The Definitive Guide to Conveyor Belts For Consumer Packaged Goods: Cost, Materials &…

Introduction: Navigating the Global Market for conveyor belts for consumer packaged goods

In today’s rapidly evolving landscape, sourcing conveyor belts for consumer packaged goods poses a significant challenge for international B2B buyers. The need for reliable, efficient, and durable conveyance systems is more critical than ever, especially as companies strive to enhance productivity while minimizing downtime. This comprehensive guide is designed to navigate the complexities of the global conveyor belt market, addressing various types, applications, and the intricacies of supplier vetting.

Buyers will find detailed insights on the latest innovations in conveyor belt technology, including modular and fabric options tailored to meet diverse operational needs across industries like food packaging, pharmaceuticals, and e-commerce. Additionally, we delve into essential factors such as cost analysis, quality assurance, and maintenance considerations, equipping you with the knowledge to make informed purchasing decisions.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—this guide serves as a crucial resource. It empowers you to evaluate suppliers effectively, ensuring that your investment in conveyor systems aligns with your operational goals and enhances your supply chain efficiency. By leveraging the insights provided, you can navigate the global market with confidence and secure the best solutions for your business.

Understanding conveyor belts for consumer packaged goods Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fabric Conveyor Belts | Flexible, layered construction; suitable for various weights | Food processing, material handling | Pros: Lightweight, versatile; Cons: Limited durability compared to modular belts. |

| Modular Conveyor Belts | Solid, customizable design; easy to clean and maintain | Pharmaceutical, food processing, manufacturing | Pros: Durable, low maintenance; Cons: Higher initial cost. |

| Flexible Chain Conveyor Belts | Exceptional product handling flexibility; open sides | Automation, bottling, secondary packaging | Pros: Adaptable to complex layouts; Cons: May require more space. |

| Cleated Conveyor Belts | Vertical cleats for product stability on inclines | Food processing, packaging, material handling | Pros: Effective for inclined transport; Cons: Limited in flat applications. |

| High-Speed Conveyor Belts | Designed for rapid product movement; optimized for throughput | E-commerce, distribution centers | Pros: Increases productivity; Cons: Higher wear and tear on components. |

What Are the Characteristics of Fabric Conveyor Belts?

Fabric conveyor belts are constructed with multiple layers, including a cover material and a strength layer, which allows for flexibility and lightweight handling. They are suitable for various applications, particularly in food processing and material handling. When considering fabric belts, B2B buyers should evaluate the belt’s weight capacity and the specific materials used, as these factors directly impact performance and durability.

How Do Modular Conveyor Belts Stand Out in the Market?

Modular conveyor belts feature a solid construction that resists fraying and delamination, making them ideal for industries requiring high hygiene standards, such as pharmaceuticals and food processing. Their customizable design allows for different widths and lengths, enhancing their versatility. Buyers should consider the initial investment versus long-term maintenance costs, as modular belts may offer greater durability and lower upkeep over time.

What Are the Benefits of Using Flexible Chain Conveyor Belts?

Flexible chain conveyor belts provide exceptional adaptability for complex layouts and various environments, making them suitable for automation and bottling applications. Their open design allows for easy cleaning and maintenance, which is crucial in industries like food and beverage. B2B buyers should assess the layout of their facilities and the specific handling requirements of their products to determine if flexible chains are the right fit.

Why Choose Cleated Conveyor Belts for Inclined Transport?

Cleated conveyor belts feature vertical cleats that help stabilize products during inclined transport, making them particularly effective in food processing and packaging applications. This design minimizes product slippage and enhances efficiency. Buyers should consider the incline angle and the types of products being transported to ensure that cleated belts meet their operational needs.

How Do High-Speed Conveyor Belts Improve Productivity?

High-speed conveyor belts are engineered for rapid product movement, making them essential for e-commerce and distribution centers where throughput is critical. They are designed to handle increased loads and maintain efficiency during high-volume operations. However, buyers must be mindful of the increased wear on components and ensure that their systems can support the speed without compromising safety or reliability.

Key Industrial Applications of conveyor belts for consumer packaged goods

| Industry/Sector | Specific Application of conveyor belts for consumer packaged goods | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Transporting packaged food products through processing lines | Ensures hygiene and efficiency, reducing contamination risks | Material compliance (FDA/EFSA), temperature resistance |

| E-commerce & Retail | Order fulfillment and sorting in distribution centers | Increases throughput and accuracy in order processing | Flexibility for custom layouts, speed capabilities |

| Pharmaceuticals | Handling and packaging of over-the-counter and prescription drugs | Enhances safety and compliance with regulatory standards | Cleanroom compatibility, material safety certifications |

| Consumer Electronics | Assembly line support for electronic goods | Streamlines production, minimizing assembly time | Durability for heavy loads, anti-static properties |

| Personal Care | Conveying packaged cosmetics and personal care items | Improves packaging efficiency and reduces labor costs | Aesthetic options, ease of cleaning |

How Are Conveyor Belts Used in the Food & Beverage Industry?

In the food and beverage sector, conveyor belts play a crucial role in transporting packaged goods through various stages of processing, from manufacturing to distribution. They are designed to meet stringent hygiene standards, which is essential for preventing contamination. Buyers in this industry must ensure that the materials used comply with food safety regulations, such as FDA or EFSA standards, and can withstand temperature fluctuations, especially for products that require refrigeration or freezing.

What Role Do Conveyor Belts Play in E-commerce & Retail?

In the fast-paced world of e-commerce and retail, conveyor belts are integral to the order fulfillment process. They efficiently transport items from storage to packing stations, enhancing throughput and accuracy in sorting orders. For international buyers, sourcing conveyor systems that can be customized to fit various warehouse layouts is critical. Additionally, these systems should have speed capabilities that can adapt to fluctuating demand, especially during peak shopping seasons.

How Do Conveyor Belts Support the Pharmaceutical Industry?

Conveyor belts are vital in the pharmaceutical industry for the handling and packaging of medications, both prescription and over-the-counter. These systems help maintain a sterile environment and ensure compliance with strict regulatory standards. Buyers must consider belts that are compatible with cleanroom environments and made from materials that are safe for handling pharmaceuticals. Certifications and safety standards are paramount in this sector to prevent contamination and ensure product integrity.

Why Are Conveyor Belts Important in Consumer Electronics Manufacturing?

In the consumer electronics industry, conveyor belts facilitate the assembly of products such as smartphones and laptops. They streamline the production process by allowing for efficient movement of components through various assembly stages, ultimately reducing assembly time. When sourcing conveyor systems, businesses should focus on durability and load-bearing capacity, as well as features like anti-static properties to protect sensitive electronic components.

How Do Conveyor Belts Enhance Personal Care Product Packaging?

Conveyor belts are essential for the efficient packaging of cosmetics and personal care products. They improve the speed and efficiency of packaging lines, helping to reduce labor costs and increase productivity. Buyers in this sector should consider the aesthetic options available for conveyor systems, as well as the ease of cleaning, given the importance of maintaining a clean environment in product presentation.

3 Common User Pain Points for ‘conveyor belts for consumer packaged goods’ & Their Solutions

Scenario 1: Downtime Due to Belt Failures

The Problem: In the fast-paced environment of consumer packaged goods (CPG), unexpected downtime can lead to significant financial losses and disrupted supply chains. A common pain point for B2B buyers is dealing with conveyor belt failures, often due to inadequate material selection or improper maintenance. For instance, a manufacturer may experience frequent breakdowns of their fabric conveyor belts due to wear and tear from abrasive packaging materials, leading to costly delays and loss of productivity.

The Solution: To mitigate this issue, it’s crucial to select conveyor belts specifically designed for the types of materials being transported. Buyers should assess the abrasion resistance of various belt materials, such as polyurethane or nitrile-butadiene rubber, which are engineered to handle rough surfaces. Additionally, implementing a regular maintenance schedule that includes inspections and timely replacements will help prevent unexpected failures. Partnering with suppliers that offer comprehensive support, including 24/7 customer service and access to technical experts, can further ensure that manufacturers are prepared for any potential issues, thereby minimizing downtime and maximizing productivity.

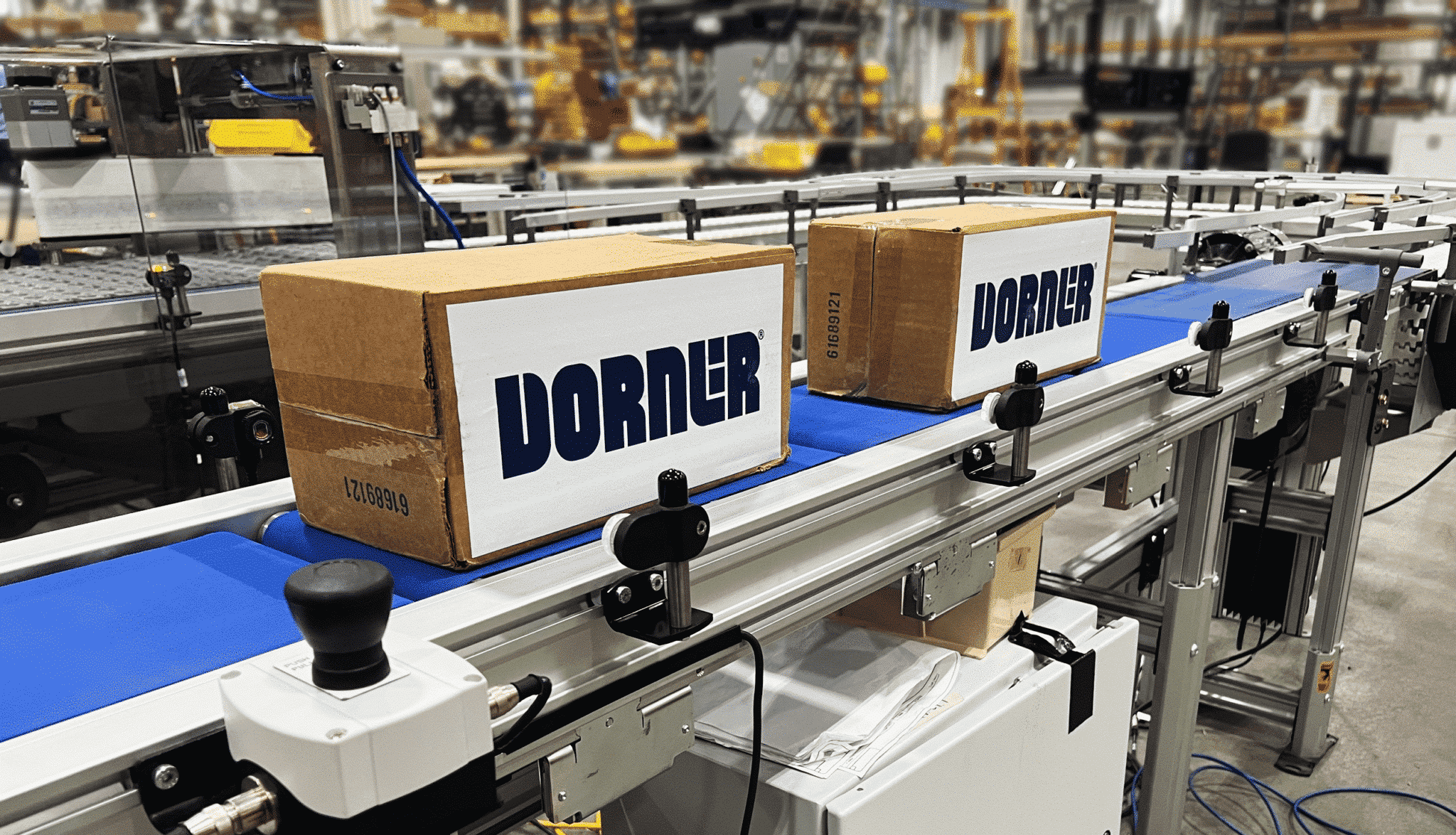

Illustrative image related to conveyor belts for consumer packaged goods

Scenario 2: Inefficient Product Flow and Sorting

The Problem: Many CPG manufacturers struggle with inefficient product flow and sorting processes, especially during peak seasons when demand surges. A common scenario involves bottlenecks at sorting stations where multiple products need to be directed to various packaging lines. This inefficiency can lead to increased labor costs and delays in getting products to market, ultimately affecting customer satisfaction.

The Solution: One effective approach to streamline product flow is to invest in modular conveyor systems that can be customized for specific sorting needs. For example, modular belts with integrated sensors can facilitate automated sorting based on product size, weight, or type, significantly improving efficiency. Buyers should also consider implementing smart conveyor solutions that incorporate real-time data tracking to monitor performance and identify bottlenecks before they become critical issues. By working closely with suppliers who offer tailored solutions, manufacturers can optimize their conveyor systems to enhance overall throughput and responsiveness to market demands.

Scenario 3: Compliance with Food Safety Standards

The Problem: In the consumer packaged goods sector, particularly in food and pharmaceuticals, compliance with stringent food safety and hygiene regulations is paramount. B2B buyers often face challenges in selecting conveyor belts that not only meet operational needs but also adhere to these regulations. Non-compliance can lead to costly recalls, legal issues, and damage to brand reputation.

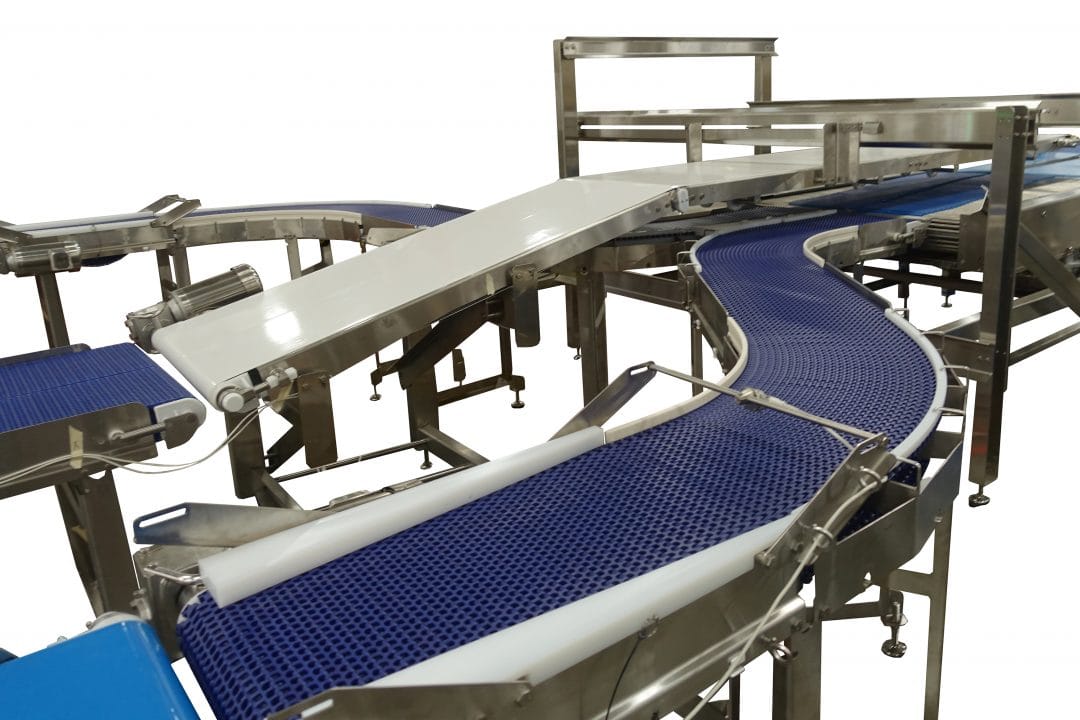

Illustrative image related to conveyor belts for consumer packaged goods

The Solution: To address this concern, manufacturers should prioritize conveyor belts made from FDA-approved materials that are easy to clean and sanitize. Options like stainless steel modular belts or plastic belts designed for hygienic applications can be highly effective. Additionally, buyers should work with suppliers who provide clear documentation of compliance with food safety standards and offer training on proper cleaning and maintenance protocols. Implementing a robust hygiene management system alongside the right conveyor solutions will ensure that manufacturers maintain compliance while optimizing their production efficiency. By taking these proactive steps, B2B buyers can safeguard their operations and uphold the integrity of their products.

Strategic Material Selection Guide for conveyor belts for consumer packaged goods

When selecting conveyor belts for consumer packaged goods (CPG), the choice of material significantly influences performance, durability, and overall operational efficiency. Below, we analyze four common materials used in conveyor belts, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Polyurethane Conveyor Belts?

Polyurethane (PU) conveyor belts are renowned for their flexibility and resistance to abrasion and chemicals. They typically have a temperature rating of -30°C to 80°C, making them suitable for a range of environments. Their excellent wear resistance ensures longevity, particularly in applications involving sharp or rough-edged products.

Pros: Polyurethane belts offer high durability and are resistant to oils, fats, and chemicals. They are lightweight, which can reduce energy consumption in conveyor systems.

Cons: While PU belts are durable, they can be more expensive than other materials. Additionally, their manufacturing complexity may lead to longer lead times.

Impact on Application: PU belts are ideal for food processing, packaging, and pharmaceutical applications due to their non-toxic properties and ease of cleaning.

Considerations for International Buyers: Buyers in regions such as Europe and the Middle East should ensure compliance with food safety regulations, including EU standards. Understanding local certifications, such as FDA or EU food contact regulations, is critical.

How Do PVC Conveyor Belts Compare in Performance?

Polyvinyl Chloride (PVC) conveyor belts are widely used due to their versatility and cost-effectiveness. They typically have a temperature range of -10°C to 60°C and offer moderate chemical resistance.

Pros: PVC belts are relatively inexpensive and easy to manufacture. They provide good grip and are suitable for light to medium-duty applications.

Cons: While cost-effective, PVC belts may not withstand high temperatures or harsh chemicals, limiting their use in specific environments.

Impact on Application: These belts are commonly used in packaging, light manufacturing, and material handling, where moderate durability is acceptable.

Considerations for International Buyers: Buyers should be aware of regional standards like ASTM in the U.S. and DIN in Europe for material safety and performance. Additionally, the availability of PVC belts may vary by region.

What Are the Benefits of Using Modular Plastic Conveyor Belts?

Modular plastic conveyor belts are constructed from interlocking plastic segments, allowing for customization in width and length. They are designed to handle a wide range of temperatures, typically from -20°C to 80°C.

Pros: Their modular design allows for easy maintenance and repair. They are highly durable and resistant to chemicals, making them suitable for a variety of applications.

Cons: The initial investment can be higher due to the complexity of design and manufacturing. Additionally, they may require specialized installation.

Impact on Application: Modular belts excel in food processing, packaging, and cleanroom environments due to their ease of cleaning and sanitation.

Considerations for International Buyers: Compliance with international standards such as ISO and FDA is crucial, especially in the food and pharmaceutical industries. Buyers should also consider the local availability of replacement parts.

Why Choose Fabric Conveyor Belts for Your Operations?

Fabric conveyor belts are constructed from multiple layers of fabric, providing flexibility and strength. They can typically handle temperatures ranging from -40°C to 100°C, depending on the specific material used.

Pros: These belts are highly customizable and can be designed for specific applications, offering excellent load-bearing capabilities. They are also lightweight, which can enhance energy efficiency.

Cons: Fabric belts may be less resistant to chemicals compared to modular or PU belts, which could limit their application in certain industries.

Illustrative image related to conveyor belts for consumer packaged goods

Impact on Application: Fabric belts are often used in heavy-duty applications, including mining, agriculture, and recycling.

Considerations for International Buyers: Buyers should ensure that the fabric belts meet local and international standards for safety and performance, such as JIS in Japan or DIN in Germany.

Summary Table of Conveyor Belt Materials

| Material | Typical Use Case for conveyor belts for consumer packaged goods | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Food processing, packaging, pharmaceuticals | High durability and chemical resistance | Higher cost and manufacturing complexity | High |

| PVC | Light manufacturing, packaging | Cost-effective and easy to manufacture | Limited temperature and chemical resistance | Low |

| Modular Plastic | Food processing, cleanrooms | Easy maintenance and high durability | Higher initial investment | Medium |

| Fabric | Heavy-duty applications (mining, agriculture) | Customizable and lightweight | Less chemical resistance | Medium |

This strategic material selection guide aims to provide international B2B buyers with essential insights into the materials available for conveyor belts in the consumer packaged goods sector, ensuring informed decision-making that aligns with operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor belts for consumer packaged goods

What Are the Main Stages in the Manufacturing Process of Conveyor Belts for Consumer Packaged Goods?

The manufacturing process of conveyor belts for consumer packaged goods typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensure that the final product meets the operational demands of diverse industries.

How Is Material Prepared for Conveyor Belt Manufacturing?

Material preparation begins with the selection of appropriate raw materials, such as rubber, fabric, or thermoplastics. Manufacturers often utilize advanced techniques like extrusion and calendaring to create the base material. This involves mixing specific compounds to achieve desired properties such as flexibility, strength, and resistance to wear and tear. The materials are then processed into sheets or rolls, which will serve as the foundation for the conveyor belts.

Illustrative image related to conveyor belts for consumer packaged goods

What Techniques Are Used in Forming Conveyor Belts?

The forming stage involves shaping the prepared materials into the desired belt configuration. Techniques such as molding and lamination are commonly used. For instance, in the case of modular belts, individual plastic modules are molded and then assembled into a continuous belt. This stage may also include the integration of features like cleats or sidewalls that enhance the belt’s functionality in specific applications, such as incline transport or product separation.

How Is Assembly Conducted for Conveyor Belts?

During the assembly phase, the formed materials are joined together, often using methods like splicing, welding, or stitching, depending on the belt type. Manufacturers may also incorporate additional components, such as rollers or drive systems, to ensure smooth operation. Quality checks are integral at this stage to confirm that the assembly aligns with design specifications.

What Finishing Processes Are Commonly Applied to Conveyor Belts?

Finishing involves finalizing the conveyor belts for delivery. This may include surface treatments to enhance durability or improve friction properties, as well as cutting belts to specific lengths. Some manufacturers apply coatings for additional protection against environmental factors, particularly in industries like food processing where hygiene is critical.

What Quality Assurance Standards Are Relevant for Conveyor Belts?

International standards such as ISO 9001 are essential for ensuring consistent quality across manufacturing processes. ISO 9001 focuses on quality management systems and is recognized globally, making it a crucial benchmark for manufacturers supplying conveyor belts to international markets. In addition, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) further validate compliance with safety and performance requirements.

What Are the Key Quality Control Checkpoints in Conveyor Belt Manufacturing?

Quality control (QC) is an ongoing process throughout the manufacturing stages. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials before they enter the production line. It ensures that materials meet predefined standards and specifications.

-

In-Process Quality Control (IPQC): Conducted at various stages during production, IPQC involves real-time monitoring and testing of the manufacturing process to identify any deviations from quality standards.

-

Final Quality Control (FQC): This final inspection phase evaluates the finished conveyor belts before they are shipped. It includes performance testing and visual inspections to ensure that the product meets all quality and safety criteria.

What Common Testing Methods Are Employed in Conveyor Belt Quality Control?

Manufacturers employ various testing methods to assess the quality and performance of conveyor belts. Common tests include:

-

Tensile Strength Testing: Evaluates the belt’s ability to withstand forces without breaking.

-

Abrasion Resistance Testing: Determines how well the belt can endure wear from materials it handles.

-

Heat Resistance Testing: Assesses the belt’s performance under high-temperature conditions, crucial for applications in food processing or manufacturing.

-

Chemical Resistance Testing: Ensures the belt’s materials can withstand exposure to various chemicals, particularly important in industries like pharmaceuticals and food production.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can ensure the reliability of their conveyor belt suppliers through various verification methods:

-

Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes and quality control measures firsthand.

-

Quality Reports: Requesting detailed quality reports can provide insight into the supplier’s quality control history, including performance metrics and compliance with international standards.

-

Third-party Inspections: Engaging independent inspectors to evaluate the manufacturing process and product quality can offer an unbiased view of the supplier’s capabilities.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and market-specific requirements is crucial. Different regions may have varying standards for materials and safety, affecting the compliance of conveyor belts. Buyers should familiarize themselves with local certifications and ensure that their suppliers can meet these requirements. Additionally, language barriers and cultural differences may impact communication, making it essential to establish clear lines of dialogue regarding quality expectations and compliance.

Conclusion: Ensuring Quality in Conveyor Belt Procurement

In conclusion, the manufacturing processes and quality assurance protocols for conveyor belts are critical to ensuring that these products meet the rigorous demands of consumer packaged goods industries. By understanding the stages of production, relevant quality standards, and verification methods, international B2B buyers can make informed decisions, thereby ensuring the reliability and effectiveness of their conveyor belt solutions.

Illustrative image related to conveyor belts for consumer packaged goods

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor belts for consumer packaged goods’

Introduction

Sourcing the right conveyor belts for consumer packaged goods is critical for optimizing production efficiency and ensuring product integrity. This guide provides a step-by-step checklist to help international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, navigate the procurement process effectively. By following these steps, you can make informed decisions that align with your operational needs and industry standards.

Step 1: Define Your Technical Specifications

Understanding your operational requirements is the first step in selecting the appropriate conveyor belt. Consider factors such as the weight and size of the products, the environment (temperature, humidity), and specific handling needs (e.g., incline, accumulation). Clearly defined specifications will streamline the selection process and ensure compatibility with your existing systems.

Step 2: Research Available Conveyor Belt Types

Familiarize yourself with the different types of conveyor belts available in the market. Key categories include fabric belts, modular belts, and flexible chain belts, each serving distinct purposes. For example, modular belts are ideal for applications requiring frequent cleaning, while fabric belts may be better suited for heavier loads. Understanding these options will help you match a belt type to your specific application.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet potential suppliers thoroughly. Request detailed company profiles, case studies, and references from businesses in similar industries or geographic locations. This will provide insight into their reliability, customer service, and ability to meet your technical requirements. Don’t hesitate to inquire about their production capabilities and lead times.

Illustrative image related to conveyor belts for consumer packaged goods

Step 4: Assess Quality and Compliance Standards

Quality assurance is paramount when selecting conveyor belts. Ensure that the suppliers adhere to relevant industry standards and certifications, such as ISO or FDA compliance for food-grade applications. High-quality belts can prevent costly downtimes and maintain production efficiency. Request documentation proving compliance with safety and quality standards.

Step 5: Inquire About Customization Options

Different production processes may require customized conveyor solutions. Discuss with suppliers their ability to tailor belts to your specifications, including dimensions, materials, and features like cleating or anti-static properties. Customization can enhance the performance and longevity of your conveyor systems, ensuring they meet unique operational needs.

Step 6: Consider Support and Maintenance Services

Evaluate the level of support and maintenance services offered by suppliers. Reliable customer service, technical support, and training can significantly reduce downtime and enhance operational efficiency. Look for suppliers that provide comprehensive maintenance programs, including installation assistance and troubleshooting resources.

Step 7: Review Pricing and Total Cost of Ownership

Finally, analyze the pricing structures of the conveyor belts and consider the total cost of ownership. This includes not only the initial purchase price but also maintenance costs, energy consumption, and the expected lifespan of the belts. A more expensive belt might offer better durability and lower long-term costs, making it a smarter investment.

By following this checklist, B2B buyers can navigate the complexities of sourcing conveyor belts for consumer packaged goods with greater confidence and precision, ultimately leading to improved operational outcomes.

Comprehensive Cost and Pricing Analysis for conveyor belts for consumer packaged goods Sourcing

What Are the Key Cost Components in Sourcing Conveyor Belts for Consumer Packaged Goods?

When sourcing conveyor belts for consumer packaged goods, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Conveyor belts can be made from various materials such as rubber, fabric, or plastic, each with different price points. High-performance materials designed for specific applications, such as FDA-approved belts for food processing, may incur higher costs.

-

Labor: Labor costs encompass both the manufacturing workforce and any specialized labor required for installation and maintenance. In regions with higher labor costs, such as Europe, this can affect the overall pricing strategy.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment depreciation. Efficient manufacturing processes can lower these overheads, which is particularly important for suppliers operating in competitive markets.

-

Tooling: Custom conveyor belts often require specific tooling for production. The initial investment in tooling can be significant but is typically amortized over larger production runs, making it critical to consider minimum order quantities (MOQs).

-

Quality Control (QC): Implementing stringent QC measures ensures that the belts meet industry standards and customer specifications. However, enhanced QC processes can add to production costs, making it essential for buyers to weigh quality against price.

-

Logistics: Shipping and handling costs vary based on the distance, mode of transport, and any applicable tariffs. For international buyers, understanding logistics is vital, as these costs can significantly impact the total price.

-

Margin: Suppliers will add their profit margin to the base cost of production, which can vary based on competition, brand positioning, and market demand.

How Do Price Influencers Affect Conveyor Belt Costs?

Several factors can influence the pricing of conveyor belts, making it essential for buyers to be aware of these elements:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, which can be advantageous for businesses looking to optimize costs.

-

Specifications and Customization: Custom specifications, such as size, material, and features, can significantly increase costs. Buyers should evaluate whether customization is necessary for their operations to avoid overspending.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO or FDA compliance) often come at a premium. However, investing in quality can lead to lower maintenance costs and increased durability, impacting the total cost of ownership.

-

Supplier Factors: Supplier reputation, service levels, and geographical location can all affect pricing. Established suppliers with a strong track record may charge more, but they often provide better reliability and support.

-

Incoterms: Understanding the agreed Incoterms is crucial for buyers to anticipate additional costs related to shipping, insurance, and customs duties. This knowledge can aid in accurate budgeting and cost management.

What Tips Can Help Buyers Negotiate Better Prices?

To maximize value and minimize costs when sourcing conveyor belts, buyers should consider the following tips:

-

Negotiate Wisely: Engage suppliers in discussions about pricing and be prepared to leverage competitive quotes. Understanding the market landscape can provide leverage in negotiations.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with maintenance, efficiency, and potential downtime. A cheaper belt may not always be the most cost-effective choice.

-

Understand Pricing Nuances for International Transactions: For buyers in Africa, South America, the Middle East, and Europe, it’s essential to factor in currency fluctuations, shipping timelines, and local regulations that can affect pricing.

-

Build Relationships with Suppliers: Establishing long-term partnerships can lead to better pricing, improved service levels, and priority treatment during high-demand periods.

Disclaimer on Pricing Information

Pricing for conveyor belts can fluctuate based on market conditions, supplier strategies, and raw material availability. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are getting the best value for their investment.

Illustrative image related to conveyor belts for consumer packaged goods

Alternatives Analysis: Comparing conveyor belts for consumer packaged goods With Other Solutions

Introduction: Exploring Alternatives to Conveyor Belts for Consumer Packaged Goods

In the realm of logistics and packaging, conveyor belts have long been the backbone of efficient product movement. However, as industries evolve and technological advancements emerge, alternative solutions are gaining traction. This section explores viable alternatives to conveyor belts for consumer packaged goods, highlighting their unique advantages and potential drawbacks. Understanding these options will empower B2B buyers to make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Conveyor Belts for Consumer Packaged Goods | Automated Guided Vehicles (AGVs) | Robotic Arm Systems |

|---|---|---|---|

| Performance | High throughput and continuous operation | Moderate, dependent on navigation | High precision and flexibility |

| Cost | Moderate initial investment, low operational costs | High initial investment, moderate operational costs | High initial investment, high operational costs |

| Ease of Implementation | Relatively easy, requires space for layout | Complex, requires infrastructure and software | Complex, requires programming and setup |

| Maintenance | Regular maintenance needed for optimal performance | Low, but requires software updates | Moderate, requires programming adjustments |

| Best Use Case | High-volume, repetitive tasks | Variable loads, flexible routing | Complex tasks, varied product handling |

Detailed Breakdown of Alternatives

Automated Guided Vehicles (AGVs)

AGVs are mobile robots that transport materials around a facility without human intervention. They excel in environments where flexibility and adaptability are paramount. AGVs can navigate through dynamic environments and adjust routes based on real-time conditions, making them an excellent choice for warehouses and distribution centers that handle diverse product types. However, the initial investment for AGV systems can be substantial, as they require sophisticated navigation and control systems. Additionally, while AGVs can enhance operational efficiency, their performance may be limited by the complexity of the infrastructure in place.

Robotic Arm Systems

Robotic arms are engineered for precision and versatility, capable of performing various tasks from assembly to packing. Their programmable nature allows them to handle different products with minimal changeover time, making them ideal for operations that require high precision. However, the implementation of robotic systems can be complex and costly, with significant upfront investments in both hardware and software. Maintenance can also be moderately demanding, as adjustments may be needed to optimize performance. Despite these challenges, robotic arm systems are invaluable for high-skill tasks and can greatly enhance productivity when integrated effectively into existing processes.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating conveyor belts against alternatives like AGVs and robotic arm systems, B2B buyers must consider their specific operational requirements, including product types, volume, and facility layout. Conveyor belts excel in high-volume, repetitive tasks where efficiency is paramount, while AGVs offer flexibility in dynamic environments. Robotic arms provide precision for varied tasks but come with a higher cost and complexity. By carefully assessing the advantages and limitations of each solution, buyers can select the most suitable technology that aligns with their operational goals and budget constraints.

Illustrative image related to conveyor belts for consumer packaged goods

Essential Technical Properties and Trade Terminology for conveyor belts for consumer packaged goods

What Are the Key Technical Properties of Conveyor Belts for Consumer Packaged Goods?

When selecting conveyor belts for consumer packaged goods (CPG), understanding the technical properties is essential for ensuring optimal performance and reliability. Here are several critical specifications to consider:

1. Material Grade

The material grade of a conveyor belt refers to the type of material used in its construction, which can range from fabric to plastic and rubber. High-quality materials enhance durability, flexibility, and resistance to environmental factors. For CPG applications, choosing the right material is crucial as it directly impacts the belt’s lifespan and maintenance requirements, leading to reduced downtime and operational costs.

2. Tension Rating

Tension rating indicates the maximum load that a conveyor belt can handle without compromising its integrity. This specification is vital for CPG manufacturers who deal with varying product weights and shapes. A belt with an appropriate tension rating ensures that products are transported safely and efficiently, minimizing the risk of slippage or breakage during operation.

3. Surface Texture

The surface texture of a conveyor belt affects its grip and the ability to transport products securely. Options range from smooth to textured surfaces, such as cleated or ribbed designs. Selecting the right surface texture is essential for preventing product slippage, especially in high-speed applications or when transporting items on inclines.

4. Temperature Resistance

Temperature resistance is the ability of a conveyor belt to withstand extreme heat or cold without degrading. This property is particularly important in the CPG sector, where products may require specific temperature conditions during processing or transportation. Choosing a belt with adequate temperature resistance helps maintain product quality and compliance with industry standards.

5. Abrasion Resistance

Abrasion resistance measures how well a conveyor belt can withstand wear and tear from rough surfaces or sharp edges. In CPG environments, where products may have varying textures, selecting a belt with high abrasion resistance is critical to prolonging its lifespan and reducing replacement costs.

What Are Common Trade Terms Used in Conveyor Belt Procurement?

Understanding industry jargon is essential for effective communication between buyers and suppliers. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components that are used in another company’s end products. In the context of conveyor belts, knowing the OEM can help buyers assess the quality and compatibility of the belts with their existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, being aware of MOQ is crucial when planning inventory purchases to ensure they meet production needs without overcommitting capital.

Illustrative image related to conveyor belts for consumer packaged goods

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. This term is essential for buyers as it initiates the procurement process and helps compare offers from multiple suppliers, ensuring the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that define the responsibilities of buyers and sellers in the delivery of goods. Familiarity with Incoterms is critical for B2B transactions, especially in international trade, as they clarify who is responsible for shipping costs, insurance, and risk at various stages of transportation.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is essential for supply chain management, as it impacts production schedules and inventory levels. Buyers should factor lead times into their planning to avoid disruptions.

Illustrative image related to conveyor belts for consumer packaged goods

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring conveyor belts for consumer packaged goods, ensuring their operations run smoothly and efficiently.

Navigating Market Dynamics and Sourcing Trends in the conveyor belts for consumer packaged goods Sector

What Are the Current Market Dynamics and Key Trends in Conveyor Belts for Consumer Packaged Goods?

The conveyor belts market for consumer packaged goods (CPG) is experiencing significant growth, driven by several global factors. The rise of e-commerce and automation in manufacturing has catalyzed demand for efficient material handling solutions. Countries in Africa, South America, the Middle East, and Europe, particularly Germany and Vietnam, are witnessing increased investments in industrial automation, which in turn boosts the need for advanced conveyor systems. Additionally, the push for shorter lead times and enhanced productivity has led manufacturers to adopt smart conveyor technologies, such as modular and flexible belt systems that can be easily customized for specific applications.

Emerging B2B technology trends include the integration of IoT (Internet of Things) and AI (Artificial Intelligence) into conveyor systems. This integration allows for real-time monitoring and predictive maintenance, which minimizes downtime and enhances operational efficiency. As supply chains become more complex, international B2B buyers are prioritizing suppliers that offer robust service levels and quick response times. Vendors that establish local assembly and distribution hubs, such as Intralox’s expansions in Mexico and China, are particularly appealing as they promise faster recovery from potential disruptions.

Furthermore, the industry is seeing a shift towards automation in warehousing and distribution centers, driven by labor shortages and the increasing demand for rapid fulfillment. This trend emphasizes the importance of selecting conveyor systems that are not only reliable but also adaptable to evolving production needs.

How Does Sustainability and Ethical Sourcing Impact the Conveyor Belts Market?

Sustainability has become a critical consideration in the procurement of conveyor belts for the CPG sector. International B2B buyers are increasingly aware of the environmental impact of their supply chains and are seeking suppliers that prioritize sustainable practices. This includes sourcing materials that are recyclable or made from biodegradable substances, as well as employing manufacturing processes that minimize waste and emissions.

Ethical sourcing is also gaining traction, with businesses looking to partner with suppliers who uphold fair labor practices and transparency in their operations. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are becoming essential for suppliers aiming to differentiate themselves in a competitive market. The use of ‘green’ materials, such as those made from recycled plastics or sustainable rubber, is not only beneficial for the environment but can also enhance a company’s brand reputation among environmentally conscious consumers.

Moreover, regulatory pressures are increasing globally, pushing companies to adopt sustainable practices. Compliance with these regulations is becoming a prerequisite for market entry, especially in regions like Europe, where stringent environmental laws are enforced. Therefore, B2B buyers must prioritize suppliers who can demonstrate a commitment to sustainability and ethical sourcing in their conveyor belt solutions.

What Is the Brief Evolution of Conveyor Belts in the Consumer Packaged Goods Sector?

The evolution of conveyor belts in the consumer packaged goods sector has been marked by significant technological advancements and a shift in industry needs. Initially, conveyor systems were primarily mechanical and limited in flexibility. However, as the CPG industry evolved, so did the demand for more sophisticated and versatile solutions. The introduction of modular conveyor belts in the late 20th century marked a turning point, allowing for easier maintenance, customization, and scalability.

Illustrative image related to conveyor belts for consumer packaged goods

In recent years, the focus has shifted towards automation and smart technologies, with conveyor systems becoming integral to modern manufacturing and distribution processes. The rise of e-commerce has further accelerated this trend, prompting manufacturers to develop systems that can handle diverse product lines efficiently. Today, the conveyor belt market is characterized by innovation and adaptability, ensuring that businesses can meet the dynamic demands of the global marketplace while maintaining operational efficiency.

This trajectory not only highlights the importance of selecting the right conveyor system but also underscores the need for suppliers to stay ahead of technological trends and sustainability practices to remain competitive in the evolving landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor belts for consumer packaged goods

-

How do I solve conveyor belt alignment issues?

Alignment problems can cause significant downtime and affect product flow. To address this, first check the installation of the conveyor system to ensure it is level and properly anchored. Regular maintenance, including tension adjustments and alignment checks, is essential. Utilizing tracking mechanisms and guides can also help maintain proper alignment during operation. For persistent issues, consider consulting with your supplier for expert support or a tailored solution to improve performance. -

What is the best conveyor belt material for food packaging applications?

For food packaging, the ideal conveyor belt material is typically FDA-approved plastic or fabric, as these materials are designed to withstand rigorous cleaning and sanitation processes. Consider options like modular plastic belts, which are easy to clean and resistant to moisture. Additionally, belts made from materials like silicone can handle temperature fluctuations, making them suitable for various food processing environments. Always ensure the chosen material complies with local food safety regulations. -

How can I customize my conveyor belt to meet specific operational needs?

Customization can enhance the efficiency of your conveyor system. Begin by assessing your operational requirements, such as the types of products being transported, weight capacities, and environmental conditions. Most manufacturers offer customization options, including belt width, length, surface texture, and material. Collaborating closely with your supplier during the design phase can ensure that the final product meets your unique specifications and enhances overall performance. -

What are the minimum order quantities (MOQs) for conveyor belts?

Minimum order quantities can vary significantly among suppliers based on the type of conveyor belt and the level of customization required. Typically, standard products may have lower MOQs, while specialized or custom belts could require larger orders. Always clarify MOQs with potential suppliers during the sourcing process to ensure they align with your production needs. Understanding these terms can help you avoid excess inventory or delays in procurement. -

What payment terms should I expect when purchasing conveyor belts internationally?

Payment terms can differ widely based on the supplier and the specific transaction. Common terms include advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60). It’s advisable to negotiate terms that provide security for both parties. Ensure that you understand any additional costs, such as shipping and customs duties, as these can affect your overall budget. Always confirm payment methods that are secure and reliable for international transactions. -

How can I ensure quality assurance (QA) for my conveyor belt purchase?

To ensure quality, request certifications from your supplier that demonstrate compliance with industry standards. Inquire about their QA processes, including materials testing and production inspections. Consider visiting the manufacturing facility if feasible, or request samples to evaluate the belt’s performance. Additionally, establishing a clear communication channel with the supplier can help address any quality concerns promptly and effectively. -

What logistics considerations should I keep in mind when sourcing conveyor belts internationally?

When sourcing internationally, consider shipping times, customs clearance, and freight costs. Work with suppliers who have a proven logistics network to facilitate timely delivery. Understanding local regulations, tariffs, and duties can also help avoid unexpected costs. Collaborating with a logistics partner experienced in international shipping can streamline the process and ensure that your conveyor belts arrive on schedule and in optimal condition. -

How do I vet potential suppliers for conveyor belts?

To effectively vet suppliers, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients. Verify their manufacturing capabilities and certifications, and assess their responsiveness to inquiries. Request references and visit their facilities if possible to gauge their operations. Establishing a good rapport and clear communication channels during initial interactions can also provide insights into their reliability and customer service standards.

Top 2 Conveyor Belts For Consumer Packaged Goods Manufacturers & Suppliers List

1. Ashland Conveyor – Conveyor Belts

Domain: ashlandconveyor.com

Registered: 1999 (26 years)

Introduction: Ashland Conveyor offers various types of conveyor belts for upgrades or replacements, including General purpose PVC, Incline and Severe Incline, Food Grade, and Heavy-Duty belts. All belts can be purchased with factory-installed lacing options, including stainless steel and endless finger lacing. Belt widths available include 6, 12, 18, 24, 30, and 36 inches.

2. QC Conveyors – Key Products

Domain: qcconveyors.com

Registered: 2013 (12 years)

Introduction: QC Conveyors offers a diverse range of conveyor systems suitable for automation, packaging, and material handling applications. Key product series include:

1. **Automation Series**:

– **AS40**: Versatile for various applications.

– **AS40-CD**: Drive can be positioned at different locations.

– **AS40-Z**: Angled design available in three configurations.

– **AS80**: Widest, longes…

Strategic Sourcing Conclusion and Outlook for conveyor belts for consumer packaged goods

In the fast-evolving landscape of consumer packaged goods, strategic sourcing of conveyor belts is paramount for operational efficiency and competitive advantage. By prioritizing quality and reliability, businesses can mitigate downtime and enhance productivity. The latest innovations in conveyor technology, such as modular and flexible chain systems, not only offer tailored solutions for diverse applications but also ensure compliance with stringent industry standards.

Understanding the specific needs of your operations—whether it’s temperature resistance, abrasion durability, or ease of maintenance—will enable you to make informed sourcing decisions. Engaging with reputable suppliers who provide robust customer support and rapid response capabilities can further streamline your operations and reduce lead times.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (e.g., Germany, Vietnam) navigate this dynamic market, embracing a strategic sourcing approach will be crucial. By investing in high-quality conveyor solutions, companies can position themselves for sustained growth and efficiency. Now is the time to partner with leading manufacturers, ensuring that your supply chain is not just reactive but proactively aligned with future demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to conveyor belts for consumer packaged goods