The Definitive Guide to Composite 2X4: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for composite 2×4

Navigating the complexities of sourcing composite 2×4 materials can be a daunting challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As demand for sustainable and durable building solutions continues to rise, understanding the nuances of composite lumber—including its types, applications, and cost structures—becomes critical. This guide is designed to provide a comprehensive overview of the composite 2×4 market, equipping buyers with the insights needed to make informed purchasing decisions.

Within these pages, you’ll discover detailed analyses of various composite materials, including their environmental benefits and performance characteristics. We will explore the diverse applications of composite 2x4s in construction and landscaping, highlighting their advantages over traditional wood. Additionally, we will cover essential strategies for vetting suppliers to ensure quality and reliability, as well as a breakdown of pricing trends to help you budget effectively.

By leveraging this guide, B2B buyers can confidently navigate the global market, mitigate risks, and enhance their procurement strategies. Whether you’re based in Brazil, Saudi Arabia, or elsewhere, understanding the composite 2×4 landscape will empower you to select the right materials that align with your project needs and sustainability goals.

Understanding composite 2×4 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solid Composite Deck Board | Solid structure, typically made from recycled materials, UV resistant | Decking, outdoor furniture, railings | Pros: Durable, low maintenance; Cons: Higher initial cost compared to wood. |

| Hollow Composite Deck Board | Lightweight, hollow core design, often more cost-effective | Residential and commercial decking | Pros: Economical, easier to handle; Cons: Less structural integrity than solid boards. |

| Plastic Lumber Composite | Made from 100% recycled plastics, completely waterproof | Fencing, docks, marine applications | Pros: Eco-friendly, rot and insect resistant; Cons: Limited color options. |

| Wood-Plastic Composite | Combination of wood fibers and plastic, mimics the appearance of wood | Landscaping, outdoor structures | Pros: Aesthetic appeal, customizable; Cons: Can be prone to fading over time. |

| Premium Composite Lumber | High-quality composite materials, enhanced durability and aesthetics | High-end construction, custom projects | Pros: Long-lasting, premium finish; Cons: Higher price point. |

What Are the Characteristics of Solid Composite Deck Boards?

Solid composite deck boards are known for their robust construction, typically made from recycled materials. These boards provide excellent durability and resistance to UV rays, making them ideal for outdoor applications such as decking and railings. B2B buyers should consider their longevity and low maintenance requirements, although the initial investment may be higher than traditional wood. Their solid structure also offers better resistance to warping and splitting, making them suitable for high-traffic areas.

How Do Hollow Composite Deck Boards Compare in Cost and Use?

Hollow composite deck boards are characterized by their lightweight and cost-effective design. The hollow core makes them easier to transport and install, which can be beneficial for large-scale projects. They are often used in both residential and commercial decking applications. While they offer significant savings, buyers should weigh the trade-off in structural integrity, especially in areas subjected to heavy loads. Their affordability makes them a popular choice for budget-conscious projects.

Why Choose Plastic Lumber Composite for Outdoor Applications?

Plastic lumber composites are crafted from 100% recycled plastics, rendering them entirely waterproof. This feature makes them particularly suitable for applications in wet environments, such as docks and marine structures, as well as fencing. B2B buyers appreciate their eco-friendly nature and resistance to rot and insect damage. However, they may face limitations in color choices, which could restrict design options for some projects.

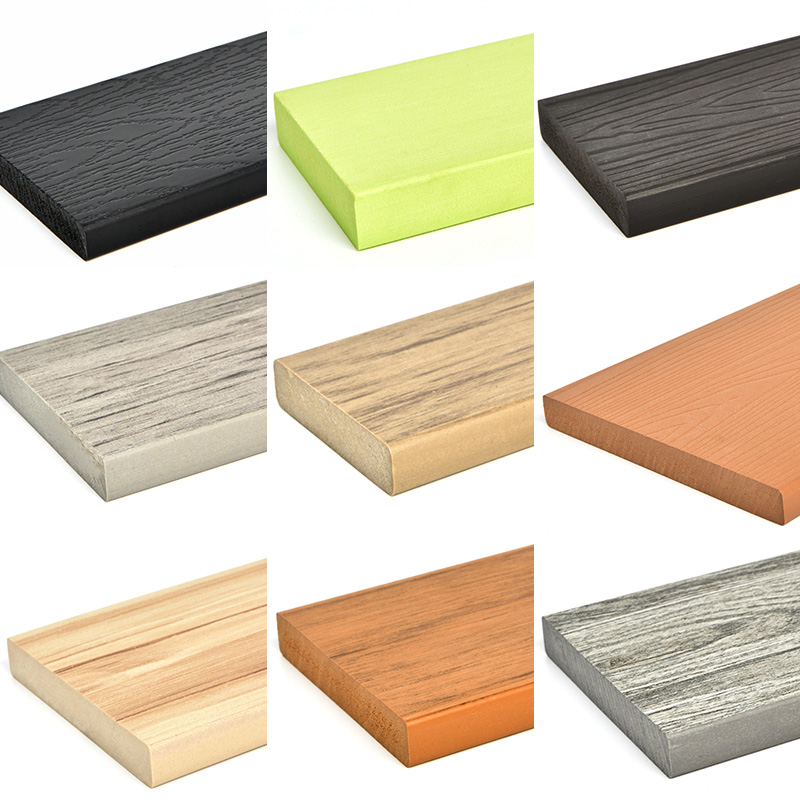

What Advantages Does Wood-Plastic Composite Offer?

Wood-plastic composites combine wood fibers with plastic, allowing them to mimic the natural appearance of wood while providing enhanced durability. These composites are often used in landscaping and outdoor structures, appealing to buyers seeking aesthetic appeal alongside functionality. Customization options are available, but potential fading over time should be considered. B2B purchasers should evaluate the balance between visual appeal and long-term performance.

What Makes Premium Composite Lumber a High-End Choice?

Premium composite lumber is manufactured from high-quality materials, providing exceptional durability and aesthetic benefits. These boards are ideal for high-end construction projects and custom applications, where appearance and longevity are critical. While the price point is higher, the investment can lead to lower maintenance costs and extended lifespan, making them a wise choice for discerning buyers. Companies looking to position themselves in the luxury market may find premium composites align well with their brand values.

Key Industrial Applications of composite 2×4

| Industry/Sector | Specific Application of composite 2×4 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Framing for commercial buildings | Lightweight yet durable, reducing overall project costs | Ensure compliance with local building codes and regulations |

| Landscaping & Outdoor | Decking and outdoor structures | Low maintenance and weather-resistant properties | Availability of various colors and finishes for aesthetic appeal |

| Marine & Waterfront | Docks and piers construction | Resistant to moisture and rotting, extending lifespan | Sourcing from suppliers with UV inhibitors for durability |

| Furniture Manufacturing | Custom furniture and fixtures | Versatile and easy to work with, enhancing design options | Consideration of weight limits and structural integrity |

| Agricultural | Fencing for livestock and crop protection | Eco-friendly and long-lasting, reducing replacement costs | Sourcing options for recycled materials to meet sustainability goals |

How is Composite 2×4 Used in Construction?

In the construction sector, composite 2×4 is increasingly utilized for framing in both residential and commercial buildings. Its lightweight nature makes transportation and handling easier, while its durability ensures longevity in structural applications. For international buyers, particularly in regions with varying climates, sourcing composite 2×4 that meets local building codes is crucial. This ensures that the materials can withstand environmental challenges, such as high humidity or extreme temperatures.

What Role Does Composite 2×4 Play in Landscaping and Outdoor Projects?

Composite 2×4 is a popular choice for decking and outdoor structures like pergolas and gazebos. Its low maintenance requirements, combined with its resistance to weather elements, make it an ideal material for outdoor applications. For businesses in regions like South America and Africa, the availability of composite 2×4 in various colors and finishes allows for customization that enhances the aesthetic appeal of outdoor spaces. Buyers should consider sourcing options that offer UV protection to prevent fading in sunny climates.

How is Composite 2×4 Beneficial for Marine and Waterfront Structures?

In marine applications, composite 2×4 is used for constructing docks and piers due to its resistance to moisture and rotting. This characteristic significantly extends the lifespan of marine structures, making it a cost-effective solution for businesses involved in waterfront development. Buyers in regions like the Middle East, where humidity levels can be high, should prioritize sourcing from suppliers that include UV inhibitors to ensure long-term durability against harsh environmental conditions.

What Advantages Does Composite 2×4 Offer in Furniture Manufacturing?

Composite 2×4 serves as a versatile material in the furniture manufacturing sector, allowing for the creation of custom furniture pieces and fixtures. Its ease of cutting and shaping makes it a favorite among designers and craftsmen. For international buyers, especially those in Europe, it is essential to consider the weight limits and structural integrity of composite 2×4 when designing furniture. Sourcing from reputable manufacturers that guarantee quality can significantly impact the final product’s durability.

How Does Composite 2×4 Support Agricultural Applications?

In agriculture, composite 2×4 is commonly used for fencing, providing effective livestock and crop protection. Its eco-friendly nature, often made from recycled materials, aligns with sustainability goals that many agricultural businesses prioritize. Buyers should focus on sourcing options that highlight the durability and low maintenance of composite 2×4, which can lead to significant cost savings over time by reducing replacement needs.

3 Common User Pain Points for ‘composite 2×4’ & Their Solutions

Scenario 1: Difficulty in Material Sourcing and Quality Assurance

The Problem:

B2B buyers often face challenges in sourcing high-quality composite 2×4 boards due to variations in material quality across suppliers. In regions like Africa and South America, where access to reliable suppliers may be limited, buyers can encounter products that do not meet specified performance standards. This can lead to increased project costs, delays, and dissatisfaction among end-users who expect durability and reliability from composite materials.

The Solution:

To ensure quality assurance, buyers should establish partnerships with reputable manufacturers and distributors who have a proven track record in producing composite materials. It’s crucial to request samples and third-party certifications that validate the quality and performance characteristics of the composite 2×4 boards. Additionally, engaging in a comprehensive vetting process that includes visiting manufacturing facilities, when feasible, can provide insights into the production processes and quality control measures. Buyers should also consider leveraging technology platforms that facilitate direct connections with verified suppliers, thereby reducing the risk of sourcing inferior products.

Scenario 2: Challenges with Installation and Compatibility

The Problem:

Another pain point for B2B buyers is the installation of composite 2×4 materials, particularly when integrating them into existing construction projects. Many contractors and builders may lack experience with composite materials compared to traditional wood, leading to improper installation techniques that can compromise the integrity of the structure. This can be especially problematic in regions with varying climates, such as the Middle East, where temperature fluctuations can affect material performance.

The Solution:

To address installation challenges, buyers should invest in training for their teams or contractors who will be working with composite 2×4 boards. Many manufacturers offer installation guides, workshops, and online tutorials that cover best practices. Additionally, buyers should ensure that they select compatible fastening systems and adhesives designed specifically for composite materials, as these can significantly enhance performance and durability. Encouraging open communication with manufacturers can also provide valuable insights and recommendations tailored to specific project requirements.

Scenario 3: Limited Knowledge About Material Lifespan and Environmental Impact

The Problem:

Buyers frequently struggle with understanding the lifespan and environmental implications of using composite 2×4 boards. Misconceptions about the durability and sustainability of composite materials can lead to hesitancy in adoption, especially in markets that prioritize eco-friendly building practices, such as parts of Europe. Buyers need to clearly convey these attributes to stakeholders to justify investment decisions.

The Solution:

Educating stakeholders about the benefits of composite 2×4 materials is essential. This can be achieved by compiling data on the longevity and low maintenance requirements of composite materials compared to traditional wood. Highlighting that many composite boards are made from recycled materials can reinforce their sustainability profile. Buyers should also leverage case studies and testimonials from previous projects that showcase the successful application of composite materials in various environments. Engaging with environmental certifications and standards can further bolster the credibility of composite 2x4s as a sustainable choice in construction.

Strategic Material Selection Guide for composite 2×4

When selecting materials for composite 2×4 products, it is essential to consider various options that offer distinct properties, advantages, and limitations. This analysis focuses on four common materials used in composite 2×4 manufacturing: High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), Wood-Plastic Composites (WPC), and Fiberglass Reinforced Plastic (FRP). Each material presents unique characteristics that can influence product performance and suitability for specific applications, especially for international buyers.

What are the Key Properties of High-Density Polyethylene (HDPE) for Composite 2×4?

High-Density Polyethylene (HDPE) is a widely used material in the production of composite 2×4 boards. It is known for its excellent resistance to moisture, chemicals, and UV radiation, making it suitable for outdoor applications. HDPE can withstand a wide temperature range, maintaining structural integrity even in extreme conditions. Its lightweight nature facilitates easier handling and installation.

Pros: HDPE is durable and low-maintenance, requiring no painting or sealing. It is also 100% recyclable, appealing to eco-conscious buyers.

Cons: The initial cost can be higher than traditional wood, and while it is resistant to warping, it can expand and contract with temperature fluctuations, which may affect dimensional stability.

Impact on Application: HDPE is ideal for environments that experience high humidity or exposure to chemicals, such as coastal regions or industrial settings.

Considerations for International Buyers: Compliance with international standards (e.g., ASTM D7031 for wood-plastic composites) is crucial. Buyers in regions like Africa and South America may prioritize eco-friendly materials, while European buyers often seek certifications for sustainability.

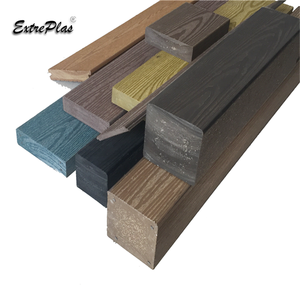

Illustrative image related to composite 2×4

How Does Polyvinyl Chloride (PVC) Compare for Composite 2×4 Use?

Polyvinyl Chloride (PVC) is another popular material for composite 2×4 applications. It is inherently resistant to moisture, insects, and rot, making it an excellent choice for outdoor structures. PVC boards are available in various colors and finishes, allowing for aesthetic customization.

Pros: PVC is highly durable and requires minimal maintenance. It does not splinter, crack, or warp, ensuring a long lifespan.

Cons: The environmental impact of PVC production is a concern, as it involves toxic chemicals. Additionally, PVC can become brittle in extreme cold, limiting its use in colder climates.

Impact on Application: PVC is suitable for decking, fencing, and outdoor furniture, particularly in regions with high rainfall or humidity.

Illustrative image related to composite 2×4

Considerations for International Buyers: Buyers should assess local regulations regarding PVC use, especially in Europe, where stringent environmental laws may apply. Understanding the market demand for sustainable alternatives is also essential.

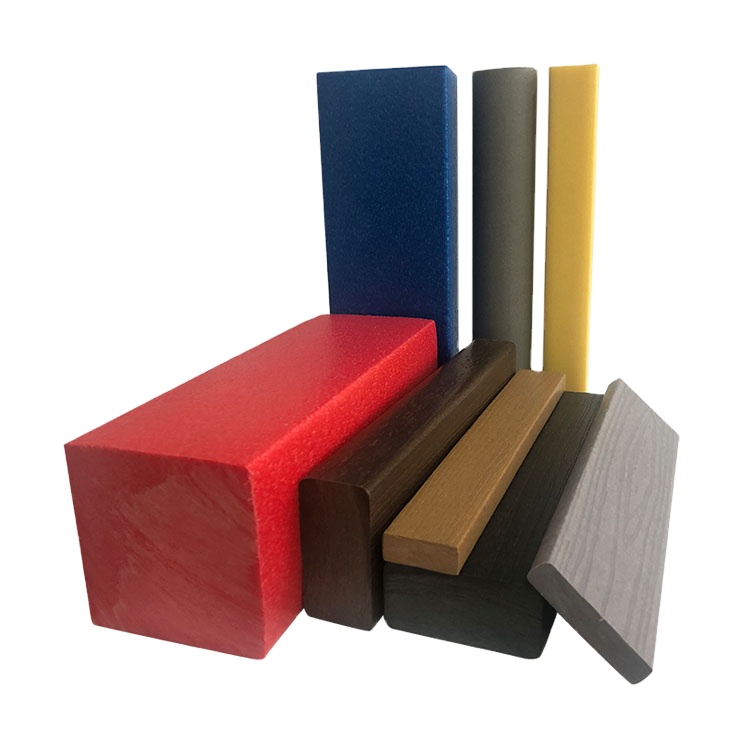

What Advantages Do Wood-Plastic Composites (WPC) Offer for Composite 2×4?

Wood-Plastic Composites (WPC) combine wood fibers with plastic materials, providing a balance of natural aesthetics and synthetic durability. WPC is designed to mimic the appearance of wood while offering enhanced resistance to moisture and pests.

Pros: WPC is versatile and can be used in various applications, from decking to furniture. It is also resistant to fading, ensuring long-lasting color retention.

Cons: The manufacturing process can be complex, potentially leading to higher costs. Additionally, WPC may not be as strong as solid wood, which could limit its use in structural applications.

Impact on Application: WPC is particularly effective in residential and commercial outdoor applications, where both aesthetics and durability are paramount.

Considerations for International Buyers: Compliance with ASTM D7031 is important for quality assurance. Buyers in the Middle East may favor WPC for its resistance to desert conditions, while European buyers might focus on its sustainability credentials.

What Role Does Fiberglass Reinforced Plastic (FRP) Play in Composite 2×4 Applications?

Fiberglass Reinforced Plastic (FRP) is a composite material known for its exceptional strength-to-weight ratio and corrosion resistance. It is often used in demanding environments, such as industrial settings or coastal areas.

Pros: FRP is highly durable, resistant to chemicals, and does not rust or corrode. It also offers excellent thermal insulation properties.

Cons: The cost of FRP can be significantly higher than other materials, which may deter budget-conscious buyers. Additionally, its rigidity can make it challenging to work with during installation.

Impact on Application: FRP is ideal for applications requiring high strength and resistance to harsh conditions, such as marine environments or chemical processing plants.

Considerations for International Buyers: Understanding local regulations regarding FRP use is essential, especially in regions with strict environmental standards. Buyers in Africa and the Middle East may find FRP beneficial for its durability in extreme climates.

Illustrative image related to composite 2×4

Summary Table of Material Selection for Composite 2×4

| Material | Typical Use Case for composite 2×4 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene | Outdoor decking, industrial applications | Excellent moisture and UV resistance | Higher initial cost, potential expansion | Medium |

| Polyvinyl Chloride | Fencing, outdoor furniture | Highly durable, low maintenance | Environmental concerns, brittleness in cold | Medium |

| Wood-Plastic Composites | Decking, furniture, landscaping | Natural wood appearance, fade resistance | Complex manufacturing, lower strength | Medium to High |

| Fiberglass Reinforced Plastic | Marine applications, industrial settings | Exceptional strength and corrosion resistance | High cost, installation challenges | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials for composite 2×4 applications. Understanding these factors will enable informed decision-making tailored to specific regional needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for composite 2×4

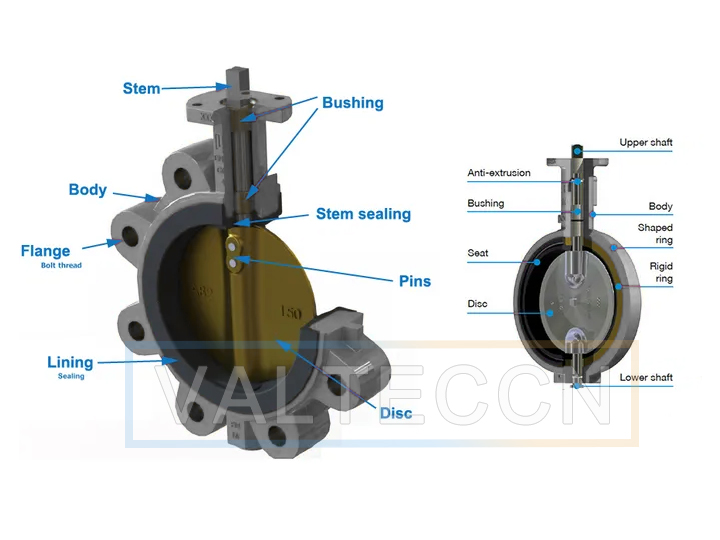

What are the Key Stages in the Manufacturing Process of Composite 2×4?

The manufacturing process of composite 2×4 boards typically involves several critical stages that ensure the final product meets the desired specifications for durability, aesthetics, and performance.

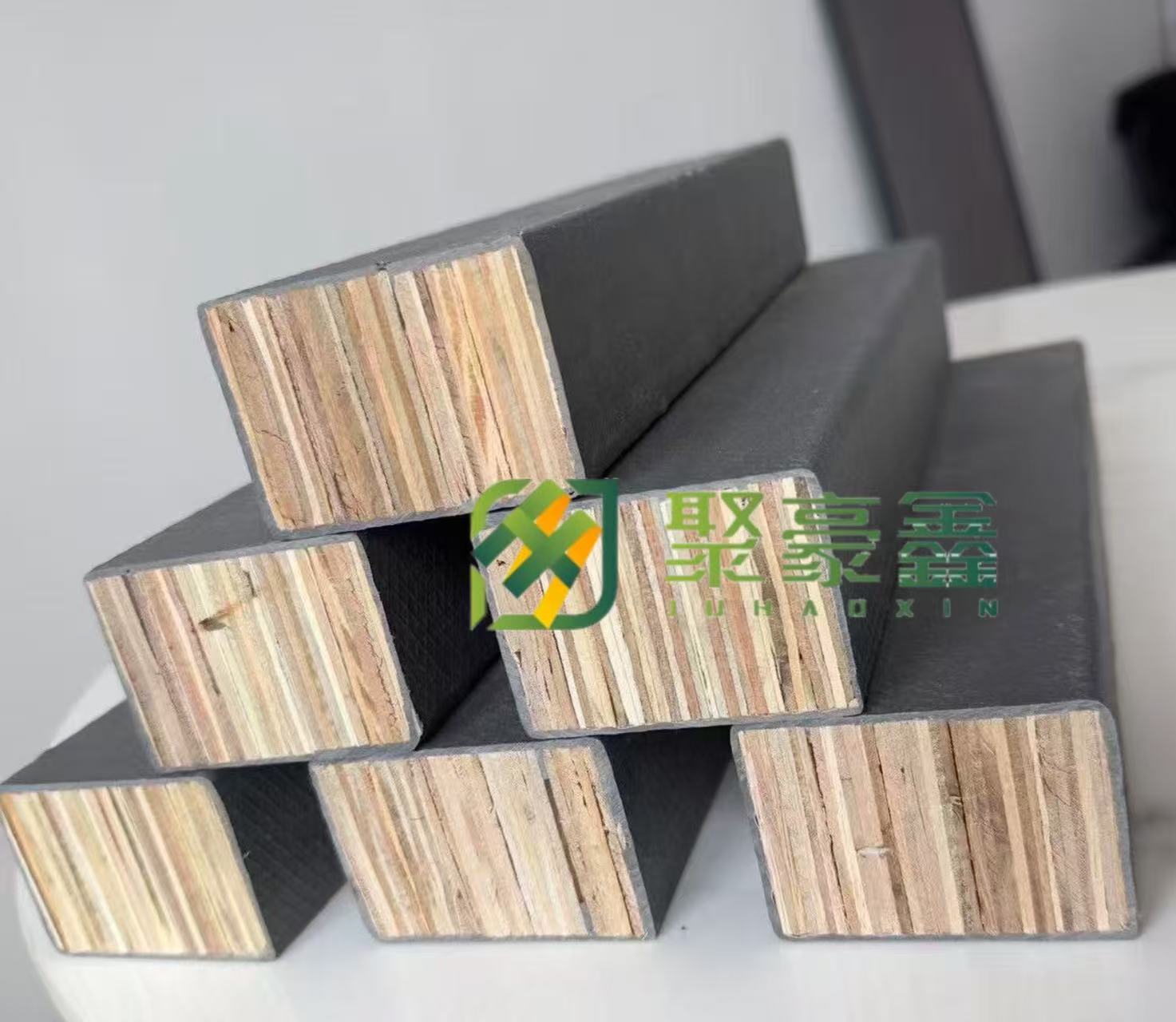

Material Preparation: Sourcing and Processing

The initial stage focuses on sourcing raw materials, which often include recycled wood fibers and plastic composites. The quality of these materials is vital, as they directly influence the board’s strength and longevity. Once sourced, materials undergo processing, which includes drying and grinding the wood fibers to the appropriate size. This preparation is crucial for ensuring uniformity and optimal bonding during the subsequent stages.

Illustrative image related to composite 2×4

Forming: Extrusion and Molding Techniques

The next step is the forming process, where the prepared materials are combined, typically through extrusion. In this method, the wood fibers and plastic are mixed and heated until they reach a malleable state. The mixture is then forced through a die to create the shape of the 2×4 boards. This stage can also include molding techniques, where the composite is poured into molds to achieve specific designs or finishes, ensuring the final product meets the aesthetic and functional requirements of the market.

Assembly: Reinforcement and Texturing

After forming, the boards may undergo additional assembly processes, such as reinforcement with additives to enhance durability or texture application for improved grip and visual appeal. This step is particularly important for applications like decking or outdoor furniture, where slip resistance and aesthetic qualities are essential.

Finishing: Quality Control and Surface Treatment

The final stage in manufacturing is finishing, which may involve sanding, staining, or applying protective coatings to enhance the board’s longevity and appearance. This is also the stage where quality control checks are implemented to ensure that each board meets industry standards.

Illustrative image related to composite 2×4

How is Quality Assurance Implemented in Composite 2×4 Production?

Quality assurance (QA) in the production of composite 2×4 boards is a multi-layered process that involves adherence to international standards, rigorous testing, and systematic checks at various stages of production.

What are the Relevant International Standards for Composite 2×4?

International standards such as ISO 9001 are essential for manufacturers to ensure quality management systems are in place. In addition, industry-specific certifications like CE marking in Europe and API standards in certain regions may also apply, especially for products intended for construction and infrastructure projects. These certifications indicate that the products meet specific safety and performance criteria, which is crucial for B2B buyers in international markets.

What are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are strategically integrated into the manufacturing process to monitor and assess quality at critical stages:

-

Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Any materials that do not conform are rejected or reprocessed.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process is vital. This involves checking parameters such as temperature, pressure, and material consistency to ensure they align with operational standards.

-

Final Quality Control (FQC): After production, finished boards undergo comprehensive testing to assess their physical and mechanical properties. This may include load testing, moisture resistance assessments, and visual inspections for defects.

What Common Testing Methods are Used for Composite 2×4?

Testing methods for composite 2×4 boards can vary by region and application, but some common techniques include:

-

Flexural Strength Testing: This evaluates the board’s ability to withstand bending forces without breaking, crucial for structural applications.

-

Moisture Content Testing: Ensuring that the boards maintain appropriate moisture levels is vital for preventing warping or degradation over time.

-

UV Resistance Testing: For outdoor applications, assessing the board’s ability to resist fading and degradation from ultraviolet light exposure is essential.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can employ several strategies to verify the quality control measures of their suppliers:

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturer’s processes, quality control systems, and adherence to industry standards.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from testing and inspections.

-

Third-Party Inspections: Engaging independent inspection services can offer an unbiased assessment of the manufacturer’s products and processes.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate specific nuances in quality control and certification:

-

Understanding Local Regulations: Different countries may have unique regulations governing the use of composite materials, especially in construction. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Language and Communication Barriers: Clear communication regarding quality expectations and standards is crucial. Buyers may need to ensure that suppliers can provide documentation in a language they understand.

-

Cultural Differences in Business Practices: Recognizing and respecting cultural differences in business practices can facilitate smoother negotiations and foster stronger supplier relationships.

By understanding these manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions, ensuring they procure high-quality composite 2×4 boards that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘composite 2×4’

In the competitive landscape of composite materials, sourcing the right composite 2×4 can significantly impact your project’s success and sustainability. This guide provides a practical checklist to assist B2B buyers in navigating the procurement process effectively.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is crucial for ensuring that the composite 2×4 meets your project requirements. Consider the intended use, such as decking, fencing, or structural applications, and specify dimensions, load-bearing capacity, and environmental conditions. This clarity helps in communicating your needs to suppliers and minimizes the risk of receiving unsuitable materials.

Step 2: Research Material Types and Properties

Different types of composite materials offer varying properties, including durability, UV resistance, and moisture resistance. Investigate the composition of the composite 2×4—whether it’s made from recycled plastics, wood fibers, or a blend. Understanding these properties can help you select a product that aligns with your project’s longevity and environmental goals.

- Consider Environmental Impact: Look for products that use recycled materials and have low emissions to align with sustainability initiatives.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request detailed company profiles, product catalogs, and references from previous clients in your industry. Assess their reputation through online reviews and industry feedback to ensure reliability and quality.

- Check for Certifications: Verify if suppliers have necessary certifications (e.g., ISO, ASTM) that indicate compliance with international quality standards.

Step 4: Request Samples for Quality Assessment

Obtaining samples allows you to assess the quality of the composite 2×4 firsthand. Inspect the samples for consistency in color, texture, and structural integrity. This step is vital to ensure that the product meets your expectations before placing a bulk order.

- Conduct Tests: If possible, perform tests on samples for performance metrics like bending strength and resistance to weathering.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers and assessed product quality, engage in negotiations. Discuss pricing, payment terms, and potential discounts for bulk orders. This step is crucial for optimizing your budget while ensuring that you receive quality materials.

- Consider Total Cost of Ownership: Factor in shipping costs, potential tariffs, and long-term maintenance costs when evaluating overall pricing.

Step 6: Finalize Order and Logistics

After finalizing your supplier, confirm your order details, including quantities, delivery schedules, and payment methods. Ensure that all agreements are documented to avoid misunderstandings. Discuss logistics options to determine the most efficient and cost-effective shipping method, particularly when sourcing internationally.

Step 7: Monitor Delivery and Quality Control

Upon receipt of your composite 2×4, conduct a thorough inspection to ensure that the delivered materials match your specifications and quality standards. Address any discrepancies with the supplier immediately to maintain a strong relationship and ensure project timelines are met.

By following these steps, B2B buyers can streamline their sourcing process for composite 2×4 materials, ensuring they acquire high-quality products that meet their project needs while fostering sustainable practices.

Comprehensive Cost and Pricing Analysis for composite 2×4 Sourcing

What Are the Key Cost Components in Composite 2×4 Pricing?

When sourcing composite 2×4 boards, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

-

Materials: The base materials for composite boards typically consist of recycled plastics and wood fibers. The quality and sourcing of these materials significantly influence the overall cost. Premium materials may come at a higher price but offer better durability and aesthetics.

-

Labor: Labor costs encompass wages for production workers, engineers, and quality control personnel. This can vary based on the region, with labor costs generally higher in developed countries than in emerging markets.

-

Manufacturing Overhead: This includes fixed costs such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, impacting the final pricing of the boards.

-

Tooling: Investments in specialized machinery for cutting and molding composite boards can be substantial. Suppliers that can spread these costs over larger production runs may offer more competitive pricing.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and performance, which can add to costs but are essential for maintaining standards, especially for B2B buyers requiring specific certifications.

-

Logistics: Transportation and warehousing costs can fluctuate based on distance, shipping mode, and fuel prices. For international buyers, understanding Incoterms is vital to gauge who bears these costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business viability. This can vary widely based on market conditions and competition.

How Do Price Influencers Affect Composite 2×4 Sourcing?

Several factors influence the pricing of composite 2×4 boards:

-

Volume/MOQ: Bulk purchasing can lead to significant discounts. Suppliers often have Minimum Order Quantities (MOQs) that, if met, can lower per-unit costs.

-

Specifications/Customization: Custom dimensions or specific color requirements can increase costs. Standard products usually have lower prices compared to custom solutions.

-

Materials: The choice between premium and standard materials can lead to substantial price differences. Buyers should weigh the long-term benefits of higher-quality materials against initial costs.

-

Quality/Certifications: Boards meeting specific international quality standards or certifications may command higher prices. This is particularly relevant for buyers in regions with strict building codes.

-

Supplier Factors: Established suppliers with a reputation for quality may charge more. However, the reliability and service they offer can justify the higher costs.

-

Incoterms: Understanding the terms of shipping and responsibility for costs is essential for international transactions. Incoterms can affect the total landed cost of goods.

What Are the Best Practices for Negotiating Composite 2×4 Prices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, employing effective negotiation strategies can yield favorable pricing outcomes:

-

Leverage Volume: When possible, consolidate orders to meet MOQs or negotiate bulk discounts. Larger orders can also provide leverage in negotiations.

-

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs associated with maintenance, durability, and replacement. This holistic view can influence negotiations.

-

Research Market Prices: Being informed about current market rates for composite 2×4 boards helps in negotiating better deals. Utilize multiple sources to benchmark prices.

-

Cultivate Relationships: Building strong relationships with suppliers can lead to better pricing and more favorable terms. Long-term partnerships often result in increased trust and flexibility.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local demand and supply conditions. Understanding these nuances can help buyers negotiate more effectively.

Disclaimer on Pricing

The prices for composite 2×4 boards can fluctuate due to market dynamics, currency exchange rates, and local conditions. It is advisable for buyers to obtain multiple quotes and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing composite 2×4 With Other Solutions

Introduction: Understanding Alternative Solutions to Composite 2×4

In the construction and landscaping sectors, selecting the right material for projects is crucial for durability, cost-effectiveness, and ease of use. While composite 2×4 boards offer a versatile solution, various alternatives exist that may better suit specific project requirements. This analysis compares composite 2×4 boards with two viable alternatives: traditional treated wood and plastic lumber. Each option has distinct advantages and disadvantages, making it essential for B2B buyers to consider performance, cost, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Composite 2X4 | Treated Wood | Plastic Lumber |

|---|---|---|---|

| Performance | High durability, resistant to rot and pests | Good strength, but susceptible to weathering | 100% waterproof, no rotting or warping |

| Cost | Moderate ($5-$15 per board) | Lower initial cost ($2-$10 per board), but potential higher long-term costs | Higher upfront cost ($50-$80 per board) |

| Ease of Implementation | Easy to cut and install | Requires careful handling and treatment | Easy to work with, can be cut and drilled like wood |

| Maintenance | Low maintenance | Requires regular sealing and staining | Minimal maintenance, no sealing needed |

| Best Use Case | Decking, outdoor furniture | Framing, structural applications | Docks, fences, outdoor furniture |

Detailed Breakdown of Alternatives

Treated Wood

Treated wood remains a popular choice for various construction projects due to its availability and lower initial cost. It is chemically treated to resist decay and insect damage, making it suitable for outdoor applications. However, its performance can be affected by environmental conditions, leading to potential warping and splitting over time. B2B buyers should factor in the ongoing maintenance required to preserve treated wood, including regular sealing and staining, which can increase long-term costs. This alternative is best suited for structural applications where cost is a significant consideration.

Illustrative image related to composite 2×4

Plastic Lumber

Plastic lumber, made from recycled materials, provides a robust and eco-friendly alternative to traditional wood products. Its 100% waterproof nature ensures that it will not rot, warp, or fade, making it an excellent choice for environments exposed to moisture, such as docks and marine applications. However, the higher upfront costs can be a barrier for some buyers. Plastic lumber is easy to work with and requires minimal maintenance, making it ideal for projects where longevity and sustainability are priorities. Buyers should consider this option for applications requiring durability and low upkeep.

Conclusion: Choosing the Right Solution for Your Project Needs

Selecting the appropriate material for construction projects involves evaluating various factors, including performance, cost, and maintenance. Composite 2×4 boards offer a balanced solution, combining durability with low maintenance. Treated wood may appeal to budget-conscious buyers, but ongoing maintenance costs should be considered. Conversely, plastic lumber is ideal for those prioritizing longevity and sustainability despite its higher initial investment. By assessing specific project requirements and constraints, B2B buyers can make informed decisions that align with their operational goals and budgetary considerations.

Essential Technical Properties and Trade Terminology for composite 2×4

What Are the Key Technical Properties of Composite 2×4?

When considering composite 2×4 lumber for your projects, understanding its technical properties is essential. These properties can significantly impact the performance, durability, and suitability of the material for various applications.

-

Material Composition

Composite 2x4s are typically made from a blend of recycled plastic and wood fibers, providing a balance between strength and flexibility. This combination ensures that the boards are resistant to rot, warping, and insect damage. For B2B buyers, selecting boards with a high percentage of recycled materials can also align with sustainability goals, which are increasingly important in international markets. -

Dimensional Tolerance

The nominal size of composite 2x4s is 2 inches by 4 inches, but actual dimensions are often slightly smaller (1.5 inches by 3.5 inches). Understanding these tolerances is crucial for ensuring compatibility with existing structures and for precise cutting during construction. Buyers should confirm that suppliers adhere to industry standards to avoid discrepancies that could lead to project delays. -

Weight and Density

Composite materials can vary in weight due to differences in composition. Typically, a 12-foot composite 2×4 weighs between 25 to 30 pounds. The weight is important for shipping and handling considerations, especially for international buyers. Lighter materials can reduce transportation costs, while heavier options might offer increased durability in high-traffic applications. -

Moisture Resistance

One of the standout properties of composite 2x4s is their moisture resistance. Unlike traditional wood, composite boards do not absorb water, which makes them ideal for outdoor applications like decking or fencing. For B2B buyers, this property translates into lower maintenance costs and a longer lifespan, making composite materials a cost-effective investment over time. -

UV Resistance

Many composite boards are treated with UV inhibitors to prevent fading and degradation from sun exposure. This is particularly relevant for buyers in sunnier regions, as UV resistance can significantly affect the aesthetic and functional longevity of outdoor installations. Understanding UV performance helps buyers choose the right product for their climate.

What Are Common Trade Terms Related to Composite 2×4?

Navigating the B2B landscape requires familiarity with industry jargon. Here are key terms related to composite 2×4 lumber that decision-makers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of composite materials, understanding OEM relationships can aid in sourcing high-quality products tailored to specific needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it can affect inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases more effectively. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This process is vital for ensuring competitive pricing and gaining insights into available options in the market, particularly when considering bulk purchases of composite 2x4s. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly concerning shipping and delivery. Understanding these terms helps buyers clarify shipping costs and liabilities, ensuring smoother transactions across borders. -

Sustainability Certification

This term refers to the accreditation that materials meet certain environmental standards, often required in international markets. Familiarity with sustainability certifications can enhance a company’s reputation and appeal in eco-conscious markets, which is increasingly important for B2B transactions. -

Lead Time

Lead time is the time between placing an order and receiving the product. Knowing the lead time for composite 2x4s is crucial for project planning, especially in construction where delays can incur significant costs.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions, ensuring they select the right composite 2×4 products for their specific applications and markets.

Navigating Market Dynamics and Sourcing Trends in the composite 2×4 Sector

What Are the Current Market Dynamics and Key Trends in the Composite 2×4 Sector?

The composite 2×4 market is experiencing significant growth, driven by increasing demand for sustainable building materials across various regions, particularly in Africa, South America, the Middle East, and Europe. Key market drivers include urbanization, a shift towards eco-friendly construction practices, and the growing popularity of composite materials due to their durability and low maintenance requirements. In regions like Brazil and Saudi Arabia, where infrastructure projects are booming, the demand for composite 2x4s is expected to rise sharply.

Emerging B2B technology trends include the adoption of digital platforms for sourcing and procurement, which streamline the purchasing process and enhance supplier transparency. Businesses are increasingly utilizing e-commerce platforms and digital marketplaces to connect with manufacturers and suppliers, facilitating easier access to composite products. Moreover, advancements in manufacturing technologies are leading to higher quality and more diverse offerings in composite materials, which can be tailored to specific regional preferences.

International buyers should also be aware of fluctuating raw material costs and supply chain disruptions, which can impact pricing and availability. Establishing strong relationships with reliable suppliers and leveraging technology for real-time inventory tracking can mitigate these risks. As competition intensifies, companies that adapt to these market dynamics and trends will be better positioned to succeed in the composite 2×4 sector.

How Is Sustainability Shaping the Sourcing of Composite 2×4 Materials?

Sustainability has become a cornerstone of sourcing strategies in the composite 2×4 sector. The environmental impact of traditional lumber production has led to increased scrutiny and a push for greener alternatives. Composite 2x4s, often made from recycled plastics and wood fibers, offer a sustainable solution that reduces deforestation and minimizes waste.

Ethical sourcing practices are gaining traction among B2B buyers who are prioritizing suppliers that adhere to sustainable practices. Buyers are increasingly looking for certifications such as Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) that indicate responsible sourcing. These certifications not only promote environmental stewardship but also enhance brand reputation and consumer trust.

Illustrative image related to composite 2×4

The importance of ethical supply chains cannot be overstated, particularly in emerging markets where regulatory frameworks are still developing. Companies that commit to sustainability and ethical sourcing can differentiate themselves in the marketplace, attracting environmentally conscious clients and complying with international regulations. As sustainability continues to influence purchasing decisions, B2B buyers in the composite 2×4 sector must align their sourcing strategies with these evolving standards.

What Is the Evolution of Composite 2×4 Materials in the B2B Sector?

The evolution of composite 2×4 materials can be traced back to the growing need for sustainable and durable building products in the late 20th century. Initially, composites were primarily used in decking applications, but their versatility and performance characteristics have led to wider adoption in structural applications, including framing and furniture manufacturing.

As technology advanced, manufacturers began to improve the formulations and production processes of composite materials, enhancing their strength, durability, and aesthetic appeal. This evolution has allowed composite 2x4s to compete more effectively with traditional lumber, offering benefits such as resistance to rot, moisture, and pests, which are critical in regions with challenging climates.

Today, the composite 2×4 market is characterized by a diverse array of products that cater to the specific needs of international B2B buyers. From eco-friendly options to high-performance materials, the sector has significantly matured, aligning with the demand for sustainable construction solutions in global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of composite 2×4

-

How do I choose the right composite 2×4 for my project?

When selecting the ideal composite 2×4, consider factors such as the intended use (e.g., decking, fencing, or furniture), environmental conditions, and desired aesthetics. Evaluate the material properties, such as UV resistance, waterproofing, and maintenance requirements. It’s also essential to assess the supplier’s offerings for variations in color, texture, and size to ensure compatibility with your project specifications. -

What are the benefits of using composite 2×4 over traditional lumber?

Composite 2×4 boards offer several advantages, including superior durability, resistance to rot and insects, and minimal maintenance needs. They are often made from recycled materials, making them an eco-friendly choice. Additionally, composite materials are less prone to warping and fading, ensuring a longer lifespan and better performance in various climates, particularly in regions with high moisture or intense sunlight. -

What customization options are available for composite 2×4 products?

Many suppliers provide customization options for composite 2×4 boards, including color, length, and texture. You can often choose from various finishes, such as smooth or wood-grain, to match your project’s aesthetic. Discuss your specific needs with potential suppliers to determine the extent of customization available and any associated costs or minimum order quantities. -

What is the minimum order quantity (MOQ) for composite 2×4 boards?

Minimum order quantities for composite 2×4 boards can vary significantly between suppliers. Generally, MOQs may range from a few hundred to several thousand units, depending on the supplier’s production capabilities and your specific requirements. It’s advisable to communicate with suppliers about your needs to find a partner that can accommodate your order volume. -

What payment terms should I expect when sourcing composite 2×4 internationally?

Payment terms can differ by supplier and region but typically include options like advance payment, letters of credit, or payment upon delivery. It’s essential to clarify these terms upfront to avoid misunderstandings. Additionally, consider discussing currency preferences, potential financing options, and any relevant fees associated with international transactions. -

How can I ensure the quality of composite 2×4 products before purchasing?

To ensure quality, request product samples and certifications from potential suppliers, verifying that their composite materials meet industry standards. Conduct thorough research on the supplier’s reputation through reviews and testimonials. If possible, arrange factory visits or third-party inspections to assess manufacturing processes and quality control measures. -

What logistics considerations should I be aware of when importing composite 2×4?

When importing composite 2×4 boards, consider shipping methods, lead times, and customs regulations in your country. Ensure that your supplier provides detailed shipping information, including packaging and handling procedures to prevent damage during transit. Additionally, familiarize yourself with import duties and taxes that may apply to your shipment. -

How do I find reliable suppliers for composite 2×4 in international markets?

To find reliable suppliers, utilize online marketplaces, trade shows, and industry directories. Engage in networking within relevant industry associations and forums to gather recommendations. Always vet potential suppliers by checking their certifications, production capabilities, and customer reviews. Establishing a good relationship with your supplier can also lead to better pricing and service.

Top 3 Composite 2X4 Manufacturers & Suppliers List

1. Bear Board – Plastic 2×4 Boards

Domain: bearboardlumber.com

Registered: 2014 (11 years)

Introduction: {‘product_name’: ‘Plastic 2×4 Boards’, ‘dimensions’: ‘2 x 4’, ‘lengths_available’: [‘6ft’, ‘8ft’, ’12ft’, ’16ft’], ‘actual_size’: ‘1.5″ x 3.5″ (38mm x 89mm)’, ‘weight’: ‘1.80lbs/ft’, ‘colors_available’: [‘White’, ‘Gray’, ‘Putty’, ‘Cedar’, ‘Tan’, ‘Black’, ‘Redwood’, ‘Chocolate Brown’, ‘Green’, ‘Weathered Wood’, ‘Anchor Gray’, ‘Harbor Wood’], ‘material’: ‘Recycled HDPE Plastic + Mineral-Fill Additiv…

2. DeckMart – TREX Composite Lumber

Domain: deckmart.com

Registered: 2000 (25 years)

Introduction: TREX dimensional Lumber includes Trex 2×4 and 2×6 composite lumber, which is a durable, low-maintenance alternative to wood. It resists rot, warping, and insects, making it suitable for outdoor structures. The lumber is made from 95% recycled materials, is eco-friendly, and weather-resistant. No staining or sealing is required, ensuring long-lasting performance. Available products include: TREX Tr…

3. Reddit – Composite 2×4 Deck Railing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Composite 2×4 for Deck Railing (Sub Railing), suitable for replacing old wood deck railings, maintenance-friendly, available in lengths longer than standard 8ft, options for dual-tone (white with black balusters), mentions Trex Transcend composite, Azek discontinued composite subrail, sourcing issues for local availability.

Strategic Sourcing Conclusion and Outlook for composite 2×4

In summary, the strategic sourcing of composite 2×4 products presents a significant opportunity for international buyers looking to enhance their construction projects with sustainable and durable materials. The versatility of composite 2×4 boards, available in various colors and dimensions, allows for diverse applications ranging from decking to custom furniture. Furthermore, the eco-friendly nature of these materials, crafted from recycled plastics, aligns with the growing demand for sustainable construction solutions, especially in markets across Africa, South America, the Middle East, and Europe.

By focusing on strategic sourcing, companies can not only ensure a steady supply of high-quality materials but also mitigate risks associated with price fluctuations and supply chain disruptions. Engaging with reliable suppliers who understand regional market dynamics will be crucial in achieving cost-efficiency and product availability.

Looking ahead, it is imperative for B2B buyers to stay informed about emerging trends and innovations in composite materials. By leveraging this knowledge, businesses can position themselves advantageously in their respective markets. We encourage international buyers to actively seek out partnerships that prioritize sustainability and innovation, paving the way for future growth and success in the ever-evolving construction landscape.

Illustrative image related to composite 2×4

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.