The Definitive Guide to Double Sided Screw Bolt With Nut: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for double sided screw bolt with nut

In today’s competitive landscape, sourcing double sided screw bolts with nuts can be a complex endeavor for international B2B buyers. One of the key challenges faced by procurement professionals, especially in regions such as Africa, South America, the Middle East, and Europe, is navigating the diverse market offerings and ensuring product reliability. This guide addresses these concerns by providing a comprehensive overview of double sided screw bolts with nuts, including various types, their applications across industries, and essential supplier vetting processes.

As businesses increasingly prioritize efficiency and quality, understanding the nuances of these fasteners becomes crucial. Whether you are looking to enhance structural integrity in construction, improve assembly processes in manufacturing, or streamline operations in automotive applications, our guide equips you with the knowledge needed to make informed purchasing decisions.

We delve into critical factors such as pricing structures, quality assurance standards, and logistical considerations that impact the sourcing of double sided screw bolts with nuts. By empowering international buyers with actionable insights and industry best practices, this guide aims to facilitate seamless procurement processes, ensuring you secure the best solutions for your operational needs.

Understanding double sided screw bolt with nut Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hanger Bolt | One end is threaded for a nut, the other end is smooth for insertion into a material. | Furniture assembly, hanging fixtures | Pros: Easy installation; versatile. Cons: Requires additional nut. |

| Double-Ended Bolt | Both ends are threaded, allowing for connection to two separate components. | Machinery, structural applications | Pros: Strong connection; high load capacity. Cons: Can be difficult to align. |

| Chicago Screw (Post) | Hollow screw with a solid head; used with a nut for fastening. | Leather goods, belts, collars | Pros: Easily adjustable; reusable. Cons: Limited to lighter applications. |

| Steel Screw Post | Nickel-plated for corrosion resistance; ideal for joining thicker materials. | Construction, automotive parts | Pros: Durable; corrosion-resistant. Cons: Heavier than alternatives. |

| Two-Sided Screw with Nut | Features a nut on one end and a screw on the other; allows for secure fastening. | Electrical installations, HVAC | Pros: Secure grip; versatile use. Cons: Requires precise fitting. |

What are the characteristics of a Hanger Bolt?

Hanger bolts are characterized by their unique design, featuring a threaded end for a nut and a smooth end for insertion into wood or other materials. They are commonly used in furniture assembly and for hanging fixtures due to their ease of installation and ability to provide a secure hold. When sourcing hanger bolts, B2B buyers should consider the material (e.g., stainless steel for corrosion resistance) and length to match their specific application needs.

How does a Double-Ended Bolt function in industrial applications?

Double-ended bolts are designed with threads on both ends, allowing them to connect two separate components securely. They are often utilized in machinery and structural applications where a strong, reliable connection is essential. Buyers should evaluate the load capacity and length of the bolts to ensure they meet the demands of their projects. Proper alignment during installation is crucial to achieve optimal performance.

What makes Chicago Screws suitable for leather goods?

Chicago screws, also known as screw posts, consist of a hollow screw with a solid head and an internal thread that acts as a nut. They are particularly popular in the production of leather goods, such as belts and collars, due to their adjustable and reusable nature. When purchasing Chicago screws, B2B buyers should consider the thickness of the materials they are joining, as the screw length must accommodate this for a secure fit.

Why choose Steel Screw Posts for construction?

Steel screw posts are often nickel-plated to enhance corrosion resistance, making them ideal for joining thicker materials in construction and automotive applications. Their durability and strength allow them to withstand harsh conditions. Buyers should assess the weight and breaking load of these screw posts to ensure they meet the requirements of their specific applications.

What are the advantages of using a Two-Sided Screw with Nut?

Two-sided screws feature a nut on one end and a screw on the other, providing a secure fastening solution for various applications, including electrical installations and HVAC systems. Their design allows for a strong grip and versatility in use. However, precision fitting is necessary to ensure optimal performance, so buyers should consider the dimensions and compatibility with their existing systems when purchasing.

Key Industrial Applications of double sided screw bolt with nut

| Industry/Sector | Specific Application of double sided screw bolt with nut | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Used for securing floating shelves and fixtures in residential and commercial spaces. | Provides strong, reliable anchoring solutions that withstand heavy loads. | Ensure compliance with local building codes and standards. Look for corrosion-resistant materials. |

| Automotive | Utilized in fastening components within vehicle assembly, such as seats and panels. | Enhances structural integrity and safety of vehicles while allowing for easy assembly and disassembly. | Consider sourcing bolts that meet automotive industry standards for strength and durability. |

| Furniture Manufacturing | Employed in assembling modular furniture and cabinetry, allowing for easy adjustments. | Facilitates quick assembly and customization, reducing labor costs and improving production efficiency. | Look for high-quality finishes to ensure aesthetic appeal and durability in various environments. |

| Aerospace | Applied in aircraft assembly for securing components like seats and cargo holds. | Ensures safety and reliability in high-stress environments, critical for aviation standards. | Source from suppliers that provide certified materials and adhere to strict aerospace regulations. |

| Textile and Leather Goods | Used in the production of leather belts, bags, and other accessories for secure fastening. | Offers versatility and ease of use for designers, enabling quick changes and repairs. | Consider sourcing options that provide a range of sizes and finishes to accommodate different designs. |

In the construction industry, double sided screw bolts with nuts are commonly used for securing floating shelves and fixtures, providing a robust anchoring solution that can withstand substantial loads. These fasteners allow for easier installation and removal of fixtures, making them ideal for both residential and commercial applications. International buyers should ensure that the sourced products comply with local building codes and are made from corrosion-resistant materials to enhance longevity.

In the automotive sector, these fasteners play a crucial role in assembling various components, such as seats and panels. The double-sided design allows for efficient assembly and disassembly, which is essential in automotive manufacturing processes. For B2B buyers, it is important to source bolts that meet rigorous automotive industry standards to ensure safety and structural integrity.

Furniture manufacturers utilize double sided screw bolts in assembling modular furniture, allowing for easy adjustments and reconfigurations. This application not only reduces labor costs but also improves production efficiency, as the fasteners enable quick assembly and disassembly. Buyers in this sector should focus on sourcing high-quality finishes that ensure both durability and aesthetic appeal in diverse environments.

In the aerospace industry, double sided screw bolts are critical for securing components like seats and cargo holds within aircraft. The reliability of these fasteners is paramount, as they must perform under high-stress conditions. International buyers should prioritize suppliers that provide certified materials and comply with strict aerospace regulations to guarantee safety and performance.

Lastly, in the textile and leather goods sector, double sided screw bolts are employed in the production of items like belts and bags. These fasteners allow for secure fastening while providing designers with the flexibility to make quick changes or repairs. Buyers should consider sourcing a variety of sizes and finishes to accommodate different design requirements, ensuring that the fasteners meet the specific needs of their products.

3 Common User Pain Points for ‘double sided screw bolt with nut’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Double-Sided Screw Bolts with Nuts

The Problem: Many international B2B buyers, particularly from regions like Africa and South America, face challenges in sourcing high-quality double-sided screw bolts with nuts. They often encounter inconsistent product quality, unreliable suppliers, and lack of standardization in specifications. This inconsistency can lead to project delays and increased costs, as subpar materials can compromise the integrity of the final product, creating safety and operational risks.

The Solution: To ensure consistent quality, buyers should prioritize suppliers who provide detailed product specifications and certifications. Engaging with established manufacturers or trusted distributors who have a proven track record in the industry can greatly reduce the risk of receiving inferior products. Additionally, implementing a quality assurance process that includes sample testing before placing large orders can help verify that the bolts meet the necessary standards. Buyers should also consider forming long-term partnerships with suppliers who are open to transparent communication and can provide ongoing support for future orders.

Scenario 2: Incompatibility with Existing Hardware

The Problem: Another common issue faced by B2B buyers is the incompatibility of double-sided screw bolts with existing hardware. This can occur when the specifications of the bolts do not match those of the nuts or the materials being joined. Such discrepancies can lead to difficulties during assembly and can result in damaged components or compromised structural integrity.

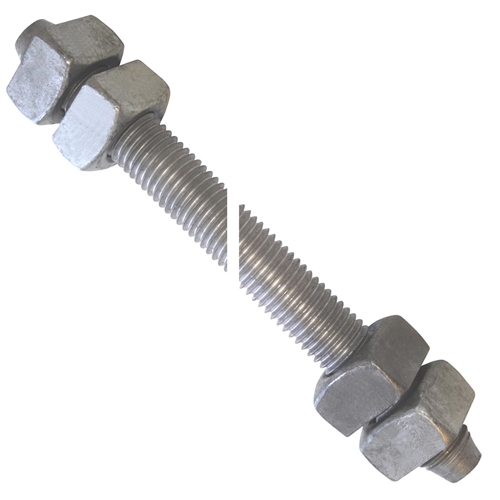

Illustrative image related to double sided screw bolt with nut

The Solution: To avoid compatibility issues, it is crucial to conduct a thorough review of all hardware specifications before making a purchase. Buyers should take into account the thread types, sizes, and material compatibility when selecting double-sided screw bolts and nuts. Utilizing a comprehensive catalog or database of available products can assist in cross-referencing specifications. Furthermore, collaborating with engineers or technical experts during the selection process can provide insights into the best combinations of hardware, ensuring a seamless integration that meets operational requirements.

Scenario 3: Installation Challenges and Technical Support

The Problem: Many buyers encounter installation challenges when working with double-sided screw bolts, particularly in complex projects where precision is critical. Misalignment during installation can lead to structural failures, and the lack of technical support from suppliers can exacerbate these challenges, leaving buyers without the guidance needed to resolve issues.

The Solution: To mitigate installation challenges, buyers should seek suppliers that offer comprehensive technical support and installation guides. These resources can include detailed instructions, video tutorials, and access to customer service representatives who can provide real-time assistance. Additionally, investing in training for installation teams can enhance their skills and knowledge, ensuring they are equipped to handle the nuances of working with double-sided screw bolts. Establishing a feedback loop with the supplier can also help in addressing common installation problems, allowing for continuous improvement in the process and product usage.

Strategic Material Selection Guide for double sided screw bolt with nut

When selecting materials for double-sided screw bolts with nuts, understanding the properties and suitability of each material is essential for ensuring optimal performance in various applications. Here, we analyze four common materials used in the manufacturing of these fasteners: stainless steel, carbon steel, brass, and nylon. Each material has distinct characteristics that influence its performance, cost, and application compatibility.

What Are the Key Properties of Stainless Steel for Double-Sided Screw Bolts?

Stainless steel is renowned for its excellent corrosion resistance, which is crucial in environments exposed to moisture, chemicals, or extreme temperatures. It typically has a high tensile strength and can withstand significant pressure, making it suitable for heavy-duty applications. The most common grades, such as 304 and 316, offer varying levels of corrosion resistance, with 316 being more resistant to chlorides and saltwater.

Illustrative image related to double sided screw bolt with nut

Pros: Stainless steel bolts are durable, resistant to rust, and maintain structural integrity over time. They are widely accepted in international standards, making them suitable for global markets.

Cons: The primary drawback is the cost, as stainless steel is generally more expensive than other materials. Additionally, the manufacturing process can be more complex, which may lead to longer lead times.

Impact on Application: Stainless steel bolts are ideal for marine, chemical, and food processing applications, where corrosion resistance is paramount.

How Does Carbon Steel Compare for Double-Sided Screw Bolts?

Carbon steel is another popular choice for double-sided screw bolts due to its strength and affordability. It is often used in construction and automotive applications where high strength is required. However, carbon steel lacks the corrosion resistance of stainless steel, making it less suitable for humid or corrosive environments unless coated.

Pros: The cost-effectiveness of carbon steel makes it a preferred option for large-scale projects. It is readily available and can be manufactured easily.

Cons: The primary limitation is its susceptibility to rust and corrosion, which can compromise the integrity of the fastener over time. Protective coatings can mitigate this, but they can add to the overall cost.

Impact on Application: Carbon steel bolts are best suited for indoor applications or environments where exposure to moisture is minimal.

What Are the Advantages of Using Brass for Double-Sided Screw Bolts?

Brass is an alloy of copper and zinc, known for its excellent machinability and aesthetic appeal. It offers good corrosion resistance, particularly in non-humid environments, and is often used in decorative applications or where electrical conductivity is essential.

Pros: Brass bolts are resistant to tarnishing and corrosion, making them suitable for electrical and plumbing applications. Their attractive finish can enhance the appearance of products.

Cons: Brass is softer than steel, which can limit its use in high-stress applications. It is also more expensive than carbon steel.

Impact on Application: Brass bolts are commonly used in electrical fittings, plumbing, and decorative hardware, where aesthetics and conductivity are important.

Illustrative image related to double sided screw bolt with nut

How Does Nylon Perform as a Material for Double-Sided Screw Bolts?

Nylon is a synthetic polymer that offers unique advantages in specific applications. It is lightweight, non-corrosive, and has good chemical resistance. Nylon bolts can absorb vibrations, making them suitable for applications where noise reduction is desired.

Pros: The non-metallic nature of nylon makes it ideal for electrical insulation and applications where metal fasteners may cause interference.

Cons: Nylon bolts have lower tensile strength compared to metal options and may not be suitable for heavy-duty applications. They can also degrade under UV exposure unless treated.

Impact on Application: Nylon bolts are often used in electronics, automotive interiors, and applications requiring lightweight and non-corrosive fasteners.

Summary Table of Material Selection for Double-Sided Screw Bolts

| Material | Typical Use Case for double sided screw bolt with nut | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine, chemical, and food processing applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Carbon Steel | Construction and automotive applications | Cost-effective and strong | Susceptible to rust without coatings | Low |

| Brass | Electrical fittings and plumbing | Aesthetic appeal and corrosion resistance | Softer material limits high-stress use | Med |

| Nylon | Electronics and automotive interiors | Lightweight and non-corrosive | Lower tensile strength | Low |

This guide provides a comprehensive overview of material selection for double-sided screw bolts with nuts, helping international B2B buyers make informed decisions based on their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for double sided screw bolt with nut

What Are the Key Manufacturing Processes for Double-Sided Screw Bolts with Nuts?

The manufacturing of double-sided screw bolts with nuts involves several critical stages, each designed to ensure the final product meets both functional and quality standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Double-Sided Screw Bolts?

The manufacturing process begins with material selection, typically involving high-strength steel or stainless steel to enhance durability and corrosion resistance. Raw materials are sourced from certified suppliers to ensure compliance with international standards. Once the materials are acquired, they undergo a thorough inspection to verify quality and composition, often utilizing techniques such as spectroscopy for metal analysis.

After initial inspections, the materials are cut to specified lengths using precision cutting tools. This stage is crucial, as the accuracy of the cut directly affects the performance and compatibility of the final product. Additionally, the cut pieces are often deburred to remove sharp edges, ensuring safety during handling and installation.

What Forming Techniques Are Used in the Production of Double-Sided Screw Bolts?

The forming stage employs various techniques, including cold forging and machining, which are critical for shaping the screw and nut components. Cold forging is typically preferred for its ability to produce high-strength parts with minimal material waste. This process involves placing the cut metal into a die and applying pressure to shape it, resulting in a uniform grain structure that enhances strength.

In some cases, machining processes such as turning or milling are used to achieve precise dimensions and threads. CNC (Computer Numerical Control) machines are commonly employed to ensure accuracy and repeatability in the production of threads and head shapes. These machines can also accommodate complex designs, allowing manufacturers to meet specific buyer requirements.

How Are the Components Assembled for Double-Sided Screw Bolts?

Once the individual components are formed, they undergo assembly. This stage may involve threading the screw into the nut, ensuring a secure fit. Automated assembly lines often facilitate this process, reducing labor costs and increasing efficiency.

During assembly, it is vital to verify the fit and function of each component. This is typically done using torque testing equipment, which ensures that the screws can withstand the necessary load without loosening. Additionally, quality control personnel may perform random checks to verify that assembly meets specified tolerances.

What Finishing Processes Are Important for Quality Assurance?

Finishing processes include surface treatments like plating or coating to enhance corrosion resistance and aesthetic appeal. Common finishes for double-sided screw bolts include zinc plating, nickel plating, or powder coating, depending on the application and environmental conditions the bolts will face.

The finishing stage also involves cleaning the products to remove any residues from manufacturing processes. This can include ultrasonic cleaning or chemical baths. Quality assurance checks during this stage ensure that the finish is uniform and meets the specified standards.

Which International Standards Govern Quality Assurance for Double-Sided Screw Bolts?

Quality assurance is paramount in the manufacturing of double-sided screw bolts with nuts. Compliance with international standards such as ISO 9001 ensures that manufacturers maintain a consistent level of quality in their production processes. ISO 9001 focuses on quality management systems, emphasizing continuous improvement and customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE marking for European markets or API (American Petroleum Institute) standards for oil and gas applications may be required. These certifications indicate that the products meet stringent safety and performance criteria specific to the respective industry.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at various stages of production, commonly referred to as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Testing methods can include tensile strength tests, hardness tests, and chemical composition analysis.

-

In-Process Quality Control (IPQC): During manufacturing, QC personnel monitor processes to ensure adherence to operational parameters. This may involve measuring dimensions, checking thread quality, and ensuring proper assembly techniques are employed.

-

Final Quality Control (FQC): Once production is complete, final inspections are conducted to confirm that the products meet all design specifications. Common testing methods include load testing, torque testing, and visual inspections for surface defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is crucial to ensure product reliability. Here are several actionable steps:

-

Audits and Inspections: Requesting third-party audits can provide an impartial assessment of a supplier’s manufacturing practices and quality control systems. Auditors can evaluate compliance with ISO standards and industry-specific requirements.

-

Quality Control Reports: Suppliers should provide documentation detailing their QC processes, including test results and compliance certifications. Buyers should review these reports to understand the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an additional layer of verification. These agencies can perform on-site inspections during production and pre-shipment to ensure that the products meet the specified quality standards.

What Nuances Should International B2B Buyers Consider Regarding QC and Certification?

International buyers must be aware of regional differences in standards and certifications. For instance, European buyers may prioritize CE marking, while buyers in the Middle East may require compliance with local standards. Understanding these nuances can help buyers select suppliers that align with their market requirements.

Additionally, language barriers and varying regulatory environments can pose challenges. Therefore, establishing clear communication with suppliers and ensuring that all quality documentation is available in a language understood by both parties is essential.

By carefully considering these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing double-sided screw bolts with nuts, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘double sided screw bolt with nut’

In the competitive landscape of B2B procurement, sourcing double-sided screw bolts with nuts can be a complex process. This guide provides a practical checklist to streamline your purchasing decisions and ensure you obtain high-quality products that meet your operational needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is critical to successful sourcing. Consider the dimensions, material specifications, load capacity, and threading types needed for your application. This clarity will help you communicate effectively with suppliers and avoid costly mistakes.

- Dimensions: Specify the length and diameter of the screws.

- Material: Decide between stainless steel, carbon steel, or other materials based on corrosion resistance and strength.

Step 2: Research Potential Suppliers

Identifying reputable suppliers is essential to ensure product quality and reliability. Utilize online platforms, trade shows, and industry networks to compile a list of potential vendors. Pay attention to their experience in manufacturing double-sided screw bolts.

- Industry Experience: Look for suppliers with a proven track record in your specific sector.

- Product Range: Ensure they offer a variety of sizes and types to meet your needs.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with international standards. This step ensures that the products you purchase meet safety and quality benchmarks.

- ISO Certification: Check for ISO 9001 or other relevant certifications indicating quality management systems.

- Material Compliance: Ensure that the materials used conform to industry regulations and standards.

Step 4: Request Samples for Testing

Obtaining samples before making a bulk order allows you to assess the quality and suitability of the products. Testing samples can help identify any discrepancies between your specifications and the supplier’s offerings.

- Functional Testing: Assess the screws for strength, durability, and ease of use.

- Material Inspection: Check for material defects or inconsistencies in finish.

Step 5: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations to secure the best pricing and terms. Consider bulk order discounts, payment terms, and delivery schedules to optimize your procurement strategy.

Illustrative image related to double sided screw bolt with nut

- Volume Discounts: Discuss pricing structures based on order quantity.

- Lead Times: Ensure delivery timelines align with your project schedules.

Step 6: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear points of contact and preferred communication methods to facilitate smooth interactions.

- Regular Updates: Request periodic updates on order status and any potential delays.

- Feedback Loop: Create a system for addressing concerns or adjustments promptly.

Step 7: Plan for Quality Control and Inspection

Implement a quality control process for incoming shipments to ensure that the products received meet your specifications. This step is crucial for maintaining operational integrity and preventing issues in production.

- Inspection Criteria: Define what constitutes acceptable quality and performance.

- Return Policies: Understand the supplier’s return policy in case of defective items.

By following this checklist, B2B buyers can navigate the complexities of sourcing double-sided screw bolts with nuts effectively, ensuring they make informed decisions that support their business operations.

Comprehensive Cost and Pricing Analysis for double sided screw bolt with nut Sourcing

What Are the Key Cost Components for Double-Sided Screw Bolts with Nuts?

When sourcing double-sided screw bolts with nuts, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall cost. Stainless steel and other high-quality alloys are preferred for their durability and corrosion resistance, leading to higher material costs. However, opting for lower-grade materials may save on initial expenses but could increase long-term costs due to replacements and failures.

-

Labor: Labor costs encompass the wages of skilled workers involved in the manufacturing process. The complexity of the design and assembly of double-sided screw bolts can lead to higher labor costs, particularly if specialized skills or additional quality checks are required.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, maintenance of machinery, and factory rent. Efficient production processes can help minimize these costs, but they are an essential consideration in the overall pricing strategy.

-

Tooling: Tooling costs refer to the expense of creating and maintaining molds or specialized equipment necessary for production. Custom designs may require significant investment in tooling, which can be amortized over larger production runs to lower per-unit costs.

-

Quality Control (QC): Ensuring product quality is paramount, particularly for international markets where standards may vary. Implementing rigorous QC processes can incur additional costs but ultimately protects against costly defects and returns.

-

Logistics: Shipping and handling expenses can vary widely based on the origin and destination. International buyers should consider freight costs, tariffs, and potential delays when evaluating the total cost of sourcing.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. This margin can vary based on market conditions, competition, and the supplier’s positioning.

How Do Price Influencers Affect the Sourcing of Double-Sided Screw Bolts?

Several factors can influence the pricing of double-sided screw bolts, particularly in international markets:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding the MOQ is crucial for buyers, as larger orders can yield significant savings.

-

Specifications and Customization: Customized products generally incur higher costs due to the additional design and production complexities. Buyers should weigh the necessity of customization against standard options.

-

Materials and Quality Certifications: Products that meet specific quality standards or certifications (e.g., ISO, ASTM) may come at a premium. Buyers in regions with stringent regulations, like Europe, should prioritize certified products to avoid compliance issues.

-

Supplier Factors: The reliability and reputation of a supplier can significantly impact pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding Incoterms is essential for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect who bears the cost and risk during transportation, influencing the overall pricing strategy.

What Are the Best Buyer Tips for Sourcing Double-Sided Screw Bolts?

To optimize sourcing strategies, international buyers should consider the following tips:

-

Negotiate Effectively: Leverage volume purchasing and long-term contracts to negotiate better pricing. Building a relationship with suppliers can also lead to favorable terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and replacement expenses. This holistic view can guide better purchasing decisions.

-

Understand Pricing Nuances: Be aware of regional pricing variations and currency fluctuations, especially when dealing with suppliers in Africa, South America, the Middle East, and Europe. Understanding local market conditions can help in making informed purchasing decisions.

-

Stay Informed About Market Trends: Keeping abreast of market trends, such as material shortages or changes in labor costs, can provide insights into potential price increases or opportunities for savings.

Disclaimer

The prices and analyses provided are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier evaluations before finalizing any purchases.

Alternatives Analysis: Comparing double sided screw bolt with nut With Other Solutions

Understanding Alternatives to Double Sided Screw Bolt with Nut

In today’s diverse B2B marketplace, selecting the right fastener solution is crucial for ensuring product integrity and performance. While the double sided screw bolt with nut is a popular choice for various applications, there are alternative solutions available that may better suit specific needs, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe. This analysis will compare the double sided screw bolt with nut to other viable fastening options, helping decision-makers make informed choices.

| Comparison Aspect | Double Sided Screw Bolt With Nut | Hanger Bolts | Double Ended Bolts |

|---|---|---|---|

| Performance | High load capacity and stability | Suitable for lightweight fixtures | Versatile for various applications |

| Cost | Moderate pricing | Generally lower cost | Variable, often cost-effective |

| Ease of Implementation | Requires precise alignment | Easy to install with tools | Simple installation, minimal tools |

| Maintenance | Low maintenance | Low maintenance | Moderate, may require periodic checks |

| Best Use Case | Heavy-duty applications | Hanging fixtures, furniture | Connecting two materials securely |

Analyzing Hanger Bolts as an Alternative

Hanger bolts are a practical alternative, particularly for lightweight fixtures and applications where ease of installation is paramount. These bolts feature a wood screw end and a machine screw end, allowing for straightforward attachment to wooden structures. Their low cost and minimal installation requirements make them attractive for projects where budget constraints are significant. However, they may not provide the same load-bearing capacity as double sided screws, making them less suitable for heavy-duty applications.

Evaluating Double Ended Bolts

Double ended bolts consist of a threaded rod with threads on both ends, allowing for versatile applications, especially in connecting two materials. They are favored for their simplicity and effectiveness in various industries, including construction and furniture manufacturing. The installation process is generally straightforward, requiring minimal tools. However, double ended bolts may necessitate periodic checks to ensure tightness, as they can loosen over time, especially in high-vibration environments.

Conclusion: Making the Right Choice for Your Business

When selecting a fastening solution, B2B buyers should consider the specific requirements of their projects, including load capacity, installation ease, and cost-effectiveness. The double sided screw bolt with nut offers robust performance for heavy-duty applications, while alternatives like hanger bolts and double ended bolts provide unique advantages for lighter or varied applications. By evaluating the comparative aspects laid out in this analysis, buyers can confidently choose the most suitable fastening solution that aligns with their operational needs and project specifications.

Essential Technical Properties and Trade Terminology for double sided screw bolt with nut

What Are the Key Technical Properties of Double Sided Screw Bolts with Nuts?

When sourcing double sided screw bolts with nuts, understanding their technical specifications is crucial for ensuring compatibility and performance in various applications. Here are several critical specifications:

-

Material Grade: The material from which the screw bolt is made significantly impacts its strength, corrosion resistance, and overall durability. Common materials include carbon steel, stainless steel, and alloy steel. For example, stainless steel (like A2 or A4 grades) is often preferred for outdoor applications due to its superior corrosion resistance, making it ideal for industries such as construction and automotive.

-

Thread Pitch and Diameter: The thread pitch (the distance between threads) and diameter are essential for compatibility with nuts and other components. Common sizes include 1/4″, 3/8″, and 5/16″, with varying thread pitches such as coarse and fine. Proper matching ensures secure fastening and reduces the risk of stripping during assembly.

-

Length: The length of the screw bolt should be appropriate for the materials being joined. This is critical for achieving a secure connection. A standard rule of thumb is that the bolt should extend through the thickness of the materials being fastened, plus the thickness of the nut.

-

Tensile Strength: This property indicates the maximum amount of tensile (pulling) stress that the bolt can withstand before failing. Measured in pounds per square inch (psi), tensile strength is vital for applications that will experience significant loads or stresses, such as in structural assemblies.

-

Coating or Finish: Coatings like zinc plating or black oxide can enhance corrosion resistance and improve aesthetics. The choice of finish may depend on environmental conditions and specific application requirements, which can vary across different regions.

What Are Common Trade Terms Used in the Industry?

Familiarity with industry jargon is essential for effective communication in the procurement process. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in another company’s end product. When purchasing double sided screw bolts, buyers may seek OEMs to ensure quality and compatibility with existing systems.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to ensure they can meet their inventory needs without over-committing resources, especially in markets with high demand fluctuations.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for specific products. It’s a crucial step in the procurement process that helps buyers compare options and negotiate terms effectively.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers. Familiarity with Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for international transactions, as they dictate shipping costs and risk management.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for planning and ensuring timely project completion, particularly in industries where delays can incur additional costs.

-

Certification Standards: Products may need to meet specific industry standards or certifications, such as ISO or ASTM. These certifications ensure that the screws and nuts are manufactured to consistent quality and safety benchmarks, which is particularly important for international buyers looking to maintain compliance with local regulations.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring that the double sided screw bolts with nuts they purchase meet their specific application requirements and standards.

Navigating Market Dynamics and Sourcing Trends in the double sided screw bolt with nut Sector

What Are the Current Market Dynamics and Key Trends in the Double-Sided Screw Bolt with Nut Sector?

The double-sided screw bolt with nut sector is witnessing significant growth driven by the increasing demand across various industries, including construction, automotive, and manufacturing. Key market drivers include the global push for infrastructure development, particularly in emerging markets such as Africa and South America, where urbanization is leading to heightened construction activities. Additionally, the expansion of manufacturing sectors in regions like Vietnam and Germany is propelling the demand for reliable fastening solutions, with double-sided screw bolts being favored for their versatility and strength.

Emerging trends in B2B sourcing indicate a shift towards digital procurement platforms that streamline the purchasing process. International buyers are increasingly leveraging e-commerce marketplaces to compare prices, quality, and delivery options. This digital transformation is accompanied by a growing emphasis on data analytics, enabling businesses to make informed sourcing decisions based on market trends and supplier performance. Furthermore, sustainability is becoming a focal point, with buyers seeking suppliers that prioritize eco-friendly materials and manufacturing processes.

As competition intensifies, suppliers are adapting by enhancing their product offerings with innovative designs and materials, including corrosion-resistant options and those that comply with international standards. The rise of automation in manufacturing processes also plays a crucial role in improving efficiency and reducing costs, making double-sided screw bolts more accessible to a wider range of businesses.

How Is Sustainability and Ethical Sourcing Reshaping the Double-Sided Screw Bolt with Nut Market?

Sustainability and ethical sourcing are increasingly vital considerations for B2B buyers in the double-sided screw bolt with nut market. The environmental impact of fasteners, particularly those made from non-recyclable materials, has prompted a shift toward more sustainable practices. Buyers are now prioritizing suppliers who implement eco-friendly production methods and utilize recyclable materials, such as stainless steel or aluminum, which not only reduce waste but also lower the carbon footprint associated with manufacturing.

Moreover, the importance of ethical supply chains cannot be overstated. International buyers are more inclined to partner with suppliers who demonstrate transparency and social responsibility in their operations. This includes adherence to fair labor practices and compliance with local and international labor laws. As a result, certifications like ISO 14001 for environmental management and ISO 9001 for quality management are becoming essential for suppliers aiming to secure contracts with conscientious buyers.

Incorporating green certifications and materials into the sourcing process not only enhances a company’s reputation but also aligns with the growing consumer demand for sustainable products. As sustainability becomes a standard expectation rather than a differentiator, businesses must adapt to remain competitive in the evolving landscape of the double-sided screw bolt market.

What Is the Historical Context Behind the Double-Sided Screw Bolt with Nut?

The double-sided screw bolt with nut has a rich history that traces back to the Industrial Revolution, where the demand for robust fastening solutions surged alongside advancements in machinery and construction techniques. Initially utilized in basic applications, these fasteners have evolved significantly over the decades, adapting to the increasing complexities of modern engineering and construction requirements.

In the late 20th century, the introduction of new materials and manufacturing technologies revolutionized the design and functionality of double-sided screw bolts. The focus shifted towards enhancing durability and corrosion resistance, which are critical in applications exposed to harsh environmental conditions. As global trade expanded, the standardization of sizes and specifications facilitated international sourcing, allowing businesses to benefit from a wider range of options.

Today, the double-sided screw bolt with nut stands as a testament to innovation, continually adapting to meet the needs of diverse industries while reflecting the broader trends of sustainability and ethical sourcing that define the modern marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of double sided screw bolt with nut

-

How do I choose the right double-sided screw bolt with nut for my project?

Choosing the right double-sided screw bolt involves considering the material, length, diameter, and thread type. Assess the materials you’ll be joining and their thickness, as these factors dictate the necessary screw length. For robust applications, stainless steel offers corrosion resistance, while a zinc-plated option may suffice for indoor uses. It’s also essential to verify the nut compatibility with the bolt to ensure a secure fit. Consulting with suppliers for specific recommendations based on your application can lead to better outcomes. -

What is the best material for double-sided screw bolts in various environments?

The best material for double-sided screw bolts depends on the application environment. Stainless steel is ideal for outdoor or marine applications due to its corrosion resistance. For indoor use, carbon steel can be a cost-effective choice, but it may require coating to prevent rust. If weight is a concern, aluminum screws may be beneficial for lightweight applications. Always consider the environmental factors such as humidity, exposure to chemicals, and load-bearing requirements when selecting the material. -

What are the typical minimum order quantities (MOQs) for double-sided screw bolts?

Minimum order quantities for double-sided screw bolts can vary significantly among suppliers, typically ranging from 100 to 1,000 units. However, many manufacturers offer flexible MOQs based on the buyer’s needs and production capabilities. When sourcing internationally, inquire about bulk discounts or tiered pricing structures, which can provide cost savings for larger orders. Establishing a good relationship with suppliers may also lead to favorable terms on MOQs. -

How can I ensure quality assurance when sourcing double-sided screw bolts?

To ensure quality assurance, request certifications and quality control reports from your suppliers. Implementing a third-party inspection service can provide an unbiased evaluation of the product quality before shipment. Additionally, establish clear specifications and tolerances in your purchase agreements. It’s beneficial to start with small orders to test the quality before committing to larger quantities. Building a relationship with reliable suppliers who understand your quality standards is crucial for long-term success. -

What payment terms are typically offered for international B2B transactions involving screws?

Payment terms in international B2B transactions can vary widely but often include options such as letter of credit, advance payment, or net 30/60/90 days. It’s common to negotiate terms that protect both parties, such as partial upfront payments followed by the balance upon delivery or after inspection. Consider using secure payment platforms to minimize risks associated with international transactions. Always clarify the terms in the contract to avoid misunderstandings. -

How can I vet suppliers for double-sided screw bolts in international markets?

Vetting suppliers involves conducting thorough research and due diligence. Start by checking their business licenses, certifications, and industry reputation through online reviews and trade associations. Request references from other clients and assess their responsiveness and communication skills. It’s also beneficial to visit the manufacturing facility if feasible or request a virtual tour. Utilizing platforms that provide supplier ratings and feedback can further enhance your vetting process. -

What logistics considerations should I keep in mind when importing double-sided screw bolts?

When importing double-sided screw bolts, consider shipping costs, customs duties, and delivery timelines. Understand the shipping methods available (air, sea, or land) and choose one that balances cost and speed. Ensure that your supplier provides necessary documentation for customs clearance, such as invoices and packing lists. Additionally, partner with a reliable freight forwarder who can navigate the complexities of international shipping and help you comply with local regulations. -

Can I customize double-sided screw bolts to meet specific requirements?

Yes, many manufacturers offer customization options for double-sided screw bolts. Customization can include variations in size, thread type, material, and even coatings to meet specific environmental conditions. When placing a custom order, provide detailed specifications and discuss any design considerations with the supplier. Be aware that customization may lead to longer lead times and potentially higher costs, so plan your sourcing strategy accordingly.

Top 4 Double Sided Screw Bolt With Nut Manufacturers & Suppliers List

1. Pet Hardware® – Double-sided Steel Screw Post 6–8 mm

Domain: pethardware.com

Registered: 2006 (19 years)

Introduction: {“Product Name”: “Double-sided Steel screw post 6–8 mm, Nickel Plated”, “Brand”: “Pet Hardware®”, “Quantity”: “100 pcs”, “Material”: “Steel”, “Surface Finish”: “Nickel plated”, “Weight”: “210 g”, “Breaking Load”: “Not specified”, “Size Options”: [{“Size”: “6 mm”, “Length”: “5 mm”, “Total Thickness”: “10 mm”, “Quantity”: “100”}, {“Size”: “8 mm”, “Length”: “5 mm”, “Total Thickness”: “10 mm”, “Quanti…

2. McMaster – Double-End Bolts

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Double-End Bolts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Reddit – Double Sided Bolts & T Nuts

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Double sided bolts and T nuts are considered strong, with even a low grade 1/4 inch bolt capable of supporting over a ton of weight in tension. The main concern is the T nut potentially pulling through the wood rather than the hardware breaking. T nuts can be secured with three tiny screws to prevent them from being pushed out under dynamic forces, but they may not hold up to significant force. Th…

4. MKS – CF Flange Double-Sided Bolt and Nut Set

Domain: mks.com

Registered: 1989 (36 years)

Introduction: {“product_name”: “CF Flange Double-Sided Bolt and Nut Set”, “description”: “These double-sided bolt sets contain 25 double-sided bolts for use with various size tapped bolt hole CF UHV flanges.”, “flange_sizes”: [“1 1/3 inch”, “2.125 inch”, “2.75 inch”, “4.5 inch”, “4.625 inch”, “3.375 inch”], “thread_sizes”: [“8-32”, “1/4-28”, “5/16-24”], “thread_lengths”: [“1.25 in.”, “1.75 in.”, “2.0 in.”, “2.5…

Strategic Sourcing Conclusion and Outlook for double sided screw bolt with nut

As the demand for high-quality double-sided screw bolts with nuts continues to rise, international B2B buyers must prioritize strategic sourcing to optimize their procurement processes. Understanding the specific needs of diverse markets in Africa, South America, the Middle East, and Europe is essential for making informed purchasing decisions. Buyers should focus on suppliers who offer a variety of materials, sizes, and finishes to ensure compatibility with their unique applications, whether in construction, manufacturing, or other industries.

Key takeaways include the importance of evaluating supplier reliability, product quality, and pricing structures. Establishing long-term relationships with reputable manufacturers can lead to better terms and access to innovative solutions. Additionally, leveraging local market insights can enhance supply chain efficiency and reduce costs.

Looking ahead, the landscape for double-sided screw bolts with nuts is poised for growth, driven by advancements in manufacturing technologies and increased global trade. B2B buyers are encouraged to stay informed about market trends and emerging suppliers, ensuring they are well-positioned to capitalize on new opportunities. By embracing strategic sourcing practices, companies can secure a competitive edge in this vital sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to double sided screw bolt with nut

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.