The Definitive Guide to Computer Keyboard Plastic Cover: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for computer keyboard plastic cover

As global businesses increasingly rely on technology for everyday operations, the demand for protective solutions like computer keyboard plastic covers has surged. Sourcing high-quality keyboard covers presents a unique challenge for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, where varying standards and product availability can complicate procurement efforts. This guide aims to streamline your purchasing process by providing a comprehensive overview of the types, applications, and benefits of computer keyboard plastic covers, ensuring that you make informed decisions tailored to your specific needs.

Within these pages, you will explore the diverse array of keyboard cover options, from disposable and washable types to custom-fit solutions designed for various industries, including healthcare, manufacturing, and education. We will also delve into supplier vetting processes, essential for identifying reliable partners who can meet your quality and compliance requirements. Additionally, cost considerations will be addressed, providing insights into budget-friendly options without compromising on durability or protection.

By equipping you with actionable insights and expert guidance, this guide empowers international B2B buyers to navigate the complexities of the global market for computer keyboard plastic covers. With the right knowledge, you can protect your valuable technology investments while maintaining operational efficiency in your organization.

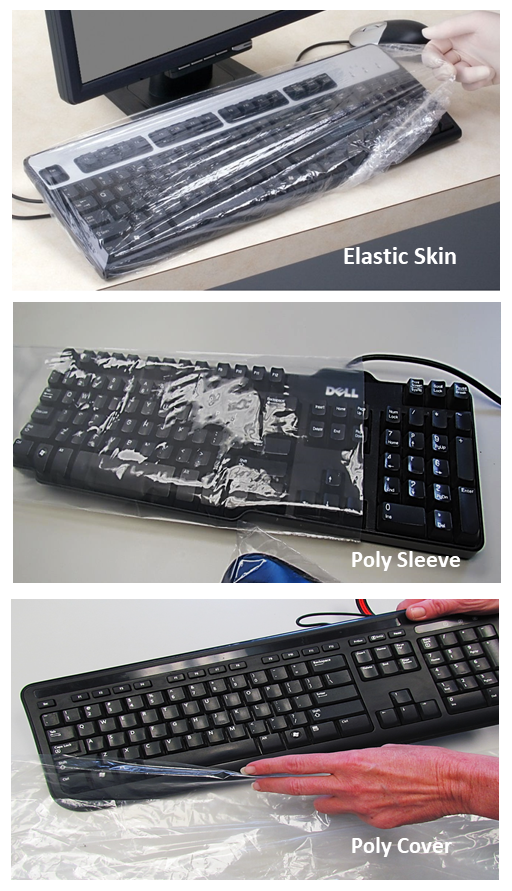

Understanding computer keyboard plastic cover Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicone Keyboard Covers | Flexible, waterproof, and dustproof; often antimicrobial | Healthcare, food processing, and industrial sectors | Pros: Easy to clean, durable; Cons: May reduce typing feel. |

| Polyurethane Keyboard Covers | Custom-fitted, sturdy, with adhesive lining for secure fit | Office environments, education, and manufacturing | Pros: Excellent protection against spills and dust; Cons: Higher cost than basic covers. |

| Disposable Keyboard Covers | Single-use, lightweight, often transparent | Medical facilities, laboratories, and food service | Pros: Hygienic, prevents cross-contamination; Cons: Not eco-friendly, ongoing cost. |

| Custom Keyboard Covers | Tailored designs, can include branding and specific layouts | Corporate offices, education, and promotional events | Pros: Enhances brand visibility, perfect fit; Cons: Longer lead times for production. |

| Rigid Plastic Keyboard Covers | Hard shell, robust protection against physical damage | Industrial settings, manufacturing, and logistics | Pros: High durability, protects against heavy use; Cons: Can be bulky and less comfortable. |

What Are Silicone Keyboard Covers and Their B2B Benefits?

Silicone keyboard covers are designed to provide flexible protection against spills, dust, and debris. Their waterproof and dustproof nature makes them particularly suitable for environments such as healthcare and food processing, where hygiene is paramount. When considering a purchase, B2B buyers should assess the cover’s antimicrobial properties, ease of cleaning, and how it affects typing comfort. While they offer durability and easy maintenance, some users may find the typing experience slightly compromised.

How Do Polyurethane Keyboard Covers Stand Out?

Polyurethane keyboard covers are custom-engineered for specific keyboard models, ensuring a snug fit that prevents slipping. These covers are ideal for office environments, educational institutions, and manufacturing facilities, where they shield keyboards from dust and spills. Buyers should evaluate the adhesive quality and the cover’s overall thickness to balance protection with typing comfort. While they provide excellent durability and protection, the cost may be a consideration for budget-conscious organizations.

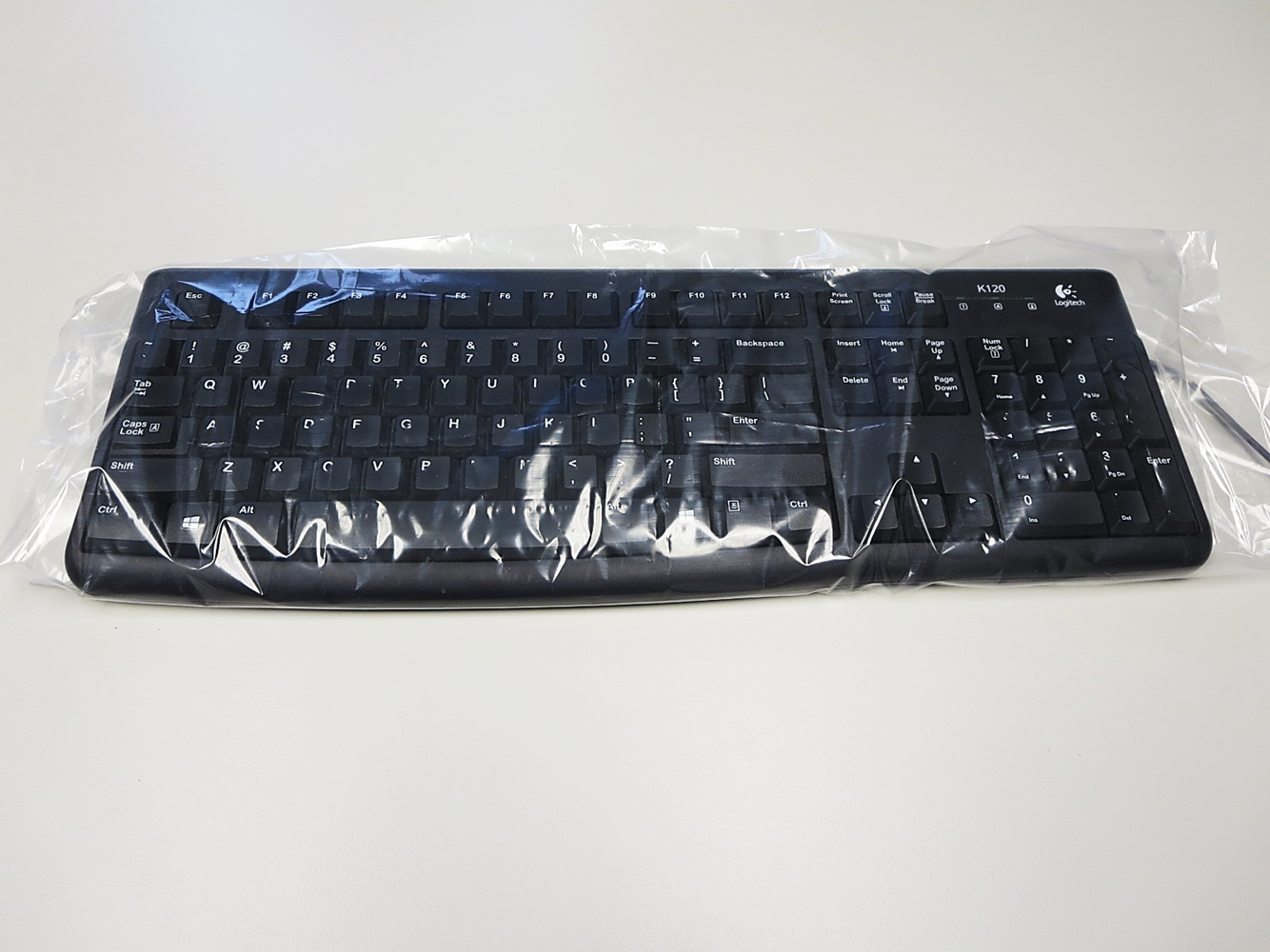

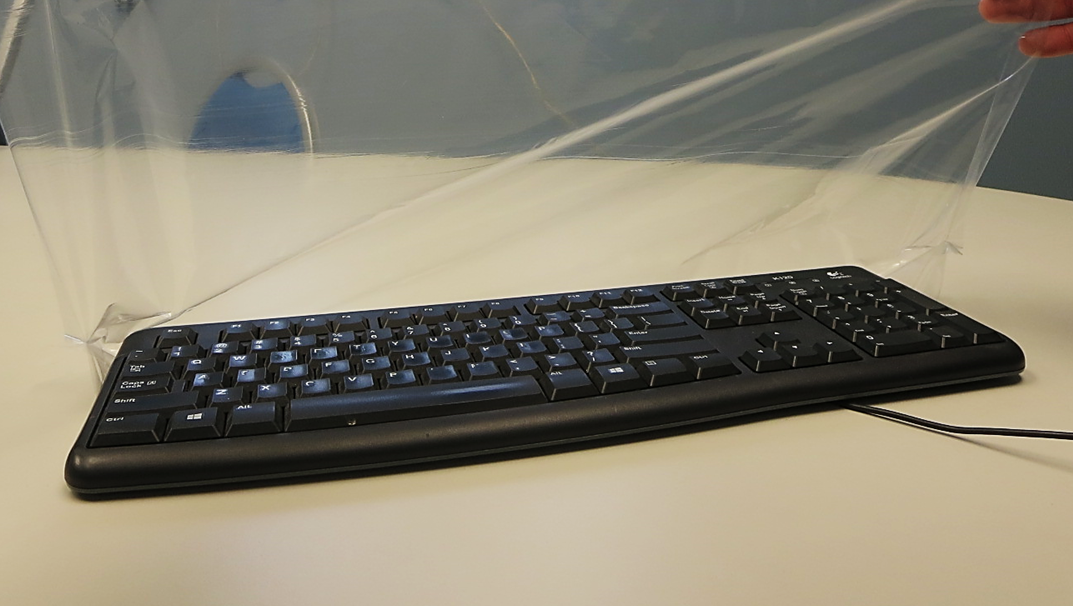

Why Choose Disposable Keyboard Covers for Hygiene?

Disposable keyboard covers are lightweight and designed for single-use, making them a go-to choice for medical facilities and laboratories. They serve as a barrier against germs, preventing cross-contamination in high-traffic areas. B2B buyers must consider the ongoing costs associated with purchasing these covers regularly, as well as their environmental impact. Despite these concerns, their hygienic nature and convenience make them a valuable asset in maintaining clean workspaces.

What Are the Advantages of Custom Keyboard Covers?

Custom keyboard covers allow businesses to tailor their protective solutions to specific needs, including branding and layout preferences. This type of cover is particularly beneficial for corporate offices and educational institutions that wish to promote their brand or provide personalized user experiences. When purchasing, organizations should consider the lead time for production and the potential for increased visibility. While they offer significant advantages in brand recognition, the customization process may require a longer turnaround.

How Do Rigid Plastic Keyboard Covers Provide Protection?

Rigid plastic keyboard covers offer robust protection against physical damage, making them suitable for industrial and manufacturing settings. They are designed to withstand heavy use and are often resistant to chemicals and moisture. Buyers should assess the weight and bulkiness of these covers, as they might affect the overall typing experience. While their durability is a strong selling point, organizations should ensure that the covers do not hinder productivity due to their design.

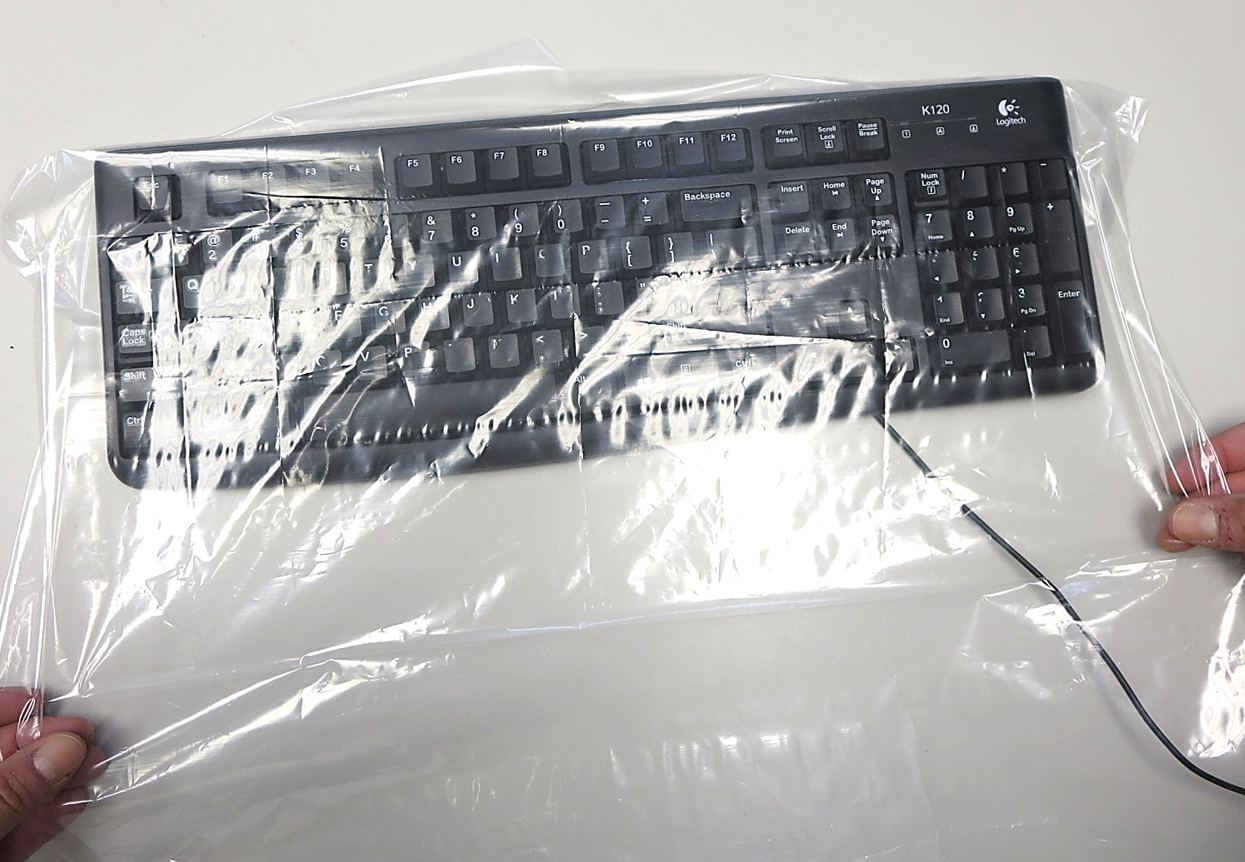

Illustrative image related to computer keyboard plastic cover

Key Industrial Applications of computer keyboard plastic cover

| Industry/Sector | Specific Application of computer keyboard plastic cover | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Protecting keyboards in hospitals and clinics | Reduces the risk of contamination and enhances hygiene | Look for antimicrobial materials and easy-to-clean designs |

| Food Processing | Safeguarding keyboards in food production environments | Ensures compliance with food safety regulations | Materials must be food-safe and resistant to spills |

| Education | Use in classrooms and labs | Protects equipment from spills and wear, extending lifespan | Consider durability and ease of installation for frequent use |

| Industrial Manufacturing | Shields keyboards in manufacturing plants | Prevents dust and debris accumulation, enhancing equipment longevity | Evaluate resistance to chemicals and heavy-duty usage |

| IT and Data Centers | Covering keyboards in server rooms | Protects sensitive equipment from dust and accidental spills | Requires custom fits for various keyboard types and layouts |

How Are Computer Keyboard Plastic Covers Used in the Healthcare Sector?

In healthcare settings, computer keyboard plastic covers are essential for maintaining hygiene and preventing cross-contamination. These covers are designed to be easily cleaned and often feature antimicrobial properties, which are crucial in environments like hospitals and clinics where infection control is paramount. Buyers in this sector should prioritize sourcing covers that are compatible with various keyboard models and can withstand regular disinfection processes without degrading.

What Role Do Keyboard Covers Play in Food Processing Environments?

In food processing facilities, keyboard plastic covers provide a crucial barrier against spills and contaminants that could compromise food safety. These covers help businesses comply with stringent hygiene regulations by preventing the accumulation of food particles and moisture, which can lead to bacterial growth. When sourcing, buyers must ensure that materials used are food-safe and easily washable to maintain compliance with health standards.

How Are Keyboard Covers Beneficial in Educational Settings?

Educational institutions utilize computer keyboard covers to protect equipment from spills, dirt, and everyday wear and tear, especially in labs and classrooms where students frequently use computers. These covers help extend the lifespan of keyboards, making them a cost-effective solution for schools. Buyers should consider durability, ease of installation, and the ability to fit various keyboard styles when sourcing for educational applications.

Why Are Keyboard Covers Important in Industrial Manufacturing?

In industrial manufacturing environments, keyboard plastic covers are vital for protecting keyboards from dust, debris, and harsh chemicals that can significantly shorten the lifespan of equipment. These covers help maintain a clean workspace and reduce maintenance costs associated with equipment failure. Buyers should focus on sourcing heavy-duty covers that offer chemical resistance and can withstand the rigors of industrial use.

Illustrative image related to computer keyboard plastic cover

How Do Keyboard Covers Benefit IT and Data Centers?

In IT and data centers, keyboard plastic covers protect sensitive equipment from dust and accidental spills, which can disrupt operations and lead to costly downtime. These covers are often custom-fitted to accommodate various keyboard layouts and types, ensuring maximum protection. When sourcing, businesses should look for covers that offer both durability and ease of cleaning, as maintenance is critical in these high-stakes environments.

3 Common User Pain Points for ‘computer keyboard plastic cover’ & Their Solutions

Scenario 1: Ensuring Compatibility with Diverse Keyboard Models

The Problem: A common challenge faced by B2B buyers, especially those managing large inventories of computers, is ensuring that keyboard plastic covers fit various keyboard models. With manufacturers producing countless models, discrepancies in dimensions and layouts can lead to frustration. When the wrong cover is ordered, it results in wasted resources and time, ultimately impacting productivity.

The Solution: To mitigate compatibility issues, B2B buyers should prioritize sourcing from suppliers that offer a comprehensive catalog of covers tailored for specific keyboard models. Before placing bulk orders, utilize samples to verify fit and functionality. Additionally, consider working closely with manufacturers who provide customization options. This might include bespoke designs that cater to unique keyboard specifications or offering covers in varying thicknesses and materials. Leveraging technology, such as 3D scanning, can also help accurately assess the required dimensions and ensure a perfect match.

Illustrative image related to computer keyboard plastic cover

Scenario 2: Balancing Durability with User Comfort

The Problem: In environments such as healthcare or manufacturing, where keyboard covers are essential for hygiene and protection, buyers often struggle to find a balance between durability and user comfort. Heavy-duty covers may protect against spills and dirt but can hinder typing speed and accuracy, which is crucial in fast-paced settings.

The Solution: The solution lies in selecting keyboard covers made from high-quality, flexible materials like silicone or polyurethane. These materials offer robust protection against liquids and contaminants while maintaining a comfortable typing experience. Buyers should also consider covers with textured surfaces that enhance grip and tactile feedback, allowing users to type efficiently without feeling obstructed. Engaging with suppliers who specialize in ergonomic designs can also yield options that cater specifically to user comfort without compromising on protection.

Scenario 3: Managing Hygiene Standards in High-Traffic Areas

The Problem: In sectors like education, food service, and healthcare, maintaining hygiene is paramount. B2B buyers often face the challenge of ensuring that keyboard covers can withstand frequent cleaning and disinfection without degrading. Inadequate protection can lead to cross-contamination, putting both staff and customers at risk.

The Solution: Buyers should look for keyboard covers that are explicitly designed to be washable and resistant to harsh cleaning agents. Selecting covers with antimicrobial properties can also provide an additional layer of defense against germs. When sourcing these products, it’s crucial to verify that they meet industry hygiene standards and are suitable for the intended environment. Implementing a regular cleaning schedule with recommended cleaning solutions will ensure that the covers remain effective. Collaborating with suppliers who offer education on proper maintenance and usage of these covers can further enhance hygiene practices and prolong the lifespan of both the covers and the keyboards they protect.

By addressing these common pain points with actionable solutions, B2B buyers can make informed decisions that enhance productivity, maintain hygiene, and protect their investments in technology.

Illustrative image related to computer keyboard plastic cover

Strategic Material Selection Guide for computer keyboard plastic cover

When selecting materials for computer keyboard plastic covers, several factors must be considered, including durability, cost, and specific application requirements. Below, we analyze four common materials used in the production of these protective covers.

What are the Key Properties of Polyurethane for Keyboard Covers?

Polyurethane is a versatile polymer known for its elasticity and resilience. It can withstand a wide range of temperatures and is resistant to abrasion and chemicals, making it suitable for various environments. Its temperature resistance typically ranges from -30°C to 80°C, allowing it to perform well under different operating conditions.

Pros and Cons: Polyurethane covers are highly durable and provide excellent protection against spills, dust, and wear. However, the manufacturing process can be complex, leading to higher costs. While it is suitable for many applications, it may not be the best choice for environments with extreme temperatures.

Illustrative image related to computer keyboard plastic cover

Impact on Application: Polyurethane’s chemical resistance makes it compatible with various cleaning agents, which is essential for maintaining hygiene in settings like healthcare and food processing.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local standards, such as ASTM or ISO certifications, to guarantee product quality and safety.

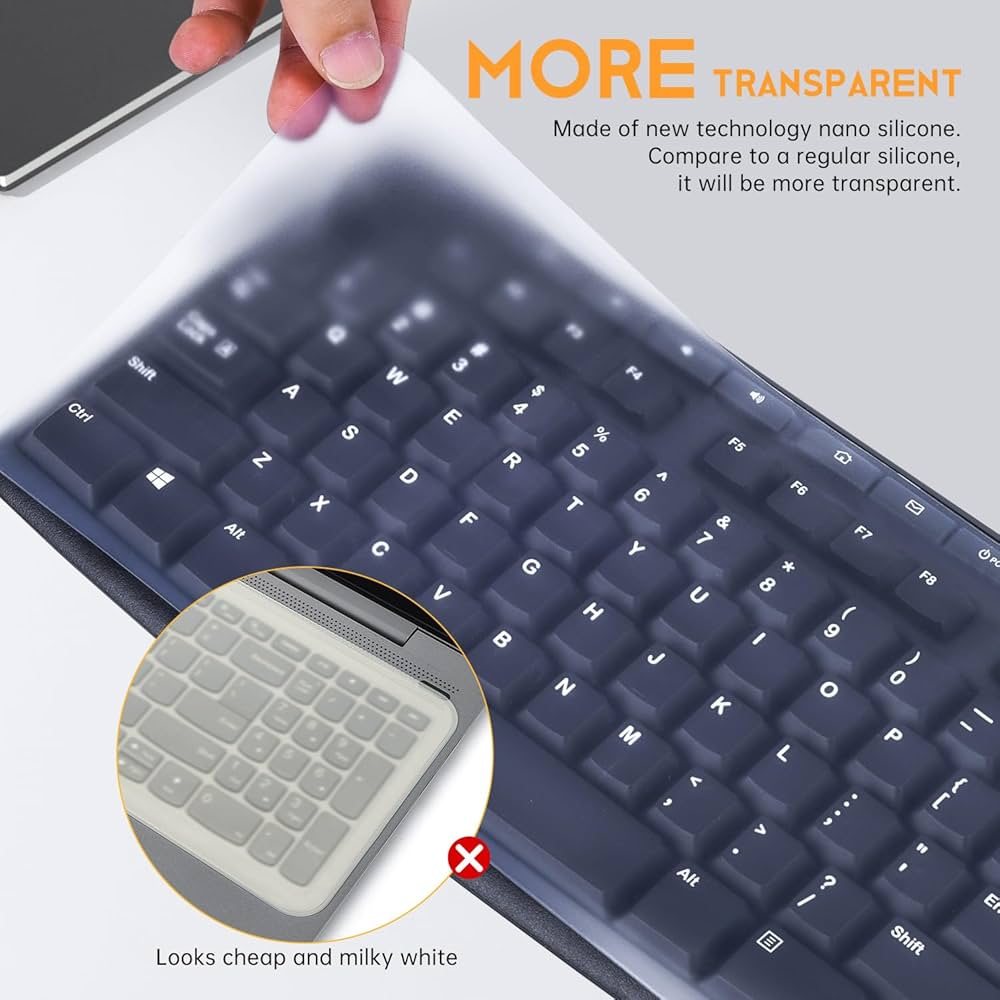

How Does Silicone Compare as a Material for Keyboard Covers?

Silicone is another popular choice for keyboard covers due to its flexibility and non-toxic properties. It can withstand extreme temperatures, typically from -60°C to 200°C, making it ideal for high-temperature environments.

Pros and Cons: Silicone covers are soft and provide a comfortable typing experience, while also being easy to clean. However, they can be more expensive than other materials, and their durability may not match that of polyurethane in high-abrasion environments.

Illustrative image related to computer keyboard plastic cover

Impact on Application: Silicone’s resistance to moisture and chemicals makes it suitable for use in laboratories and industrial settings where spills are common.

Considerations for International Buyers: B2B buyers should look for silicone products that meet international safety standards, especially in industries such as food processing and healthcare.

What are the Benefits of Using PVC for Keyboard Covers?

Polyvinyl chloride (PVC) is a widely used plastic known for its affordability and durability. It is resistant to many chemicals and can be manufactured in various thicknesses.

Pros and Cons: PVC covers are cost-effective and provide decent protection against dust and spills. However, they may not be as durable as silicone or polyurethane and can become brittle over time, especially when exposed to UV light.

Illustrative image related to computer keyboard plastic cover

Impact on Application: PVC is suitable for standard office environments but may not hold up well in high-temperature or high-abrasion applications.

Considerations for International Buyers: Buyers should be aware of environmental regulations regarding PVC, as some regions have restrictions on its use due to environmental concerns.

How Does ABS Fit into the Material Selection for Keyboard Covers?

Acrylonitrile Butadiene Styrene (ABS) is a strong and impact-resistant thermoplastic. It is known for its toughness and ability to withstand moderate temperatures, typically ranging from -20°C to 80°C.

Illustrative image related to computer keyboard plastic cover

Pros and Cons: ABS covers are durable and provide good protection against physical impacts. However, they are less resistant to chemicals compared to silicone and polyurethane, which may limit their application in certain environments.

Impact on Application: ABS is often used in environments where impact resistance is critical, such as manufacturing facilities.

Considerations for International Buyers: Compliance with international standards like ISO is crucial for ensuring product safety and effectiveness, especially in industrial applications.

Summary of Material Selection for Keyboard Covers

| Material | Typical Use Case for computer keyboard plastic cover | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Healthcare, food processing, industrial environments | Excellent durability and chemical resistance | Higher manufacturing complexity and cost | Medium |

| Silicone | Laboratories, industrial settings, high-temperature environments | Flexible, comfortable, and easy to clean | More expensive, durability may vary | High |

| PVC | Standard office environments | Cost-effective and decent protection | Can become brittle and less durable over time | Low |

| ABS | Manufacturing facilities, environments requiring impact resistance | Strong and impact-resistant | Less chemical resistance compared to others | Medium |

This guide provides a comprehensive overview of the materials available for computer keyboard plastic covers, assisting international B2B buyers in making informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for computer keyboard plastic cover

What are the Main Stages in the Manufacturing Process of Computer Keyboard Plastic Covers?

The manufacturing process of computer keyboard plastic covers involves several critical stages, each essential for producing high-quality protective products. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to computer keyboard plastic cover

-

Material Preparation: The first step begins with sourcing high-quality materials. Typically, polyurethane and silicone are used due to their durability and flexibility. Suppliers must ensure that these materials meet industry standards for safety and performance. The raw materials are then cut and prepped to the required specifications for the keyboard models they will cover.

-

Forming: In this phase, the prepared materials are shaped into covers using techniques such as injection molding or thermoforming. Injection molding involves injecting molten plastic into a mold, allowing for precise shapes and dimensions. Thermoforming, on the other hand, entails heating a plastic sheet until pliable and then forming it over a mold. Both methods require careful control of temperature and pressure to ensure consistency and prevent defects.

-

Assembly: Once the covers are formed, they may require additional components, such as adhesive linings or branding elements. This assembly process is often automated to enhance efficiency and accuracy. Automated systems also help maintain uniformity across large production runs, which is crucial for B2B buyers requiring bulk orders.

-

Finishing: The final stage involves applying any necessary finishing touches to the covers. This may include surface treatments for additional durability or aesthetics, such as anti-static coatings or custom printing. Quality checks are conducted throughout this stage to ensure that the final product meets the specified requirements.

Which Key Techniques Are Used in Manufacturing Keyboard Covers?

Several advanced manufacturing techniques enhance the quality and functionality of keyboard plastic covers. These include:

-

Injection Molding: This technique is particularly favored for its ability to produce high volumes of uniform products quickly. It allows for intricate designs and the incorporation of features like flexible key areas.

-

Thermoforming: This method is utilized for creating custom shapes that fit specific keyboard layouts. It’s often used for lower production runs or specialized orders.

-

UV Printing: For branding and customization, UV printing allows for high-resolution graphics directly onto the surface of the covers. This is essential for B2B clients seeking unique designs or logos.

-

Adhesive Technology: Many covers utilize advanced adhesive solutions for a secure fit. This technology ensures that the covers remain in place, even with regular use.

What Quality Assurance Standards Are Relevant for Keyboard Cover Manufacturing?

Quality assurance is paramount in the manufacturing of keyboard covers to ensure product reliability and safety. International standards such as ISO 9001 are critical for manufacturers, as they outline requirements for a quality management system. Compliance with this standard signifies that the manufacturer consistently meets customer and regulatory requirements.

Additionally, industry-specific certifications may be relevant, such as:

- CE Marking: Ensures that the product meets European safety and health requirements.

- API Standards: Relevant for manufacturers supplying industries where contamination control is crucial, such as healthcare or food processing.

What Are the Key Quality Control Checkpoints in the Production of Keyboard Covers?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure that the final product meets specifications. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection involves evaluating raw materials upon delivery. Suppliers should verify that the materials conform to specifications and are free from defects.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor production parameters, such as temperature and pressure during forming. This ensures that any deviations are addressed promptly.

-

Final Quality Control (FQC): After finishing, covers undergo a final inspection to assess overall quality, appearance, and functionality. This step may include physical testing, such as flexibility and durability assessments.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability. Here are actionable steps to achieve this:

Illustrative image related to computer keyboard plastic cover

-

Supplier Audits: Conduct regular audits of potential suppliers. This can include on-site inspections to evaluate their manufacturing processes, QC procedures, and compliance with relevant standards.

-

Request Quality Reports: Buyers should ask for detailed quality reports that outline the results of inspections and tests conducted at various checkpoints. This documentation provides insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engage third-party inspection agencies to conduct independent evaluations of the supplier’s facilities and products. This adds an extra layer of assurance regarding compliance and quality.

-

Certification Verification: Buyers should verify the authenticity of certifications claimed by suppliers, such as ISO 9001 or CE marking. This can typically be done through the certifying body’s website or by contacting them directly.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

B2B buyers operating across different regions must navigate various certification requirements and quality control nuances. For instance:

-

Regional Compliance: Understand the specific compliance requirements of each target market. For example, while CE marking is essential for European markets, other regions may have distinct standards.

-

Cultural Considerations: Different cultures may have varying expectations regarding quality. Buyers should familiarize themselves with the local market’s standards and practices.

-

Language Barriers: Ensure that all documentation, including certifications and reports, is available in a language that is understandable to the buyer. This facilitates better communication and understanding of quality standards.

-

Long-Term Partnerships: Establishing long-term relationships with suppliers can enhance trust and facilitate smoother quality assurance processes. Regular communication and feedback can help improve product quality over time.

By understanding these manufacturing processes, quality assurance standards, and verification methods, B2B buyers can make informed decisions when sourcing computer keyboard plastic covers. This knowledge not only aids in selecting reliable suppliers but also ensures that the products meet their operational needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘computer keyboard plastic cover’

Introduction

This practical sourcing guide aims to assist B2B buyers in procuring high-quality computer keyboard plastic covers. These covers are essential for protecting keyboards from dust, spills, and wear, ultimately extending their lifespan. By following this checklist, buyers can ensure they select the right products and suppliers that meet their specific needs.

Step 1: Define Your Technical Specifications

Before starting the procurement process, it’s vital to identify the technical specifications required for the keyboard covers. Consider factors such as size, material (e.g., polyurethane, silicone), and compatibility with specific keyboard models. This clarity will help you narrow down your options and ensure that the covers fit perfectly and function effectively.

- Material Considerations: Look for covers that are durable, easy to clean, and resistant to spills and contaminants.

- Compatibility: Ensure that the covers match the exact model of keyboards you intend to protect.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in computer keyboard covers. Evaluate their product offerings, reputation, and market presence. This step is crucial as it sets the foundation for your sourcing process.

- Industry Experience: Look for suppliers with experience in your specific industry, as they will better understand your needs.

- Customer Reviews: Check testimonials and case studies to gauge the quality of their products and services.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and comply with industry standards. Certifications can indicate quality assurance and adherence to safety regulations, which are particularly important in sectors like healthcare and education.

- Quality Standards: Look for ISO certifications or similar quality management certifications.

- Compliance: Ensure that the products meet any specific regional regulations that may apply, especially if importing.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples from shortlisted suppliers. Testing samples allows you to evaluate the product quality, fit, and usability firsthand. This step minimizes the risk of dissatisfaction after purchase.

- Functionality Testing: Check for ease of use, comfort while typing, and how well the cover protects against spills and dirt.

- Durability Assessment: Assess the material’s resilience to wear and tear, especially if used in high-traffic environments.

Step 5: Inquire About Customization Options

Many suppliers offer customization for keyboard covers, including size, color, and branding options. Discuss these possibilities with your suppliers, as customization can enhance the functionality and aesthetic appeal of the covers.

- Branding: Consider adding your logo to the covers for brand visibility.

- Specific Features: Ask about additional features like antimicrobial properties, which can be beneficial in certain environments.

Step 6: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations to secure favorable pricing and payment terms. Bulk purchasing often leads to discounts, so inquire about volume pricing and any available promotions.

- Payment Terms: Clarify payment terms, including deposit requirements and payment methods.

- Shipping Costs: Discuss shipping options and costs, particularly for international deliveries, to avoid unexpected expenses.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan with your chosen supplier. Effective communication is essential for addressing any concerns that may arise during the procurement process and ensuring timely deliveries.

- Regular Updates: Schedule regular check-ins to discuss order status and resolve any issues promptly.

- Feedback Mechanism: Establish a process for providing feedback on product quality and service, which can help improve future orders.

By following this checklist, B2B buyers can streamline their sourcing process for computer keyboard plastic covers and make informed decisions that meet their operational needs.

Comprehensive Cost and Pricing Analysis for computer keyboard plastic cover Sourcing

What Are the Key Cost Components for Sourcing Computer Keyboard Plastic Covers?

When sourcing computer keyboard plastic covers, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of material significantly impacts the overall cost. Common options include polyurethane, silicone, and PVC, each offering varying levels of durability and protection. Premium materials may offer better resistance to spills and dust but will come at a higher price point.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with lower labor costs may provide more competitive pricing, but it’s essential to balance this with quality and reliability.

-

Manufacturing Overhead: This includes costs associated with running manufacturing facilities, such as utilities and equipment maintenance. Efficient production processes can help minimize these costs.

-

Tooling: Custom designs may require specialized tooling, which can be a significant upfront investment. However, this cost can be amortized over larger production runs, making it more economical for high-volume orders.

-

Quality Control: Ensuring product quality through rigorous QC processes is vital, especially for industries requiring compliance with safety standards. Higher QC costs can lead to better product performance and customer satisfaction.

-

Logistics: Shipping costs are influenced by the volume of the order, the distance to the destination, and the chosen Incoterms. Understanding these factors can help buyers budget effectively.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. This can vary widely depending on the supplier’s market position and the competitiveness of their offerings.

What Influences Pricing for Computer Keyboard Plastic Covers?

Several factors can influence the pricing of keyboard plastic covers, including volume, specifications, materials, quality certifications, and supplier relationships.

-

Volume/MOQ: Suppliers often offer tiered pricing based on order volume. Higher Minimum Order Quantities (MOQs) can lead to significant savings per unit. Buyers should consider their usage rates to negotiate favorable pricing.

-

Specifications and Customization: Custom designs or specific features (like antimicrobial properties) can increase costs. Buyers should assess whether these features align with their needs and if the added expense justifies the benefits.

-

Materials and Quality Certifications: Premium materials and products that meet international quality standards (like ISO certifications) generally command higher prices. Buyers in regulated industries, such as healthcare, may need to prioritize certified products despite the higher cost.

-

Supplier Factors: Establishing a strong relationship with suppliers can lead to better pricing and terms. Suppliers who understand your business needs may offer more competitive rates or flexible payment terms.

-

Incoterms: The choice of Incoterms impacts the total cost of ownership. Understanding who is responsible for shipping, insurance, and customs can help buyers avoid unexpected expenses.

What Are the Best Practices for B2B Buyers in Negotiating Prices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation and understanding pricing nuances are vital.

Illustrative image related to computer keyboard plastic cover

-

Conduct Market Research: Familiarize yourself with market prices and trends to negotiate effectively. Knowing the average costs can empower you during discussions.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with the product, including shipping, duties, and potential warranty or service costs. This broader perspective will inform your purchasing decision.

-

Leverage Long-Term Relationships: Building a long-term partnership with suppliers can lead to better pricing and terms. Regular orders or commitments can often result in discounts.

-

Be Open to Alternatives: If a supplier cannot meet your budget, consider discussing alternative materials or designs that may lower costs without sacrificing quality.

-

Understand Payment Terms: Negotiate favorable payment terms, such as extended payment periods, to improve cash flow while still securing the necessary supplies.

By considering these factors and strategies, B2B buyers can navigate the complexities of sourcing computer keyboard plastic covers, ensuring they achieve the best possible value for their investment.

Alternatives Analysis: Comparing computer keyboard plastic cover With Other Solutions

Exploring Alternatives to Computer Keyboard Plastic Covers

In the pursuit of protecting computer keyboards from dust, spills, and wear, several solutions exist beyond traditional plastic covers. Understanding the strengths and weaknesses of these alternatives can help B2B buyers make informed decisions tailored to their specific needs. Below, we compare computer keyboard plastic covers with two viable alternatives: silicone keyboard covers and disposable keyboard covers.

| Comparison Aspect | Computer Keyboard Plastic Cover | Silicone Keyboard Cover | Disposable Keyboard Cover |

|---|---|---|---|

| Performance | Excellent protection against spills and dust; maintains a comfortable typing feel. | Good protection; flexible and durable but may not fit all keyboard designs perfectly. | Provides basic protection against dirt and germs; less durable. |

| Cost | Moderate ($13 – $19 per unit) | Similar price range ($15 – $25 per unit) | Lower cost per unit ($0.50 – $3 per unit) |

| Ease of Implementation | Easy to install; fits securely to specific keyboard models. | Simple to apply but may require adjustments for snug fit. | Extremely easy; just place over the keyboard. |

| Maintenance | Low maintenance; easy to clean and reuse. | Washable and reusable but requires regular cleaning to maintain hygiene. | Single-use; no maintenance required but must be replaced frequently. |

| Best Use Case | Ideal for long-term protection in offices, schools, and homes. | Suitable for environments needing frequent cleaning, such as healthcare or food service. | Best for high-traffic areas where hygiene is critical, such as hospitals or labs. |

Detailed Breakdown of Alternatives

What Are Silicone Keyboard Covers and How Do They Compare?

Silicone keyboard covers are flexible, often molded to fit various keyboard designs. They offer decent protection against spills and dirt while allowing for a tactile typing experience. However, their adaptability can be a double-edged sword; they might not fit all keyboard models perfectly, leading to potential gaps that could allow debris to infiltrate. On the cost front, silicone covers are generally priced similarly to plastic covers but may require more frequent cleaning to maintain hygiene, especially in environments with high contamination risks.

What Are Disposable Keyboard Covers and Their Advantages?

Disposable keyboard covers are designed for single-use applications, making them particularly attractive in settings like hospitals, laboratories, and food service areas. These covers are cost-effective, typically priced between $0.50 and $3 each, which allows for easy replacement without a significant financial burden. The major downside, however, is their lack of durability and environmental impact, as they generate more waste compared to reusable solutions. While they provide basic protection against dirt and germs, they do not offer the same level of comfort and usability as their plastic or silicone counterparts.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a keyboard protection solution, B2B buyers should evaluate their specific environment and requirements. For long-term protection with a focus on comfort, computer keyboard plastic covers are often the best choice. In contrast, silicone covers may serve well in environments requiring frequent cleaning, while disposable covers are ideal for settings where hygiene is paramount but budget constraints exist. Assessing the balance between cost, performance, and maintenance will empower buyers to make the most effective choice for their organizational needs.

Essential Technical Properties and Trade Terminology for computer keyboard plastic cover

What Are the Key Technical Properties of Computer Keyboard Plastic Covers?

When selecting computer keyboard plastic covers, several technical properties should be considered to ensure product quality and compatibility with various applications. Here are some critical specifications:

-

Material Grade:

Keyboard covers are typically made from materials such as polyurethane, silicone, or PVC. Polyurethane is preferred for its durability and resistance to chemicals, while silicone offers flexibility and ease of cleaning. Understanding material grade helps buyers assess the cover’s lifespan and suitability for specific environments, such as medical or industrial settings. -

Thickness:

The thickness of the cover affects its durability and tactile response. A thicker cover may provide better protection against spills and dust but can reduce the tactile feel of the keyboard. Buyers should balance protection needs with usability, especially in environments where quick typing is essential. -

Fit and Compatibility:

Covers should be tailored to specific keyboard models to ensure a snug fit. This is crucial for preventing slippage and ensuring that the cover does not interfere with key functionality. Providing precise dimensions and compatibility information helps buyers make informed decisions and reduces the risk of returns. -

Chemical Resistance:

Given that keyboard covers are often used in environments with exposure to cleaning agents or other harsh substances, chemical resistance is a vital property. This ensures that the cover will not degrade or become discolored over time, maintaining its protective qualities and appearance. -

Washability:

Many covers are designed to be washable, either by hand or machine. This feature is essential for maintaining hygiene, particularly in healthcare and food service environments. Buyers should inquire about the washability of the cover to ensure compliance with their cleaning protocols. -

Antimicrobial Properties:

Some keyboard covers are treated with antimicrobial agents to inhibit the growth of bacteria and fungi. This property is especially important in healthcare settings, where infection control is paramount. Understanding the antimicrobial capabilities can help buyers select products that enhance workplace safety.

What Are Common Trade Terms Associated with Computer Keyboard Plastic Covers?

Familiarity with industry terminology can significantly enhance communication and negotiation with suppliers. Here are essential trade terms relevant to computer keyboard plastic covers:

-

OEM (Original Equipment Manufacturer):

This term refers to companies that produce parts or products that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in sourcing high-quality, compatible covers for specific keyboard brands. -

MOQ (Minimum Order Quantity):

MOQ is the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of MOQ requirements, as they can affect inventory management and cost efficiency, especially for businesses that may not need large volumes. -

RFQ (Request for Quotation):

An RFQ is a document issued when an organization wants to procure products or services and invites suppliers to submit price proposals. This is a crucial step in the purchasing process, allowing buyers to compare prices and terms from multiple vendors. -

Incoterms (International Commercial Terms):

These are standardized international trade terms that define the responsibilities of buyers and sellers. Understanding Incoterms is essential for clarifying shipping responsibilities, costs, and risk management, particularly in cross-border transactions. -

Lead Time:

This term refers to the amount of time from the placement of an order to the delivery of the product. Knowing the lead time is crucial for planning and inventory management, especially for businesses operating in fast-paced environments. -

Custom Options:

Many suppliers offer customizable features for keyboard covers, such as size, color, and branding. This flexibility allows buyers to tailor products to their specific needs, enhancing brand visibility and user experience.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product effectiveness in their respective markets.

Navigating Market Dynamics and Sourcing Trends in the computer keyboard plastic cover Sector

What Are the Current Market Dynamics and Key Trends in the Computer Keyboard Plastic Cover Sector?

The global market for computer keyboard plastic covers is evolving, driven by increasing awareness of hygiene and equipment longevity. In regions like Africa, South America, the Middle East, and Europe, demand for protective solutions has surged, particularly in sectors such as healthcare, education, and industrial environments. B2B buyers are increasingly looking for durable, high-quality products that can withstand harsh conditions while providing a clean and safe working environment.

Emerging trends include the growing preference for custom-fit covers tailored to specific keyboard models, as well as a rise in disposable options for environments requiring high hygiene standards, such as medical facilities. Additionally, there is a notable shift towards multifunctional covers that not only protect but also enhance the user experience—features like touchpad integration and antimicrobial properties are becoming standard.

Moreover, the expansion of e-commerce platforms has facilitated international trade, allowing buyers from diverse regions to access a broader range of products. With the integration of advanced materials like polyurethane and silicone, manufacturers are focusing on creating covers that offer both protection and comfort, catering to the preferences of modern workplaces.

How Is Sustainability and Ethical Sourcing Influencing B2B Purchases in the Keyboard Plastic Cover Market?

Sustainability has become a pivotal consideration in the B2B purchasing process for computer keyboard plastic covers. As businesses globally face increasing pressure to adopt environmentally responsible practices, buyers are keen to source products that minimize environmental impact. This includes a preference for covers made from recyclable or biodegradable materials, which help in reducing plastic waste.

Ethical sourcing is equally important; companies are scrutinizing their supply chains to ensure compliance with labor laws and environmental regulations. B2B buyers are increasingly favoring suppliers who can demonstrate a commitment to sustainable practices through certifications such as ISO 14001 or the use of recycled materials in their products.

The demand for ‘green’ products is not just a trend; it reflects a shift in consumer behavior that values sustainability. By aligning their purchasing decisions with these values, B2B buyers can enhance their brand reputation and appeal to environmentally conscious consumers, thereby gaining a competitive edge in the market.

How Has the Computer Keyboard Plastic Cover Market Evolved Over Time?

The computer keyboard plastic cover market has undergone significant transformation since its inception. Initially, these covers were simple, utilitarian products designed solely for protection against dust and spills. However, as technology advanced and user needs evolved, manufacturers began to innovate, introducing features that enhance both functionality and aesthetics.

The shift towards customization became prominent in the late 2000s, as businesses sought tailored solutions that fit specific keyboard models and user preferences. The introduction of materials that offer antimicrobial properties and improved durability has further expanded the market, catering to a diverse range of applications from healthcare to corporate environments.

Today, the market is characterized by a blend of practicality and advanced design, reflecting a deeper understanding of user needs and environmental considerations. As the demand for high-quality protective solutions continues to grow, the industry is poised for further innovation and expansion, paving the way for future developments that prioritize both performance and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of computer keyboard plastic cover

-

How can I ensure the keyboard plastic covers I purchase are compatible with my specific models?

To ensure compatibility, always provide your keyboard model number to suppliers when inquiring about plastic covers. Most manufacturers offer a variety of custom-fit options based on specific keyboard models. You can also request samples or product specifications to verify the fit before placing a bulk order. Additionally, check if the supplier has a comprehensive catalog or product guide that lists compatible models to simplify your sourcing process. -

What is the best material for keyboard plastic covers in high-use environments?

Polyurethane is often regarded as the best material for keyboard plastic covers in high-use environments due to its durability and resistance to spills, dust, and harsh chemicals. It provides a comfortable typing experience while ensuring long-lasting protection. For environments such as healthcare or manufacturing, where hygiene is paramount, consider antimicrobial options that prevent the growth of bacteria and viruses, enhancing workplace safety. -

What are the typical minimum order quantities (MOQs) for keyboard plastic covers?

MOQs for keyboard plastic covers can vary significantly based on the supplier and the level of customization required. Standard products may have MOQs as low as 100 units, while custom designs could require orders of 500 units or more. Always confirm MOQs with suppliers during the initial inquiry to avoid surprises later. Some suppliers may offer flexibility in MOQs for first-time buyers or larger partnerships. -

How can I vet suppliers for keyboard plastic covers effectively?

To effectively vet suppliers, start by checking their industry reputation through reviews and testimonials. Look for suppliers that have a proven track record of delivering quality products on time. Request certifications and quality assurance processes they follow, such as ISO certifications. Additionally, ask for references from other businesses in your region or industry to gain insight into their reliability and customer service. -

What payment terms should I expect when sourcing keyboard plastic covers internationally?

Payment terms can vary widely among international suppliers. Common terms include upfront payment, 30% deposit with the balance upon shipment, or net 30/60 days after delivery. It’s crucial to establish clear terms before finalizing any agreement. Always consider using secure payment methods like letters of credit or escrow services to mitigate risks associated with international transactions. -

What logistics considerations should I keep in mind when importing keyboard plastic covers?

When importing keyboard plastic covers, consider shipping costs, customs duties, and potential delays at ports. Ensure your supplier can provide accurate shipping information and documentation to facilitate customs clearance. Additionally, evaluate the logistics provider’s experience with your specific region, as this can affect delivery times and reliability. It may also be beneficial to explore bulk shipping options to reduce costs. -

How can I customize keyboard plastic covers to meet my branding needs?

Many suppliers offer customization options for keyboard plastic covers, including color, logo printing, and design modifications. When inquiring, specify your branding requirements, including any specific colors or logos you want to incorporate. Be prepared to discuss minimum order quantities for custom designs, as these may differ from standard products. Request samples to ensure that the final product aligns with your branding vision. -

What quality assurance measures should be in place for keyboard plastic covers?

Quality assurance measures should include rigorous testing for durability, fit, and material safety. Suppliers should have a documented quality control process, including pre-production samples and batch testing. Inquire about warranties or return policies in case of defects. For added assurance, consider suppliers who comply with international quality standards, which can provide peace of mind regarding the integrity of the products you receive.

Top 2 Computer Keyboard Plastic Cover Manufacturers & Suppliers List

1. WetKeys – Seal Shield Clean-Wipe Medical Grade Keyboard Cover

Domain: wetkeys.com

Registered: 2007 (18 years)

Introduction: Keyboard and Laptop Covers – Disposable & Reusable Covers, Drapes, Protectors for Medical & Healthcare, Laboratory, Food Processing, Manufacturing and Industrial. Top Selling & Featured Products include: 1. Seal Shield Clean-Wipe Medical Grade “Chiclet” Keyboard Cover, Antimicrobial (Silicone Cover Only) (Clear) | MSRP: $15.99 2. Man and Machine Cool-Drape All Purpose Keyboard Covers, Laptop Drape…

2. MDS Associates – Clear Protection® Keyboard Covers

Domain: mdsassociates.com

Registered: 2002 (23 years)

Introduction: Product Name: Clear Protection® Disposable Computer Keyboard Covers, Tapered Edge 22in x 14in (250ct)\nProduct Code: 33-PS400\nDescription: Disposable surface barriers that prevent the spread of germs and keep keyboards free of debris. Clear plastic design does not block operation or visibility. Features a folded tapered end for secure placement.\nDimensions: 22″W x 14″L\nPacked: 250 per box (2 bo…

Strategic Sourcing Conclusion and Outlook for computer keyboard plastic cover

In the competitive landscape of B2B procurement, strategic sourcing of computer keyboard plastic covers emerges as a pivotal strategy for businesses aiming to enhance their operational efficiency and product longevity. As highlighted, the diverse range of protective solutions—from custom-fitted covers to disposable options—addresses the unique needs of various industries, including healthcare, education, and manufacturing. Investing in high-quality keyboard covers not only safeguards equipment against spills and debris but also promotes a hygienic work environment, crucial in today’s health-conscious market.

International buyers, especially from emerging markets in Africa, South America, the Middle East, and Europe, should consider the benefits of sourcing from reputable manufacturers that offer customization and bulk purchase options. By leveraging strategic partnerships, businesses can access tailored solutions that meet specific operational requirements while optimizing costs.

Looking ahead, the demand for innovative and durable keyboard protection solutions is set to rise. Companies that prioritize strategic sourcing will be well-positioned to adapt to evolving market trends and customer needs. We encourage B2B buyers to explore these opportunities and invest in protective solutions that not only enhance the lifespan of their technology but also contribute to overall workplace safety and efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.