The Definitive Guide to Fluid Bed Coating: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for fluid bed coating

In today’s competitive landscape, sourcing reliable and effective fluid bed coating solutions presents a significant challenge for international B2B buyers. Whether you’re operating in the aerospace, automotive, or medical sectors, understanding the intricacies of fluid bed coating can greatly influence product quality and longevity. This guide aims to demystify the fluid bed coating process, exploring various types, applications, and the critical factors to consider when vetting suppliers.

From the environmental benefits of powder coatings to the technological advancements in Wurster systems, we will delve into the nuances that make fluid bed coating an attractive option for manufacturers across Africa, South America, the Middle East, and Europe, including emerging markets like Vietnam and Brazil. Furthermore, we will provide insights on cost considerations and performance metrics, empowering you to make informed purchasing decisions that align with your business objectives.

By the end of this guide, you will be equipped with the knowledge necessary to navigate the global market for fluid bed coating, ensuring that you select the right products and partners to enhance your operational efficiency and product durability. Embrace the opportunity to leverage fluid bed coating technology to elevate your manufacturing capabilities and achieve a competitive edge in your industry.

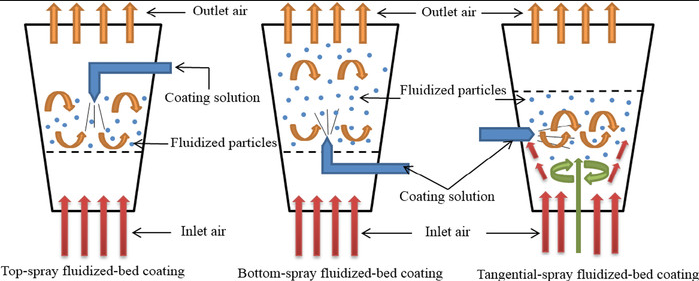

Understanding fluid bed coating Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fluidized Bed Powder Coating | Utilizes thermoplastic powders; creates a thick, durable layer through dipping. | Aerospace, Automotive, Medical Devices | Pros: High durability, uniform coating; Cons: Not suitable for complex geometries. |

| Wurster Coating | Uses a bottom spray system to coat fine powders and pellets. | Pharmaceutical, Food Processing | Pros: High efficiency, reduced attrition; Cons: Limited to specific particle sizes. |

| Electrostatic Fluidized Bed | Combines electrostatic charge with fluidization for enhanced adhesion. | Electronics, Automotive Components | Pros: Improved coverage, excellent adhesion; Cons: Requires precise setup and control. |

| Batch vs. Continuous Fluid Bed | Batch systems process discrete quantities; continuous systems enable ongoing production. | Manufacturing, Bulk Coating | Pros: Flexibility in production scale; Cons: Batch systems may have longer lead times. |

| Hybrid Fluid Bed Systems | Integrates multiple coating techniques for versatility. | Diverse Industries (e.g., Automotive, Aerospace) | Pros: Customizable solutions; Cons: Complexity in setup and maintenance. |

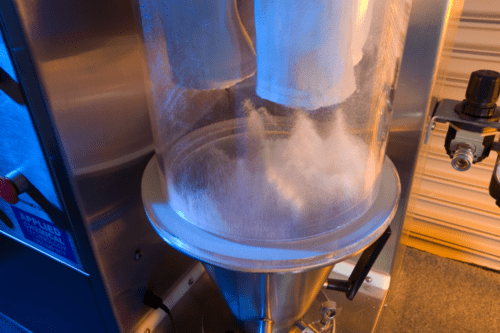

What are the Characteristics and Suitability of Fluidized Bed Powder Coating?

Fluidized bed powder coating is renowned for its robust application process, where preheated metal parts are immersed in a bed of thermoplastic powders. This method is particularly advantageous for industries like aerospace and automotive, where durability and resistance to corrosion are paramount. Buyers should consider the thickness of the coating, which can effectively conceal minor surface imperfections, making it ideal for less complex shapes. However, the technique may not be suitable for intricate designs, as the thick layer can obscure fine details.

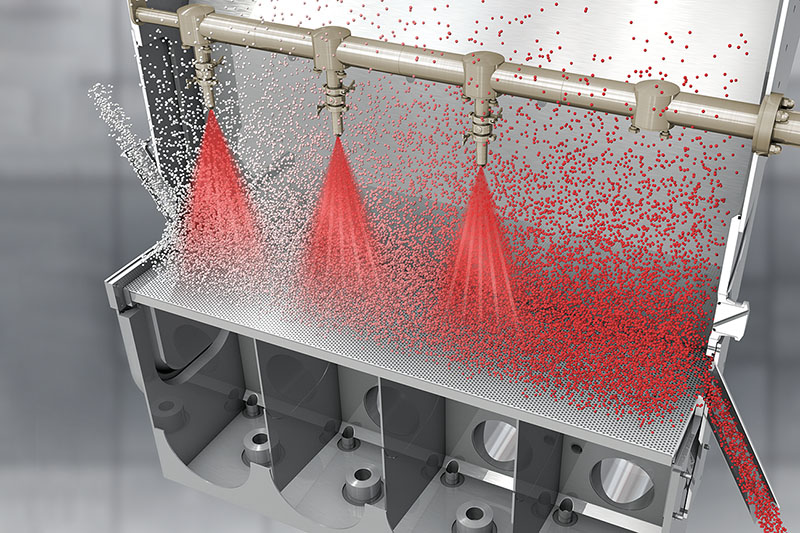

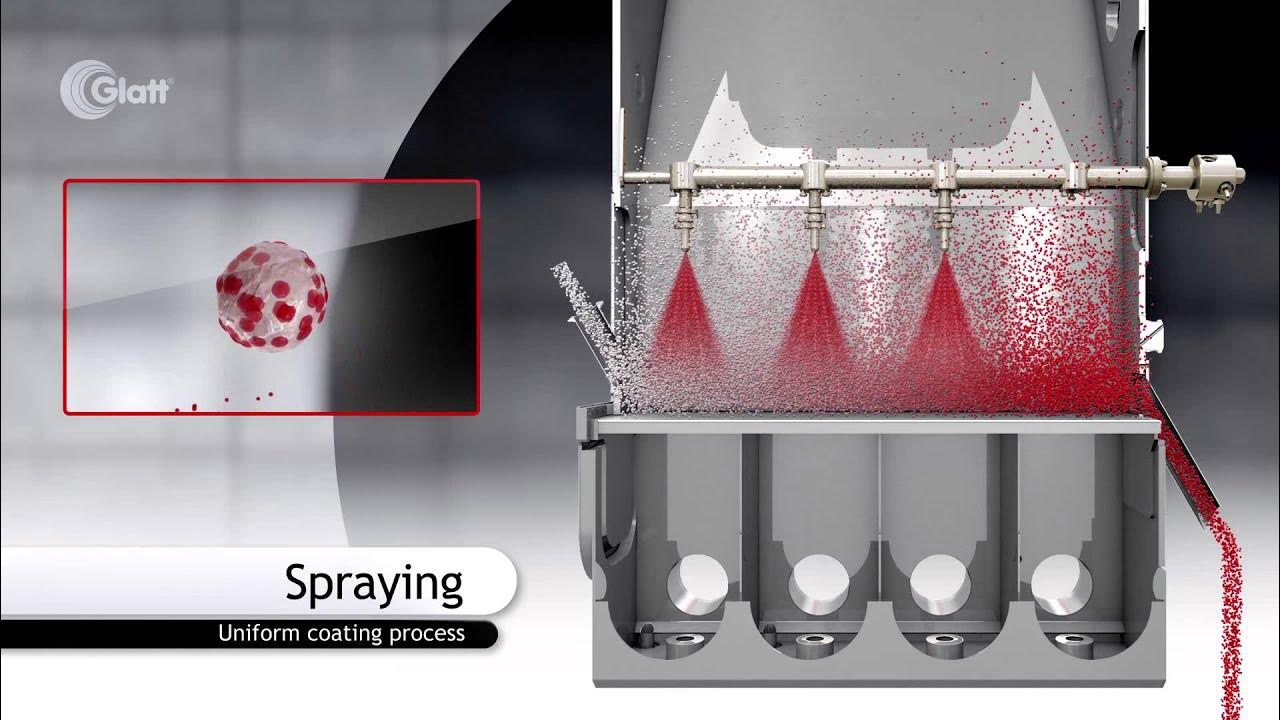

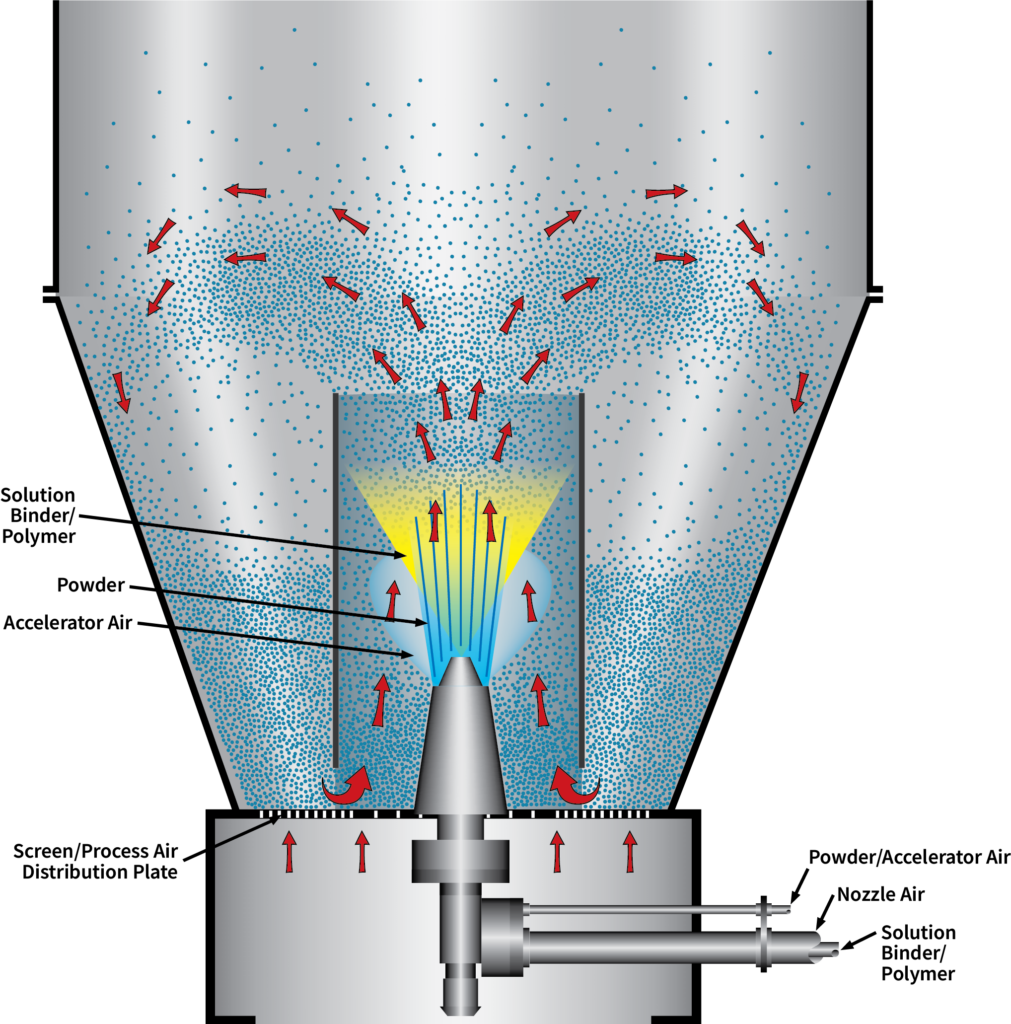

How Does Wurster Coating Stand Out in the Market?

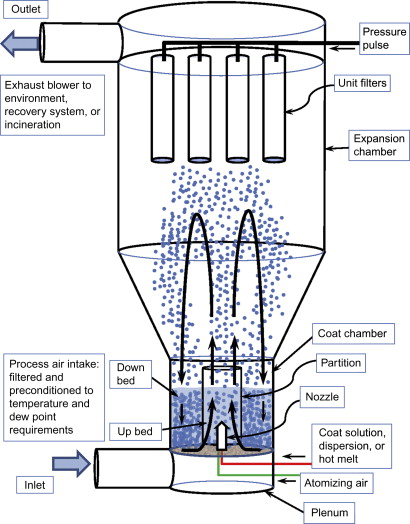

The Wurster coating system is specifically designed for coating fine powders and small pellets, making it a preferred choice in pharmaceuticals and food processing. Its unique bottom spray mechanism enhances efficiency by minimizing particle agglomeration and maximizing spray rates. B2B buyers should note the system’s high throughput and reduced attrition, which can lead to significant cost savings. However, the technology is limited to specific particle sizes, which may restrict its application in broader manufacturing contexts.

Illustrative image related to fluid bed coating

What Are the Advantages of Electrostatic Fluidized Bed Coating?

Electrostatic fluidized bed coating combines traditional fluidization with electrostatic charge, enhancing particle adhesion to surfaces. This technology is particularly beneficial in sectors like electronics and automotive components, where precise coating is essential. The electrostatic charge ensures a uniform application, reducing the likelihood of defects. Buyers should be aware that while this method offers superior results, it requires careful setup and control to achieve optimal performance.

What Should Buyers Know About Batch vs. Continuous Fluid Bed Systems?

The choice between batch and continuous fluid bed systems significantly impacts production efficiency. Batch systems are ideal for manufacturers requiring flexibility, allowing for the processing of various products in discrete quantities. Conversely, continuous systems are designed for high-volume production, offering streamlined operations. B2B buyers should weigh the benefits of flexibility against potential lead time delays in batch systems, considering their specific production needs and volume requirements.

How Do Hybrid Fluid Bed Systems Offer Customization?

Hybrid fluid bed systems bring together multiple coating techniques, allowing for tailored solutions across various industries, including automotive and aerospace. This versatility can be a significant advantage for businesses looking to optimize their coating processes. However, the complexity of hybrid systems may lead to increased setup and maintenance challenges. Buyers should evaluate their operational capabilities and the potential return on investment when considering hybrid solutions.

Key Industrial Applications of fluid bed coating

| Industry/Sector | Specific Application of Fluid Bed Coating | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Coating of engine components and structural parts | Enhanced durability and resistance to extreme conditions | Compliance with aerospace standards and certifications |

| Agriculture | Coating of equipment and machinery components | Improved corrosion resistance and extended equipment life | Compatibility with agricultural chemicals and environmental regulations |

| Medical Devices | Coating of surgical instruments and implants | Biocompatibility and enhanced surface properties | Strict adherence to medical safety standards and testing |

| Automotive | Coating of metal chassis and components | Weight reduction and improved aesthetics | Ability to meet automotive industry specifications and durability requirements |

| Marine | Coating of boat hulls and marine equipment | Protection against saltwater corrosion and wear | Resistance to harsh marine environments and regulatory compliance |

How is Fluid Bed Coating Used in Aerospace Applications?

In the aerospace industry, fluid bed coating is utilized for engine components and structural parts that require high durability. This process enhances resistance to extreme temperatures and environmental conditions, which is critical for aircraft performance and safety. Buyers in this sector must consider compliance with stringent aerospace standards and certifications to ensure that the coatings meet performance and safety benchmarks.

What are the Benefits of Fluid Bed Coating in Agriculture?

Fluid bed coating is applied to agricultural equipment and machinery components to provide a robust layer that resists corrosion from fertilizers and other chemicals. This significantly extends the life of equipment, reducing maintenance costs and downtime. For international buyers, it is essential to ensure that the coatings are compatible with various agricultural chemicals and adhere to local environmental regulations to avoid potential penalties.

How Does Fluid Bed Coating Improve Medical Devices?

In the medical field, fluid bed coating is used for surgical instruments and implants to enhance biocompatibility and surface properties. This coating process ensures that devices are safe for patient use while providing an additional layer of protection against wear and tear. Buyers in this sector need to focus on strict adherence to medical safety standards and rigorous testing to ensure that the coatings do not compromise the integrity of the devices.

Why is Fluid Bed Coating Important in the Automotive Industry?

Automotive manufacturers employ fluid bed coating for metal chassis and components to achieve both weight reduction and improved aesthetics. This coating method not only protects against corrosion but also enhances the visual appeal of vehicles. Buyers should ensure that the coatings meet automotive industry specifications regarding durability and performance, as well as the ability to withstand various environmental factors.

What Role Does Fluid Bed Coating Play in Marine Applications?

In marine applications, fluid bed coating is vital for protecting boat hulls and marine equipment from the corrosive effects of saltwater. This process provides a durable barrier that significantly prolongs the lifespan of marine assets. Buyers in this sector must prioritize coatings that demonstrate resistance to harsh marine environments and ensure compliance with relevant regulatory standards to maintain operational integrity and safety.

3 Common User Pain Points for ‘fluid bed coating’ & Their Solutions

Scenario 1: Inconsistent Coating Thickness Leading to Quality Issues

The Problem: B2B buyers often face challenges with inconsistent coating thickness when using fluid bed coating. This inconsistency can lead to quality control issues, as some parts may not receive adequate protection against corrosion and wear. For manufacturers, this means potential product failures, increased warranty claims, and damage to their brand reputation. When coatings are too thick, they can obscure important details or features of the product, while insufficient coating can leave parts vulnerable to environmental damage.

The Solution: To overcome this challenge, it is essential to collaborate closely with coating specialists who understand the specific requirements of your parts. Start by ensuring that the preheating process is precisely calibrated, as the temperature must be high enough to allow the powder to melt and adhere uniformly. Utilize advanced equipment that can monitor and control the immersion time in the fluidized bed. Additionally, consider implementing a quality assurance protocol that includes regular checks of the coating thickness using non-destructive testing methods, such as ultrasonic testing. This proactive approach will help identify inconsistencies early and allow for corrective measures before the product reaches the market.

Scenario 2: Difficulties in Handling Complex Geometries

The Problem: Many manufacturers encounter difficulties when trying to apply fluid bed coating to parts with complex geometries or intricate details. The nature of fluid bed coating can sometimes lead to uneven coverage in recessed areas or complex shapes, resulting in inadequate protection and aesthetic issues. This challenge is particularly pronounced in industries like aerospace or automotive, where precision and durability are non-negotiable.

The Solution: To address this issue, manufacturers should consider pre-treating parts with a specific focus on their geometry. Techniques such as sandblasting or applying a primer can improve the adhesion of the powder coating. Furthermore, utilizing a fluid bed system designed for complex shapes can greatly enhance coverage. Seek out equipment that allows for adjustable airflow and fluidization rates, as this can help direct the powder more effectively into hard-to-reach areas. Lastly, conducting a thorough design review of the parts prior to coating can help identify potential problem areas and adjust the design or coating process accordingly.

Scenario 3: Environmental Concerns and Regulatory Compliance

The Problem: As global awareness of environmental issues grows, B2B buyers are increasingly pressured to adopt sustainable practices in their manufacturing processes. Fluid bed coating, while generally considered more environmentally friendly than traditional liquid coatings, can still pose challenges in terms of VOC emissions and waste management. Companies must navigate local regulations that govern emissions and waste disposal, which can vary significantly across different regions, particularly in Africa, South America, and the Middle East.

The Solution: To ensure compliance and minimize environmental impact, it is crucial to select fluid bed coating materials that are low in VOCs and free from harmful substances. Work with suppliers who offer eco-friendly powder coating options, as these products are not only compliant with regulations but also improve the overall sustainability of your operations. Implement a comprehensive waste management system that includes recycling of overspray and proper disposal of any waste generated during the coating process. Regular training for staff on environmental best practices can also enhance compliance and foster a culture of sustainability within your organization.

Strategic Material Selection Guide for fluid bed coating

What Are the Key Materials for Fluid Bed Coating?

When selecting materials for fluid bed coating, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. Below is an analysis of four common materials used in fluid bed coating, tailored for international B2B buyers.

What Are the Key Properties of Thermoplastic Powders in Fluid Bed Coating?

Thermoplastic powders, such as polyvinyl chloride (PVC), nylon, and polyethylene, are widely used in fluid bed coating due to their ability to melt and re-harden. These materials typically exhibit excellent temperature resistance, withstanding temperatures up to 200°C (392°F). They also offer good corrosion resistance, making them suitable for outdoor applications and environments prone to moisture.

Pros: Thermoplastic powders provide high durability and flexibility, allowing for a thick coating that can hide surface imperfections. They are also environmentally friendly, as they emit fewer volatile organic compounds (VOCs) compared to liquid coatings.

Cons: The manufacturing complexity can be higher due to the need for precise temperature control during the coating process. Additionally, the cost can be moderate to high, depending on the specific type of thermoplastic used.

Impact on Application: Thermoplastic powders are compatible with various media, including metals and some plastics, making them versatile for multiple industries.

Considerations for International Buyers: Compliance with local regulations regarding VOC emissions is essential, especially in regions like Europe, which has stringent environmental standards. Buyers should also ensure that the selected material meets relevant standards such as ASTM or DIN.

How Do Epoxy Powders Perform in Fluid Bed Coating Applications?

Epoxy powders are known for their excellent adhesion properties and chemical resistance. They can withstand harsh environments, making them ideal for industrial applications. Epoxy coatings generally perform well under a wide range of temperatures, typically up to 180°C (356°F).

Pros: The primary advantage of epoxy powders is their exceptional durability and resistance to corrosion, chemicals, and abrasion. They provide a hard, protective layer that is ideal for heavy-duty applications.

Illustrative image related to fluid bed coating

Cons: However, epoxy coatings can be more brittle than thermoplastics, which may lead to cracking under stress. Additionally, they can be more expensive than other options, which may affect budget-sensitive projects.

Impact on Application: Epoxy powders are particularly suitable for applications requiring high chemical resistance, such as automotive or industrial equipment. Their compatibility with various substrates enhances their applicability.

Considerations for International Buyers: Buyers should be aware of specific regulations regarding chemical safety and environmental impact in their regions. Compliance with standards like JIS in Japan or EN in Europe may be necessary.

What Advantages Do Polyester Powders Offer for Fluid Bed Coating?

Polyester powders are another popular choice for fluid bed coating, known for their excellent weatherability and UV resistance. They can typically withstand temperatures up to 200°C (392°F) and are suitable for outdoor applications.

Illustrative image related to fluid bed coating

Pros: The key advantage of polyester powders is their resistance to fading and chalking, making them ideal for products exposed to sunlight. They also provide a smooth finish and are available in a wide range of colors.

Cons: One limitation is that polyester powders may not offer the same level of chemical resistance as epoxy powders. Additionally, they can be more sensitive to application conditions, requiring careful control during the coating process.

Impact on Application: Polyester powders are particularly effective for architectural applications and outdoor furniture, where aesthetics and durability are crucial.

Considerations for International Buyers: Buyers should consider the local climate conditions when selecting polyester powders, as UV exposure can significantly impact performance. Compliance with local standards for outdoor coatings is also essential.

How Do Hybrid Powders Combine the Benefits of Different Materials?

Hybrid powders combine the properties of both epoxy and polyester, offering a balance of durability and aesthetic appeal. They can typically withstand temperatures up to 200°C (392°F) and provide good chemical resistance.

Pros: The primary advantage of hybrid powders is their versatility, making them suitable for various applications, including automotive and industrial uses. They offer a good balance between durability and appearance.

Cons: However, hybrid powders may not excel in specific areas compared to pure epoxy or polyester options. This can lead to compromises in performance depending on the application.

Impact on Application: Hybrid powders are suitable for a wide range of applications, providing flexibility for manufacturers looking to coat different substrates.

Considerations for International Buyers: Buyers should evaluate the specific performance requirements of their applications and ensure that hybrid powders meet local compliance standards.

Summary Table of Materials for Fluid Bed Coating

| Material | Typical Use Case for fluid bed coating | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Powders | General industrial applications | Environmentally friendly, flexible | Higher manufacturing complexity | Medium |

| Epoxy Powders | Heavy-duty industrial equipment | Excellent chemical resistance | Brittle under stress, higher cost | High |

| Polyester Powders | Architectural and outdoor applications | UV resistance, smooth finish | Less chemical resistance | Medium |

| Hybrid Powders | Versatile applications across industries | Balanced durability and aesthetics | May not excel in specific areas | Medium |

This strategic material selection guide provides a comprehensive overview of the key materials used in fluid bed coating, enabling international B2B buyers to make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fluid bed coating

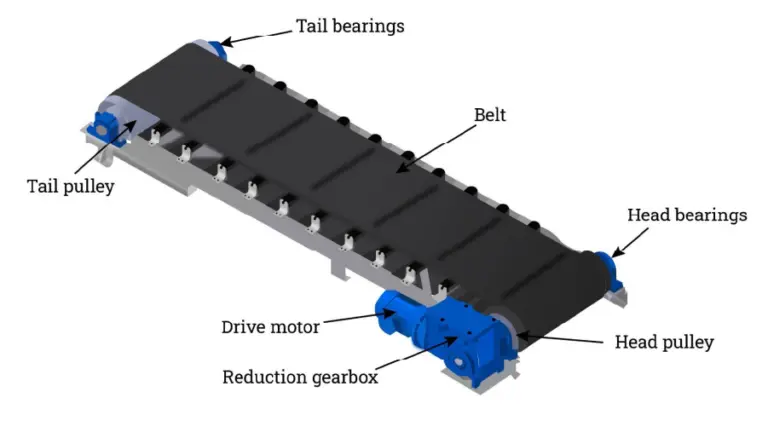

What Are the Key Stages in the Manufacturing Process for Fluid Bed Coating?

Fluid bed coating is a sophisticated manufacturing process that offers high-quality finishes for various substrates, particularly metals. Understanding the key stages involved in this process is crucial for B2B buyers who prioritize quality and efficiency in their production lines.

How Is Material Prepared for Fluid Bed Coating?

The first step in the fluid bed coating process is material preparation, which lays the foundation for a successful coating application. This stage involves cleaning the substrate to remove any contaminants that could interfere with adhesion. Common cleaning methods include sandblasting, chemical cleaning, or ultrasonic cleaning. Following this, the substrate must be preheated to a temperature between 350°F and 450°F. This preheating is essential because it ensures that the fluidized powder adheres properly when the substrate is immersed in the coating medium.

What Techniques Are Used in the Forming Stage?

Once the substrate is prepared, it moves into the forming stage, where it is immersed in the fluidized bed of powder coating. The fluidized bed consists of finely ground thermoplastic powders that are suspended in air, allowing for uniform coating. The substrate is dipped into this bed, and the heat causes the powder particles to melt and fuse onto the surface. The application of heat is critical; if the substrate is not adequately preheated, the powder may not adhere effectively, leading to poor coating quality.

What Are the Finishing Steps in the Fluid Bed Coating Process?

After the substrate is coated, it undergoes a post-fusion process. The coated item is transferred to a curing oven where it is subjected to a lower temperature than the preheating phase, typically around 300°F to 350°F. This step solidifies the coating, resulting in a smooth and durable finish. It is essential that the curing temperature is monitored closely to prevent issues such as sagging or dripping of the coating.

How Is Quality Assurance Integrated into the Fluid Bed Coating Process?

Quality assurance (QA) is a critical component of the fluid bed coating process, ensuring that the final product meets industry standards and customer expectations.

What International Standards Are Relevant for Fluid Bed Coating?

For B2B buyers, adherence to international quality standards like ISO 9001 is a must. This standard focuses on consistent quality management systems, helping manufacturers ensure that their processes are efficient and effective. Additionally, depending on the industry, other certifications like CE (Conformité Européenne) for products sold in Europe, or API (American Petroleum Institute) for oil and gas applications, may also be relevant.

What Quality Control Checkpoints Should Be Monitored?

The quality control process typically includes several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components for compliance with specifications before they enter the production process.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing monitoring is essential. This includes checking the temperature and consistency of the fluidized bed, ensuring that the coating is applied uniformly.

-

Final Quality Control (FQC): After the coating process is complete, finished products undergo a thorough inspection to assess coating thickness, adhesion, and overall appearance.

Which Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are integral to the quality assurance process in fluid bed coating:

-

Adhesion Testing: This assesses how well the coating bonds to the substrate, typically performed using tape tests or pull-off adhesion tests.

-

Thickness Measurement: Utilizing tools like micrometers or ultrasonic thickness gauges ensures that the coating meets specified thickness requirements.

-

Visual Inspections: Aesthetic checks for uniformity, color consistency, and absence of defects are crucial for product quality.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing fluid bed coating services, B2B buyers should conduct thorough due diligence on potential suppliers:

Illustrative image related to fluid bed coating

-

Audits: Regular audits of suppliers’ facilities can provide insights into their quality assurance practices and adherence to international standards.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s quality metrics and performance history.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s capabilities and compliance with industry standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions may have varying compliance requirements. Understanding local standards is essential to ensure that the products meet the necessary regulations for each market.

-

Cultural Considerations: Communication styles and expectations regarding quality can differ across regions. Building strong relationships and clear communication with suppliers can mitigate misunderstandings.

-

Logistical Challenges: Quality assurance processes may also be impacted by logistical considerations, such as shipping times and handling procedures. Ensure that suppliers have robust systems in place to handle international shipping without compromising quality.

In summary, understanding the manufacturing processes and quality assurance measures associated with fluid bed coating is critical for B2B buyers seeking reliable suppliers. By focusing on material preparation, forming techniques, finishing processes, and rigorous quality control measures, buyers can ensure they partner with manufacturers capable of delivering high-quality coated products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fluid bed coating’

Fluid bed coating is an increasingly popular method for applying protective coatings to metal and other substrates, especially for industries requiring durability and corrosion resistance. This guide provides a practical checklist for B2B buyers looking to source fluid bed coating services effectively.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements of your project, including the type of material to be coated, desired coating thickness, and any environmental considerations. This step is vital as it helps in identifying suppliers who can meet your exact needs. Consider factors such as:

– Material compatibility: Ensure the coating process is suitable for the type of substrate you are using.

– Thickness requirements: Specify if a standard or custom coating thickness is needed for your application.

Illustrative image related to fluid bed coating

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in fluid bed coating. Look for companies with a proven track record in your industry. Key aspects to investigate include:

– Experience and expertise: Suppliers with extensive experience often have refined processes and better quality control.

– Client testimonials: Seek reviews or case studies from previous clients to gauge satisfaction and reliability.

Step 3: Evaluate Supplier Capabilities

Assess the technical capabilities of potential suppliers to ensure they can meet your project needs. This includes evaluating their equipment, processes, and quality assurance protocols. Important considerations are:

– Technology and equipment: Suppliers should utilize modern fluid bed coating technologies that enhance efficiency and coating quality.

– Quality control measures: Inquire about their quality assurance processes to ensure consistent results.

Step 4: Request Samples and Conduct Trials

Before committing to a large order, request samples of their work or conduct a trial run. This step allows you to evaluate the quality of the coating and the supplier’s ability to meet your specifications. Pay attention to:

– Adhesion and durability: Test the samples for resistance to wear and environmental factors.

– Finish quality: Ensure the finish meets your aesthetic and functional requirements.

Step 5: Verify Certifications and Compliance

Ensure that the supplier adheres to industry standards and has the necessary certifications for fluid bed coating. This is crucial for maintaining product quality and meeting regulatory requirements. Look for:

– ISO certifications: Such certifications indicate adherence to international quality standards.

– Environmental compliance: Check if they follow environmental regulations related to coating processes.

Step 6: Discuss Lead Times and Flexibility

Communicate your timeline and assess the supplier’s ability to meet your deadlines. Understanding their production capacity and flexibility is essential for planning your operations. Key points to discuss include:

– Production lead times: Ensure their timelines align with your project schedule.

– Scalability: Determine if the supplier can handle fluctuations in order volume as your needs change.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, carefully negotiate terms, including pricing, payment schedules, and warranties. This step ensures clarity and protects your interests. Important aspects to cover are:

– Pricing structure: Understand all costs involved, including any additional charges for custom work.

– Warranty terms: Ensure that the supplier provides a warranty for the coating’s performance and durability.

Following this checklist will help you navigate the complexities of sourcing fluid bed coating services, ensuring you select a supplier that meets your specific needs while maintaining quality and efficiency.

Illustrative image related to fluid bed coating

Comprehensive Cost and Pricing Analysis for fluid bed coating Sourcing

What Are the Key Cost Components of Fluid Bed Coating?

Understanding the cost structure of fluid bed coating is crucial for B2B buyers aiming to optimize their procurement strategies. The primary components influencing the overall cost include:

-

Materials: The choice of powder materials significantly impacts pricing. Thermoplastic powders like PVC, nylon, and polyethylene, which are commonly used in fluid bed applications, can vary widely in cost depending on their quality and supplier. Specialty powders with specific performance characteristics may incur higher costs.

-

Labor: Skilled labor is essential for operating fluid bed coating machinery and ensuring quality control. Labor costs can fluctuate based on regional wage standards, with variations seen across different markets such as Africa, South America, the Middle East, and Europe.

-

Manufacturing Overhead: This includes costs related to equipment maintenance, energy consumption, and facility expenses. Efficient production processes can help minimize these overheads, making it essential to partner with suppliers who prioritize operational efficiency.

-

Tooling: Custom tooling may be required for unique parts, affecting initial setup costs. While initial tooling investments can be high, they often lead to lower per-unit costs in larger production runs.

-

Quality Control (QC): Implementing stringent QC measures ensures that the final products meet the required specifications. This includes testing for adhesion, thickness, and finish quality, which can add to the overall costs but are critical for maintaining product integrity.

-

Logistics: Transportation and handling costs must also be considered, particularly for international shipments. Factors such as shipping methods, distance, and customs duties can influence logistics expenses.

-

Margin: Suppliers typically build a margin into their pricing to account for risk and profit. Understanding the standard margins in your specific market can aid in negotiations.

How Do Price Influencers Impact Fluid Bed Coating Costs?

Several factors can influence the pricing of fluid bed coating services:

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes often lead to reduced per-unit costs. Suppliers may offer tiered pricing structures, incentivizing bulk purchases.

-

Specifications and Customization: Custom requirements such as specific colors, finishes, or thickness levels can lead to increased costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials Quality and Certifications: Higher quality materials and certifications (such as ISO or environmental compliance) can raise costs. However, investing in quality often results in better durability and performance, ultimately reducing long-term costs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may charge premium prices but offer better service and reliability.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) between buyers and sellers can influence shipping costs and responsibilities. Understanding these terms is critical for calculating total landed costs.

What Are the Best Practices for Buyers Negotiating Fluid Bed Coating Prices?

To achieve cost efficiency in fluid bed coating procurement, buyers should consider the following strategies:

-

Negotiate Early: Engage with suppliers during the planning phase of your project to discuss pricing based on anticipated volumes and specifications. Early negotiation can help lock in better rates.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the coating, including maintenance, durability, and performance, rather than just the initial purchase price. This holistic view can guide better decision-making.

-

Research Market Trends: Stay informed about pricing trends and market conditions in your region. Understanding the competitive landscape can empower you during negotiations.

-

Explore Multiple Suppliers: Solicit quotes from various suppliers to compare pricing and service offerings. This competitive approach can reveal hidden costs and opportunities for negotiation.

-

Consider Local Suppliers: Especially for international buyers from regions like Africa and South America, sourcing locally can reduce logistics costs and lead times, making it a cost-effective option.

Disclaimer on Pricing

The prices and cost components discussed in this analysis are indicative and may vary based on specific project requirements, supplier agreements, and market conditions. Always consult with multiple suppliers to obtain accurate and tailored pricing.

Illustrative image related to fluid bed coating

Alternatives Analysis: Comparing fluid bed coating With Other Solutions

When evaluating coating options for metal and other substrates, it’s essential to consider various methods that fulfill specific requirements. Fluid bed coating is a popular choice, but alternative solutions may offer distinct advantages depending on the application and context. Below is a comparative analysis of fluid bed coating against two viable alternatives: electrostatic spray coating and traditional liquid coating.

| Comparison Aspect | Fluid Bed Coating | Electrostatic Spray Coating | Traditional Liquid Coating |

|---|---|---|---|

| Performance | High durability, excellent adhesion, and uniform thickness | Good finish quality, better for complex shapes | Variable quality, prone to drips and sags |

| Cost | Moderate initial investment, low material waste | Moderate cost with potential for overspray waste | Generally lower upfront costs, higher material waste |

| Ease of Implementation | Requires specialized equipment and preheating | Easier setup, requires skilled operators | Simple application, minimal training required |

| Maintenance | Requires regular cleaning of equipment | Moderate maintenance; needs calibration | Generally lower maintenance, but equipment can wear out faster |

| Best Use Case | Ideal for large, simple parts needing thick coating | Best for intricate shapes and detailed parts | Suitable for low-cost projects and quick applications |

What Are the Pros and Cons of Electrostatic Spray Coating?

Electrostatic spray coating involves applying a charged powder to a grounded substrate, which helps the powder adhere effectively. Its main advantage is the ability to coat complex shapes and detailed parts without the risk of thick layering that can obscure design features. However, it may produce overspray, leading to material waste and higher costs. While it offers good finish quality, the durability may not match that of fluid bed coating, making it less ideal for applications requiring heavy wear resistance.

How Does Traditional Liquid Coating Compare to Fluid Bed Coating?

Traditional liquid coating is a widely used method due to its simplicity and lower initial costs. It is easy to apply and doesn’t require specialized equipment, making it accessible for various manufacturers. However, the quality of the finish can be inconsistent, often resulting in drips and sags that compromise the coating’s integrity. Moreover, it typically involves higher material waste due to solvent evaporation and overspray, which can increase overall project costs. For projects where aesthetics are less critical and cost is a primary concern, liquid coatings can be a viable option.

How Should B2B Buyers Choose the Right Coating Solution?

When selecting a coating method, B2B buyers should assess their specific needs, including the type of substrate, complexity of the part, desired durability, and budget constraints. Fluid bed coating excels in applications requiring robust protection and uniformity, while electrostatic spray coating is ideal for intricate designs. Traditional liquid coatings may suffice for less demanding projects. By understanding the strengths and weaknesses of each method, buyers can make informed decisions that align with their operational goals and product requirements.

Essential Technical Properties and Trade Terminology for fluid bed coating

What Are the Key Technical Properties of Fluid Bed Coating?

Understanding the essential technical specifications of fluid bed coating can significantly enhance decision-making for B2B buyers. Here are some critical properties to consider:

1. Material Grade

Material grade refers to the specific type of powder used in the coating process, often categorized by its chemical composition and physical properties. Common materials include thermoplastics such as polyvinyl chloride (PVC) and polyethylene. Selecting the appropriate material grade is vital for ensuring the durability and performance of the coating, particularly in industries like aerospace and automotive, where environmental resistance is paramount.

Illustrative image related to fluid bed coating

2. Coating Thickness

Coating thickness is a critical parameter that affects the performance of the coating. In fluid bed coating, thickness is controlled by the duration of submersion in the fluidized bed and the preheating temperature of the part. A thicker coating provides enhanced protection against corrosion and wear, making it particularly beneficial for industrial applications. Buyers should specify the desired thickness to align with operational requirements.

3. Adhesion Strength

Adhesion strength measures how well the coating bonds to the substrate material. This property is influenced by the surface preparation of the part and the characteristics of the powder. Strong adhesion is essential for ensuring the longevity of the coating, especially in high-stress environments. Buyers should prioritize suppliers who can demonstrate high adhesion levels through rigorous testing.

4. Curing Temperature

Curing temperature is the range of heat required to properly set the powder coating after application. Proper curing ensures that the powder melts and bonds effectively to the substrate, resulting in a smooth and durable finish. Understanding the curing temperature is crucial for maintaining production efficiency and avoiding defects in the final product.

5. Transfer Efficiency

Transfer efficiency refers to the proportion of powder that adheres to the part versus what is wasted during application. High transfer efficiency indicates lower material costs and reduced environmental impact due to less waste. Buyers should inquire about a supplier’s transfer efficiency rates to optimize cost-effectiveness in their coating processes.

What Are Common Trade Terms in Fluid Bed Coating?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms in fluid bed coating:

Illustrative image related to fluid bed coating

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are used in another company’s end products. In the context of fluid bed coating, OEMs often require specific coating solutions to enhance the performance and aesthetics of their products. Understanding OEM requirements can help suppliers tailor their offerings effectively.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For fluid bed coating services, MOQs can affect inventory management and production planning. Buyers should negotiate MOQs that align with their operational needs to avoid overstocking or underutilization.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by buyers to solicit price quotes from suppliers for specific products or services. In fluid bed coating, an RFQ should outline technical specifications, required quantities, and delivery timelines. A well-prepared RFQ can streamline the procurement process and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in the shipping process. These terms clarify who is responsible for costs, risks, and logistics at various stages of transportation. Understanding Incoterms is crucial for avoiding disputes and ensuring smooth cross-border transactions in fluid bed coating procurement.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the finished product. In fluid bed coating, lead times can vary based on the complexity of the coating process and the supplier’s capacity. Clear communication regarding lead times is essential for effective project management and meeting production deadlines.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that lead to successful partnerships in the fluid bed coating sector.

Navigating Market Dynamics and Sourcing Trends in the fluid bed coating Sector

What Are the Current Market Dynamics and Key Trends in Fluid Bed Coating?

The fluid bed coating market is witnessing robust growth driven by the increasing demand for durable, high-performance coatings across various industries, including automotive, aerospace, and medical devices. As global manufacturing continues to expand, particularly in regions like Africa and South America, B2B buyers are seeking innovative coating solutions that enhance product longevity and performance. The rise of advanced technologies such as the Wurster coating system has significantly improved process efficiency, allowing for faster application rates and reduced material waste. Additionally, the growing trend towards automation in manufacturing processes is leading to enhanced quality control and consistency in fluid bed coating applications.

Another emerging trend is the customization of coating solutions tailored to specific industry requirements. For instance, industries like marine and defense are increasingly requiring coatings that offer enhanced corrosion resistance and durability under extreme conditions. This shift is prompting suppliers to invest in R&D to develop specialized powder coatings that meet these stringent demands. Furthermore, the ongoing globalization of supply chains necessitates that international B2B buyers remain agile in sourcing materials that align with both quality standards and regulatory compliance across different markets.

How Does Sustainability Influence Sourcing Decisions in Fluid Bed Coating?

The fluid bed coating sector is increasingly aligning itself with sustainability practices, as B2B buyers prioritize eco-friendly solutions. Traditional solvent-based coatings are being scrutinized for their environmental impact, including high levels of volatile organic compounds (VOCs). In contrast, fluid bed powder coatings offer a more sustainable alternative, as they emit zero VOCs and produce minimal waste during application. This shift towards environmentally friendly products is not only beneficial for the planet but also aligns with corporate social responsibility (CSR) goals that many companies are adopting.

Moreover, the importance of ethical sourcing cannot be overstated in today’s market. Buyers are increasingly demanding transparency in supply chains to ensure that materials are sourced responsibly and sustainably. This includes looking for suppliers that possess relevant certifications, such as ISO 14001 for environmental management and other green certifications. These certifications indicate that suppliers are committed to reducing their ecological footprint and are investing in sustainable practices, which can enhance brand reputation and customer loyalty.

What Is the Historical Context of Fluid Bed Coating in the B2B Landscape?

Fluid bed coating technology has evolved significantly since its inception, with its roots tracing back to the 1960s when it was primarily used in the pharmaceutical industry for coating tablets. Over the decades, advancements in coating materials and processes have expanded its application to various industrial sectors. The introduction of thermoplastic powders and innovations like the Wurster coating system have transformed the fluid bed coating process, enhancing its efficiency and versatility.

Illustrative image related to fluid bed coating

Today, fluid bed coating is recognized for its ability to provide uniform thickness and excellent adhesion, making it a preferred choice for metal and plastic components. This historical evolution underscores the technology’s adaptability and its increasing relevance in meeting the demands of modern manufacturing. As industries continue to innovate, the fluid bed coating sector is poised for further growth, particularly among international B2B buyers seeking high-quality, sustainable coating solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of fluid bed coating

-

How do I choose the right fluid bed coating supplier?

Choosing the right fluid bed coating supplier involves evaluating several key factors. Start by assessing their experience and expertise in the industry, particularly with your specific application needs. Look for suppliers who can demonstrate quality assurance processes and offer customized solutions. Request samples of their previous work and client testimonials to gauge their reliability. It’s also crucial to ensure they have the capacity to meet your production demands and are compliant with international quality standards, especially if you are sourcing from regions like Africa, South America, or the Middle East. -

What are the advantages of fluid bed coating over traditional methods?

Fluid bed coating offers several advantages compared to traditional coating methods. It provides a uniform coating thickness, reducing the risk of drips and uneven surfaces. This method is also more environmentally friendly, as it typically involves fewer volatile organic compounds (VOCs). Additionally, fluid bed coatings exhibit excellent adhesion and durability, making them ideal for applications requiring resistance to corrosion and wear. For businesses looking to improve product longevity, fluid bed coating can be a more cost-effective and sustainable solution in the long run. -

What customization options are available for fluid bed coatings?

Customization options for fluid bed coatings can vary widely among suppliers. Common customization includes selecting specific powder types, colors, and finishes tailored to your product requirements. Some suppliers may also offer custom formulations that enhance particular properties, such as UV resistance or additional durability. It’s advisable to discuss your specific needs with potential suppliers to explore available options and ensure they can meet your expectations for both performance and aesthetics. -

What is the minimum order quantity (MOQ) for fluid bed coating services?

The minimum order quantity (MOQ) for fluid bed coating services can differ based on the supplier and the specific project requirements. Typically, suppliers may set MOQs to ensure efficient production and cost-effectiveness. For international buyers, it’s essential to clarify MOQs upfront, especially if you are sourcing from diverse regions. If your order volume is lower than the MOQ, some suppliers may offer flexibility, such as combining orders or providing a tiered pricing structure based on volume. -

What payment terms should I expect when sourcing fluid bed coating?

Payment terms when sourcing fluid bed coating can vary significantly depending on the supplier and your location. Common practices include upfront deposits (usually 30-50% of the total cost) with the balance due upon delivery or acceptance of the product. Some suppliers may offer credit terms for established clients or larger orders. Ensure you discuss payment options and negotiate terms that suit your cash flow needs while also considering any potential currency fluctuations, especially when dealing with international transactions. -

How does quality assurance work in fluid bed coating processes?

Quality assurance in fluid bed coating processes typically involves several critical steps. Suppliers should conduct thorough inspections of raw materials and finished products to ensure they meet specified standards. This may include testing for adhesion, thickness, and durability of the coating. Additionally, many suppliers will employ standardized processes and documentation to track quality metrics throughout production. As a B2B buyer, inquire about the supplier’s quality assurance protocols and certifications to ensure they align with your expectations and industry standards. -

What logistics considerations should I be aware of when sourcing fluid bed coating?

When sourcing fluid bed coating, logistics considerations are vital to ensure timely delivery and product integrity. Evaluate the supplier’s shipping capabilities, including their experience with international shipments and customs clearance processes. Consider the potential lead times for production and shipping, especially if you require a specific delivery date. Additionally, clarify the terms of delivery, such as Incoterms, and whether the supplier offers assistance with logistics coordination, which can be particularly beneficial for international buyers navigating complex supply chains. -

How can I ensure the fluid bed coating process meets my specific industry standards?

To ensure the fluid bed coating process meets your industry standards, begin by communicating your requirements clearly to potential suppliers. Provide them with specifications related to your industry, including any regulatory compliance or certifications needed. It’s advisable to review their quality control measures and ask for documentation of past projects that align with your requirements. Additionally, consider requesting a trial coating on a sample product to evaluate the process before placing a larger order, ensuring it meets both performance and aesthetic expectations.

Top 4 Fluid Bed Coating Manufacturers & Suppliers List

1. Freund Global – Wurster Coating Technology

Domain: freundglobal.com

Registered: 2024 (1 years)

Introduction: Fluid Bed: Wurster Coating technology is designed for coating particles ranging from fine powders (~10 micron) to small pellets (2-3 mm). It features the patented Wurster Accelerator System, which optimizes product movement through the spray zone, allowing for faster spray rates and reduced process times. Improvements of spray rates up to 600% have been achieved with this system. The Wurster proce…

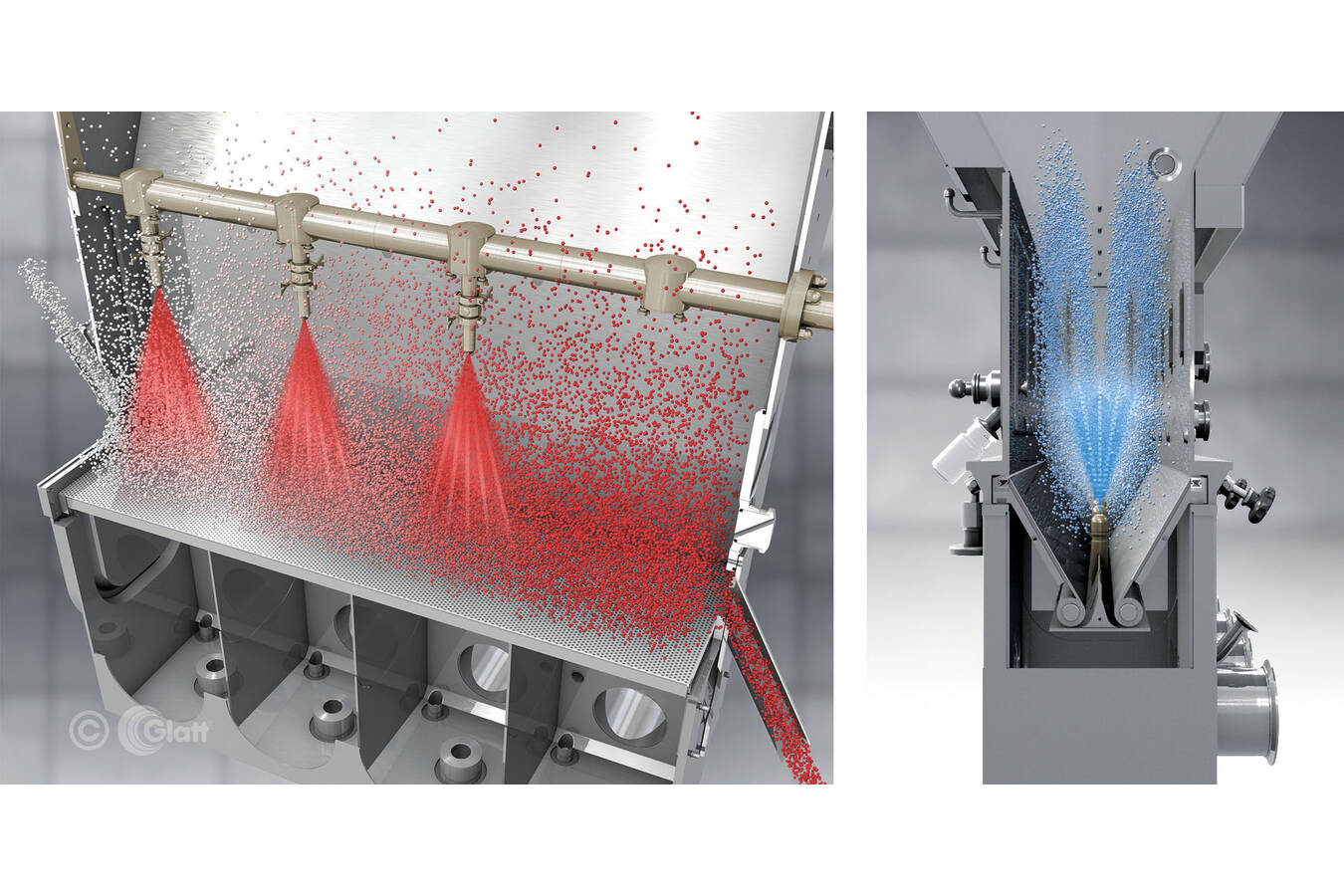

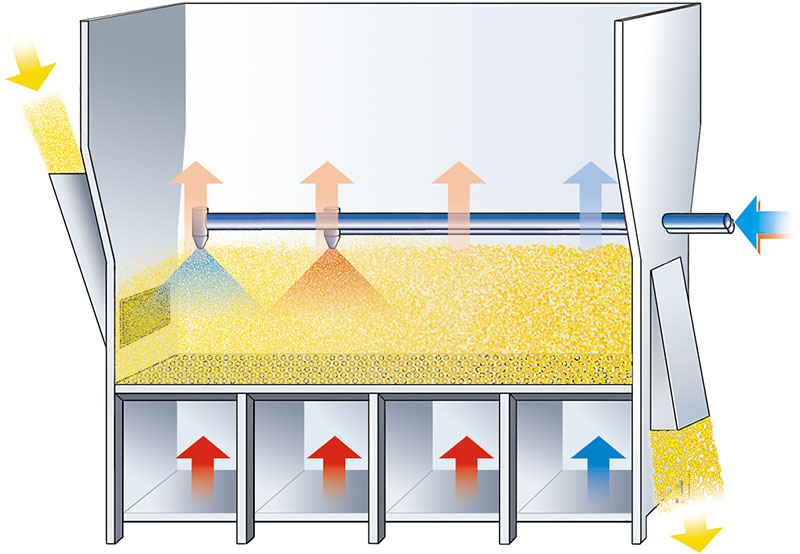

2. Glatt – Spray Coating Solutions

Domain: glatt.com

Registered: 1995 (30 years)

Introduction: Spray coating in fluidized or spouted bed technology by Glatt coats small particles using a method that applies a film material evenly, producing optimal coating of the particle surface. The process involves moving particles in a fluid bed or spouted bed and spraying them with a liquid (aqueous or organic solution, suspension, or melt). The coating layer enhances shelf life, storage stability, and…

3. Fluid Air – Coating Technologies

Domain: fluidairinc.com

Registered: 1997 (28 years)

Introduction: Coating technologies offered by Fluid Air include Wurster Coating and Top-Spray Coating. The Wurster process is recognized for superior fluid bed layering, ideal for coating particles, spheres, granules, and tablets using an air stream and a spray nozzle positioned at the bottom of the fluid bed. It accommodates various coating formulations, including aqueous and organic solvents, hot saturated so…

4. Precision Dip Coating – Fluid Bed Powder Coating

Domain: precisiondipcoating.com

Registered: 2007 (18 years)

Introduction: Fluid Bed Powder Coating at Precision Dip Coating involves immersing a hot part into a bed of plastic powder resins, allowing the powder to melt and build a continuous film. Typical thickness ranges from .007″ to .025″ with no drip activity. It can use both thermoplastic and thermoset powders, including Epoxy, Nylon, Vinyl, Polyethylene, Polyolefins, Polyester, Sterilization Coating, and Halar. Th…

Strategic Sourcing Conclusion and Outlook for fluid bed coating

As industries increasingly prioritize durability and sustainability, fluid bed coating emerges as a compelling solution for businesses seeking reliable protection for their metal products. This coating method not only enhances corrosion resistance and wear protection but also offers an environmentally friendly alternative to traditional liquid coatings, minimizing VOC emissions. By leveraging fluid bed technology, companies can achieve consistent coating thickness, significantly reducing waste and ensuring a high-quality finish that meets diverse application needs.

Strategic sourcing becomes paramount in this context, allowing international buyers from regions such as Africa, South America, the Middle East, and Europe to capitalize on the efficiency and versatility of fluid bed coating. Engaging with experienced coating service providers ensures access to cutting-edge technologies like the Wurster Accelerator, which enhances coating processes and reduces cycle times, ultimately translating to cost savings and improved product performance.

Illustrative image related to fluid bed coating

Looking ahead, the demand for fluid bed coating solutions will continue to grow as global markets evolve. Businesses are encouraged to explore partnerships with reputable coating manufacturers to enhance product longevity and market competitiveness. Embrace the future of coating technology and elevate your offerings by integrating fluid bed solutions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.