The Definitive Guide to Crofton Pans: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for crofton pans

In today’s competitive culinary landscape, international B2B buyers face the challenge of sourcing high-quality Crofton pans that balance performance, durability, and affordability. As the demand for reliable cookware continues to rise across regions such as Africa, South America, the Middle East, and Europe, businesses must navigate a complex market filled with diverse options and varying supplier standards. This comprehensive guide on Crofton pans addresses these challenges by providing insights into the different types of cookware available, their applications, and essential considerations for supplier vetting.

With a focus on understanding the nuances of the global market, this guide empowers buyers to make informed purchasing decisions. It delves into the specifications that set Crofton pans apart, such as their PFOA and BPA-free materials, even heating capabilities, and ease of maintenance. Additionally, it outlines cost-effective strategies for procurement while ensuring adherence to quality standards. By equipping B2B buyers with the necessary knowledge and tools, this guide aims to simplify the sourcing process, ultimately enhancing the culinary experiences they provide to their customers. Whether you’re a distributor in Brazil or a retailer in Nigeria, this resource is designed to help you confidently navigate the dynamic world of Crofton cookware and optimize your product offerings.

Understanding crofton pans Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Pans | Durable, non-reactive surface, excellent heat retention | Restaurants, catering, food service | Pros: Long-lasting, easy to clean. Cons: Can be more expensive than alternatives. |

| Nonstick Frying Pans | PFOA-free coating, easy food release, and cleanup | Home kitchens, small eateries | Pros: Convenient for low-fat cooking, quick cleanup. Cons: Coating may wear over time. |

| Cast Iron Cookware | Excellent heat retention, versatile for stovetop/oven | High-end restaurants, specialty shops | Pros: Durable, ideal for slow cooking. Cons: Heavy and requires maintenance. |

| Ceramic Cookware | Non-toxic, stylish, even heating | Health-conscious cafes, bakeries | Pros: Aesthetic appeal, non-stick properties. Cons: Can chip easily, less durable than metal. |

| Specialty Pancake Pans | Unique shapes and sizes for pancakes | Breakfast diners, family restaurants | Pros: Fun for kids, consistent results. Cons: Limited versatility beyond pancakes. |

What are the Key Characteristics of Stainless Steel Pans?

Stainless steel pans are renowned for their durability and non-reactive surfaces, making them ideal for a variety of cooking applications. Their excellent heat retention properties ensure even cooking, which is essential in professional kitchens. B2B buyers should consider the lifespan and maintenance requirements, as these pans can withstand high temperatures and are generally dishwasher safe, although they may require some initial investment.

How Do Nonstick Frying Pans Benefit Food Service Operations?

Nonstick frying pans are particularly beneficial for establishments focused on health-conscious cooking, as they require less oil for food preparation. The PFOA-free coating allows for easy food release and simplifies cleaning, which is a significant advantage for busy kitchens. However, B2B buyers should keep in mind that the nonstick coating can wear down over time, so sourcing from reputable manufacturers is crucial to ensure quality.

Why Choose Cast Iron Cookware for Your Business?

Cast iron cookware is celebrated for its exceptional heat retention and versatility, suitable for stovetop, oven, and even grilling applications. This type of cookware is particularly favored in high-end restaurants and specialty shops that emphasize traditional cooking methods. While cast iron is incredibly durable, it does require proper maintenance to prevent rusting, making it essential for buyers to consider training staff on care procedures.

Illustrative image related to crofton pans

What Advantages Does Ceramic Cookware Offer for B2B Buyers?

Ceramic cookware is gaining popularity due to its non-toxic properties and stylish designs, appealing to health-conscious consumers. It provides even heating and a non-stick surface, making it suitable for both cooking and serving. However, B2B buyers should be aware that ceramic can chip more easily than metal options, which may affect longevity in high-traffic kitchens. Evaluating supplier warranties and return policies can mitigate these risks.

How Can Specialty Pancake Pans Enhance a Dining Experience?

Specialty pancake pans come in various fun shapes and sizes, making them an excellent choice for breakfast diners and family restaurants looking to create memorable dining experiences. These pans ensure consistent cooking results, which is vital for customer satisfaction. However, their limited versatility means they are best used in establishments that specialize in breakfast items. B2B buyers should assess market demand for unique offerings when considering these pans.

Key Industrial Applications of crofton pans

| Industry/Sector | Specific Application of Crofton Pans | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality and Catering | Restaurant Cookware | Consistent quality cooking results and durability | Bulk purchasing options, compatibility with various heat sources, and safety certifications. |

| Food Processing | Bulk Cooking Equipment | Efficient large-scale meal preparation | Need for high-capacity options, ease of cleaning, and robust construction for frequent use. |

| Retail and Distribution | Kitchenware Retailing | Affordable luxury for consumers, enhancing brand image | Competitive pricing, quality assurance, and availability of diverse product ranges. |

| Education and Training | Culinary School Equipment | Reliable tools for teaching cooking techniques | Safety standards, ease of use for students, and durability for continuous training. |

| Home and Lifestyle | Direct-to-Consumer Sales | Attracts budget-conscious customers with quality products | Effective marketing strategies, partnerships with influencers, and after-sales support. |

How Are Crofton Pans Used in the Hospitality and Catering Sector?

In the hospitality and catering industry, Crofton pans are essential for professional chefs who require reliable cookware for consistent quality in meal preparation. These pans are designed for durability and even heating, ensuring that dishes are cooked uniformly and efficiently. For B2B buyers in this sector, sourcing Crofton pans involves considering bulk purchasing options, compatibility with various heat sources (gas, electric, induction), and ensuring that the cookware meets safety certifications to protect both staff and customers.

What Role Do Crofton Pans Play in Food Processing?

In food processing, Crofton pans are utilized for bulk cooking applications, where large quantities of food need to be prepared efficiently. Their robust construction and nonstick surfaces allow for easy handling and cleaning, making them ideal for high-volume operations. Buyers in this sector should prioritize high-capacity options and consider the durability of the pans, as well as their ease of cleaning to maintain hygiene standards in fast-paced environments.

How Can Retail and Distribution Benefit from Crofton Pans?

Retailers and distributors can leverage Crofton pans as part of their kitchenware offerings, appealing to consumers seeking affordable luxury. The quality and design of these pans can enhance a retailer’s brand image, attracting budget-conscious customers. When sourcing, businesses should focus on competitive pricing, quality assurance, and the availability of a diverse product range to meet varying consumer needs.

Illustrative image related to crofton pans

Why Are Crofton Pans Important for Educational Institutions?

Culinary schools and training institutions benefit significantly from using Crofton pans in their programs. These pans provide reliable tools for teaching students essential cooking techniques, allowing for practical learning experiences. Buyers in this sector should ensure that the cookware meets safety standards, is easy to use for novice cooks, and is durable enough to withstand continuous training sessions.

How Do Crofton Pans Cater to Home and Lifestyle Markets?

In the home and lifestyle sector, Crofton pans appeal to consumers through direct-to-consumer sales channels, emphasizing quality at an affordable price. These pans can attract budget-conscious buyers who desire reliable kitchenware without compromising on performance. Effective marketing strategies, partnerships with influencers, and strong after-sales support are critical for businesses looking to capitalize on this market segment.

3 Common User Pain Points for ‘crofton pans’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Sourcing Crofton Pans

The Problem: B2B buyers often face the challenge of ensuring that the cookware they source meets rigorous quality standards. With Crofton pans being manufactured in various facilities, there may be inconsistencies in quality control, leading to concerns about product durability and safety. Buyers may worry about receiving batches of pans that do not adhere to the expected standards, potentially damaging their reputation and customer trust.

The Solution: To mitigate these risks, B2B buyers should establish a robust supplier evaluation process. Start by requiring detailed quality certifications from manufacturers, such as ISO 9001, which indicates adherence to quality management systems. Additionally, consider conducting factory audits, either remotely or in-person, to assess manufacturing practices and quality control measures firsthand. It’s also beneficial to request product samples before placing large orders. By examining these samples for performance, durability, and safety features, buyers can make informed decisions. Regular communication with suppliers about quality expectations and performance feedback from end-users can further ensure that Crofton pans consistently meet the desired standards.

Illustrative image related to crofton pans

Scenario 2: Understanding Compatibility with Diverse Cooking Systems

The Problem: Many B2B buyers cater to a wide range of customers with varying cooking systems. Crofton pans are designed to be versatile, but there can be confusion regarding their compatibility with different heat sources such as induction, gas, or electric stoves. This uncertainty can lead to customer dissatisfaction if the pans do not perform well on their chosen cooking systems.

The Solution: To address this issue, buyers should take the initiative to educate themselves about the specific features of Crofton pans. Detailed product specifications should be obtained from suppliers, including the types of cooking surfaces each pan is compatible with. Create informative materials, such as brochures or online content, that clearly outline which Crofton pans work best with induction, gas, or electric stoves. Additionally, consider offering a customer consultation service where your team can guide end-users on selecting the right pans for their cooking systems. This proactive approach not only enhances customer satisfaction but also reduces the likelihood of returns or complaints.

Scenario 3: Managing Post-Purchase Care and Maintenance Concerns

The Problem: After purchasing Crofton pans, B2B buyers may find that their clients struggle with proper care and maintenance, leading to premature wear and unsatisfactory performance. Many end-users are not fully aware of how to maintain nonstick surfaces or the best cleaning practices, which can result in damage to the cookware and a negative perception of the brand.

The Solution: To foster long-term satisfaction with Crofton pans, B2B buyers should develop comprehensive care and maintenance guides tailored for their clients. These guides should include best practices for cleaning, such as using non-abrasive sponges and avoiding harsh chemicals, to preserve the nonstick coating. Providing visual content, such as instructional videos or infographics, can enhance understanding and retention. Additionally, consider creating a customer support hotline or online forum where users can ask questions and share experiences. By offering ongoing support and resources, buyers can help their clients maintain their Crofton pans effectively, ensuring durability and performance while reinforcing brand loyalty.

Strategic Material Selection Guide for crofton pans

What are the Key Properties of Stainless Steel in Crofton Pans?

Stainless steel is a widely used material for Crofton pans due to its remarkable properties. It boasts excellent corrosion resistance, which is crucial for maintaining hygiene and longevity in cookware. Stainless steel can withstand high temperatures, making it suitable for various cooking methods, including frying, sautéing, and baking. Its durability ensures that it can handle the rigors of daily use without warping or scratching.

However, while stainless steel pans are highly durable, they can be more expensive than other materials. The manufacturing process is also complex, involving multiple stages to achieve the desired finish and performance. For international B2B buyers, particularly from regions like Africa and South America, it is essential to ensure compliance with local health and safety standards, as well as international certifications such as ASTM and DIN.

How Does Hard-Anodized Aluminum Enhance Cooking Performance?

Hard-anodized aluminum is another popular choice for Crofton pans, known for its excellent heat conduction properties. This material heats up quickly and evenly, reducing cooking times and enhancing food quality. It is also lightweight, making it easier to handle during cooking. The anodization process provides a hard surface that is resistant to scratching and corrosion, ensuring a longer lifespan.

Illustrative image related to crofton pans

On the downside, hard-anodized aluminum can be more susceptible to damage from high heat if not properly maintained. Additionally, it may not be suitable for all cooking surfaces, particularly induction, unless specifically designed for it. For buyers in the Middle East and Europe, understanding the specific compatibility with various cooking technologies is crucial to avoid dissatisfaction post-purchase.

What are the Benefits of Nonstick Coatings in Crofton Pans?

Nonstick coatings, such as Teflon or ceramic-based options, are designed to enhance the cooking experience by preventing food from sticking to the surface. This feature is particularly advantageous for low-fat cooking, as it requires less oil or butter. Nonstick pans are also easier to clean, which is a significant selling point for busy kitchens.

However, nonstick coatings can have limitations in terms of durability, as they may wear off over time, especially under high heat or abrasive cleaning methods. B2B buyers should consider the specific coating used and its longevity, especially in regions like Brazil and Nigeria, where cooking practices may vary widely. Compliance with safety standards regarding PFOA and BPA is also essential for ensuring consumer safety and product acceptance.

How Does Cast Iron Compare for Durability and Versatility?

Cast iron pans are renowned for their exceptional heat retention and even cooking capabilities. They are ideal for slow-cooking, frying, and baking, providing versatility in the kitchen. Cast iron is incredibly durable and can last a lifetime if properly cared for, making it a worthwhile investment for both consumers and commercial kitchens.

However, cast iron pans are heavier and require more maintenance than other materials, such as seasoning to prevent rusting. They may also be more expensive to produce due to the casting process. For international buyers, understanding the maintenance requirements and the potential need for additional seasoning can impact purchasing decisions, especially in regions with varying levels of culinary expertise.

Illustrative image related to crofton pans

Summary Table of Material Selection for Crofton Pans

| Material | Typical Use Case for crofton pans | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General cooking, frying, baking | Excellent durability and corrosion resistance | Higher manufacturing complexity and cost | High |

| Hard-Anodized Aluminum | Sautéing, frying, quick cooking | Quick and even heat conduction | Not suitable for all cooking surfaces | Medium |

| Nonstick Coatings | Low-fat cooking, easy cleanup | Prevents sticking, easy to clean | Limited durability under high heat | Medium |

| Cast Iron | Slow-cooking, frying, baking | Exceptional heat retention and durability | Requires maintenance, heavier to handle | High |

This strategic material selection guide aims to equip B2B buyers with insights into the properties, advantages, and limitations of various materials used in Crofton pans, enabling informed purchasing decisions tailored to regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for crofton pans

What Are the Main Stages of Manufacturing Crofton Pans?

The manufacturing process for Crofton pans involves several critical stages, each designed to ensure the final product meets high standards of quality and functionality.

1. Material Preparation

The first step in the manufacturing process is sourcing and preparing the raw materials. Crofton utilizes high-grade stainless steel and hard-anodized aluminum, known for their durability and superior heat conductivity. These materials are procured from vetted suppliers to ensure consistency in quality. The materials undergo initial inspections to confirm they meet specified standards, including thickness and finish, which are crucial for performance.

2. Forming

Once the materials are prepared, they are subjected to various forming techniques. For stainless steel pans, methods like deep drawing and stamping are employed to shape the metal into the desired form. Hard-anodized aluminum pans may go through die-casting or extrusion processes. These techniques not only create the shape but also enhance the structural integrity of the pans.

3. Assembly

After forming, the components of the pans are assembled. This may include attaching handles, lids, and other features. Assembly lines are designed for efficiency, allowing for high-volume production while maintaining precision. Each component is aligned and secured using robust methods to ensure longevity and performance under regular use.

4. Finishing

The finishing stage is vital for both aesthetics and functionality. Crofton pans undergo treatments such as polishing, coating, and anodizing to enhance their appearance and non-stick properties. The non-stick coating, often a proprietary formula, is applied to ensure ease of use and cleaning. This stage also involves rigorous quality checks to ensure that the surface treatments adhere correctly and meet safety standards.

How Is Quality Assurance Implemented in Crofton Pan Manufacturing?

Quality assurance is an integral part of Crofton’s manufacturing process, ensuring that each pan produced meets stringent international standards.

Illustrative image related to crofton pans

What International Standards Guide Crofton’s Quality Control?

Crofton pans are manufactured in accordance with international quality standards such as ISO 9001, which focuses on quality management systems, ensuring consistent quality across all products. Additionally, specific certifications like CE (Conformité Européenne) for safety and compliance in the European market and FDA approval for materials that come into contact with food are also adhered to. This adherence to standards not only assures buyers of the product quality but also aligns with global trade requirements.

What Are the Key Quality Control Checkpoints?

Quality control is implemented at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. This ensures that only materials meeting quality specifications are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested for dimensional accuracy, surface finish, and other critical parameters. This ongoing assessment helps identify and rectify any issues in real-time.

-

Final Quality Control (FQC): Before packaging, each finished product undergoes a final inspection. This includes testing for non-stick performance, heat distribution, and overall aesthetic quality. Any pans that do not meet the specified criteria are rejected and reworked or discarded.

What Testing Methods Are Commonly Used for Crofton Pans?

Testing methods play a crucial role in ensuring that Crofton pans deliver on their promises of durability and performance. Common testing methods include:

-

Heat Distribution Tests: Pans are subjected to heating under controlled conditions to assess how evenly they distribute heat. This is crucial for achieving consistent cooking results.

-

Non-Stick Performance Tests: The effectiveness of the non-stick coating is evaluated by cooking food items and assessing adherence and ease of cleaning post-use.

-

Durability Tests: Pans are tested for resistance to scratching, chipping, and warping. These tests simulate prolonged use to ensure that the pans maintain their integrity over time.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are actionable steps to ensure supplier credibility:

-

Conduct Supplier Audits: Regular audits of the manufacturing facility can provide insights into the quality management practices in place. Audits can be performed by the buyer or third-party inspectors to ensure objectivity.

-

Request Quality Assurance Reports: Suppliers should provide detailed documentation of their quality control processes, including inspection reports, test results, and compliance certifications. This documentation can help assess whether the supplier adheres to international standards.

-

Engage Third-Party Inspection Services: Utilizing third-party services for inspections and testing can add an extra layer of assurance. These organizations can provide unbiased evaluations of the manufacturing processes and product quality.

-

Review Certification Validity: Ensure that the certifications held by the supplier are current and recognized in your market. This includes checking the validity of ISO, CE, and other relevant certifications.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate several nuances when dealing with quality control in overseas manufacturing:

-

Cultural Differences: Understanding local manufacturing practices and cultural attitudes towards quality can influence negotiations and expectations. This may require tailored communication strategies.

-

Logistical Considerations: Shipping and handling can affect product quality. Ensure that suppliers have robust logistics strategies to minimize damage during transit.

-

Regulatory Compliance: Different regions may have specific regulations regarding cookware safety. B2B buyers should ensure that products meet local regulations in their respective markets, which may differ from those in the supplier’s country.

By understanding the manufacturing processes and quality assurance measures in place at Crofton, B2B buyers can make informed decisions, ensuring they procure high-quality, reliable cookware that meets their market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘crofton pans’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring Crofton pans effectively. Given the diverse culinary markets across Africa, South America, the Middle East, and Europe, this checklist will help you navigate the essential steps in selecting high-quality cookware that meets your operational needs and budget constraints.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for the Crofton pans you wish to source is critical. Consider factors such as material (e.g., stainless steel, aluminum), size, and intended use (e.g., frying, baking). Clearly defined specifications will streamline your search and ensure that the pans meet your culinary standards.

- Material Quality: Look for PFOA and BPA-free materials to ensure safety and compliance with health regulations.

- Size Options: Identify the sizes that best fit your kitchen operations, whether for commercial kitchens or smaller establishments.

Step 2: Research Potential Suppliers

A thorough investigation of suppliers is vital to ensure reliability and quality. Start by compiling a list of potential manufacturers that specialize in Crofton cookware. Use online directories, trade shows, and industry contacts to gather information.

- Reputation Check: Look for reviews and testimonials from other B2B buyers to gauge supplier reliability and product performance.

- Experience in Market: Prioritize suppliers with a proven track record in your target market region, as they will understand local preferences and regulatory requirements.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. This step is crucial to ensure that the products meet safety and quality benchmarks.

Illustrative image related to crofton pans

- Quality Assurance Certifications: Look for ISO certifications or equivalent that confirm rigorous quality control processes.

- Health and Safety Compliance: Ensure that the cookware meets local and international health regulations, particularly regarding non-toxic materials.

Step 4: Request Samples

Obtaining samples is an essential step in the sourcing process. It allows you to assess the quality of Crofton pans firsthand before making bulk purchases.

- Performance Testing: Use the samples in real cooking scenarios to evaluate heat distribution, nonstick performance, and ease of cleaning.

- Durability Assessment: Test the pans for signs of wear and tear after repeated use to ensure they can withstand your kitchen demands.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier and tested the products, initiate negotiations on pricing and terms. This stage is crucial to secure a favorable deal that aligns with your budget.

- Bulk Purchase Discounts: Inquire about discounts for larger orders, as many suppliers are willing to offer better pricing for bulk commitments.

- Payment Terms: Clarify payment options, including deposits and payment timelines, to ensure financial flexibility.

Step 6: Finalize Contracts and Place Orders

After successful negotiations, it’s time to formalize the agreement. Ensure that all terms discussed are clearly outlined in a contract to protect both parties.

- Order Confirmation: Make sure the order includes all specifications, quantities, and delivery timelines to avoid misunderstandings.

- Follow-Up Procedures: Establish clear communication channels for updates on order status and potential issues during the shipping process.

Step 7: Plan for Quality Control Upon Delivery

Upon receiving your order, conduct a thorough inspection of the Crofton pans to ensure they meet your specifications and quality standards. This step is crucial to address any discrepancies before they impact your operations.

- Inspection Checklist: Create a checklist to evaluate the condition and specifications of the pans against your original order.

- Return and Exchange Policy: Familiarize yourself with the supplier’s policies on returns or exchanges in case of defects or quality issues.

By following this structured checklist, you can streamline the sourcing process for Crofton pans, ensuring that you acquire high-quality cookware that meets your business needs.

Comprehensive Cost and Pricing Analysis for crofton pans Sourcing

What Are the Key Cost Components in Sourcing Crofton Pans?

When sourcing Crofton pans, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: Crofton pans are typically manufactured from high-quality stainless steel and hard-anodized aluminum. The choice of materials significantly affects the price, as premium materials can increase production costs but also enhance product durability and performance.

-

Labor: Labor costs can vary depending on the manufacturing location. Factories in regions with higher labor costs may lead to a higher price point. However, Crofton’s partnership with Asian manufacturers often allows for competitive labor rates, contributing to overall cost efficiency.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and equipment depreciation. Effective management of overhead costs is crucial for maintaining competitive pricing.

-

Tooling: Initial tooling costs for molds and equipment can be substantial, especially for custom designs. These costs are typically amortized over large production runs, making it advantageous to order in bulk.

-

Quality Control (QC): Rigorous QC processes ensure that each product meets high standards before it reaches the market. While this adds to costs, it protects brand reputation and reduces returns or defects.

-

Logistics: Shipping and handling costs can significantly impact the final price. This includes freight charges, customs duties, and warehousing fees. Buyers should consider these factors when evaluating total costs.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the cookware industry can help buyers gauge whether a quoted price is competitive.

How Do Price Influencers Affect Crofton Pan Sourcing?

Several factors influence the pricing of Crofton pans, including:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often leads to discounts. Negotiating favorable MOQs can significantly reduce unit costs.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should assess whether customization is necessary or if standard products meet their needs.

-

Materials and Quality Certifications: Higher quality materials or certifications (such as food safety standards) can elevate costs. Buyers should balance the need for quality with budget constraints.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers may charge more but offer better quality assurance and consistency.

-

Incoterms: Understanding the delivery terms is crucial. Different Incoterms can lead to variations in total costs, affecting who bears the shipping and insurance responsibilities.

What Are the Best Negotiation Tips for B2B Buyers of Crofton Pans?

Effective negotiation can lead to cost savings and better terms. Here are some actionable tips for B2B buyers:

-

Research Market Prices: Understanding typical price ranges for Crofton pans can empower buyers during negotiations.

-

Leverage Volume Discounts: When possible, consolidate orders to reach higher volumes, thus qualifying for better pricing.

-

Discuss Payment Terms: Flexible payment options can enhance cash flow. Propose terms that can work for both parties without compromising supplier margins.

-

Evaluate Total Cost of Ownership (TCO): Consider factors like durability and maintenance when assessing costs. Higher upfront costs for premium pans may lead to lower long-term expenses.

-

Be Transparent About Needs: Clearly communicating specifications and budget constraints can foster a cooperative negotiation environment.

What Pricing Nuances Should International B2B Buyers Consider?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, several nuances are critical:

-

Currency Fluctuations: Exchange rates can affect pricing, making it essential to negotiate in stable currencies or consider hedging options.

-

Import Duties and Taxes: Understanding local regulations regarding import duties can prevent unexpected costs.

-

Cultural Differences: Familiarize yourself with negotiation styles and business etiquette in the supplier’s country to build rapport and trust.

-

Shipping Challenges: Factor in potential delays and additional logistics costs due to geographical distance or political instability in certain regions.

Conclusion

Sourcing Crofton pans involves a comprehensive understanding of the cost structure and influencing factors. By leveraging negotiation strategies and being aware of pricing nuances, international B2B buyers can secure favorable terms and ensure quality cookware that meets their culinary needs. Always consider the total cost of ownership alongside initial pricing to make informed purchasing decisions.

Illustrative image related to crofton pans

Alternatives Analysis: Comparing crofton pans With Other Solutions

Exploring Alternatives to Crofton Pans for Culinary Solutions

In today’s competitive kitchenware market, B2B buyers are constantly seeking the best options for their culinary needs. Crofton pans are renowned for their quality and affordability, but there are alternative solutions worth considering. This section compares Crofton pans with two notable alternatives: non-stick ceramic cookware and cast iron pans. Each option presents unique advantages and challenges, making it essential to understand their characteristics to make an informed purchasing decision.

| Comparison Aspect | Crofton Pans | Non-Stick Ceramic Cookware | Cast Iron Pans |

|---|---|---|---|

| Performance | Excellent heat distribution; durable non-stick surface. | Good heat retention; may require careful handling. | Superior heat retention; versatile for stovetop and oven. |

| Cost | Budget-friendly, offering good value for quality. | Mid-range pricing; can be more expensive than Crofton. | Higher initial investment; long-term durability justifies cost. |

| Ease of Implementation | Simple to use; compatible with various stovetops. | Easy to use; lightweight and often dishwasher safe. | Requires seasoning and maintenance; heavier to handle. |

| Maintenance | Easy to clean; non-stick surfaces reduce effort. | Generally easy to clean; some may not be dishwasher safe. | Requires regular seasoning and careful cleaning to avoid rust. |

| Best Use Case | Ideal for everyday cooking and casual use. | Great for health-conscious cooking with minimal oil. | Perfect for high-heat cooking and traditional recipes. |

What Are the Benefits and Drawbacks of Non-Stick Ceramic Cookware?

Non-stick ceramic cookware has gained popularity due to its eco-friendly materials and ease of use. These pans are free from harmful chemicals, making them a safe choice for health-conscious buyers. However, while they offer good heat retention and a lightweight design, they may not withstand high temperatures as well as other materials. Additionally, their non-stick surface can wear down over time, requiring careful handling to avoid scratches.

How Do Cast Iron Pans Compare to Crofton Pans?

Cast iron pans are renowned for their durability and versatility. They excel in heat retention, making them suitable for high-heat cooking, frying, and even baking. While they can be more expensive upfront, their longevity can justify the initial investment. However, cast iron pans require regular maintenance, including seasoning and specific cleaning methods to prevent rust. Their weight can also be a disadvantage for some users who prefer lighter cookware options.

Conclusion: How to Choose the Right Cookware for Your Needs

When selecting cookware for your business, consider your specific cooking requirements, budget constraints, and the level of maintenance you are willing to undertake. Crofton pans offer an excellent balance of quality and affordability, making them suitable for everyday use. Non-stick ceramic cookware is an excellent choice for health-conscious buyers seeking an eco-friendly option. Cast iron pans, while requiring more care, provide unmatched versatility and durability for those who prioritize traditional cooking methods. By evaluating these factors, B2B buyers can make a well-informed decision tailored to their culinary operations.

Illustrative image related to crofton pans

Essential Technical Properties and Trade Terminology for crofton pans

What Are the Key Technical Properties of Crofton Pans?

When evaluating Crofton pans for procurement, understanding their technical properties is crucial for ensuring quality, performance, and value. Here are some essential specifications:

-

Material Composition

– Definition: Crofton pans are primarily made from high-grade materials such as stainless steel, hard-anodized aluminum, and enameled cast iron.

– B2B Importance: The choice of material affects durability, heat distribution, and cooking performance. For buyers, selecting pans made from premium materials ensures longevity and consistent cooking results, which can enhance customer satisfaction. -

Nonstick Coating

– Definition: Many Crofton pans feature a nonstick coating, often made with Greblon C3 technology, which is free from PFOA and APEO.

– B2B Importance: Nonstick properties reduce the need for cooking oils, making pans healthier and easier to clean. This feature is a selling point for retailers targeting health-conscious consumers and can significantly influence purchasing decisions. -

Heat Resistance

– Definition: Crofton pans can typically withstand temperatures up to 400°F, with some specialty bakeware exceeding 500°F.

– B2B Importance: Understanding heat resistance is essential for buyers who require pans that can perform under various cooking conditions. This specification ensures that the cookware can handle a wide range of culinary techniques, from frying to baking. -

Compatibility with Heat Sources

– Definition: Crofton pans are designed to work on multiple heat sources, including gas, electric, glass top, and induction ranges.

– B2B Importance: Compatibility increases the versatility of the product, making it appealing to a broader market segment. Retailers can confidently stock these pans knowing they cater to diverse cooking preferences. -

Maintenance Requirements

– Definition: Crofton cookware is designed for easy cleaning, with many pieces being dishwasher safe, although hand washing is recommended for longevity.

– B2B Importance: Understanding maintenance needs is vital for buyers who want to minimize customer complaints and returns. Products that are easy to care for tend to have higher customer satisfaction and repeat purchases.

What Are Common Trade Terms in the Crofton Pans Industry?

Familiarity with industry jargon can enhance communication and negotiation effectiveness in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers navigate sourcing options, especially when seeking customized products or branding opportunities. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budgeting and inventory planning. Buyers must align their purchasing strategy with the supplier’s MOQ to avoid excess costs or stock shortages. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to potential suppliers requesting a price quote for specific products or services.

– Importance: An RFQ helps buyers obtain competitive pricing and terms, ensuring they make informed purchasing decisions. It is a critical step in the procurement process. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce, used in international trade contracts.

– Importance: Understanding Incoterms is crucial for buyers engaged in international transactions, as they clarify responsibilities regarding shipping, insurance, and tariffs. This knowledge minimizes risks and fosters smoother logistics. -

Lead Time

– Definition: The amount of time from placing an order to receiving the goods.

– Importance: Buyers must consider lead time when planning inventory levels and product launches. Efficient lead time management can enhance supply chain effectiveness and customer satisfaction. -

Warranty and Return Policy

– Definition: A guarantee provided by the manufacturer regarding the condition of the product and its expected lifespan.

– Importance: Knowledge of warranty terms can influence purchasing decisions and impact customer trust. A robust warranty can be a significant selling point for Crofton pans, assuring buyers of their quality and durability.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right Crofton pans that meet their needs and expectations.

Navigating Market Dynamics and Sourcing Trends in the crofton pans Sector

What Are the Key Market Dynamics and Trends Influencing Crofton Pans in Global Markets?

The global cookware market is witnessing substantial growth driven by rising disposable incomes, increasing culinary interest among consumers, and a shift towards healthier cooking options. For Crofton pans, which are positioned as affordable yet high-quality kitchenware, this trend presents a significant opportunity. In regions like Africa, South America, the Middle East, and Europe, B2B buyers are increasingly looking for products that offer both quality and value, making Crofton’s competitive pricing and durable materials attractive.

Emerging technologies in manufacturing and e-commerce are transforming sourcing strategies. Automation in production is enhancing efficiency and quality control, while digital platforms are streamlining procurement processes. B2B buyers are leveraging these advancements to source cookware more effectively, reducing lead times and costs. Furthermore, there is a growing demand for products that cater to diverse cooking styles and dietary preferences, prompting brands like Crofton to innovate and expand their product lines to include non-toxic, easy-to-clean options.

How Is Sustainability and Ethical Sourcing Transforming the Crofton Pans Sector?

Sustainability is becoming a pivotal factor in the purchasing decisions of B2B buyers. The environmental impact of cookware production, particularly in terms of materials used and manufacturing processes, is under scrutiny. Crofton pans are made from materials such as stainless steel and hard-anodized aluminum, which not only enhance cooking performance but also support sustainability efforts.

Ethical sourcing practices are essential for building trust with consumers and partners. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to responsible sourcing and transparency in their supply chains. Certifications such as PFOA-free and BPA-free are critical, as they assure buyers of the safety and environmental integrity of the products. By aligning with these values, Crofton can enhance its appeal to eco-conscious buyers in global markets.

What Is the Historical Context of Crofton Cookware’s Market Position?

Founded in 2017 under the ALDI brand umbrella, Crofton has rapidly established itself in the global cookware market by focusing on affordability without compromising quality. The brand’s strategic partnerships with Asian manufacturers allow it to maintain low production costs while ensuring high standards through rigorous quality control processes. This approach has enabled Crofton to cater to a diverse international audience, particularly in regions where budget-friendly yet durable cookware is in demand. As culinary trends continue to evolve, Crofton remains well-positioned to adapt to changing consumer preferences and market dynamics, solidifying its reputation as a leader in affordable kitchenware.

Illustrative image related to crofton pans

Frequently Asked Questions (FAQs) for B2B Buyers of crofton pans

-

How do I ensure the quality of Crofton pans when sourcing?

To ensure quality when sourcing Crofton pans, it is crucial to partner with reputable suppliers who adhere to rigorous quality control standards. Request detailed product specifications, certifications, and samples to assess material quality and manufacturing processes. Conduct factory visits or audits to observe production practices firsthand. Additionally, consider third-party inspections before shipment to verify compliance with international quality standards. Establishing clear communication channels with suppliers can help address any concerns promptly. -

What are the minimum order quantities (MOQ) for Crofton pans?

Minimum order quantities (MOQ) for Crofton pans can vary depending on the supplier and the specific product line. Typically, MOQs may range from 500 to 1,000 units. It is advisable to discuss your purchasing needs with potential suppliers directly to negotiate favorable terms. Some suppliers may offer flexibility with MOQs for first-time buyers or bulk orders. Always confirm the MOQ in the initial discussions to avoid misunderstandings during the ordering process. -

What payment terms are generally accepted when importing Crofton pans?

Payment terms for importing Crofton pans can vary widely among suppliers. Common options include payment in full upfront, a 30% deposit with the balance due before shipment, or net 30/60 terms. It is essential to clarify these terms before finalizing any agreements. Additionally, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Establishing a good relationship with suppliers can also lead to more favorable payment terms over time. -

How do I vet suppliers for Crofton pans effectively?

Vetting suppliers for Crofton pans involves a multi-step process. Begin by researching potential suppliers’ backgrounds, including their business history, reputation, and customer reviews. Request references from past clients to gauge their reliability. Assess their manufacturing capabilities and compliance with safety and quality standards. Consider using third-party services for due diligence checks. Finally, engage in direct communication to evaluate their responsiveness and willingness to address your concerns. -

Can I customize Crofton pans for my brand?

Yes, many suppliers offer customization options for Crofton pans, including branding, color variations, and packaging design. When discussing customization, provide clear specifications and artwork to ensure your vision is accurately realized. Be mindful that customization may impact the MOQ and lead times, so plan accordingly. Collaborating with the supplier during the design process can help ensure that the final product aligns with your brand identity and market expectations. -

What logistics considerations should I keep in mind when importing Crofton pans?

Logistics plays a vital role in importing Crofton pans. Key considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder with experience in handling kitchenware imports. Understand the import regulations and duties applicable in your region, as these can affect overall costs. Establishing a clear timeline for shipping and delivery will help manage inventory effectively and meet market demands. -

What quality assurance practices should I expect from suppliers of Crofton pans?

Reputable suppliers of Crofton pans should implement stringent quality assurance practices throughout the manufacturing process. This includes raw material inspections, in-process quality checks, and final product evaluations. Request documentation of their quality control protocols and any relevant certifications, such as ISO or FDA compliance. Additionally, inquire about their procedures for handling defective products and customer complaints to ensure you are partnering with a supplier committed to quality. -

How can I address potential issues with Crofton pans after purchase?

To address potential issues with Crofton pans after purchase, maintain open communication with your supplier. Establish a clear return policy and warranty terms in your contract. Should any issues arise, document them with photos and descriptions, and promptly communicate with the supplier for resolution. Building a strong relationship with your supplier can facilitate smoother problem-solving processes. Consider implementing a feedback loop to improve product quality in future orders based on customer experiences.

Top 6 Crofton Pans Manufacturers & Suppliers List

1. Crofton Cookware – Cast Iron French Oven

Domain: crofton.us

Registered: 2023 (2 years)

Introduction: Crofton Cookware offers premium kitchenware including high-quality stainless steel pans and pots, bakeware, cutlery, and more. Key products include: 1. Cast Iron French Oven (4.6 Quart) – Heavy cast iron for even heat distribution, oven-safe up to 500°F, easy to clean porcelain enamel interior. 2. Nonstick Pancake Pans – Available in various fun shapes, featuring durable nonstick coating for easy …

2. Aldi – Crofton Cast Iron Cookware

Domain: aldi.us

Registered: 2002 (23 years)

Introduction: Crofton Cast Iron Sauce Pan, White – $19.99

Crofton Large Pumpkin Bowl, Orange – $14.99

Crofton Cast Iron Skillet, Black – $12.99

Crofton Large Pumpkin Bowl, White – $14.99

Crofton Cast Iron Grill Pan, White – $19.99

Crofton Cast Iron Fry Pan, White – $19.99

Crofton 18″ Acacia Wood Lazy Susan – $14.99

Crofton 4 Piece Swedish Dish Cloths – Floral Print – $4.99

Crofton 4 Piece Swedish Dish Cloths – …

3. Crofton Cookware – Elegant and Durable Cookware

Domain: mycrofton.com

Registered: 2023 (2 years)

Introduction: Crofton Cookware offers elegantly designed and durable cookware made from high-quality materials. Key features include:

– Construction: Stainless steel and ceramic, with an aluminum core for even heating and easy cleaning.

– Performance: Even heating prevents hot spots, allowing for lower cooking temperatures and energy savings.

– Versatility: Oven safe up to 500°F, suitable for frying, sautéing, …

4. Facebook – Affordable Cookware

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Affordable Cookware, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

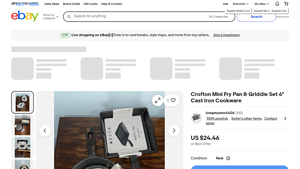

5. Crofton – Mini Fry Pan & Griddle Set

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“product_name”:”Crofton Mini Fry Pan & Griddle Set”,”size”:”6-inch”,”material”:”Cast Iron”,”condition”:”New”,”quantity_available”:1,”item_number”:”126644071601″,”brand”:”Crofton”,”set_items”:”Two-Piece”,”price”:”$24.46 or Best Offer”,”shipping_cost”:”$6.28″,”delivery_time”:”2–4 days”,”local_pickup”:”Available from Parker, Pennsylvania, United States”}

6. Crofton – Kitchen Essentials

Domain: thecroftoncookware.com

Registered: 2024 (1 years)

Introduction: Crofton cookware combines style, durability, and performance, offering a wide range of kitchen essentials including nonstick pans and versatile pots. Crafted with premium materials for even heat distribution and long-lasting durability, Crofton products are designed for hassle-free cooking. The collection includes sauté pans, Dutch ovens, and various other cookware options suitable for both beginn…

Strategic Sourcing Conclusion and Outlook for crofton pans

In evaluating the strategic sourcing of Crofton pans, several key insights emerge for B2B buyers. Crofton, under the esteemed ALDI brand, offers high-quality cookware at competitive prices, making it an attractive option for international markets. The brand’s commitment to using premium materials, such as stainless steel and hard-anodized aluminum, ensures durability and excellent cooking performance, catering to diverse culinary needs. Moreover, the rigorous quality control processes in their Asian manufacturing facilities help maintain consistent standards, which is crucial for wholesale buyers seeking reliable products.

Strategic sourcing not only enhances cost efficiency but also aligns with the growing demand for non-toxic and environmentally friendly cookware. Crofton pans are PFOA and BPA-free, addressing health-conscious consumer trends across regions.

As the culinary landscape evolves, international buyers from Africa, South America, the Middle East, and Europe should consider Crofton as a partner in delivering quality and affordability. Embrace the opportunity to enhance your product offerings with Crofton’s reliable cookware solutions. Connect with suppliers today to explore how Crofton pans can elevate your kitchenware portfolio and meet the needs of your diverse customer base.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.