The Definitive Guide to Cord Elastic Black: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for cord elastic black

In the competitive landscape of global sourcing, finding reliable suppliers for cord elastic black can pose significant challenges for B2B buyers. This versatile material, essential for various applications from clothing and accessories to industrial uses, requires careful consideration regarding quality, price, and supplier reliability. As international buyers from regions such as Africa, South America, the Middle East, and Europe seek to optimize their supply chains, understanding the nuances of cord elastic black becomes paramount.

This comprehensive guide delves into the myriad types of cord elastic black available in the market, exploring their unique properties and applications. From round to braided varieties, each type serves distinct purposes across industries, whether for fashion, home decor, or outdoor gear. Additionally, we will provide insights on effective supplier vetting processes, ensuring that you partner with reputable manufacturers who meet your quality standards.

Cost considerations are also a crucial aspect of the sourcing process. By analyzing market trends and pricing strategies, this guide equips B2B buyers with the knowledge to negotiate effectively and make informed purchasing decisions. As you navigate the complexities of sourcing cord elastic black, this resource empowers you to enhance your procurement strategy, ensuring that your business remains competitive and responsive to market demands.

Understanding cord elastic black Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Round Cord Elastic | Typically made from polyester and rubber, offers light stretch. | Apparel, crafting, DIY projects | Pros: Versatile, easy to sew; Cons: Limited strength for heavy-duty applications. |

| Shock Cord Elastic | Features a braided sleeve with an elastic inner core; highly durable. | Outdoor gear, sports equipment, automotive | Pros: High strength, resistant to wear; Cons: May be overkill for light applications. |

| Braided Elastic Cord | Offers a textured surface and greater grip; available in various widths. | Home decor, crafts, apparel | Pros: Excellent for holding items securely; Cons: Can be bulkier than other types. |

| Beading Elastic Cord | Thinner diameter ideal for jewelry-making; often latex-free. | Jewelry, crafts, decorative projects | Pros: Flexible, lightweight; Cons: Less suitable for heavy-duty use. |

| Flat Elastic Cord | Flat design allows for even distribution of tension; often used in waistbands. | Clothing, accessories | Pros: Comfortable, prevents rolling; Cons: Limited stretch compared to round types. |

What are the Characteristics of Round Cord Elastic?

Round cord elastic is characterized by its small diameter and light stretch capabilities, typically made from a blend of polyester and rubber. This type is ideal for various applications, particularly in the apparel industry, where it is used in garments like pants and skirts, as well as for crafting projects. B2B buyers should consider its ease of sewing and versatility, but also note that it may not provide the strength required for heavy-duty applications.

How Does Shock Cord Elastic Stand Out?

Shock cord elastic is distinguished by its durable braided sleeve and elastic inner core, making it suitable for demanding applications such as outdoor gear, sports equipment, and automotive uses. It offers high tensile strength and resistance to wear, which is crucial for products that undergo significant stress. Buyers should evaluate the need for such durability against the potential for higher costs, as this type may be excessive for lighter uses.

What are the Benefits of Braided Elastic Cord?

Braided elastic cord features a textured surface that enhances grip, making it a preferred choice for applications requiring secure fastening. It is commonly used in home decor, crafts, and apparel, providing a reliable hold for various items. When purchasing, B2B buyers should weigh the benefits of its secure grip against the bulkiness that may not suit all designs.

Why Choose Beading Elastic Cord for Jewelry Projects?

Beading elastic cord is specifically designed for jewelry-making, characterized by its thinner diameter and often latex-free composition. This type is ideal for flexible, lightweight designs, making it perfect for crafting intricate jewelry pieces. B2B buyers should consider its flexibility and lightweight nature, but keep in mind that it may not be suitable for projects requiring higher strength.

How Does Flat Elastic Cord Enhance Comfort in Clothing?

Flat elastic cord is designed to distribute tension evenly, making it a popular choice for waistbands in clothing and accessories. Its flat design enhances comfort and prevents rolling, which is particularly beneficial in apparel. B2B buyers should assess the comfort advantages of flat elastic against its limited stretch compared to round elastic types, ensuring it meets the specific needs of their products.

Key Industrial Applications of cord elastic black

| Industry/Sector | Specific Application of cord elastic black | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel Manufacturing | Used as drawstrings in garments like hoodies and pants | Enhances product functionality and comfort | Ensure elasticity and durability; consider local climate factors |

| Sports Equipment | Utilized in securing gear and accessories in sports bags | Provides reliable performance under stress | Look for UV resistance and weather durability for outdoor use |

| Automotive Industry | Employed in securing components and for tie-downs in vehicles | Increases safety and reliability of vehicle parts | Sourcing should focus on heat and abrasion resistance |

| Craft and Hobby Supplies | Integral in DIY projects, such as jewelry making and crafts | Supports creativity and customization opportunities | Quality consistency and availability in various lengths and widths |

| Medical Supplies | Used in the construction of medical devices and wearables | Ensures comfort and functionality for users | Compliance with health regulations and hypoallergenic materials |

How is ‘cord elastic black’ utilized in the apparel manufacturing sector?

In the apparel manufacturing sector, cord elastic black is primarily used as drawstrings in garments such as hoodies, sweatpants, and athletic wear. Its stretchability allows for a snug fit, enhancing comfort and functionality. Buyers in this industry need to ensure the elastic maintains its properties after multiple washes, particularly in regions with varying climate conditions, like Africa and South America, where humidity can affect material performance. Sourcing high-quality cord elastic that can withstand the rigors of frequent use is essential.

What role does cord elastic black play in sports equipment manufacturing?

In sports equipment, cord elastic black is commonly used to secure gear and accessories within bags, providing a reliable means of organization. Its durability under stress is crucial for athletes who require dependable equipment. B2B buyers in this sector should prioritize sourcing elastic cords that offer UV resistance, especially for outdoor sports, to prevent degradation from sun exposure. Ensuring the elastic can handle different weather conditions is vital for maintaining product integrity.

Why is cord elastic black important in the automotive industry?

The automotive industry employs cord elastic black for securing various components and as tie-downs for cargo. This application is critical for enhancing the safety and reliability of vehicle parts, particularly in high-stress environments. Buyers must consider the elastic’s heat and abrasion resistance to ensure it can withstand the demanding conditions often found in vehicles. Sourcing from reputable manufacturers who understand automotive standards is crucial for maintaining quality.

Illustrative image related to cord elastic black

How is cord elastic black beneficial in craft and hobby supplies?

In the craft and hobby supplies sector, cord elastic black is an integral component for DIY projects, including jewelry making, scrapbooking, and general crafts. It allows for creative expression and customization, appealing to a wide range of consumers. Buyers should focus on the quality and consistency of the elastic, as variations can affect the final product. Availability in various lengths and widths can also cater to diverse crafting needs, particularly for international markets.

What is the significance of cord elastic black in medical supplies?

Cord elastic black finds application in the medical supplies sector, particularly in the construction of medical devices and wearables. Its elasticity ensures comfort for users, which is essential for devices that are worn for extended periods. B2B buyers must ensure compliance with health regulations and consider hypoallergenic materials to avoid adverse reactions. Sourcing from manufacturers who specialize in medical-grade materials can enhance product safety and efficacy.

3 Common User Pain Points for ‘cord elastic black’ & Their Solutions

Scenario 1: Sourcing Quality Black Elastic Cord for Diverse Applications

The Problem: B2B buyers often struggle to source high-quality black elastic cord that meets specific project requirements. Given the diverse applications of cord elastic—from apparel manufacturing to crafting—buyers may find that the available products do not align with their quality standards or technical specifications. Inconsistent product quality can lead to production delays, increased costs, and ultimately, customer dissatisfaction. This challenge is particularly pronounced when sourcing from international suppliers who may not meet local regulatory standards or fail to deliver consistent product quality.

Illustrative image related to cord elastic black

The Solution: To address this issue, buyers should establish clear quality criteria based on the intended application of the elastic cord. Begin by creating a detailed specification sheet outlining the desired diameter, stretchability, material composition, and any necessary certifications (e.g., OEKO-TEX for textiles). Engage with multiple suppliers and request samples to assess the quality firsthand. Utilizing platforms that provide reviews and ratings for suppliers can also aid in making informed decisions. Furthermore, consider sourcing from manufacturers who offer customizable options, ensuring the elastic cord meets your precise needs without compromise.

Scenario 2: Managing Inventory and Supply Chain Fluctuations

The Problem: Another common pain point for B2B buyers is managing inventory levels and navigating supply chain fluctuations. Given the increasing demand for elastic cord in various industries, buyers may experience stockouts or overstock situations, leading to cash flow issues. Additionally, unexpected disruptions in the supply chain—whether due to geopolitical factors or raw material shortages—can create significant hurdles in maintaining a steady flow of production.

The Solution: To mitigate these challenges, implement a robust inventory management system that integrates forecasting tools. Analyzing historical sales data can help predict future demand and adjust orders accordingly. Establishing strong relationships with multiple suppliers can also provide a safety net; if one supplier faces delays, you can quickly pivot to another. Additionally, consider implementing just-in-time (JIT) inventory practices to reduce holding costs while ensuring you have enough stock to meet demand. Regularly reviewing and updating your supply chain strategies will also keep your operations agile and responsive to market changes.

Scenario 3: Ensuring Compliance with Regulatory Standards

The Problem: B2B buyers often face difficulties ensuring that their black elastic cord complies with various international and local regulatory standards. This is particularly relevant in industries such as apparel and safety gear, where materials must meet stringent safety and environmental regulations. Non-compliance can lead to costly recalls, fines, and damage to brand reputation.

The Solution: To navigate this complex landscape, buyers should familiarize themselves with the relevant regulations governing the use of elastic materials in their target markets. This includes standards related to chemical safety, product labeling, and environmental impact. Collaborate closely with suppliers to obtain all necessary documentation, such as safety data sheets (SDS) and certification of compliance. Additionally, conducting regular audits of suppliers can ensure that they adhere to these standards. Investing in a compliance management system can streamline the process of tracking regulatory changes, ensuring that your products always meet the required guidelines.

Illustrative image related to cord elastic black

Strategic Material Selection Guide for cord elastic black

When selecting materials for cord elastic black, B2B buyers must consider various factors that affect performance, cost, and suitability for specific applications. Below is an analysis of four common materials used in the production of cord elastic black, focusing on their properties, advantages, disadvantages, and considerations for international markets.

What are the Key Properties of Polyester in Cord Elastic Black?

Polyester is a popular choice for cord elastic due to its excellent tensile strength and elasticity. It typically performs well under a wide range of temperatures, maintaining its properties from -40°C to 120°C. Polyester also exhibits good resistance to UV light and moisture, making it suitable for outdoor applications. However, it may not be as resistant to chemicals and abrasion compared to other materials.

Pros: Durable, cost-effective, and versatile for various applications such as clothing, upholstery, and outdoor gear.

Cons: Limited resistance to extreme chemicals and potential degradation over time when exposed to harsh environmental conditions.

Impact on Application: Ideal for products requiring moderate stretch and durability, such as sportswear and casual apparel.

International Considerations: Buyers should ensure compliance with ASTM standards for textiles, particularly in regions like Europe and the Middle East where regulations are stringent.

How Does Natural Rubber Compare for Cord Elastic Black?

Natural rubber is known for its exceptional elasticity and flexibility, making it a prime candidate for applications requiring significant stretch. It can handle varying loads and maintains its properties well under pressure. However, natural rubber has a lower temperature tolerance, typically between -10°C and 70°C, and can degrade when exposed to UV light and ozone.

Illustrative image related to cord elastic black

Pros: Excellent elasticity, ideal for applications like medical devices, sports equipment, and fashion accessories.

Cons: Limited durability in outdoor applications and higher susceptibility to environmental degradation.

Impact on Application: Best suited for indoor uses or products that require frequent stretching without exposure to harsh conditions.

International Considerations: Compliance with JIS standards is crucial for buyers in Asia, while European buyers may prefer materials that meet REACH regulations.

What Advantages Does Nylon Offer for Cord Elastic Black?

Nylon is another widely used material for cord elastic black, known for its high strength and abrasion resistance. It can withstand a temperature range of -40°C to 90°C and has good resistance to chemicals and UV light. This makes nylon suitable for outdoor applications and products exposed to varying environmental conditions.

Pros: High durability, excellent tensile strength, and resistance to wear, making it suitable for heavy-duty applications.

Cons: Higher production costs compared to polyester and natural rubber, which may affect pricing for end products.

Impact on Application: Ideal for applications in outdoor gear, automotive, and industrial uses where durability is paramount.

International Considerations: Buyers should verify compliance with ISO standards, especially in regions with strict manufacturing regulations.

How Does Polypropylene Stack Up for Cord Elastic Black?

Polypropylene is a lightweight and cost-effective alternative for cord elastic applications. It offers moderate elasticity and is resistant to moisture and chemicals, making it suitable for a variety of environments. However, its temperature tolerance is lower than that of nylon and polyester, typically ranging from -20°C to 80°C.

Pros: Cost-effective, lightweight, and resistant to moisture, making it ideal for budget-sensitive applications.

Cons: Lower elasticity and durability compared to other materials, which may limit its use in high-stress applications.

Impact on Application: Suitable for disposable products, packaging, and light-duty applications.

International Considerations: Buyers in South America and Africa should be aware of local standards for plastics, ensuring compliance with relevant regulations.

Summary Table of Material Selection for Cord Elastic Black

| Material | Typical Use Case for cord elastic black | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Clothing, upholstery, outdoor gear | Durable and versatile | Limited chemical resistance | Medium |

| Natural Rubber | Medical devices, sports equipment | Excellent elasticity | Degrades under UV exposure | Medium |

| Nylon | Outdoor gear, automotive applications | High durability and strength | Higher production costs | High |

| Polypropylene | Disposable products, packaging | Cost-effective and lightweight | Lower elasticity and durability | Low |

This strategic material selection guide provides essential insights for B2B buyers across diverse regions, helping them make informed decisions based on their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cord elastic black

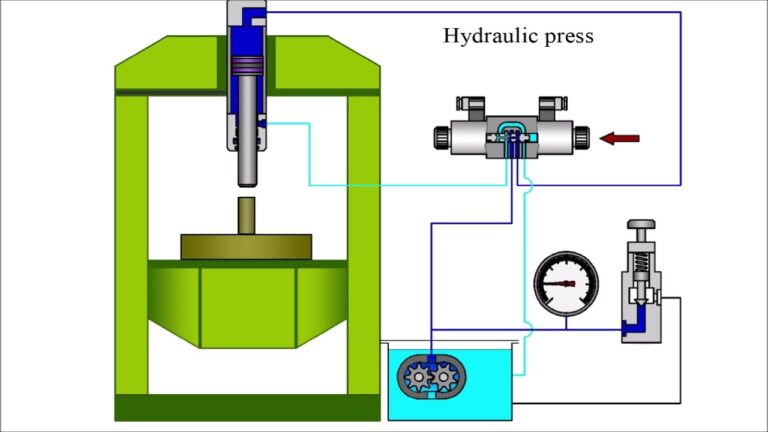

What Are the Main Stages of Manufacturing Cord Elastic Black?

The manufacturing process of cord elastic black involves several key stages that ensure the final product meets the necessary quality standards. Understanding these stages is crucial for B2B buyers seeking reliable suppliers.

-

Material Preparation: The first step in the manufacturing process is the selection and preparation of raw materials. Cord elastic is typically made from a blend of polyester and rubber, which provides the desired elasticity and durability. Suppliers must source high-quality materials, as the performance of the elastic cord heavily relies on the quality of these raw inputs. During this stage, materials are tested for their elasticity, tensile strength, and resistance to environmental factors, ensuring they meet industry specifications.

-

Forming: Once the materials are prepared, they undergo a forming process, which involves extruding the rubber and polyester mixture into the desired cord shape. This is often done using specialized machinery that applies heat and pressure to mold the cord into its final form. The diameter and elasticity can be adjusted during this stage, allowing manufacturers to produce various sizes and strengths of cord elastic. Precision in this step is crucial, as even minor deviations can affect the product’s performance.

-

Assembly: After forming, the elastic cord may require additional components, such as braiding or weaving to enhance its strength and aesthetic appeal. This assembly process might also include the integration of other materials for specific applications, such as reflective threads for safety gear. The assembled products undergo initial quality checks to identify any immediate defects.

-

Finishing: The final stage involves finishing processes, including cutting the elastic cord to specified lengths, applying surface treatments, and packaging. Quality control measures are implemented at this stage to ensure the final product adheres to the desired specifications. Finishing also includes labeling and preparing products for shipment, ensuring compliance with international standards.

How Is Quality Assurance Integrated into the Manufacturing of Cord Elastic Black?

Quality assurance (QA) is an integral part of the manufacturing process for cord elastic black, ensuring that the final products meet the required safety and performance standards.

-

International Standards: Manufacturers often adhere to international quality standards such as ISO 9001, which outlines the criteria for an effective quality management system. Compliance with these standards is crucial for B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, where quality expectations can vary significantly. Additionally, certifications like CE for products sold in Europe and API for specific applications in the oil and gas industry may also be relevant.

-

Quality Control Checkpoints: The QA process typically includes several checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to monitor the quality of the cord elastic at various stages, such as forming and assembly.

– Final Quality Control (FQC): Once the manufacturing process is complete, the finished products undergo thorough inspections and testing to verify they meet all quality standards before shipment. -

Common Testing Methods: Various testing methods are employed to evaluate the quality of cord elastic. These may include tensile strength tests, elongation tests, and fatigue tests to determine the durability and performance of the elastic cord under different conditions. Furthermore, environmental resistance tests can assess the product’s longevity when exposed to UV light, moisture, and extreme temperatures.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions with diverse manufacturing standards, verifying a supplier’s quality control practices is essential to ensure product reliability.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing capabilities, quality management systems, and adherence to international standards. These audits provide insight into the supplier’s processes and can reveal any potential weaknesses in their QA procedures.

-

Quality Control Reports: Requesting regular quality control reports from suppliers can help buyers stay informed about the production quality. These reports typically detail the results of various tests conducted on the cord elastic, providing transparency and accountability.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can perform quality checks at various stages of production, ensuring that the products meet the agreed-upon specifications. This is particularly important for buyers who may not have the capacity to conduct thorough audits themselves.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances when sourcing cord elastic black, particularly from manufacturers in different regions.

-

Understanding Regional Standards: Different regions have varying quality standards and certifications. For instance, European buyers may prioritize CE marking, while buyers from the Middle East might focus on local compliance standards. Familiarizing oneself with these requirements is crucial for avoiding compliance issues.

-

Cultural and Regulatory Differences: Buyers should be aware of cultural differences that may affect quality perceptions. For example, in some regions, emphasis may be placed on price over quality, leading to potential risks in sourcing decisions. Establishing clear communication regarding quality expectations can mitigate these risks.

-

Sustainability Considerations: Increasingly, B2B buyers are looking for suppliers that prioritize sustainability in their manufacturing processes. Certifications related to environmental management, such as ISO 14001, can be indicative of a supplier’s commitment to sustainable practices. This is particularly relevant for buyers in Europe, where sustainability is often a significant purchasing factor.

In conclusion, understanding the manufacturing processes and quality assurance measures for cord elastic black is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, along with robust quality control practices, buyers can make informed decisions when selecting suppliers. Verifying supplier quality through audits, reports, and third-party inspections further ensures that products meet international standards, ultimately leading to successful business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cord elastic black’

To assist international B2B buyers in procuring high-quality black cord elastic, this guide provides a practical step-by-step checklist. It is designed to streamline the sourcing process while ensuring that key considerations are addressed to meet specific business needs.

Step 1: Define Your Technical Specifications

Before initiating your search, outline the technical requirements for the black cord elastic you need. Consider factors such as diameter, material composition (e.g., polyester, rubber), and stretchability. This clarity will help you communicate effectively with suppliers and ensure you receive products that meet your quality standards.

Step 2: Identify Potential Suppliers

Research and compile a list of suppliers specializing in elastic cord products. Utilize online directories, trade shows, and industry-specific platforms to find reputable manufacturers. Focus on suppliers with a proven track record of delivering to your target markets, such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to their experience in fulfilling large orders and their ability to meet international shipping requirements.

- Verify Certifications: Ensure suppliers comply with international quality standards (e.g., ISO certifications) and have any necessary safety certifications relevant to your market.

Step 4: Request Samples for Quality Assessment

Once you have narrowed down your list, request samples of the black cord elastic. Assess the samples for quality, elasticity, and durability. This hands-on evaluation is critical as it allows you to gauge how well the product meets your specifications before placing a larger order.

- Test in Real Applications: Use the samples in actual projects to see how they perform under typical conditions.

Step 5: Negotiate Pricing and Terms

After selecting a supplier based on the quality of samples, engage in negotiations regarding pricing, minimum order quantities, and payment terms. Consider the overall value, including shipping costs and potential discounts for bulk orders.

- Explore Payment Options: Look for secure payment methods that provide protection for both parties, such as letters of credit or escrow services.

Step 6: Confirm Shipping and Delivery Times

Discuss shipping options and delivery timelines with your supplier. Ensure they can meet your project deadlines and understand the logistics involved in shipping to your location. This includes customs clearance and any potential delays.

- Monitor Shipping Costs: Be aware of fluctuations in shipping costs that could affect your budget.

Step 7: Establish a Long-term Relationship

Once your first order is complete, consider establishing a long-term relationship with your supplier. Consistent orders can lead to better pricing and priority service. Regular communication will help address any issues quickly and foster a collaborative partnership.

Illustrative image related to cord elastic black

By following these steps, B2B buyers can confidently source high-quality black cord elastic that meets their specific needs while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for cord elastic black Sourcing

What Are the Key Cost Components in Sourcing Cord Elastic Black?

When sourcing cord elastic black, understanding the cost structure is crucial for effective budgeting and pricing negotiations. The primary cost components include:

-

Materials: The raw materials for cord elastic typically consist of polyester, rubber, or a blend of both. The quality and source of these materials significantly influence pricing. Higher-grade materials may incur additional costs but can result in better durability and performance.

-

Labor: Labor costs vary based on the region of production. In countries with lower wage standards, such as some in Africa and South America, labor may be less expensive, which can decrease the overall cost of production. However, this could also reflect on the quality of the final product.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these overheads, thereby allowing suppliers to offer more competitive pricing.

-

Tooling: The investment in molds and machinery for producing various sizes and specifications of elastic cord can be significant. Custom orders may require additional tooling costs, which can impact pricing.

-

Quality Control (QC): Ensuring that the product meets industry standards often requires an investment in quality assurance processes. Rigorous QC can lead to higher costs but is essential for maintaining product integrity, especially for buyers in regions with stringent safety regulations.

-

Logistics: Shipping and handling costs can vary widely based on the destination and chosen Incoterms. Costs can be affected by shipping method, distance, and volume of the order.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market demand and competition. Understanding the margin expectations in different regions can aid in negotiation.

How Do Price Influencers Affect Cord Elastic Black Pricing?

Several factors can influence the pricing of cord elastic black, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract bulk discounts, which can significantly lower the per-unit cost. Buyers should consider their inventory needs and negotiate for favorable MOQs.

-

Specifications and Customization: Custom specifications, such as diameter, elasticity, and color, can affect pricing. Standard products generally have lower costs compared to customized solutions, so buyers should evaluate their actual needs against potential savings.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., OEKO-TEX, ISO) can justify higher prices due to enhanced product reliability and safety. Buyers must weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can also impact pricing. Established suppliers may charge more but offer better quality assurance and timely delivery.

-

Incoterms: The choice of Incoterms influences logistics costs and responsibilities. For example, DDP (Delivered Duty Paid) may lead to higher upfront costs but simplifies the import process for buyers.

What Are Essential Tips for Negotiating Cord Elastic Black Prices?

For B2B buyers looking to source cord elastic black effectively, consider the following tips:

-

Negotiate Terms: Engage in discussions around price, MOQ, and payment terms. Establishing a long-term relationship with suppliers can lead to better pricing and terms over time.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also shipping, handling, and potential wastage. A slightly higher initial cost may result in lower TCO if it leads to higher quality and fewer returns.

-

Be Aware of Pricing Nuances: Understand the regional market dynamics in Africa, South America, the Middle East, and Europe. Factors such as currency fluctuations and local demand can influence pricing.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers allows for comparison and provides leverage in negotiations. It’s essential to ensure that all quotes are for comparable products and terms.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and other factors. Always conduct thorough market research and supplier evaluations before making purchasing decisions.

Illustrative image related to cord elastic black

Alternatives Analysis: Comparing cord elastic black With Other Solutions

Exploring Alternatives to Cord Elastic Black

In the realm of elastic materials, ‘cord elastic black’ serves as a versatile solution for various applications, from apparel to crafting. However, it’s essential for B2B buyers to consider alternative options that may offer unique advantages depending on specific use cases. This analysis compares ‘cord elastic black’ with two viable alternatives: polyester heavy stretch elastic and shock cord elastic.

Comparison Table

| Comparison Aspect | Cord Elastic Black | Polyester Heavy Stretch Elastic | Shock Cord Elastic |

|---|---|---|---|

| Performance | Offers moderate stretch; ideal for crafting and light-duty applications. | Provides high elasticity and durability; suitable for heavy-duty uses. | Excellent for dynamic applications requiring significant stretch and recovery. |

| Cost | Generally low-cost; varies by supplier. | Higher initial cost, but often more durable. | Mid-range pricing; cost-effective for bulk purchases. |

| Ease of Implementation | Simple to use for basic sewing and crafting. | Requires careful handling and sewing techniques. | Easy to install with various applications, including drawstrings. |

| Maintenance | Minimal; can be machine washed. | Requires careful washing to maintain elasticity. | Low maintenance; resistant to wear and tear. |

| Best Use Case | Ideal for casual wear, crafts, and simple garments. | Best for activewear, heavy garments, and items requiring robust elasticity. | Perfect for outdoor gear, drawstrings, and applications needing high tension. |

Pros and Cons of Each Alternative

Polyester Heavy Stretch Elastic

Polyester heavy stretch elastic stands out for its exceptional durability and high elasticity, making it a preferred choice for applications in activewear and heavy-duty garments. Its resilience under strain ensures that it maintains its shape and function over time. However, the initial cost is typically higher compared to cord elastic black, which could be a consideration for budget-conscious buyers. Additionally, it may require more specialized sewing techniques, which could complicate the implementation process for some users.

Shock Cord Elastic

Shock cord elastic is known for its excellent stretch and recovery properties, making it ideal for applications such as drawstrings on outdoor gear and bags. Its ability to handle dynamic loads without losing elasticity is a significant advantage, particularly in environments where flexibility and strength are crucial. The price point is generally moderate, and it can be a cost-effective option when purchased in bulk. However, it may not be suitable for all types of crafting or sewing projects, limiting its versatility compared to cord elastic black.

Conclusion: How to Choose the Right Solution

When selecting between cord elastic black and its alternatives, B2B buyers should assess their specific needs based on application, budget, and the desired performance characteristics. If the project demands high durability and elasticity, particularly for activewear, polyester heavy stretch elastic may be the best fit. Conversely, for applications requiring significant stretch and recovery, shock cord elastic could be the optimal choice. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for cord elastic black

What Are the Key Technical Properties of Cord Elastic Black?

When sourcing cord elastic black, understanding its technical properties is crucial for ensuring it meets the requirements of your specific applications. Here are the critical specifications to consider:

-

Material Composition

Cord elastic black is typically made from a blend of polyester and rubber, which provides durability and elasticity. The polyester offers resistance to UV rays and moisture, making it suitable for outdoor applications, while the rubber core ensures stretchability. In B2B contexts, knowing the material composition helps buyers assess the cord’s performance in various environmental conditions. -

Diameter and Tolerance

Cord elastic black comes in various diameters, commonly ranging from 1/16 inch to 1/4 inch. The tolerance indicates the acceptable variation in diameter, which is crucial for applications requiring precise fit, such as garment construction or industrial uses. Accurate diameter specifications ensure that the elastic fits correctly within casings or devices, enhancing overall product quality. -

Elasticity and Recovery Rate

The elasticity of cord elastic black defines how much it can stretch and return to its original shape. A high recovery rate is essential for applications like clothing and outdoor gear, where repeated stretching occurs. Understanding these properties helps businesses choose the right cord for their products, minimizing returns and enhancing customer satisfaction. -

Break Strength

This refers to the maximum load the elastic can withstand before breaking. Cord elastic black typically has a break strength measured in pounds, which varies based on diameter and material quality. B2B buyers must consider break strength to ensure that the elastic can handle the intended load in their applications, whether it be for sewing, crafting, or industrial use. -

Colorfastness

This property indicates how well the color of the cord withstands washing and exposure to sunlight. High colorfastness is particularly important for products that will be frequently washed or exposed to outdoor conditions. Buyers should verify this property to avoid issues related to fading, which can affect the aesthetics and marketability of the final product.

What Are the Common Trade Terms Associated with Cord Elastic Black?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products based on the specifications provided by another company. In the context of cord elastic black, an OEM may produce elastic cord to specific design requirements for brands looking to incorporate it into their products. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for businesses to plan their inventory and manage costs effectively. For cord elastic black, MOQs may vary significantly between suppliers, impacting purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing for specific products. When seeking cord elastic black, businesses often use RFQs to compare prices and terms from multiple suppliers, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping responsibilities, costs, and risk management when sourcing cord elastic black from overseas suppliers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the elastic cord industry, lead times can vary based on factors like production capacity and shipping methods. Knowing the lead time helps businesses plan their production schedules and manage customer expectations effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their sourcing of cord elastic black meets their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the cord elastic black Sector

What are the Current Market Dynamics and Key Trends in the Cord Elastic Black Sector?

The global market for cord elastic black is witnessing significant growth, driven by diverse applications across various industries, including fashion, textiles, and outdoor gear. The increasing demand for lightweight, durable, and versatile materials is propelling the expansion of this sector. Key trends include the rise of customization and personalization in products, leading to a growing preference for elastic cords that can be tailored to specific requirements. Additionally, the integration of digital technologies in sourcing processes, such as e-commerce platforms and data analytics, is enhancing the efficiency of procurement for international buyers.

For B2B buyers from Africa, South America, the Middle East, and Europe, particularly in emerging markets like Brazil and Vietnam, understanding local consumer preferences is crucial. These regions are experiencing a burgeoning interest in DIY crafts and personalized fashion, which is further driving the demand for cord elastic products. Buyers are also leveraging online marketplaces to source materials directly from manufacturers, reducing intermediary costs and improving supply chain transparency.

Moreover, the push towards sustainability is influencing sourcing strategies, with buyers increasingly seeking suppliers who demonstrate a commitment to environmentally friendly practices. The incorporation of innovative materials and eco-friendly production processes is becoming a key differentiator in the competitive landscape, allowing buyers to align with global sustainability goals while meeting local market demands.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the Cord Elastic Black Sector?

Sustainability and ethical sourcing are paramount in today’s business environment, particularly for B2B buyers in the cord elastic black sector. The environmental impact of production processes, including resource extraction, manufacturing, and waste management, underscores the importance of adopting sustainable practices. Buyers should prioritize suppliers who utilize eco-friendly materials, such as recycled plastics or organic fibers, which help reduce carbon footprints and promote a circular economy.

Furthermore, ethical supply chains are increasingly relevant, as consumers demand transparency and social responsibility from brands. B2B buyers can enhance their sourcing strategies by partnering with manufacturers who adhere to ethical labor practices and provide fair wages, ensuring that their supply chains are not only environmentally sustainable but also socially responsible.

Illustrative image related to cord elastic black

Buyers should also seek out products with recognized ‘green’ certifications, such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which indicate compliance with stringent environmental and safety standards. These certifications not only help in making informed purchasing decisions but also serve as a marketing advantage, appealing to environmentally conscious consumers.

What is the Brief Evolution and History of Cord Elastic Black?

The evolution of cord elastic black can be traced back to its initial use in various crafting and textile applications. Originally, elastic cords were primarily manufactured from natural rubber, providing limited versatility. However, advancements in material science have led to the development of synthetic elastics, allowing for a wider range of applications and improved durability.

Over the years, the cord elastic black has found its way into various industries, from fashion to outdoor gear, due to its lightweight and stretchable nature. The introduction of advanced manufacturing techniques has further enhanced its properties, making it a preferred choice for both manufacturers and consumers. As markets continue to evolve, the cord elastic black sector is poised for continued growth, driven by innovation and the increasing demand for sustainable solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of cord elastic black

-

How do I choose the right cord elastic black for my manufacturing needs?

Selecting the appropriate cord elastic black depends on several factors, including the specific application, required stretchability, and durability. For applications like clothing and accessories, a lighter elastic cord may suffice, while heavy-duty applications, such as outdoor gear, may require thicker options. Always consider the material composition, such as polyester and rubber blends, which can affect elasticity and longevity. Request samples from suppliers to evaluate performance before making bulk purchases. -

What is the best cord elastic black for crafting and DIY projects?

For crafting and DIY projects, round cord elastic black is often recommended due to its versatility and ease of use. It can be utilized in a variety of applications, from making buttonhole loops to gathering fabric for skirts and bags. A cord with a diameter of about 1/8 inch typically offers a good balance of stretch and strength, suitable for most crafting needs. Always ensure that the elasticity matches the intended use to avoid premature wear. -

What are the minimum order quantities (MOQs) for cord elastic black?

Minimum order quantities for cord elastic black can vary significantly between suppliers. Typically, MOQs range from as low as 100 meters to several thousand meters, depending on the manufacturer and the specific product type. It’s advisable to communicate directly with suppliers to negotiate MOQs that align with your business needs, especially for custom orders. Bulk purchasing may also lead to discounts, making it economically advantageous. -

How can I verify the quality of cord elastic black from suppliers?

To ensure quality, consider requesting certification documents, such as ISO certifications or material safety data sheets (MSDS), from your suppliers. Conducting factory audits or using third-party inspection services can also provide insights into manufacturing practices. Additionally, ordering samples before committing to larger orders allows you to assess the elasticity, durability, and overall quality of the product firsthand. -

What payment terms are typically offered by suppliers of cord elastic black?

Payment terms can vary widely among suppliers and often depend on the relationship established. Common terms include advance payment, partial upfront payments with the balance due upon shipment, or net 30/60 days after delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify payment terms in your purchase agreements to avoid misunderstandings. -

What are the shipping options for cord elastic black, and how do they affect delivery times?

Shipping options for cord elastic black generally include air freight, sea freight, and express courier services. Air freight is faster but more expensive, suitable for urgent orders. Sea freight is cost-effective for larger shipments but can take weeks. Delivery times also depend on the destination and customs clearance processes. It’s essential to discuss shipping methods with your supplier to choose the best option for your timeline and budget. -

Can I customize the specifications of cord elastic black, such as thickness or color?

Yes, many suppliers offer customization options for cord elastic black, including variations in thickness, color, and material blend. Customization usually requires larger order quantities and may involve additional lead time. When requesting custom specifications, provide detailed requirements and any relevant samples to ensure the final product meets your expectations. Discuss potential costs associated with customization upfront. -

What are the common applications of cord elastic black in various industries?

Cord elastic black is widely used across several industries, including fashion for clothing and accessories, sports for gear and equipment, and industrial applications for securing items. In the home decor sector, it is often employed in upholstery and curtains. Understanding the specific requirements of your industry can help you select the right product and approach suppliers with tailored inquiries to meet your business needs effectively.

Top 5 Cord Elastic Black Manufacturers & Suppliers List

1. Paracord Planet – High Quality Elastic Cords

Domain: paracordplanet.com

Registered: 2011 (14 years)

Introduction: High Quality Elastic Cords in various sizes including 1/32″ and 1/16″. Prices range from $3.99 to $72.99 with free standard shipping on orders over $8.99 (US only). Available colors include White, Black, Royal Blue, Neon Yellow, Camo Green, Silver Gray, Charcoal Gray, Federal Standard Navy Blue, Purple, Goldenrod, Neon Pink, Imperial Red, Red, Orange, and Brown. Elastic cord is versatile for indoo…

2. B. Black & Sons – Round Cord Elastic

Domain: bblackandsons.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Round Cord Elastic”, “brand”: “B. Black & Sons Fabrics”, “price”: “$2.95”, “colors_available”: [“Black”, “White”, “Clear”], “SKU”: “T510”, “category”: “Elastic”, “description”: “Light Stretch Elastic Cord”, “related_products”: [{“name”: “Black Polyester Braided Elastic”, “price_range”: “$11.20 – $80.45”, “availability”: “Out of stock, custom order available”}, {“name”: “Polyester…

3. Dritz – Black Round Cord Elastic

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: Dritz Black Round Cord Elastic, 5 yards

4. Fire Mountain Gems – Powercord® Elastic

Domain: firemountaingems.com

Registered: 1998 (27 years)

Introduction: Elastic Cord from Fire Mountain Gems and Beads, available in various sizes and colors. Key products include: 1) Powercord® elastic, clear, 0.8mm, 8.5 pound test, sold per 25-meter spool, priced from $7.55 to $6.04 based on quantity. 2) Powercord® elastic, clear, 0.5mm, 4-pound test, sold per 25-meter spool, priced from $6.23 to $4.98 based on quantity. 3) Powercord® elastic, clear, 1mm, 14-pound t…

5. Ribbon Connections – EE Elastic Cord: Black

Domain: ribbonconnections.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “EE Elastic Cord: Black”, “brand”: “Ribbon Connections, Inc.”, “price_range”: “$16.00 – $62.00”, “current_stock”: “available”, “sku”: “EE”, “length_per_hank”: “55 yards (50m)”, “sizes”: [{“size”: “Small”, “width”: “1.8mm (approx. 1/16″)”, “composition”: {“Polyester”: “40%”, “Rubber”: “60%”}}, {“size”: “Medium”, “width”: “2.5mm (approx. 3/16″)”, “composition”: {“Polyester”: “30%”, …

Strategic Sourcing Conclusion and Outlook for cord elastic black

In navigating the evolving landscape of cord elastic black, strategic sourcing emerges as a cornerstone for B2B success. Buyers must prioritize sourcing from reliable suppliers who offer consistent quality and timely delivery, ensuring that their production lines remain uninterrupted. The versatility of cord elastic black, from crafting to industrial applications, underscores its significance across multiple sectors, making it essential for businesses to engage with manufacturers that understand regional market demands and can provide tailored solutions.

Moreover, international buyers from Africa, South America, the Middle East, and Europe should focus on establishing long-term partnerships with suppliers who can adapt to their specific needs. Leveraging local market insights and understanding global trends will enhance sourcing strategies, ultimately leading to better product offerings and customer satisfaction.

Looking ahead, the demand for cord elastic black is projected to grow, driven by its applications in fashion, home decor, and various industrial uses. Buyers are encouraged to act now—evaluate your current suppliers, explore new sourcing opportunities, and invest in relationships that will empower your business to thrive in this competitive environment. The future is bright for those who strategically embrace these opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to cord elastic black

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.