Properties of Frosted Plexiglass 4 x 8 Sheets?

Frosted plexiglass, commonly known as acrylic, offers a variety of technical properties that make it suitable for various applications in commercial environments. Understanding these properties is crucial for B2B buyers looking to make informed purchasing decisions.

1. Material Grade

Frosted plexiglass is primarily made from polymethyl methacrylate (PMMA), which is known for its excellent optical clarity, UV resistance, and impact strength. The material grade can impact the sheet’s durability and performance in different environments. Higher-grade materials typically offer better weather resistance and longevity, making them ideal for outdoor applications or areas with high wear and tear.

2. Thickness Tolerance

Thickness tolerance refers to the allowable variation in the sheet’s thickness. Most manufacturers provide a tolerance of ±10%, which means that a 1/4-inch sheet could vary between 0.217 and 0.236 inches. Understanding thickness tolerance is essential for applications requiring precise fittings, such as signage or display cases, where consistency in thickness can affect aesthetics and functionality.

3. Surface Finish

Frosted plexiglass has a textured surface that diffuses light, providing privacy while allowing light to pass through. This property is particularly valuable in office environments, where it can be used for partitions or decorative elements. The finish can also influence the sheet’s susceptibility to scratches and other wear, which is a consideration for buyers looking for longevity.

4. Impact Resistance

Frosted plexiglass is approximately 17 times stronger than glass and is shatter-resistant, making it a safer alternative for various applications, including safety barriers and protective screens. This property is especially important for businesses in sectors such as retail, where safety and durability are paramount.

Illustrative image related to frosted plexiglass 4 x 8 sheet

5. Weight

Plexiglass is significantly lighter than glass, which reduces shipping costs and makes handling easier during installation. For international buyers, especially in regions with high shipping costs, the lightweight nature of frosted plexiglass can lead to considerable savings.

6. UV Resistance

The UV resistance of frosted plexiglass protects against discoloration and degradation from sunlight exposure. This is particularly beneficial for applications in sunny climates, ensuring that the material maintains its appearance and structural integrity over time.

What Common Trade Terms Should B2B Buyers Know?

Navigating the procurement process for frosted plexiglass involves familiarizing oneself with industry jargon. Understanding these terms can facilitate smoother transactions and better communication with suppliers.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of frosted plexiglass, understanding whether a supplier is an OEM can impact the quality and reliability of the product.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ is essential for budgeting and inventory planning, as it can affect the overall cost and feasibility of purchasing.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products. This is a crucial step for buyers to assess market rates and negotiate favorable terms. An RFQ can also include specifications like size, thickness, and surface finish.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost of acquiring frosted plexiglass sheets.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is vital for project planning, especially in industries where timely delivery is critical.

6. Cut-to-Size

This term refers to the practice of customizing sheets to specific dimensions as per the buyer’s requirements. This service can save time and reduce waste, making it a popular option for businesses needing precise measurements for installation.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategy for frosted plexiglass 4 x 8 sheets, ensuring they make informed and efficient purchasing decisions.

Navigating Market Dynamics and Sourcing Trends in the frosted plexiglass 4 x 8 sheet Sector

What Are the Key Market Dynamics and Trends in the Frosted Plexiglass 4 x 8 Sheet Sector?

The global market for frosted plexiglass 4 x 8 sheets is driven by several factors, including the rising demand for versatile and lightweight materials across various sectors such as construction, interior design, and signage. The acrylic sheets, renowned for their durability and clarity, are increasingly favored over glass alternatives due to their shatter-resistant properties and ease of handling. Emerging trends indicate a shift towards customization and cut-to-size solutions, allowing businesses to meet specific project requirements efficiently. Additionally, advancements in manufacturing techniques, such as laser cutting and CNC machining, are enhancing the precision and quality of these sheets, making them more appealing to international buyers.

In regions like Africa, South America, the Middle East, and Europe, the demand for frosted plexiglass is being fueled by urbanization and infrastructural development. For example, in Brazil and Nigeria, the construction of commercial and residential properties is on the rise, creating a substantial market for decorative and functional acrylic sheets. Furthermore, the increasing focus on sustainable building materials is pushing suppliers to innovate and provide eco-friendly options that align with global sustainability goals.

How Is Sustainability Influencing the Sourcing of Frosted Plexiglass 4 x 8 Sheets?

Sustainability is a critical consideration for B2B buyers in the frosted plexiglass sector. The environmental impact of sourcing materials is under scrutiny, prompting businesses to seek suppliers who prioritize ethical and sustainable practices. The production of acrylic sheets involves significant energy consumption and resource use, making it essential for manufacturers to adopt greener technologies and materials.

Buyers are increasingly looking for certifications that validate the sustainability of their suppliers, such as ISO 14001 for environmental management and the use of recycled materials in production. Furthermore, manufacturers are innovating by developing eco-friendly frosted plexiglass options that minimize UV transmission and reduce energy costs in applications like signage and lighting. This shift not only meets regulatory requirements but also enhances brand reputation in an increasingly eco-conscious market.

What Is the Evolution of Frosted Plexiglass in B2B Applications?

The evolution of frosted plexiglass can be traced back to the early adoption of acrylic materials as a lightweight alternative to glass in the mid-20th century. Initially used primarily in signage and displays, advancements in manufacturing processes have broadened its application range significantly. Today, frosted plexiglass is integral in sectors such as architecture, interior design, and furniture manufacturing, where aesthetics and functionality are paramount.

Over the years, innovations in surface treatments have allowed for the production of frosted finishes that not only diffuse light but also provide privacy without sacrificing clarity. This evolution has positioned frosted plexiglass as a preferred choice for modern design projects, catering to the diverse needs of international B2B buyers who require both performance and aesthetic appeal in their sourcing decisions. As trends continue to evolve, the adaptability and versatility of frosted plexiglass will likely drive further growth in this sector.

Frequently Asked Questions (FAQs) for B2B Buyers of frosted plexiglass 4 x 8 sheet

-

How do I choose the right thickness for a frosted plexiglass 4 x 8 sheet?

Choosing the right thickness for your frosted plexiglass sheets largely depends on the intended application. Common thicknesses range from 1/8 inch (3mm) for lightweight projects like displays to 1/4 inch (6mm) for more substantial uses such as partitions or furniture. Consider factors such as structural integrity, weight limitations, and exposure to environmental elements. It’s also advisable to consult with suppliers about the best thickness for your specific needs, ensuring durability and cost-effectiveness in your purchase. -

What are the best applications for frosted plexiglass 4 x 8 sheets?

Frosted plexiglass sheets are highly versatile and ideal for various applications, including office partitions, signage, and decorative elements. Their ability to diffuse light makes them perfect for creating privacy while allowing natural light to filter through. Additionally, they are commonly used in retail displays, furniture design, and architectural elements. When considering a project, assess both aesthetic and functional requirements to determine how frosted plexiglass can enhance your design. -

How can I verify the quality of frosted plexiglass from suppliers?

To verify the quality of frosted plexiglass, request samples from potential suppliers to assess clarity, finish, and durability. Check for certifications that ensure compliance with industry standards, such as ASTM or ISO. Additionally, inquire about the manufacturing process, including whether the sheets are cast or extruded, as this affects their quality and application. Reading reviews and testimonials from previous clients can also provide insight into a supplier’s reputation and the quality of their products. -

What is the minimum order quantity (MOQ) for frosted plexiglass sheets?

Minimum order quantities for frosted plexiglass sheets can vary significantly among suppliers. Some may offer cut-to-size options with no MOQ, while others might require bulk orders starting at several sheets. When sourcing, it’s essential to clarify MOQ policies and explore options for bulk purchasing, which may provide cost savings. If your project requires a smaller quantity, consider looking for suppliers who specialize in custom orders or smaller-scale manufacturing. -

What payment terms should I expect when purchasing frosted plexiglass internationally?

Payment terms for international purchases can differ based on the supplier and the region. Common terms include upfront payment, a deposit with the remainder upon shipment, or net terms ranging from 30 to 90 days. It’s crucial to establish clear payment conditions before finalizing the order. Ensure that you understand any applicable taxes, tariffs, or additional fees that may arise during international transactions to avoid surprises. -

What are the shipping options for frosted plexiglass sheets?

Shipping options for frosted plexiglass sheets typically include air freight for expedited delivery or sea freight for cost-effective bulk shipping. The choice of shipping method will depend on your timeline and budget. Confirm with suppliers about their logistics partners and shipping policies, including packaging methods to ensure the sheets arrive undamaged. Additionally, consider the possibility of local distribution centers to reduce shipping times and costs. -

How should I handle and store frosted plexiglass sheets to prevent damage?

Proper handling and storage are crucial for maintaining the quality of frosted plexiglass sheets. Always wear protective gloves when handling to avoid fingerprints and scratches. Store the sheets flat in a cool, dry environment away from direct sunlight to prevent warping. If possible, use protective covers or padding to minimize the risk of damage during storage and transportation. Training your team on best practices for handling can also help maintain product integrity. -

What customization options are available for frosted plexiglass sheets?

Customization options for frosted plexiglass sheets often include varying thicknesses, sizes, and finishes, as well as the ability to incorporate specific colors or patterns. Many suppliers also offer cutting services to meet precise dimensions for your project. When discussing customization, provide detailed specifications and inquire about lead times and costs associated with these modifications. This will ensure that the final product meets your project requirements effectively.

Top 4 Frosted Plexiglass 4 X 8 Sheet Manufacturers & Suppliers List

1. Acme Plastics – Acrylic Sheets

Domain: acmeplastics.com

Registered: 1997 (28 years)

Introduction: Acrylic Sheets 4 ’x 8’ | 48” x 96” | Available in various types including Acrylic Cast Clear Sheet, Acrylic Extruded Clear Sheet, Acrylic P95 Sheets, Acrylic Non-Glare Sheet, Lucite L Clear Sheet, Acrylic Bullet Resistant Sheet, Acrylic Mirror Sheet, Acrylic Cast Color Sheet, Acrylic Cast White Sheet, Recycled Acrylic Clear Sheet, and Glowforge®-Compatible Acrylic Sheets. Options for custom sizes …

2. ePlastics – Frosted Plexiglass Sheets

Domain: eplastics.com

Registered: 1998 (27 years)

Introduction: This company, ePlastics – Frosted Plexiglass Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Tap Plastics – Acrylic Sheets

Domain: tapplastics.com

Registered: 1999 (26 years)

Introduction: Acrylic Sheets – Cast Clear, available in various sizes, ideal for a range of applications including displays, signage, and protective barriers. Offers high clarity, durability, and UV resistance.

4. Plaskolite – Optix Clear Acrylic Sheets

Domain: acehardware.com

Registered: 1995 (30 years)

Introduction: Acrylic Sheets & Plexiglass Sheets: 109 items found. Key brands include Plaskolite and Aetna Glass. Products available in various sizes and thicknesses, including:

– Plaskolite Optix Clear Single Acrylic Sheets (sizes: 36×72 in., 24×48 in., 30×36 in., 36×36 in., 18×24 in., 20×32 in., 28×30 in., 48×96 in., etc.) with thickness of .100 in. and .220 in. for double sheets.

– Plaskolite Lexan Clear Sin…

Strategic Sourcing Conclusion and Outlook for frosted plexiglass 4 x 8 sheet

In conclusion, the strategic sourcing of frosted plexiglass 4 x 8 sheets offers significant advantages for businesses across various industries, particularly for international buyers in Africa, South America, the Middle East, and Europe. This versatile material combines aesthetic appeal with practicality, being lightweight, shatter-resistant, and easy to work with, making it ideal for applications ranging from signage to interior design.

Key takeaways include understanding the diverse thickness options available, the importance of selecting high-quality suppliers, and the potential for customization to meet specific project requirements. Strategic sourcing not only ensures better pricing and supply chain efficiency but also fosters long-term partnerships that can enhance product innovation and market reach.

As global demand for frosted plexiglass continues to rise, now is the time for B2B buyers to explore new suppliers and expand their networks. By embracing strategic sourcing practices, companies can position themselves to capitalize on emerging opportunities and stay ahead in a competitive marketplace. Engage with trusted suppliers today to unlock the full potential of frosted plexiglass and drive your business growth forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to frosted plexiglass 4 x 8 sheet