The Definitive Guide to Centrifugal Blower Design: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for centrifugal blower design

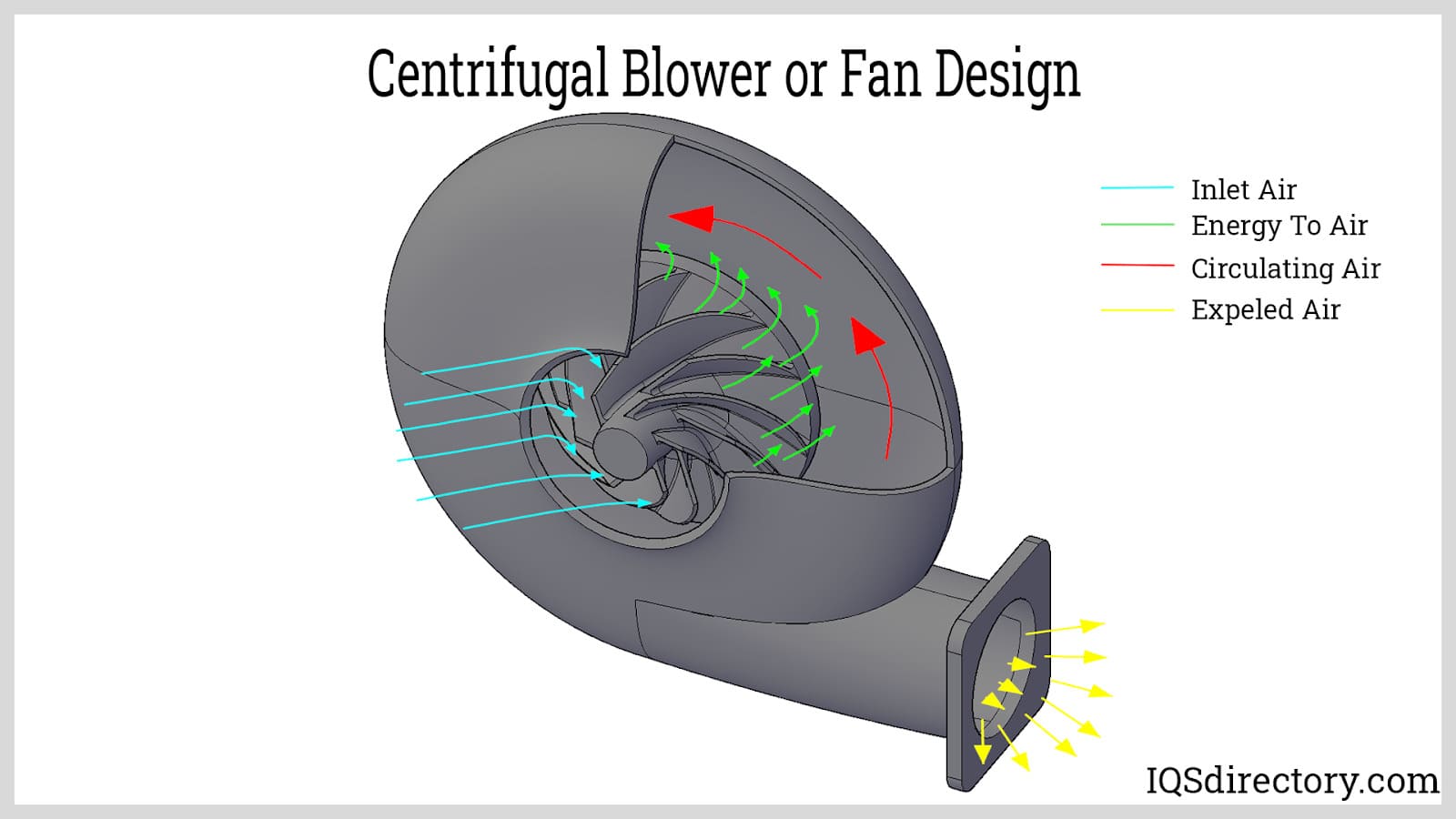

In today’s competitive landscape, sourcing the right centrifugal blower design can significantly impact operational efficiency and cost-effectiveness for businesses across various industries. As global markets expand, particularly in regions such as Africa, South America, the Middle East, and Europe—including key players like Saudi Arabia and Germany—B2B buyers face the challenge of navigating a complex array of options that cater to unique industrial needs. This comprehensive guide addresses critical factors such as types and applications of centrifugal blowers, supplier vetting processes, and cost considerations to help you make informed purchasing decisions.

Understanding the diverse applications of centrifugal blowers is essential for optimizing performance in sectors ranging from HVAC to food processing and pharmaceuticals. We will delve into the specifics of each blower type, enabling you to select the ideal solution tailored to your operational requirements. Additionally, this guide emphasizes the importance of evaluating suppliers to ensure reliability and quality in your procurement process. By equipping you with actionable insights and practical strategies, this resource empowers international B2B buyers to confidently navigate the global market for centrifugal blower design, ultimately enhancing your business’s productivity and sustainability.

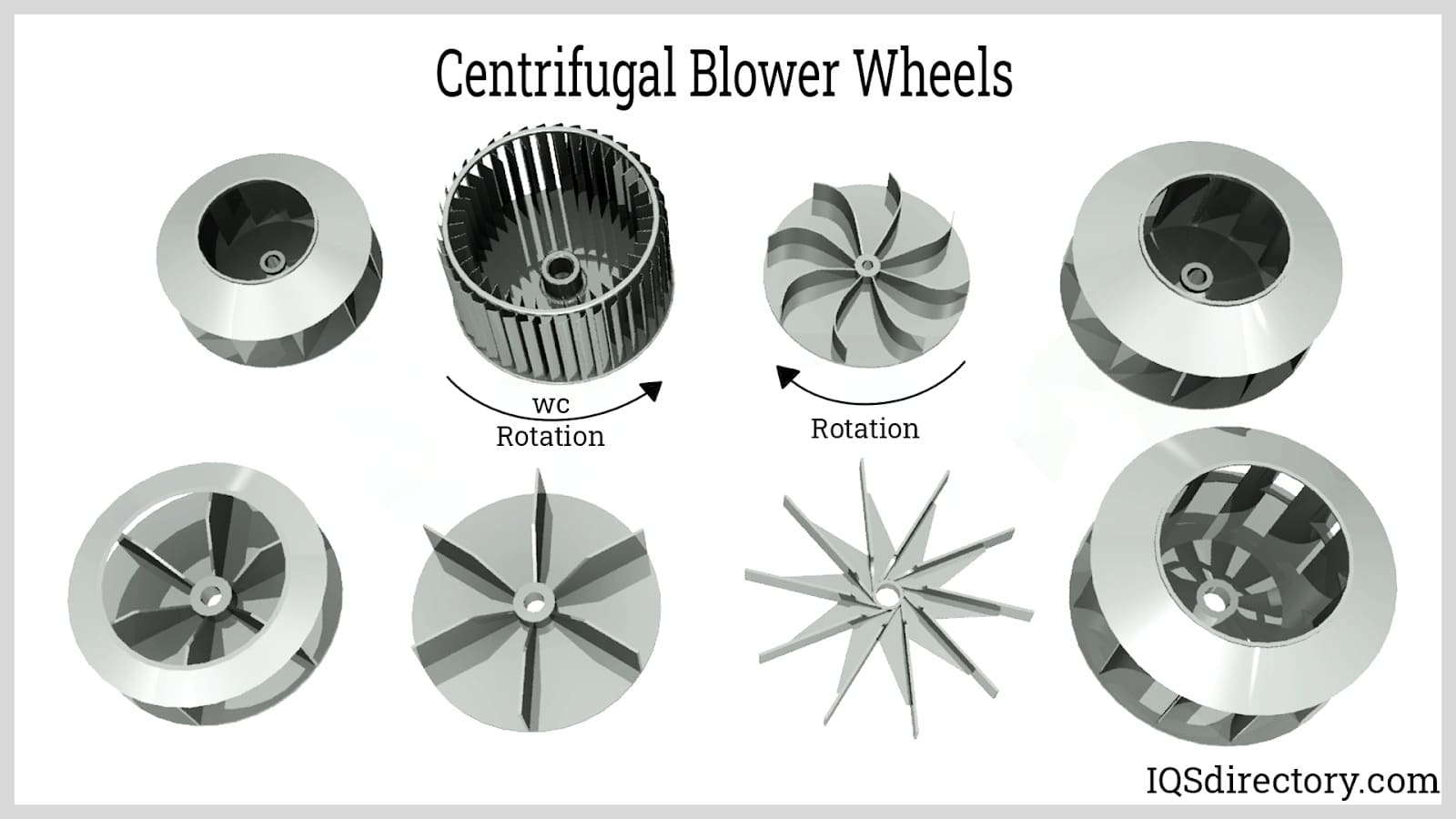

Understanding centrifugal blower design Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Forward-Curved | Impeller blades curve in the direction of rotation, producing high airflow at low pressure. | HVAC systems, dust collection, ventilation | Pros: High airflow efficiency; compact design. Cons: Limited pressure capabilities; may require more maintenance. |

| Backward-Curved | Blades curve against the direction of rotation, allowing for higher pressure and efficiency. | Industrial exhaust, pneumatic conveying | Pros: High efficiency at variable speeds; durable. Cons: Larger footprint; more complex installation. |

| Radial | Blades are perpendicular to the airflow, generating high pressure and suitable for high-density applications. | Steel manufacturing, power generation | Pros: Excellent performance in high pressure; versatile. Cons: Noise levels can be higher; less efficient at low flow rates. |

| Airfoil | Designed with airfoil-shaped blades, optimizing aerodynamic performance for energy efficiency. | Aerospace, high-performance HVAC | Pros: Very efficient; low noise levels. Cons: Higher initial cost; may require specialized maintenance. |

| Double-Inlet | Two inlets allow air to enter from both sides, increasing airflow capacity and flexibility. | Large industrial applications, cooling towers | Pros: High airflow capacity; flexible installation options. Cons: Larger size; potentially higher installation costs. |

What are the Characteristics and Suitability of Forward-Curved Centrifugal Blowers?

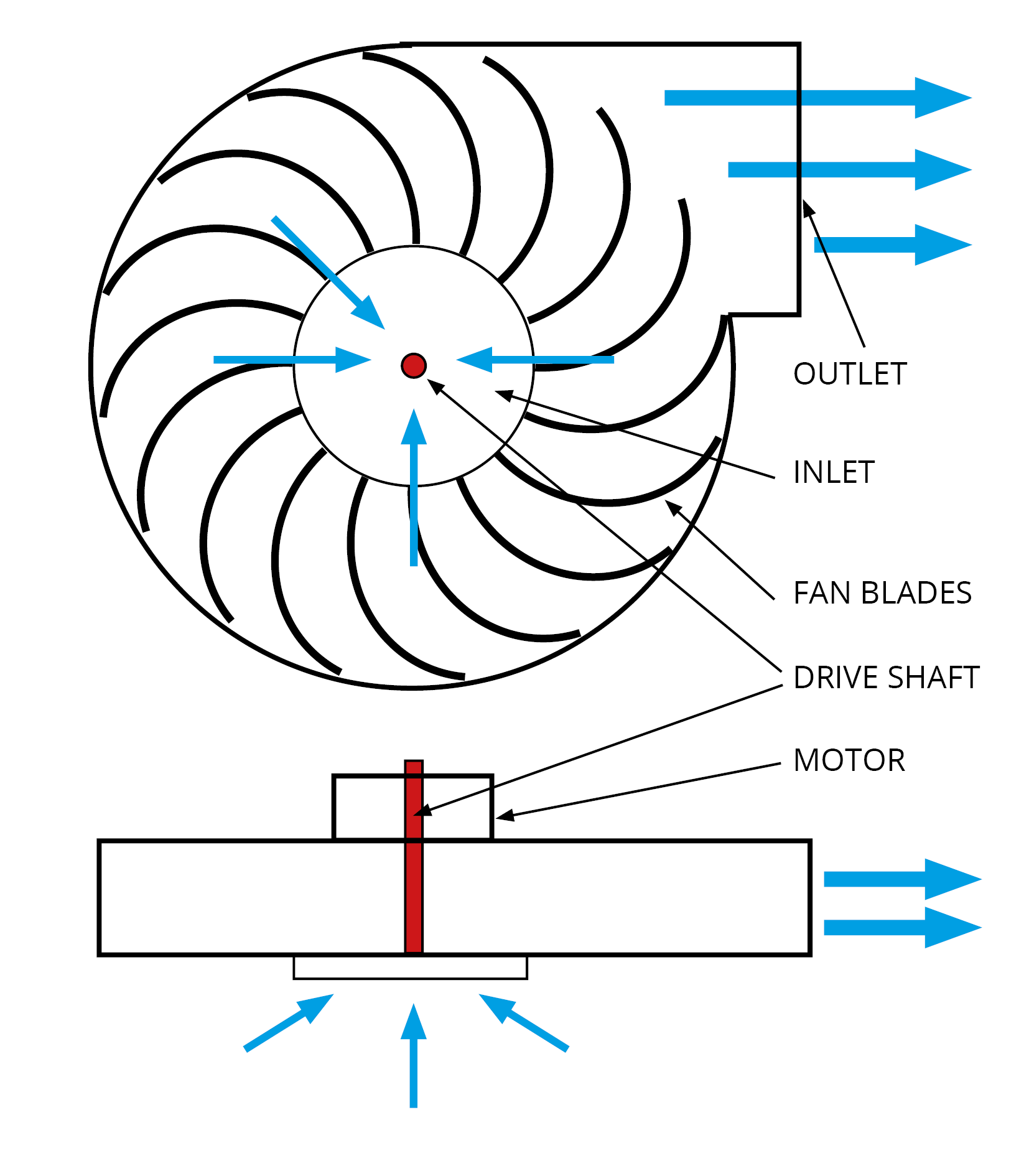

Forward-curved centrifugal blowers are characterized by their impeller design, where the blades curve in the direction of rotation. This design enables them to move a large volume of air at lower pressures, making them ideal for applications like HVAC systems and dust collection. When considering a forward-curved blower, buyers should evaluate the specific airflow requirements and ensure that the low-pressure capabilities align with their system needs. Additionally, while they offer a compact design, maintenance can be more frequent due to the high-speed operation.

How Do Backward-Curved Centrifugal Blowers Stand Out?

Backward-curved centrifugal blowers feature blades that curve against the direction of rotation, allowing them to generate higher static pressure and efficiency. These blowers are commonly used in industrial exhaust systems and pneumatic conveying applications. Buyers should consider their need for variable speed operation and durability, as backward-curved blowers excel in these areas. However, they typically require more space and can be more complex to install, which may affect overall project timelines and costs.

What Makes Radial Centrifugal Blowers a Good Choice for High Pressure?

Radial centrifugal blowers have blades positioned perpendicular to the airflow, creating high static pressure suitable for dense applications such as steel manufacturing and power generation. They are versatile and perform exceptionally well in high-pressure environments. B2B buyers should assess noise levels, as radial blowers can be noisier than other types, and consider their efficiency at lower flow rates. The balance between pressure capability and operational noise is crucial for optimal application performance.

Why Are Airfoil Centrifugal Blowers Considered High-Performance?

Airfoil centrifugal blowers are designed with blades shaped like airfoils, optimizing aerodynamic performance for energy efficiency. They are particularly suited for aerospace and high-performance HVAC applications where both efficiency and noise levels are critical. Buyers interested in airfoil blowers should be prepared for a higher initial investment, as well as the potential for specialized maintenance requirements. The long-term operational savings can outweigh these initial costs, making them a wise investment for specific high-demand applications.

What Advantages Do Double-Inlet Centrifugal Blowers Offer?

Double-inlet centrifugal blowers feature two inlets that allow air to enter from both sides, significantly increasing airflow capacity and providing flexibility in installation. They are commonly used in large industrial settings, such as cooling towers. Buyers should consider the larger size and potential higher installation costs associated with double-inlet blowers. However, their ability to handle high airflow makes them an appealing choice for applications requiring substantial air movement, particularly in expansive environments.

Key Industrial Applications of centrifugal blower design

| Industry/Sector | Specific Application of Centrifugal Blower Design | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Ventilation of hazardous fumes and gases | Ensures a safe working environment, reducing health risks and regulatory fines | Compliance with safety standards; durability against corrosive substances |

| Food Processing | Airflow management in drying and cooling processes | Enhances product quality and reduces spoilage, leading to cost savings | Hygiene standards; energy efficiency; ease of maintenance |

| HVAC Systems | Air circulation in large commercial buildings | Improves energy efficiency and indoor air quality, reducing operational costs | Compatibility with existing systems; performance under varying loads |

| Mining and Minerals | Dust control and ventilation in underground operations | Protects worker health and maintains operational efficiency | High durability; ability to operate in extreme conditions; noise control |

| Pharmaceutical Production | Controlled airflow in clean rooms | Maintains product integrity and compliance with stringent regulations | Precision in airflow control; reliability under varying humidity and temperature |

How is Centrifugal Blower Design Used in Chemical Manufacturing?

In chemical manufacturing, centrifugal blowers are crucial for ventilating hazardous fumes and gases generated during production processes. By effectively removing these contaminants, businesses can create a safer work environment, thereby reducing health risks for employees and minimizing the likelihood of regulatory fines. Buyers in this sector should prioritize blowers that comply with safety standards and are constructed from durable materials to withstand exposure to corrosive substances.

What Role Does Centrifugal Blower Design Play in Food Processing?

Centrifugal blowers are employed in food processing for applications such as drying and cooling products. By managing airflow efficiently, these blowers enhance product quality and help reduce spoilage, ultimately leading to significant cost savings. Buyers in the food industry must consider hygiene standards, energy efficiency, and ease of maintenance when sourcing centrifugal blowers to ensure compliance with food safety regulations.

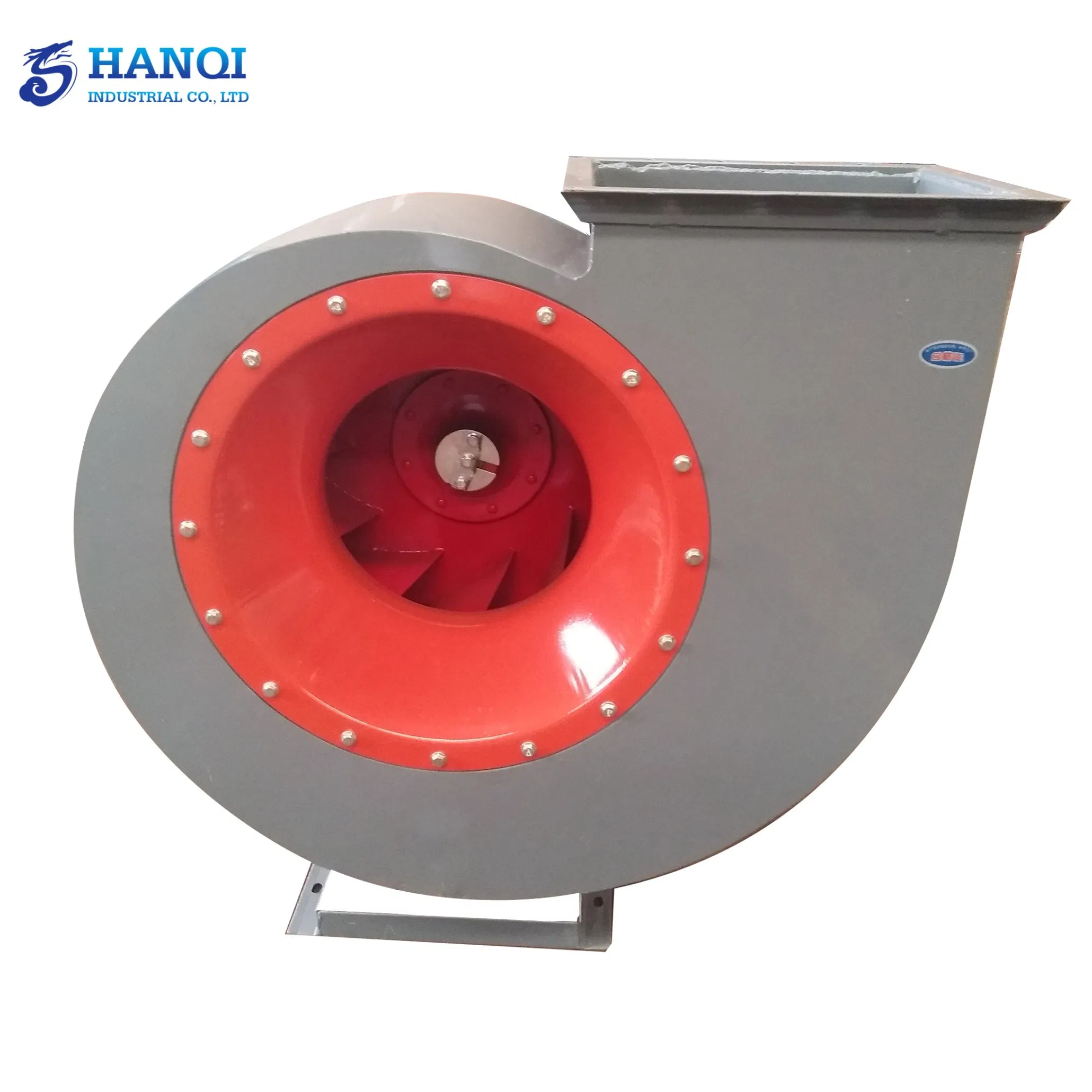

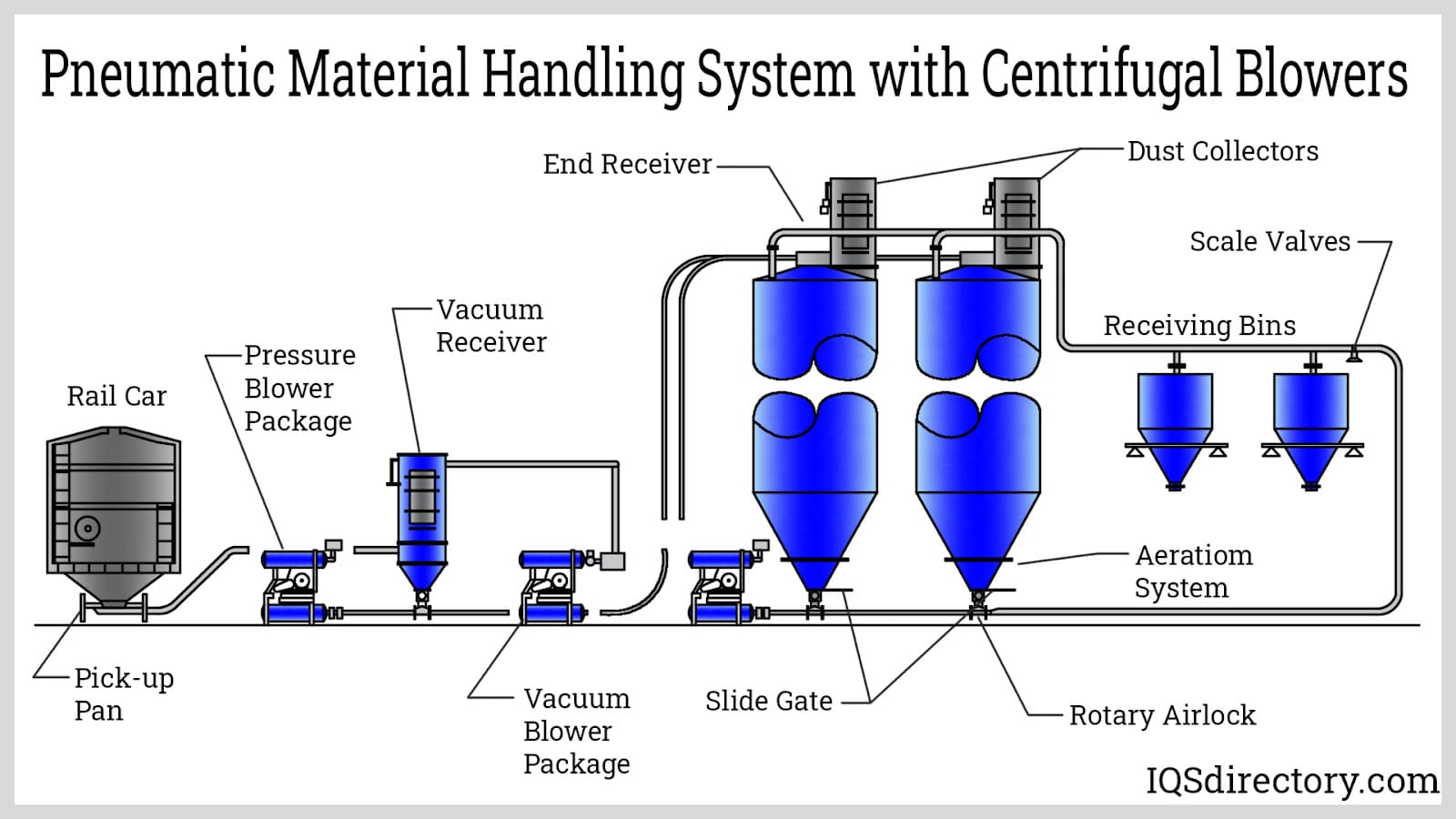

Illustrative image related to centrifugal blower design

Why are Centrifugal Blowers Essential for HVAC Systems?

In large commercial buildings, centrifugal blowers are integral to effective air circulation within HVAC systems. They not only improve indoor air quality but also contribute to energy efficiency, leading to lower operational costs. International buyers should ensure that the blowers they select are compatible with existing systems and can perform well under varying load conditions to maximize their investment.

How Do Centrifugal Blowers Aid in Mining and Minerals Operations?

In mining and minerals extraction, centrifugal blowers are vital for dust control and ventilation in underground operations. These blowers help protect worker health by minimizing dust exposure and maintaining operational efficiency. Buyers in this sector should focus on sourcing blowers that are highly durable, capable of operating in extreme conditions, and designed to minimize noise, ensuring a safe and productive work environment.

What is the Importance of Centrifugal Blower Design in Pharmaceutical Production?

Centrifugal blowers are essential in pharmaceutical production for maintaining controlled airflow in clean rooms. This precise airflow is critical for product integrity and compliance with stringent industry regulations. Buyers in the pharmaceutical sector must seek blowers that offer reliable performance under varying humidity and temperature conditions, ensuring the highest standards of quality and safety in their production processes.

3 Common User Pain Points for ‘centrifugal blower design’ & Their Solutions

Scenario 1: Selecting the Right Centrifugal Blower for Diverse Applications

The Problem: B2B buyers often encounter significant challenges when selecting a centrifugal blower that fits their unique operational requirements. For instance, a manufacturing facility in Saudi Arabia may need a blower that not only handles high-temperature air but also operates efficiently in a dusty environment. Failure to accurately assess these factors can lead to suboptimal performance, resulting in increased operational costs and potential equipment failure. Buyers may feel overwhelmed by the technical specifications and performance metrics available from manufacturers, leading to confusion and misalignment with their needs.

The Solution: To effectively source the right centrifugal blower, buyers should begin by conducting a thorough needs assessment. This includes defining the required airflow rate (CFM), static pressure, and environmental conditions (like temperature and humidity). Collaborating with manufacturers to understand the specific performance curves of blowers is critical. This will help buyers visualize how different models will perform under their unique operating conditions. Additionally, creating a checklist of essential features—such as corrosion resistance or noise levels—can streamline the selection process. Engaging with experienced engineers or consultants who specialize in airflow systems can provide invaluable insights, ensuring that the selected blower aligns with both current needs and future scalability.

Scenario 2: Overcoming Maintenance Challenges with Centrifugal Blowers

The Problem: Many B2B buyers face ongoing maintenance issues with their centrifugal blowers, which can lead to costly downtime and repairs. For example, a food processing plant in Germany may experience frequent breakdowns due to inadequate maintenance protocols, resulting in lost productivity and increased operational expenses. Buyers may struggle with understanding the maintenance requirements specific to their blower type, leading to neglect and premature wear of critical components.

The Solution: To mitigate maintenance challenges, buyers should develop a comprehensive maintenance plan tailored to their specific centrifugal blower model. This plan should include regular inspections, cleaning schedules, and component replacements based on manufacturer recommendations. Implementing a predictive maintenance approach, utilizing IoT sensors, can help monitor the blower’s performance in real time and predict potential failures before they occur. Additionally, training in-house maintenance staff on the specific requirements and common failure points of the blower can empower teams to address issues proactively. Establishing a relationship with the blower manufacturer for support and training can further enhance maintenance efficiency and reduce the risk of unplanned downtime.

Scenario 3: Navigating Regulatory Compliance in Centrifugal Blower Applications

The Problem: B2B buyers in industries such as pharmaceuticals or chemical processing frequently navigate complex regulatory landscapes that dictate stringent airflow and emission standards. For instance, a buyer in South America may struggle to ensure that their centrifugal blower meets local environmental regulations while also maintaining operational efficiency. The potential for non-compliance can lead to hefty fines and disruptions to production, creating significant stress for buyers tasked with compliance.

The Solution: To successfully navigate regulatory compliance, buyers should conduct a detailed review of local and international regulations applicable to their industry. This includes understanding emission limits, noise ordinances, and safety standards that influence blower design and operation. Collaborating with regulatory consultants or legal experts can provide clarity on compliance requirements. Furthermore, buyers should work closely with blower manufacturers who understand these regulations and can offer compliant solutions, such as energy-efficient models or those equipped with filtration systems to minimize emissions. Incorporating compliance checks into the procurement process can ensure that all purchased blowers meet necessary standards, reducing the risk of costly penalties and enhancing operational reliability.

Strategic Material Selection Guide for centrifugal blower design

What Are the Most Common Materials Used in Centrifugal Blower Design?

When designing centrifugal blowers, the selection of materials is critical to ensure optimal performance, longevity, and cost-effectiveness. Below, we analyze four common materials used in centrifugal blower construction, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

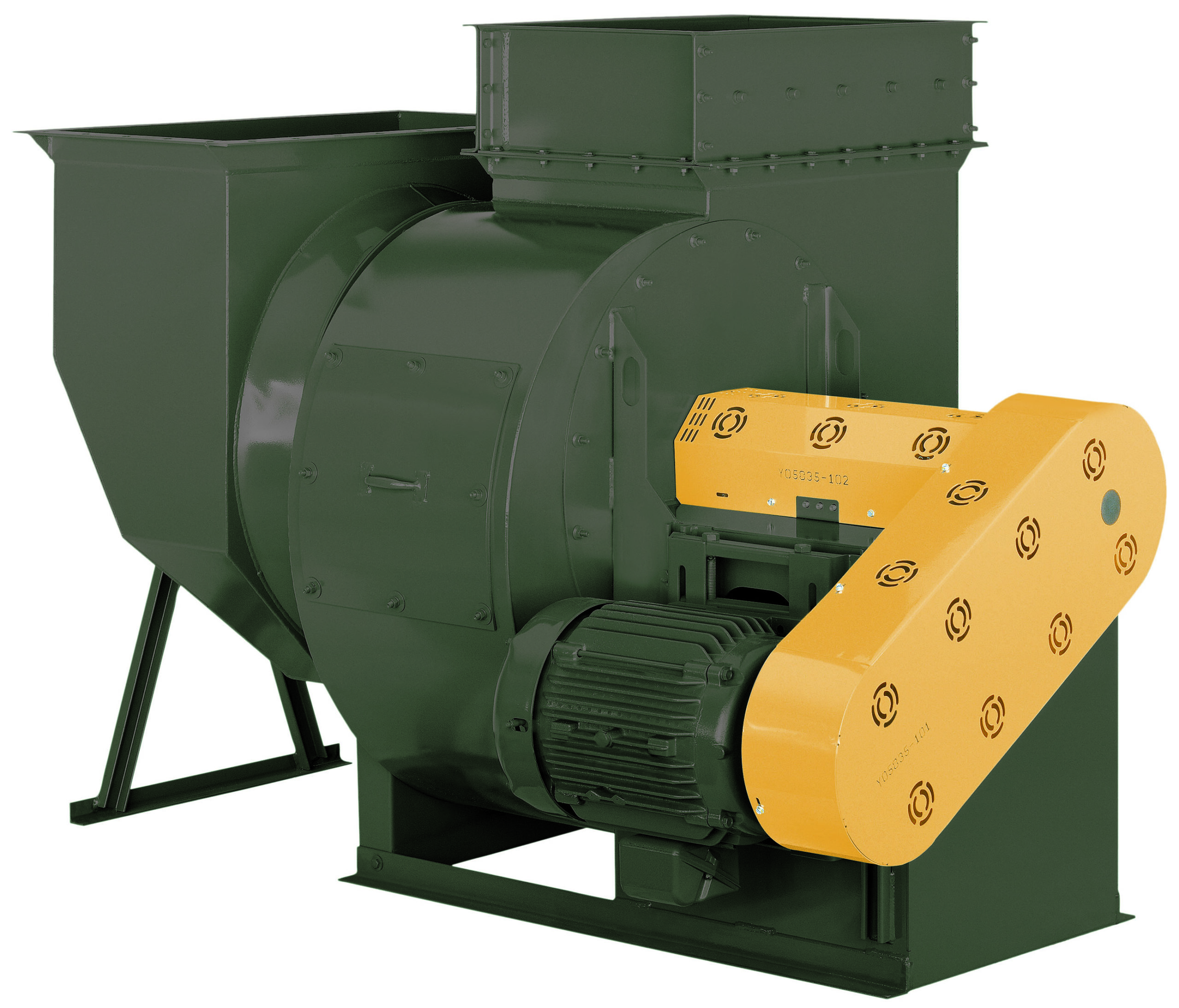

Illustrative image related to centrifugal blower design

How Does Carbon Steel Perform in Centrifugal Blower Applications?

Key Properties: Carbon steel is known for its high tensile strength and ability to withstand significant mechanical stress. It typically has a temperature rating of up to 400°F (204°C) and can handle moderate pressure levels.

Pros & Cons: The primary advantage of carbon steel is its durability and cost-effectiveness, making it a popular choice for industrial applications. However, it has limited corrosion resistance, which can lead to rust and degradation in humid or corrosive environments. Manufacturing complexity is moderate, as carbon steel can be easily welded and machined.

Impact on Application: Carbon steel is suitable for applications involving air and non-corrosive gases. However, its susceptibility to corrosion may limit its use in environments where moisture or chemical exposure is prevalent.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as EN 10025 for structural steel. In humid climates like parts of Africa, additional protective coatings may be necessary.

Illustrative image related to centrifugal blower design

What Are the Advantages of Stainless Steel in Centrifugal Blower Design?

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand high temperatures (up to 1500°F or 815°C) and pressures, making it ideal for demanding environments.

Pros & Cons: The main advantage of stainless steel is its longevity and resistance to rust and corrosion, which reduces maintenance costs over time. However, it is more expensive than carbon steel and can complicate manufacturing processes due to its hardness.

Impact on Application: Stainless steel is suitable for applications involving corrosive gases or high temperatures, such as in chemical processing or food production.

Considerations for International Buyers: Compliance with standards like ASTM A240 is crucial for buyers in the U.S. and Europe. In regions like Saudi Arabia, where environmental conditions can be harsh, stainless steel is often preferred for its durability.

Illustrative image related to centrifugal blower design

How Does Aluminum Compare for Centrifugal Blower Applications?

Key Properties: Aluminum is lightweight and has good thermal conductivity, making it suitable for applications requiring efficient heat dissipation. It typically has a temperature rating of around 300°F (149°C).

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which facilitates easier installation and reduced energy consumption. However, it has lower strength compared to steel and can be prone to deformation under high pressure.

Impact on Application: Aluminum is often used in applications where weight is a concern, such as in automotive and aerospace industries. However, it may not be suitable for high-pressure applications.

Considerations for International Buyers: Buyers should be aware of standards such as ASTM B221 for aluminum extrusions. In regions with high humidity, additional coatings may be necessary to prevent oxidation.

Illustrative image related to centrifugal blower design

What Role Does Composite Material Play in Centrifugal Blower Design?

Key Properties: Composite materials, often made from a combination of polymers and fibers, offer excellent corrosion resistance and can operate at moderate temperatures (up to 250°F or 121°C).

Pros & Cons: The key advantage of composites is their lightweight and corrosion-resistant properties, making them ideal for specialized applications. However, they can be more expensive and complex to manufacture.

Impact on Application: Composites are suitable for applications involving corrosive environments, such as in chemical processing or marine applications.

Considerations for International Buyers: Compliance with standards like ASTM D638 for plastics is essential. Buyers in regions like South America should consider the local availability of composite materials, which may affect cost and lead times.

Illustrative image related to centrifugal blower design

Summary Table of Material Selection for Centrifugal Blower Design

| Material | Typical Use Case for centrifugal blower design | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General industrial applications | Cost-effective and durable | Limited corrosion resistance | Low |

| Stainless Steel | Chemical processing, food production | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Automotive, aerospace applications | Lightweight and efficient | Lower strength under high pressure | Medium |

| Composite | Chemical processing, marine applications | Corrosion-resistant and lightweight | Higher cost and manufacturing complexity | High |

This strategic material selection guide provides essential insights for B2B buyers looking to optimize centrifugal blower design for their specific applications, ensuring compliance with regional standards and operational requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for centrifugal blower design

What Are the Main Stages in the Manufacturing Process of Centrifugal Blowers?

The manufacturing process of centrifugal blowers involves several crucial stages, each contributing to the overall performance and reliability of the final product. Understanding these stages can help B2B buyers assess the capabilities of their suppliers.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first step in manufacturing centrifugal blowers is material preparation. High-quality materials are essential for durability and efficiency. Common materials include:

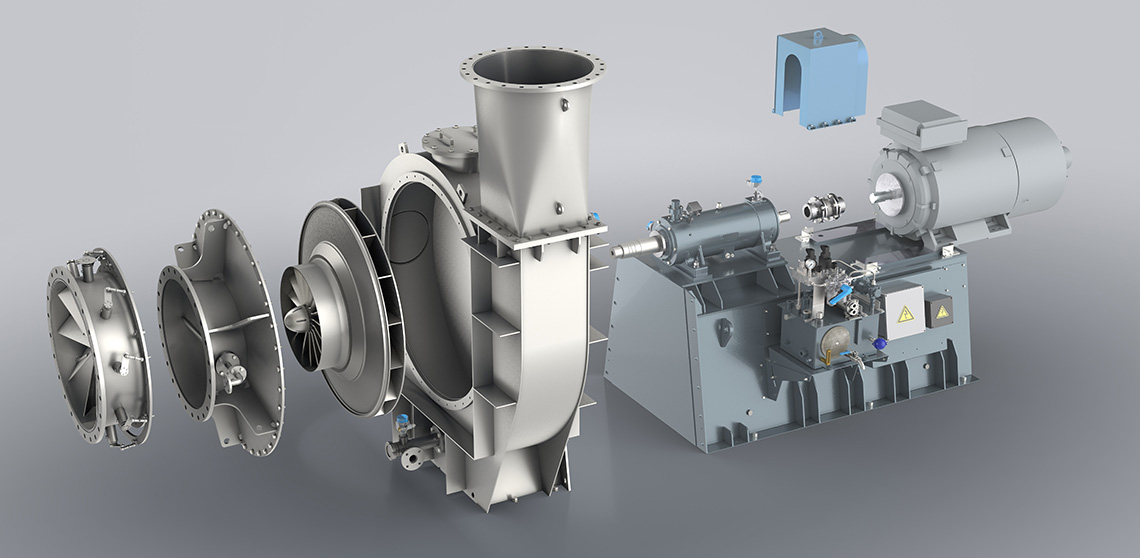

Illustrative image related to centrifugal blower design

- Steel and Stainless Steel: Often used for impellers and housings due to their strength and resistance to corrosion.

- Aluminum: Lightweight and often used in applications where weight is a concern.

- Plastic Composites: Sometimes employed for specific applications to reduce weight and cost.

These materials undergo processes such as cutting, machining, and surface treatment to ensure they meet the required specifications. The preparation stage also includes quality checks to eliminate any substandard materials before proceeding to forming.

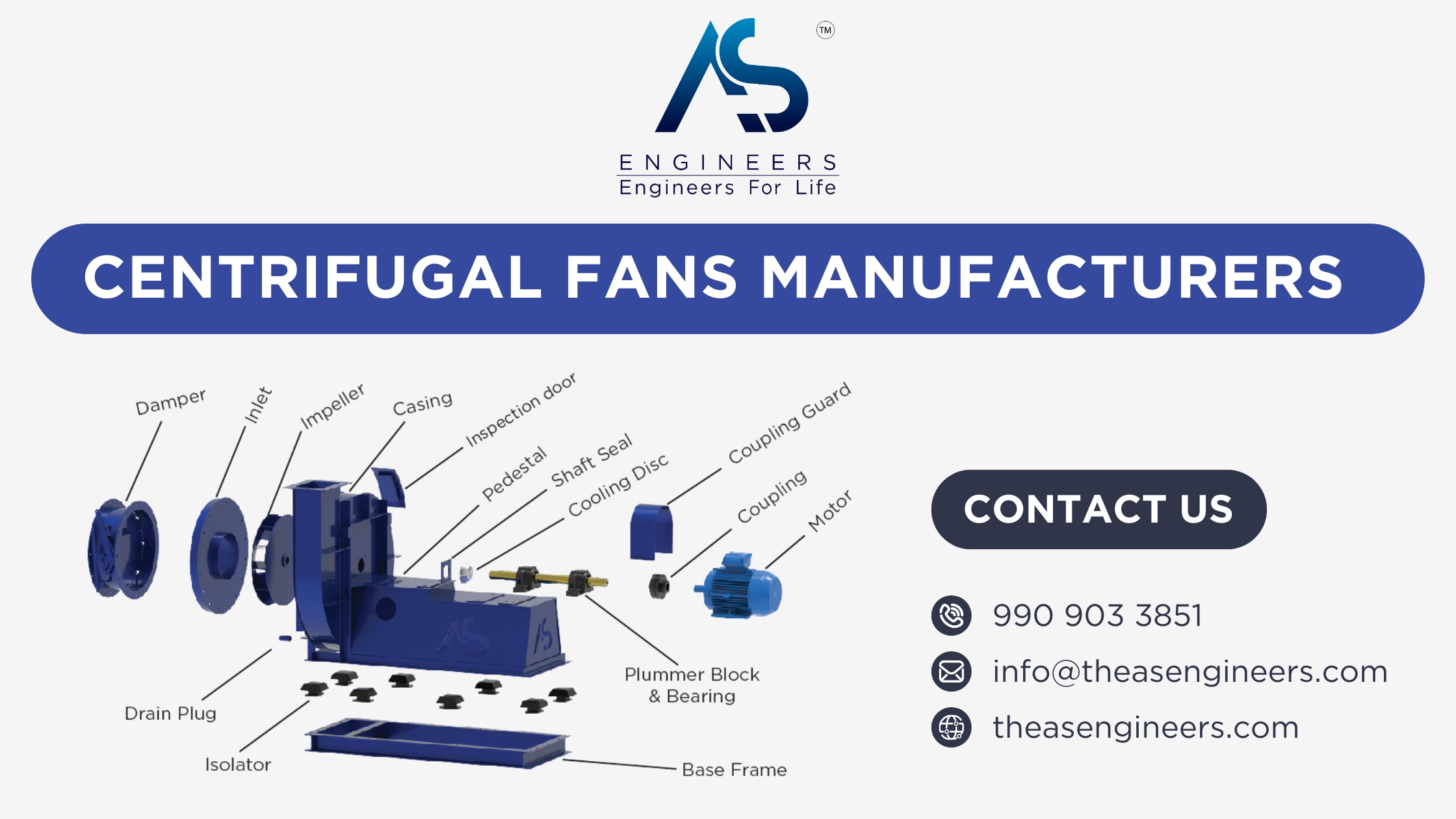

How Are Impellers and Housings Formed?

The forming stage involves shaping the prepared materials into specific components. Key techniques include:

- Casting: Used for creating complex shapes like impellers. It involves pouring molten metal into molds, allowing it to solidify.

- Machining: This process refines the cast components to achieve precise dimensions and surface finishes. CNC (Computer Numerical Control) machines are typically employed for high accuracy.

- Sheet Metal Fabrication: For housing components, techniques like bending, welding, and assembling cut sheets are used.

Each method has its advantages, and the choice depends on the design requirements and material properties.

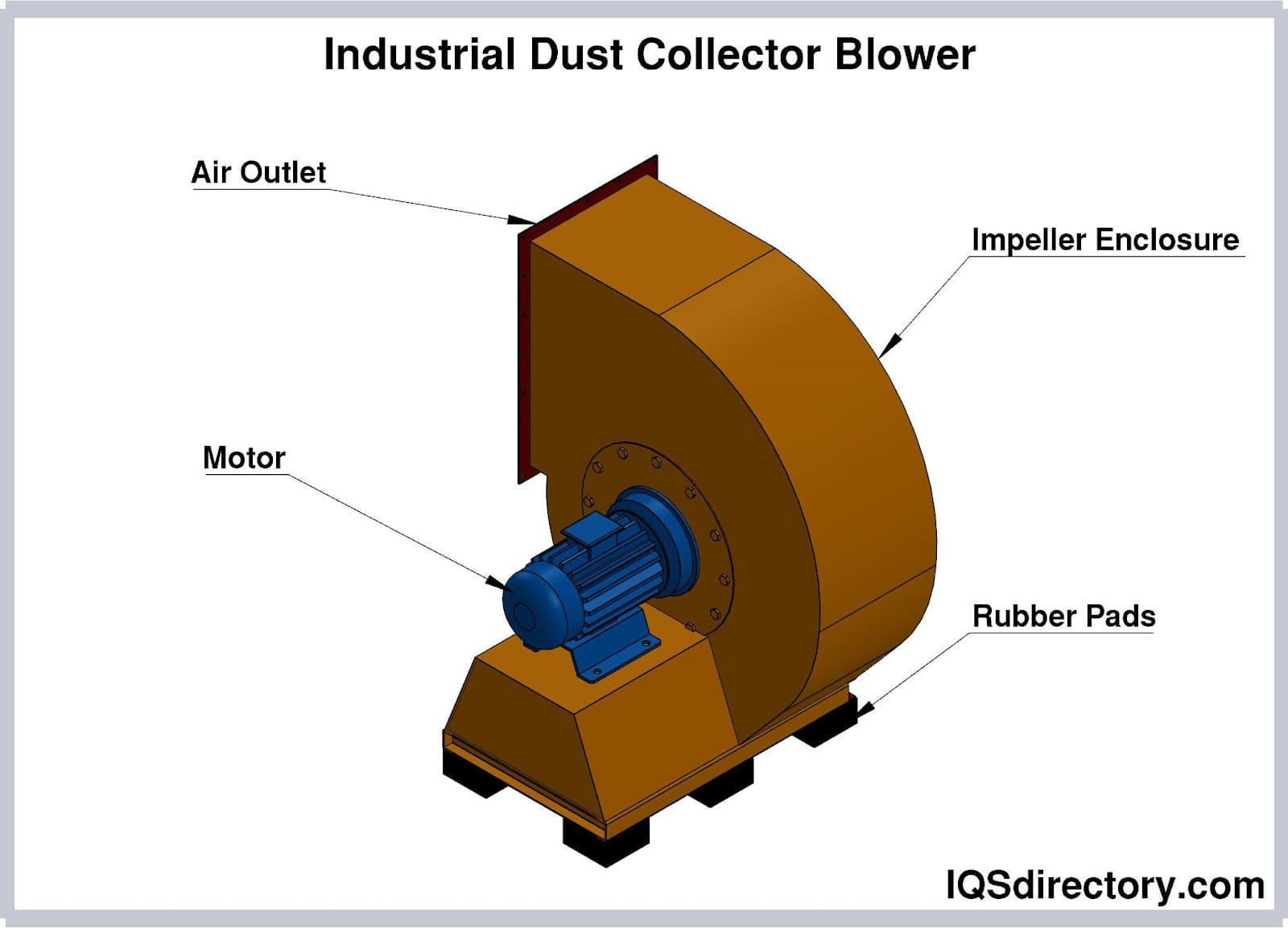

What Is Involved in the Assembly Process?

Once the individual components are formed, the assembly process begins. This stage includes:

- Component Integration: Joining the impeller to the motor and attaching the housing. This is often done with precision tools to ensure alignment and fit.

- Balancing: Critical for performance, impellers must be dynamically balanced to minimize vibration during operation. This process involves adjusting the weight distribution on the impeller.

- Sealing and Insulation: Ensuring that all joints and connections are sealed to prevent air leaks, which can reduce efficiency.

Proper assembly is vital for the longevity and performance of the blower, and it is closely monitored throughout the process.

Illustrative image related to centrifugal blower design

What Finishing Techniques Are Applied to Centrifugal Blowers?

The finishing stage enhances the durability and aesthetic appeal of the centrifugal blowers. Common techniques include:

- Coating: Applying protective coatings to prevent corrosion and wear. This may include powder coating or anodizing for aluminum parts.

- Polishing and Surface Treatment: Improving surface finishes to reduce friction and enhance airflow efficiency.

- Final Inspection: Conducting a thorough inspection of all assembled parts to ensure they meet specifications before packaging.

These finishing touches are essential for ensuring the blower performs well in its intended environment.

What Quality Assurance Measures Are Critical for Centrifugal Blower Design?

Quality assurance (QA) is paramount in the manufacturing of centrifugal blowers. International standards and industry-specific certifications guide these practices, ensuring that products meet global expectations for performance and safety.

Which International Standards Should B2B Buyers Be Aware Of?

International standards, such as ISO 9001, provide a framework for quality management systems. This certification indicates that the manufacturer adheres to systematic processes that enhance product quality and customer satisfaction. Other relevant certifications include:

Illustrative image related to centrifugal blower design

- CE Marking: Demonstrates compliance with European safety, health, and environmental protection standards.

- API Standards: Relevant for blowers used in oil and gas applications, ensuring equipment meets industry-specific safety and performance criteria.

These standards are crucial for B2B buyers looking to ensure compliance and reliability in their supply chain.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated into various stages of the manufacturing process, with specific checkpoints including:

- Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to verify they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process at various stages to ensure adherence to quality standards.

- Final Quality Control (FQC): Conducting comprehensive tests on the finished product, including performance testing, vibration analysis, and visual inspections.

Implementing these checkpoints helps identify and rectify issues before they escalate, ensuring only high-quality products reach the market.

What Common Testing Methods Are Employed in Quality Assurance?

Testing is a critical component of quality assurance in centrifugal blower manufacturing. Common testing methods include:

Illustrative image related to centrifugal blower design

- Performance Testing: Evaluating airflow, pressure, and efficiency under various operating conditions to ensure the blower meets design specifications.

- Vibration Analysis: Assessing the operational stability of the blower to prevent premature failure due to imbalances or misalignments.

- Noise Level Testing: Measuring the sound output to ensure compliance with industry noise regulations.

These tests provide valuable data that can be used to improve design and manufacturing processes.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control measures of suppliers is critical to ensuring reliable performance. Here are several strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits allows buyers to assess the manufacturer’s quality management systems firsthand. Key steps include:

- On-Site Visits: Engaging in physical inspections of manufacturing facilities to observe processes and QA measures in action.

- Documentation Review: Examining quality assurance documentation, including certificates, test reports, and quality manuals, to verify compliance with standards.

How Can Buyers Utilize Third-Party Inspections?

Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can perform unbiased assessments of the manufacturer’s processes and products, providing detailed reports that highlight any discrepancies.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of specific nuances that may affect quality assurance, including:

- Regulatory Compliance: Different countries may have varying regulations regarding product standards. Understanding local requirements in regions like Africa, South America, the Middle East, and Europe is essential.

- Cultural Differences: Recognizing that manufacturing practices and quality perceptions may differ across regions can help buyers manage expectations and negotiate effectively.

By understanding these nuances, B2B buyers can make informed decisions when selecting suppliers and ensure that their centrifugal blowers meet the necessary quality and performance standards.

Illustrative image related to centrifugal blower design

Conclusion: Why Quality Assurance Is Vital for Centrifugal Blower Performance

In summary, the manufacturing process of centrifugal blowers encompasses several key stages, from material preparation to finishing, each critical to the product’s overall performance. Quality assurance measures, guided by international standards and rigorous testing methods, ensure that the blowers operate efficiently and reliably in demanding industrial environments. For B2B buyers, understanding these processes and verifying supplier quality control is essential for securing high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘centrifugal blower design’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure centrifugal blower designs. The right centrifugal blower is vital for enhancing airflow and optimizing operations across various industries. This guide will help you navigate the complexities of selecting and sourcing the ideal blower for your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first crucial step in the sourcing process. Determine the required airflow rate (measured in CFM), static pressure, and operational conditions, including temperature and humidity. Understanding these parameters ensures that the blower you select meets the unique demands of your application.

Step 2: Research Different Types of Centrifugal Blowers

Familiarize yourself with the various types of centrifugal blowers available, such as forward-curved, backward-curved, radial, and airfoil designs. Each type has its own strengths and is suited to different applications. Selecting the appropriate type based on your specific needs is essential for achieving optimal performance and efficiency.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and expertise. Request company profiles, certifications, and case studies that demonstrate their experience in your industry. Pay particular attention to references from businesses in similar regions, as regional challenges may affect blower performance.

Step 4: Assess Supplier Capabilities and Customization Options

Examine the capabilities of potential suppliers in terms of manufacturing and customization. Can they tailor the blower design to meet your specific requirements? Look for suppliers who offer flexibility in design modifications, which can be crucial for addressing unique operational challenges.

Step 5: Verify Compliance with Industry Standards

Ensure that the centrifugal blowers comply with relevant industry standards and regulations. This includes certifications such as ISO, CE, or local standards specific to your region. Compliance not only guarantees quality and safety but also helps mitigate risks associated with non-compliance.

Step 6: Request Detailed Performance Data

Ask suppliers for performance curves and data that illustrate the blower’s efficiency, power consumption, and operational limits. Understanding these metrics is vital for making informed decisions and ensuring that the blower can handle the required airflow and pressure needs in your application.

Step 7: Negotiate Terms and Warranty Options

Once you have selected a supplier, negotiate terms, including pricing, delivery schedules, and warranty options. A solid warranty can provide peace of mind and protect your investment. Ensure that you understand the service and support available post-purchase, as this can significantly impact long-term operational efficiency.

By following these steps, you can effectively navigate the procurement process for centrifugal blowers, ensuring that you choose a solution that meets your operational needs and contributes to the success of your business.

Comprehensive Cost and Pricing Analysis for centrifugal blower design Sourcing

What Are the Key Cost Components in Centrifugal Blower Design?

When considering the cost structure for centrifugal blower design, several key components must be accounted for:

-

Materials: The selection of materials significantly impacts costs. Common materials include steel, aluminum, and specialized alloys for high-performance applications. The choice depends on the blower’s intended use, environmental conditions, and durability requirements.

-

Labor: Labor costs encompass the workforce needed for design, assembly, and testing. Skilled labor is often required for precision manufacturing, which can drive up costs. Labor rates vary by region, influencing overall expenses, especially for international buyers.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, equipment maintenance, and administrative expenses. A higher overhead can lead to increased pricing, particularly in regions with stringent regulations or high operational costs.

-

Tooling: Initial tooling costs are a significant factor in custom designs. This encompasses the expenses for molds, dies, and jigs necessary for production. The complexity of the blower design will determine tooling costs, with more intricate designs requiring more sophisticated tooling.

-

Quality Control (QC): Ensuring the reliability and safety of centrifugal blowers necessitates a robust QC process. This involves testing and inspection protocols that can add to the overall cost but are crucial for compliance with industry standards and certifications.

-

Logistics: The cost of transporting the blowers to their final destination can vary widely based on distance, mode of transport, and the need for special handling. International shipments may involve additional tariffs or fees, influencing the total landed cost.

-

Margin: Suppliers typically add a margin to cover their risks and profit expectations. This margin can vary based on competition, market demand, and the relationship with the buyer.

What Influences Pricing in Centrifugal Blower Design?

Several factors influence the pricing of centrifugal blowers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk discounts, significantly lowering the per-unit cost. Buyers should assess their needs to leverage pricing effectively.

-

Specifications and Customization: Customized blowers tailored to specific applications may incur higher costs. Standard models typically offer better pricing due to economies of scale.

-

Materials and Quality Certifications: Higher-grade materials and certifications (like ISO or CE) can elevate costs. Buyers should balance the need for quality with budget constraints, especially in industries where reliability is critical.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers can affect pricing. Established suppliers may offer higher quality and better service, justifying a premium.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they define the responsibilities of buyers and sellers in shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence overall costs.

How Can Buyers Negotiate for Better Pricing on Centrifugal Blowers?

-

Understand Total Cost of Ownership (TCO): Evaluate the long-term costs associated with operating the blower, including maintenance, energy consumption, and downtime. This perspective can justify higher initial investments if long-term savings are evident.

-

Leverage Volume Purchases: Buyers should consider consolidating orders to meet MOQ for discounts, or collaborate with other companies to increase order sizes.

-

Request Multiple Quotes: Engaging multiple suppliers can provide a clearer picture of the market and help negotiate better terms. Be transparent about competing offers to encourage favorable pricing.

-

Focus on Long-Term Relationships: Building a solid relationship with suppliers can lead to better pricing and priority service. Regular communication and feedback can foster trust and collaboration.

-

Be Aware of Regional Pricing Nuances: Different regions may have varying price structures due to local manufacturing costs, labor rates, and material availability. Buyers from Africa, South America, the Middle East, and Europe should consider these factors when sourcing.

Conclusion: What Should Buyers Keep in Mind?

While the prices for centrifugal blowers can vary significantly based on the factors mentioned, buyers should approach sourcing with a comprehensive understanding of the cost structure and pricing influences. This knowledge allows for informed decision-making, fostering successful procurement strategies.

Illustrative image related to centrifugal blower design

Disclaimer: Prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Always consult with suppliers for accurate pricing tailored to your needs.

Alternatives Analysis: Comparing centrifugal blower design With Other Solutions

Understanding the Alternatives to Centrifugal Blower Design

When considering airflow solutions for industrial applications, it’s essential to analyze various options available in the market. Centrifugal blowers are widely recognized for their efficiency and versatility, but alternative technologies may offer unique advantages depending on specific operational requirements. In this analysis, we will compare centrifugal blower design with two viable alternatives: Positive Displacement Blowers and Axial Fans.

Comparison Table

| Comparison Aspect | Centrifugal Blower Design | Positive Displacement Blowers | Axial Fans |

|---|---|---|---|

| Performance | High static pressure, suitable for various air volumes | Consistent flow at varying pressures, less affected by changes in system resistance | High volume airflow, effective in low-pressure applications |

| Cost | Moderate initial investment, energy-efficient long-term | Higher initial cost, but lower operational costs | Generally lower upfront cost, but variable efficiency |

| Ease of Implementation | Requires specific installation considerations and ducting | Easy to install, often compact | Simple installation, minimal ducting needed |

| Maintenance | Regular maintenance required, especially for bearings and impellers | Low maintenance due to fewer moving parts | Requires regular cleaning and bearing checks |

| Best Use Case | HVAC systems, industrial ventilation, and exhaust applications | Pneumatic conveying, wastewater treatment | Large space ventilation, cooling in industrial settings |

What Are the Advantages and Disadvantages of Positive Displacement Blowers?

Positive Displacement (PD) blowers operate by trapping a fixed volume of air and then displacing it into the system. This method provides a consistent flow rate, making PD blowers ideal for applications where air pressure must remain stable despite varying system resistance. One of the main advantages of PD blowers is their efficiency at lower speeds, which can result in lower energy costs over time. However, they tend to have a higher initial investment compared to centrifugal blowers, which may deter some buyers. Furthermore, while PD blowers require less maintenance, they can be less effective in applications requiring high static pressures.

How Do Axial Fans Compare to Centrifugal Blowers?

Axial fans move air parallel to the axis of the fan, making them well-suited for applications requiring high volumes of airflow at low pressures. Their design allows for straightforward installation and minimal ducting, which can lead to cost savings in setup. However, axial fans may not perform as well in systems with high resistance or where precise air pressure control is needed. While they are typically less expensive upfront, their efficiency can vary significantly based on application, potentially leading to higher operational costs over time if not matched correctly to the application requirements.

Illustrative image related to centrifugal blower design

How Should B2B Buyers Choose the Right Airflow Solution?

Selecting the right airflow solution requires a thorough understanding of the operational needs of your facility. B2B buyers should assess the specific application, including airflow requirements, pressure needs, budget constraints, and maintenance capabilities. Centrifugal blowers are excellent for high-pressure applications and consistent airflow, while positive displacement blowers excel in stable pressure situations. Axial fans are best for large volume needs with lower pressure demands. Evaluating these factors will enable buyers to make informed decisions that align with their operational goals and financial parameters.

Essential Technical Properties and Trade Terminology for centrifugal blower design

What Are the Critical Technical Properties of Centrifugal Blower Design?

When considering the design and selection of centrifugal blowers, understanding key technical properties is essential. These specifications not only influence the blower’s performance but also its longevity and efficiency in various applications.

1. Airflow Rate (CFM)

Airflow rate, measured in cubic feet per minute (CFM), indicates the volume of air a blower can move. This metric is crucial for determining if a blower can adequately ventilate a space or support an industrial process. A higher CFM is often required for larger spaces or systems, making it a primary consideration for B2B buyers.

2. Static Pressure

Static pressure, measured in inches of water gauge (WG), reflects the resistance against which the blower must work to move air through the system. Understanding the static pressure requirements helps in selecting a blower that can overcome system restrictions, ensuring efficient airflow and reducing energy consumption.

3. Motor Power

The motor power rating, typically expressed in horsepower (HP) or kilowatts (kW), is vital for determining the blower’s operational capability. A higher motor power generally translates to increased airflow and pressure capacity. B2B buyers must align motor specifications with operational needs to avoid underperformance or excessive energy costs.

4. Material Grade

Material grade refers to the quality and type of materials used in the construction of the blower. Common materials include carbon steel, stainless steel, and thermoplastics. The choice of material impacts durability, resistance to corrosion, and overall lifespan, making it a critical factor for industries operating in harsh environments.

5. Efficiency Rating

Efficiency ratings, often provided as a percentage, measure how effectively a blower converts electrical energy into airflow. Higher efficiency ratings indicate lower operational costs and reduced environmental impact. Buyers should prioritize efficiency to achieve long-term savings and sustainability goals.

6. Noise Level

Noise level, measured in decibels (dB), is an important consideration, especially in environments where sound control is necessary. Selecting a blower with acceptable noise levels ensures compliance with workplace regulations and enhances worker comfort.

Illustrative image related to centrifugal blower design

What Common Trade Terms Should B2B Buyers Know When Sourcing Centrifugal Blowers?

Navigating the procurement of centrifugal blowers requires familiarity with industry-specific terminology. Understanding these terms can facilitate smoother transactions and better communication with suppliers.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of centrifugal blowers, partnering with an OEM can ensure that buyers receive high-quality components designed for specific applications, which is crucial for maintaining system integrity.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan their budgets and inventory effectively. It can also impact supply chain management and overall cost efficiency.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For buyers, issuing an RFQ is an important step in the procurement process, allowing for comparison of prices and terms from different manufacturers.

4. Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk transfer, and cost allocation, which can significantly affect overall project budgets.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is critical for project planning, especially in industries where timely delivery is essential to avoid operational delays.

6. Warranty

A warranty is a guarantee from the manufacturer regarding the performance and quality of the blower. It is vital for buyers to understand warranty terms to ensure protection against defects and to facilitate future maintenance or replacements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting centrifugal blowers, ensuring they meet their operational needs while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the centrifugal blower design Sector

What Are the Current Market Dynamics Affecting Centrifugal Blower Design?

The centrifugal blower design sector is currently influenced by several global drivers, including increasing industrialization and the need for efficient ventilation systems across various industries. With the rise of manufacturing and processing industries in regions such as Africa and South America, there is a growing demand for reliable airflow solutions to optimize operations. In Europe and the Middle East, stringent regulations on air quality and energy efficiency are propelling companies to invest in advanced blower technologies that minimize energy consumption while maximizing performance.

Emerging technologies, such as IoT-enabled blowers, are gaining traction in the market. These smart devices provide real-time data on performance metrics, enabling proactive maintenance and reducing downtime. Additionally, the integration of artificial intelligence in blower design allows for improved performance analytics, optimizing airflow based on operational needs. As international B2B buyers navigate these dynamics, they must consider suppliers who offer innovative solutions and can adapt to evolving market requirements.

How Is Sustainability Influencing Sourcing Trends in the Centrifugal Blower Design Sector?

Sustainability has become a pivotal concern in the centrifugal blower design sector, driving buyers to prioritize eco-friendly sourcing practices. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. As a result, businesses are increasingly seeking suppliers that implement sustainable practices throughout their supply chains.

Ethical sourcing is essential for maintaining corporate responsibility and enhancing brand reputation. Buyers are encouraged to collaborate with manufacturers who prioritize sustainable materials and processes, such as using recyclable components and reducing emissions during production. Certifications such as ISO 14001 and Energy Star are becoming crucial indicators of a supplier’s commitment to sustainability. By integrating these considerations into sourcing strategies, companies can not only comply with regulations but also meet the growing demand from consumers and stakeholders for environmentally responsible practices.

How Has the Centrifugal Blower Design Sector Evolved Over Time?

The centrifugal blower design sector has undergone significant evolution over the decades, transitioning from basic mechanical devices to sophisticated, high-efficiency systems. Initially, blowers were primarily designed for simple airflow applications, but advancements in material science and engineering have led to the development of specialized blowers capable of handling complex industrial needs.

The introduction of computational fluid dynamics (CFD) in the design phase has allowed engineers to create more efficient and effective blower designs tailored to specific applications. This evolution is also marked by the shift towards energy-efficient technologies, driven by regulatory changes and the global push for sustainability. As the sector continues to innovate, B2B buyers must stay informed about these advancements to make strategic sourcing decisions that align with their operational goals.

Frequently Asked Questions (FAQs) for B2B Buyers of centrifugal blower design

-

How do I choose the right centrifugal blower for my application?

Choosing the right centrifugal blower involves assessing several key factors. First, determine the required airflow rate (measured in CFM) for your specific application, as larger spaces will necessitate higher ratings. Additionally, consider the static pressure needed to overcome system resistance, which can be calculated based on duct layout and fittings. Evaluate the blower’s speed requirements and ensure it aligns with your operational needs. Lastly, consider the blower’s duty cycle, including environmental factors like temperature and humidity, to ensure optimal performance and longevity. -

What are the common applications of centrifugal blowers in various industries?

Centrifugal blowers are versatile and widely used across multiple industries. Common applications include HVAC systems for air circulation, exhaust systems in manufacturing for removing contaminants, and process ventilation in food processing and chemical plants. They are also integral in agricultural settings for grain aeration and in the power generation sector for combustion air supply. Understanding the specific application needs will help in selecting the appropriate blower design for efficient operation. -

What customization options are available for centrifugal blowers?

Many manufacturers offer customization options to meet specific operational requirements. Customizations can include variations in size, material, impeller design (e.g., forward or backward curved), and motor type (e.g., variable speed motors). Additionally, modifications can be made for specific environmental conditions, such as corrosion resistance or enhanced airflow characteristics. Discussing your unique requirements with the manufacturer can lead to a tailored solution that optimizes performance for your application. -

What is the minimum order quantity (MOQ) for centrifugal blowers?

The minimum order quantity (MOQ) for centrifugal blowers can vary significantly between manufacturers. Some suppliers may have an MOQ of one unit for standard models, while custom designs may require larger orders to justify production costs. It is essential to communicate with potential suppliers to understand their MOQ policies, especially if you are looking for unique or tailored solutions, to ensure they align with your purchasing strategy. -

What payment terms should I expect when sourcing centrifugal blowers internationally?

Payment terms can vary based on the supplier’s policies and your negotiation with them. Common terms include advance payment, letters of credit, or net payment options (e.g., net 30 or net 60 days). Some suppliers may offer discounts for upfront payments or bulk orders. Always clarify payment terms before finalizing the order to avoid any misunderstandings and ensure a smooth transaction process. -

How do I vet suppliers for centrifugal blowers?

Vetting suppliers is crucial to ensure reliability and quality. Start by researching their reputation through online reviews, industry forums, and references from other clients. Request certifications, such as ISO standards, to confirm their manufacturing quality. Additionally, inquire about their experience in your specific industry and their capacity to provide support and service post-purchase. Conducting a factory visit or requesting product samples can also provide insights into their operations and product quality. -

What are the key quality assurance practices to look for in centrifugal blower manufacturing?

Quality assurance practices are vital in ensuring the reliability and efficiency of centrifugal blowers. Look for suppliers that implement rigorous testing protocols, including performance testing under various conditions and materials inspections. Certifications such as ISO 9001 can indicate a commitment to quality management systems. Additionally, inquire about warranty policies and after-sales support, which can provide peace of mind regarding the blower’s performance and longevity. -

What logistics considerations should I be aware of when importing centrifugal blowers?

When importing centrifugal blowers, consider factors such as shipping methods, lead times, and customs regulations in your country. Choose a reliable freight forwarder who understands the logistics of your specific region, especially for international shipments. Be aware of potential tariffs and import duties that may apply. Proper documentation, including commercial invoices and shipping manifests, is essential to avoid delays at customs. Planning these logistics in advance can ensure a smooth delivery process.

Top 6 Centrifugal Blower Design Manufacturers & Suppliers List

1. IQS Directory – Centrifugal Blowers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Centrifugal blowers are mechanisms designed to propel air using centrifugal force from a spinning impeller. Key components include the impeller, housing, and drive mechanism. Types of centrifugal blowers include: 1. Forward Curved Centrifugal Blowers: High static pressure and airflow, used in low-pressure, high-volume applications like HVAC systems. 2. Backward Inclined Centrifugal Blowers: Higher…

2. Air Blower Fan – Centrifugal Blowers

Domain: airblowerfan.com

Registered: 2020 (5 years)

Introduction: Centrifugal Blowers: Types include Single Fan Type (2,800~3,400 RPM), Single Fan Type (1,400~1,800 RPM), Duo-Fan Type, Double Suction Type, Centrifugal DC Blowers, Combustion Air Blowers, Draft Inducer/Air Blower Fan, Furnace Blowers, HVAC Blowers, Blower Fan Motors, Air Shower Blowers, Cross Flow Fan, Inflatable Blower Fans, Carpet Dryer, Air Booster Fans, Blower Wheel, Centrifugal Strip Type, Ce…

3. Acdcecfan – Centrifugal Fans

Domain: acdcecfan.com

Registered: 2024 (1 years)

Introduction: Centrifugal fans are mechanical devices designed for transporting large volumes of air in industrial applications and HVAC systems. They utilize centrifugal force to draw air from the center and expel it radially. Key benefits of proper centrifugal fan design include enhanced energy efficiency, lower operating costs, increased airflow and pressure, reduced noise levels, and improved longevity. The…

4. Northern Blower – Custom Centrifugal Fans & Blowers

Domain: northernblower.com

Registered: 1996 (29 years)

Introduction: Custom Centrifugal Fans & Blowers designed for challenging industrial processes. Key series and specifications include:

– Series 4000: Backward Curved Industrial, SISW, Performance 5,000 to 250,000 ACFM to 48″ WG SP.

– Design 5010: Airfoil, SISW & DIDW, Wheel Diameter 13-1/2″ to 80-3/4″, Performance 1,000 to 250,000 ACFM to 21″ WG SP.

– Design 5020: Backward Inclined Blower, SISW & DIDW, Wheel Di…

5. Softinway – Centrifugal Fans

Domain: softinway.com

Registered: 1999 (26 years)

Introduction: Centrifugal fans are turbomachines designed for high efficiency, featuring an impeller in a spirally shaped casing. They generate high pressures compared to axial flow fans. There are three types of blades: forward, backward, and radial. Sizing can be done using specific speed (Ns) and specific diameter (Ds) classifications, and initial sizing can be performed through inverse calculations using pa…

6. Paxton Products – Centrifugal Air Blowers

Domain: paxtonproducts.com

Registered: 1996 (29 years)

Introduction: Centrifugal Air Blowers by Paxton Products offer high efficiency solutions for drying, blow off, air rinsing, process air, and vacuum applications. They replace compressed air blow off and less efficient blowers like squirrel cage or regenerative blowers. Energy savings of 50-80% are achievable, with a typical return on investment (ROI) of about one year. Available sizes range from 2 hp to 20 hp, …

Strategic Sourcing Conclusion and Outlook for centrifugal blower design

In navigating the complexities of centrifugal blower design, strategic sourcing emerges as a pivotal element for international B2B buyers. Understanding the specific applications and operational requirements of centrifugal blowers—ranging from airflow and static pressure to speed and intended duty—ensures optimal performance in diverse industrial settings. By prioritizing quality and efficiency, companies can enhance their operational capabilities, reduce long-term costs, and improve overall productivity.

Moreover, as global markets continue to evolve, the demand for reliable and efficient air management solutions will only grow. Buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany, should leverage strategic sourcing to identify and collaborate with reputable manufacturers that offer tailored solutions to their unique challenges.

As you move forward, consider engaging with suppliers who not only understand your industry’s specific needs but also provide innovative technologies and robust support services. By doing so, you position your business for sustained growth and success in an increasingly competitive landscape. Embrace the future of centrifugal blower technology—make informed sourcing decisions today.

Illustrative image related to centrifugal blower design

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.