The Definitive Guide to Foam Pumpkins: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for foam pumpkins

In the ever-evolving landscape of seasonal décor, sourcing high-quality foam pumpkins poses a significant challenge for B2B buyers. As demand for durable, aesthetically appealing decorations grows, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of the foam pumpkin market becomes essential. This guide offers a comprehensive overview of the types of foam pumpkins available, their various applications—from retail to event planning—and crucial insights into supplier vetting processes.

With a focus on cost-effective purchasing strategies, this resource equips international buyers with the knowledge needed to navigate a market flooded with options. From identifying reliable manufacturers to understanding material specifications and pricing structures, this guide empowers businesses to make informed decisions that align with their unique needs. By addressing key considerations such as design trends and quality benchmarks, we aim to streamline the sourcing process, enabling buyers from diverse markets, including Nigeria and Germany, to enhance their product offerings and meet customer expectations effectively.

Whether you’re looking to stock seasonal items for retail or seeking unique décor solutions for events, our guide serves as a vital tool for optimizing your purchasing strategy in the competitive foam pumpkin market.

Understanding foam pumpkins Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Decorative Foam Pumpkins | Available in various colors and sizes; lightweight and durable | Seasonal decorations, retail displays | Pros: Cost-effective, reusable, diverse styles. Cons: May lack realism compared to natural pumpkins. |

| Carvable Foam Pumpkins | Designed for carving; often larger with a hollow interior | Halloween events, theatrical props | Pros: Safe for children, long-lasting. Cons: Higher initial cost, limited to specific seasonal use. |

| Miniature Foam Pumpkins | Small sizes ideal for tabletop displays; often sold in bulk | Crafting, home decor, event decorations | Pros: Versatile, easy to transport. Cons: Limited visibility in larger displays. |

| Glittered and Sequined Foam Pumpkins | Enhanced aesthetics with glitter or sequins; suitable for upscale decor | Weddings, premium retail displays | Pros: Eye-catching, unique appearance. Cons: Can be more expensive, may require careful handling. |

| Assorted Foam Gourds and Pumpkins | Includes various shapes and sizes; often mixed assortments | Seasonal merchandising, crafting | Pros: Variety adds interest, bulk purchasing options. Cons: Quality may vary within assortments. |

What are Decorative Foam Pumpkins and Their Applications?

Decorative foam pumpkins are lightweight, versatile items available in an array of colors and sizes, making them ideal for seasonal decorations and retail displays. They are designed for repeated use, allowing businesses to save on costs over time. When purchasing, buyers should consider the specific color schemes and sizes that align with their branding or event themes, as well as the durability of the foam material to withstand multiple seasons.

How Do Carvable Foam Pumpkins Stand Out?

Carvable foam pumpkins are specifically designed for Halloween activities, featuring a hollow interior for easy carving. These pumpkins provide a safer alternative for children and are commonly used in schools and community events. Buyers should evaluate the size and density of the foam, as well as the availability of various designs, to ensure they meet the needs of their target audience while considering the initial investment compared to traditional pumpkins.

What Are the Benefits of Miniature Foam Pumpkins?

Miniature foam pumpkins are small, often sold in bulk, making them perfect for tabletop displays, crafting, and event decorations. Their compact size allows for easy transportation and arrangement in various settings, such as retail environments or parties. Buyers should look for bulk purchasing options to maximize cost efficiency and ensure that the colors and styles fit their specific decorative needs.

Why Choose Glittered and Sequined Foam Pumpkins?

Glittered and sequined foam pumpkins offer a unique, upscale aesthetic that can enhance the visual appeal of any display. They are particularly popular for weddings and premium retail environments where a touch of glamour is desired. However, buyers should be mindful of the price point and handling requirements, as these decorative items may be more delicate than their standard counterparts.

How Do Assorted Foam Gourds and Pumpkins Cater to Diverse Needs?

Assorted foam gourds and pumpkins come in various shapes and sizes, often packaged together for seasonal merchandising and crafting projects. This variety adds visual interest to displays, making them attractive for retailers looking to enhance their seasonal offerings. When purchasing, businesses should consider the quality of the items in the assortment and ensure they can effectively meet customer expectations for both aesthetics and durability.

Key Industrial Applications of foam pumpkins

| Industry/Sector | Specific Application of foam pumpkins | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Seasonal decorations for stores | Enhances visual merchandising and customer engagement | Bulk purchasing options, customization of sizes and colors |

| Event Planning | Thematic decor for events and festivals | Creates immersive experiences, attracting more attendees | Need for a diverse range of styles and sizes for various themes |

| Education | Teaching tools for art and craft projects | Encourages creativity and hands-on learning | Safety standards for materials, availability of different sizes |

| Hospitality | Decorative elements for hotels and restaurants | Improves ambiance and seasonal appeal | Durability and weather resistance for outdoor settings |

| Film and Theater | Props for productions and set designs | Cost-effective alternatives to real pumpkins | Sourcing from reliable suppliers for consistency in quality |

How Are Foam Pumpkins Used in Retail Settings?

In retail, foam pumpkins are extensively used as seasonal decorations, particularly during Halloween and Thanksgiving. They enhance visual merchandising by creating themed displays that attract customers and encourage purchases. Retailers benefit from their durability and reusability, allowing for cost-effective seasonal promotions. International buyers should consider bulk purchasing options to maximize cost savings, as well as the ability to customize colors and sizes to align with local cultural themes, especially in markets like Nigeria or Germany.

What Role Do Foam Pumpkins Play in Event Planning?

Event planners utilize foam pumpkins as thematic decor for a variety of occasions, from weddings to festivals. These decorations help create immersive environments that resonate with attendees, enhancing their overall experience. The lightweight nature of foam pumpkins simplifies transport and setup, making them a practical choice for planners. Buyers should focus on sourcing a diverse range of styles and sizes to cater to different event themes, ensuring they can meet the expectations of clients in various regions, including South America and the Middle East.

How Are Foam Pumpkins Beneficial in Educational Settings?

In educational contexts, foam pumpkins serve as versatile teaching tools for art and craft projects. They encourage creativity among students, allowing for safe carving and decorating without the mess associated with real pumpkins. Educational institutions benefit from their affordability and the potential for repeated use in various projects. Buyers must prioritize safety standards for materials used in foam pumpkins and ensure a variety of sizes are available to accommodate different age groups and project requirements.

Why Are Foam Pumpkins Important for Hospitality Businesses?

In the hospitality industry, foam pumpkins are employed as decorative elements in hotels and restaurants, particularly during seasonal events. They contribute to creating a festive atmosphere, which can enhance guest satisfaction and encourage longer stays or repeat visits. Businesses benefit from the durability of foam pumpkins, which can withstand various environmental conditions, especially in outdoor settings. When sourcing, hospitality buyers should focus on the durability and weather resistance of the products to ensure they maintain their aesthetic appeal throughout the season.

How Are Foam Pumpkins Used in Film and Theater Productions?

Foam pumpkins are increasingly popular in film and theater for use as props and set designs. They provide a cost-effective alternative to real pumpkins, reducing the need for constant replacement due to decay. The lightweight and versatile nature of foam pumpkins allows for easy manipulation on stage or in film scenes. Buyers in this sector should prioritize sourcing from reliable suppliers to ensure consistency in quality and availability, particularly when working on large productions that require a significant number of props.

3 Common User Pain Points for ‘foam pumpkins’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Foam Pumpkins

The Problem:

B2B buyers, especially those operating in retail or event planning sectors, often struggle to find suppliers that offer high-quality foam pumpkins. These buyers may encounter issues such as inconsistent product quality, limited stock availability, and a lack of variety in sizes and colors. When preparing for seasonal displays or events, the inability to source reliable products can lead to wasted time, financial losses, and dissatisfaction among customers who expect a certain standard.

The Solution:

To overcome these sourcing challenges, buyers should establish relationships with reputable suppliers who specialize in seasonal décor, particularly foam pumpkins. Engaging with manufacturers directly can ensure better quality control and more personalized service. Buyers should consider placing bulk orders well in advance of the season to secure their desired quantities and product types. Additionally, leveraging trade shows and industry expos can provide firsthand access to new suppliers and product innovations. When negotiating, buyers should request product samples to assess quality before committing to larger orders. This proactive approach will help ensure that the products meet the necessary standards and align with customer expectations.

Scenario 2: Challenges with Product Durability and Lifespan

The Problem:

Another significant pain point for B2B buyers is the durability of foam pumpkins. Many buyers have experienced issues with pumpkins that are prone to damage, such as cracking or fading when exposed to outdoor conditions. This is particularly problematic for businesses that use these items for events or displays that last several weeks, as replacing damaged products can be costly and disruptive.

The Solution:

To address durability concerns, buyers should prioritize sourcing foam pumpkins made from high-quality, UV-resistant materials. When evaluating suppliers, it’s essential to inquire about the materials used and their performance in various weather conditions. Buyers can also benefit from asking for testimonials or case studies from other businesses that have used the product in similar applications. Additionally, implementing proper storage techniques can extend the lifespan of foam pumpkins. This includes keeping them in a climate-controlled environment when not in use and avoiding direct sunlight to prevent fading. By taking these steps, buyers can minimize the risk of product failure and ensure a longer-lasting investment.

Scenario 3: Customization Limitations for Branding Needs

The Problem:

B2B buyers often face challenges when trying to customize foam pumpkins for branding or thematic purposes. Many suppliers offer limited options for colors, sizes, and printing capabilities, which can hinder a buyer’s ability to create unique displays that resonate with their target audience. This lack of customization can lead to generic presentations that fail to capture customer interest.

The Solution:

To tackle the issue of customization, buyers should seek out suppliers that offer bespoke services. This includes options for custom colors, sizes, and the ability to print logos or messages directly onto the foam pumpkins. Engaging with manufacturers who specialize in custom products can open up new avenues for creative displays. It’s advisable to provide suppliers with clear specifications and desired outcomes to ensure that the final product aligns with branding goals. Furthermore, buyers can explore partnerships with local artists or designers who can help create unique designs that reflect the brand’s identity. By prioritizing customization, businesses can enhance their marketing efforts and create memorable experiences for their customers.

Strategic Material Selection Guide for foam pumpkins

What Are the Key Materials Used in Foam Pumpkins?

When selecting materials for foam pumpkins, international B2B buyers must consider various factors that affect product performance, durability, cost, and compliance with regional standards. Here, we analyze four common materials used in the production of foam pumpkins: polyurethane foam, polyethylene foam, EVA foam, and polystyrene foam.

How Does Polyurethane Foam Perform in Foam Pumpkins?

Polyurethane foam is a versatile material known for its excellent cushioning properties and durability. It has a good temperature range, typically performing well in environments from -30°C to 80°C. This material is resistant to degradation from UV exposure, making it suitable for both indoor and outdoor use.

Pros: Polyurethane foam is lightweight, flexible, and can be molded into intricate shapes, allowing for detailed designs in foam pumpkins. It also offers good sound absorption properties.

Cons: However, it can be more expensive than other foam types and may require specialized manufacturing processes. Additionally, it may not be as resistant to moisture, which could be a concern in humid climates.

Impact on Application: Polyurethane foam is ideal for decorative pumpkins that require a high level of detail and durability. However, buyers in humid regions should consider the moisture resistance of this material.

What Are the Benefits of Polyethylene Foam for Foam Pumpkins?

Polyethylene foam is another popular choice for foam pumpkins, known for its lightweight and closed-cell structure. It is resistant to water, chemicals, and UV radiation, making it suitable for various environmental conditions.

Pros: The material is cost-effective and provides excellent shock absorption, making it a good choice for transportation and storage. It is also easy to cut and shape, which simplifies manufacturing.

Cons: On the downside, polyethylene foam may not offer the same level of detail in designs as polyurethane foam. It can also be less flexible, which may limit its applications.

Impact on Application: This material is particularly suitable for bulk production of foam pumpkins intended for outdoor use, where moisture resistance is critical.

How Does EVA Foam Compare for Foam Pumpkin Production?

Ethylene-vinyl acetate (EVA) foam is known for its elasticity and softness. It performs well in a range of temperatures and is resistant to UV radiation, making it another good option for foam pumpkins.

Pros: EVA foam is lightweight and provides a soft touch, which can enhance the aesthetic appeal of decorative pumpkins. It is also relatively affordable and easy to manufacture.

Cons: However, EVA foam may not be as durable as polyurethane foam, particularly in high-stress applications. It can also be more susceptible to tearing.

Impact on Application: EVA foam is suitable for decorative pumpkins that require a softer feel and vibrant colors. Buyers should consider the trade-off between aesthetic appeal and durability.

What Are the Characteristics of Polystyrene Foam in Foam Pumpkins?

Polystyrene foam, often used in craft applications, is lightweight and can be molded into various shapes. It is generally less expensive than other foam materials but has limitations in terms of durability.

Pros: This material is easy to work with and can be produced in large quantities at a low cost. It is also readily available in various densities.

Cons: However, polystyrene foam is less durable and can be easily damaged. It is also less resistant to moisture and UV light, which may limit its use in outdoor applications.

Impact on Application: Polystyrene foam is best suited for temporary decorative pumpkins or those intended for indoor use. Buyers should be cautious about its limitations in outdoor settings.

Summary Table of Material Selection for Foam Pumpkins

| Material | Typical Use Case for foam pumpkins | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Foam | High-detail decorative pumpkins | Excellent durability and detail | Higher cost and moisture sensitivity | High |

| Polyethylene Foam | Bulk production of outdoor pumpkins | Cost-effective and moisture-resistant | Limited design detail | Medium |

| EVA Foam | Decorative pumpkins with a soft feel | Lightweight and vibrant colors | Less durable, prone to tearing | Medium |

| Polystyrene Foam | Temporary indoor decorations | Low cost and easy to mold | Less durable and moisture-sensitive | Low |

This strategic material selection guide provides insights for B2B buyers in diverse markets, ensuring informed decisions that align with product performance and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for foam pumpkins

In the production of foam pumpkins, manufacturers follow a systematic approach that emphasizes efficiency, quality, and compliance with international standards. Understanding the manufacturing processes and quality assurance measures is crucial for B2B buyers seeking reliable suppliers, particularly in regions like Africa, South America, the Middle East, and Europe. This section outlines the key stages in the manufacturing process, the quality control checkpoints, and how buyers can verify supplier quality assurance.

What Are the Main Stages in the Manufacturing Process of Foam Pumpkins?

The manufacturing of foam pumpkins typically involves several key stages: material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Foam Pumpkin Production?

The primary material used in foam pumpkin production is polyurethane foam, which is lightweight, durable, and versatile. Suppliers often procure raw foam blocks that are then cut into specific shapes. During this stage, manufacturers may also prepare additional materials for decoration and detailing, such as paint, glitter, and other embellishments.

Forming: How Are Foam Pumpkins Shaped?

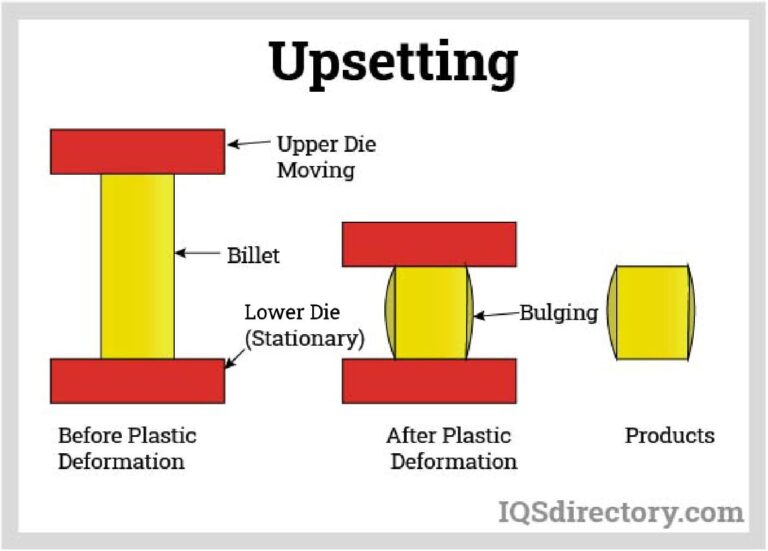

In the forming stage, the prepared foam is shaped into the desired pumpkin forms. This can be accomplished using various techniques, including:

- Molding: Manufacturers utilize molds to create specific shapes. High-quality molds ensure uniformity and precision in the final product.

- Cutting and Shaping: Foam blocks are cut and shaped into pumpkin designs, including traditional round shapes and more unique forms. Techniques such as CNC cutting can enhance accuracy.

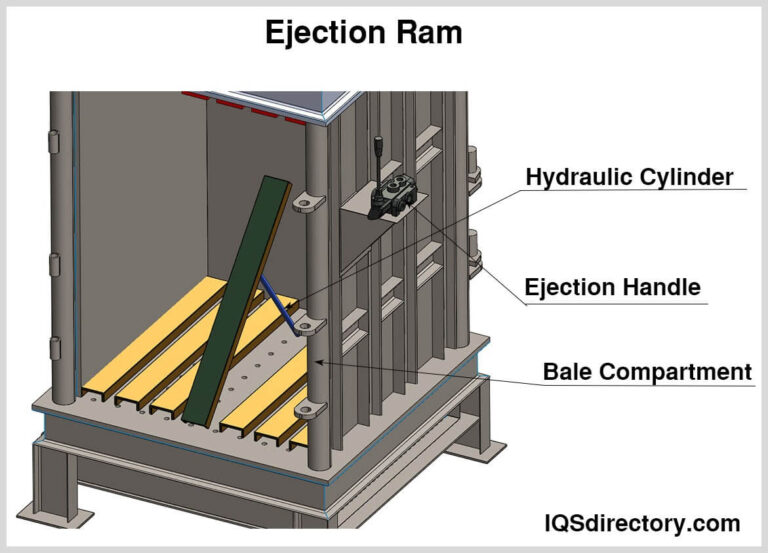

Assembly: How Are Different Components Put Together?

Once the base shapes are formed, the assembly stage involves attaching any additional components, such as stems or decorative elements. This may include gluing or fastening parts together to create a cohesive product. Quality adhesives are essential to ensure durability, especially for products intended for repeated use or outdoor display.

Finishing: What Final Touches Are Added?

The finishing stage includes painting, coating, and detailing the foam pumpkins. Manufacturers may apply multiple layers of paint to achieve the desired color and texture. Protective coatings may also be added to enhance weather resistance and durability.

What Are the Key Quality Assurance Measures in Foam Pumpkin Production?

Quality assurance is a critical component of the manufacturing process, ensuring that foam pumpkins meet international standards and customer expectations.

Which International Standards Are Relevant for Foam Pumpkin Manufacturers?

Adhering to international quality standards is essential for suppliers aiming to serve a global market. Relevant standards include:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring that organizations consistently provide products that meet customer and regulatory requirements.

- CE Marking: In the European market, products must often meet safety, health, and environmental protection standards, indicated by the CE mark.

What Are the Quality Control Checkpoints in Foam Pumpkin Manufacturing?

Quality control (QC) is typically integrated at various stages of the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested to identify any deviations from quality standards.

- Final Quality Control (FQC): Completed products undergo thorough inspections, including visual checks, dimensional accuracy, and durability tests.

What Common Testing Methods Are Used for Foam Pumpkins?

Several testing methods are commonly employed to verify the quality of foam pumpkins:

- Visual Inspection: Inspectors check for defects such as color inconsistencies, surface imperfections, and structural integrity.

- Dimensional Testing: Ensures that the products meet the specified measurements and tolerances.

- Durability Testing: Foam pumpkins may undergo stress tests to assess their resilience to impacts or environmental factors.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, particularly those in international markets, verifying a supplier’s quality assurance processes is essential to ensure product reliability.

What Steps Can Buyers Take to Audit Suppliers?

Buyers can conduct supplier audits to assess their manufacturing processes and quality control measures. This can include:

- On-Site Visits: Visiting the manufacturing facility provides firsthand insight into production practices and quality management systems.

- Document Review: Requesting quality assurance documentation, including reports from previous audits and certifications, can help evaluate a supplier’s commitment to quality.

How Important Are Third-Party Inspections for Quality Assurance?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality practices. These services typically include:

- Pre-Shipment Inspections: Conducting inspections before shipment ensures that products meet specified quality standards.

- Random Sampling: Third-party inspectors can perform random sampling to verify that the entire production batch adheres to quality specifications.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control and certification is vital. Factors to consider include:

- Regional Compliance: Different regions may have specific regulations and standards that products must meet. Buyers should be familiar with local requirements, especially when importing goods.

- Supplier Certifications: Verify that suppliers possess relevant certifications that align with the buyer’s market requirements. This may include ISO certifications, safety standards, and environmental compliance.

In conclusion, the manufacturing processes and quality assurance measures for foam pumpkins are designed to ensure that products meet high standards of quality and safety. B2B buyers should prioritize suppliers who demonstrate a commitment to quality through established manufacturing practices and rigorous quality control measures. By understanding these processes, buyers can make informed decisions and foster successful partnerships in the foam pumpkin market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘foam pumpkins’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to source foam pumpkins. With the increasing demand for artificial decorations in various markets, understanding the nuances of sourcing can lead to better purchasing decisions and successful partnerships with suppliers. This step-by-step approach will help you streamline your procurement process.

1. Identify Your Market Needs

Understanding your target market is crucial. Research the preferences of your customer base regarding sizes, colors, and styles of foam pumpkins. This insight will guide your sourcing decisions, ensuring that the products you procure align with market demand.

2. Define Your Technical Specifications

Establish clear specifications for the foam pumpkins you wish to source. Consider factors such as:

– Material Quality: Look for low-density foam with a durable outer shell to ensure longevity.

– Size Variations: Determine a range of sizes to cater to different customer needs, from miniatures to larger decorative pieces.

3. Conduct Supplier Research

Thoroughly investigate potential suppliers. Utilize online platforms, trade shows, and industry networks to gather information. Focus on:

– Supplier Reputation: Look for reviews and testimonials from other B2B buyers.

– Product Range: Ensure the supplier offers a variety of options to meet your specifications.

4. Request Samples

Before finalizing your order, request product samples. This step is vital to assess the quality of the foam pumpkins firsthand. Pay attention to:

– Construction Quality: Check for any defects or inconsistencies in the foam and outer shell.

– Color Accuracy: Ensure that the colors match your specifications and are appealing for your target market.

5. Verify Certifications and Compliance

Ensure that your chosen supplier meets industry standards and certifications. This is particularly important for international purchases, where regulations may vary. Look for:

– Safety Certifications: Confirm that products are safe for consumer use, especially if they will be used in decorations for children.

– Sustainability Practices: Consider suppliers who follow eco-friendly manufacturing processes, which can be a significant selling point in your market.

6. Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate terms that are favorable for your business. Key points to discuss include:

– Pricing and Discounts: Inquire about bulk pricing or discounts for long-term contracts.

– Shipping and Delivery: Confirm lead times and shipping costs to avoid unexpected expenses.

7. Establish a Communication Plan

Maintain open lines of communication with your supplier throughout the procurement process. Regular updates can help manage expectations and resolve any issues promptly. Consider:

– Regular Check-ins: Schedule periodic meetings to discuss order status and future needs.

– Feedback Mechanism: Provide feedback on product quality and service to foster a collaborative relationship.

By following this checklist, B2B buyers can navigate the sourcing of foam pumpkins more effectively, ensuring they meet both their business requirements and customer expectations.

Comprehensive Cost and Pricing Analysis for foam pumpkins Sourcing

What Are the Key Cost Components for Sourcing Foam Pumpkins?

When sourcing foam pumpkins, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of foam used significantly affects the overall cost. Low-density foams are generally cheaper, while higher-quality, durable foams tend to be pricier. Additionally, decorative elements, such as glitter or paint, can add to material costs.

-

Labor: Labor costs vary based on the manufacturing location. In regions with lower labor costs, such as parts of Asia, the overall production expenses can be minimized. However, buyers should also consider the expertise required for quality craftsmanship, which can affect labor rates.

-

Manufacturing Overhead: This includes utilities, rent, and equipment costs. A well-optimized factory may offer better pricing due to lower overhead, making it essential to assess suppliers’ operational efficiencies.

-

Tooling: Custom molds for unique designs or sizes will incur additional costs. For large orders, the tooling cost can be amortized over the production run, resulting in lower per-unit costs.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability but may increase costs. Buyers should evaluate the balance between quality assurance and cost-effectiveness.

-

Logistics: Shipping costs depend on the geographical distance from the supplier to the buyer and the chosen Incoterms. Costs can escalate with express shipping options or if customs duties are involved.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market standard for margins in the foam pumpkin industry can aid in negotiation.

How Do Pricing Influencers Impact Foam Pumpkins Costs?

Several factors influence the pricing of foam pumpkins:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to significant discounts. Buyers should consider their inventory needs to negotiate favorable terms.

-

Specifications and Customization: Customized products generally come at a premium. Buyers should weigh the necessity of customization against the potential added costs.

-

Material Quality and Certifications: High-quality materials that comply with safety regulations (like CE or ASTM certifications) may increase costs but can also enhance marketability in regions with strict safety standards.

-

Supplier Factors: The supplier’s reputation, reliability, and history of fulfilling orders can influence pricing. Established suppliers with proven track records may charge more but provide peace of mind regarding delivery and quality.

-

Incoterms: The choice of Incoterms affects who bears the shipping and customs responsibilities, impacting the overall cost. For example, FOB (Free on Board) can be more economical for buyers who can handle logistics effectively.

What Are the Best Buyer Tips for Cost-Efficiency in Foam Pumpkin Sourcing?

To maximize cost-efficiency when sourcing foam pumpkins, consider the following tips:

-

Negotiate Terms: Always engage in discussions regarding price, payment terms, and delivery schedules. Suppliers are often willing to negotiate, especially for larger orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the costs related to shipping, storage, and potential returns. A lower initial price may not always equate to a better deal if TCO is higher.

-

Understand Pricing Nuances for International Buyers: When sourcing from different regions (like Africa, South America, the Middle East, and Europe), be aware of currency fluctuations, import duties, and local market conditions that could affect pricing.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing, exclusive deals, and priority during high-demand seasons.

-

Stay Informed on Market Trends: Regularly monitoring market trends can provide insights into pricing fluctuations and help buyers make informed decisions regarding timing and volume of orders.

Conclusion

While sourcing foam pumpkins, understanding the intricate cost components and pricing influencers is essential for B2B buyers. By implementing strategic negotiation practices and evaluating the total cost of ownership, buyers can optimize their sourcing strategies to achieve the best value. Always remember to remain flexible and informed to navigate the complexities of international trade efficiently.

Alternatives Analysis: Comparing foam pumpkins With Other Solutions

Understanding the Alternatives to Foam Pumpkins

In the realm of decorative solutions, particularly during festive seasons, foam pumpkins have gained popularity for their versatility and durability. However, various alternatives exist that may better suit specific needs depending on factors such as cost, performance, and application. This section analyzes foam pumpkins in comparison to two viable alternatives: carved real pumpkins and decorative ceramic pumpkins.

Comparison Table

| Comparison Aspect | Foam Pumpkins | Carved Real Pumpkins | Decorative Ceramic Pumpkins |

|---|---|---|---|

| Performance | High durability, reusable, and weather-resistant | Short lifespan, prone to decay and rot | Long-lasting, can be decorative year-round |

| Cost | Moderate initial investment, reusable | Low cost but requires annual purchase | Higher upfront cost, but durable |

| Ease of Implementation | Easy to store and transport; requires minimal setup | Requires carving skills and tools | Ready to use, no setup required |

| Maintenance | Low maintenance; easy to clean | High maintenance; needs regular replacement | Minimal maintenance; occasional cleaning |

| Best Use Case | Seasonal decorations, events, craft projects | Halloween displays, traditional decorations | Year-round decor, upscale events |

Pros and Cons of Each Alternative

Carved Real Pumpkins

Carved real pumpkins are a traditional choice that embodies the essence of autumn and Halloween. Their natural appearance provides an authentic aesthetic that synthetic alternatives may lack. However, they have a short lifespan, typically lasting only a few weeks before rotting. This necessitates frequent purchases, which can become costly over time. Additionally, they require carving skills and tools, making them less convenient for those looking for a hassle-free solution.

Decorative Ceramic Pumpkins

Decorative ceramic pumpkins are an attractive option for year-round decor. They offer a more permanent solution than real pumpkins, available in various designs and colors to fit different aesthetics. Although they have a higher initial cost compared to foam pumpkins, their durability and resistance to wear make them a long-term investment. Ceramic pumpkins are easy to maintain, requiring only occasional cleaning, but their weight can pose challenges in terms of transport and display.

Making the Right Choice for Your Needs

When selecting the appropriate decorative solution, B2B buyers must consider their specific requirements and context. Foam pumpkins offer a practical, cost-effective option for seasonal decorations, particularly for events where durability is essential. In contrast, carved real pumpkins may appeal to those seeking authenticity, albeit with higher maintenance and cost implications. Decorative ceramic pumpkins provide a sophisticated, long-lasting alternative that can enhance year-round decor. Ultimately, the decision should align with the buyer’s budget, desired aesthetic, and intended use case, ensuring that the selected solution meets both practical and decorative needs effectively.

Essential Technical Properties and Trade Terminology for foam pumpkins

What Are the Key Technical Properties of Foam Pumpkins?

Understanding the essential technical properties of foam pumpkins is crucial for B2B buyers to make informed purchasing decisions. Here are some critical specifications to consider:

-

Material Composition

– Definition: Foam pumpkins are typically made from materials such as polyurethane foam or polyethylene foam, often with a painted or coated outer surface.

– B2B Importance: The choice of material affects durability, weight, and aesthetic appeal. High-quality materials ensure longevity, making them suitable for repeated use in decorations or events. -

Density

– Definition: Density refers to the mass per unit volume of the foam. It is often categorized as low, medium, or high density.

– B2B Importance: Higher density foam pumpkins are more durable and resistant to wear and tear, making them ideal for commercial applications where longevity is crucial. Buyers should consider density based on intended usage, such as decorative displays or event props. -

Size and Tolerance

– Definition: Size specifications typically include diameter and height, while tolerance indicates the acceptable variation in these measurements.

– B2B Importance: Accurate sizing is essential for fitting pumpkins into specific display contexts. Tolerance ensures that products meet buyer requirements, reducing returns and dissatisfaction. -

Colorfastness

– Definition: This property measures how well the color of the foam pumpkin holds up against fading due to exposure to sunlight or other environmental factors.

– B2B Importance: For international buyers, especially in regions with strong sunlight, colorfastness is critical for maintaining the visual appeal of products over time, thus ensuring customer satisfaction and reducing replacement costs. -

Carvability

– Definition: This refers to how easily the foam can be carved or shaped, particularly for jack-o-lantern designs.

– B2B Importance: Carvable pumpkins are popular for seasonal events, and understanding this property helps buyers select products that meet the creative needs of their customers.

What Are Common Trade Terms Related to Foam Pumpkins?

Familiarity with industry jargon is essential for effective communication and negotiation in the foam pumpkin market. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or products that are used in another company’s end product.

– Importance: Understanding OEM relationships can help buyers identify potential suppliers who can provide custom foam pumpkins tailored to specific design requirements. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers gauge their purchasing power and plan inventory levels effectively. It is especially relevant for international buyers who may face shipping constraints. -

RFQ (Request for Quotation)

– Definition: A document issued to suppliers asking for a price quote on specific products or services.

– Importance: RFQs are crucial for comparing prices and terms across different suppliers, allowing buyers to make cost-effective decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms is vital for international transactions as it dictates shipping costs, risks, and responsibilities, ensuring smoother logistics and legal compliance. -

Lead Time

– Definition: The time taken from placing an order to the delivery of goods.

– Importance: Understanding lead times is essential for inventory management and planning, especially for seasonal products like foam pumpkins, which may have fluctuating demand.

By recognizing these properties and terms, B2B buyers can navigate the foam pumpkin market more effectively, ensuring they make informed purchasing decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the foam pumpkins Sector

What Are the Key Market Trends Influencing the Foam Pumpkins Sector?

The foam pumpkins market is experiencing a robust transformation driven by several global factors. The rising popularity of Halloween and autumn-themed decorations has amplified demand across international markets, particularly in regions such as Africa, South America, the Middle East, and Europe. As consumers increasingly seek sustainable and reusable decoration options, the demand for foam pumpkins, which can be utilized year after year, is on the rise. Additionally, the growth of e-commerce platforms has made it easier for B2B buyers to source these products from global suppliers, enhancing market accessibility.

Emerging technologies are also shaping sourcing trends in this sector. Innovations in manufacturing processes, such as 3D printing and advanced foam molding techniques, are enabling suppliers to create more intricate designs and varied sizes. This technological advancement not only improves product quality but also allows for greater customization to meet specific buyer preferences. Furthermore, the integration of AI and data analytics in supply chain management is optimizing inventory levels and reducing lead times, making it easier for international buyers to source foam pumpkins efficiently.

How Is Sustainability and Ethical Sourcing Affecting Foam Pumpkin Purchases?

Sustainability has become a pivotal concern for B2B buyers in the foam pumpkins sector. The environmental impact of traditional foam production, often derived from non-renewable resources, has prompted a shift towards more sustainable materials. Buyers are increasingly prioritizing suppliers who utilize eco-friendly foam alternatives, such as biodegradable options or recycled materials, thereby minimizing their carbon footprint.

Ethical sourcing practices are also gaining traction, with many buyers looking for transparency in their supply chains. Companies that can demonstrate adherence to fair labor practices and responsible sourcing are more likely to attract B2B partnerships. Certifications such as FSC (Forest Stewardship Council) or ISO 14001 can enhance credibility and appeal to environmentally conscious buyers. This focus on sustainability not only meets the rising consumer demand for responsible products but also positions companies favorably in a competitive market landscape.

What Is the Historical Context of Foam Pumpkins in the B2B Market?

The evolution of foam pumpkins can be traced back to the late 20th century when artificial decorations began gaining popularity as a practical and reusable alternative to natural pumpkins. Initially, these foam pumpkins were primarily used for Halloween displays, but over time, they have expanded to encompass a broader range of seasonal decorations, including Thanksgiving and harvest themes. As manufacturing techniques improved, the quality and realism of foam pumpkins also enhanced, making them more appealing to both consumers and B2B buyers.

Today, the foam pumpkin market is characterized by a diverse array of designs, colors, and sizes, catering to various aesthetic preferences and market demands. This evolution reflects broader trends in consumer behavior, where there is a growing emphasis on sustainability, creativity, and versatility in decorative products. For B2B buyers, understanding this historical context can provide valuable insights into market dynamics and buyer preferences, facilitating more informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of foam pumpkins

-

How do I ensure the quality of foam pumpkins from international suppliers?

To ensure the quality of foam pumpkins, start by vetting suppliers through online reviews, industry forums, and trade directories. Request product samples to assess material quality and craftsmanship. It’s also beneficial to inquire about their manufacturing processes and quality assurance protocols. Look for certifications that indicate adherence to international safety and quality standards. Establishing a clear communication channel with your supplier can help address any concerns during production. -

What is the best way to customize foam pumpkins for my market?

The best way to customize foam pumpkins is to collaborate closely with your supplier. Discuss your specific market needs, such as size, color, and design preferences. Many suppliers offer customization options, including branding and unique patterns. Provide clear specifications and reference images to help the supplier understand your vision. Additionally, consider the cultural significance of colors and designs in your target market to enhance appeal. -

What are the minimum order quantities (MOQs) for foam pumpkins?

Minimum order quantities (MOQs) for foam pumpkins can vary significantly among suppliers, often depending on the type of product and customization options. Typically, MOQs range from 100 to 1,000 units. It’s advisable to discuss your needs upfront and negotiate MOQs if you require a smaller batch for testing or initial market entry. Some suppliers may offer flexibility for established relationships or larger orders in the future. -

What payment terms should I expect when sourcing foam pumpkins internationally?

Payment terms for international orders typically include options like a deposit upfront (often 30-50%) with the balance due before shipment. Some suppliers may accept letters of credit or escrow services for larger transactions. Always clarify payment terms before finalizing orders to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees, especially when dealing with suppliers in different regions. -

How can I effectively manage logistics when importing foam pumpkins?

Effectively managing logistics involves selecting a reliable freight forwarder familiar with the import/export process in your region. Ensure that you understand all customs regulations and duties applicable to your shipment. It’s also crucial to plan for potential delays by allowing adequate time for shipping and customs clearance. Regular communication with your supplier regarding shipment status can help mitigate issues and ensure timely delivery. -

What are the common challenges faced when sourcing foam pumpkins internationally?

Common challenges include language barriers, cultural differences, and varying quality standards. Additionally, navigating customs regulations and potential delays in shipping can complicate the sourcing process. To overcome these challenges, establish clear communication with your supplier, consider using third-party inspection services, and stay informed about the import regulations in your country. Building strong relationships with suppliers can also enhance cooperation and problem-solving. -

How do I verify the credibility of a foam pumpkin supplier?

Verifying a supplier’s credibility involves several steps: check their business registration and industry certifications, read reviews from previous clients, and ask for references. Conducting a background check through trade associations or platforms like Alibaba can also provide insights. Additionally, visiting their manufacturing facility (if possible) or requesting a video tour can help confirm their operations and commitment to quality. -

What trends should I be aware of in the foam pumpkin market?

Current trends in the foam pumpkin market include an increasing demand for eco-friendly materials and unique, customizable designs. Seasonal decorations are becoming more varied, with consumers looking for items that can serve multiple purposes beyond Halloween, such as fall-themed décor. Additionally, online sales channels are expanding, so consider how e-commerce can play a role in your sourcing strategy. Staying updated with market trends can help you make informed purchasing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Foam Pumpkins Manufacturers & Suppliers List

1. Pinterest – Creative Pumpkin Decorating Ideas

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Foam pumpkins, Halloween pumpkin decorating ideas, no carve pumpkin decorating, DIY pumpkin crafts, themed pumpkin decorations, various creative pumpkin designs including gumball machine, unicorn, Venus fly trap, and pirate ship, use of faux pumpkins for topiary and flower arrangements, painted pumpkin designs inspired by Van Gogh’s Starry Night.

2. Refresh Restyle – Foam Pumpkin Crafts

Domain: refreshrestyle.com

Registered: 2010 (15 years)

Introduction: Foam Pumpkins Crafts using Dollar Tree Pumpkins, Paper Napkins, and Mod Podge. Active Time: 15 minutes, Total Time: 15 minutes, Difficulty: Easy. Tools needed: Small paint brush, Scissors. Instructions include removing the foam stem, applying Mod Podge, using decorative napkin layers, and letting it dry. Additional notes suggest working in sections to avoid sticking fingers and using a skewer for …

Strategic Sourcing Conclusion and Outlook for foam pumpkins

How Can Strategic Sourcing Enhance Your Foam Pumpkin Procurement?

In the competitive landscape of foam pumpkin sourcing, strategic procurement is essential for B2B buyers aiming to optimize their supply chains and maximize profitability. By understanding market trends and leveraging supplier relationships, businesses can secure high-quality foam pumpkins that cater to diverse customer needs, from seasonal decorations to theatrical props. The focus should be on identifying reliable suppliers that offer a variety of products, including customizable options, to meet specific market demands across different regions.

As foam pumpkins continue to gain popularity for their durability and aesthetic appeal, international buyers, especially from Africa, South America, the Middle East, and Europe, should prioritize building a robust sourcing strategy. This involves not only assessing product quality and price but also considering logistical aspects to ensure timely deliveries and reduce overhead costs.

Looking ahead, the foam pumpkin market is poised for growth, driven by increasing consumer interest in sustainable and reusable decorations. Buyers are encouraged to act now—evaluate your sourcing strategies, engage with suppliers, and seize the opportunity to enhance your product offerings. By doing so, you position your business to thrive in an evolving market landscape.