The Definitive Guide to Eyelet Ring: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for eyelet ring

In the competitive landscape of global sourcing, international B2B buyers face the critical challenge of sourcing eyelet rings that not only meet specific design and functional requirements but also adhere to varying standards across different markets. Eyelet rings serve diverse applications, from fashion accessories to industrial components, making it essential for buyers to understand the nuances of quality, material, and compliance. This comprehensive guide delves into the multifaceted world of eyelet rings, covering essential topics such as types, applications, supplier vetting processes, and cost considerations.

By equipping buyers with actionable insights and best practices, this guide empowers decision-makers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Germany—to make informed purchasing choices. Understanding the dynamics of the eyelet ring market not only enhances procurement strategies but also fosters long-term supplier relationships. From evaluating product specifications to navigating shipping logistics, the information provided herein is designed to streamline the sourcing process, ensuring that businesses can secure high-quality eyelet rings that align with their operational needs and market demands.

With this resource, B2B buyers can confidently navigate the complexities of the global market, ultimately driving their business success through strategic sourcing.

Understanding eyelet ring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Eyelet Ring | Metal construction, typically 1 1/8 inch diameter, smooth finish | Drapery hardware, curtain systems | Pros: Durable, versatile; Cons: Limited design options |

| C-Ring with Eyelet | C-shaped design for easier installation | Window treatments, display setups | Pros: Easy to use; Cons: May not fit all decorative styles |

| Square Eyelet Ring | Square profile for a modern aesthetic | Contemporary decor, commercial settings | Pros: Unique look; Cons: Can be more expensive |

| Decorative Eyelet Ring | Embellished with finishes like antique brass or matte black | High-end residential projects | Pros: Enhances aesthetic appeal; Cons: Higher cost |

| Heavy-Duty Eyelet Ring | Reinforced for heavy drapery or industrial applications | Industrial curtains, partition systems | Pros: High strength; Cons: Bulkier design |

What Are the Characteristics of Standard Eyelet Rings?

Standard eyelet rings are commonly made of durable metal and designed to fit poles with a diameter of 1 1/8 inches. They typically feature a smooth finish, which allows for easy gliding of curtains or drapes. These rings are widely used in B2B applications such as drapery hardware and curtain systems due to their versatility and robustness. When purchasing, buyers should consider the material quality and compatibility with their existing hardware to ensure seamless integration.

How Do C-Ring with Eyelet Variations Benefit Buyers?

C-rings with eyelets are designed with a unique C-shaped profile that simplifies the installation process. This type of ring is particularly advantageous for window treatments and display setups, where ease of use is paramount. B2B buyers should look for options that offer a range of finishes to match their design aesthetics. While they are user-friendly, buyers may need to assess whether this design aligns with their overall decorative style.

Illustrative image related to eyelet ring

Why Choose Square Eyelet Rings for Modern Aesthetics?

Square eyelet rings present a modern alternative to traditional round rings, making them suitable for contemporary decor and commercial settings. Their distinctive shape offers a unique visual appeal that can elevate the overall design of a space. When sourcing square eyelet rings, B2B buyers should consider the cost, as they can be pricier than standard options. However, their ability to create a standout feature in interior design can justify the investment.

What Are the Advantages of Decorative Eyelet Rings?

Decorative eyelet rings come embellished with various finishes, such as antique brass or matte black, catering to high-end residential projects. These rings not only serve a functional purpose but also enhance the aesthetic appeal of the drapery. Buyers in the B2B space should evaluate the cost versus the visual impact these rings can provide. Although they may come at a higher price point, the added elegance can significantly enhance a project’s value.

In What Situations Are Heavy-Duty Eyelet Rings Necessary?

Heavy-duty eyelet rings are specifically designed for applications requiring additional strength, such as industrial curtains or partition systems. These rings are reinforced to support heavier drapery, making them essential for commercial environments. When purchasing heavy-duty options, B2B buyers should assess the weight capacity and compatibility with their installation systems. While they offer high strength, the bulkier design may not be suitable for all decorative applications.

Key Industrial Applications of eyelet ring

| Industry/Sector | Specific Application of Eyelet Ring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Curtain and Drapery Systems | Enhances aesthetic appeal and functionality of spaces | Compliance with local safety standards and durability |

| Transportation | Cargo Tie-Down Systems | Secures loads effectively during transport | Material strength and resistance to environmental factors |

| Textile Manufacturing | Garment Production and Finishing | Provides structural integrity and style in clothing | Compatibility with various fabric types and finishes |

| Event Management | Temporary Structures and Decorations | Facilitates quick assembly and disassembly of setups | Lightweight options for ease of transport and handling |

| Marine Industry | Sail and Canvas Applications | Ensures durability and reliability under harsh conditions | Corrosion resistance and material quality for longevity |

How is the Eyelet Ring Used in Construction Projects?

In the construction industry, eyelet rings are integral components in curtain and drapery systems. They allow for smooth operation and aesthetic appeal, enhancing the overall design of commercial and residential spaces. Buyers should consider sourcing eyelet rings that comply with local safety standards, ensuring they can withstand various environmental conditions. Additionally, the durability of the materials used is crucial, especially in high-traffic areas where wear and tear are common.

What Role Do Eyelet Rings Play in Transportation?

Eyelet rings are essential in cargo tie-down systems within the transportation sector. They provide a reliable mechanism for securing loads, minimizing the risk of cargo shifting during transit. This application is particularly valuable for logistics companies seeking to enhance safety and efficiency. When sourcing, businesses should prioritize rings made from high-strength materials that can endure the rigors of transportation and resist environmental factors such as moisture and temperature fluctuations.

How Are Eyelet Rings Utilized in Textile Manufacturing?

In textile manufacturing, eyelet rings are used to reinforce garments, providing structural integrity while adding a stylish element to clothing. This application is vital for fashion designers and manufacturers aiming to create high-quality products. Buyers in this sector should focus on eyelet rings that are compatible with various fabric types and finishes, ensuring seamless integration into the production process. Additionally, the ability to customize sizes and finishes can enhance product offerings.

Why Are Eyelet Rings Important for Event Management?

Event management companies utilize eyelet rings in temporary structures and decorations, facilitating quick assembly and disassembly of setups. This application allows for flexibility and creativity in event design, crucial for meeting client demands. When sourcing eyelet rings, businesses should consider lightweight options for ease of transport and handling, as well as durability to withstand varying weather conditions during outdoor events.

How Do Eyelet Rings Contribute to the Marine Industry?

In the marine industry, eyelet rings are vital for sail and canvas applications, providing reliable support and durability in harsh marine environments. This application is crucial for boat manufacturers and marine service providers seeking long-lasting solutions. Buyers should prioritize sourcing eyelet rings that are corrosion-resistant and made from high-quality materials to ensure longevity and performance in saltwater conditions.

3 Common User Pain Points for ‘eyelet ring’ & Their Solutions

Scenario 1: Sourcing Quality Eyelet Rings for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality eyelet rings that meet specific application requirements, such as load-bearing capacity or aesthetic finishes. In industries like construction, fashion, or drapery, the eyelet ring must not only perform well but also align with design specifications. Buyers may experience frustration when suppliers offer inconsistent quality or fail to deliver on promised specifications, leading to project delays and increased costs.

The Solution: To effectively source eyelet rings, buyers should establish relationships with reputable manufacturers known for their quality assurance processes. Conduct thorough research to identify suppliers who specialize in the desired material (metal, plastic, etc.) and finish (brushed nickel, oil-rubbed bronze, etc.). Request samples to evaluate quality firsthand before placing larger orders. Additionally, consider utilizing a supplier with a solid return policy and support for custom specifications to ensure that the eyelet rings will fit the intended applications seamlessly. Leveraging platforms that aggregate supplier reviews can also help identify reliable partners.

Scenario 2: Navigating Shipping Challenges for Eyelet Rings in International Trade

The Problem: International buyers frequently encounter shipping complications when ordering eyelet rings, which can lead to unexpected costs and delays. Different regions may have varying regulations regarding shipping materials, and additional fees can arise from customs duties, taxes, or shipping errors. This unpredictability can disrupt supply chains, especially in time-sensitive projects.

The Solution: To mitigate shipping challenges, B2B buyers should work with suppliers that offer clear shipping policies and flat-rate shipping options, which can simplify budgeting and planning. Establishing a logistics plan that includes understanding local customs regulations and potential tariffs can also prevent surprises. Utilizing freight forwarders who specialize in international shipping can streamline the process, ensuring that shipments comply with all regulations and arrive on time. Buyers should also consider consolidating orders to minimize shipping frequency and costs, which can further enhance efficiency.

Illustrative image related to eyelet ring

Scenario 3: Ensuring Compatibility of Eyelet Rings with Existing Hardware

The Problem: Many buyers face compatibility issues when integrating new eyelet rings with existing hardware, such as poles or drapery systems. Mismatched sizes or designs can lead to functionality problems or aesthetic mismatches, resulting in wasted materials and time. This issue is especially prevalent in industries where customization is standard, yet standardization is essential for efficiency.

The Solution: To ensure compatibility, buyers should take precise measurements of their existing hardware before sourcing eyelet rings. Communicating these specifications with suppliers can help identify the right size and type. Suppliers often provide detailed product specifications, including dimensions and installation instructions, which should be thoroughly reviewed. Additionally, buyers can opt for customizable solutions where manufacturers can tailor eyelet rings to fit specific hardware. Engaging in pre-order consultations with suppliers can also clarify compatibility concerns and enhance the overall purchasing experience.

Strategic Material Selection Guide for eyelet ring

What are the Key Properties of Common Materials for Eyelet Rings?

When selecting materials for eyelet rings, it is crucial to consider properties such as strength, corrosion resistance, and thermal stability. Here, we analyze four common materials used in the manufacturing of eyelet rings: stainless steel, aluminum, brass, and plastic. Each material offers unique advantages and disadvantages that can significantly impact performance and application suitability.

How Does Stainless Steel Perform as a Material for Eyelet Rings?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it ideal for demanding applications. It can withstand high temperatures and pressures, which is beneficial in environments where eyelet rings are subjected to stress. However, stainless steel can be more expensive than other materials, and its manufacturing process may be complex due to the need for specialized equipment.

Illustrative image related to eyelet ring

For international buyers, particularly in regions like Germany and Nigeria, compliance with standards such as ASTM and DIN is essential. Stainless steel eyelet rings are often preferred in construction and industrial applications due to their durability and reliability.

What are the Benefits of Using Aluminum for Eyelet Rings?

Aluminum is a lightweight and cost-effective alternative to stainless steel. It offers good corrosion resistance and is easy to machine, which simplifies the manufacturing process. However, aluminum has lower strength compared to stainless steel, making it less suitable for high-stress applications.

International buyers should consider that aluminum eyelet rings are commonly used in decorative applications, such as in the fashion and home décor industries. Compliance with local regulations regarding material safety and environmental impact is also critical, particularly in regions like South America and the Middle East.

Illustrative image related to eyelet ring

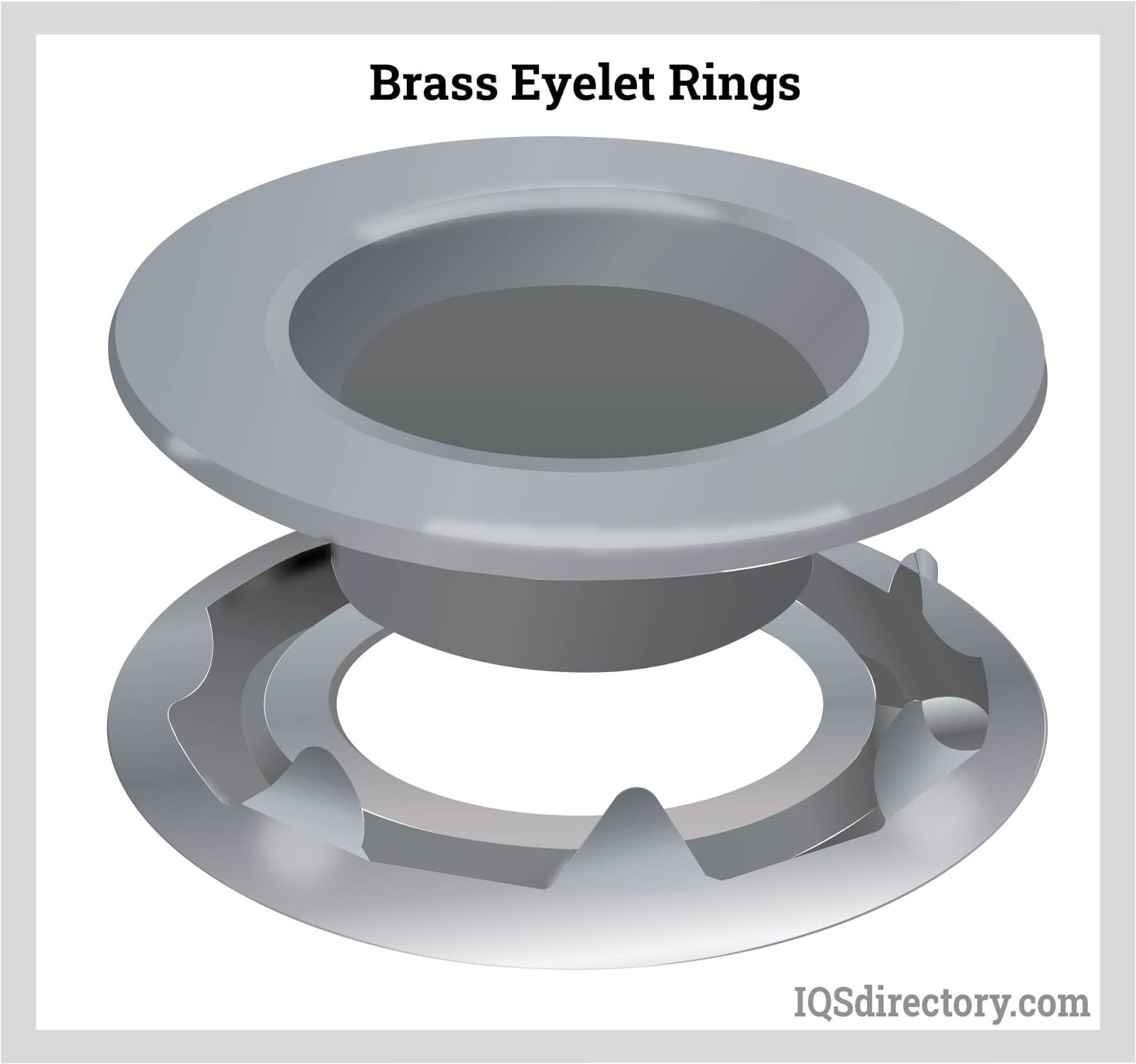

Why Choose Brass for Eyelet Rings?

Brass is a popular choice for eyelet rings due to its aesthetic appeal and good corrosion resistance. It has excellent machinability and can be easily formed into intricate designs, making it suitable for decorative applications. However, brass is less durable than stainless steel and may tarnish over time, which can affect its appearance.

For B2B buyers in Europe, brass eyelet rings often comply with EU regulations regarding material safety. They are frequently used in the jewelry and decorative hardware industries, where appearance is as important as functionality.

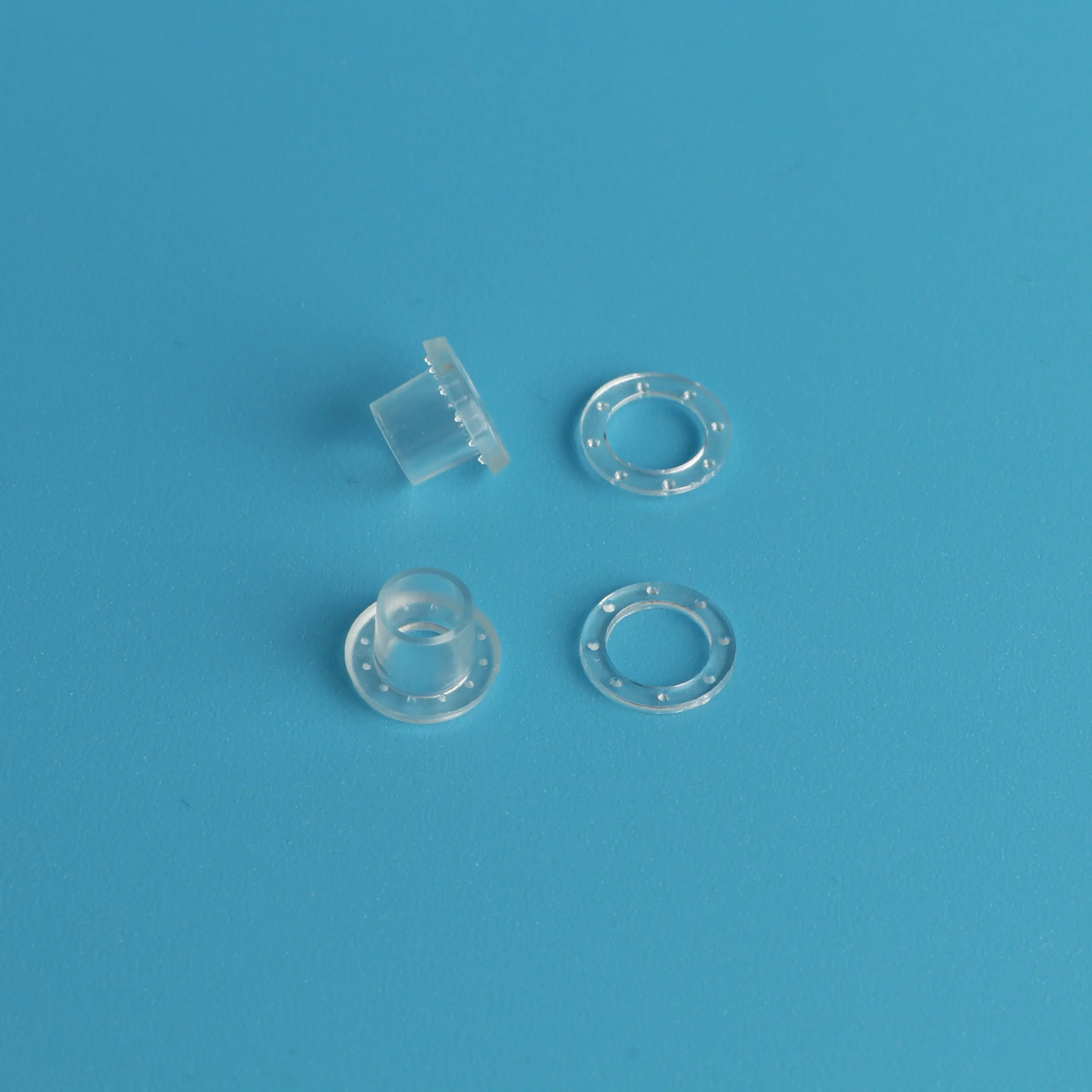

What Role Does Plastic Play in Eyelet Ring Manufacturing?

Plastic eyelet rings offer a lightweight and cost-effective solution, particularly in applications where corrosion resistance is crucial. They are available in various colors and designs, making them suitable for decorative uses. However, plastic may not withstand high temperatures or heavy loads, limiting its application in industrial settings.

International buyers should note that plastic eyelet rings can be manufactured to comply with a range of standards, including JIS and ASTM. They are often used in the textile and fashion industries, where flexibility and design variety are essential.

Summary Table of Material Selection for Eyelet Rings

| Material | Typical Use Case for eyelet ring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial and construction applications | High strength and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Decorative applications | Lightweight and cost-effective | Lower strength compared to steel | Medium |

| Brass | Jewelry and decorative hardware | Aesthetic appeal and good machinability | Tarnishes over time | Medium |

| Plastic | Textile and fashion industries | Lightweight and versatile | Limited thermal and load resistance | Low |

This analysis provides a comprehensive overview of the materials commonly used for eyelet rings, highlighting their properties, advantages, and limitations. Understanding these factors will enable international B2B buyers to make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for eyelet ring

What Are the Key Stages in the Manufacturing Process of Eyelet Rings?

The manufacturing of eyelet rings involves several critical stages that ensure the final product meets both functional and aesthetic requirements. Understanding these stages can help B2B buyers assess suppliers more effectively.

Material Preparation: What Materials Are Used in Eyelet Ring Production?

The primary materials used in eyelet ring manufacturing include various types of metals such as stainless steel, brass, and aluminum. Each material offers distinct advantages in terms of durability, weight, and finish. Suppliers typically source raw materials from certified vendors to ensure quality. Before manufacturing begins, the materials are cut into manageable sizes, and any necessary coatings or treatments are applied to enhance corrosion resistance or aesthetic appeal.

How Are Eyelet Rings Formed and Shaped?

The forming process is crucial as it defines the eyelet’s shape and functionality. This can involve several techniques, including:

- Stamping: A die is used to cut and shape the metal into the required form. Stamping is efficient for large volume production.

- Casting: This method involves pouring molten metal into a mold. While less common for eyelet rings, it can be used for custom designs.

- Extrusion: Metal is pushed through a die to create long shapes, which are then cut to size.

Each technique has its pros and cons, and the choice often depends on the desired finish, production volume, and cost considerations.

What Does the Assembly Process Entail?

Once the individual components are formed, they are assembled. This stage may involve:

- Joining Techniques: Methods such as welding, soldering, or riveting are employed to connect parts securely.

- Inserting Components: For eyelet rings that require additional features, like clips or plastic inserts for smoother gliding, these are added during assembly.

Quality at this stage is paramount as any defects can compromise the functionality of the eyelet ring.

How Is the Finishing Process Completed?

The finishing stage enhances the aesthetic appeal and durability of the eyelet ring. Common finishing techniques include:

Illustrative image related to eyelet ring

- Polishing: This process removes surface imperfections and provides a shiny finish.

- Coating: Various coatings can be applied for protection against scratches and corrosion, such as powder coating or electroplating.

- Inspection: A thorough inspection is conducted to ensure that the finish meets the required specifications.

Finishing not only affects the appearance but also the longevity of the product, making it a crucial step in manufacturing.

What International Standards Apply to Quality Assurance in Eyelet Ring Production?

Quality assurance in eyelet ring manufacturing is governed by various international standards, which help ensure consistency and reliability.

Which International Quality Standards Should B2B Buyers Look For?

One of the most recognized standards is ISO 9001, which outlines a framework for quality management systems. Compliance with ISO 9001 indicates that a supplier has established processes to consistently meet customer and regulatory requirements.

Additionally, industry-specific certifications, such as CE marking for European products and API standards for components used in oil and gas applications, can also be relevant. These certifications demonstrate adherence to safety and quality benchmarks specific to certain markets.

What Quality Control Checkpoints Are Essential During Manufacturing?

Quality control is integrated throughout the manufacturing process, with specific checkpoints to ensure that products meet the required standards.

What Are the Key Quality Control Checkpoints?

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During manufacturing, random samples may be taken to verify that production processes are being followed correctly and that products meet quality specifications.

- Final Quality Control (FQC): After the manufacturing process is complete, a final inspection assesses the finished eyelet rings for defects and overall compliance with design specifications.

What Testing Methods Are Commonly Used for Eyelet Rings?

Various testing methods help verify the quality and functionality of eyelet rings:

- Mechanical Testing: This includes tensile strength tests to measure the material’s ability to withstand forces without breaking.

- Corrosion Testing: Eyelet rings are subjected to environments that simulate potential corrosive conditions to evaluate their durability.

- Dimensional Inspection: Precision measurement tools ensure that the eyelet rings meet exact specifications.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

Verifying a supplier’s quality assurance processes is vital for establishing a reliable partnership.

What Steps Can Buyers Take to Confirm Supplier QC?

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into quality control practices and adherence to standards.

- Request Quality Reports: Suppliers should be willing to share quality assurance reports, including results from IQC, IPQC, and FQC checkpoints.

- Engage Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased evaluation of the supplier’s quality processes and the final product.

What Nuances Should International Buyers Consider Regarding QC and Certification?

For B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial.

How Do Regional Differences Impact Quality Assurance?

- Regulatory Compliance: Different regions may have varying regulations regarding material safety and product quality. Buyers should familiarize themselves with local requirements.

- Logistical Considerations: International shipping can impact product integrity. Suppliers should demonstrate how they maintain quality during transport.

- Cultural Expectations: Understanding regional preferences for product aesthetics and functionality can influence quality standards and expectations.

By paying close attention to these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing eyelet rings, ensuring they receive products that meet their operational needs and compliance requirements.

Illustrative image related to eyelet ring

Practical Sourcing Guide: A Step-by-Step Checklist for ‘eyelet ring’

To assist international B2B buyers in sourcing eyelet rings efficiently, this guide provides a step-by-step checklist. Eyelet rings are essential components in various applications, from decorative hardware to functional items, making it crucial to choose the right supplier and product specifications.

Step 1: Define Your Technical Specifications

Before initiating your sourcing process, clearly define the technical specifications of the eyelet rings you require. This includes dimensions, materials (such as metal types), and any specific features like finishes or coatings. Precise specifications will help you communicate effectively with suppliers and ensure that the products meet your needs.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in eyelet rings. Look for companies with a proven track record in your industry and a strong reputation for quality. Utilize online platforms, industry directories, and trade fairs to gather a list of candidates.

Step 3: Evaluate Supplier Capabilities and Certifications

Before committing to a supplier, evaluate their manufacturing capabilities and certifications. Verify if they comply with relevant industry standards, such as ISO certifications or safety standards for materials. This step is crucial to ensure the quality and reliability of the products you will receive.

- Key Considerations:

- Inquire about their production processes.

- Ask for samples to assess quality firsthand.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of potential suppliers, request detailed quotes that outline pricing, minimum order quantities, and lead times. Comparing these quotes will help you understand the market rate and identify the most cost-effective option without compromising quality.

- Comparison Metrics:

- Price per unit

- Shipping costs

- Payment terms

Step 5: Assess Shipping and Logistics Options

Evaluate the shipping and logistics options offered by suppliers, especially if you are sourcing internationally. Consider factors such as delivery times, shipping costs, and the supplier’s ability to handle customs clearance. This information is vital to ensure a smooth procurement process and timely delivery of your eyelet rings.

Step 6: Check References and Reviews

Before finalizing your supplier choice, check references and online reviews from other buyers. This step provides insights into the supplier’s reliability, customer service, and product quality. Engaging with other businesses that have sourced from the supplier can yield valuable information that may influence your decision.

Step 7: Negotiate Terms and Place Your Order

Once you have selected a supplier, engage in negotiations regarding terms of service, payment options, and warranties. Clear agreements will protect your interests and ensure that both parties are aligned on expectations. After finalizing these details, place your order and confirm the delivery timeline.

By following this checklist, B2B buyers can streamline the sourcing process for eyelet rings, ensuring that they acquire high-quality products tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for eyelet ring Sourcing

What are the Key Cost Components in Sourcing Eyelet Rings?

When sourcing eyelet rings, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the price. Eyelet rings are typically made from various metals, such as aluminum, brass, or stainless steel, with prices varying based on quality and finish. Higher-grade materials or specialized finishes will increase costs.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process. These can vary widely based on the country of production, skill level, and labor laws. Automation can reduce labor costs but may require higher initial investments in machinery.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance, which are allocated to the production of eyelet rings. Overhead costs can be minimized by selecting suppliers with efficient operational practices.

-

Tooling: Initial costs for molds or specialized tools necessary for producing customized eyelet rings can be significant. Buyers should consider the amortization of these costs over larger production runs to reduce per-unit pricing.

-

Quality Control (QC): Implementing stringent QC processes ensures product quality and compliance with standards, which may add to costs. However, investing in QC can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping costs are influenced by the distance from the supplier to the buyer, shipping method, and freight terms. Options like Incoterms can affect total logistics costs; for instance, FOB (Free on Board) pricing may require buyers to manage their own shipping costs.

-

Margin: Suppliers typically add a markup to cover their costs and profit margin. Understanding the typical margin in your industry can help in negotiations.

How Do Price Influencers Affect Eyelet Ring Costs?

Several factors can influence the pricing of eyelet rings in the B2B market:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQ). Ordering larger volumes can lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs based on their projected needs.

-

Specifications and Customization: Custom-designed eyelet rings, whether in size, material, or finish, will typically incur higher costs than standard products. Detailed specifications help suppliers provide accurate quotes.

-

Material Quality and Certifications: Rings made from higher-quality materials or those that meet specific certifications (like ISO) may have higher upfront costs but can offer better durability and performance, influencing long-term value.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but offer better quality assurance, timely deliveries, and customer service.

-

Incoterms: The chosen Incoterms can significantly impact total costs. For instance, DDP (Delivered Duty Paid) means the supplier covers all shipping and customs costs, which can simplify budgeting for buyers.

What Tips Can B2B Buyers Use for Cost-Efficiency in Eyelet Ring Procurement?

To maximize cost-efficiency when sourcing eyelet rings, B2B buyers should consider the following strategies:

-

Negotiate Pricing: Always enter negotiations with a clear understanding of market prices and supplier margins. Leverage volume commitments or long-term contracts to secure better rates.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also ongoing costs such as maintenance, shipping, and potential quality issues. A lower-priced product may lead to higher long-term costs if it requires frequent replacements.

-

Understand Pricing Nuances for International Buyers: Buyers from regions like Africa and South America may face additional logistics challenges and tariffs. Familiarize yourself with local regulations, potential import duties, and the impact of currency fluctuations on pricing.

-

Build Strong Supplier Relationships: Establishing good relationships with suppliers can lead to better pricing, priority in production, and flexibility in terms of order changes.

Disclaimer

The prices and cost components mentioned are indicative and can fluctuate based on market conditions, supplier negotiations, and specific order requirements. Always conduct thorough market research and seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing eyelet ring With Other Solutions

Understanding Alternatives to Eyelet Rings for B2B Buyers

When considering eyelet rings for various applications, it is essential to explore alternative solutions that may better meet specific business needs. Eyelet rings are commonly used in drapery and textile applications for their functionality and aesthetic appeal. However, other solutions may offer distinct advantages, making them worthy of consideration. This analysis compares eyelet rings with two viable alternatives: grommets and curtain clips.

Comparison Table

| Comparison Aspect | Eyelet Ring | Grommets | Curtain Clips |

|---|---|---|---|

| Performance | Smooth gliding for drapery | Durable and secure hold | Easy to attach and detach |

| Cost | Moderate price range | Generally lower cost | Low-cost option |

| Ease of Implementation | Requires specific installation | Simple installation process | Quick and straightforward |

| Maintenance | Low maintenance, durable material | Low maintenance, sturdy | Moderate maintenance needed |

| Best Use Case | Aesthetic drapery solutions | Heavy-duty applications | Temporary or adjustable setups |

In-Depth Look at Alternatives

What Are Grommets and Their Advantages?

Grommets are reinforced eyelets that are often used in heavy-duty applications, such as tarps, banners, and industrial fabrics. Their primary advantage lies in their durability, providing a secure hold even under stress. They are typically less expensive than eyelet rings, making them a cost-effective solution for bulk purchases. However, grommets may lack the aesthetic appeal that eyelet rings offer, making them less suitable for decorative applications. Installation is straightforward, often requiring only a hole punch and a setting tool, which can save time during the setup process.

How Do Curtain Clips Serve as an Alternative?

Curtain clips are a versatile solution for hanging curtains or drapes, allowing for quick attachment and detachment. They are particularly useful for temporary installations or when frequent adjustments are necessary. The primary advantage of curtain clips is their low cost and ease of use, making them accessible for businesses with budget constraints. However, they may not provide the same level of durability or aesthetic appeal as eyelet rings, especially in high-end applications. Maintenance can be slightly higher, as clips may wear out over time or require replacement due to lost clips.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the right solution for your drapery or textile applications requires careful consideration of the specific requirements of your project. Eyelet rings offer a blend of performance and aesthetic appeal, making them ideal for decorative uses. Grommets provide a robust alternative for heavy-duty needs at a lower cost, while curtain clips present a flexible and economical choice for temporary setups. B2B buyers should evaluate their priorities—whether it’s performance, cost, ease of installation, or maintenance—before making a decision. By understanding these alternatives, businesses can optimize their procurement strategies and enhance their operational efficiency.

Essential Technical Properties and Trade Terminology for eyelet ring

What Are the Key Technical Properties of Eyelet Rings That B2B Buyers Should Know?

When sourcing eyelet rings, understanding their technical specifications is crucial for ensuring compatibility and quality. Here are the essential properties to consider:

1. Material Composition

Eyelet rings are typically made from metals such as stainless steel, brass, or aluminum. The choice of material affects durability, corrosion resistance, and overall aesthetics. For instance, stainless steel offers high strength and resistance to rust, making it suitable for outdoor applications. Buyers should specify material grades to ensure they meet industry standards.

Illustrative image related to eyelet ring

2. Diameter and Size Specifications

The diameter of the eyelet ring, often measured in inches, is a critical specification that determines compatibility with poles or other components. Common sizes include 1 1/8 inches, which are often used in drapery hardware. Accurate sizing is essential to ensure proper fit and function, reducing installation issues and enhancing customer satisfaction.

3. Load Capacity and Tolerance

Load capacity refers to the maximum weight the eyelet ring can support. Tolerance indicates the allowable deviation from specified dimensions. Understanding these values is vital for applications in which weight-bearing is a concern, such as in curtains or heavy drapery. Manufacturers typically provide load capacity ratings, and buyers should verify these against their needs.

4. Finishing Options

Eyelet rings come in various finishes, such as brushed nickel, oil-rubbed bronze, and antique brass. The finish not only impacts the visual appeal but also affects corrosion resistance and wear over time. Buyers should consider the finish that aligns with their brand aesthetics while ensuring durability.

5. Compliance and Safety Standards

Products like eyelet rings should comply with relevant safety standards, such as ANSI 100.1 for window coverings. Compliance guarantees that the products are safe to use and meet regulatory requirements, which is particularly important for B2B buyers in industries involving consumer safety.

What Are Common Trade Terms Related to Eyelet Rings in the B2B Market?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. Understanding OEM relationships is important for buyers looking for customization options or specific product requirements.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum number of units a supplier is willing to sell. This term is crucial for buyers to understand inventory management and cost-effectiveness. Knowing the MOQ helps businesses plan their purchasing strategies and avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting a price quote from suppliers for specific products. It is vital for buyers to issue RFQs to compare prices and terms across multiple suppliers, ensuring they secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities associated with their orders.

5. LTL (Less Than Truckload) Shipping

LTL shipping refers to the transportation of freight that does not require a full truckload. This is a cost-effective option for smaller shipments, allowing buyers to save on logistics costs while still receiving their products in a timely manner.

Understanding these technical properties and trade terms can significantly enhance decision-making for B2B buyers in the eyelet ring market. By being well-informed, businesses can ensure they make strategic purchases that align with their operational needs and market standards.

Navigating Market Dynamics and Sourcing Trends in the eyelet ring Sector

What Are the Key Market Dynamics and Trends Influencing the Eyelet Ring Sector?

The eyelet ring sector is witnessing transformative changes driven by evolving consumer preferences, technological advancements, and global market dynamics. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focused on quality and design innovation. The demand for eyelet rings is bolstered by a growing interest in customizable and aesthetically diverse products, with materials such as metal and eco-friendly options gaining traction. In response, manufacturers are investing in advanced production technologies that enhance efficiency and reduce costs, making it easier for B2B buyers to source competitively priced products.

Emerging B2B tech trends are also reshaping the sourcing landscape. Digital platforms and marketplaces are facilitating connections between suppliers and buyers, enabling streamlined procurement processes. Additionally, the rise of data analytics tools is allowing businesses to gain insights into market trends, customer preferences, and inventory management, enhancing decision-making capabilities. For instance, platforms that offer real-time tracking of shipments and inventory levels are becoming essential for maintaining supply chain efficiency.

Furthermore, the global eyelet ring market is experiencing shifts due to geopolitical factors and trade regulations. Buyers must stay informed about tariffs, import/export restrictions, and local market conditions that could impact sourcing strategies. In particular, navigating these complexities is crucial for businesses operating in diverse markets such as Nigeria and Germany, where consumer behaviors and regulatory environments can vary significantly.

How Can Sustainability and Ethical Sourcing Influence Your Eyelet Ring Procurement?

Sustainability and ethical sourcing are becoming pivotal in the eyelet ring sector, reflecting broader societal shifts towards environmental consciousness and corporate responsibility. The environmental impact of production processes is under scrutiny, prompting manufacturers to adopt greener practices. This includes using recycled materials and minimizing waste, aligning with the increasing demand for sustainable products among consumers and businesses alike.

For B2B buyers, prioritizing suppliers with robust sustainability practices can enhance brand reputation and meet the expectations of environmentally conscious clients. Certifications such as ISO 14001 for environmental management and Fair Trade accreditation can serve as indicators of a supplier’s commitment to sustainable practices. Additionally, opting for eyelet rings made from responsibly sourced materials not only reduces environmental impact but also contributes to a positive narrative around brand ethics.

The importance of transparency in the supply chain cannot be overstated. Buyers are encouraged to engage with suppliers who provide detailed information about sourcing practices, including the origins of raw materials and labor conditions. This focus on ethical sourcing can lead to stronger partnerships and foster trust between businesses and consumers, ultimately driving loyalty and sales.

What Is the Historical Context of Eyelet Rings in B2B Markets?

The eyelet ring has evolved significantly over the years, transitioning from a simple functional component to a stylish and sought-after accessory in various industries, including fashion and home decor. Historically, eyelet rings were primarily utilized in textiles and curtain hardware, designed for functionality rather than aesthetics. However, as consumer tastes evolved, these rings began to be incorporated into jewelry and decorative hardware, offering both practicality and visual appeal.

Illustrative image related to eyelet ring

This evolution has been driven by advancements in manufacturing techniques and materials, allowing for greater design flexibility and customization. Today, eyelet rings are available in various finishes and materials, catering to diverse market segments and consumer preferences. For B2B buyers, understanding this historical context can provide valuable insights into market trends and consumer behavior, informing sourcing strategies that align with current demands.

In summary, navigating the eyelet ring sector requires a keen understanding of market dynamics, a commitment to sustainability, and an appreciation for the historical evolution of these products. By leveraging these insights, international B2B buyers can make informed procurement decisions that align with their business goals and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of eyelet ring

-

How do I ensure the quality of eyelet rings from suppliers?

To ensure quality, establish clear specifications and standards for the eyelet rings you require. Request samples from potential suppliers to assess material quality, durability, and finish. Additionally, inquire about their quality assurance processes, including certifications and adherence to international standards. Regular audits and checks can also help maintain quality control throughout the production and shipping process, ensuring the products meet your expectations upon delivery. -

What are the key factors to consider when selecting a supplier for eyelet rings?

When selecting a supplier, evaluate their experience in manufacturing eyelet rings, their production capabilities, and their reputation in the market. Look for suppliers that offer customization options to meet your specific needs, as well as those who provide reliable customer service. It’s also essential to assess their logistics capabilities, including shipping terms and lead times, especially if you’re sourcing internationally from regions like Africa or South America. -

What is the minimum order quantity (MOQ) for eyelet rings?

The MOQ for eyelet rings can vary significantly between suppliers, ranging from a few hundred to several thousand units, depending on production capabilities and the type of customization required. It’s advisable to communicate your needs clearly and negotiate the MOQ to ensure it aligns with your business requirements. Some suppliers may offer flexible terms for first-time orders or bulk purchases. -

What payment terms should I expect when sourcing eyelet rings internationally?

Payment terms can differ by supplier, but common practices include a deposit upfront, followed by the balance upon shipment or delivery. Some suppliers may accept letters of credit or escrow services to secure transactions, especially for larger orders. Always clarify payment methods, currency, and any additional fees, such as for international transfers, to avoid misunderstandings. -

How can I customize eyelet rings to fit my brand?

Customization options for eyelet rings typically include variations in size, material, finish, and packaging. Communicate your specific design requirements to the supplier, and request prototypes or samples to evaluate the final product. Some suppliers may also offer branding options, such as custom logos or packaging, which can enhance your brand visibility and appeal in the market. -

What logistics considerations should I be aware of when importing eyelet rings?

When importing eyelet rings, consider shipping methods, lead times, and customs regulations in your country. Choose a reliable shipping partner that can provide tracking and insurance for your shipment. Be aware of any import duties or tariffs that may apply, and ensure compliance with local regulations to avoid delays at customs. Discuss these logistics aspects with your supplier to streamline the process. -

What are the common materials used in manufacturing eyelet rings?

Eyelet rings are typically made from various materials, including metal (such as brass, stainless steel, or aluminum), plastic, or a combination of both. The choice of material affects the durability, aesthetic appeal, and cost of the rings. When sourcing, discuss material options with your supplier to ensure they align with your product specifications and market demands. -

How can I verify the credibility of a supplier for eyelet rings?

To verify a supplier’s credibility, conduct thorough research by checking their business licenses, certifications, and customer reviews. Request references from other clients and inquire about their experience with the supplier. Additionally, consider visiting their manufacturing facility if possible or working with third-party inspection services to assess their operations and product quality. This due diligence helps mitigate risks associated with international sourcing.

Top 5 Eyelet Ring Manufacturers & Suppliers List

1. Shane Co. – Marquise Diamond Engagement Ring

Domain: shaneco.com

Registered: 1996 (29 years)

Introduction: This company, Shane Co. – Marquise Diamond Engagement Ring, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Two Pages – Metal Curtain Rings

Domain: twopagescurtains.com

Registered: 2019 (6 years)

Introduction: Metal Curtain Rings with Eyelets, Pack of 12, Price: $34.00

3. Select Blinds – Metal Eyelet Curtain Rings

Domain: selectblinds.com

Registered: 2003 (22 years)

Introduction: Product Name: Metal Eyelet Curtain Rings

Price: $35.39 (MSRP: $58.99)

Discount: 40% Off

Shipping: Free

Warranty Options: 3-Year Limited Warranty, Free 5-Year Limited Warranty ($2.36), 5-Year Unlimited Warranty ($8.26)

Color Options: Black, Satin Nickel, Light Gold, Antique Brass, Bronze

Size: 10 Rings per pack

Dimensions: 1 3/8-inch steel eyelet rings

Weight Capacity: 18 lbs

Product Weight: 0.3 lb…

4. American Plastics – Plastic 10mm Eyelet Ring

Domain: americanplastics.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Plastic 10mm Eyelet Ring (AP027)”, “price”: “$0.12”, “SKU”: “PSTAP027705SM”, “barcode”: “Available Now!”, “sold_by”: “piece”, “case_quantity”: 20000, “bag_quantity”: 5000, “contact_number”: “(209) 834-0287”}

5. Paso Robles Ironworks – 2in Curtain Ring with Eyelet

Domain: ironhardware.com

Registered: 2000 (25 years)

Introduction: {“name”: “2in Curtain Ring with Eyelet”, “brand”: “Paso Robles Ironworks”, “price”: “$2.75 USD”, “dimensions”: {“outside_diameter”: “2 inches”, “inside_diameter”: “1.5 inches”, “drop”: “7/16 inches”}, “eyelet_diameter”: “1.75 inches”, “material”: “hand forged wrought iron”, “features”: [“welded eyelet rings”, “durable”, “can be used with drapery pins or sewn onto curtains”], “shipping_info”: “Curt…

Strategic Sourcing Conclusion and Outlook for eyelet ring

In today’s competitive landscape, strategic sourcing of eyelet rings offers B2B buyers a significant advantage. By understanding supplier capabilities, shipping options, and product specifications, international buyers can streamline their procurement processes while ensuring quality and compliance with safety standards. The availability of diverse finishes and materials also allows for customization, catering to various market demands across regions such as Africa, South America, the Middle East, and Europe.

Moreover, leveraging flat-rate shipping programs can reduce logistical complexities and costs, particularly for bulk orders. This strategic approach not only enhances operational efficiency but also fosters long-term partnerships with reliable suppliers, ensuring consistent product availability and support.

Illustrative image related to eyelet ring

Looking ahead, B2B buyers should remain proactive in assessing market trends and supplier innovations in the eyelet ring sector. Embracing digital platforms for sourcing can further enhance transparency and efficiency. As you explore your options, consider the unique needs of your target market and the potential for growth. Take the next step in optimizing your supply chain by connecting with trusted manufacturers and suppliers who can meet your specific requirements. Your strategic sourcing decisions today will shape the success of your business tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.