The Definitive Guide to Check Valve For Spa: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for check valve for spa

In today’s competitive landscape, sourcing the right check valve for spa applications poses significant challenges for international B2B buyers. Ensuring optimal water circulation and preventing unwanted water backflow are critical factors that can influence the efficiency and longevity of spa systems. This guide serves as a comprehensive resource for understanding the various types of check valves available, their applications, and the essential criteria for supplier vetting. By delving into factors such as cost considerations, installation requirements, and maintenance practices, buyers can make informed decisions that align with their specific operational needs.

This guide is particularly tailored for B2B buyers from regions like Africa, South America, the Middle East, and Europe, including key markets such as Germany and Brazil. It equips them with the knowledge to navigate the complexities of the global check valve market, ensuring they select products that not only meet regulatory standards but also enhance the performance of their spa systems. With actionable insights and expert recommendations, this resource empowers businesses to optimize their purchasing strategies, reduce operational risks, and ultimately achieve a better return on investment. Whether you are a seasoned industry player or new to the spa equipment sector, this guide will provide the clarity and direction needed to succeed in sourcing high-quality check valves.

Understanding check valve for spa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Swing Check Valve | Uses a swinging disc to allow flow in one direction only | Spa return lines, water features | Pros: Simple design, low cost. Cons: Limited flow rate, sensitive to debris. |

| Spring-Loaded Check Valve | Features a spring mechanism to prevent backflow | Spa suction lines, plumbing systems | Pros: Reliable closure, suitable for low-pressure systems. Cons: Higher cost, potential for spring fatigue. |

| Dual-Disc Check Valve | Equipped with two discs for reduced pressure loss | High-flow applications, commercial spas | Pros: Efficient flow, minimal turbulence. Cons: More complex design, higher maintenance needs. |

| PVC Check Valve | Made from durable PVC, resistant to corrosion | Residential and commercial spas | Pros: Lightweight, easy to install. Cons: Less durable than metal options, can be brittle in extreme temperatures. |

| Electronic Check Valve | Utilizes electronic sensors for precise control | Automated spa systems, advanced plumbing | Pros: High precision, programmable. Cons: Higher initial investment, requires power source. |

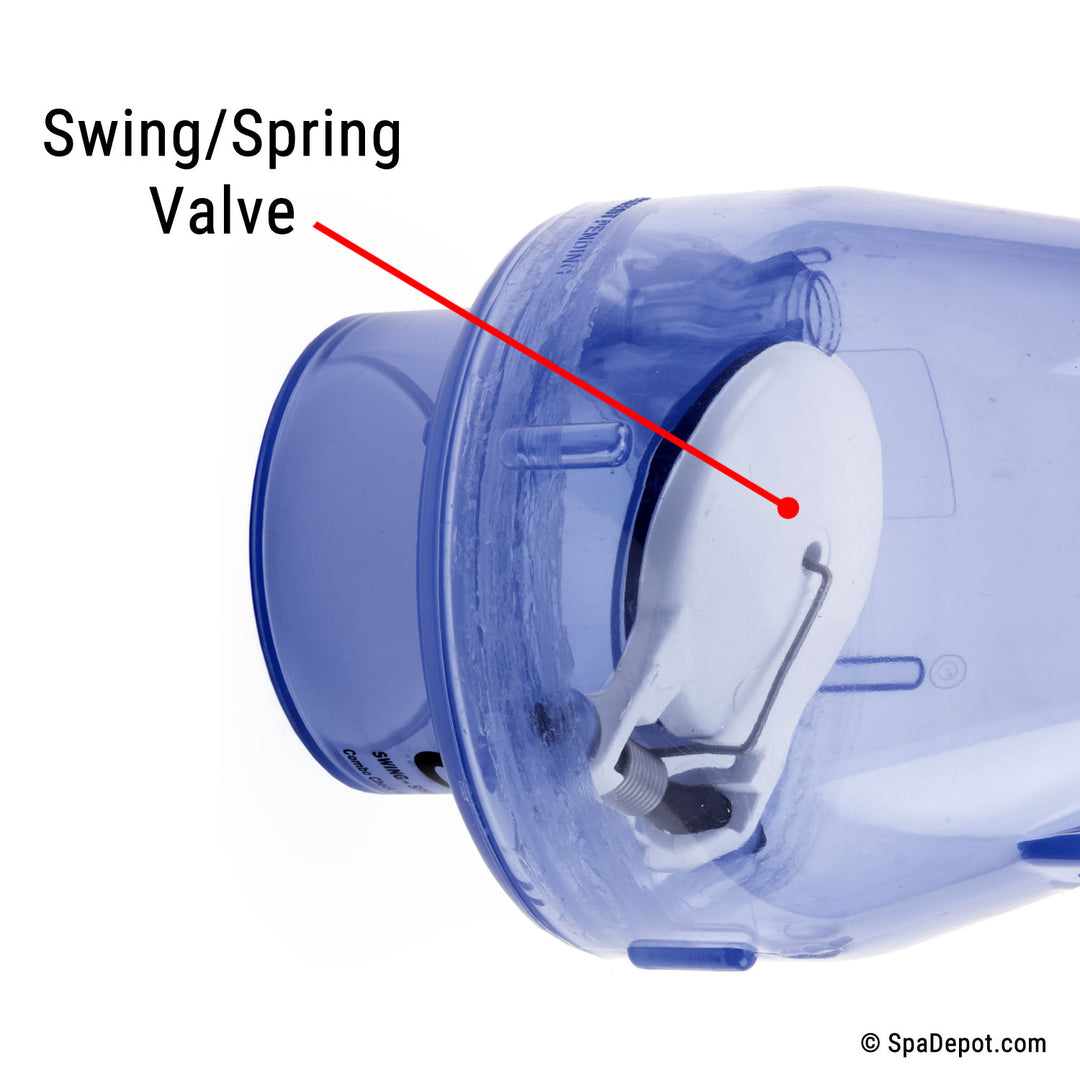

What Are the Characteristics of Swing Check Valves for Spas?

Swing check valves are commonly used in spa return lines due to their straightforward design, which incorporates a swinging disc that opens to allow flow and closes to prevent backflow. They are particularly suitable for applications where the flow direction is consistent. B2B buyers should consider the valve’s compatibility with existing systems and the potential for debris accumulation, which may hinder operation.

Why Choose Spring-Loaded Check Valves for Spa Systems?

Spring-loaded check valves feature a spring mechanism that ensures reliable closure, making them ideal for spa suction lines where backflow prevention is critical. Their design allows for effective operation even at low pressures, catering to various spa setups. Buyers should evaluate the valve’s durability and the potential for spring fatigue over time, particularly in high-use environments.

How Do Dual-Disc Check Valves Enhance Flow in Spa Applications?

Dual-disc check valves are designed with two discs that open and close to allow flow, resulting in reduced pressure loss and improved efficiency. These valves are suitable for high-flow applications, including commercial spas. When purchasing, B2B buyers must consider the complexity of the design, which may require more frequent maintenance compared to simpler options.

What Advantages Do PVC Check Valves Offer for Spa Installations?

PVC check valves are lightweight and resistant to corrosion, making them a popular choice for both residential and commercial spa installations. Their ease of installation is a significant advantage for B2B buyers looking for cost-effective solutions. However, it is essential to consider their durability, as PVC can become brittle in extreme temperatures, potentially leading to failure.

When to Invest in Electronic Check Valves for Spa Systems?

Electronic check valves offer precise control over flow direction, making them ideal for automated spa systems. These valves can be programmed for specific operational requirements, enhancing efficiency. However, B2B buyers should weigh the higher initial investment against the benefits of automation and precision, as well as the need for a consistent power source to operate effectively.

Key Industrial Applications of check valve for spa

| Industry/Sector | Specific Application of check valve for spa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality and Wellness | Spa and wellness center water management systems | Prevents backflow, maintaining water quality and hygiene | Certification standards, material compatibility, durability |

| Residential Pool & Spa | Home spa installations | Ensures efficient operation, preventing water loss | Size specifications, installation compatibility, cost |

| Aquatic Facility Management | Public spa and pool facilities | Enhances water circulation and filtration efficiency | Compliance with local regulations, maintenance requirements |

| Construction and Renovation | New spa construction projects | Facilitates proper water flow management | Technical specifications, installation ease, warranty terms |

| Industrial Water Systems | Large-scale spa systems in resorts or hotels | Reduces operational costs by minimizing water waste | Performance ratings, supplier reliability, lead times |

How Are Check Valves Used in Hospitality and Wellness Industries?

In the hospitality and wellness sector, check valves are vital for managing water flow in spas and wellness centers. They prevent backflow, ensuring that the water remains clean and hygienic for guests. This is particularly important in regions with strict health regulations, such as Europe and the Middle East. Businesses must consider certifications and materials that can withstand various water treatments, ensuring longevity and reliability.

What Role Do Check Valves Play in Residential Pool and Spa Applications?

For residential installations, check valves are essential in home spas to maintain optimal water levels and prevent backflow into the pool. This functionality not only enhances the efficiency of the spa but also helps homeowners avoid costly water loss. When sourcing, buyers should focus on the size specifications and compatibility with existing systems, as well as the cost-effectiveness of the valves.

Why Are Check Valves Important for Aquatic Facility Management?

Public aquatic facilities rely on check valves to enhance water circulation and filtration systems. These valves help maintain water quality by preventing contaminants from flowing back into clean water supplies. In regions like South America and Africa, where water management is critical, compliance with local regulations is a key consideration for facility managers when sourcing these components.

How Do Check Valves Contribute to Construction and Renovation Projects?

In new spa construction projects, check valves facilitate effective water flow management, which is crucial for the overall functionality of the system. Builders need to ensure that the valves meet technical specifications and are easy to install. Additionally, warranty terms can be a significant factor for construction companies looking to minimize future liabilities.

What Are the Advantages of Check Valves in Industrial Water Systems?

In large-scale industrial water systems, such as those found in resorts or hotels, check valves play a critical role in reducing operational costs by minimizing water waste. By preventing backflow, these valves ensure that the system operates efficiently. Buyers in this sector should prioritize performance ratings and supplier reliability to ensure they receive high-quality products that can withstand heavy use.

Illustrative image related to check valve for spa

3 Common User Pain Points for ‘check valve for spa’ & Their Solutions

Scenario 1: Spa Water Level Drop During Pump Downtime

The Problem: Many spa operators face a frustrating issue where the water level in the spa drops significantly when the pump is not running. This situation can lead to various complications, including the risk of air entering the pump, which can cause damage or inefficient operation. Furthermore, if the spa is connected to a pool, the water might drain into the pool, creating a lack of water in the spa and potential water quality issues. This problem is particularly common in raised spas that are linked to a pool system without adequate backflow prevention measures.

The Solution: To address this challenge, it is essential to install a check valve on the spa return line. The check valve will prevent water from flowing back into the pool when the pump is off, maintaining the desired water level in the spa. When sourcing check valves, B2B buyers should look for those specifically designed for spa applications, ensuring they can withstand the unique pressures and chemical compositions present in spa water. Additionally, checking the compatibility with existing plumbing systems is crucial. For best results, consider a professional assessment of the spa’s plumbing layout to identify the optimal placement for the check valve.

Scenario 2: Inadvertent Water Spillover from Spa to Pool

The Problem: Another common issue faced by spa operators is inadvertent spillover, where water leaks from the spa into the pool even when the spa is not in use. This can be particularly detrimental in commercial settings where water levels need to be controlled for aesthetic and operational reasons. The spillover can result from improperly functioning valves or a lack of proper backflow prevention, leading to not only loss of water but also potential contamination of the pool water.

The Solution: To mitigate this problem, B2B buyers should install a reliable check valve on the spa return line. This valve will prevent backflow and stop water from the spa from spilling into the pool. It’s vital to choose a check valve with a high-quality seal to ensure it functions effectively under varying water pressures. Additionally, regular maintenance checks on the spa’s valve systems should be performed to ensure they are closing properly and not allowing any leakage. For those looking to upgrade their systems, investing in smart valves that can provide feedback on their operational status could further enhance system reliability.

Scenario 3: Inefficient Heating Due to Air Lock Issues

The Problem: Spa operators often encounter inefficient heating issues due to air locks caused by improper water flow when the pump is turned off. An air lock can prevent the water from circulating properly, leading to uneven heating or even complete failure of the heating system. This is especially problematic in commercial settings where consistent water temperature is critical for customer satisfaction and operational efficiency.

The Solution: The installation of a check valve on the spa suction line can effectively counteract this issue. By preventing backflow, the check valve helps maintain water in the lines, reducing the likelihood of air locks forming. When selecting a check valve, it is crucial to ensure it is designed to handle the specific flow rates and water chemistry of spa systems. Additionally, regular inspections of the spa’s plumbing system should be conducted to identify any signs of wear or inefficiency. Implementing a preventive maintenance schedule can further enhance system performance and minimize the risk of heating issues arising from air locks.

Strategic Material Selection Guide for check valve for spa

What Are the Key Materials for Check Valves in Spa Applications?

When selecting check valves for spa applications, the choice of material is crucial for ensuring optimal performance, durability, and compatibility with the specific conditions of the spa environment. Here, we analyze four common materials used in the manufacturing of check valves, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does PVC Perform as a Material for Check Valves?

Key Properties: PVC (Polyvinyl Chloride) check valves are lightweight, corrosion-resistant, and have a temperature rating of up to 140°F (60°C). They are suitable for low-pressure applications and can handle various chemicals, making them ideal for spa environments.

Illustrative image related to check valve for spa

Pros & Cons: PVC is cost-effective and easy to manufacture, which lowers production costs. However, its lower temperature tolerance limits its use in high-heat applications. Additionally, while it is resistant to many chemicals, prolonged exposure to certain solvents can degrade the material.

Impact on Application: PVC check valves are particularly effective for spas that utilize chlorine or bromine sanitization systems. However, they may not be suitable for spas that experience extreme temperature fluctuations.

International Considerations: PVC is widely accepted globally, but buyers should ensure compliance with local regulations regarding chemical resistance and safety standards, such as ASTM in the U.S. or DIN in Germany.

Illustrative image related to check valve for spa

Why Choose Brass for Check Valves in Spa Systems?

Key Properties: Brass check valves are known for their excellent strength and durability, withstanding high temperatures (up to 200°F or 93°C) and pressures. They offer good corrosion resistance, particularly in chlorinated water environments.

Pros & Cons: The primary advantage of brass is its robustness and long lifespan, making it a reliable choice for spas. However, brass is more expensive than plastic options and can be susceptible to dezincification if not properly alloyed.

Impact on Application: Brass check valves are ideal for spas that require high-pressure systems or where durability is essential. They are compatible with a wide range of fluids, including hot water.

International Considerations: Brass check valves must meet specific standards, such as JIS in Japan or ISO standards in Europe. Buyers should verify the alloy composition to ensure it meets local corrosion resistance requirements.

Illustrative image related to check valve for spa

What Are the Benefits of Stainless Steel for Spa Check Valves?

Key Properties: Stainless steel check valves offer exceptional corrosion resistance and can handle high temperatures (up to 250°F or 121°C) and pressures. They are robust and can withstand harsh environments, making them suitable for various spa applications.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to corrosion, which ensures a long service life. However, the cost is significantly higher compared to PVC and brass, and manufacturing complexity can lead to longer lead times.

Impact on Application: Stainless steel check valves are particularly beneficial in spas that use saltwater systems, as they resist corrosion from salt. They are also suitable for high-performance spas that require reliable operation under varying conditions.

International Considerations: Buyers should ensure that stainless steel components comply with international standards like ASTM A312 for seamless pipes or ASTM A351 for castings. Additionally, the choice of grade (e.g., 304 vs. 316) can affect performance in specific environments.

How Does EPDM Rubber Enhance Check Valve Functionality?

Key Properties: EPDM (Ethylene Propylene Diene Monomer) rubber check valves are designed to withstand a wide temperature range (-40°F to 250°F or -40°C to 121°C) and offer excellent resistance to ozone and UV exposure.

Illustrative image related to check valve for spa

Pros & Cons: The flexibility and resilience of EPDM make it ideal for applications where movement or vibration is present. However, it may not be suitable for all chemical environments, particularly those involving petroleum products.

Impact on Application: EPDM check valves are commonly used in spas with water treatment systems that require flexibility and adaptability. They are particularly effective in preventing backflow in dynamic environments.

International Considerations: EPDM rubber products must meet specific compliance standards, such as FDA regulations for materials in contact with water. Buyers should also consider the local climate and environmental conditions that may affect the material’s performance.

Summary Table of Check Valve Materials

| Material | Typical Use Case for check valve for spa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Low-pressure spa applications | Cost-effective and lightweight | Limited temperature tolerance | Low |

| Brass | High-pressure spa systems | Durable and long-lasting | Higher cost and potential corrosion | Med |

| Stainless Steel | Saltwater spas and high-performance systems | Excellent corrosion resistance | High cost and manufacturing complexity | High |

| EPDM Rubber | Flexible applications in spas | Flexible and resilient | Chemical compatibility limitations | Med |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions regarding check valves for spa applications, considering factors like performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for check valve for spa

What Are the Main Stages in the Manufacturing Process of Check Valves for Spas?

The manufacturing process of check valves specifically designed for spas involves several critical stages: material preparation, forming, assembly, and finishing.

Material Preparation: Selecting Quality Materials for Durability

The first step in the manufacturing process is the selection of appropriate materials. Common materials used in check valves include brass, stainless steel, and high-quality plastics. These materials are chosen for their corrosion resistance and ability to withstand high temperatures and pressures typical in spa environments.

Once the materials are selected, they undergo rigorous testing to ensure they meet industry standards. This may include checking for tensile strength, ductility, and resistance to chemical corrosion, which are essential for ensuring longevity and performance.

Forming: Precision Techniques for Component Creation

After material preparation, the next stage is forming. Various techniques such as casting, forging, and machining are employed to create the individual components of the check valve. For instance, brass components may be cast using sand casting methods, while stainless steel parts might be machined for precise tolerances.

The forming process is crucial, as the dimensions and shapes of the components directly influence the valve’s performance. Precision engineering ensures that parts fit together correctly and function as intended, minimizing the risk of leaks or malfunctions.

Assembly: Bringing Components Together

Once all components are formed, they proceed to the assembly stage. This typically involves fitting together the valve body, disc, and seat. Depending on the design, the assembly process may utilize manual labor or automated machinery to enhance efficiency.

During assembly, special attention is paid to the sealing mechanisms, which are vital for preventing backflow. The use of high-quality seals, often made from elastomers, ensures that the valve operates effectively under varying pressure conditions.

Finishing: Ensuring Quality and Aesthetics

The final stage of manufacturing involves finishing processes such as polishing, coating, and sometimes plating. These not only improve the aesthetic appeal of the check valves but also enhance their resistance to environmental factors, particularly in outdoor spa installations.

Finishing processes also include the application of protective coatings to prevent corrosion and wear. This is especially important for valves used in regions with harsh climates, ensuring that they maintain performance over time.

How is Quality Assurance Implemented in the Manufacturing of Check Valves?

Quality assurance (QA) is integral to the manufacturing of check valves, ensuring that products meet both industry standards and customer expectations.

What Are the Relevant International Standards for Check Valves?

For manufacturers targeting international markets, adherence to quality standards such as ISO 9001 is critical. This standard outlines the criteria for a quality management system and is recognized globally. Other relevant certifications may include CE marking for compliance with European health and safety regulations and API (American Petroleum Institute) certifications for valves used in specific applications.

These standards help ensure that the products are manufactured consistently and reliably, providing a framework for continuous improvement.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before production begins. Tests for material properties, certifications, and supplier quality history are common practices.

-

In-Process Quality Control (IPQC): During the manufacturing process, random sampling and testing of components are conducted to identify any deviations from specifications. This may involve dimensional checks, visual inspections, and functional tests.

-

Final Quality Control (FQC): Once the valves are assembled, final inspections are performed. This includes tests for pressure resistance, flow rate, and leak testing to ensure that the valves function correctly under operational conditions.

What Common Testing Methods Are Used for Check Valves?

Testing methods vary depending on the specific requirements of the check valves. Some of the most common testing methods include:

-

Hydrostatic Testing: This method involves filling the valve with water and applying pressure to check for leaks and structural integrity.

-

Functional Testing: The valve is subjected to operational conditions to ensure it opens and closes as designed. This may involve simulating spa conditions, including temperature and pressure variations.

-

Material Testing: This includes tensile strength tests, hardness tests, and corrosion resistance evaluations, ensuring that materials perform well in the intended environment.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure product reliability. Here are several methods to achieve this:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control processes, and compliance with industry standards. This can be arranged through third-party services or directly by the buyer.

-

Quality Reports: Requesting detailed quality reports from the supplier, including results from IQC, IPQC, and FQC, can provide insights into their quality management practices.

-

Third-Party Inspections: Engaging third-party inspection agencies to evaluate the manufacturing process and conduct product testing ensures an unbiased assessment of quality.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must be aware of regional regulations and standards that may affect the quality and certification of check valves. For example:

-

Regional Compliance: Different regions may have specific requirements for materials, manufacturing processes, and product certifications. Buyers should familiarize themselves with local regulations in regions like Europe, Africa, and South America.

-

Documentation: Ensuring that suppliers provide all necessary documentation, including compliance certificates, test reports, and warranty information, is crucial for smooth international transactions.

-

Cultural Considerations: Understanding cultural and business practices in different regions can facilitate better communication and collaboration with suppliers, enhancing quality assurance efforts.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions, ensuring they source reliable and high-quality check valves for spas that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘check valve for spa’

When sourcing check valves for spas, a structured approach can streamline the procurement process and ensure you select the best components for your needs. This guide provides a practical checklist to help international B2B buyers navigate their purchasing decisions effectively.

Illustrative image related to check valve for spa

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of any successful procurement. Identify the size, material, and pressure ratings needed for the check valves based on your spa system. Consider the environment in which the valves will operate, as factors such as temperature and chemical exposure can influence material selection.

- Size: Ensure the valve fits your existing piping.

- Material: Choose between PVC, brass, or stainless steel based on durability and chemical compatibility.

Step 2: Research Industry Standards and Compliance

Before purchasing, familiarize yourself with relevant industry standards and regulations that apply to check valves in spa applications. Compliance with local and international standards (such as ISO or ANSI) can affect safety, performance, and warranty aspects.

- Certifications: Look for certifications that indicate compliance with health and safety regulations.

- Quality Assurance: Verify that the valves meet quality control standards during manufacturing.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, including their experience in supplying check valves for spa applications. Look for customer testimonials and case studies, particularly from regions similar to your target market.

- References: Ask for references from previous clients to gauge satisfaction and performance.

- Experience: Consider suppliers with a strong track record in the spa industry.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the check valves you are considering. Testing samples in your specific spa system can help identify any compatibility or performance issues.

- Performance Testing: Evaluate flow rates and sealing capabilities under real conditions.

- Material Compatibility: Ensure the materials used can withstand your spa’s operating environment.

Step 5: Compare Pricing and Payment Terms

Once you have shortlisted suppliers, compare pricing structures and payment terms. Keep in mind that the lowest price may not always equate to the best value, especially if it compromises quality or service.

Illustrative image related to check valve for spa

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Payment Flexibility: Assess payment options that suit your financial planning, including credit terms and upfront costs.

Step 6: Assess After-Sales Support and Warranty Options

A supplier’s after-sales support can be as important as the product itself. Ensure that the supplier offers robust customer service and clear warranty terms. This is crucial for addressing any issues post-purchase.

- Technical Support: Confirm that the supplier provides technical assistance for installation and maintenance.

- Warranty Coverage: Understand the warranty terms, including what is covered and for how long.

Step 7: Finalize and Place Your Order

After completing all evaluations and comparisons, finalize your supplier choice and place the order. Ensure that all specifications are clearly communicated in the purchase order to avoid misunderstandings.

- Order Confirmation: Request confirmation that includes details about delivery timelines and shipping methods.

- Documentation: Ensure you receive all necessary documentation, including invoices and compliance certificates.

By following this checklist, B2B buyers can make informed decisions when sourcing check valves for spas, ensuring the best fit for their applications and operational requirements.

Comprehensive Cost and Pricing Analysis for check valve for spa Sourcing

Analyzing the cost structure and pricing for check valves used in spa applications is essential for international B2B buyers looking to make informed purchasing decisions. Understanding the various components and influencers can lead to better negotiations and enhanced cost-efficiency.

What Are the Key Cost Components for Check Valves in Spa Applications?

The total cost of a check valve for a spa includes several critical components:

-

Materials: The choice of materials significantly impacts the cost. Common materials include PVC, brass, and stainless steel. Each material offers different durability and performance characteristics, influencing the overall price.

-

Labor: Labor costs vary by region and manufacturer. Skilled labor is required for both the assembly of the valves and any specialized customization that may be needed for specific applications.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Initial tooling costs can be high, especially for custom designs. These costs are usually amortized over the production run, affecting the unit price.

-

Quality Control (QC): Investing in robust QC processes ensures that the products meet specified standards, which can prevent costly returns and warranty claims. This investment is reflected in the pricing.

-

Logistics: Shipping costs depend on the distance from the manufacturer to the buyer, as well as the mode of transport. International shipping may incur additional tariffs and duties, impacting the final cost.

-

Margin: The profit margin applied by suppliers varies widely based on market competition, supplier reputation, and the perceived value of the product.

How Do Price Influencers Affect the Cost of Check Valves?

Several factors can influence the pricing of check valves for spas:

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often leads to discounts. Suppliers are more likely to offer favorable pricing for bulk orders, making it essential to assess your needs carefully.

-

Specifications and Customization: Custom-designed valves tailored to specific spa requirements can increase costs. Buyers should weigh the need for customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO or ANSI) often command a premium. Buyers should consider whether the additional cost aligns with their operational needs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding shipping terms (like FOB, CIF, etc.) is crucial for calculating total landed costs. Different terms can shift responsibilities and costs between buyers and sellers.

What Tips Can Help Buyers Negotiate Better Prices?

For international buyers, especially those in Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation power:

-

Conduct Thorough Market Research: Understanding the market landscape helps buyers identify competitive pricing and potential suppliers.

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term factors such as maintenance, reliability, and operational efficiency.

-

Negotiate Terms: Engage suppliers in discussions about payment terms, delivery schedules, and warranty provisions. Flexible terms can lead to better overall pricing.

-

Explore Alternative Suppliers: While established suppliers might provide reliability, emerging manufacturers may offer competitive pricing. Assessing multiple sources can yield better deals.

-

Be Mindful of Pricing Nuances for International Transactions: Currency fluctuations, import duties, and local regulations can affect costs. Being aware of these factors can lead to more informed budgeting.

Disclaimer on Indicative Prices

Prices for check valves can vary widely based on the factors outlined above. It is essential for buyers to request quotes tailored to their specific requirements and to consider all relevant cost components when making purchasing decisions.

Alternatives Analysis: Comparing check valve for spa With Other Solutions

In the realm of spa maintenance, ensuring water retention and preventing backflow are critical concerns. While check valves are a popular solution for these issues, various alternatives exist that may cater to specific requirements, budgets, and operational contexts. This analysis explores these alternatives, offering a clear comparison to aid B2B buyers in making informed decisions.

| Comparison Aspect | Check Valve For Spa | Manual Valve System | Electronic Flow Control System |

|---|---|---|---|

| Performance | Prevents backflow effectively; maintains water levels | Requires manual operation; may not consistently prevent backflow | Automates flow control; highly effective in managing water levels |

| Cost | Moderate initial investment; low maintenance costs | Low initial cost; higher long-term labor costs | Higher upfront costs; potential savings in labor and operational efficiency |

| Ease of Implementation | Easy to install; minimal technical knowledge required | Simple installation; requires user training for effective operation | Requires professional installation; more complex integration |

| Maintenance | Low maintenance; periodic checks recommended | Regular manual checks and adjustments needed | Low maintenance; software updates may be required |

| Best Use Case | Ideal for standard spa setups with consistent water levels | Suitable for smaller or less frequently used spas | Best for large or automated spa systems requiring precise control |

What Are the Pros and Cons of Using a Manual Valve System as an Alternative?

A manual valve system is a straightforward alternative that allows users to control water flow manually. The primary advantage of this system is its low initial cost and simplicity in installation. However, it requires regular user intervention to adjust the valves, which may lead to inconsistent performance. For spas that are used less frequently, this solution can work effectively, but it may not be suitable for those requiring precise water level management or frequent usage.

How Does an Electronic Flow Control System Compare?

An electronic flow control system offers a more sophisticated approach to managing water levels in spas. This technology automates the flow control process, ensuring optimal water retention and minimal backflow. While the initial investment is higher compared to check valves and manual systems, the long-term savings on labor and improved efficiency can justify the cost. However, this system requires professional installation and may involve more complex maintenance, including software updates and troubleshooting electronic components.

Illustrative image related to check valve for spa

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting a solution for spa water management, B2B buyers should consider their specific operational needs, budget constraints, and desired performance levels. Check valves provide a reliable and low-maintenance option for standard installations. In contrast, manual valve systems may be more cost-effective for less frequent use, while electronic flow control systems excel in environments requiring precision and automation. Understanding these alternatives allows buyers to make informed decisions that align with their operational goals and enhance the overall spa experience.

Essential Technical Properties and Trade Terminology for check valve for spa

When considering the procurement of check valves for spas, understanding the essential technical properties and terminology is crucial for making informed decisions. Here, we outline the key specifications and trade terms relevant to this niche.

What are the Critical Specifications of Check Valves for Spas?

-

Material Grade

The material grade of a check valve is critical as it affects durability and resistance to corrosion. Common materials include PVC, brass, and stainless steel. For spas, where water chemistry can vary, materials that withstand chlorination and mineral buildup are preferred. Understanding the right material helps buyers select valves that last longer and reduce maintenance costs. -

Pressure Rating

This specification indicates the maximum pressure the valve can withstand without failing. For spas, typical pressure ratings range from 150 to 300 psi. Buyers must ensure the pressure rating aligns with their system’s operating conditions to avoid leaks or valve failure, which can lead to costly repairs and downtime. -

Flow Rate

The flow rate of a check valve determines how efficiently it can move water through the system. Measured in gallons per minute (GPM), this specification is essential for maintaining optimal spa performance. An inadequate flow rate can lead to poor circulation, affecting the spa’s heating and cleaning processes. -

Size and Connection Type

Check valves come in various sizes, typically measured in inches, and feature different connection types, such as threaded or slip fittings. Ensuring the correct size and compatibility with existing plumbing is vital for a seamless installation. Incorrect sizing can lead to leaks or reduced efficiency. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions. High tolerance ensures that the valve fits perfectly within the system, preventing leaks and improving overall performance. For B2B buyers, understanding tolerance levels can help in assessing the quality and reliability of the valve. -

Temperature Rating

The temperature rating indicates the maximum temperature the valve can handle without degrading. For spas, valves need to withstand temperatures that can reach up to 104°F (40°C). Selecting a valve with an appropriate temperature rating is crucial for safety and longevity.

What Trade Terms Should B2B Buyers Know for Check Valves?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify high-quality, reliable products that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ specifies the minimum number of units a supplier will sell. Knowing the MOQ is essential for buyers to plan inventory and avoid over-committing to unnecessary stock, especially in smaller markets or projects. -

RFQ (Request for Quotation)

An RFQ is a formal request for a price quotation from suppliers. Buyers use RFQs to gather pricing information for bulk orders, ensuring they can compare costs and negotiate better deals. -

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery responsibilities, which are crucial for effective supply chain management. -

Lead Time

Lead time is the time taken from placing an order to delivery. Understanding lead times helps buyers manage their inventory and project timelines effectively, reducing the risk of operational delays. -

Warranty and Return Policy

The warranty and return policy outlines the terms under which a product can be returned or exchanged. Familiarity with these terms is vital for buyers to protect their investment and ensure they can address potential defects or incompatibilities without incurring additional costs.

By grasping these specifications and terminology, B2B buyers in the spa industry can make well-informed purchasing decisions that enhance operational efficiency and product performance.

Navigating Market Dynamics and Sourcing Trends in the check valve for spa Sector

What Are the Current Market Dynamics for Check Valves in the Spa Sector?

The global check valve market for spas is influenced by several key drivers, reflecting broader trends in the pool and spa industry. Rising disposable incomes in regions such as Africa, South America, and the Middle East are leading to increased investment in home wellness and recreational facilities. International buyers, particularly from Europe and emerging markets like Brazil, are increasingly seeking high-quality, durable check valves that can withstand varying water temperatures and chemical treatments typical in spa environments. Additionally, the shift towards automation in pool management systems is prompting demand for advanced check valve technologies, including those equipped with smart sensors and IoT capabilities that enhance operational efficiency.

Emerging trends include a focus on modular designs, which allow for easier installation and maintenance. Buyers are also increasingly looking for suppliers who can offer customization options to fit unique spa configurations. The integration of eco-friendly materials in product design is becoming a crucial factor, with many manufacturers responding to consumer preferences for sustainable solutions. Furthermore, the ongoing impact of global supply chain disruptions highlights the need for international buyers to establish relationships with reliable suppliers who can ensure consistent quality and timely delivery.

How Is Sustainability Influencing Sourcing Decisions for Check Valves in the Spa Sector?

The importance of sustainability in the sourcing of check valves for spas cannot be overstated. Environmental concerns are reshaping the industry, leading to a heightened focus on minimizing the ecological impact of manufacturing processes. B2B buyers are increasingly prioritizing suppliers who adhere to ethical sourcing practices and demonstrate a commitment to reducing waste and energy consumption. This shift is particularly relevant in regions like Europe, where regulations surrounding environmental standards are stringent.

Buyers should also be aware of the availability of ‘green’ certifications and materials that indicate a product’s sustainability. For instance, check valves made from recycled materials or those that contribute to energy savings can enhance a company’s reputation and appeal to environmentally conscious consumers. Additionally, suppliers who provide transparency in their supply chains and demonstrate social responsibility are more likely to attract business from discerning buyers in the international market.

What Is the Historical Context of Check Valves in the Spa Industry?

The evolution of check valves in the spa sector has been marked by significant technological advancements and changing consumer preferences. Initially, check valves were simple mechanical devices designed to prevent backflow, primarily focusing on functionality. However, as the spa industry evolved, so did the design and application of check valves.

The introduction of materials resistant to corrosion and chemical damage has transformed their durability and reliability, enabling them to cater to diverse environmental conditions. Over the years, the integration of automation and smart technology has further revolutionized their use, allowing for enhanced control and monitoring of water systems. This historical progression highlights the importance of selecting suppliers who are not only aware of these advancements but are also committed to innovation and quality in their product offerings, ensuring they meet the demands of today’s international B2B buyers.

Illustrative image related to check valve for spa

Frequently Asked Questions (FAQs) for B2B Buyers of check valve for spa

-

How do I solve water drainage issues in my spa?

To address water drainage problems in your spa, first, ensure that the valves are functioning correctly. Installing a check valve on the spa return line can prevent backflow, maintaining water levels. If drainage persists, inspect the suction side for any leaks or issues with the diverter valves. Consulting with a pool and spa professional can provide tailored solutions based on your specific setup. -

What is the best check valve for spa systems?

The best check valve for spa systems typically depends on the specific plumbing configuration and flow requirements. Look for durable materials like PVC or brass, which resist corrosion and ensure longevity. The valve should have a low-pressure drop and be easy to install. It’s advisable to consult with suppliers who can provide options tailored to your spa’s specifications and usage. -

How can I ensure the quality of check valves from suppliers?

To ensure quality, request certifications such as ISO or CE from suppliers, which indicate adherence to international standards. Ask for product samples to assess material quality and performance. Additionally, consider suppliers with a proven track record and positive reviews from other B2B clients. Conducting factory visits or audits can further assure product integrity. -

What are the minimum order quantities (MOQ) for check valves?

Minimum order quantities for check valves can vary significantly among suppliers. Typically, MOQs range from 100 to 1,000 units, depending on the manufacturer and the specific product line. It’s beneficial to communicate directly with suppliers to negotiate terms that align with your purchasing needs, especially for bulk orders or customized solutions. -

What payment terms should I expect when sourcing check valves?

Payment terms often depend on the supplier’s policies and the nature of the order. Common terms include a 30% upfront deposit with the balance due before shipment or upon delivery. Some suppliers may offer credit terms for established relationships. Always clarify payment options and conditions in advance to avoid any misunderstandings. -

How do I handle logistics for international shipping of check valves?

When managing logistics for international shipping, collaborate closely with your supplier to understand shipping methods, costs, and estimated delivery times. Consider using freight forwarders who specialize in your target regions, as they can navigate customs regulations effectively. Ensure that you have clear documentation to avoid delays and additional charges upon arrival. -

What customization options are available for check valves?

Customization options for check valves can include size, material, and specific design features tailored to your spa’s requirements. Many suppliers offer the ability to modify existing designs or create entirely new solutions. Engaging in early discussions about your needs will help suppliers provide the most suitable options and pricing. -

How can I vet potential suppliers for check valves?

To vet potential suppliers, conduct thorough research by checking their business credentials, certifications, and customer feedback. Request references from previous clients and analyze their responsiveness and communication. Engaging in a trial order can also provide insights into their reliability and product quality before committing to larger purchases.

Top 7 Check Valve For Spa Manufacturers & Suppliers List

1. Trouble Free Pool – Spa Valves and Pumps

Domain: troublefreepool.com

Registered: 2007 (18 years)

Introduction: Check valves for spa return line, motorized Jandy valve for SPA RETURN, actuator for SPA SUCTION valve, booster pump supply line, air blower supply line.

2. Hayward – Check Valve PSCV2S2

Domain: poolsupply4less.com

Registered: 1999 (26 years)

Introduction: This company, Hayward – Check Valve PSCV2S2, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Masters PA Parts – Check Valve

Domain: masterspaparts.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “Check Valve”, “sku”: “X320055”, “price”: “$12.08”, “availability”: “In stock”, “shipping_info”: {“free_shipping_threshold”: “$99”, “flat_rate_shipping”: “$9.99”}, “customer_support”: {“live_chat”: “Available 7 Days a Week”, “customer_reviews”: “1 Customer Review”}}

4. Spa Depot – Spa Ozone Check Valve PX1906

Domain: spadepot.com

Registered: 1997 (28 years)

Introduction: Spa Ozone One Way Check Valve, 1/4 inch, model PX1906

5. Pool Spa Forum – Check Valve Solutions

Domain: poolspaforum.com

Registered: 2005 (20 years)

Introduction: Check valve for spa and pool systems; potential issues include water draining from spa to pool when equipment is off; difficulty in locating and replacing the check valve; related components include gray 3-way valves; user experiences indicate that replacing valves may resolve water flow issues; additional plumbing components mentioned include red handled valve for overflow.

6. In The Swim – Check Valves

Domain: intheswim.com

Registered: 1997 (28 years)

Introduction: Check valves are one-way flow valves used in pool, spa, and fountain plumbing to prevent water from flowing backwards and to maintain water levels in systems when the pump shuts off. They are commonly used to hold water in the pump, prevent gravity draining, and ensure quick pump priming. Check valves are typically installed on the incoming suction pipe, 12”-18” in front of the pump for optimal pe…

7. Hot Tub Warehouse – Check Valves & Spa Parts

Domain: hottubwarehouse.com

Registered: 2001 (24 years)

Introduction: Hot Tub & Spa Check Valves, Ozonator, Air Blower and Standard Check Valves. Free Shipping on orders $50+. Various parts available including hot tub control systems, heaters, electrical components, pumps, plumbing parts, jets, and more.

Strategic Sourcing Conclusion and Outlook for check valve for spa

In summary, the strategic sourcing of check valves for spas is integral to maintaining optimal performance and water management within spa systems. By understanding the importance of installing check valves on both the return and suction lines, buyers can prevent water loss and ensure efficient heating and circulation. This not only enhances the spa experience but also reduces operational costs, making it a valuable investment for businesses in regions such as Africa, South America, the Middle East, and Europe.

As international B2B buyers, it is crucial to prioritize reliable suppliers who offer quality check valves tailored to your specific needs. Evaluating vendors based on their product durability, service support, and compliance with regional standards will further enhance your sourcing strategy.

Looking ahead, the demand for high-quality spa components will continue to rise, driven by the growing wellness and leisure industry. Seize this opportunity to strengthen your supply chain by collaborating with manufacturers who are committed to innovation and customer satisfaction. By doing so, you position your business to thrive in an evolving market landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to check valve for spa

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.