The Definitive Guide to Burn Cans: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for burn cans

In today’s diverse and rapidly evolving global market, sourcing effective burn cans poses a significant challenge for B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, including countries such as Vietnam and Germany. As environmental regulations tighten and the demand for sustainable waste management solutions grows, understanding the various types of burn cans, their applications, and the intricacies of supplier vetting becomes crucial. This guide aims to provide a comprehensive overview of the burn can landscape, equipping international buyers with the knowledge to make informed purchasing decisions.

Throughout this guide, we will explore the different types of burn cans available on the market, from traditional burn barrels to advanced incinerators designed for efficiency and safety. We will also discuss their diverse applications across various industries, including waste disposal, agricultural waste management, and even outdoor recreational use. Additionally, we will delve into critical aspects of supplier vetting, examining how to assess reliability, quality, and compliance with international standards.

By the end of this guide, B2B buyers will be empowered to navigate the complexities of sourcing burn cans, ensuring they choose products that not only meet their operational needs but also align with sustainability goals. This resource is designed to facilitate smarter investments, ultimately contributing to a more efficient and responsible approach to waste management in a global context.

Understanding burn cans Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

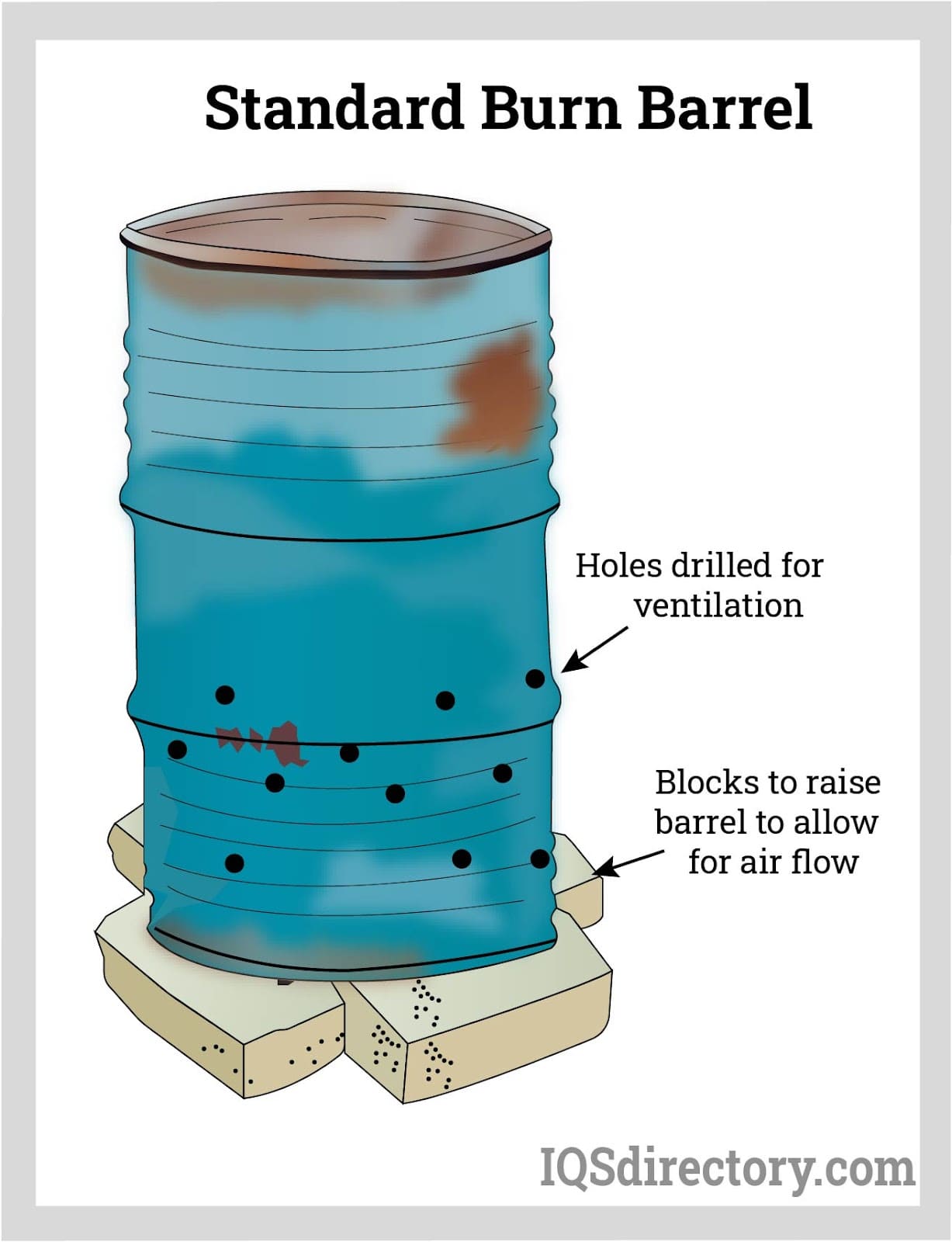

| Standard Burn Barrel | Typically made of steel, designed for burning waste. | Waste disposal for agricultural and industrial sectors. | Pros: Cost-effective, simple design. Cons: Less efficient, can produce smoke. |

| Stainless Steel Incinerator | High durability, patented airflow system for efficient burning. | Ideal for municipal waste management and landscaping. | Pros: High burn temperatures, cleaner emissions. Cons: Higher initial investment. |

| Portable Burn Cage | Lightweight, often collapsible; designed for easy transport. | Ideal for camping, outdoor events, and small-scale waste disposal. | Pros: Versatile, easy to set up. Cons: Limited capacity for large waste. |

| Pyro Incinerator | Engineered for maximum efficiency with innovative design. | Suitable for industrial applications, including hazardous waste incineration. | Pros: Very efficient, reduces smoke and emissions. Cons: Requires more maintenance. |

| Custom Burn Solutions | Tailored designs based on specific client needs. | Large-scale operations, specialized waste management. | Pros: Meets unique requirements, potentially more efficient. Cons: Higher costs, longer lead times. |

What are the Characteristics and Suitability of Standard Burn Barrels?

Standard burn barrels are commonly constructed from steel and are designed primarily for waste disposal. They are frequently used in agricultural and industrial settings where the burning of organic waste is necessary. While they are relatively inexpensive and straightforward in design, buyers should be aware that they may produce more smoke and pollutants compared to more advanced incinerators. B2B buyers must consider local regulations regarding smoke emissions and waste disposal when opting for standard burn barrels.

How Do Stainless Steel Incinerators Enhance Waste Management?

Stainless steel incinerators are built for durability and efficiency, featuring a patented airflow system that allows for hotter burns, often exceeding 1800°F. This design results in cleaner emissions, making them suitable for municipal waste management and landscaping operations. Although the initial cost is higher than standard burn barrels, the long-term benefits in terms of reduced emissions and operational efficiency can justify the investment. B2B buyers should evaluate their waste volume and disposal needs to determine if this option aligns with their sustainability goals.

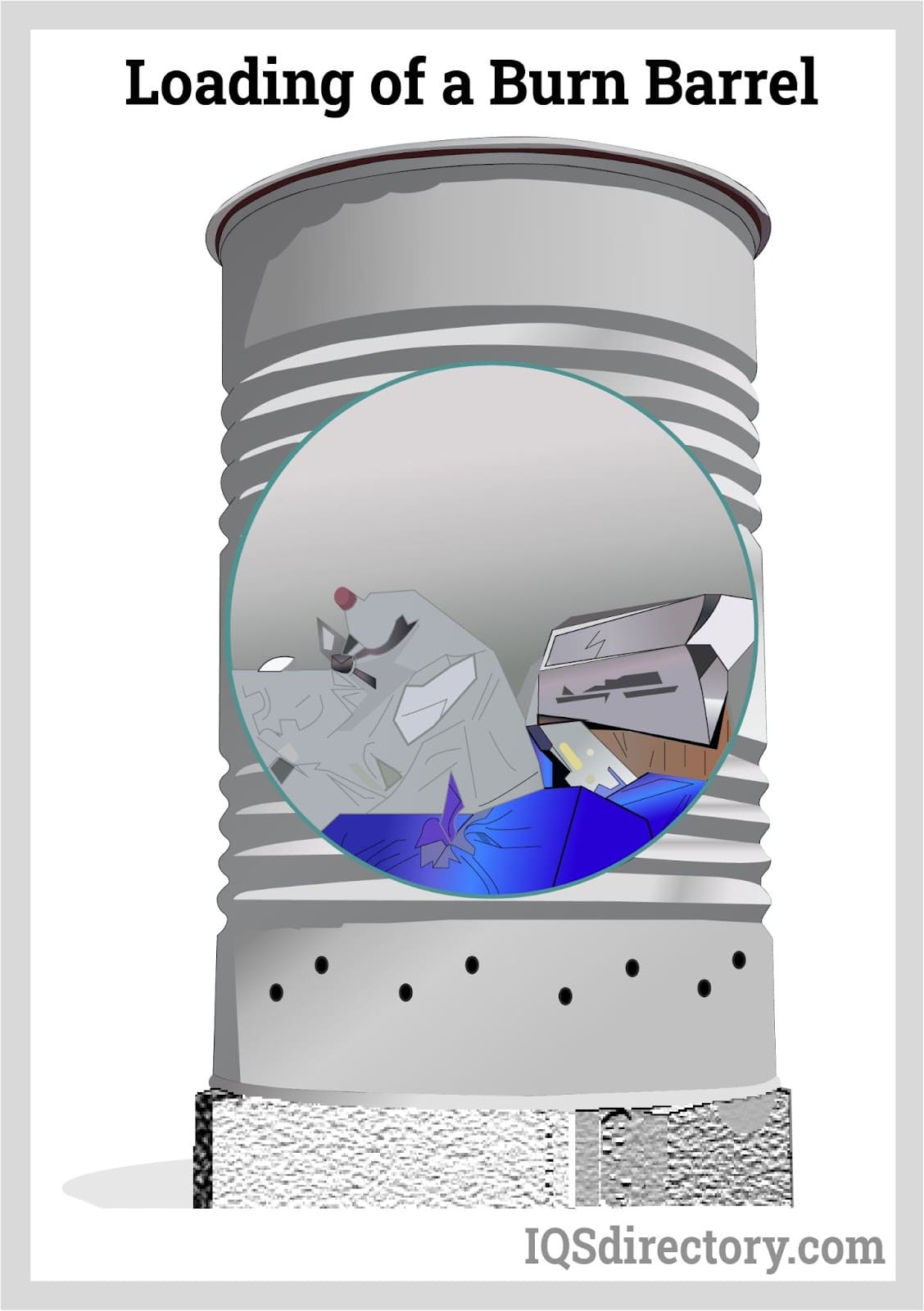

Illustrative image related to burn cans

What Advantages Do Portable Burn Cages Offer for B2B Use?

Portable burn cages are designed for easy transport and are ideal for smaller-scale operations, such as outdoor events or camping. Their lightweight and often collapsible nature allows for convenient setup and use in various locations. However, they have a limited capacity, making them less suitable for large waste disposal needs. Businesses involved in event management or outdoor recreation should consider these for their versatility and ease of use, while also being mindful of their waste volume to avoid overloading.

Why Choose Pyro Incinerators for Industrial Applications?

Pyro incinerators are engineered for maximum efficiency and are particularly suited for industrial applications, including the incineration of hazardous waste. Their innovative design minimizes smoke and emissions, aligning with stringent environmental regulations. While they may require more maintenance compared to simpler models, their effectiveness in waste reduction makes them a valuable investment for businesses focused on sustainability. B2B buyers must assess their specific waste management requirements to determine if the benefits of a Pyro incinerator outweigh the maintenance considerations.

How Can Custom Burn Solutions Meet Unique B2B Needs?

Custom burn solutions are tailored to meet specific client requirements, making them ideal for large-scale operations and specialized waste management needs. These solutions can address unique challenges such as waste type, volume, and environmental regulations. While they often come with higher costs and longer lead times, their ability to provide efficient waste disposal tailored to a business’s operational needs can lead to significant long-term savings. B2B buyers should conduct a thorough needs assessment to ensure that custom solutions align with their strategic goals.

Key Industrial Applications of burn cans

| Industry/Sector | Specific Application of burn cans | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Waste Management | Incineration of non-recyclable waste | Reduces landfill dependency and environmental impact | Compliance with local regulations on emissions |

| Agriculture | Disposal of agricultural waste and debris | Efficient waste management and reduced pest control | Durability and resistance to harsh weather |

| Construction | Burning of construction debris and waste | Streamlines project cleanup and reduces costs | Size and capacity to handle specific waste types |

| Forestry | Controlled burning for land clearing | Promotes land regeneration and fire prevention | Temperature control features for safety |

| Military & Defense | Disposal of sensitive documents and materials | Ensures confidentiality and security | Portability and ease of use in remote locations |

How are burn cans utilized in waste management, and what benefits do they offer?

In the waste management industry, burn cans are primarily used for the incineration of non-recyclable waste. This application helps municipalities and private waste management companies reduce their reliance on landfills, thus minimizing environmental impact. By effectively incinerating waste, businesses can achieve higher efficiency in waste disposal and comply with stringent environmental regulations. International buyers should consider the burn can’s compliance with local emission standards, as these can vary significantly across regions, particularly in Africa and South America.

What role do burn cans play in agriculture, and what should buyers prioritize?

In agriculture, burn cans serve as a practical solution for disposing of agricultural waste, such as crop residues and debris. This method not only streamlines waste management but also aids in pest control by eliminating breeding grounds for insects. For agricultural businesses, sourcing durable burn cans that can withstand harsh weather conditions is crucial. Buyers in the Middle East and Europe should also evaluate the burn can’s capacity to ensure it meets the volume of waste generated during peak seasons.

How do construction firms benefit from using burn cans for debris disposal?

Construction companies utilize burn cans for the efficient disposal of construction debris and waste, which can significantly streamline project cleanup. This practice reduces costs associated with transporting waste to disposal sites and helps maintain a cleaner work environment. When sourcing burn cans, construction firms should consider the size and capacity to accommodate specific types of waste, ensuring that the chosen solution aligns with project requirements. Buyers from Europe may also need to verify compliance with local construction waste regulations.

In what ways do burn cans assist in forestry applications?

In the forestry sector, burn cans are employed for controlled burning, which is crucial for land clearing and forest management. This application not only promotes land regeneration but also reduces the risk of uncontrolled wildfires by managing undergrowth. Buyers in this sector should prioritize burn cans with features that allow for precise temperature control, ensuring safety during use. As forestry practices may differ significantly across regions, understanding local regulations regarding controlled burns is essential for international buyers.

Illustrative image related to burn cans

How are burn cans utilized by military and defense sectors for secure waste disposal?

The military and defense sectors use burn cans for the secure disposal of sensitive documents and materials, ensuring confidentiality and compliance with security protocols. This application is particularly vital in remote locations where traditional waste management options may be limited. Buyers in this sector should focus on the portability and ease of use of burn cans, as well as their ability to handle various waste types. Military buyers from different regions, including Europe and the Middle East, should also consider the logistical aspects of transporting these units to remote sites.

3 Common User Pain Points for ‘burn cans’ & Their Solutions

Scenario 1: Inefficient Waste Management in Remote Areas

The Problem: Many businesses operating in remote areas face significant challenges in waste disposal. Traditional waste management services may be unavailable, leading to the accumulation of organic and non-organic waste. This not only creates an unsightly environment but also poses health risks due to pests and pollutants. For B2B buyers, the inability to efficiently manage waste can lead to operational disruptions and compliance issues with environmental regulations.

The Solution: To overcome this challenge, B2B buyers should consider investing in high-quality burn cans that are designed for efficient waste incineration. Look for models that are portable, have a robust design, and can withstand extreme conditions. Stainless steel burn barrels, for instance, provide durability and longevity, which is crucial in harsh environments. Additionally, ensure that the burn can is equipped with features that promote complete combustion, such as airflow systems that enhance burning efficiency. Educating staff on proper use—such as not overloading the barrel and ensuring adequate ventilation—can also maximize performance and minimize smoke emissions. Regular maintenance checks will help in prolonging the lifespan of the burn cans, ensuring they remain effective waste management solutions.

Scenario 2: Safety and Compliance Concerns with Open Burning

The Problem: In many regions, open burning of waste can lead to serious safety hazards, including uncontrolled fires and air pollution. B2B buyers are increasingly aware of the need to comply with local regulations regarding waste disposal and environmental protection. Failure to adhere to these regulations can result in heavy fines and damage to a company’s reputation. This is particularly concerning for industries such as agriculture and construction, where waste disposal is a regular part of operations.

Illustrative image related to burn cans

The Solution: B2B buyers can mitigate safety and compliance issues by selecting burn cans specifically engineered for safe burning. Look for products that include safety features such as spark arrestors and secure lids, which can help contain flames and prevent the spread of fire. Furthermore, buyers should familiarize themselves with local regulations regarding waste burning to ensure compliance. Partnering with suppliers who offer guidance on legal requirements can be beneficial. Implementing a scheduled burning plan, with clearly defined safety protocols, will also enhance operational safety. Training employees on the correct procedures for using burn cans will further reduce risks and ensure that waste is disposed of responsibly.

Scenario 3: High Operational Costs Due to Ineffective Burning Solutions

The Problem: Companies often face escalating operational costs when using inefficient burning solutions for waste disposal. Poorly designed burn cans may lead to incomplete combustion, resulting in higher ash production and the need for additional clean-up. This not only increases labor costs but also can require more frequent purchases of waste disposal equipment, adding to overall expenses.

The Solution: To address this issue, B2B buyers should invest in advanced burn cans that promise a more efficient and cleaner burn. Products with patented designs that enhance airflow and combustion temperatures are likely to provide a more complete incineration process, resulting in less ash and smoke. It’s essential to assess the burn can’s specifications and choose one that aligns with the types of waste generated by the business. For example, if burning yard debris is common, a burn can designed for high heat and quick ash reduction will be more cost-effective in the long run. Additionally, establishing a maintenance schedule to clean and inspect the burn cans will ensure they operate at peak efficiency, thereby reducing the frequency of replacements and minimizing operational costs.

Strategic Material Selection Guide for burn cans

What Are the Key Materials Used in Burn Cans and Their Properties?

When selecting materials for burn cans, it is crucial to consider the specific properties and performance characteristics that will meet the demands of various applications. Below, we analyze four common materials used in the construction of burn cans, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

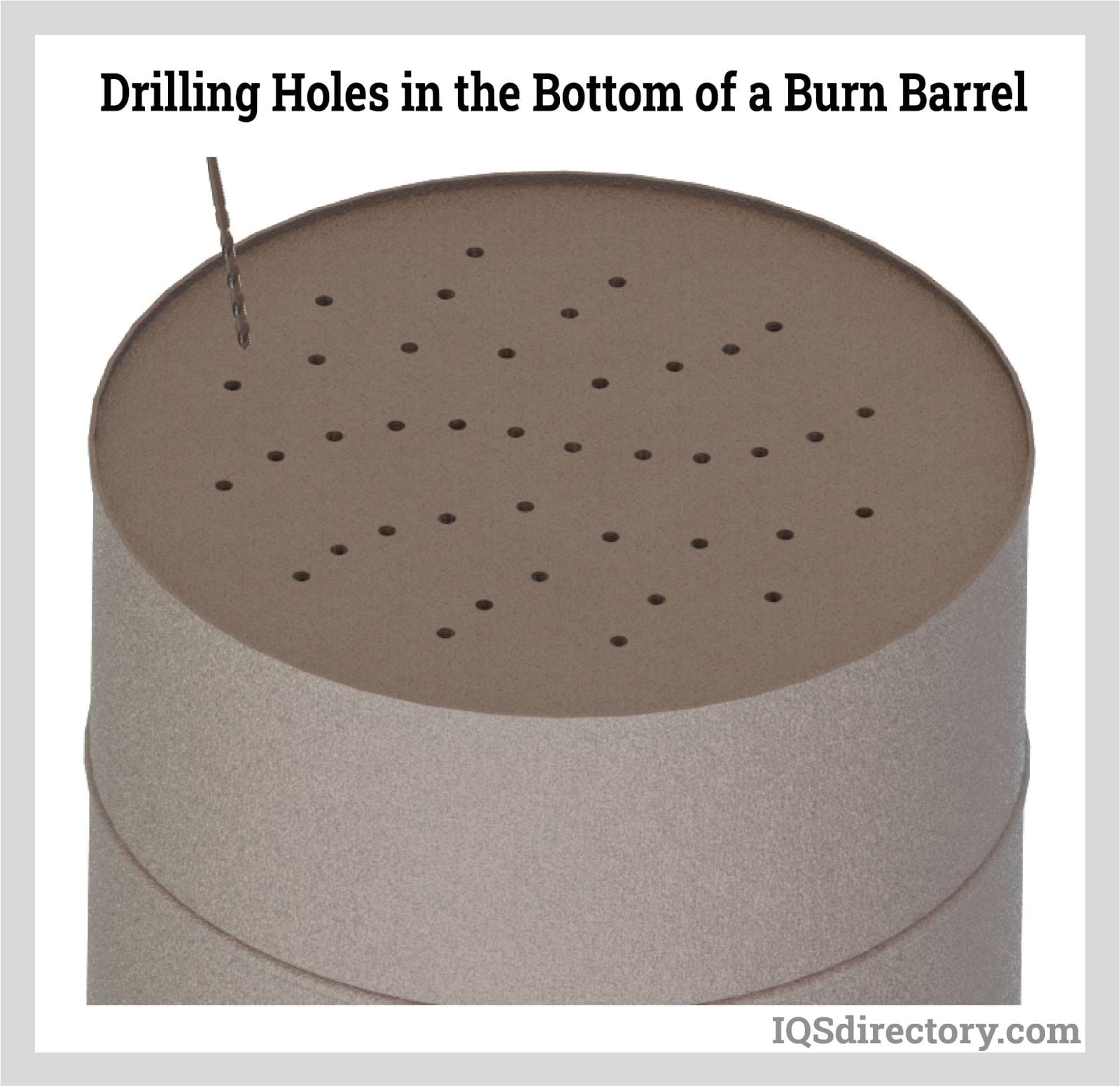

Illustrative image related to burn cans

How Does Steel Perform as a Material for Burn Cans?

Steel, particularly carbon steel, is a popular choice for burn cans due to its strength and durability. It can withstand high temperatures, typically up to 1,500°F (815°C), making it suitable for incinerating various waste materials. Steel’s corrosion resistance can be enhanced with coatings, though bare steel may rust over time when exposed to moisture.

Pros: Steel is relatively inexpensive and widely available, making it a cost-effective option. Its high strength ensures longevity, and it can be easily fabricated into various shapes.

Cons: Without protective coatings, steel is susceptible to corrosion, especially in humid environments. Additionally, it may require more maintenance over time compared to other materials.

For international buyers, particularly in humid regions like parts of Africa and South America, it is essential to consider protective coatings or stainless steel alternatives to enhance longevity.

Illustrative image related to burn cans

What Are the Benefits of Using Stainless Steel in Burn Cans?

Stainless steel is another common material for burn cans, known for its excellent corrosion resistance and ability to withstand high temperatures, often exceeding 1,800°F (982°C). This material is particularly advantageous for applications involving hazardous waste or where cleanliness is paramount.

Pros: Stainless steel’s resistance to rust and corrosion makes it ideal for long-term use, especially in harsh environments. It also requires minimal maintenance and provides a cleaner burn, reducing smoke and emissions.

Cons: The primary drawback is the higher cost compared to carbon steel. Additionally, stainless steel can be more challenging to fabricate due to its toughness.

Illustrative image related to burn cans

International buyers should be aware of various grades of stainless steel, such as 304 and 316, which are commonly used in burn can applications. Compliance with international standards, such as ASTM or DIN, is vital for ensuring quality.

How Does Aluminum Compare as a Material for Burn Cans?

Aluminum is less common but still a viable option for burn cans, especially for portable models. It can withstand temperatures up to about 1,200°F (649°C) and is lightweight, making it easy to transport.

Pros: Aluminum’s lightweight nature makes it ideal for portable applications. It also has good corrosion resistance and can be anodized for additional protection.

Cons: The lower temperature tolerance compared to steel and stainless steel limits its use in high-heat applications. Additionally, aluminum can be more expensive than carbon steel.

For buyers in regions with a focus on portability, such as outdoor or camping applications, aluminum burn cans can be an attractive option. However, compliance with local regulations regarding burning materials is essential.

Illustrative image related to burn cans

What Role Does Composite Material Play in Burn Can Applications?

Composite materials, which may include reinforced plastics or fiberglass, are emerging as alternatives for burn cans. These materials can be engineered to withstand high temperatures and provide excellent chemical resistance.

Pros: Composites can be designed to be lightweight, durable, and resistant to corrosion. They can also be tailored to meet specific performance criteria, such as thermal insulation.

Cons: The manufacturing process for composites can be complex and costly. Additionally, not all composites are suitable for high-temperature applications, so careful selection is necessary.

International buyers should consider the specific application and local regulations regarding the use of composite materials in burn cans. Compliance with environmental standards is crucial, especially in regions with strict waste management laws.

Summary Table of Material Properties for Burn Cans

| Material | Typical Use Case for burn cans | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General waste incineration | Cost-effective and durable | Prone to corrosion without coating | Low |

| Stainless Steel | Hazardous waste and high-temperature burns | Excellent corrosion resistance | Higher cost and fabrication complexity | High |

| Aluminum | Portable burn cans for outdoor use | Lightweight and easy to transport | Lower temperature tolerance | Medium |

| Composite | Specialized applications with chemical resistance | Customizable performance | Complex manufacturing process | Medium to High |

This analysis provides valuable insights for international B2B buyers, allowing them to make informed decisions based on material properties, application suitability, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for burn cans

What Are the Main Stages in the Manufacturing Process of Burn Cans?

Manufacturing burn cans involves several critical stages that ensure the final product meets quality and safety standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of appropriate materials, typically high-grade stainless steel or heavy-duty carbon steel. These materials are chosen for their durability and resistance to corrosion and warping. The raw materials undergo rigorous quality checks to confirm their compliance with international standards.

-

Forming: In this stage, sheets of metal are cut and shaped into the required dimensions using techniques such as stamping, rolling, or laser cutting. Advanced machinery ensures precision in forming, which is crucial for the structural integrity of the burn cans. Techniques like hydroforming may also be employed for creating complex shapes while minimizing waste.

-

Assembly: Following the forming stage, components are assembled. This may include welding the body of the burn can, attaching lids, and integrating any additional features such as airflow systems designed to enhance combustion efficiency. Skilled technicians oversee this process to ensure that each unit is correctly assembled and meets design specifications.

-

Finishing: The final stage includes surface treatment processes like painting, powder coating, or galvanization. These not only enhance the aesthetic appeal but also add a layer of protection against environmental factors. Quality checks are performed to ensure uniformity in coating and adherence to safety standards.

Which Quality Control Standards Are Relevant for Burn Can Manufacturing?

Quality assurance is paramount in the manufacturing of burn cans, particularly for B2B buyers who require reliable and safe products. International standards such as ISO 9001 provide a framework for maintaining high-quality processes. Additionally, industry-specific certifications, like CE marking in Europe or API standards for products used in petroleum applications, are crucial for demonstrating compliance with safety and quality regulations.

What Are the Key Quality Control Checkpoints in Burn Can Production?

Quality control in burn can manufacturing typically incorporates several checkpoints:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials for compliance with specified standards. Testing for material properties, such as tensile strength and corrosion resistance, is essential at this stage.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that the processes adhere to predetermined specifications. This includes monitoring temperature settings during welding and ensuring dimensional accuracy throughout the forming process.

-

Final Quality Control (FQC): Once the burn cans are fully assembled, a comprehensive inspection is performed. This may involve pressure testing to check for leaks and visual inspections for surface defects. Additionally, functionality tests are conducted to ensure that the burn cans perform as intended under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control measures employed by suppliers. Here are several methods to consider:

-

Supplier Audits: Conducting an audit of the manufacturing facility can provide invaluable insights into the supplier’s quality management systems. Audits should assess compliance with international standards and internal quality procedures.

-

Quality Control Reports: Requesting detailed quality control reports can help buyers understand the supplier’s testing methodologies and results. This documentation should include results from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an objective assessment of the supplier’s quality control processes. These inspections can verify compliance with international standards and the effectiveness of the supplier’s quality management systems.

What Testing Methods Are Commonly Used for Burn Cans?

Several testing methods are commonly employed in the quality assurance of burn cans:

-

Material Testing: This includes tensile strength tests, impact tests, and corrosion resistance tests to ensure that the materials used can withstand the intended operational conditions.

-

Pressure Testing: For burn cans that may be exposed to varying pressures, pressure testing ensures that they can safely contain materials without risk of failure.

-

Performance Testing: This evaluates how well the burn cans perform under actual burning conditions. Testing for burn efficiency, smoke production, and emissions are crucial for environmental compliance.

-

Durability Testing: Simulated environmental exposure tests can assess how well burn cans hold up against factors like UV radiation, temperature fluctuations, and moisture.

What Quality Control Nuances Should International B2B Buyers Be Aware Of?

For international buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Here are key considerations:

-

Regulatory Compliance: Different regions have varying regulations regarding burn can safety and emissions. Buyers should ensure that suppliers meet local and international regulations, such as REACH in Europe or environmental standards in Africa.

-

Cultural Differences in Quality Standards: What may be considered acceptable quality in one region could be deemed inadequate in another. Buyers should communicate their specific quality requirements clearly to avoid discrepancies.

-

Supply Chain Transparency: Given the complexity of international supply chains, buyers should seek suppliers that provide transparency in their production processes and quality control measures. This helps mitigate risks associated with supply chain disruptions and quality failures.

-

Currency and Economic Factors: Fluctuations in currency exchange rates can impact pricing and the cost of quality assurance measures. B2B buyers should factor in these economic variables when negotiating contracts.

By understanding the manufacturing processes and quality assurance practices for burn cans, international B2B buyers can make informed purchasing decisions and establish reliable partnerships with suppliers. This knowledge not only enhances product quality but also strengthens compliance with safety and environmental standards, ultimately leading to successful business outcomes.

Illustrative image related to burn cans

Practical Sourcing Guide: A Step-by-Step Checklist for ‘burn cans’

In this guide, we will provide a practical checklist for B2B buyers interested in sourcing burn cans. This checklist is designed to streamline the procurement process, ensuring that buyers make informed decisions based on their specific needs and regional considerations.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for the burn cans you require. Consider factors such as size, material (e.g., stainless steel versus galvanized steel), and capacity. This step is essential as it helps you communicate your needs effectively to potential suppliers and ensures that the products meet your operational requirements.

Step 2: Research Regulatory Compliance

Investigate the local regulations and standards that apply to burn cans in your target markets. Compliance with environmental and safety regulations is critical to avoid legal issues and ensure safe usage. Look for certifications such as ISO or local environmental certifications that indicate adherence to relevant laws.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, case studies, and references from buyers in similar industries or regions. Pay attention to supplier reputation, customer service quality, and their ability to meet delivery timelines. This due diligence can prevent future issues related to product quality and supply chain disruptions.

Step 4: Assess Product Quality and Durability

Product quality is paramount when selecting burn cans. Look for features such as warp resistance, corrosion resistance, and overall durability, particularly if the cans will be used in harsh environments. Request samples if possible, or ask for third-party testing reports to verify claims about product performance.

Illustrative image related to burn cans

Step 5: Request Pricing and Payment Terms

Gather pricing information from multiple suppliers to compare costs effectively. Be clear about your budget and request detailed quotes that include all potential fees, such as shipping and handling. Understanding payment terms is also crucial; clarify conditions for deposits, credit terms, and any available discounts for bulk purchases.

Step 6: Understand Shipping Logistics

Shipping logistics can significantly impact your procurement timeline. Discuss shipping options with suppliers, including estimated delivery times and costs. Consider the implications of importing goods, such as customs duties and taxes, especially if sourcing from international suppliers. This understanding will help you plan accordingly and avoid unexpected delays.

Step 7: Establish a Communication Plan

Effective communication is key to a successful sourcing process. Establish a clear line of communication with your chosen supplier, including points of contact for inquiries and updates. Regular check-ins can help address any issues promptly and keep your project on track.

By following this checklist, B2B buyers can ensure a more efficient and effective sourcing process for burn cans, ultimately leading to better purchasing decisions and operational success.

Comprehensive Cost and Pricing Analysis for burn cans Sourcing

What Are the Key Cost Components for Sourcing Burn Cans?

When sourcing burn cans, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: Burn cans are often made from various materials, such as steel or stainless steel, which influence durability and performance. High-quality materials can significantly increase the upfront costs but may lead to lower maintenance and replacement expenses over time.

-

Labor: Labor costs can vary depending on the manufacturing location. In regions with higher labor costs, such as Germany, you may encounter higher prices for burn cans. Conversely, sourcing from countries with lower labor costs, such as Vietnam, may offer savings.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and factory management. Efficient manufacturing processes can lower overhead costs, which can be passed on to buyers.

-

Tooling: Custom designs or specifications for burn cans require specialized tooling, which can add to the initial costs. However, investing in tooling may be justified if it results in higher quality or unique product features.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the burn cans meet safety and performance standards. This may incur additional costs but is essential for maintaining product integrity, especially when exporting to regions with strict regulations.

-

Logistics: Transportation costs can vary significantly based on distance, shipping mode, and Incoterms. Understanding these factors is crucial for calculating total delivery expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary widely based on competition, market demand, and supplier reputation.

What Influences Pricing in the Burn Can Market?

Several factors can influence the pricing of burn cans, particularly in the B2B market:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers may offer discounts for larger orders, making it advantageous for buyers to negotiate minimum order quantities (MOQs).

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should clearly communicate their requirements to receive accurate quotes and avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials and any certifications (such as environmental standards) can affect pricing. Higher quality or certified products often come at a premium but provide long-term benefits.

-

Supplier Factors: Supplier reputation, reliability, and service level can influence costs. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact total costs and delivery responsibilities.

What Are the Best Negotiation Tips for International Buyers of Burn Cans?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation is key to securing favorable pricing on burn cans:

-

Understand Total Cost of Ownership (TCO): Beyond initial purchase price, consider maintenance, replacement, and operational costs. A lower-priced burn can may not be cost-effective if it requires frequent replacements or has high maintenance costs.

-

Leverage Market Research: Familiarize yourself with market prices and trends. This knowledge empowers you during negotiations, allowing you to challenge inflated pricing.

-

Establish Long-term Relationships: Building strong relationships with suppliers can lead to better pricing and service. Long-term partnerships often yield benefits like priority support and flexible payment terms.

-

Be Clear on Specifications: Clearly outline your needs and expectations to avoid misunderstandings that could lead to increased costs or delays.

-

Explore Multiple Suppliers: Don’t settle for the first offer. Comparing prices and offerings from various suppliers can provide leverage in negotiations.

Conclusion: Understanding Pricing Nuances for International Buyers

While indicative prices for burn cans can vary widely—from budget options around $115 to premium models exceeding $700—buyers should focus on the total cost of ownership rather than just initial prices. By considering the outlined cost components and pricing influencers, international buyers can make informed decisions that align with their operational needs and budget constraints.

Illustrative image related to burn cans

Alternatives Analysis: Comparing burn cans With Other Solutions

When considering waste management solutions, burn cans are a popular choice for incinerating waste materials. However, various alternative methods and technologies can also effectively achieve similar goals. This analysis will explore how burn cans compare to incinerators and burn cages, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Burn Cans | Incinerators | Burn Cages |

|---|---|---|---|

| Performance | Moderate efficiency | High efficiency, complete combustion | Moderate efficiency, less control over emissions |

| Cost | Low to moderate | High initial investment | Low to moderate |

| Ease of Implementation | Simple setup | Requires professional installation | Easy to set up, portable options available |

| Maintenance | Low maintenance | Moderate, requires regular checks | Low, easy to clean |

| Best Use Case | General waste disposal | Industrial and municipal waste | Backyard burning, recreational use |

What are the Advantages and Disadvantages of Incinerators Compared to Burn Cans?

Incinerators are designed for high-efficiency waste disposal, achieving complete combustion and significantly reducing the volume of waste. They operate at higher temperatures, ensuring that harmful emissions are minimized. However, the initial investment for incinerators can be substantial, making them less accessible for small businesses or individual users. Regular maintenance is required to ensure optimal performance and compliance with environmental regulations, which can add to operational costs. Incinerators are best suited for industrial or municipal applications where large volumes of waste are generated and strict emission standards must be met.

How Do Burn Cages Offer a Different Approach to Waste Burning?

Burn cages provide a versatile and user-friendly alternative to burn cans, especially for backyard burning and recreational use. They allow for a more controlled burn while being relatively easy to set up and maintain. However, burn cages do not achieve the same level of combustion efficiency as incinerators, and the open design can lead to increased smoke and emissions compared to enclosed systems like burn cans. They are ideal for small-scale waste disposal, such as yard debris or recreational burning, but may not be suitable for commercial applications where waste volume and environmental regulations are more stringent.

Illustrative image related to burn cans

Conclusion: How Can B2B Buyers Choose the Right Waste Management Solution?

Choosing the right waste management solution involves assessing the specific needs of your business or operation. For companies handling large volumes of waste and requiring compliance with environmental regulations, investing in an incinerator may be justified despite the higher upfront costs. Alternatively, for smaller operations or individual users looking for a simple solution for yard waste disposal, burn cans or burn cages may be more appropriate. Evaluate factors such as performance efficiency, cost, and ease of maintenance when making your decision, ensuring that the chosen solution aligns with your operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for burn cans

What Are the Key Technical Properties of Burn Cans?

When evaluating burn cans for purchase, several technical properties are critical for ensuring quality, safety, and efficiency. Understanding these specifications can guide B2B buyers in making informed decisions that align with their operational needs.

-

Material Grade

Burn cans are typically constructed from various materials, with stainless steel being the most preferred due to its durability and resistance to corrosion and warping. The material grade, often denoted by standards such as ASTM (American Society for Testing and Materials), indicates the can’s ability to withstand high temperatures and harsh environmental conditions. For businesses, investing in higher-grade materials can lead to reduced maintenance costs and longer product life. -

Burn Temperature

The burn temperature of a can is crucial as it affects combustion efficiency and emissions. High-quality burn cans can reach temperatures exceeding 1800°F, ensuring complete incineration of waste and minimizing smoke production. This property is vital for businesses looking to comply with environmental regulations and to operate sustainably. -

Capacity

Burn cans come in various sizes, commonly measured in gallons, with 55-gallon models being standard. Understanding the capacity is essential for businesses to gauge how much waste can be processed at once, impacting operational efficiency. Selecting the right capacity ensures that waste disposal aligns with the volume of materials generated. -

Design Features

Innovative design features, such as airflow systems or integrated safety mechanisms, play a significant role in the performance of burn cans. For example, a design that allows for better airflow can enhance combustion efficiency, leading to cleaner burns and reduced emissions. B2B buyers should look for designs that not only optimize performance but also prioritize safety to minimize the risk of fire hazards. -

Compliance Standards

Compliance with local and international regulations is a non-negotiable aspect of burn can specifications. Certifications such as EPA (Environmental Protection Agency) approvals or local environmental guidelines ensure that the products meet safety and environmental standards. Businesses should verify that the burn cans they consider are compliant, as this can prevent legal issues and potential fines.

What Are Common Trade Terms Related to Burn Cans?

Navigating the procurement process for burn cans involves understanding specific trade terminology that can facilitate effective communication and decision-making.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce equipment that may be marketed by another manufacturer. In the context of burn cans, purchasing from an OEM can ensure that the products are made to specific standards and quality benchmarks set by the buyer. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure that their order meets supplier requirements, which can impact pricing and availability. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. This process allows businesses to compare prices and negotiate terms, ensuring they receive the best value for their investment in burn cans. -

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international trade transactions. Familiarity with these terms helps businesses understand shipping costs, risk management, and delivery responsibilities, which are essential when importing burn cans. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is vital for businesses to manage inventory effectively and ensure that they have the necessary equipment when needed.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed purchasing decisions regarding burn cans, ultimately leading to enhanced operational efficiency and compliance.

Illustrative image related to burn cans

Navigating Market Dynamics and Sourcing Trends in the burn cans Sector

What Are the Current Market Dynamics and Key Trends in the Burn Cans Sector?

The burn cans sector is experiencing significant evolution driven by various global factors. A surge in urbanization and population growth has led to increased waste generation, necessitating efficient waste disposal solutions. In regions like Africa and South America, traditional waste management systems are often underdeveloped, creating opportunities for innovative products like burn cans. Simultaneously, technological advancements are shaping the market; for instance, the integration of improved airflow designs in burn cans has enhanced combustion efficiency, reducing smoke emissions and environmental impact.

B2B buyers are also increasingly focused on product diversity. There’s a growing demand for specialized burn cans that cater to specific uses, such as outdoor burning, waste incineration, or even recreational fire pits. This trend is particularly evident in Europe, where consumers are looking for multifunctional products that combine aesthetics with practicality. Furthermore, the rise of e-commerce has transformed sourcing strategies, allowing international buyers to access a wider array of suppliers and products, facilitating better price comparisons and supplier evaluations.

How Does Sustainability Impact the Sourcing of Burn Cans?

Sustainability has become a cornerstone in the sourcing of burn cans, influencing both buyer preferences and supplier practices. The environmental impact of waste disposal methods is under scrutiny, with burn cans being positioned as a cleaner alternative to open burning or landfilling. This shift is prompting manufacturers to adopt sustainable materials and processes, such as utilizing recycled steel or eco-friendly coatings, which not only minimize environmental footprints but also appeal to conscious consumers.

Moreover, ethical sourcing is gaining traction among B2B buyers. Companies are increasingly seeking suppliers who adhere to environmental regulations and ethical labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade standards can enhance supplier credibility and attract discerning buyers. By prioritizing sustainability and ethical sourcing, companies can not only meet regulatory compliance but also build strong brand loyalty and trust with environmentally-conscious customers.

Illustrative image related to burn cans

What Is the Historical Context of Burn Cans in the B2B Market?

The evolution of burn cans can be traced back to traditional waste disposal methods, which often involved open burning. These methods posed significant health and environmental risks, leading to stricter regulations and a demand for safer alternatives. Over the years, manufacturers have innovated, transitioning from basic metal drums to sophisticated designs that incorporate advanced combustion technology. Modern burn cans, often made from stainless steel, are engineered to provide efficient, controlled burns that minimize smoke and emissions, thus appealing to a broader B2B audience focused on compliance and sustainability.

As the market continues to evolve, international buyers are encouraged to stay informed about emerging trends and advancements in burn can technology, which can significantly impact their sourcing decisions and operational efficiencies.

Frequently Asked Questions (FAQs) for B2B Buyers of burn cans

-

How do I choose the right burn can for my needs?

Selecting the right burn can involves considering your specific use case, such as waste management, yard debris burning, or document incineration. Assess the capacity you require; for larger operations, a 55-gallon drum may be suitable, while smaller models work for residential use. Additionally, evaluate the materials and design—stainless steel options offer durability and efficiency. Lastly, check for compliance with local regulations to ensure safe and legal usage. -

What features should I look for in a burn can to ensure safety?

Key safety features include a secure lid, proper ventilation for airflow, and a sturdy design to withstand high temperatures. Look for models that prevent flame escape, reducing the risk of wildfires. Some burn cans come with additional safety accessories, like spark arrestors and ash catchers, which enhance operational safety. Always verify if the product meets safety standards relevant to your region. -

What are the minimum order quantities (MOQ) for burn cans when sourcing internationally?

Minimum order quantities for burn cans can vary significantly by manufacturer and region. Generally, MOQs range from 10 to 100 units, depending on the supplier’s production capacity and your negotiation terms. It’s advisable to discuss your requirements directly with potential suppliers to understand their MOQ policies, as some may be flexible, especially for first-time buyers. -

What payment terms are common in international transactions for burn cans?

Common payment terms in international transactions include advance payment, letters of credit, and payment upon delivery. Many suppliers prefer a 30% deposit upfront with the balance due prior to shipping. Discussing payment terms upfront can help establish trust and ensure a smooth transaction. Be aware of currency fluctuations and transaction fees that may affect the total cost. -

How can I vet suppliers when sourcing burn cans internationally?

To vet suppliers, begin by reviewing their business credentials, such as registration and certifications. Check online reviews and ratings from previous customers to gauge their reliability. Request references and samples of their products for quality assessment. Consider visiting their facilities if feasible, or use third-party inspection services to ensure compliance with international standards. -

What logistics considerations should I keep in mind when importing burn cans?

Logistics involves several key considerations, including shipping methods (air vs. sea), customs regulations, and lead times. Understand the total landed cost, which includes shipping, tariffs, and handling fees. Ensure that your supplier provides the necessary documentation for customs clearance. Working with a freight forwarder can help navigate complex logistics, particularly when dealing with international shipments. -

What quality assurance measures should I expect from burn can suppliers?

Reputable suppliers should have established quality assurance protocols, including material inspections, manufacturing process checks, and final product testing. Request documentation of quality certifications (e.g., ISO standards) and inquire about their return policy for defective products. Understanding their QA process can provide assurance regarding the durability and safety of the burn cans you intend to purchase. -

Can I customize burn cans to meet specific operational needs?

Many manufacturers offer customization options, such as size, color, and additional features like ventilation systems or branding. Discuss your specific requirements with potential suppliers, as they may provide tailored solutions to enhance functionality. Customization may affect lead times and pricing, so ensure these factors are considered in your procurement strategy.

Top 2 Burn Cans Manufacturers & Suppliers List

1. Burn Right® – Small Incinerator & XL Burn Barrel

Domain: burnrightproducts.com

Registered: 2003 (22 years)

Introduction: Burn Right® Products offers a range of incinerators and burn barrels, including:

1. **Small Incinerator** – Price: $429.00

– Features: Designed for backyard use, effective for burning yard debris.

2. **XL Burn Barrel Incinerator** – Price: $699.00

– Rated 5.00 out of 5.

– Features: Patented cylindrical design, built with 100% stainless steel to prevent warping, and capable of burn tempe…

2. Proud Pyro – The Pyro Cage

Domain: proudpyro.com

Registered: 2017 (8 years)

Introduction: The Pyro Cage is a burn cage designed as a replacement for traditional burn barrels. It is engineered for burning yard debris, cardboard boxes, and sensitive documents. Key features include:

– Excellent airflow for hotter flames and thorough burns.

– Constructed from strong 14 gauge steel, which is over 2 times thicker than typical burn barrels.

– Consists of 4 panels that easily assemble without …

Strategic Sourcing Conclusion and Outlook for burn cans

The strategic sourcing of burn cans presents a unique opportunity for international buyers to enhance their operational efficiency while adhering to environmental standards. As outlined in this guide, selecting high-quality burn barrels and incinerators is crucial for effective waste management and compliance with increasingly stringent regulations. Key considerations include material durability, design innovation, and cost-effectiveness—elements that directly impact both performance and longevity.

Illustrative image related to burn cans

For buyers in regions such as Africa, South America, the Middle East, and Europe, investing in advanced burn technologies can significantly reduce waste-related challenges. The transition from traditional burn barrels to modern incinerators not only promotes cleaner air but also aligns with global sustainability goals.

As the market evolves, staying informed about technological advancements and supplier capabilities will be essential. Engage with reputable manufacturers and distributors to explore customized solutions that meet your specific needs. By prioritizing strategic sourcing now, you can position your business for success in an increasingly competitive landscape. Embrace this opportunity to enhance your waste management strategy and contribute to a cleaner, more sustainable future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.