The Definitive Guide to Circuit Of Dc Motor: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for circuit of dc motor

In the rapidly evolving landscape of industrial automation, sourcing an effective circuit for DC motors presents a significant challenge for B2B buyers across diverse global markets. Understanding the intricacies of DC motor circuits—specifically the various drive configurations, such as H-bridges and PWM control—is crucial for optimizing motor performance and ensuring operational efficiency. This guide delves into the comprehensive aspects of DC motor circuits, including the types of circuits available, their wide-ranging applications, and essential criteria for supplier vetting.

Moreover, it addresses critical considerations like cost factors and the latest technological advancements, providing buyers with the insights needed to make informed purchasing decisions. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—this guide serves as an indispensable resource. By equipping decision-makers with the knowledge to navigate the complexities of sourcing DC motor circuits, it fosters confidence in selecting the right components that align with their operational requirements and budget constraints. Ultimately, this guide empowers businesses to enhance their productivity and drive innovation in an increasingly competitive marketplace.

Understanding circuit of dc motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| H-Bridge Circuit | Allows bidirectional control of motor direction using MOSFETs. | Robotics, Electric Vehicles, Automation | Pros: Versatile, efficient speed control. Cons: Complexity in design and potential EMI issues. |

| PWM Control Circuit | Utilizes Pulse Width Modulation for speed regulation. | Conveyor Systems, HVAC, Fan Control | Pros: Energy-efficient, precise speed control. Cons: Requires careful tuning of frequency. |

| Full-Bridge Driver | Drives all four switches in an H-bridge for full control. | Industrial Machinery, CNC Machines | Pros: Robust control of larger motors. Cons: Higher cost and complexity in implementation. |

| Low-Side Driver | Controls the lower switches in the H-bridge. | Simple Motor Applications | Pros: Cost-effective, straightforward design. Cons: Limited to unidirectional control. |

| High-Side Driver | Manages the upper switches in the H-bridge. | Automotive Applications, Robotics | Pros: Greater control over motor direction. Cons: More expensive than low-side drivers. |

What are the characteristics and applications of H-Bridge Circuits?

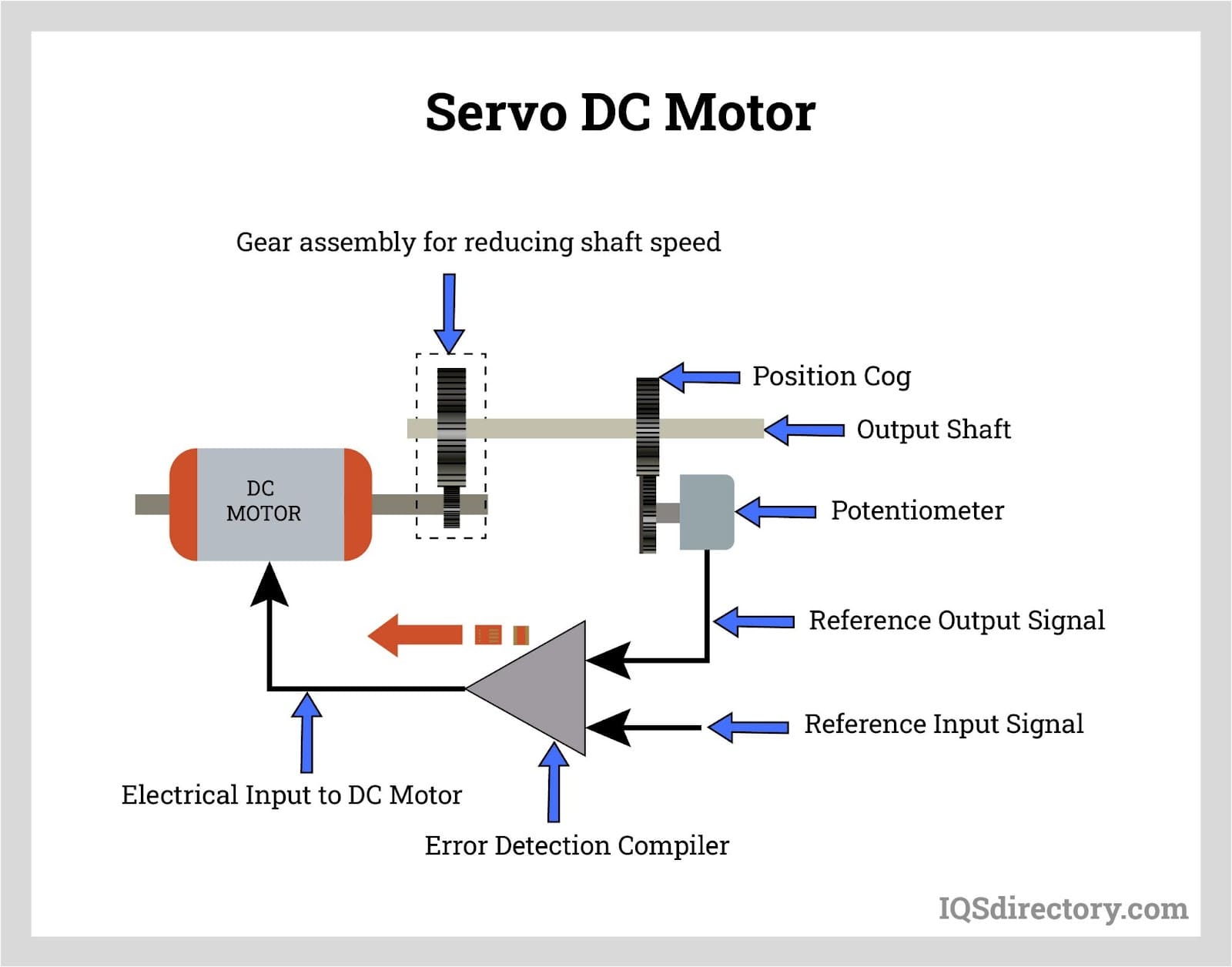

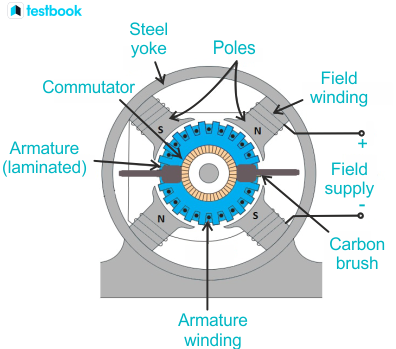

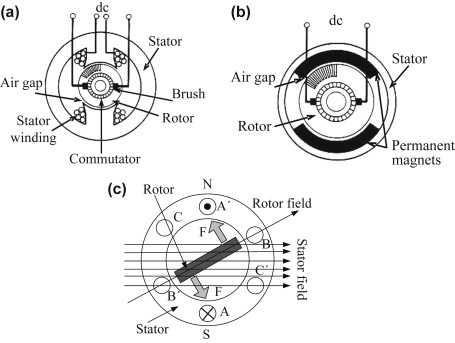

H-Bridge circuits are pivotal in applications requiring bidirectional motor control, enabling motors to rotate in both clockwise and counter-clockwise directions. This circuit utilizes four MOSFETs arranged in an H-shape, allowing for dynamic control of motor speed and direction through PWM signals. B2B buyers should consider the complexity of design and potential electromagnetic interference (EMI) when implementing this technology, as it may require additional filtering solutions to mitigate noise.

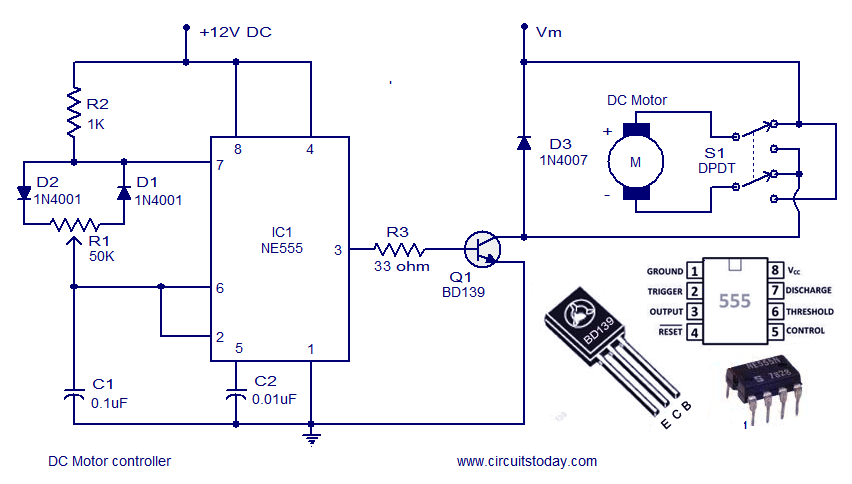

How does PWM Control Circuit enhance motor performance?

PWM control circuits are designed to modulate motor speed efficiently by adjusting the duty cycle of the voltage supplied to the motor. This method is prevalent in applications like conveyor systems and HVAC, where energy efficiency is crucial. B2B buyers should be aware of the need for precise tuning of the PWM frequency to avoid power loss and ensure optimal performance, making it essential to choose components that can handle the specific operational demands.

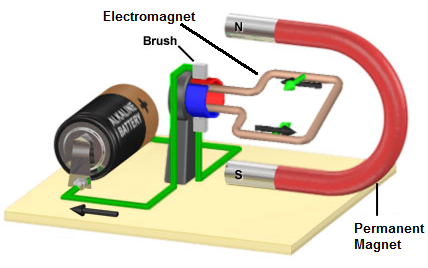

Illustrative image related to circuit of dc motor

What advantages does a Full-Bridge Driver offer?

Full-bridge drivers provide comprehensive control over motor functions by managing all four switches in an H-bridge configuration. This capability makes them suitable for industrial machinery and CNC applications where robust motor performance is required. While they offer enhanced control and flexibility, B2B buyers should be mindful of the higher costs and complexity associated with installation and maintenance, which may impact overall project budgets.

In what scenarios are Low-Side Drivers the best choice?

Low-side drivers are ideal for simple motor applications where unidirectional control suffices. They are cost-effective and straightforward to implement, making them attractive for businesses looking for basic solutions. However, buyers should recognize the limitations of low-side drivers, particularly in applications where bidirectional control is necessary, as this could necessitate additional circuitry.

How do High-Side Drivers improve motor control in automotive applications?

High-side drivers are essential in automotive and robotics applications, where they control the upper switches of an H-bridge. This setup allows for greater flexibility in motor direction control. While they offer distinct advantages, such as improved performance in high-voltage environments, B2B buyers must consider the increased costs and complexity associated with high-side drivers, ensuring that their selection aligns with the specific requirements of their projects.

Key Industrial Applications of circuit of dc motor

| Industry/Sector | Specific Application of circuit of dc motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhanced automation and efficiency in production | High torque requirements, durability, and compatibility with control systems |

| Automotive | Electric Vehicles (EVs) | Improved energy efficiency and performance | Regulatory compliance, battery integration, and thermal management |

| Agriculture | Automated Irrigation Systems | Increased yield through precision farming | Environmental resistance, power efficiency, and scalability |

| Robotics | Robotic Arms and Assemblers | Greater precision and adaptability in tasks | Size constraints, feedback systems, and integration with sensors |

| Mining | Material Handling Equipment | Enhanced safety and operational efficiency | Robustness under harsh conditions, high torque, and reliability |

How is the circuit of DC motors utilized in manufacturing conveyor systems?

In manufacturing, DC motor circuits are integral to conveyor systems, providing precise control over speed and direction. This automation enhances production efficiency by minimizing manual labor and reducing operational delays. International buyers, particularly from regions like Africa and South America, should consider sourcing motors with high torque capabilities and robust designs to withstand continuous operation. Additionally, compatibility with existing control systems is crucial to ensure seamless integration into current manufacturing setups.

What role do DC motor circuits play in electric vehicles (EVs)?

In the automotive sector, DC motor circuits are pivotal in the development of electric vehicles, where they are employed for propulsion and auxiliary systems. The efficiency of these motors translates to extended battery life and improved vehicle performance. Buyers in the Middle East and Europe must prioritize sourcing motors that meet stringent regulatory standards for emissions and safety. Moreover, effective thermal management solutions are essential to maintain motor performance in varying climate conditions.

How do automated irrigation systems benefit from DC motor circuits in agriculture?

Automated irrigation systems utilize DC motor circuits to control water flow precisely, thereby optimizing resource use and increasing crop yield. This technology allows for the automation of irrigation schedules based on soil moisture levels, significantly enhancing agricultural productivity. Buyers from regions with varying climates, such as Africa, should focus on sourcing motors that are energy-efficient and resistant to environmental factors like humidity and dust. Scalability is also a key consideration, as agricultural needs may expand over time.

In what ways do robotic arms utilize DC motor circuits in robotics?

DC motor circuits are fundamental in robotic arms, enabling precise movement and control for various applications, from assembly to packaging. These motors allow for adaptable and programmable operations, enhancing productivity and precision in manufacturing processes. International buyers must consider size constraints and the need for feedback systems that ensure accuracy in motion. Integrating these motors with advanced sensors can further enhance robotic capabilities, making them suitable for diverse industrial applications.

How do DC motor circuits enhance safety and efficiency in mining operations?

In the mining industry, DC motor circuits drive material handling equipment, such as conveyors and excavators, improving operational safety and efficiency. These motors provide the necessary torque to manage heavy loads while maintaining control over speed and direction. Buyers in challenging environments like mining should prioritize sourcing robust and reliable motors capable of operating under extreme conditions. Additionally, features such as overload protection and durability are critical for minimizing downtime and ensuring consistent performance.

3 Common User Pain Points for ‘circuit of dc motor’ & Their Solutions

Scenario 1: Difficulty in Achieving Precise Motor Control

The Problem: B2B buyers often encounter challenges in achieving precise control over the speed and direction of DC motors, particularly in complex applications like robotics or automated manufacturing. This lack of precision can lead to inefficiencies, increased wear and tear on equipment, and ultimately higher operational costs. Buyers may find that their current motor drive circuits are not responsive enough to the required control inputs or fail to deliver the necessary torque at varying speeds.

The Solution: To overcome these challenges, it’s crucial to select a high-quality motor driver IC that is specifically designed for precision control. Look for components that support advanced control techniques like pulse width modulation (PWM) and feedback mechanisms. Implementing an H-bridge configuration can also enhance control over motor direction and speed. Buyers should ensure that the driver circuit is compatible with their microcontroller to facilitate seamless communication. Additionally, integrating sensors that provide real-time feedback on motor performance can significantly improve control accuracy. Regularly testing and calibrating the system can help maintain optimal performance and prolong the lifespan of the motor and drive circuit.

Scenario 2: Overheating and Component Failure in Motor Drives

The Problem: A common pain point for B2B buyers is the overheating of DC motor drive circuits, which can lead to component failure and system downtime. This issue is particularly pressing in high-load applications where motors are subjected to continuous operation. Excessive heat can damage MOSFETs and other components, resulting in costly repairs and potential safety hazards. Buyers may struggle to find reliable solutions that prevent overheating while ensuring consistent performance.

The Solution: To address overheating issues, buyers should focus on proper thermal management strategies. This includes selecting MOSFETs with low ON-state resistance, which can minimize heat generation during operation. Implementing heat sinks and fans can also help dissipate heat effectively. Additionally, buyers should consider integrating thermal sensors into their systems to monitor temperature in real time. This data can be fed back to the microcontroller, enabling adaptive control strategies that reduce power output when temperatures rise beyond safe levels. Incorporating over-current protection features in the driver circuit can further safeguard against overheating by shutting down the motor when excessive current is detected.

Scenario 3: EMI Interference and System Reliability

The Problem: Electromagnetic interference (EMI) is a significant concern for B2B buyers using DC motor circuits, especially in industrial environments. EMI can disrupt the operation of nearby electronic components, leading to erratic motor performance and reduced system reliability. Buyers may find that their systems are vulnerable to noise, which can compromise the integrity of control signals and lead to operational inefficiencies.

The Solution: To mitigate EMI issues, buyers should prioritize the selection of components that are designed to minimize interference. This includes using shielded cables and employing ferrite beads to filter out high-frequency noise. Additionally, the layout of the PCB should be optimized to reduce lead inductance and minimize loop areas that can pick up EMI. Implementing proper grounding techniques can also help in reducing noise. Buyers should consider using low-pass filters on the power supply lines to further clean the signals before they reach sensitive components. Regular EMI testing and validation during the design phase can help identify potential sources of interference and ensure that the circuit is robust against EMI-related issues.

Strategic Material Selection Guide for circuit of dc motor

What are the Key Materials for Circuit Design in DC Motors?

When selecting materials for the circuit of a DC motor, it is essential to consider their properties, advantages, and limitations. The choice of materials directly impacts the performance, durability, and cost-effectiveness of the motor system. Below, we analyze four common materials used in DC motor circuits: copper, aluminum, polyimide, and silicon.

How Does Copper Contribute to DC Motor Circuits?

Copper is widely recognized for its excellent electrical conductivity, making it a preferred choice for wiring and connections in DC motor circuits. Its key properties include a high melting point (1,984°F or 1,085°C) and good corrosion resistance when properly treated.

Pros: The high conductivity of copper minimizes energy losses, which is crucial for efficient motor operation. Its durability allows it to withstand mechanical stress, making it suitable for various applications.

Cons: Copper can be relatively expensive compared to other metals, and its weight can be a drawback in applications where weight reduction is critical. Additionally, copper can corrode if exposed to harsh environments without adequate protection.

Impact on Application: Copper’s compatibility with various media makes it an excellent choice for circuits in diverse environments, including those found in Africa and the Middle East, where humidity and temperature fluctuations can be significant.

What Role Does Aluminum Play in DC Motor Circuits?

Aluminum is another popular material, particularly for components like heat sinks and casings. It is lightweight, has good thermal conductivity, and is resistant to corrosion due to the formation of a protective oxide layer.

Pros: The lower cost and lighter weight of aluminum compared to copper make it an attractive option for manufacturers looking to reduce overall system weight and cost.

Cons: While aluminum has decent electrical conductivity, it is not as efficient as copper. Additionally, its mechanical strength is lower, which may necessitate thicker components to achieve the same durability.

Impact on Application: In regions like South America, where manufacturing costs are a significant concern, aluminum can provide a cost-effective solution without compromising too much on performance.

Why is Polyimide Important for Insulation in DC Motor Circuits?

Polyimide is a high-performance polymer used primarily for insulation in DC motor circuits. It boasts excellent thermal stability, withstanding temperatures up to 500°F (260°C) without degradation.

Pros: Polyimide’s high dielectric strength makes it ideal for insulating sensitive electronic components, reducing the risk of short circuits and electrical failures.

Cons: The primary drawback of polyimide is its higher cost compared to traditional insulating materials, which may deter some manufacturers, especially in price-sensitive markets.

Impact on Application: In regions with high operational temperatures, such as parts of Africa and the Middle East, polyimide’s thermal stability can significantly enhance the reliability of DC motor circuits.

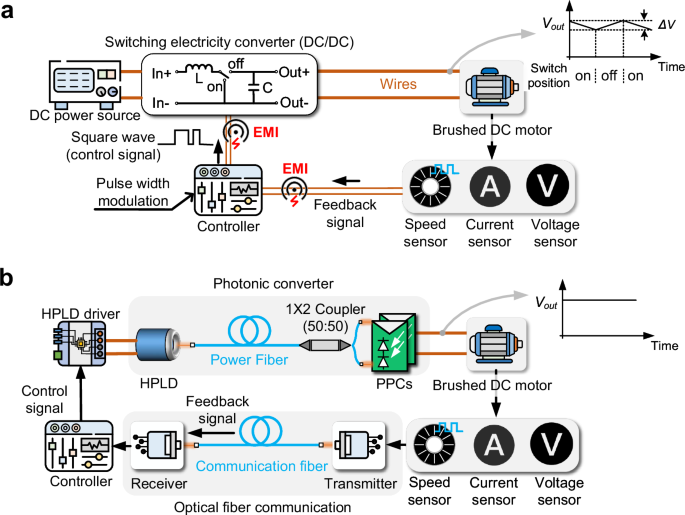

Illustrative image related to circuit of dc motor

How Does Silicon Influence DC Motor Circuit Performance?

Silicon is a fundamental material used in semiconductor devices, including motor driver ICs. It has a high melting point (2,577°F or 1,414°C) and excellent thermal conductivity.

Pros: Silicon’s ability to function effectively at high temperatures and its compatibility with various electronic components make it indispensable for modern DC motor control systems.

Cons: The primary limitation of silicon is its brittleness, which can lead to failure under mechanical stress. Additionally, silicon components can be more expensive to manufacture.

Impact on Application: Given the growing demand for advanced motor control in Europe, where high-performance standards are expected, silicon-based components are increasingly favored for their reliability and efficiency.

Summary Table of Material Selection for DC Motor Circuits

| Material | Typical Use Case for circuit of dc motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and connections | High electrical conductivity | Expensive and heavy | High |

| Aluminum | Heat sinks and casings | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Polyimide | Insulation for electronic components | Excellent thermal stability | Higher cost compared to traditional insulators | High |

| Silicon | Semiconductor devices in motor drivers | High performance at elevated temperatures | Brittleness under mechanical stress | Medium |

In conclusion, the selection of materials for DC motor circuits should be based on a careful analysis of their properties, pros and cons, and the specific requirements of the application. International buyers should also consider regional factors such as compliance with local standards and the availability of materials to ensure optimal performance and cost-effectiveness.

In-depth Look: Manufacturing Processes and Quality Assurance for circuit of dc motor

What Are the Main Stages in the Manufacturing Process of DC Motor Circuits?

The manufacturing process of DC motor circuits involves several critical stages, each essential for ensuring the final product meets quality standards. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for DC Motor Circuits?

Material preparation begins with sourcing high-quality components, such as MOSFETs, resistors, capacitors, and printed circuit boards (PCBs). Suppliers should be vetted for reliability and compliance with international standards. The materials are often subjected to incoming quality control (IQC) checks to ensure they meet specifications. This process may involve visual inspections and electrical testing to verify component integrity before production begins.

What Techniques Are Used in Forming DC Motor Circuits?

During the forming stage, the prepared materials undergo various techniques to create the circuit layout. This typically involves PCB fabrication, where the circuit design is transferred onto the board through processes like photolithography and etching. Additionally, surface mount technology (SMT) is commonly used to place components on the PCB. Automated pick-and-place machines enhance precision and efficiency, reducing the likelihood of human error.

How Is the Assembly of DC Motor Circuits Conducted?

The assembly stage involves the integration of all components onto the PCB. This may include soldering components using reflow or wave soldering techniques. After assembly, the circuits often undergo a visual inspection to identify any obvious defects. Automated optical inspection (AOI) can also be employed to ensure that all components are correctly placed and soldered.

What Finishing Processes Are Applied to DC Motor Circuits?

Finishing processes focus on enhancing the durability and functionality of the DC motor circuits. This can include conformal coating for moisture and dust protection, as well as labeling and packaging. Final quality checks are essential at this stage to ensure compliance with specifications. The finished products are often subjected to functional testing to verify that they operate correctly under various conditions.

How Are Quality Assurance Measures Implemented in DC Motor Circuit Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of DC motor circuits. Adherence to international standards, such as ISO 9001, provides a framework for quality management systems. This standard emphasizes continuous improvement and customer satisfaction, which are critical for B2B transactions.

What International and Industry-Specific Standards Should Buyers Be Aware Of?

In addition to ISO 9001, various industry-specific certifications may apply, such as CE marking for compliance with European safety standards and API standards for quality assurance in the oil and gas sector. Buyers from different regions, including Africa, South America, the Middle East, and Europe, should be aware of the specific standards relevant to their market to ensure compliance and safety.

What Are the Key Quality Control Checkpoints in DC Motor Circuit Production?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure product integrity. These checkpoints typically include:

- Incoming Quality Control (IQC): Inspect materials and components upon arrival.

- In-Process Quality Control (IPQC): Monitor production processes to catch defects early.

- Final Quality Control (FQC): Conduct thorough testing and inspections before shipping.

By implementing these checkpoints, manufacturers can identify and rectify issues before they escalate.

How Are Common Testing Methods Used to Ensure Quality in DC Motor Circuits?

Common testing methods include functional testing, where the circuit’s performance is evaluated under load conditions. Other tests may include thermal cycling, vibration testing, and electromagnetic compatibility (EMC) testing. These methods help ensure that the circuits can withstand operational stresses and maintain performance over time.

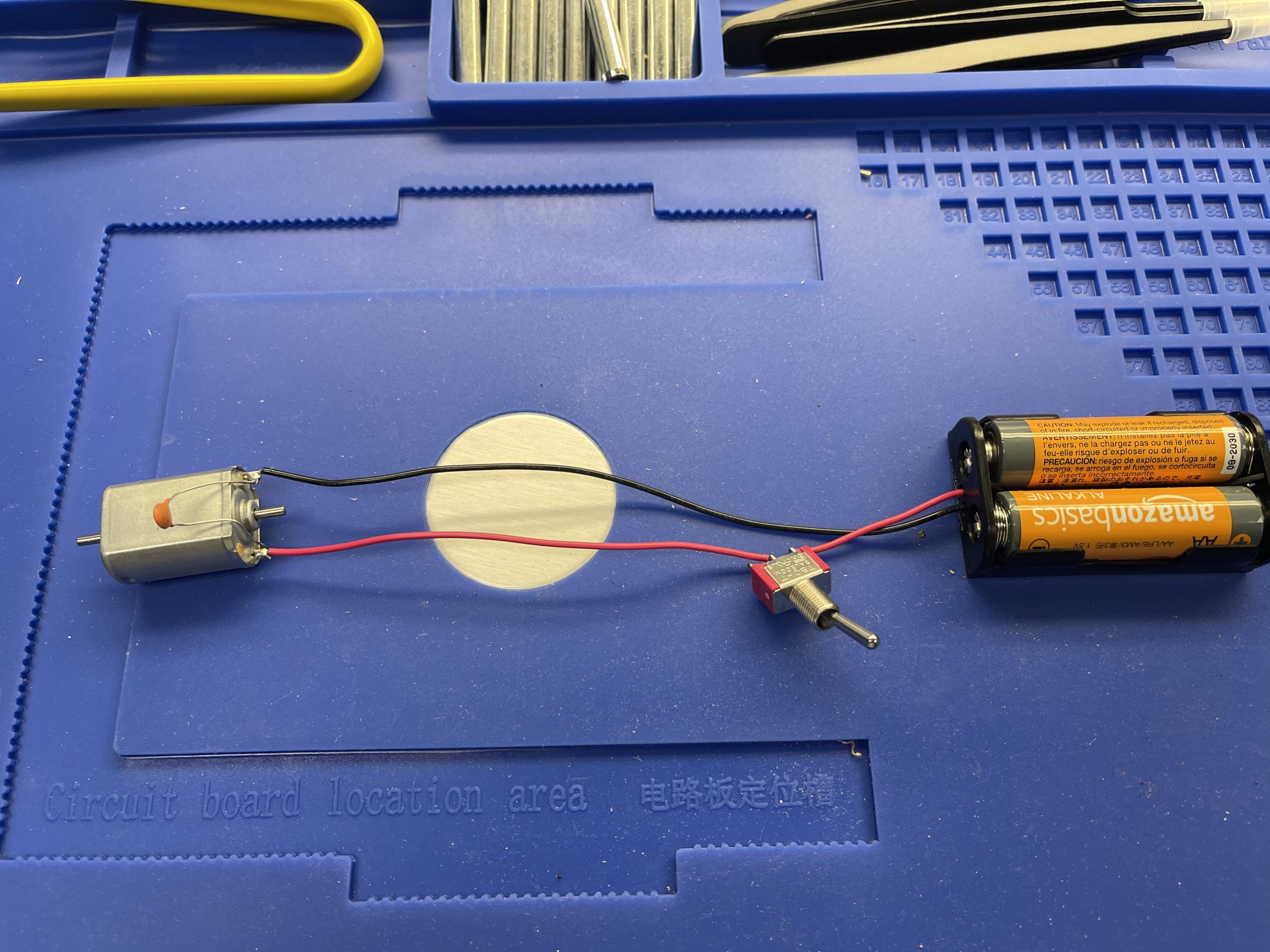

Illustrative image related to circuit of dc motor

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should actively verify the quality control processes of potential suppliers through several methods:

- Audits: Conduct regular audits of suppliers to assess compliance with quality standards and operational processes.

- Reports: Request detailed quality reports that outline testing results, defect rates, and corrective actions taken.

- Third-Party Inspections: Engage independent third-party inspectors to evaluate the supplier’s manufacturing processes and quality assurance practices.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers face unique challenges related to quality control and certification. Understanding the regulatory environment in different regions is crucial. For example, buyers from the Middle East may require specific certifications that differ from those needed in Europe. Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Buyers should establish clear specifications and maintain open lines of communication with suppliers to mitigate these challenges.

Conclusion: The Importance of Quality Assurance in DC Motor Circuit Manufacturing

In summary, the manufacturing processes and quality assurance measures for DC motor circuits are critical to ensuring product reliability and performance. By understanding the key stages of manufacturing, relevant quality standards, and testing methods, B2B buyers can make informed decisions when selecting suppliers. Establishing robust quality assurance practices not only helps in achieving compliance but also enhances customer satisfaction in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘circuit of dc motor’

In the realm of B2B procurement, sourcing a reliable circuit of a DC motor requires a structured approach to ensure that you meet your operational needs while maintaining quality and cost-efficiency. This guide provides a practical checklist to facilitate a smooth sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is paramount when sourcing DC motor circuits. Outline the required voltage, current ratings, and operational characteristics, such as speed and torque. This clarity will aid in identifying suitable suppliers who can meet your specific requirements.

Illustrative image related to circuit of dc motor

- Voltage and Current Ratings: Ensure these align with your application’s needs to avoid underperformance.

- Operational Characteristics: Determine if you need features like speed control or directional rotation.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers specializing in DC motor circuits. Utilize online platforms, industry forums, and trade shows to gather insights on their offerings and reputation.

- Industry Reputation: Look for suppliers with a proven track record in your specific industry.

- Customer Reviews: Analyze feedback from existing clients to gauge satisfaction levels and reliability.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold the necessary certifications. Compliance with international standards, such as ISO and RoHS, indicates a commitment to quality and safety.

- Quality Assurance: Certifications ensure that the products meet specific quality benchmarks.

- Regulatory Compliance: This is particularly important in regions with strict regulatory requirements, such as Europe.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that outline pricing, lead times, and payment terms. This will enable you to compare offers effectively.

- Breakdown of Costs: Ensure the quotation includes all costs, including shipping and handling.

- Lead Times: Assess how quickly suppliers can fulfill your order, which is critical for project timelines.

Step 5: Assess Technical Support and Warranty

Evaluate the level of technical support and warranty services offered by the supplier. Strong support can be invaluable for troubleshooting and maintenance.

- Technical Assistance: Ensure the supplier provides adequate technical support during installation and operation.

- Warranty Terms: A comprehensive warranty can protect your investment and provide peace of mind.

Step 6: Check Availability of Replacement Parts

Confirm that the supplier offers easy access to replacement parts and components. This is crucial for minimizing downtime in the event of a malfunction.

- Parts Availability: Suppliers should have a reliable inventory of critical components.

- Long-term Support: Ensure they have a history of supporting products over the long term.

Step 7: Finalize Your Order with Clear Terms

Once you’ve selected a supplier, finalize your order with clear terms and conditions. This should include delivery schedules, payment terms, and return policies.

- Contractual Clarity: A well-defined contract can prevent misunderstandings and disputes.

- Return Policies: Understand the terms regarding returns or exchanges in case the product does not meet specifications.

By following this checklist, you can streamline the procurement process for DC motor circuits, ensuring that you select the right suppliers who align with your technical and business needs.

Comprehensive Cost and Pricing Analysis for circuit of dc motor Sourcing

What Are the Key Cost Components in Sourcing DC Motor Circuits?

When sourcing circuits for DC motors, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: This includes the costs of electronic components such as MOSFETs, resistors, capacitors, and integrated circuits. The choice of materials can significantly affect the performance and reliability of the motor drive circuit.

-

Labor: Labor costs pertain to the workforce involved in the design, assembly, and testing of the circuits. Skilled labor is particularly crucial for high-quality production and can vary significantly by region.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Tooling costs include the expenses for molds, dies, and other manufacturing tools necessary for producing the circuits. Custom designs may require specialized tooling, which can increase costs.

-

Quality Control (QC): Ensuring the reliability and performance of DC motor circuits necessitates rigorous QC processes. This includes testing for functionality, durability, and compliance with industry standards, which adds to the overall cost.

-

Logistics: Shipping and handling costs can vary based on the origin and destination of the products. Factors such as distance, mode of transportation, and packaging requirements contribute to logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the margins can help buyers negotiate better deals.

How Do Price Influencers Impact the Cost of DC Motor Circuits?

Several factors can influence the pricing of DC motor circuits:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. However, suppliers may impose MOQs that can affect smaller buyers.

-

Specifications and Customization: Custom designs tailored to specific applications can significantly increase costs. Buyers should evaluate whether off-the-shelf solutions meet their needs to avoid unnecessary expenses.

-

Materials Quality and Certifications: High-quality materials and certifications (e.g., ISO, RoHS) can lead to increased costs but may provide long-term reliability and compliance, particularly important for international markets.

-

Supplier Factors: Supplier reputation, location, and financial stability can affect pricing. Established suppliers may offer better quality assurance but at a premium.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can significantly impact total costs. Understanding these terms is crucial for budgeting logistics expenses accurately.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, here are some valuable negotiation tips:

-

Leverage Total Cost of Ownership (TCO): Consider not just the upfront costs but the long-term costs associated with maintenance, repairs, and energy consumption. This holistic view can justify higher initial investments in better quality products.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and even prices. Building a relationship with suppliers can lead to better deals over time.

-

Explore Multiple Suppliers: Comparing quotes from multiple suppliers can provide leverage in negotiations and help identify the best value for your specific needs.

-

Stay Informed on Market Trends: Understanding global supply chain dynamics and market trends can help you anticipate price changes and negotiate from a position of knowledge.

-

Be Culturally Sensitive: When dealing with suppliers from diverse regions, be aware of cultural differences in negotiation styles and practices. Building rapport can lead to more favorable terms.

Conclusion

In conclusion, the sourcing of DC motor circuits involves a complex interplay of various cost components and price influencers. By understanding these factors and employing strategic negotiation tactics, international B2B buyers can optimize their procurement processes and achieve better value. Always remember that indicative prices can vary based on market conditions and specific project requirements, so conducting thorough market research and analysis is crucial for making informed purchasing decisions.

Alternatives Analysis: Comparing circuit of dc motor With Other Solutions

When evaluating the circuit of a DC motor, it’s crucial to consider alternative technologies that can fulfill similar operational requirements. These alternatives may offer different performance characteristics, cost implications, and ease of implementation, which can significantly impact the decision-making process for B2B buyers. Below, we compare the DC motor circuit against two viable alternatives: Stepper Motors and Brushless DC Motors (BLDC).

Illustrative image related to circuit of dc motor

| Comparison Aspect | Circuit Of DC Motor | Stepper Motor | Brushless DC Motor (BLDC) |

|---|---|---|---|

| Performance | High torque at low speeds; variable speed control via PWM | Precise position control; suitable for open-loop control | High efficiency and speed; good torque at high RPMs |

| Cost | Generally lower initial cost | Moderate cost; higher for advanced systems | Higher initial cost due to complexity |

| Ease of Implementation | Relatively simple; requires basic electronic knowledge | Requires specific driver circuits; more complex | Requires sophisticated controllers for operation |

| Maintenance | Low; generally durable with minimal upkeep | Moderate; depends on usage and environment | Low; fewer moving parts reduce wear |

| Best Use Case | Robotics, automotive applications, and general machinery | 3D printers, CNC machines, and applications requiring precise control | Electric vehicles, drones, and high-speed applications |

What Are the Advantages and Disadvantages of Using Stepper Motors?

Stepper motors are particularly advantageous for applications requiring precise control of position and speed. They operate in discrete steps, making them ideal for open-loop control systems where feedback is not necessary. However, they tend to be less efficient than DC motors and may experience resonance issues at higher speeds, which can lead to a loss of precision. Additionally, their cost can be moderate, especially for high-performance models.

How Do Brushless DC Motors Compare in Performance and Cost?

Brushless DC motors (BLDC) are known for their high efficiency and performance, especially at elevated RPMs. They provide excellent torque characteristics and are quieter than traditional brushed motors. However, their initial cost is typically higher due to the complexity of their controllers and the need for precise electronic control. Maintenance is generally low, as there are fewer moving parts, but the complexity of setup can pose a challenge for implementation.

Conclusion: Which Solution Should B2B Buyers Choose?

Selecting the right motor solution depends heavily on the specific application requirements. For tasks that require high torque at lower speeds and straightforward control, the circuit of a DC motor remains a strong contender. On the other hand, if precision and step control are paramount, stepper motors should be considered despite their moderate complexity and cost. For high-efficiency applications, particularly in fast-moving environments, BLDC motors present an excellent option, albeit at a higher price point. B2B buyers should evaluate their operational needs, budget constraints, and desired performance characteristics to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for circuit of dc motor

What are the Key Technical Properties of a DC Motor Circuit?

Understanding the technical specifications of DC motor circuits is essential for decision-makers in B2B contexts, particularly when selecting components for specific applications. Here are some critical specifications to consider:

1. Voltage Rating

The voltage rating indicates the maximum voltage that the motor can handle without risking damage. It’s crucial for B2B buyers to ensure that the voltage rating matches their application requirements. Operating a motor beyond its rated voltage can lead to overheating and failure, resulting in costly downtime and repairs.

2. Current Rating

Current rating defines the maximum current the motor circuit can draw. This specification is vital for choosing the right driver components and ensuring they can supply sufficient power without overheating. A mismatch can lead to inefficiencies and potential circuit failure, which can impact production timelines and operational costs.

3. PWM Frequency

Pulse Width Modulation (PWM) frequency determines how fast the motor can be switched on and off, directly influencing speed control and efficiency. A suitable PWM frequency minimizes power loss and ensures smooth operation. Buyers must consider this when designing systems, as it affects overall performance and energy consumption.

4. Thermal Resistance

Thermal resistance measures a component’s ability to dissipate heat. In motor circuits, this is crucial for maintaining operational integrity and longevity. Components with high thermal resistance can overheat, leading to premature failure. Understanding this property helps in selecting suitable heat sinks and ensuring reliability in various operational environments.

5. Inductance

Inductance in the motor circuit affects how quickly the motor responds to changes in current. Low inductance is preferable for faster switching and better performance in dynamic applications. Buyers should consider inductance to optimize motor performance and control, particularly in applications requiring precise speed and position control.

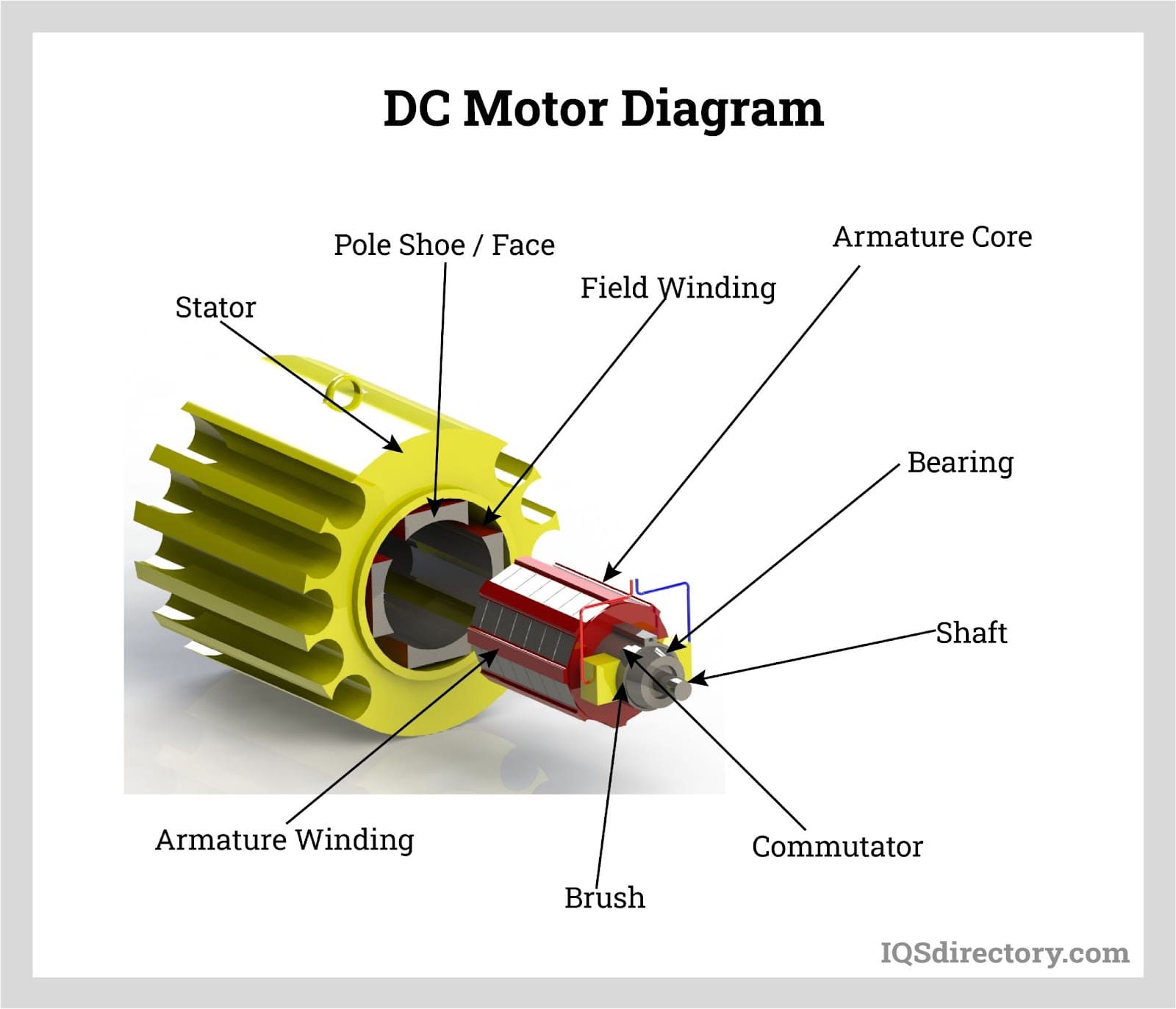

Illustrative image related to circuit of dc motor

6. Efficiency Rating

Efficiency rating reflects how effectively the motor converts electrical energy into mechanical energy. Higher efficiency ratings lead to reduced energy costs and less heat generation. For B2B buyers, selecting high-efficiency motors can significantly impact operational expenses and sustainability efforts.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B sector. Here are some essential terms related to DC motor circuits:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of DC motors, understanding OEM relationships can help buyers assess quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers, as it affects inventory levels and cash flow. Buyers should negotiate MOQs that align with their operational needs while ensuring supplier viability.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. Issuing an RFQ for DC motor components allows buyers to compare prices and terms across suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping costs and risk transfer. Familiarity with Incoterms is crucial for B2B buyers to understand their obligations and ensure smooth logistics when importing DC motor components.

5. Tolerance

Tolerance specifies the allowable deviation from a specified value in manufacturing. In DC motor circuits, precise tolerances are essential to ensure compatibility and functionality. Buyers should prioritize suppliers who maintain tight tolerances to guarantee performance and reliability.

6. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for B2B buyers to manage project timelines effectively and avoid delays that could affect production schedules.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and support their long-term goals in the competitive market of DC motor applications.

Navigating Market Dynamics and Sourcing Trends in the circuit of dc motor Sector

What Are the Current Market Dynamics and Key Trends in the Circuit of DC Motor Sector?

The global circuit of DC motor market is witnessing significant growth, driven by the increasing demand for automation across various industries, including manufacturing, automotive, and renewable energy. The rise of electric vehicles (EVs) and advancements in robotics are pivotal in shaping this landscape. In regions like Africa and South America, the growth of industrial infrastructure is accelerating the adoption of DC motors, while Europe and the Middle East are focusing on energy efficiency and automation technologies.

Emerging B2B tech trends include the integration of IoT with DC motor circuits, enabling real-time monitoring and control, which enhances operational efficiency. Additionally, the use of advanced motor driver technologies, such as H-bridge configurations, is gaining traction as businesses seek to optimize motor performance while minimizing energy consumption. International buyers are increasingly looking for suppliers who can offer modular solutions that are easy to integrate and provide scalability, catering to diverse application requirements.

Illustrative image related to circuit of dc motor

Another key trend is the shift towards digital transformation in manufacturing processes, which necessitates sourcing partnerships that can provide not only components but also complete drive solutions. This evolution is particularly relevant for international buyers from regions with burgeoning industrial bases, such as Nigeria and Saudi Arabia, where there is a strong push toward adopting cutting-edge technologies to improve production capabilities.

How Can Sustainability and Ethical Sourcing Impact the Circuit of DC Motor Sector?

Sustainability is becoming a crucial factor in the sourcing strategies of B2B buyers in the circuit of DC motor sector. The environmental impact of manufacturing processes, particularly in terms of resource consumption and waste generation, is under scrutiny. Companies are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon footprints and employing renewable energy sources in production.

Ethical sourcing is equally important, as businesses strive to ensure that their supply chains are free from labor exploitation and environmental degradation. B2B buyers are now looking for partners who can provide transparency in their sourcing practices and adhere to international standards for labor rights and environmental protection. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the demand for ‘green’ materials, such as recyclable components and eco-friendly packaging, is on the rise. Buyers are increasingly interested in suppliers who utilize low-impact manufacturing techniques and offer products that contribute to energy efficiency, such as advanced motor drives that lower energy consumption without sacrificing performance. This focus on sustainability not only enhances brand reputation but also aligns with the growing consumer demand for environmentally responsible products.

What Is the Brief Evolution and History of DC Motor Circuit Technology?

The evolution of DC motor circuit technology dates back to the late 19th century, when the first electric motors were developed, revolutionizing industries and transportation. Early DC motors were simple, relying on basic electromagnetic principles. As technology advanced, the introduction of transistors and integrated circuits in the mid-20th century allowed for more sophisticated motor drive systems, paving the way for modern applications.

The transition from analog to digital control systems in the 1980s marked a significant milestone, enabling precise control of speed and torque, which has become essential in today’s automated environments. The introduction of pulse width modulation (PWM) techniques further enhanced the efficiency of DC motor circuits, allowing for more effective power management and control.

Today, the integration of smart technologies and IoT capabilities represents the latest phase in the evolution of DC motor circuits. This technological advancement provides businesses with enhanced data analytics and control mechanisms, driving the future of automation and energy efficiency across various sectors. As international B2B buyers continue to seek innovative solutions, the historical context of DC motor circuit technology underscores its critical role in modern industrial applications.

Illustrative image related to circuit of dc motor

Frequently Asked Questions (FAQs) for B2B Buyers of circuit of dc motor

-

How do I troubleshoot issues with my DC motor drive circuit?

To troubleshoot a DC motor drive circuit, start by checking the power supply and connections to ensure they are secure and functioning. Use a multimeter to measure voltage levels at various points, including the motor terminals and driver ICs. Additionally, inspect the H-bridge configuration for any faulty MOSFETs or components. If the circuit is not responding as expected, verify the PWM signal from the microcontroller and ensure that there is no electromagnetic interference (EMI) affecting the operation. Document your findings and systematically eliminate potential problems. -

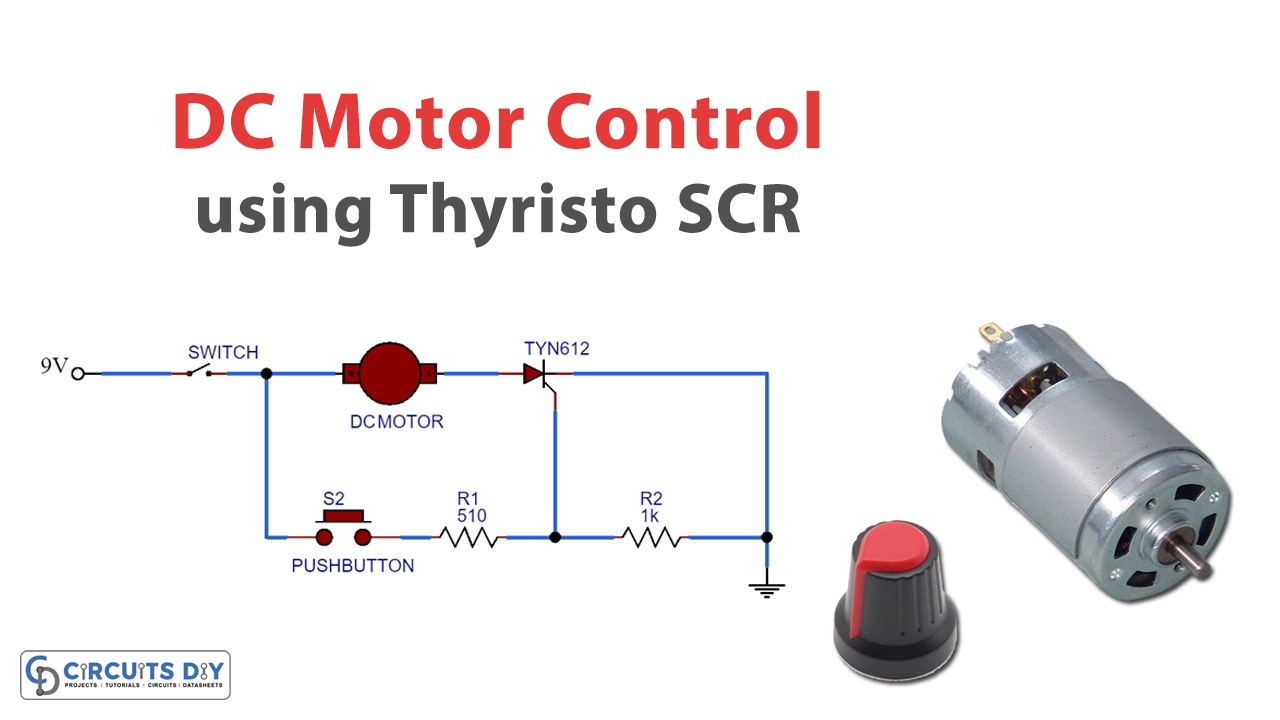

What is the best configuration for a DC motor drive circuit?

The H-bridge configuration is widely regarded as the best for controlling DC motors due to its ability to reverse motor direction and control speed using PWM. This topology allows for precise control over the motor’s rotation and can handle varying loads effectively. Depending on the application, you may also consider alternative configurations like half-bridge or full-bridge drivers, which can be beneficial for specific operational requirements. Selecting the right configuration depends on your project’s power needs, complexity, and cost considerations. -

What factors should I consider when selecting a supplier for DC motor circuits?

When selecting a supplier for DC motor circuits, consider their experience in the industry, product quality, and the ability to meet your specific requirements. Verify their certifications and quality assurance processes to ensure compliance with international standards. Additionally, assess their responsiveness to inquiries and ability to provide technical support. It’s also crucial to check their logistics capabilities, especially if you are sourcing from regions like Africa or South America, to ensure timely delivery and service continuity. -

What customization options are available for DC motor drive circuits?

Many suppliers offer customization options for DC motor drive circuits to meet specific application needs. Customizations can include variations in voltage and current ratings, integration of additional safety features like over-current protection, or tailored PWM frequency settings. You can also request modifications to the circuit layout or the inclusion of specific connectors and interfaces. Discuss your requirements with potential suppliers to explore the extent of their customization capabilities and how they can align with your project goals. -

What are the typical minimum order quantities (MOQs) for DC motor drive circuits?

Minimum order quantities (MOQs) for DC motor drive circuits vary by supplier and can range from small quantities for prototypes to larger batches for mass production. Many suppliers may have flexible MOQs depending on the complexity and customization of the circuit. It’s essential to communicate your needs upfront and inquire about MOQs, especially if you are testing a new application or entering a new market. Establishing a good relationship with your supplier can also lead to more favorable terms. -

What payment terms are standard for purchasing DC motor circuits internationally?

Standard payment terms for international purchases of DC motor circuits typically include options like wire transfers, letters of credit, or PayPal, depending on the supplier’s policies. Payment terms may range from upfront payment to net 30 or net 60 days after delivery. It’s important to discuss and agree on payment terms before finalizing the order to avoid any misunderstandings. Additionally, consider the currency fluctuations and transaction fees that may affect the overall cost of your purchase. -

How can I ensure quality assurance (QA) in my DC motor circuit procurement?

To ensure quality assurance in your procurement of DC motor circuits, request detailed specifications and certifications from suppliers. Conduct a thorough supplier audit, which may include site visits to their manufacturing facilities. It’s also beneficial to ask for samples before placing a large order to evaluate product quality firsthand. Establish a clear agreement on quality standards and testing procedures, and consider implementing a post-delivery inspection process to ensure that the received products meet your requirements. -

What logistics considerations should I keep in mind when sourcing DC motor circuits?

When sourcing DC motor circuits, logistics considerations include shipping methods, lead times, and import regulations in your country. Evaluate the supplier’s shipping capabilities and their experience with international deliveries, especially if you’re sourcing from regions with complex customs processes. Discuss potential delays and their impact on your project timeline. Additionally, consider the costs associated with shipping and customs duties, and factor these into your overall budget to avoid unexpected expenses.

Top 3 Circuit Of Dc Motor Manufacturers & Suppliers List

1. Electronics Tutorials – H-Bridge Circuit for DC Motor Control

Domain: electronics-tutorials.ws

Introduction: H-bridge Circuit for DC Motor Bidirectional Control; Allows bidirectional rotation of DC motors; Controls rotational speed and direction; Uses fixed DC voltage or pulse width modulation (PWM); Suitable for permanent magnet DC motors and stepper motors; Configuration resembles the letter ‘H’; Comprises four switching elements (mechanical switches, relays, BJTs, or MOSFETs); Enables control of motor…

2. Circuit Basics – L293D Motor Driver

Domain: circuitbasics.com

Registered: 2014 (11 years)

Introduction: L293D Motor Driver: A popular motor driver IC that can drive two DC motors simultaneously. It supplies up to 1A of current and operates at voltages from 4.5V to 36V, making it ideal for multi-wheel robot platforms. Key pin descriptions include: 1 (Enable 1-2), 2 (Input-1), 3 (Output-1), 4 & 5 (Ground), 6 (Output-2), 7 (Input-2), 8 (Vcc2), 9 (Enable 3-4), 10 (Input-3), 11 (Output-3), 12 & 13 (Groun…

3. KiCad Forum – Brushed DC Electric Motor

Domain: forum.kicad.info

Introduction: Brushed DC electric motor is an internally commutated electric motor designed to be run from a direct current power source and utilizing an electric brush for contact. Brushed motors were the first commercially important application of electric power to driving mechanical energy, and DC distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings….

Strategic Sourcing Conclusion and Outlook for circuit of dc motor

In conclusion, the strategic sourcing of DC motor circuits is pivotal for optimizing performance and ensuring reliability in diverse applications. By understanding the intricacies of motor drive technologies, particularly H-bridge configurations, B2B buyers can make informed decisions that enhance operational efficiency. The integration of advanced components, such as MOSFETs and microcontrollers, not only improves control over speed and direction but also facilitates energy savings and reduces maintenance costs.

As the demand for efficient and innovative motor solutions continues to rise across global markets, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing practices will be essential. Engaging with reputable suppliers who prioritize quality and innovation will empower businesses to stay competitive in their respective industries.

Looking ahead, we encourage international B2B buyers to explore partnerships that align with their technological needs and sustainability goals. Investing in high-quality DC motor circuits today will pave the way for enhanced productivity and future-proofing against evolving market demands. Seize the opportunity to lead in your sector by prioritizing strategic sourcing in your procurement processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to circuit of dc motor

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.