The Definitive Guide to Flow Switch: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for flow switch

In the rapidly evolving industrial landscape, sourcing the right flow switch can be a daunting challenge for B2B buyers, especially when navigating diverse global markets. Flow switches are crucial components in various applications, from monitoring fluid dynamics in manufacturing to ensuring safety in HVAC systems. This guide aims to demystify the complexities of selecting the ideal flow switch by providing an extensive overview of the different types available, their applications across industries, and the critical factors to consider during supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Brazil and Vietnam, often face unique hurdles, including varied regulatory standards and local market conditions. By offering actionable insights into pricing structures, quality assurance, and compliance considerations, this guide empowers decision-makers to make informed purchasing choices that align with their operational needs and budget constraints.

Whether you are looking for reliable low-flow protection for pumps or robust switches for harsh environments, understanding the nuances of flow switch technology will enhance your procurement strategy. This guide serves as a comprehensive resource to help you navigate the global market effectively, ensuring that you invest wisely in the right solutions for your business.

Understanding flow switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vane Flow Switch | Uses a paddle mechanism to detect flow; suitable for liquids and gases | HVAC systems, chemical processing | Pros: Durable, versatile; Cons: Limited to certain flow rates. |

| Thermal Dispersion Flow Switch | Measures flow based on temperature differences; ideal for non-coating liquids | Boiler systems, cooling applications | Pros: High accuracy; Cons: Sensitive to liquid properties. |

| Piston Flow Switch | Employs a piston mechanism for flow detection; FDA compliant options available | Food and beverage, pharmaceutical industries | Pros: Compact, reliable; Cons: Limited to lower flow rates. |

| Compact Flotect® Flow Switch | Compact design with weatherproof enclosure; suitable for various pipe sizes | General industrial, HVAC systems | Pros: Space-saving, versatile; Cons: May require specific installation conditions. |

| Globe Valve Flow Switch | Provides precise flow detection with adjustable settings; designed for liquids | Lubrication systems, cooling applications | Pros: High repeatability; Cons: More complex installation. |

What are the characteristics and suitability of Vane Flow Switches for B2B applications?

Vane flow switches are characterized by their paddle mechanism that detects the movement of fluids, making them ideal for both liquids and gases. They are commonly used in HVAC systems and chemical processing applications, where reliable flow detection is critical. When considering a vane flow switch, B2B buyers should assess the durability and versatility of the device, while also being aware that these switches may have limitations regarding the flow rates they can handle.

How do Thermal Dispersion Flow Switches function and where are they best applied?

Thermal dispersion flow switches operate by measuring the temperature difference created by flowing liquids. They are particularly effective for non-coating liquids, making them suitable for boiler systems and cooling applications. Buyers should consider the high accuracy and responsiveness of these switches, but they must also be cautious about the sensitivity to the properties of the liquid being monitored, which can affect performance.

What advantages do Piston Flow Switches offer in food and pharmaceutical industries?

Piston flow switches utilize a piston mechanism to detect flow, often featuring FDA-compliant materials that ensure safety and reliability. These switches are well-suited for the food and beverage and pharmaceutical industries, where compliance with health standards is crucial. While they are compact and dependable, buyers should note that piston flow switches may be limited to lower flow rates, necessitating careful selection for specific applications.

Why choose Compact Flotect® Flow Switches for general industrial use?

Compact Flotect® flow switches are designed with a weatherproof enclosure and a compact form factor, making them suitable for a wide range of industrial applications, including HVAC systems. Their space-saving design allows for easy installation in confined spaces. Buyers should appreciate their versatility; however, they should also consider that specific installation conditions may be required to ensure optimal performance.

What makes Globe Valve Flow Switches a preferred choice for lubrication systems?

Globe valve flow switches are known for their precise flow detection capabilities and adjustable settings, which make them ideal for lubrication and cooling applications. Their high repeatability ensures consistent performance, which is critical in industrial settings. While they offer significant advantages, buyers should be aware that the installation process can be more complex compared to other flow switch types, requiring additional planning and resources.

Key Industrial Applications of flow switch

| Industry/Sector | Specific Application of flow switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water and Wastewater Treatment | Monitoring flow in treatment plants | Ensures optimal operation, preventing system failures | Compliance with environmental regulations and standards |

| Oil and Gas | Flow monitoring in pipelines | Enhances safety by detecting leaks and flow issues | Resistance to harsh chemicals and high pressures |

| HVAC Systems | Flow control in heating and cooling systems | Increases energy efficiency and equipment lifespan | Compatibility with various refrigerants and fluids |

| Food and Beverage | Flow measurement in processing lines | Maintains product quality and safety | FDA compliance and materials suitable for food contact |

| Pharmaceutical Manufacturing | Monitoring flow in production processes | Ensures precise dosing and compliance with regulations | Strict adherence to industry standards and certifications |

How are Flow Switches Utilized in Water and Wastewater Treatment?

Flow switches play a crucial role in water and wastewater treatment by continuously monitoring flow rates in various processes such as filtration and chemical dosing. They help prevent overflow conditions and ensure that treatment systems operate within their design parameters. For international buyers, it is vital to select flow switches that comply with local environmental regulations and standards, as these can vary significantly across regions, particularly in Africa and South America.

What Role Do Flow Switches Play in the Oil and Gas Industry?

In the oil and gas sector, flow switches are essential for monitoring the flow of crude oil and natural gas through pipelines. They provide real-time data that can detect leaks or blockages, thereby enhancing safety and minimizing environmental impact. Buyers in this industry must consider the materials used in flow switches to ensure they can withstand corrosive substances and high-pressure conditions typical in oil and gas applications, especially in the Middle East and Europe.

How Do Flow Switches Enhance HVAC System Efficiency?

In HVAC systems, flow switches are used to monitor the flow of air and refrigerants, ensuring that heating and cooling systems operate efficiently. By detecting low or no flow conditions, they can prevent equipment damage and improve energy efficiency. International B2B buyers should prioritize flow switches that are compatible with a variety of refrigerants and can withstand varying temperatures, considering the diverse climate conditions across regions like Europe and Brazil.

Why Are Flow Switches Important in Food and Beverage Processing?

In the food and beverage industry, flow switches are crucial for ensuring that liquids are processed accurately and safely. They help maintain consistent flow rates during production, which is essential for product quality and safety. Buyers should look for flow switches that meet FDA compliance and are constructed from materials suitable for food contact, as the regulations can be stringent, particularly in regions with strict food safety standards.

How Are Flow Switches Critical in Pharmaceutical Manufacturing?

Flow switches are integral to pharmaceutical manufacturing, where they monitor the flow of liquids in production processes. Accurate flow measurement is vital for precise dosing and compliance with stringent regulations. International buyers must ensure that the flow switches sourced are certified for pharmaceutical use, adhering to the highest industry standards and certifications, which can vary by region, particularly in Europe and South America.

3 Common User Pain Points for ‘flow switch’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Flow Switch for Diverse Applications

The Problem:

B2B buyers often face the challenge of selecting the appropriate flow switch for their specific application needs. With numerous types available—including thermal dispersion, paddle, and piston switches—determining which one will perform optimally in a given environment can be overwhelming. This decision is critical, as choosing an incompatible flow switch can lead to system inefficiencies, increased operational costs, and even equipment damage. Buyers may also struggle with understanding the technical specifications required for their processes, such as media compatibility and operating temperature ranges, leading to further complications.

The Solution:

To effectively navigate this selection process, buyers should start with a comprehensive assessment of their application requirements. This includes understanding the type of fluid being monitored (liquid, gas, or air), the expected flow rate, and the environmental conditions (temperature, pressure, and potential exposure to corrosive substances). Engage with manufacturers or distributors who offer a variety of flow switches and can provide insights into their performance in similar applications. Moreover, buyers should consider flow switches with adjustable settings to accommodate varying flow conditions. Utilizing resources such as technical datasheets and user manuals will further aid in making an informed choice.

与flow switch相关的说明性图片

Scenario 2: Inadequate Maintenance Leading to Flow Switch Failures

The Problem:

Many organizations neglect the maintenance of flow switches, which can lead to failures that disrupt operations. Flow switches are critical for monitoring flow rates and ensuring the safe operation of equipment such as pumps and boilers. When these devices fail, it can result in unmonitored system conditions, leading to potential equipment damage, safety hazards, or production downtime. B2B buyers may struggle with establishing a routine maintenance plan due to limited resources or lack of expertise in their teams.

The Solution:

To mitigate the risk of flow switch failures, it is essential to implement a proactive maintenance schedule. Buyers should develop a maintenance checklist that includes regular inspections, cleaning, and testing of flow switches to ensure they function correctly. Collaborating with manufacturers for training sessions or workshops can enhance the team’s understanding of maintenance best practices. Additionally, consider investing in flow switches with self-diagnostic features or indicators that alert users when maintenance is needed. This approach not only extends the lifespan of the devices but also minimizes unexpected operational interruptions.

Scenario 3: Compliance with International Standards and Regulations

The Problem:

International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, often encounter challenges related to compliance with varying regional standards and regulations for flow switches. These regulations can affect product specifications, including material safety, environmental impact, and performance criteria. Non-compliance can lead to legal ramifications, product recalls, and damage to a company’s reputation. Buyers may feel overwhelmed by the complexity of ensuring that their flow switches meet these diverse requirements.

The Solution:

To navigate compliance issues effectively, it is crucial for buyers to conduct thorough research on the specific regulations applicable in their target markets. This includes understanding local standards such as ISO, ANSI, or regional safety certifications. Partnering with suppliers who have a solid understanding of these regulations can streamline the process, as they can provide compliant products and relevant documentation. Buyers should also consider sourcing flow switches that are certified for multiple international standards, which can reduce the complexity of dealing with various suppliers and enhance their operational efficiency. Regular audits and updates on compliance practices should be integrated into procurement processes to ensure ongoing adherence to evolving regulations.

Strategic Material Selection Guide for flow switch

What Are the Key Properties of Common Materials Used in Flow Switches?

When selecting materials for flow switches, it’s essential to consider their properties, especially in terms of temperature and pressure ratings, as well as corrosion resistance. The most common materials include brass, stainless steel, plastic (such as polypropylene), and aluminum. Each material has unique characteristics that can significantly influence the performance and suitability of the flow switch for specific applications.

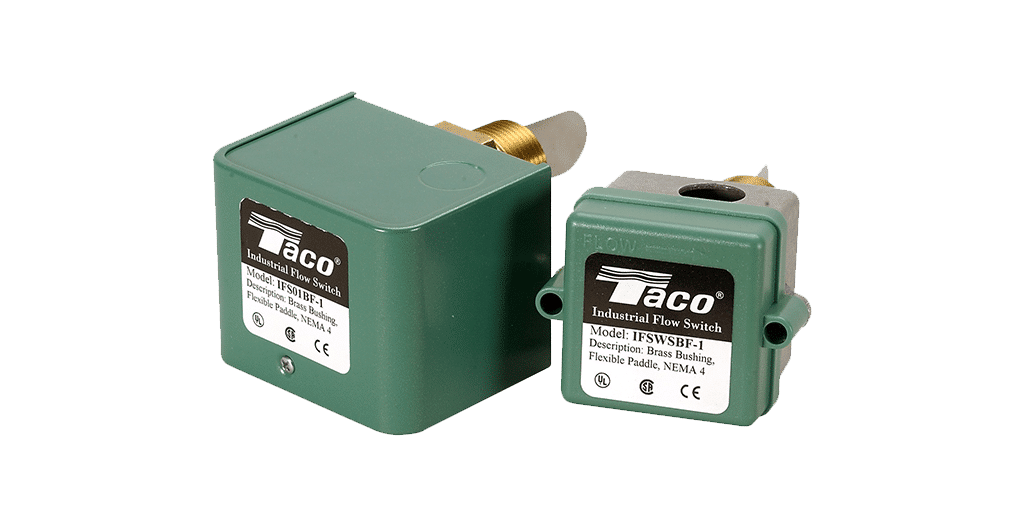

How Does Brass Material Perform in Flow Switch Applications?

Brass is a popular choice for flow switches due to its excellent machinability and good corrosion resistance. It typically offers a temperature rating up to 200°C and can withstand moderate pressure levels, making it suitable for many liquid applications.

Pros: Brass is durable, relatively low-cost compared to stainless steel, and provides good conductivity, which is beneficial for electrical connections.

Cons: However, brass can corrode in certain environments, particularly in the presence of chlorides, and may not be suitable for aggressive chemicals.

Impact on Application: Brass flow switches are commonly used in water and oil applications but should be avoided in highly corrosive environments.

Considerations for International Buyers: Compliance with standards such as ASTM B453 and DIN 17660 is crucial. Buyers from regions with high humidity or saline environments, like parts of South America and the Middle East, should be cautious about using brass.

What Are the Advantages of Stainless Steel in Flow Switches?

Stainless steel is favored for its superior strength and excellent corrosion resistance, making it ideal for harsh environments. It can handle high temperatures (up to 300°C) and pressures, often exceeding 200 psi.

Pros: Its durability and resistance to oxidation and corrosion make it suitable for a wide range of applications, including food and chemical processing.

Cons: The primary drawback is its higher cost compared to brass and other materials, along with a more complex manufacturing process.

Impact on Application: Stainless steel flow switches are perfect for aggressive media, including acids and bases, and are often used in industries that require stringent hygiene standards.

Considerations for International Buyers: Compliance with international standards such as ASTM A312 and JIS G4303 is essential, particularly for buyers in Europe and the Middle East, where food safety regulations are stringent.

How Do Plastic Materials Like Polypropylene Compare?

Plastic materials, especially polypropylene, are increasingly used in flow switches due to their lightweight nature and excellent chemical resistance. They can typically withstand temperatures up to 100°C and moderate pressures.

Pros: Polypropylene is cost-effective and resistant to many chemicals, making it suitable for a variety of applications, including water treatment.

Cons: However, plastics are generally less durable than metals and can deform under high temperatures or pressures.

Impact on Application: These flow switches are ideal for non-corrosive liquids and applications where weight is a concern.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM D4101. In regions like Africa and South America, where cost is often a significant factor, polypropylene can be an attractive option.

What Role Does Aluminum Play in Flow Switch Design?

Aluminum is another material used in flow switches, known for its lightweight and good corrosion resistance. It typically operates effectively at temperatures up to 120°C and moderate pressures.

Pros: Aluminum is relatively inexpensive and easy to machine, making it suitable for various applications.

Cons: However, it is not as strong as stainless steel and can corrode in acidic or alkaline environments.

与flow switch相关的说明性图片

Impact on Application: Aluminum flow switches are often used in HVAC applications and other environments where weight and cost are critical factors.

Considerations for International Buyers: Compliance with standards like ASTM B221 is important. Buyers from regions with high industrial activity, such as Europe, should consider the material’s longevity in their specific applications.

Summary Table of Material Selection for Flow Switches

| Material | Typical Use Case for flow switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Water and oil applications | Good conductivity and machinability | Corrosion in aggressive environments | Medium |

| Stainless Steel | Chemical processing and food industries | Superior corrosion resistance | Higher cost and manufacturing complexity | High |

| Polypropylene | Water treatment and non-corrosive liquids | Lightweight and cost-effective | Less durable under high temperatures | Low |

| Aluminum | HVAC systems and lightweight applications | Inexpensive and easy to machine | Not suitable for acidic or alkaline media | Medium |

This material selection guide provides B2B buyers with crucial insights into the properties, advantages, and limitations of different materials used in flow switches, enabling informed purchasing decisions tailored to specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for flow switch

What Are the Key Stages in the Manufacturing Process of Flow Switches?

The manufacturing process of flow switches typically involves several critical stages that ensure the final product meets industry standards and customer expectations.

Material Preparation: Sourcing and Quality Control

The process begins with the careful selection of raw materials, which may include metals like brass or stainless steel, and various polymers for non-corrosive applications. Suppliers must adhere to international standards such as ISO 9001 to ensure that materials are of high quality. Material verification includes checking certificates of compliance and conducting initial quality control inspections (IQC) upon receipt to confirm that the materials meet specified requirements.

Forming: Techniques and Equipment Used

Once materials are prepared, the next stage is forming, which can involve various techniques such as machining, molding, or stamping. For example, precision machining is often used for metal components to achieve tight tolerances necessary for accurate flow measurement. Advanced technologies like CNC (Computer Numerical Control) machining may be employed to enhance accuracy and reduce waste. Additionally, injection molding might be utilized for plastic components, ensuring uniformity and efficiency in production.

Assembly: Integration of Components

The assembly stage is crucial as it involves the integration of all components, including sensors, switches, and enclosures. This process often employs automated assembly lines to ensure consistency and reduce human error. Skilled technicians perform manual assembly for more complex components, ensuring that each flow switch is assembled according to stringent guidelines. Quality assurance checkpoints are established throughout the assembly process to identify and rectify any issues immediately.

Finishing: Surface Treatment and Testing

Finishing processes such as surface treatment, coating, or painting are applied to enhance durability and corrosion resistance. For flow switches designed for harsh environments, special coatings may be necessary to withstand extreme temperatures or chemical exposure. Following the finishing processes, each unit undergoes rigorous testing to ensure functionality and reliability. This includes pressure testing, flow rate calibration, and electrical testing to confirm that the switch operates within specified parameters.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is an integral part of the flow switch manufacturing process, with a focus on compliance with international standards and industry-specific regulations.

What International Standards Should Flow Switch Manufacturers Adhere To?

Manufacturers often seek certifications such as ISO 9001 for general quality management, CE marking for products sold in Europe, and API standards for oil and gas applications. These certifications indicate that the manufacturer adheres to internationally recognized quality management principles and has implemented a quality management system (QMS) that consistently provides products that meet customer and regulatory requirements.

What Are the Key Quality Control Checkpoints in the Production Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This checkpoint verifies that raw materials meet specified standards before they enter production.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process ensure that components are produced within tolerance levels and identify any defects early.

- Final Quality Control (FQC): This stage involves comprehensive testing of the finished flow switches to ensure they meet design specifications and functional requirements.

Common testing methods include flow rate testing, pressure testing, and electrical continuity testing, which are crucial for validating the operational integrity of the switches.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers to ensure that they receive reliable products.

What Steps Can Buyers Take to Assess Supplier Quality?

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to evaluate their manufacturing processes, quality control measures, and adherence to international standards. This can be done through on-site visits or third-party audit services.

-

Requesting Quality Assurance Reports: Buyers should request quality assurance documentation, including inspection reports, test results, and compliance certificates. This documentation serves as evidence of the supplier’s commitment to quality.

-

Third-party Inspections: Engaging independent third-party inspection agencies can provide unbiased assessments of the supplier’s quality control processes and product quality.

-

Certifications Verification: Buyers should verify that suppliers hold valid certifications for quality standards relevant to their industry. This can typically be done through the certifying body’s online database.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control practices that may affect their purchasing decisions.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying standards and regulations that suppliers must comply with. For instance, CE marking is crucial for products sold in the European market, while UL certification may be necessary for North American markets. Buyers should ensure that suppliers are familiar with and compliant with the relevant standards in their target market to avoid regulatory issues.

What Challenges Might Buyers Face in Ensuring Quality?

Cultural differences and varying levels of regulatory enforcement can pose challenges for international buyers. It is essential for buyers to establish clear communication channels and set expectations regarding quality standards upfront. Additionally, building long-term relationships with suppliers can facilitate better quality assurance practices and mutual understanding of quality expectations.

Conclusion: Ensuring Quality in Flow Switch Manufacturing

Understanding the manufacturing processes and quality assurance protocols in the production of flow switches is vital for B2B buyers aiming to source reliable and high-quality products. By focusing on the key stages of manufacturing, adhering to international standards, and implementing effective quality control measures, buyers can ensure that they partner with suppliers who prioritize quality and reliability in their offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flow switch’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure flow switches. Flow switches are critical components in various industrial applications, ensuring optimal flow conditions for liquids and gases. By following this step-by-step guide, buyers can make informed decisions that align with their operational needs and compliance requirements.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for the flow switch. Consider the type of media (liquid or gas), flow rate, and pressure specifications.

- Key parameters: Determine the required pipe size, operating temperature range, and switch type (e.g., vane, thermal dispersion).

- Application context: Understand the specific applications, such as HVAC systems or chemical processing, to ensure compatibility.

Step 2: Research Regulatory Compliance Standards

Ensure that the flow switch meets relevant industry standards and regulatory requirements. This is crucial for operational safety and legal compliance.

- Common certifications: Look for certifications such as NEMA ratings for environmental protection and ATEX for explosive atmospheres.

- Regional regulations: Be aware of local standards in your region, especially if sourcing from international suppliers.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to ensure reliability and quality. This step is vital for establishing a trustworthy supply chain.

- Request documentation: Ask for company profiles, product catalogs, and case studies to gauge their expertise.

- Check references: Contact existing customers in similar industries or regions to obtain feedback on the supplier’s reliability and service quality.

Step 4: Assess Product Quality and Features

Examine the specific features and quality of the flow switches you are considering. This includes the materials used and the technology employed in the switch design.

- Material compatibility: Ensure that the materials are suitable for the media they will handle, particularly in corrosive environments.

- Durability and maintenance: Consider the switch’s lifespan and ease of maintenance to minimize downtime and replacement costs.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare pricing and contractual terms. This will help you understand the cost implications and value for money.

与flow switch相关的说明性图片

- Transparent pricing: Look for detailed quotes that break down costs, including shipping and installation.

- Negotiation opportunities: Be prepared to negotiate terms, especially for bulk purchases or long-term contracts.

Step 6: Verify After-Sales Support and Warranty

Assess the after-sales support and warranty options provided by suppliers. This is crucial for ensuring long-term operational success and addressing any issues that may arise.

- Support availability: Check if the supplier offers technical support, training, or maintenance services post-purchase.

- Warranty terms: Review warranty coverage to understand what is included and the process for claiming support.

Step 7: Finalize Your Purchase Decision

After completing the previous steps, compile all gathered information and make an informed decision. This step is about consolidating your findings and ensuring all criteria are met.

- Consensus among stakeholders: Involve relevant team members in the decision-making process to ensure alignment with organizational goals.

- Documentation: Keep records of all communications and agreements for future reference and accountability.

Following this checklist will empower B2B buyers to effectively source flow switches that meet their operational needs while ensuring compliance and quality.

Comprehensive Cost and Pricing Analysis for flow switch Sourcing

What Are the Key Cost Components in Flow Switch Manufacturing?

The cost structure for flow switches encompasses several critical components. Materials represent a significant portion of the cost, influenced by the type of flow switch being produced—whether it’s made from brass, stainless steel, or plastic. Each material has different price points and availability, which can impact the overall cost.

Labor costs also play a pivotal role. Skilled labor is required for assembly and quality control, which can vary by region. In countries with lower labor costs, such as some in Africa and South America, manufacturers can offer more competitive pricing, but this must be balanced with quality assurance.

与flow switch相关的说明性图片

Manufacturing overhead includes expenses related to utilities, facility maintenance, and equipment depreciation. This is particularly relevant for manufacturers who utilize advanced technology or automation in their production processes.

Tooling costs are incurred for the creation of molds and equipment needed to manufacture specific switch types. These costs can be amortized over production volume, making them a crucial factor in pricing.

Quality Control (QC) is essential in ensuring that flow switches meet required specifications and standards, especially for industries like oil and gas, where safety is paramount. Enhanced QC processes can increase costs but are necessary for maintaining product integrity.

Logistics expenses encompass transportation, warehousing, and handling, which can be particularly complex for international shipments. These costs can vary significantly based on the shipping terms agreed upon (Incoterms) and the distance to the buyer.

Margin is the final component, representing the profit that manufacturers and distributors aim to achieve. This margin can fluctuate based on market competition, demand, and the overall economic landscape.

与flow switch相关的说明性图片

How Do Price Influencers Affect Flow Switch Costs?

Several factors influence the pricing of flow switches. Volume and Minimum Order Quantity (MOQ) are crucial; purchasing in larger quantities often results in lower per-unit costs due to economies of scale.

Specifications and customization can significantly affect pricing. Custom solutions tailored to specific applications may incur higher costs due to the need for specialized materials or additional engineering resources.

Material selection impacts both the upfront costs and the durability of the product. High-quality materials may require a higher initial investment but can lead to lower total costs over time due to reduced failure rates and maintenance needs.

与flow switch相关的说明性图片

Quality certifications (such as ISO or CE) can also influence pricing. Suppliers that provide certified products may charge a premium, but this investment can be justified by the assurance of reliability and compliance with international standards.

Supplier factors, including reputation and reliability, can affect pricing. Established suppliers with proven track records may command higher prices, but they often deliver better quality and service.

What Are the Best Buyer Tips for Cost-Efficiency in Flow Switch Sourcing?

Negotiating effectively is key to achieving cost efficiency. Buyers should engage in discussions about pricing structures and be prepared to explore options for bulk discounts or long-term contracts that can lead to more favorable pricing.

Understanding the Total Cost of Ownership (TCO) is essential. Buyers should consider not just the purchase price but also installation, maintenance, and operational costs over the product’s lifespan. Investing in higher-quality flow switches may result in lower overall costs due to reduced downtime and maintenance.

For international buyers, especially those in regions like Africa, South America, the Middle East, and Europe, it’s important to be aware of pricing nuances related to tariffs, taxes, and shipping costs. Familiarity with Incoterms can help buyers negotiate better terms and avoid unexpected costs.

Lastly, buyers should be aware that prices can vary significantly based on market conditions. Engaging multiple suppliers for quotes and conducting thorough market research can provide insights into fair pricing and help identify the best sourcing options.

Disclaimer

The prices mentioned in various sources are indicative and can fluctuate based on market conditions, supplier negotiations, and regional factors. Buyers are encouraged to conduct thorough research and obtain multiple quotations to ensure competitive pricing.

Alternatives Analysis: Comparing flow switch With Other Solutions

Understanding Alternatives to Flow Switches for Flow Monitoring

In the realm of flow monitoring, flow switches are widely recognized for their efficiency and reliability in various applications. However, businesses often seek alternative solutions that may better align with their specific operational needs, budget constraints, or environmental conditions. This analysis will compare flow switches against two viable alternatives: flow meters and pressure switches.

Comparison Table

| Comparison Aspect | Flow Switch | Flow Meter | Pressure Switch |

|---|---|---|---|

| Performance | Reliable for detecting flow presence | Provides continuous flow rate readings | Detects pressure changes related to flow |

| Cost | Moderate, varies by type and features | Generally higher due to complexity | Typically lower than flow meters |

| Ease of Implementation | Straightforward installation | May require calibration and setup | Simple installation, but less versatile |

| Maintenance | Low maintenance needs | Requires periodic calibration | Minimal maintenance required |

| Best Use Case | On/Off control for pumps and systems | Accurate flow rate measurement | Systems where pressure correlates with flow |

What Are the Advantages and Disadvantages of Flow Meters?

Flow meters are designed to measure the actual flow rate of liquids or gases within a system. They provide continuous data, making them ideal for applications requiring precise flow management, such as in chemical processing or water treatment. The advantages of flow meters include high accuracy and the ability to monitor flow trends over time. However, they typically come at a higher cost and may require more complex installation and calibration processes, which can be a barrier for some businesses.

How Do Pressure Switches Compare to Flow Switches?

Pressure switches are devices that detect changes in pressure within a system, which can indicate flow conditions. They are generally less expensive than flow meters and can be easier to install, making them suitable for simpler applications. However, their reliance on pressure changes can limit their applicability in certain systems where flow characteristics may vary independently of pressure. While pressure switches are effective for certain monitoring tasks, they lack the direct flow measurement capabilities that flow switches provide.

How Can B2B Buyers Choose the Right Solution?

Selecting the right flow monitoring solution involves evaluating specific operational needs, including the desired level of accuracy, budget, and installation capabilities. Flow switches are excellent for straightforward flow detection and control in various industrial applications. In contrast, flow meters are better suited for scenarios demanding precise flow rate measurements, albeit at a higher price point. Pressure switches may offer a cost-effective alternative for simpler systems where pressure serves as a reliable indicator of flow. Ultimately, understanding the unique requirements of your application will guide you in choosing the most suitable technology for your business.

Essential Technical Properties and Trade Terminology for flow switch

When evaluating flow switches for industrial applications, understanding their essential technical properties and common trade terminology is crucial for informed decision-making. This guide outlines the key specifications and terms that can significantly impact procurement and operational efficiency.

What Are the Key Technical Properties of Flow Switches?

-

Material Grade

– The material used in flow switches can vary widely, with common options including stainless steel, brass, and polypropylene. The choice of material affects durability, corrosion resistance, and compatibility with various fluids. For instance, stainless steel is ideal for harsh environments, while polypropylene may be suitable for less aggressive applications. Selecting the right material ensures longevity and reliability in operations. -

Process Connection Type

– Flow switches can be fitted with different types of process connections, such as NPT (National Pipe Thread), flange, or compression fittings. The type of connection impacts installation ease and compatibility with existing piping systems. Understanding the available options helps buyers ensure seamless integration into their processes, reducing downtime and maintenance needs. -

Operating Temperature Range

– Each flow switch is rated for specific temperature ranges, indicating the maximum and minimum temperatures it can withstand. This specification is vital for applications in industries such as HVAC, chemical processing, and food production, where temperature fluctuations can be significant. Ensuring that the chosen flow switch can operate within the required temperature limits prevents failures and enhances system efficiency. -

Switch Rating

– The switch rating, typically expressed in terms of voltage and current (e.g., 10A at 250VAC), defines the electrical capacity of the flow switch. This specification is essential when integrating the switch with control systems, as using a switch with an inadequate rating can lead to electrical failures. Buyers must ensure that the switch rating aligns with their operational requirements to avoid costly disruptions. -

Accuracy and Sensitivity

– Flow switches vary in their accuracy and sensitivity to flow changes. Specifications may include repeatability (e.g., ±1%) and response time. High accuracy is crucial for applications where precise flow control is necessary, such as in water treatment facilities or chemical processes. Understanding these metrics allows buyers to select switches that meet their operational precision needs. -

Enclosure Rating

– The enclosure rating, often categorized by the NEMA (National Electrical Manufacturers Association) standard, indicates the level of protection against environmental factors such as dust and moisture. Common ratings include NEMA 4 (weatherproof) and NEMA 7 (explosion-proof). Selecting the appropriate enclosure rating is vital for ensuring that the flow switch can function reliably in its intended environment, particularly in industries with stringent safety requirements.

Which Trade Terms Are Essential for Flow Switch Procurement?

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding this term helps buyers identify reputable suppliers who can provide reliable flow switches tailored to specific applications. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units that a supplier is willing to sell. This term is significant for buyers looking to manage inventory costs while meeting production demands. Knowing the MOQ helps in negotiating better terms and planning purchases effectively. -

RFQ (Request for Quotation)

– An RFQ is a formal document that buyers send to suppliers to request pricing and terms for specific products. This process is critical for comparing offers and making informed purchasing decisions. A well-structured RFQ can streamline procurement and ensure competitive pricing. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk transfer, and delivery obligations, essential for effective logistics management. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the product. This term is crucial for project planning and inventory management, as longer lead times may impact operational efficiency and project timelines. -

Certification Compliance

– Certification compliance refers to adherence to industry standards and regulations, such as ISO or CE marking. Understanding these requirements is crucial for ensuring that flow switches meet safety and quality standards, particularly in regulated industries.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing flow switches, ultimately leading to enhanced operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the flow switch Sector

What Are the Key Trends Influencing the Flow Switch Market?

The flow switch market is experiencing significant growth, driven by global industrialization, advancements in automation technology, and increasing regulatory standards for safety and efficiency. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly investing in flow switches to enhance operational reliability in sectors such as manufacturing, oil and gas, and water treatment. Emerging technologies like IoT and Industry 4.0 are shaping the landscape, enabling real-time monitoring and control of fluid dynamics, which enhances operational efficiency and minimizes downtime.

Moreover, the shift towards smart manufacturing is prompting buyers to look for flow switches that integrate seamlessly with existing systems. This demand is resulting in a trend towards customizable solutions that cater to specific industry needs, such as weatherproof designs for harsh environments or explosion-proof switches for hazardous applications. Additionally, the growing focus on predictive maintenance is driving the need for advanced flow monitoring solutions that can provide alerts before equipment failures occur, thus reducing operational costs and improving safety.

How Are Sustainability and Ethical Sourcing Impacting Flow Switch Procurement?

In today’s market, sustainability and ethical sourcing have become paramount for B2B buyers. The environmental impact of manufacturing processes is under scrutiny, with companies seeking to minimize their carbon footprints. As a result, there is a growing demand for flow switches made from eco-friendly materials and those that adhere to stringent environmental regulations. Buyers are increasingly looking for products with certifications such as ISO 14001, which indicates a commitment to sustainable practices.

Ethical supply chains are also gaining prominence, as buyers prefer suppliers who demonstrate transparency and responsibility in their sourcing practices. This includes ensuring that raw materials are sourced from reputable suppliers who adhere to ethical labor practices and environmental standards. Additionally, many companies are adopting circular economy principles, focusing on products that can be recycled or repurposed at the end of their life cycle, further emphasizing the importance of sustainability in procurement decisions.

What Is the Brief History and Evolution of Flow Switch Technology?

Flow switch technology has evolved significantly since its inception. Initially developed in the early 20th century for basic flow detection, these devices have undergone substantial advancements to meet the needs of modern industries. Early flow switches relied on mechanical components, which often led to reliability issues and maintenance challenges. However, with the introduction of electronic and digital technologies in the late 20th century, flow switches became more accurate and easier to integrate into automated systems.

Today, flow switches are equipped with advanced features such as adjustable flow rates, LED indicators, and compatibility with various media types, including corrosive substances. This evolution has enabled them to serve a wide range of applications, from HVAC systems to chemical processing, making them indispensable in various industrial sectors. As technology continues to advance, the flow switch market is poised for further innovation, driven by the need for enhanced efficiency and sustainability in fluid management.

Frequently Asked Questions (FAQs) for B2B Buyers of flow switch

-

How do I choose the right flow switch for my application?

Selecting the appropriate flow switch involves evaluating several factors. First, consider the type of media—liquids, gases, or air—as different switches are designed for specific applications. Next, assess the required flow rate and pressure ratings to ensure compatibility with your system. Environmental factors such as temperature, humidity, and exposure to chemicals should also influence your choice. Finally, take into account any industry standards or certifications needed for your application, particularly if you’re operating in regulated sectors. -

What are the key features to look for in a flow switch?

When sourcing a flow switch, key features to consider include the switch type (mechanical, thermal, or electronic), actuation set points, and materials used for construction. Look for options with adjustable flow rates and clear visual indicators for easy monitoring. Ensure that the switch has an appropriate enclosure rating (such as NEMA) to withstand environmental conditions. Additionally, consider the maintenance requirements and the availability of spare parts to minimize downtime. -

What are common applications for flow switches in industrial settings?

Flow switches are utilized in various industrial applications, including HVAC systems, water treatment facilities, and chemical processing. They are essential for monitoring flow in boilers, chillers, and cooling systems, ensuring equipment protection and operational efficiency. Additionally, flow switches are used in lubrication systems to maintain optimal flow and prevent damage to machinery. Understanding your specific application will guide you in selecting the right flow switch for your needs. -

What is the minimum order quantity (MOQ) for flow switches?

Minimum order quantities (MOQs) for flow switches can vary significantly based on the supplier and the specific product. Typically, MOQs may range from a single unit for standard items to larger quantities for customized solutions or specialized applications. When sourcing internationally, confirm the MOQ with your supplier and consider the implications for your inventory management and cash flow. Negotiating lower MOQs or bulk discounts can also be beneficial if you anticipate future needs. -

How can I ensure quality and compliance when sourcing flow switches?

To ensure quality and compliance, verify that the flow switches adhere to relevant industry standards and certifications, such as ISO, CE, or UL. Request product documentation, including datasheets and test reports, from suppliers. Consider conducting factory audits or utilizing third-party quality assurance services to assess manufacturing practices. Building a long-term relationship with reputable suppliers who prioritize quality control can also help ensure consistent product performance. -

What payment terms should I expect when sourcing flow switches internationally?

Payment terms for international sourcing can vary depending on the supplier and the nature of the transaction. Common options include upfront payments, letter of credit, or payment upon delivery. Be sure to clarify payment methods (e.g., bank transfer, PayPal) and any associated fees. Additionally, discuss the possibility of credit terms for established relationships, as this can improve cash flow management and foster trust between parties. -

What are the logistics considerations when importing flow switches?

Logistics considerations for importing flow switches include shipping methods, customs clearance, and delivery timelines. Assess the most cost-effective shipping options based on urgency and budget, whether air freight or sea freight. Ensure that all necessary documentation, such as invoices and packing lists, is in order for smooth customs processing. Familiarize yourself with local regulations and tariffs that may impact the overall cost of importing flow switches. -

How do I vet suppliers for flow switches effectively?

To effectively vet suppliers for flow switches, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies to gauge their reliability. Verify their manufacturing capabilities and compliance with international standards. Request references from other clients and assess their responsiveness to inquiries. Engaging in direct communication and possibly visiting the facility can also provide valuable insights into their operational practices and commitment to quality.

Top 8 Flow Switch Manufacturers & Suppliers List

1. Dwyer – Pressure Measurement Solutions

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: {“price_ranges”:[{“min”:50,”max”:199.99,”count”:8},{“min”:200,”max”:499.99,”count”:11},{“min”:500,”max”:999.99,”count”:15},{“min”:1000,”max”:9999.99,”count”:5}],”brands”:[“Dwyer”,”Omega”],”media_compatibility”:[“Air”,”Alcohols”,”Alkaline solutions”,”Argon”,”Compatible Gases”,”Compatible Liquids”,”Dilute Acids”,”Gases”,”Hydraulic Oil”,”Light Oil”,”Liquids”,”Nitrogen”,”Oil”,”Oils”,”Solvents”,”Water”…

2. Mcdonnell & Miller – Flow Switches

Domain: nationalpumpsupply.com

Registered: 2012 (13 years)

Introduction: Mcdonnell & Miller Flow Switches

3. Pentair AES – Flow Switch

Domain: pentairaes.com

Registered: 2012 (13 years)

Introduction: Flow Switch – Pentair AES

– Price: $142.14

– SKU: ST9 to ST12

– Function: Can turn on or off a heater, chiller, alarm, pump, etc., up to 2 HP (@ 230V).

– Pressure Rating: Rated to 50 psi.

– Voltage Ratings: 125VAC to 25 A for a 1 HP motor or 250VAC to 25 A for a 2 HP motor.

– Plumbing Connection: PVC slip sockets (2″ Spig for ST11).

– Dimensions: Switches measure 6″ x 6″.

– UL Recognized.

– Warran…

4. Kobold – Flow Switches

Domain: koboldusa.com

Registered: 1996 (29 years)

Introduction: Flow switches monitor the flow of liquid, gas, or steam, triggering a switch when a pre-set flow rate is reached. Common media include water and air. Flow switches differ from flow meters, which provide continuous flow rate measurements. Types of flow switches include:

1. **Water Flow Switches**: Available in all metal versions for high pressures, low flow water switches, and plastic flow switche…

5. Fluid Components – Flow Switches

Domain: fluidcomponents.com

Registered: 1996 (29 years)

Introduction: FCI Flow Switches are electronic devices that provide signals based on flow rates exceeding or falling below setpoint values. They utilize thermal dispersion flow measurement technology for accurate and repeatable flow rate detection in liquids (water, hydrocarbons, oils) and gases (air, gas flows). Key specifications include:

– Fluid temperature range: up to 850°F/454°C

– Line sizes: from 1/8 inc…

6. Telematic – Flow Switches

Domain: telematic.com

Registered: 1996 (29 years)

Introduction: This company, Telematic – Flow Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. SMC USA – Liquid Flow Devices

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: This company, SMC USA – Liquid Flow Devices, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Ameritrol – FX Series Flow Switch

Domain: ameritrol.com

Registered: 2002 (23 years)

Introduction: Flow Switches:

1. FX Series:

– Price: From $475.00

– Features: Explosion Proof, Nema 4X Locations, 316L Stainless Steel Sensor, Exotic Alloys Available, Temperatures to 900 F, Pressures to 10,000 PSIG, Extremely Low Flow Rate Detection.

– Details: Most reliable flow switch, thermal dispersion principle, no moving parts, cost-effective, same day shipping available.

2. FM Series:

– Pr…

Strategic Sourcing Conclusion and Outlook for flow switch

What Are the Key Takeaways for Sourcing Flow Switches?

In summary, strategic sourcing of flow switches is essential for ensuring operational efficiency across various industries. Buyers should prioritize compatibility with specific applications, such as HVAC, chemical processing, and water treatment, while considering factors like environmental conditions and regulatory compliance. Selecting reliable manufacturers who offer diverse options—ranging from basic models to advanced, explosion-proof designs—can significantly mitigate risks associated with flow monitoring.

How Can International Buyers Leverage Strategic Sourcing?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, the importance of understanding local market dynamics cannot be overstated. Engaging with suppliers who have a strong understanding of regional requirements and logistical capabilities can enhance supply chain resilience. Furthermore, exploring innovations in flow switch technology, such as thermal dispersion and smart monitoring systems, can provide competitive advantages.

What’s Next for B2B Buyers in Flow Switch Procurement?

As industries evolve, the demand for advanced flow monitoring solutions will continue to rise. Buyers are encouraged to stay informed about emerging technologies and best practices in sourcing. By fostering strategic partnerships and remaining agile in procurement strategies, businesses can position themselves for long-term success in a dynamic market. Embrace these insights to enhance your sourcing strategy and drive operational excellence in your organization.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.