The Definitive Guide to Electrical Plug For Scotland: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for electrical plug for scotland

In the ever-evolving landscape of international trade, sourcing electrical plugs for Scotland presents unique challenges that can significantly impact your business operations. With Scotland utilizing type G sockets and operating on a 230V, 50Hz electrical system, international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, must navigate the complexities of voltage compatibility and adapter requirements. This guide serves as a comprehensive resource, offering insights into various plug types, their applications across industries, and essential considerations for supplier vetting.

Understanding the nuances of electrical infrastructure is vital for making informed purchasing decisions. Buyers will find detailed information on the different types of electrical plugs used in Scotland, alongside practical advice on voltage converters and adapters necessary to ensure device compatibility. Additionally, this guide delves into the cost implications of sourcing these components, helping businesses budget effectively while securing quality products.

By equipping international buyers with the knowledge needed to navigate Scotland’s electrical plug market, this guide not only facilitates seamless integration of devices but also enhances operational efficiency. Empower your procurement strategy with the insights provided here, ensuring that your business remains competitive and compliant in the global market.

Understanding electrical plug for scotland Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type G Plug | Three rectangular prongs; grounded | Electronics, medical devices, industrial equipment | Pros: Safe, reliable; Cons: Requires adapters for non-compatible devices. |

| Universal Travel Adapter | Multi-socket compatibility; compact design | Travelers, international businesses | Pros: Versatile, convenient; Cons: May not support high power devices. |

| Voltage Converter | Converts voltage from 230V to 120V | Electronics, appliances with non-dual voltage | Pros: Protects devices; Cons: Bulky, may be expensive. |

| Power Strip with Adapters | Multiple sockets; includes Type G adapters | Offices, hotels, event venues | Pros: Multiple devices can charge; Cons: May overload if not rated properly. |

| Combined Adapter/Converter | Integrates adapter and voltage conversion | Travelers, expatriates | Pros: Space-saving; Cons: Limited to lower wattage devices. |

What Are the Key Characteristics of Type G Plugs in Scotland?

Type G plugs are the standard electrical connectors used in Scotland, characterized by their three rectangular prongs, with the top prong serving as a fuse for added safety. These plugs are designed to handle a voltage of 230V and a frequency of 50Hz, making them suitable for a variety of applications, including electronics and industrial equipment. For B2B buyers, it’s crucial to ensure compatibility with devices to avoid damage, as non-compatible devices will require adapters or converters.

How Do Universal Travel Adapters Benefit International Businesses?

Universal travel adapters are designed to accommodate multiple plug types, making them an essential tool for international businesses that operate across different regions. Their compact design allows for easy transportation, which is particularly beneficial for frequent travelers. However, businesses should note that while these adapters offer versatility, they may not support high-power devices, thus requiring careful selection based on device specifications.

Why Are Voltage Converters Essential for Certain Devices?

Voltage converters are critical for devices that are not designed to handle the higher voltage of 230V found in Scotland. These converters step down the voltage to a safer level (typically 120V), protecting sensitive electronics and appliances. B2B buyers must assess the voltage requirements of their devices before purchasing, as using a device without the appropriate converter can lead to irreversible damage.

What Advantages Do Power Strips with Adapters Offer?

Power strips equipped with Type G adapters allow multiple devices to charge simultaneously, making them ideal for offices, hotels, and event venues. They facilitate the connection of various electronic devices, enhancing productivity and convenience. However, buyers should ensure that the power strip is rated for the total wattage of the devices being used to prevent overload and potential hazards.

How Do Combined Adapter/Converters Simplify International Travel?

Combined adapter/converters serve as a dual solution for travelers by integrating the functions of both an adapter and a voltage converter into a single unit. This feature is particularly advantageous for expatriates and business travelers who wish to minimize luggage while ensuring device compatibility. However, these units typically support lower wattage devices, so it’s essential for buyers to evaluate their power needs when selecting this option.

Key Industrial Applications of electrical plug for scotland

| Industry/Sector | Specific Application of electrical plug for scotland | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Charging stations for guests’ electronic devices | Enhances guest experience by providing convenience | Ensure compatibility with type G plugs; consider voltage converters |

| Manufacturing | Powering machinery and tools in production facilities | Ensures operational efficiency and minimizes downtime | Sourcing durable plugs that can handle 230V and 50Hz; safety certifications |

| Telecommunications | Installation of communication equipment | Reliable connectivity for business operations | Check for compliance with local electrical standards; type G compatibility |

| Healthcare | Medical equipment requiring stable power supply | Supports critical operations and patient safety | Ensure plugs meet healthcare standards; consider voltage converters |

| Construction | Temporary power for tools and equipment on-site | Facilitates efficient project execution | Source robust adapters for various equipment; consider dual voltage options |

How is ‘Electrical Plug for Scotland’ Used in Different Industries?

In the hospitality sector, electrical plugs are essential for charging stations in hotels, bed and breakfasts, and guesthouses. By providing type G plug adapters and voltage converters, businesses can enhance the guest experience, allowing visitors from various countries to charge their devices seamlessly. International B2B buyers should ensure that the sourced products comply with local electrical standards to avoid any operational issues.

In manufacturing, the need for reliable power sources is critical. Electrical plugs are used to power machinery, tools, and equipment in production facilities. By sourcing plugs that can handle 230V and 50Hz, manufacturers can ensure operational efficiency and minimize downtime. Buyers should focus on durability and safety certifications when sourcing electrical plugs to support the rigorous demands of manufacturing environments.

The telecommunications industry relies heavily on electrical plugs for the installation of communication equipment. A stable power supply is crucial for maintaining reliable connectivity and ensuring business operations run smoothly. International buyers should prioritize sourcing plugs that comply with local standards and are compatible with type G sockets to facilitate seamless integration into existing infrastructure.

In the healthcare sector, medical equipment requires a stable power supply to ensure patient safety and support critical operations. Electrical plugs used in this context must meet stringent healthcare standards, and international buyers should consider sourcing plugs that include voltage converters for devices that require specific voltage inputs. This ensures that all medical devices function correctly and safely in a healthcare environment.

Finally, in construction, electrical plugs are used to provide temporary power for tools and equipment on job sites. This is vital for facilitating efficient project execution and ensuring that work is completed on time. Buyers in this sector should look for robust adapters that can accommodate various types of equipment and consider dual voltage options to cater to international workers who may bring their own tools.

3 Common User Pain Points for ‘electrical plug for scotland’ & Their Solutions

Scenario 1: Incompatible Devices Causing Operational Delays

The Problem:

B2B buyers often face significant challenges when attempting to use devices that are not compatible with Scotland’s electrical system. For instance, a company based in Brazil may send employees to Scotland for a conference. Their laptops and other electronic devices, designed for 120V systems, will not work without the appropriate voltage converter and plug adapter. This situation can lead to delays in operations, communication failures, and potential financial losses if important presentations or meetings are disrupted due to uncharged devices.

The Solution:

To avoid these complications, it is crucial for B2B buyers to conduct a thorough inventory of all electronic devices and their voltage specifications prior to travel. Implement a checklist system that includes not only the voltage requirements but also the type of plug adapters needed for Scotland’s type G sockets. For devices that only accept 120V, sourcing a combined plug adapter and voltage converter is advisable. Suppliers that specialize in international travel adapters can be great partners, ensuring that the correct adapters and converters are ordered in advance. Consider purchasing a universal adapter that can handle multiple devices and voltages to streamline your travel kit and reduce the risk of device incompatibility.

Scenario 2: Budget Constraints with Adapter and Converter Purchases

The Problem:

Budget-conscious companies may hesitate to invest in high-quality adapters and converters due to the initial costs involved. This is especially true for smaller firms that may not have the financial flexibility to absorb unexpected expenses. When employees arrive in Scotland without the necessary equipment, they face the risk of being unable to use essential devices like laptops and mobile phones, leading to lost productivity and increased frustration.

The Solution:

To navigate budget constraints, B2B buyers should consider bulk purchasing options from reputable suppliers. By buying in larger quantities, companies can often negotiate better rates and ensure that they have a sufficient supply of high-quality adapters and converters. Additionally, investing in durable, multi-use adapters can offer long-term savings, as they can be reused for future trips. Educate employees on the importance of these tools and incorporate the costs into travel budgets ahead of time. An organized procurement strategy that includes travel accessories can prevent last-minute, costly purchases and ensure smooth operations while abroad.

Scenario 3: Misunderstandings About Voltage and Frequency Requirements

The Problem:

A common pitfall for B2B buyers is the misunderstanding surrounding voltage and frequency requirements. Many assume that all electronics will work universally without realizing that Scotland operates at 230V and 50Hz, which can damage devices designed for lower voltages. This lack of awareness can result in burnt-out devices, leading to unexpected costs and the need for replacements.

The Solution:

To mitigate this risk, B2B buyers should implement an educational program for employees that highlights the differences in electrical standards across regions. A pre-travel training session can help employees understand the specifications of their devices and the importance of checking voltage compatibility. Encourage them to look for labels indicating dual voltage capability (e.g., 100-240V) on their devices, which means they can be used in Scotland without a converter. Providing a guide or resource document that outlines the voltage and frequency differences, along with recommendations for reliable voltage converters, can empower employees to make informed decisions. This proactive approach not only protects company assets but also enhances employee confidence during international assignments.

Strategic Material Selection Guide for electrical plug for scotland

What Materials Are Commonly Used for Electrical Plugs in Scotland?

When selecting materials for electrical plugs specifically designed for the Scottish market, international B2B buyers must consider several factors including electrical standards, environmental conditions, and compliance with local regulations. Below, we analyze four common materials used in the manufacturing of electrical plugs, focusing on their properties, advantages, disadvantages, and implications for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

How Does Polycarbonate Perform as a Material for Electrical Plugs?

Polycarbonate is a popular choice for electrical plugs due to its excellent electrical insulation properties and high impact resistance. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various environments.

Pros: Polycarbonate plugs are durable and resistant to shattering, which is critical for maintaining safety in high-traffic areas. They are also lightweight and can be manufactured at a relatively low cost.

Cons: While polycarbonate is resistant to UV light, prolonged exposure can lead to yellowing and degradation. Additionally, it may not be as heat-resistant as other materials, which could limit its use in high-temperature applications.

Impact on Application: Polycarbonate’s compatibility with a wide range of electrical devices makes it a versatile choice. However, buyers should ensure that the plugs meet local compliance standards such as BS 1363 in the UK.

What About Thermoplastic Elastomers (TPE) for Electrical Plugs?

Thermoplastic elastomers (TPE) combine the properties of rubber and plastic, providing flexibility and durability. They are particularly useful for plugs that need to withstand repeated use and bending.

Pros: TPE offers excellent abrasion resistance and can operate effectively within a temperature range of -40°C to 90°C. Its flexibility makes it ideal for applications where plugs may be frequently connected and disconnected.

Cons: The manufacturing process for TPE can be more complex and costly compared to traditional plastics. Additionally, TPE may not provide the same level of electrical insulation as materials like polycarbonate.

Impact on Application: TPE is suitable for applications requiring frequent handling, such as portable devices. Buyers should assess the specific electrical ratings and compliance with international standards.

How Does Metal Influence the Performance of Electrical Plugs?

Metals, such as brass or copper, are often used for the conductive components of electrical plugs. These materials are essential for ensuring efficient electrical conductivity and durability.

Pros: Metals like brass have excellent corrosion resistance and can handle high electrical loads, making them suitable for heavy-duty applications. They also provide a reliable connection, reducing the risk of overheating.

Cons: Metal components can be more expensive and may require additional treatments to prevent corrosion. They can also be heavier, which may not be ideal for portable applications.

Impact on Application: Metal components are crucial for ensuring compliance with safety standards, particularly in high-load applications. International buyers should ensure that the metal used meets relevant standards such as ASTM B16 for brass.

What Role Does PVC Play in Electrical Plug Manufacturing?

Polyvinyl chloride (PVC) is commonly used for insulation and casing in electrical plugs. It is known for its versatility and cost-effectiveness.

Pros: PVC is resistant to moisture, chemicals, and abrasion, making it suitable for a variety of environments. It also has good electrical insulation properties and can be produced at a low cost.

Cons: PVC can become brittle over time, especially when exposed to extreme temperatures. Additionally, its production and disposal raise environmental concerns, which may be a consideration for buyers focused on sustainability.

Impact on Application: PVC’s compatibility with various electrical devices makes it a common choice for plugs. However, international buyers should be aware of potential regulatory restrictions on PVC materials in their respective markets.

Summary of Material Selection for Electrical Plugs in Scotland

| Material | Typical Use Case for electrical plug for scotland | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | General-purpose plugs | High impact resistance and durability | Limited heat resistance | Medium |

| Thermoplastic Elastomers (TPE) | Flexible plugs for portable devices | Excellent abrasion resistance and flexibility | Higher manufacturing complexity | Medium |

| Metal (Brass/Copper) | Heavy-duty applications | Excellent conductivity and corrosion resistance | Higher cost and weight | High |

| Polyvinyl Chloride (PVC) | Insulation and casing for plugs | Cost-effective and moisture-resistant | Can become brittle over time | Low |

This detailed analysis provides B2B buyers with the necessary insights to make informed decisions regarding material selection for electrical plugs tailored to the Scottish market. Understanding these materials’ properties and implications will help ensure compliance with local standards and enhance product performance.

In-depth Look: Manufacturing Processes and Quality Assurance for electrical plug for scotland

What Are the Key Manufacturing Processes for Electrical Plugs in Scotland?

The manufacturing of electrical plugs for Scotland involves several critical stages that ensure both functionality and compliance with safety standards. Understanding these processes is essential for B2B buyers to ensure they are sourcing reliable and quality products.

How Is Material Prepared for Electrical Plug Manufacturing?

The first stage in the manufacturing process is material preparation. High-quality thermoplastics are commonly used for the outer casing of electrical plugs, providing durability and electrical insulation. Copper is typically used for the internal wiring due to its excellent conductivity.

Before production, these materials undergo rigorous testing to confirm their suitability. Suppliers must ensure that plastics meet fire-resistance and insulation properties, while copper must be checked for purity and conductivity. This stage sets the foundation for the plug’s performance and safety.

What Are the Forming Techniques Used in Plug Manufacturing?

Following material preparation, the forming process begins. This involves molding the thermoplastic casing into the specific shape required for type G plugs, which are standard in Scotland. Injection molding is the most common technique employed, allowing for precision and repeatability in production.

During this phase, manufacturers also create the metal prongs that will be inserted into the casing. The prongs are typically stamped from copper sheets, followed by a plating process to enhance corrosion resistance. Quality control measures are vital at this stage to ensure that the dimensions and shapes of components meet industry specifications.

How Are Electrical Plugs Assembled?

Once the individual components are formed, the assembly process begins. This stage involves inserting the copper prongs into the molded plastic casing and connecting them to the internal wiring. Automated machinery often assists in this process, ensuring consistent assembly quality and reducing human error.

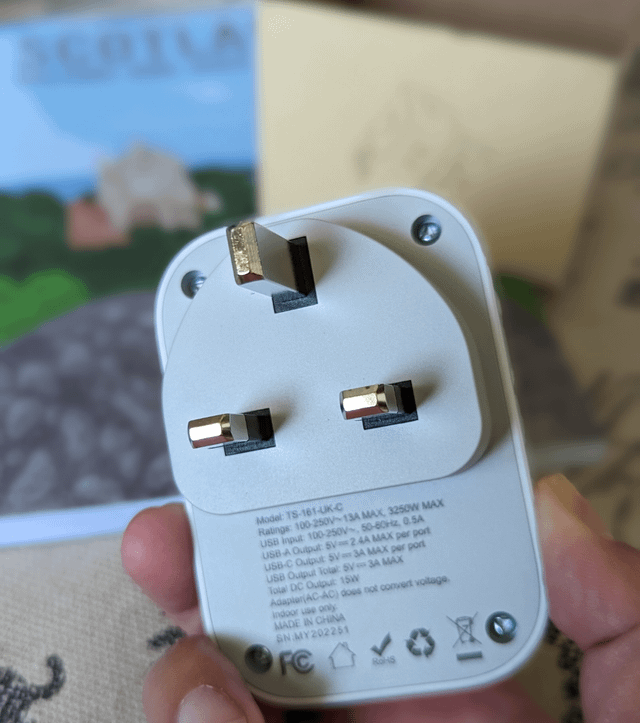

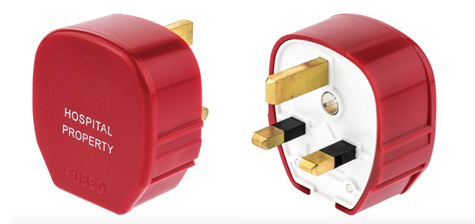

Illustrative image related to electrical plug for scotland

Additionally, each assembly undergoes a visual inspection to check for any obvious defects, such as improper fits or material inconsistencies. This step is crucial, as the integrity of the assembly directly impacts the safety and reliability of the electrical plug.

What Finishing Processes Are Involved in Electrical Plug Production?

The finishing stage includes several processes aimed at enhancing both the aesthetics and functionality of the electrical plugs. This may involve surface treatment to improve the appearance and durability of the plugs, such as applying a textured finish to enhance grip.

Furthermore, any necessary certifications or markings (such as CE marks) are added during this phase. This ensures compliance with international standards and makes it easier for B2B buyers to verify the product’s legitimacy in their respective markets.

Illustrative image related to electrical plug for scotland

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is a critical aspect of the manufacturing process for electrical plugs. It is imperative for B2B buyers to understand how quality is maintained at every stage, as this affects product reliability and compliance with international standards.

What Are the Relevant International Standards for Electrical Plugs?

Manufacturers must adhere to various international standards to ensure the safety and functionality of electrical plugs. ISO 9001 is a widely recognized standard that focuses on quality management systems. Compliance with this standard demonstrates a manufacturer’s commitment to maintaining high-quality processes.

In addition, products destined for the European market must meet CE marking requirements, which signify conformity with health, safety, and environmental protection standards. For B2B buyers, these certifications are crucial indicators of product quality and safety.

What Are the Key Quality Control Checkpoints in Electrical Plug Production?

Quality control checkpoints are integrated throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials and components before they enter the production line. Suppliers should provide certificates of compliance for all materials used.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular checks ensure that components are being produced within specified tolerances. This includes measuring dimensions, checking for defects, and ensuring proper assembly.

-

Final Quality Control (FQC): Once production is complete, finished plugs undergo rigorous testing to ensure they meet all required standards. This may include electrical testing, stress tests, and safety inspections.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for mitigating risks associated with product failure.

What Methods Can Be Used to Audit Supplier Quality?

Buyers can utilize several methods to assess a supplier’s quality control systems:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing processes, quality assurance measures, and compliance with international standards. This first-hand assessment can highlight areas of strength and potential weaknesses.

-

Quality Reports: Requesting detailed quality reports provides insight into a supplier’s adherence to standards. These reports should include data on defect rates, testing procedures, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control measures. This is particularly valuable for buyers unfamiliar with local manufacturing practices or standards.

What Are the Unique Quality Control Considerations for International Buyers?

B2B buyers from different regions must be aware of certain nuances when it comes to quality control. For instance, cultural differences may affect communication regarding quality standards and expectations.

Additionally, differing regulations and standards across regions can complicate the verification process. It is vital for buyers to familiarize themselves with the specific quality standards relevant to their markets and ensure that suppliers can meet these requirements.

In conclusion, understanding the manufacturing processes and quality assurance measures for electrical plugs in Scotland is essential for B2B buyers. By focusing on materials, forming techniques, assembly, and finishing, as well as robust quality control practices, buyers can make informed decisions when sourcing electrical plugs that meet both safety standards and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electrical plug for scotland’

In this guide, we provide a structured approach for B2B buyers looking to procure electrical plugs suitable for use in Scotland. Understanding the specific requirements for electrical plugs and adapters is crucial to ensure compatibility and safety for devices when operating in a different voltage environment.

Step 1: Understand Local Electrical Standards

Before sourcing electrical plugs for Scotland, familiarize yourself with the local electrical standards. Scotland uses Type G plugs, which feature three rectangular prongs, and operates at a standard voltage of 230V with a frequency of 50Hz. Ensuring that your products comply with these standards is essential to avoid device damage and ensure user safety.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications required for the plugs you wish to source. This includes:

– Type of Plug: Confirm that you need Type G plugs.

– Voltage and Frequency Compatibility: Ensure the plugs can handle 230V and 50Hz without risk of failure.

Defining these specifications will help streamline the sourcing process and avoid miscommunication with suppliers.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure reliability and quality. Request:

– Company Profiles and Certifications: Look for suppliers with relevant certifications to guarantee adherence to safety standards.

– References and Case Studies: Seek testimonials from other B2B clients, especially those in similar markets or industries.

A comprehensive evaluation will help mitigate risks associated with poor-quality products.

Step 4: Assess Product Quality and Compliance

Quality assurance is paramount in electrical components. Verify that the plugs:

– Meet International Standards: Look for compliance with IEC or other relevant safety standards.

– Undergo Rigorous Testing: Ensure that the plugs have been tested for voltage, current, and heat resistance.

This step is crucial to ensure the longevity and safety of the products you are sourcing.

Step 5: Check Availability and Lead Times

Discuss the availability of the electrical plugs and the lead times for delivery. Factors to consider include:

– Stock Levels: Ensure the supplier can meet your quantity requirements.

– Shipping Times: Confirm estimated delivery dates to align with your project timelines.

Understanding these factors can help avoid delays in your supply chain and ensure timely project execution.

Step 6: Negotiate Pricing and Payment Terms

Once you’ve selected potential suppliers, engage in discussions about pricing and payment terms. Consider:

– Bulk Purchase Discounts: Inquire about pricing structures for large orders.

– Payment Flexibility: Discuss terms that may allow for credit or staggered payments.

Negotiating favorable terms can significantly impact your procurement budget and cash flow.

Step 7: Plan for After-Sales Support

Lastly, consider the level of after-sales support provided by the supplier. This includes:

– Warranty and Return Policies: Understand the terms regarding product defects or incompatibilities.

– Technical Support Availability: Ensure that the supplier offers assistance for any technical issues that may arise.

Having robust after-sales support can save your business time and resources in the long run.

Illustrative image related to electrical plug for scotland

By following these steps, B2B buyers can effectively source electrical plugs for Scotland, ensuring compatibility, safety, and reliability for their devices.

Comprehensive Cost and Pricing Analysis for electrical plug for scotland Sourcing

What Are the Key Cost Components for Sourcing Electrical Plugs for Scotland?

When considering the sourcing of electrical plugs for Scotland, various cost components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials are a primary expense, with the cost influenced by the type of plastic, metal, and other components used in the plug’s construction. For instance, plugs made from durable, fire-resistant materials may incur higher initial costs but result in greater safety and longevity.

Illustrative image related to electrical plug for scotland

Labor costs vary significantly based on the region of production. Countries with lower labor costs may offer competitive pricing, but this can also lead to variations in quality.

Manufacturing overhead encompasses indirect costs related to production, such as utilities and facility maintenance. Efficient manufacturing processes can help reduce these overheads, ultimately lowering the cost per unit.

Tooling costs are associated with the creation of molds and equipment necessary for production. Custom designs or specifications may require additional investment in tooling, which should be factored into the overall cost.

Quality Control (QC) is crucial in ensuring that electrical plugs meet international standards. Rigorous QC processes may increase initial costs but can prevent costly recalls and enhance brand reputation.

Logistics expenses include shipping, handling, and customs duties, which are particularly significant for international buyers. Understanding shipping routes and Incoterms can help mitigate these costs.

Margins represent the profit that suppliers build into their pricing. Higher quality or certified products typically command larger margins, reflecting the additional value they offer.

How Do Price Influencers Affect Sourcing Decisions for Electrical Plugs?

Several factors influence the pricing of electrical plugs, which are vital for international B2B buyers to consider.

Volume and Minimum Order Quantities (MOQs) play a significant role in pricing. Suppliers often provide discounts for larger orders, making it essential for buyers to assess their needs and negotiate favorable terms.

Specifications and Customization can lead to price variations. Custom designs or unique features, such as enhanced safety certifications, may increase costs but can also meet specific market demands.

Illustrative image related to electrical plug for scotland

Material quality and certifications are critical when sourcing electrical plugs. Products that adhere to recognized safety standards will often come at a premium but are necessary for compliance and consumer trust.

Supplier factors—such as reputation, reliability, and past performance—should influence sourcing decisions. A well-established supplier may charge more but can provide assurances regarding quality and delivery timelines.

Incoterms determine the responsibilities of buyers and sellers in shipping. Choosing the right terms can influence total landed costs, impacting overall pricing.

Illustrative image related to electrical plug for scotland

What Negotiation Strategies Can B2B Buyers Use for Cost-Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings.

Start by conducting thorough market research to understand average pricing and supplier capabilities. This knowledge empowers buyers during negotiations and aids in establishing fair expectations.

Consider building long-term relationships with suppliers. Establishing trust can lead to better pricing, priority service, and access to exclusive deals on future orders.

Leverage volume discounts by consolidating orders. This not only reduces per-unit costs but can also streamline logistics, minimizing shipping expenses.

Lastly, always evaluate the Total Cost of Ownership (TCO) rather than just the initial price. This includes maintenance, energy efficiency, and potential warranty claims. A higher upfront cost may yield better long-term savings through durability and lower replacement rates.

Conclusion

In summary, sourcing electrical plugs for Scotland requires a comprehensive understanding of cost components, pricing influencers, and effective negotiation strategies. By considering these factors, international B2B buyers can make informed decisions that optimize their procurement processes, ensuring they receive quality products at competitive prices. Always remember that prices are indicative and can vary based on market conditions and specific supplier agreements.

Alternatives Analysis: Comparing electrical plug for scotland With Other Solutions

Understanding Alternatives for Electrical Plugs in Scotland

When considering electrical solutions for devices used in Scotland, international B2B buyers must evaluate various options to ensure compatibility, efficiency, and safety. The primary focus is on the type G electrical plug used in Scotland, but alternatives also exist that can meet the diverse needs of businesses operating across different regions. This analysis will compare the electrical plug for Scotland with alternative solutions to help buyers make informed decisions.

Comparison Table

| Comparison Aspect | Electrical Plug For Scotland | Universal Travel Adapter | Voltage Converter with Adapter |

|---|---|---|---|

| Performance | Standardized for type G devices, reliable for 230V | Versatile, accommodates multiple plug types | Allows safe use of 120V devices in 230V environments |

| Cost | Moderate (typically $10-$50 for sets) | Varies ($10-$30) | Higher initial cost ($30-$100) depending on wattage |

| Ease of Implementation | Simple installation; direct plug-in | Plug and play; requires no setup | May require understanding of wattage limits |

| Maintenance | Minimal; replace if damaged | Minimal; replace if damaged | Requires monitoring for device compatibility |

| Best Use Case | Permanent installations or frequent travel to Scotland | Casual travelers or short-term use | Long-term use of 120V devices in 230V regions |

Detailed Breakdown of Alternatives

Universal Travel Adapter

Universal travel adapters are designed to work in multiple countries, making them a flexible option for international travelers. They can accommodate various plug types, including the type G plug used in Scotland. One of the main advantages is their convenience, as they eliminate the need to purchase different adapters for each country. However, they do not convert voltage, meaning they are only suitable for devices that can handle the higher voltage (230V) used in Scotland. For devices that operate solely at 120V, a universal adapter would not suffice without a voltage converter.

Voltage Converter with Adapter

A voltage converter with an integrated adapter is an excellent solution for businesses or individuals who regularly use 120V devices in regions with 230V systems, such as Scotland. This option provides the necessary step-down voltage, ensuring that devices are protected from damage. While they may have a higher upfront cost, they offer robust protection for sensitive electronics like hair dryers or medical equipment. The downside is that they can be bulkier and may require an understanding of wattage limits to avoid overloading the converter, which could lead to device failure.

Conclusion: Choosing the Right Electrical Solution for Scotland

When selecting the appropriate electrical solution for use in Scotland, B2B buyers should assess their specific needs, including device types, frequency of use, and budget constraints. The type G plug is essential for ensuring compatibility with local electrical infrastructure, while alternatives like universal travel adapters and voltage converters offer flexibility and safety for diverse device requirements. Ultimately, the decision should hinge on balancing convenience, cost, and the operational demands of the devices being used, ensuring a seamless experience in the Scottish market.

Essential Technical Properties and Trade Terminology for electrical plug for scotland

What Are the Key Technical Properties of Electrical Plugs Used in Scotland?

When sourcing electrical plugs for use in Scotland, understanding the critical specifications is essential for ensuring compatibility, safety, and performance. Here are some key properties to consider:

Illustrative image related to electrical plug for scotland

1. Voltage Rating (230 V)

The standard voltage in Scotland is 230 V, operating at a frequency of 50 Hz. This higher voltage compared to many countries, such as the United States (120 V), necessitates that devices and plugs must be rated appropriately to avoid damage. For B2B buyers, this means confirming that any devices intended for use in Scotland can operate safely at this voltage.

2. Current Rating (13 A)

Scottish plugs are typically rated for a maximum current of 13 A. This specification is crucial when determining the load that a plug can handle. Choosing plugs with adequate current ratings ensures that they can safely power devices without risk of overheating or failure, which is particularly important for industrial applications.

3. Plug Type (Type G)

In Scotland, the type G plug is used, characterized by three rectangular prongs. Understanding this specification is vital for B2B buyers looking to import electrical devices, as it dictates the necessary adapters and compatibility with existing infrastructure. Failing to account for plug type can result in operational delays and additional costs.

4. Material Composition

The materials used in electrical plugs significantly impact their durability and safety. Common materials include polycarbonate or thermoplastic for the casing and brass for the pins. Selecting plugs made from high-grade materials ensures longevity and resistance to wear and tear, which is essential for businesses that require reliable performance over time.

Illustrative image related to electrical plug for scotland

5. Grounding Features

Grounding is a critical safety feature in electrical plugs, particularly in Scotland, where many devices are designed with three-prong plugs for added safety. Grounding reduces the risk of electric shock and equipment damage. Buyers should ensure that plugs meet grounding standards to comply with safety regulations.

6. Certification Standards (BS 1363)

Plugs used in Scotland must comply with the British Standard BS 1363. This certification guarantees that the plugs have undergone rigorous testing for safety and performance. B2B buyers should prioritize sourcing certified products to ensure compliance and reduce liability.

What Are Common Trade Terms Related to Electrical Plugs for Scotland?

Familiarity with industry terminology enhances communication and negotiation in B2B transactions. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of electrical plugs, understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to plan their orders effectively, manage inventory, and optimize purchasing costs.

3. RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on providing specific goods or services. For electrical plugs, submitting an RFQ allows buyers to receive competitive pricing and terms from multiple suppliers, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is essential for B2B buyers involved in importing electrical plugs to Scotland, as they clarify who is responsible for shipping, insurance, and tariffs.

5. CE Marking

CE marking indicates that a product complies with EU safety, health, and environmental protection standards. For electrical plugs sold in Scotland, ensuring CE compliance is vital for market acceptance and regulatory adherence.

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their electrical plugs meet the necessary standards and requirements for use in Scotland.

Navigating Market Dynamics and Sourcing Trends in the electrical plug for scotland Sector

What are the Key Trends and Dynamics in the Electrical Plug Market for Scotland?

The electrical plug market in Scotland is shaped by several global drivers, including advancements in technology, rising international trade, and evolving consumer preferences. With Scotland’s unique Type G power plugs operating at 230V and 50Hz, international B2B buyers must consider the compatibility of devices from various regions, particularly those operating on 120V systems like North America. As more businesses expand their operations internationally, the demand for reliable and compliant electrical solutions is surging, especially from regions such as Africa, South America, and the Middle East.

Emerging sourcing trends include the integration of smart technology into electrical plugs, such as built-in USB ports and energy monitoring features, which cater to a tech-savvy consumer base. Additionally, the shift towards e-commerce platforms for sourcing components has made it easier for international buyers to access a wider variety of products, enhancing competition and driving innovation. Furthermore, as sustainability becomes a priority, buyers are increasingly seeking products that are not only functional but also environmentally friendly. The growing trend of dual-voltage appliances simplifies sourcing for B2B buyers, as they can cater to multiple markets without needing extensive adapters or converters.

How is Sustainability Influencing the Sourcing of Electrical Plugs in Scotland?

Sustainability and ethical sourcing are becoming pivotal in the electrical plug sector. As environmental concerns rise globally, B2B buyers are increasingly looking for suppliers that prioritize green practices and materials. The production of electrical plugs can have significant environmental impacts, from resource extraction to manufacturing processes. Consequently, buyers are encouraged to seek suppliers who utilize eco-friendly materials and processes, such as recyclable plastics or renewable energy sources in manufacturing.

Moreover, certifications like RoHS (Restriction of Hazardous Substances) and CE marking not only ensure compliance with safety standards but also signal a commitment to sustainability. Buyers should prioritize suppliers who demonstrate transparency in their supply chains, showcasing efforts to minimize carbon footprints and reduce waste. These practices not only resonate with environmentally conscious consumers but also align with governmental regulations aimed at promoting sustainable development.

What is the Historical Context of Electrical Plugs in Scotland?

The evolution of electrical plugs in Scotland has been marked by the transition from early unregulated systems to standardized models. Initially, electrical installations were inconsistent, with various plug designs emerging. The introduction of the Type G plug in the UK in the 1940s established a uniform standard, enhancing safety and compatibility for electrical devices. This evolution reflects the broader trends in electrical engineering and consumer safety, paving the way for the modern electrical infrastructure that supports today’s varied and complex device ecosystem. Understanding this historical context is crucial for international B2B buyers, as it underlines the importance of compliance with established standards to ensure device safety and reliability in the Scottish market.

In summary, navigating the electrical plug market for Scotland requires an understanding of its unique characteristics, the importance of sustainability, and the historical context that has shaped its current landscape. By staying informed about these dynamics, B2B buyers can make strategic sourcing decisions that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of electrical plug for scotland

-

How do I ensure my devices are compatible with Scotland’s electrical standards?

To ensure compatibility, first check the voltage and frequency requirements of your devices. Scotland operates on a standard voltage of 230V and a frequency of 50Hz. Devices that indicate a voltage range of 100-240V can be used with just a plug adapter. However, devices designed for 120V may require a voltage converter to prevent damage. Always verify the specifications on your device’s label and consider investing in dual-voltage devices for flexibility. -

What type of plug adapter do I need for Scotland?

Scotland uses type G plug sockets, which have three rectangular prongs. For international devices, you will need a type G adapter to connect your plugs to Scottish outlets. When sourcing adapters, ensure they are compatible with both grounded and non-grounded plugs, as certain devices, such as laptops and shavers, may require specific types. It’s advisable to procure adapters in bulk to meet your operational needs and ensure all devices can be charged simultaneously. -

What are the common quality assurance practices for sourcing electrical plugs?

When sourcing electrical plugs, ensure that suppliers comply with international safety standards, such as IEC and BS1363 for the UK. Request certifications and test reports that validate the safety and performance of the products. Conducting factory audits and quality inspections can also help verify that manufacturing processes meet your specifications. Consider establishing a quality control agreement that outlines acceptable quality metrics and inspection protocols to mitigate risks. -

What are the minimum order quantities (MOQ) when sourcing electrical plugs?

Minimum order quantities for electrical plugs can vary significantly by supplier. Typically, MOQs may range from 500 to 10,000 units, depending on the manufacturer and the type of plugs required. Always confirm the MOQ with potential suppliers, as negotiating flexibility in MOQs can be possible for new partnerships or larger orders. Discussing your projected demand can also aid in finding a supplier willing to accommodate your needs. -

What payment terms are standard when purchasing electrical plugs from international suppliers?

Common payment terms in international trade include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit of 30% upfront, with the balance due before shipment or upon delivery. It’s crucial to clarify payment terms in your contract to avoid misunderstandings. Consider using secure payment methods and escrow services to protect both parties during transactions. -

How can I vet suppliers when sourcing electrical plugs for Scotland?

To vet suppliers, start by researching their reputation and history in the industry. Look for reviews and ratings from previous clients. Request references and follow up to gather insights on their reliability and product quality. Additionally, consider visiting the supplier’s manufacturing facilities if possible, or use third-party inspection services to assess their production capabilities and adherence to quality standards. -

What logistics considerations should I keep in mind when importing electrical plugs?

When importing electrical plugs, consider factors such as shipping methods, customs regulations, and lead times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure compliance with local regulations in Scotland regarding electrical products, including CE marking and safety certifications. Collaborating with a reliable logistics partner can streamline the process, helping you navigate customs and ensure timely delivery. -

Can I customize electrical plugs for my business needs?

Yes, many manufacturers offer customization options for electrical plugs, such as branding, color, or specific features tailored to your market. Discuss your requirements with potential suppliers to explore available customization options. Be mindful that customized orders may have higher MOQs and longer lead times. Ensure that you clearly communicate your specifications and expectations to avoid any discrepancies during production.

Top 6 Electrical Plug For Scotland Manufacturers & Suppliers List

1. Power Plugs & Sockets – Type G Adapters

Domain: power-plugs-sockets.com

Registered: 2013 (12 years)

Introduction: In Scotland, power plugs and sockets (outlets) of type G are used. The standard voltage is 230 V at a frequency of 50 Hz. Travelers from the United States need a power plug travel adapter for sockets type G, as plugs A and B do not fit. A voltage converter is also necessary due to the voltage difference (230 V in Scotland vs. 120 V in the USA) and frequency difference (50 Hz in Scotland vs. 60 Hz …

2. Traveling Savage – Voltage Guide for Scotland

Domain: traveling-savage.com

Registered: 2009 (16 years)

Introduction: Voltage in Scotland is 220v-240v; devices must accept this range. Most modern devices (laptops, smartphones) do not require a voltage converter if they accept 100-240v. Older devices (like hair dryers) may need a voltage converter. UK outlet adapters have three rectangular prongs; ensure to get adapters for both grounded and non-grounded plugs. Check devices for voltage compatibility before travel…

3. Going In Style – Scotland Adapter Plugs Set

Domain: goinginstyle.net

Registered: 2000 (25 years)

Introduction: Scotland (UK) Adapter Plugs Set includes various options for travelers to Scotland. The sets available are: Deluxe Adapter Set (4 adapters), Standard PLUS Adapter Set (2 grounded adapters + travel power strip), Standard Adapter Set (2 grounded adapters), and Basic Adapter Set (2 non-grounded adapters). Prices range from $13.00 to $47.00. The adapters are CE Certified and allow electrical connectio…

4. Electrical Safety First – UK Travel Adaptor

Domain: electricalsafetyfirst.org.uk

Registered: 2013 (12 years)

Introduction: Travel adaptor for the United Kingdom allows UK electrical appliances to be plugged into foreign sockets. It does not convert voltage or frequency. UK plug type is G (three rectangular pins in a triangular pattern). UK operates on 230V supply voltage and 50Hz frequency. Voltage converters or transformers may be needed for appliances rated at different voltages. Dual voltage appliances (110-240V) o…

5. Wise – Power Solutions for Scotland

Domain: wise.com

Registered: 1994 (31 years)

Introduction: Scotland uses plug type G, which has three flat pins. The standard voltage is 230V at a frequency of 50Hz. Travelers may need a power plug adaptor if their home country’s plug shape is different. A power converter may be necessary if the voltage differs from their home country. Dual voltage appliances display ‘INPUT: 110-240V’, while single voltage appliances show just one voltage, such as 230V. T…

6. Anker – Type G Plug Adapter

Domain: community.ricksteves.com

Registered: 1996 (29 years)

Introduction: Type G three-prong plug adapter; recommended product link: https://www.amazon.com/International-Adapter-Anker-Travel-Compact/dp/B0CPPGTLPC/ref=asc_df_B0CPPGTLPC?mcid=6ba91a5af0bd3fa786d8cbd6cacf48aa&hvocijid=18077646793316620692-B0CPPGTLPC-&hvexpln=73&tag=hyprod-20&linkCode=df0&hvadid=721245378154&hvpos=&hvnetw=g&hvrand=18077646793316620692&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocp…

Strategic Sourcing Conclusion and Outlook for electrical plug for scotland

In summary, understanding the electrical plug requirements in Scotland is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. The predominant type G plug and the standard voltage of 230 V at 50 Hz necessitate careful consideration for device compatibility and safety. Buyers should prioritize sourcing dual-voltage devices or invest in reliable voltage converters and adapters to avoid potential damage to equipment.

Strategic sourcing of electrical plugs and related accessories not only ensures compliance with local standards but also enhances operational efficiency for businesses operating in or with Scotland. By building partnerships with reputable suppliers and manufacturers, companies can secure high-quality products that meet the specific needs of their clientele.

Looking ahead, the growing demand for electronic devices across various sectors presents a significant opportunity for B2B buyers to expand their offerings. Engaging with local distributors and understanding market trends will be essential for successful navigation of the Scottish electrical market. Make informed sourcing decisions today to position your business for future growth in this evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.