The Definitive Guide to Expanded Metal For Grill: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for expanded metal for grill

In today’s competitive landscape, sourcing expanded metal for grills presents unique challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The diverse applications of expanded metal—from commercial grilling solutions to bespoke outdoor cooking equipment—require a nuanced understanding of material specifications, quality standards, and supplier reliability. This comprehensive guide is designed to equip you with the knowledge needed to navigate these complexities confidently.

Throughout this guide, we will explore various types of expanded metal suited for grilling, including steel and stainless steel options, along with their respective benefits and limitations. We will also delve into essential applications, helping you identify the best products for your specific needs. Understanding the intricacies of supplier vetting is crucial; therefore, we will provide actionable insights on how to assess potential partners to ensure they meet your quality and service expectations.

Additionally, we will address cost considerations and how to optimize your purchasing decisions without compromising on quality. By leveraging the information within this guide, you will be empowered to make informed choices, ensuring that your sourcing of expanded metal for grills is efficient, effective, and aligned with your business objectives. This resource is tailored to support international buyers in making strategic decisions that enhance their operations and product offerings in an increasingly global market.

Understanding expanded metal for grill Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Expanded Metal | Available in various thicknesses and hole sizes; typically made from carbon steel. | General grilling, construction | Pros: Cost-effective, versatile; Cons: Prone to rust without treatment. |

| Stainless Steel Expanded Metal | Made from stainless steel for enhanced corrosion resistance; polished finish available. | High-end grills, food processing | Pros: Durable, aesthetically pleasing; Cons: Higher cost, requires specialized welding. |

| Flattened Expanded Metal | Rolled and flattened design for a smooth surface; less sharp edges. | Cooking grates, smoker baskets | Pros: Easy to clean, safe for food contact; Cons: Slightly more expensive than standard. |

| Heavy-Duty Expanded Metal | Thicker gauge for increased strength; larger hole sizes available. | Industrial applications, heavy-duty grills | Pros: High load-bearing capacity; Cons: Heavier, may require specialized handling. |

| Decorative Expanded Metal | Unique patterns and designs for aesthetic appeal; often used in upscale settings. | Restaurant decor, custom grills | Pros: Enhances visual appeal; Cons: Typically more expensive, limited availability. |

What Are the Characteristics of Standard Expanded Metal for Grills?

Standard expanded metal is a staple in the grilling industry, known for its affordability and versatility. It is made from carbon steel and comes in various thicknesses and hole sizes, making it suitable for diverse applications, from general grilling to construction. When considering this option, buyers should be aware that while it is cost-effective, it may require protective coatings to prevent rust, especially in humid environments.

Why Choose Stainless Steel Expanded Metal for High-End Grills?

Stainless steel expanded metal is favored for high-end grilling applications and food processing due to its superior corrosion resistance. This material not only withstands high temperatures but also maintains its aesthetic appeal with a polished finish. B2B buyers should note that while the initial investment is higher compared to carbon steel, the longevity and reduced maintenance costs can justify the expense in the long run.

How Does Flattened Expanded Metal Improve Safety and Usability?

Flattened expanded metal features a rolled and flattened design, resulting in a smooth surface that minimizes sharp edges. This makes it an excellent choice for cooking grates and smoker baskets, where safety and ease of cleaning are paramount. Buyers should consider that while this type may come at a slightly higher price, its usability and safety benefits are significant, particularly in food-related applications.

What Are the Advantages of Heavy-Duty Expanded Metal for Industrial Use?

Heavy-duty expanded metal is designed for applications requiring increased strength and load-bearing capacity. It is ideal for industrial settings and heavy-duty grills, providing durability in demanding environments. However, B2B buyers should keep in mind that the heavier gauge may complicate handling and installation, necessitating specialized equipment or personnel for effective use.

How Can Decorative Expanded Metal Enhance Aesthetic Appeal in Grilling?

Decorative expanded metal offers unique patterns and designs, making it an attractive choice for upscale grilling environments or restaurant decor. This type not only serves a functional purpose but also enhances the visual appeal of grilling stations. While typically more expensive and less widely available, B2B buyers looking to differentiate their product offerings may find that the investment pays off in customer satisfaction and brand image.

Key Industrial Applications of expanded metal for grill

| Industry/Sector | Specific Application of expanded metal for grill | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Grilling and smoking equipment for meat processing | Enhanced heat distribution and durability | Material thickness, corrosion resistance, and compliance with food safety standards |

| Outdoor Cooking | Custom grills and outdoor kitchens for restaurants | Customizable designs and improved cooking efficiency | Sizing options, weight capacity, and aesthetics |

| Construction & Fabrication | Structural support for commercial grill installations | Increased strength and stability | Load specifications, installation ease, and local regulations |

| Retail & Distribution | Display racks for grill products in retail environments | Effective product showcasing and ventilation | Design flexibility, surface finish, and weight capacity |

| Hospitality & Catering | BBQ catering equipment for outdoor events | Portability and enhanced cooking area | Material sourcing, weight considerations, and durability |

How is Expanded Metal for Grill Used in Food Processing?

In the food processing industry, expanded metal is widely utilized in the manufacturing of grilling and smoking equipment, particularly for meat processing. Its design allows for optimal heat distribution, ensuring even cooking while maintaining structural integrity under high temperatures. Buyers in this sector should prioritize materials that meet food safety standards and are resistant to corrosion, as these factors significantly influence the longevity and performance of the equipment in a high-volume environment.

What Role Does Expanded Metal Play in Outdoor Cooking?

For restaurants and catering businesses, custom grills made from expanded metal provide an efficient solution for outdoor kitchens. These grills can be tailored to specific dimensions, accommodating various cooking needs and enhancing overall cooking efficiency. Sourcing considerations include the desired thickness for durability and the ability to withstand outdoor elements, ensuring that the grills remain functional and visually appealing over time.

How is Expanded Metal Beneficial in Construction & Fabrication?

In construction and fabrication, expanded metal serves as a robust structural support for commercial grill installations. Its strength and durability make it an ideal choice for supporting heavy grill components, ensuring stability during use. When sourcing expanded metal for this application, businesses should consider load specifications and the ease of installation, as these factors will affect the overall safety and functionality of the grill setup.

How Does Expanded Metal Enhance Retail & Distribution?

Retail environments benefit from the use of expanded metal in the creation of display racks for grill products. The material’s inherent ventilation properties allow for effective showcasing of merchandise while maintaining an aesthetic appeal. Key sourcing considerations for retailers include design flexibility, surface finish options, and weight capacity, as these elements can significantly impact the effectiveness of product displays.

Why is Expanded Metal Important for Hospitality & Catering?

In the hospitality sector, expanded metal is essential for creating portable BBQ catering equipment used in outdoor events. Its lightweight yet durable nature enhances portability, allowing caterers to easily transport and set up grilling stations. Buyers should focus on material sourcing and weight considerations, ensuring that the equipment is not only easy to move but also durable enough to withstand outdoor conditions and frequent use.

3 Common User Pain Points for ‘expanded metal for grill’ & Their Solutions

Scenario 1: Sourcing Quality Expanded Metal for Grills

The Problem: B2B buyers often struggle with finding high-quality expanded metal that meets specific requirements for grilling applications. They may encounter issues such as inconsistent material quality, varying thicknesses, and subpar finishes that do not withstand the rigors of high-heat grilling. These challenges can lead to premature wear and tear, affecting the overall performance and safety of the grills they manufacture or supply.

The Solution: To ensure the procurement of quality expanded metal, buyers should prioritize sourcing from reputable suppliers who specialize in industrial metal products. It is essential to request product specifications that detail the thickness, type of metal (such as carbon steel or stainless steel), and the finish (e.g., galvanized or uncoated). Additionally, buyers should inquire about the supplier’s quality control processes, including certifications like ISO or ASTM standards. Visiting the supplier’s facility or requesting samples can also help verify the quality before placing a bulk order. For grilling applications, opt for flattened expanded metal that minimizes sharp edges, and consider a thickness of #9 with a hole size of 3/4″ to ensure optimal cooking performance and longevity.

Scenario 2: Understanding Material Coating Options

The Problem: Buyers may be confused about the various coating options available for expanded metal used in grills. Some may assume that stainless steel is the best choice for its corrosion resistance, while others might consider coated metals for easier cleaning and maintenance. This uncertainty can lead to over-specifying or under-specifying the materials, resulting in increased costs or decreased performance.

The Solution: To navigate material coating options effectively, buyers should evaluate the specific environmental conditions in which the grills will be used. For instance, if grills are to be used in humid or coastal environments, stainless steel is indeed a wise choice due to its resistance to rust and corrosion. However, for applications where cost-efficiency is paramount, uncoated carbon steel can suffice, especially since the surface will develop a protective layer over time through carbonization. Buyers should also consider coatings like powder coating or ceramic finishes, which can enhance durability and make cleaning easier. When specifying materials, it’s helpful to consult with industry experts or metallurgists to understand the trade-offs involved with each option.

Scenario 3: Customization Challenges for Expanded Metal Grates

The Problem: B2B buyers often face difficulties when customizing expanded metal grates to fit specific grill designs. This can result from limitations in standard sizes, which may not meet the unique dimensions or aesthetic requirements of their products. Additionally, the inability to easily modify or cut the expanded metal can lead to delays in production timelines.

The Solution: To address customization challenges, buyers should work closely with suppliers that offer tailored solutions. Many manufacturers can provide custom cutting and fabrication services, enabling buyers to specify exact dimensions and designs. When placing an order, it is crucial to provide detailed drawings or specifications, including measurements and any desired modifications, such as rounded edges or specific hole patterns. If a local supplier does not provide these services, consider partnering with a fabrication shop that specializes in expanded metal. This collaboration can significantly reduce lead times and ensure that the final product aligns perfectly with the intended grill design. It’s also beneficial to explore options for modular designs, which can enhance flexibility and allow for easier adjustments in future production runs.

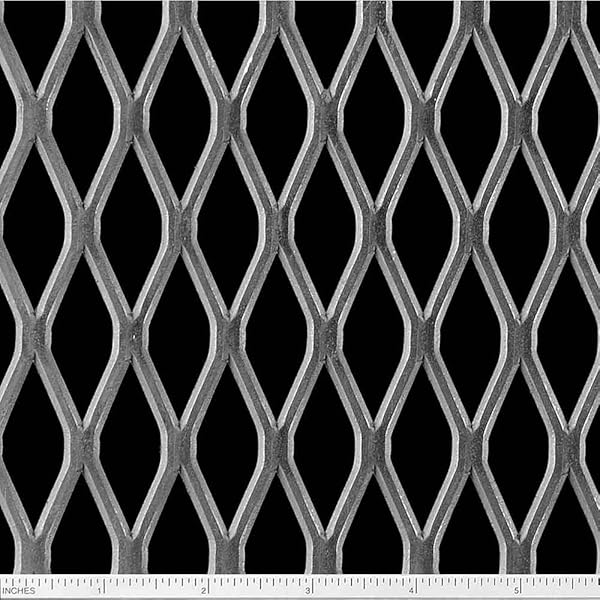

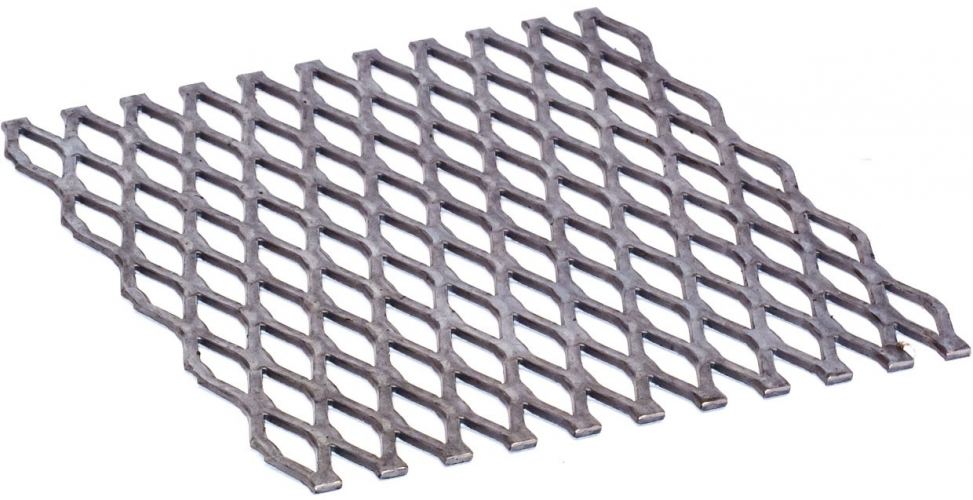

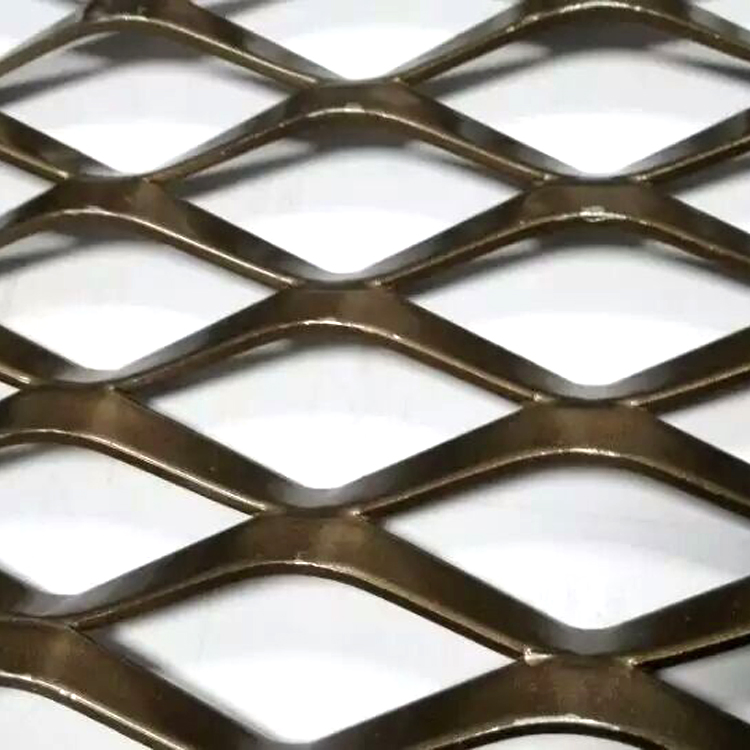

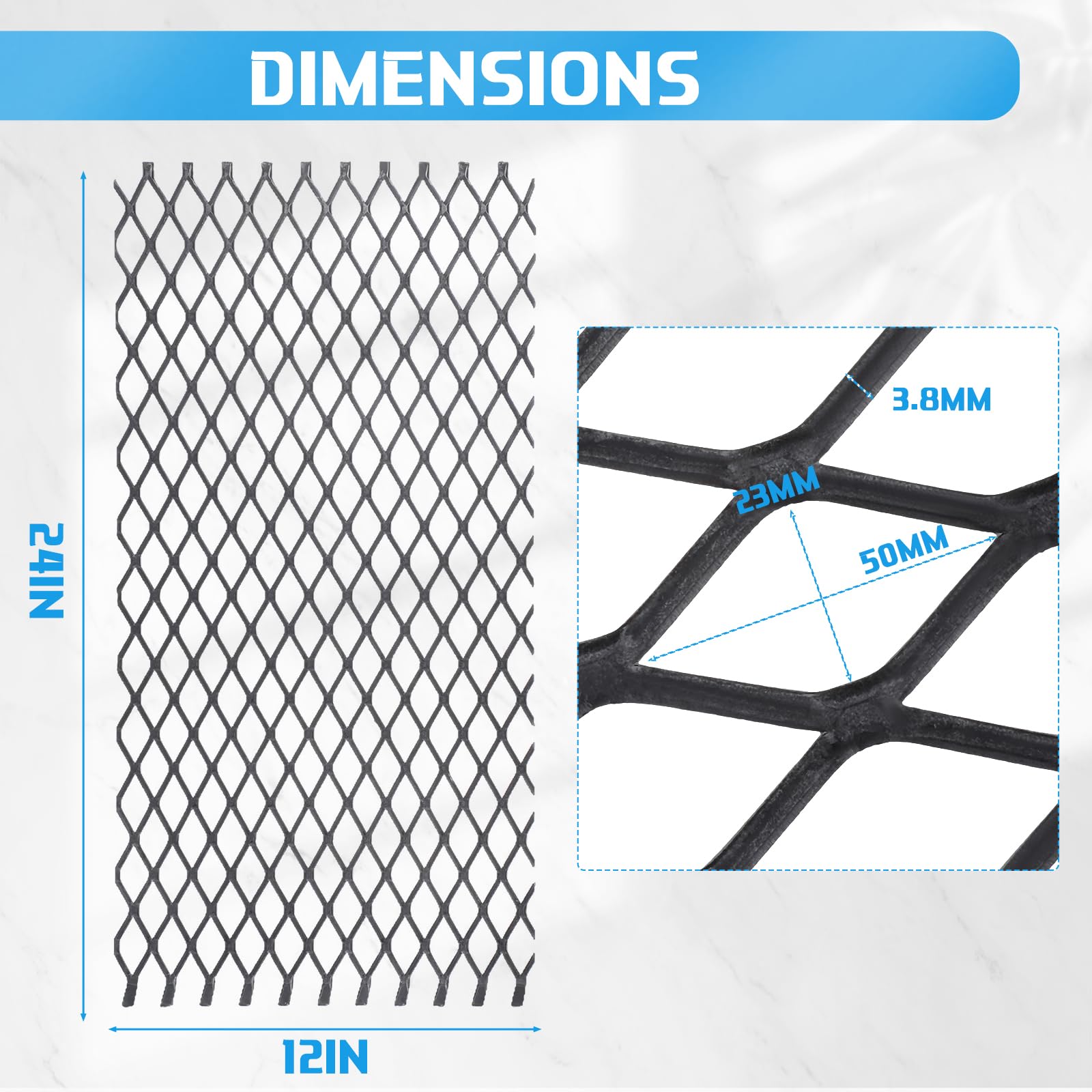

Illustrative image related to expanded metal for grill

Strategic Material Selection Guide for expanded metal for grill

What Are the Key Materials for Expanded Metal Used in Grills?

When selecting expanded metal for grill applications, it’s crucial to consider the material properties that align with performance, durability, and cost-effectiveness. Here, we analyze four common materials: carbon steel, stainless steel, aluminum, and galvanized steel. Each material presents unique benefits and challenges, particularly for international B2B buyers.

How Does Carbon Steel Perform in Grill Applications?

Key Properties: Carbon steel is known for its strength and heat retention, making it ideal for high-temperature grilling. It can withstand significant pressure and heat, which is essential for grilling applications.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and durability. However, it is prone to rust and corrosion if not properly maintained, which can affect its longevity. Manufacturing complexity is relatively low, making it accessible for various applications.

Impact on Application: Carbon steel is best suited for direct grilling and smoking applications. Its ability to retain heat enhances cooking efficiency, but it requires regular maintenance to prevent rust, especially in humid environments.

Illustrative image related to expanded metal for grill

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, should consider protective coatings or regular maintenance schedules. Compliance with local standards (e.g., ASTM) is essential for ensuring product safety and performance.

What Are the Advantages of Stainless Steel for Grilling?

Key Properties: Stainless steel offers excellent corrosion resistance and high-temperature tolerance, making it suitable for outdoor grilling environments. It is also easy to clean, which is a significant advantage for food safety.

Pros & Cons: While stainless steel is more expensive than carbon steel, its durability and resistance to rust justify the investment. The manufacturing process can be more complex, requiring specialized equipment for welding and shaping.

Impact on Application: Stainless steel is ideal for high-end grills and commercial applications where longevity and aesthetics are essential. Its compatibility with various cooking media makes it versatile for different grilling techniques.

Considerations for International Buyers: Buyers should verify that the stainless steel grade meets local standards for food safety and corrosion resistance. In regions like the Middle East, where high temperatures and humidity are common, selecting high-grade stainless steel (e.g., 304 or 316) is advisable.

Illustrative image related to expanded metal for grill

How Does Aluminum Compare in Grilling Applications?

Key Properties: Aluminum is lightweight and has good thermal conductivity, allowing for quick heating and cooling. However, it has a lower melting point compared to steel, which may limit its use in high-heat applications.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, making it easy to handle and install. However, it is less durable than steel and can warp under extreme heat, which may not be suitable for all grilling applications.

Impact on Application: Aluminum is often used in portable grills and lightweight cooking equipment. Its thermal properties are beneficial for even cooking, but users should be cautious about using it in high-temperature scenarios.

Illustrative image related to expanded metal for grill

Considerations for International Buyers: In regions with strict weight restrictions for transport, such as some areas in Europe and South America, aluminum may be preferred. Compliance with local regulations regarding aluminum use in food applications is also critical.

What Role Does Galvanized Steel Play in Grill Manufacturing?

Key Properties: Galvanized steel is coated with zinc to enhance its corrosion resistance. It can withstand outdoor conditions, making it suitable for grill applications.

Pros & Cons: The main advantage of galvanized steel is its affordability and resistance to rust. However, the coating can wear off over time, exposing the underlying steel to corrosion. The manufacturing process is straightforward, making it a popular choice.

Impact on Application: Galvanized steel is suitable for budget-friendly grills and outdoor cooking equipment. Its durability in various weather conditions makes it a viable option for many regions.

Considerations for International Buyers: Buyers should ensure that the galvanization process meets local standards to avoid premature corrosion. In humid climates, additional protective measures may be necessary to prolong the lifespan of galvanized components.

Summary Table of Material Selection for Expanded Metal Grills

| Material | Typical Use Case for expanded metal for grill | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Direct grilling and smoking | Cost-effective and durable | Prone to rust without maintenance | Low |

| Stainless Steel | High-end grills and commercial applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Portable grills and lightweight equipment | Lightweight and good thermal conductivity | Less durable, may warp under heat | Med |

| Galvanized Steel | Budget-friendly grills | Affordable and rust-resistant | Coating can wear off, exposing steel | Low |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific grilling applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for expanded metal for grill

What Are the Main Stages of Manufacturing Expanded Metal for Grills?

The manufacturing process for expanded metal suitable for grills involves several key stages: material preparation, forming, assembly, and finishing.

Illustrative image related to expanded metal for grill

Material Preparation

The initial step in the manufacturing process is the selection of the appropriate base material, typically steel or aluminum, based on the intended application and environmental factors. The material is then cut into sheets that meet specific dimensions, which are essential for consistent product quality. For grilling applications, the choice between plain steel and stainless steel is crucial, with considerations for durability, resistance to rust, and heat retention properties.

Forming Techniques

Forming is the core stage of producing expanded metal. The selected sheets are subjected to a process known as slitting, where precise cuts are made to create a lattice-like pattern. This is followed by stretching the material, which expands the cuts into the final shape. The typical thickness used for grill grates is around #9 gauge, with a hole size of 3/4 inch, allowing for optimal airflow and cooking efficiency. Advanced techniques such as hydraulic pressing may be employed to enhance precision and reduce waste.

Assembly and Quality Control

After forming, the expanded metal undergoes assembly processes, which may include welding or joining different sections together, depending on the design requirements of the grill. This stage also includes a thorough inspection to ensure that all components meet specified tolerances and functionality.

How is the Quality of Expanded Metal for Grills Ensured?

Quality assurance is a critical aspect of the manufacturing process, particularly for B2B buyers who require reliable products for their operations. Various international standards and industry-specific guidelines govern quality control in expanded metal production.

Illustrative image related to expanded metal for grill

What Are the Relevant International Standards for Expanded Metal Quality?

Many manufacturers adhere to the ISO 9001 standard, which outlines quality management systems and ensures consistent product quality. Additionally, industry-specific certifications, such as CE marking for compliance with European health, safety, and environmental protection standards, are essential for products sold in international markets.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery to verify compliance with specifications. Suppliers should provide material certifications to confirm the quality of the steel or aluminum used.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor production parameters and ensure that the forming techniques are yielding consistent results. This may involve measuring the dimensions of expanded metal sheets and assessing the quality of the lattice pattern.

-

Final Quality Control (FQC): Once the manufacturing process is complete, final inspections are performed to assess the overall quality of the expanded metal. This includes visual inspections for defects, dimensional checks, and, where applicable, testing for structural integrity.

What Testing Methods Are Commonly Used in Expanded Metal Production?

Several testing methods are applied to ensure the quality and performance of expanded metal for grills:

-

Dimensional Testing: This involves measuring the thickness, width, and length of the expanded metal sheets to ensure they conform to specified standards.

-

Mechanical Testing: Tensile strength and yield strength tests assess the material’s ability to withstand operational stresses. This is particularly important for grill applications, where durability is paramount.

-

Corrosion Resistance Testing: For stainless steel products, tests such as salt spray tests may be conducted to evaluate resistance to rust and corrosion over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure a reliable supply chain.

Illustrative image related to expanded metal for grill

What Should B2B Buyers Look for in Supplier Audits and Reports?

Buyers should request and review quality management system documentation, including certificates of compliance with international standards. Regular audits of suppliers can provide insights into their quality control practices. It’s advisable to establish partnerships with suppliers that conduct third-party inspections, as these provide an unbiased assessment of product quality.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of regional standards and certifications that may differ from their home markets. For instance, products exported to the EU must comply with CE standards, while those intended for Middle Eastern markets may require specific local certifications. Understanding these nuances can help buyers navigate the complexities of international trade and ensure compliance with local regulations.

Conclusion

In summary, the manufacturing processes and quality assurance for expanded metal used in grills are multifaceted and critical for ensuring product reliability and performance. By understanding the manufacturing stages, relevant quality standards, and testing methods, B2B buyers can make informed decisions when sourcing expanded metal. Establishing robust supplier relationships and verifying quality control practices will further enhance the reliability of their supply chains, ultimately leading to successful operations in their respective markets.

Illustrative image related to expanded metal for grill

Practical Sourcing Guide: A Step-by-Step Checklist for ‘expanded metal for grill’

To assist B2B buyers in sourcing expanded metal for grills effectively, this guide provides a step-by-step checklist that outlines critical considerations for procurement. The aim is to ensure that buyers make informed decisions that align with their operational needs and quality standards.

Step 1: Define Your Technical Specifications

Start by identifying the specific requirements for the expanded metal you need. Consider factors such as thickness, type of metal (e.g., carbon steel vs. stainless steel), and the size of the openings in the mesh.

– Thickness: A common choice for food grates is #9 thickness, which balances durability and weight.

– Type of Metal: While stainless steel offers corrosion resistance, plain steel may be more cost-effective for certain applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in expanded metal products. Look for companies with a strong reputation in the industry and positive reviews from other B2B buyers.

– Supplier Experience: Consider how long the supplier has been in business and their expertise in manufacturing expanded metal for grilling applications.

– Customer Reviews: Seek out testimonials and case studies from previous clients, especially those in similar markets.

Illustrative image related to expanded metal for grill

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that demonstrate quality and safety standards. This is crucial for ensuring that the materials meet industry regulations and customer expectations.

– Quality Certifications: Look for ISO certifications or similar standards that indicate a commitment to quality.

– Material Safety: Ensure that the metal used is free from harmful coatings, especially if it will come into contact with food.

Step 4: Request Sample Products

Before placing a bulk order, request samples of the expanded metal. This step allows you to assess the material’s quality, finish, and suitability for your specific grilling needs.

– Inspection of Samples: Check for consistency in thickness, hole size, and overall finish.

– Compatibility: Ensure that the samples fit your grill design and meet your functional requirements.

Step 5: Discuss Customization Options

Inquire whether suppliers offer customization options tailored to your specific needs. Customization can include dimensions, hole patterns, and finishes.

– Tailored Solutions: Many suppliers can modify their products to better suit unique grill designs or operational processes.

– Cost Implications: Understand how customization might affect pricing and lead times.

Step 6: Review Pricing and Terms

Once you’ve narrowed down potential suppliers, review their pricing structures and terms of sale. Consider not only the cost of the expanded metal but also shipping, lead times, and payment terms.

– Total Cost of Ownership: Evaluate how factors like durability and maintenance costs may impact the overall value of your investment.

– Negotiation: Don’t hesitate to negotiate terms to secure the best deal possible.

Illustrative image related to expanded metal for grill

Step 7: Finalize Your Order and Ensure After-Sales Support

After selecting a supplier, finalize your order and confirm that you will receive adequate after-sales support. This is important for addressing any issues that may arise post-purchase.

– Support Services: Ensure the supplier offers assistance with installation or maintenance if needed.

– Return Policies: Understand the supplier’s return policy in case the product does not meet your expectations.

By following this checklist, B2B buyers can streamline their sourcing process for expanded metal for grills, ensuring they select the right materials and suppliers to meet their business needs effectively.

Comprehensive Cost and Pricing Analysis for expanded metal for grill Sourcing

What Are the Key Cost Components in Sourcing Expanded Metal for Grills?

When sourcing expanded metal for grills, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials, primarily steel or stainless steel, significantly impacts pricing. Variations in global steel prices can affect the overall cost, making it crucial to stay informed about market trends.

-

Labor: Labor costs encompass wages for skilled workers involved in production, welding, and finishing processes. Labor rates can vary by region, influencing total costs, particularly in countries with higher labor standards.

-

Manufacturing Overhead: This includes costs associated with factory maintenance, utilities, and other operational expenses. Efficient manufacturing processes can help lower overhead costs, which may benefit buyers through competitive pricing.

-

Tooling: Initial setup costs for molds and dies used in the manufacturing process can be significant. Custom specifications may require specialized tooling, increasing upfront costs but potentially leading to cost savings in larger production runs.

-

Quality Control: Ensuring product quality often necessitates additional inspections and testing, which can add to costs. Certifications for compliance with international standards may also incur fees, but they enhance product credibility and marketability.

-

Logistics: Transportation and handling costs are essential to factor in, especially for international buyers. Freight charges, customs duties, and insurance can significantly affect the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market demand, competition, and supplier reputation.

How Do Price Influencers Affect Expanded Metal Costs?

Several factors can influence the pricing of expanded metal, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract bulk discounts, reducing the per-unit cost. Buyers should negotiate MOQs to optimize savings.

-

Specifications and Customization: Custom sizes, thicknesses, and finishes can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-grade materials and certifications, such as ISO or ASTM, can lead to higher prices. However, they often ensure durability and safety, justifying the cost.

-

Supplier Factors: Established suppliers with a good track record may charge a premium for their products. Reliability, customer service, and delivery timelines should also be considered when assessing costs.

-

Incoterms: Understanding Incoterms is vital for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall costs.

What Are Effective Buyer Tips for Cost-Efficient Sourcing?

To navigate the complexities of sourcing expanded metal for grills, buyers should consider the following strategies:

-

Negotiate Pricing: Always engage in negotiations with suppliers. Highlighting potential long-term partnerships or bulk orders can yield better pricing.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, maintenance, and replacement costs over time. A lower initial price might lead to higher TCO if the quality is subpar.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations can impact costs, particularly for buyers in Africa, South America, and the Middle East. Locking in prices or using forward contracts can mitigate risks.

-

Seek Local Suppliers: Whenever possible, sourcing from local suppliers can reduce logistics costs and lead times, enhancing overall efficiency.

-

Stay Informed About Market Trends: Regularly monitor market conditions for steel and metal products. Awareness of price trends can empower buyers to make informed purchasing decisions.

Conclusion

In summary, sourcing expanded metal for grills involves a comprehensive understanding of cost structures, price influencers, and effective negotiation strategies. By applying these insights, international B2B buyers can optimize their sourcing decisions, enhance cost-efficiency, and ensure high-quality products that meet their specific needs. Always remember that prices can vary widely based on numerous factors, and staying informed is key to successful procurement.

Alternatives Analysis: Comparing expanded metal for grill With Other Solutions

Exploring Alternatives to Expanded Metal for Grilling Solutions

When it comes to grilling applications, expanded metal is a popular choice due to its unique properties and versatility. However, several alternatives offer varying performance, cost, and ease of use, which may suit different business needs. This analysis compares expanded metal for grills against wire mesh and ceramic grilling grates, providing B2B buyers with insights to make informed decisions.

| Comparison Aspect | Expanded Metal For Grill | Wire Mesh Grate | Ceramic Grate |

|---|---|---|---|

| Performance | High heat retention and even cooking | Good airflow, may warp under high heat | Excellent heat retention, even cooking |

| Cost | Moderate | Low to moderate | High |

| Ease of Implementation | Easy to install and modify | Simple installation, limited customization | Requires special handling and care |

| Maintenance | Requires occasional cleaning, may rust | Easy to clean, prone to rust | Low maintenance, easy to clean |

| Best Use Case | Commercial grills, smokers, and backyard setups | Home grilling and light commercial use | High-end grilling, specialty cooking |

In-Depth Analysis of Alternatives

Wire Mesh Grate: Is It Right for Your Grilling Needs?

Wire mesh grates are a cost-effective alternative to expanded metal. They are lightweight and easy to handle, making them suitable for home grilling and light commercial applications. However, they may warp under high temperatures, which can compromise cooking performance. While their maintenance is straightforward, users must be cautious about rust, especially if they are made of mild steel. For budget-conscious buyers looking for a simple solution for occasional use, wire mesh can be a viable choice.

Illustrative image related to expanded metal for grill

Ceramic Grate: A Premium Grilling Experience

Ceramic grates represent a high-end option for grilling, known for their exceptional heat retention and even cooking capabilities. They are ideal for specialty cooking methods such as indirect grilling or smoking. While they require careful handling to avoid chipping or cracking, their low maintenance and ease of cleaning make them attractive for serious grillers. However, the higher cost may deter businesses with tighter budgets. For those targeting premium markets or high-quality cooking experiences, ceramic grates can enhance the overall grilling experience.

How to Choose the Right Grilling Solution for Your Business

Selecting the right grilling solution depends on several factors, including budget, intended use, and maintenance preferences. Expanded metal is an excellent all-rounder for commercial applications that require durability and performance. In contrast, wire mesh is suitable for budget-conscious buyers needing simplicity. For businesses focused on high-end grilling experiences, ceramic grates may justify their premium pricing with superior cooking results. Ultimately, understanding these alternatives will help B2B buyers align their choice with their operational needs and customer expectations.

Essential Technical Properties and Trade Terminology for expanded metal for grill

What Are the Key Technical Properties of Expanded Metal for Grills?

When selecting expanded metal for grills, understanding its essential technical properties is crucial for ensuring product quality and performance. Here are several critical specifications that B2B buyers should consider:

-

Material Grade

Expanded metal is typically made from carbon steel or stainless steel. Carbon steel is cost-effective and widely used, while stainless steel offers superior corrosion resistance, making it ideal for outdoor applications. Selecting the right material grade impacts durability, maintenance requirements, and overall longevity of the grill. -

Thickness

The thickness of the expanded metal, often denoted in gauge or inches, plays a significant role in its strength and load-bearing capacity. Common thicknesses for grill applications range from 0.045 inches to 0.125 inches. Thicker metal provides enhanced durability and resistance to warping under high heat, which is essential for grilling applications. -

Mesh Size and Opening Dimensions

The mesh size refers to the pattern of openings in the expanded metal, which can vary widely. For grilling, a common specification is a #9 gauge with a ¾ inch opening. This size allows for even heat distribution while preventing food from falling through. Proper mesh size is vital for optimizing cooking performance and ensuring food safety. -

Finish

The surface finish of expanded metal can significantly affect its appearance and resistance to rust. Options include plain, galvanized, or powder-coated finishes. Galvanized metal is coated with zinc for added corrosion resistance, while powder coating provides a variety of color choices and further protects the metal from the elements. Choosing the right finish impacts not only aesthetics but also maintenance and lifespan. -

Weight Per Unit Area

This specification indicates how much the expanded metal weighs per square foot. It is crucial for understanding the load capacity of the grill and its compatibility with other components. Lighter materials may reduce shipping costs but could compromise strength, while heavier materials may offer more stability but increase overall weight. -

Yield Strength

Yield strength refers to the amount of stress that a material can withstand without permanent deformation. For expanded metal used in grilling, a yield strength of around 30,000 psi is common. This property is critical for ensuring that the grill can handle the weight of food and withstand the heat without bending or breaking.

What Are Common Trade Terminology and Jargon Related to Expanded Metal for Grills?

Familiarizing yourself with industry terminology is essential for effective communication and negotiation. Here are several key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of expanded metal for grills, an OEM might provide the metal components that are assembled into a final grill product. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for budgeting and inventory management, as it directly affects purchasing decisions and supply chain efficiency. -

RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on specific products or services. It outlines the buyer’s requirements and helps in obtaining competitive pricing. Crafting a clear RFQ can lead to better negotiations and favorable purchasing terms. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, insurance, and risk management. -

Lead Time

This term refers to the time taken from placing an order to its delivery. Lead time can significantly impact project timelines, especially in manufacturing settings where delays can lead to increased costs. -

Certifications

Certifications, such as ISO or ASTM standards, indicate that a product meets specific quality and safety standards. For expanded metal used in grilling, certifications can assure buyers of the material’s quality, enhancing trust and reliability in their purchasing decisions.

Understanding these properties and terms will empower B2B buyers to make informed decisions when sourcing expanded metal for grilling applications, ensuring that their products meet market demands and quality expectations.

Navigating Market Dynamics and Sourcing Trends in the expanded metal for grill Sector

What are the Current Market Dynamics and Key Trends in the Expanded Metal for Grill Sector?

The global market for expanded metal, particularly for grill applications, is currently witnessing robust growth driven by several factors. The increasing popularity of outdoor cooking, especially in regions like Africa, South America, and the Middle East, is a significant driver. As more consumers and businesses invest in grilling equipment, the demand for durable and efficient grill grates made from expanded metal continues to rise. Additionally, the trend towards customization in grilling experiences is prompting manufacturers to explore innovative designs and materials, enhancing the aesthetic and functional appeal of expanded metal products.

Emerging technologies are also reshaping the sourcing landscape. The integration of e-commerce platforms has made it easier for international B2B buyers to access a wider range of products and suppliers. Digital procurement solutions are streamlining sourcing processes, enabling buyers to compare options and negotiate prices more effectively. In regions like Europe and the Middle East, where quality and sustainability are paramount, buyers are increasingly looking for suppliers who can demonstrate compliance with international quality standards and certifications.

Furthermore, the growth of the hospitality sector, particularly in developing economies, is fueling demand for high-quality grilling equipment. This trend highlights the importance of reliable sourcing channels that can meet the fluctuating needs of the market while ensuring product availability and competitive pricing.

How is Sustainability and Ethical Sourcing Addressed in the Expanded Metal for Grill Sector?

Sustainability has become a critical consideration in the sourcing of expanded metal for grills. The environmental impact of manufacturing processes, particularly in terms of energy consumption and waste generation, is under scrutiny. As international regulations tighten, B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices. This includes utilizing recycled materials and implementing energy-efficient production techniques.

Ethical sourcing is equally important, as buyers are keen to ensure that their supply chains are free from exploitative labor practices and environmental degradation. Certifications such as ISO 14001 for environmental management systems and FSC certification for sustainable sourcing can enhance a supplier’s credibility in the eyes of discerning buyers.

In addition, there is a growing interest in ‘green’ materials that minimize environmental impact without compromising on quality. For instance, expanded metal products made from recycled steel not only reduce waste but also appeal to environmentally conscious consumers. As more buyers demand transparency in their supply chains, suppliers that can provide detailed information about their sourcing and manufacturing processes will be better positioned to capture market share.

What is the Brief Evolution and History of Expanded Metal in Grilling?

The use of expanded metal in grilling applications dates back to the early 20th century when it was primarily utilized for industrial purposes. Over the decades, as outdoor cooking gained popularity, manufacturers began to recognize the advantages of expanded metal for grill grates, such as its lightweight nature, durability, and ability to retain heat.

Initially, expanded metal was used mainly in commercial settings, but its adoption in residential grilling expanded significantly with the rise of the backyard barbecue culture in the 1950s and 1960s. Today, expanded metal is a staple in both professional and home grilling environments, with advancements in production techniques leading to a variety of finishes and coatings that enhance its performance and aesthetic appeal.

This evolution reflects broader trends in consumer preferences, as the market continues to adapt to the demands for more versatile and high-quality grilling solutions, positioning expanded metal as a go-to material for grill manufacturers and B2B buyers alike.

Frequently Asked Questions (FAQs) for B2B Buyers of expanded metal for grill

-

How do I choose the right thickness of expanded metal for my grill?

Selecting the appropriate thickness of expanded metal depends on the grill’s intended use and the type of food being cooked. Commonly, a #9 gauge thickness (approximately 0.148 inches) is preferred for its durability and heat distribution properties. However, if your grill is designed for heavy-duty use or high-heat applications, consider opting for a thicker gauge. Always consult with your supplier about the specific requirements based on your cooking style and frequency of use. -

What material is best for expanded metal grates in grills?

For grill applications, plain carbon steel is often the most economical choice due to its excellent heat retention and cooking performance. However, if you are concerned about rusting or want a longer-lasting option, stainless steel is recommended. While stainless steel can be more costly, it offers superior resistance to corrosion and is easier to clean. Evaluate your budget and long-term usage to determine the best material for your needs. -

What customization options are available for expanded metal?

Many suppliers offer customization options for expanded metal, including varying hole sizes, thicknesses, and finishes. You can request specific dimensions tailored to your grill design. Additionally, some manufacturers may provide options for coatings that enhance durability and resistance to rust. Discuss your requirements with potential suppliers to explore all available options that meet your project specifications. -

What are typical minimum order quantities (MOQs) for expanded metal?

Minimum order quantities for expanded metal can vary significantly depending on the supplier and the specific product. Generally, MOQs can range from 100 square meters to several tons. When sourcing, inquire about the MOQ for your desired specifications and whether the supplier can accommodate smaller orders, especially if you are testing a new design or entering a new market. -

How can I vet suppliers for expanded metal products?

To effectively vet suppliers, consider checking their certifications, such as ISO or other relevant industry standards. Review customer testimonials and case studies to gauge their reputation. It’s also beneficial to request samples of their expanded metal products to evaluate quality firsthand. Finally, consider their ability to meet your delivery timelines and customer service responsiveness during your inquiry process. -

What are common payment terms in international trade for expanded metal?

Payment terms can vary based on the supplier and your negotiation. Common terms include a 30% deposit upfront with the balance due upon delivery or a letter of credit for larger orders. Be sure to clarify payment methods accepted (such as wire transfers, credit cards, or PayPal) and any potential currency conversion fees. Understanding these terms can prevent delays and ensure smooth transactions. -

How do I ensure quality assurance (QA) for my expanded metal order?

To ensure quality assurance, request a detailed specification sheet from your supplier that outlines the material properties, dimensions, and manufacturing processes. Many reputable suppliers will conduct QA tests, such as tensile strength and corrosion resistance tests, and can provide certification for these results. Additionally, consider a third-party inspection service to verify quality before shipment, especially for large orders. -

What logistics considerations should I keep in mind when importing expanded metal?

When importing expanded metal, consider shipping methods, lead times, and customs regulations in your country. Choose a reliable freight forwarder experienced in handling metal products to navigate logistics smoothly. It’s crucial to understand the potential for tariffs or duties on imported materials. Additionally, ensure that the supplier can provide all necessary documentation, such as certificates of origin and compliance, to facilitate customs clearance.

Top 7 Expanded Metal For Grill Manufacturers & Suppliers List

1. MetalsDepot® – Expanded Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Buy Expanded Steel Sheet Online! Steel Expanded Metal is a sheet product that has been slit and stretched to a wide array of diamond shaped openings. Offers savings in weight and metal, free passage of light, liquid, sound and air, while providing a decorative or ornamental effect. Specifications: MIL-M-17194D, ASTM F1267-91, Type I Standard (Raised) & Type II Flattened (smooth) sur…

2. Char-Griller – Cooking Grate, Expanded, Metal (8250)

Domain: chargriller.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Cooking Grate, Expanded, Metal (8250)”, “model”: “201455”, “price”: “$37.99”, “availability”: “Sold Out”, “compatible_with”: “Model 8250 Grand Champ™ Offset Smoker Grill”}

3. Expanded Metal Grates – Key Specifications

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Expanded metal grates for cooking in a pit-style smoker; specifications to consider include thickness of the metal, type of steel (avoid galvanized), and profile type (flat vs. standard/raised). Recommended material is regular flat expanded carbon steel, ungalvanized, with a focus on thickness to prevent warping. Opening size should not be too large to prevent food from falling through.

4. BBQ Smoker Mods – VORTEX (IN)DIRECT HEAT Grill Grate

Domain: bbqsmokermods.com

Registered: 2014 (11 years)

Introduction: Expanded Metal Grates / Fire Baskets – Smoker Parts

Key Products:

1. VORTEX (IN)DIRECT HEAT Grill Grate – 21.5″ with 9″ Center – Special Price: $21.00 (Regular Price: $39.99)

2. Middle Griddle™ Flat top Grill – Special Price: $17.99 (Regular Price: $22.00)

3. Vortex (in)direct heat® Grill Grate – 22 in – Special Price: $68.99 (Regular Price: $79.99)

4. LavaLock® Minion Method Maze Bars – STAINLES…

5. Smoking Meat Forums – Expanded Steel Cooking Surfaces

Domain: smokingmeatforums.com

Registered: 2005 (20 years)

Introduction: Expanded steel is commonly used for cooking surfaces in smokers. Key details include: 1. Thickness: #9 thickness is most common for food grates. 2. Size: 3/4″ hole size is preferred. 3. Material: Plain steel is recommended for ease of welding and modification, while stainless steel is more expensive and requires specialty welding equipment. 4. Finish: Flattened type is preferred to avoid sharp edg…

6. Expanded Metal Sheet Mesh – Ideal BBQ Grill Mesh

Domain: expandedmetalsheetmesh.com

Registered: 2020 (5 years)

Introduction: Ideal mesh size for BBQ grill: holes around 1/2 to 3/4 inch. Recommended types: raised expanded metal (strong but rough edges) and flattened expanded metal (smoother surface, easier to clean). Importance of mesh size: affects functionality and aesthetics, ensures even cooking and grill marks.

7. BBQ Brethren – Expanded Metal Charcoal Baskets

Domain: bbq-brethren.com

Registered: 2003 (22 years)

Introduction: Expanded metal for charcoal basket, commonly used gauges include 9 gauge and 18 gauge. Standard mesh sizes mentioned are 1/2″ and 3/4″. Recommended sources for purchase include Home Depot (H.D.) and Lowe’s, with options for pre-cut sheets. Some users suggest using thicker gauge for durability, especially for the bottom of the basket to prevent bowing. Alternative suppliers mentioned include Graing…

Strategic Sourcing Conclusion and Outlook for expanded metal for grill

In conclusion, strategic sourcing of expanded metal for grills presents a compelling opportunity for international B2B buyers across Africa, South America, the Middle East, and Europe. As the demand for high-quality grilling solutions continues to rise, understanding the nuances of material selection—such as thickness, finish, and manufacturing processes—becomes essential. Buyers should prioritize sourcing from reputable manufacturers who offer a variety of options, including plain steel and stainless steel, while considering cost-effectiveness and durability.

Illustrative image related to expanded metal for grill

Investing in expanded metal not only enhances the performance and longevity of grilling equipment but also aligns with trends towards more sustainable and efficient cooking methods. By leveraging strategic sourcing practices, companies can ensure they are obtaining the best materials at competitive prices, ultimately leading to improved product offerings and customer satisfaction.

Looking ahead, the global market for expanded metal is poised for growth, driven by innovation in grilling technologies and consumer preferences for outdoor cooking. Now is the time for B2B buyers to engage with suppliers and explore partnerships that can elevate their product lines. Take the initiative to secure your supply chain and position your business for success in this thriving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to expanded metal for grill