The Definitive Guide to Breeding Bench: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for breeding bench

Navigating the complexities of the global market for breeding benches presents a significant challenge for B2B buyers looking to source high-quality equipment tailored to their specific needs. With the growing demand for specialized breeding solutions across various industries—ranging from agriculture to aquaculture—understanding the nuances of breeding bench types and their applications is crucial. This comprehensive guide delves into the essential aspects of breeding benches, including the different types available, their intended applications, and key considerations for supplier vetting and cost analysis.

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe—including major markets like Brazil and Germany—will find actionable insights designed to empower informed purchasing decisions. By offering a thorough overview of market trends, product specifications, and supplier qualifications, this guide serves as a valuable resource for navigating the intricate landscape of breeding bench procurement. With a focus on quality, functionality, and cost-effectiveness, B2B buyers can confidently approach their sourcing processes, ensuring they select the right breeding benches to meet their operational requirements and enhance productivity.

Through this guide, we aim to demystify the global breeding bench market, equipping buyers with the knowledge necessary to make strategic decisions that align with their business goals.

Understanding breeding bench Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wooden Breeding Bench | Crafted from durable hardwood, often includes compartments | Bird breeding, small animal husbandry | Pros: Durable, aesthetic appeal; Cons: Heavier, may require maintenance. |

| Portable Breeding Bench | Lightweight, foldable design for easy transport | Mobile animal shows, temporary setups | Pros: Easy to transport, versatile; Cons: Less sturdy, may have limited space. |

| Steel Breeding Bench | Constructed from heavy-duty steel for maximum durability | Industrial breeding facilities | Pros: Extremely durable, resistant to wear; Cons: Higher cost, less aesthetic. |

| Modular Breeding Bench | Configurable sections to adjust size and shape | Custom setups for varied breeding needs | Pros: Flexible design, accommodates different species; Cons: Complexity in assembly. |

| Eco-Friendly Breeding Bench | Made from sustainable materials with non-toxic finishes | Organic farms, eco-conscious breeders | Pros: Environmentally friendly, safe for animals; Cons: May be pricier, limited styles. |

What Are the Characteristics of a Wooden Breeding Bench?

Wooden breeding benches are typically constructed from high-quality hardwood, providing both durability and aesthetic appeal. They often feature built-in compartments for storing breeding supplies or separating animals. These benches are ideal for bird breeding and small animal husbandry, offering a stable environment. When purchasing, B2B buyers should consider the weight and maintenance needs, as wooden benches may require periodic treatment to protect against moisture and pests.

How Does a Portable Breeding Bench Benefit Mobile Operations?

Portable breeding benches are designed for easy transport, making them suitable for mobile animal shows or temporary setups. Their lightweight and foldable design allows breeders to set up in various locations without hassle. Buyers should assess the balance between portability and stability, as these benches may not be as sturdy as their stationary counterparts. However, their versatility makes them a popular choice for breeders on the go.

What Are the Advantages of a Steel Breeding Bench in Industrial Settings?

Steel breeding benches are built for extreme durability, making them ideal for use in industrial breeding facilities. Their heavy-duty construction can withstand significant wear and tear, making them a long-term investment. While the initial cost may be higher, the longevity and low maintenance requirements can offset this for B2B buyers. However, the aesthetic appeal is often less than that of wooden options, which may be a consideration for some buyers.

How Does a Modular Breeding Bench Provide Flexibility?

Modular breeding benches are designed with configurable sections that can be adjusted to meet varying breeding needs. This flexibility allows breeders to create custom setups for different species or breeding programs. While they offer significant advantages in terms of adaptability, buyers should be aware of the complexity involved in assembly and potential costs associated with additional modules.

Why Choose an Eco-Friendly Breeding Bench?

Eco-friendly breeding benches are constructed from sustainable materials and feature non-toxic finishes, making them a great choice for organic farms and eco-conscious breeders. These benches not only contribute to environmental sustainability but also ensure the safety of the animals being bred. However, buyers may find that these benches come at a higher price point and may have a more limited selection of styles compared to traditional options.

Key Industrial Applications of breeding bench

| Industry/Sector | Specific Application of Breeding Bench | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Livestock Breeding Facilities | Enhances breeding efficiency, leading to higher yield. | Durability, ease of cleaning, compliance with animal welfare standards. |

| Aviculture | Bird Breeding Programs | Optimizes space and conditions for breeding success. | Material quality, climate control features, and ease of maintenance. |

| Research & Development | Genetic Research Labs | Facilitates controlled breeding experiments for research. | Customization options, safety standards, and flexibility in design. |

| Educational Institutions | Agricultural Training Programs | Provides hands-on experience for students in breeding techniques. | Cost-effectiveness, scalability, and adaptability to various species. |

| Horticulture | Plant Breeding Nurseries | Supports the development of new plant varieties efficiently. | Environmental sustainability, space optimization, and material sourcing. |

How is the Breeding Bench Used in the Agriculture Sector?

In the agriculture sector, breeding benches are essential for livestock breeding facilities. They are designed to enhance breeding efficiency by providing a controlled environment that promotes optimal health and reproduction rates among animals. Buyers from regions like Africa and South America should consider the durability and ease of cleaning of these benches, ensuring they meet local animal welfare standards. This not only improves yield but also contributes to better overall animal husbandry practices.

What Role Does the Breeding Bench Play in Aviculture?

In aviculture, breeding benches are utilized in bird breeding programs to create a conducive environment for mating and raising young birds. These benches help optimize space and breeding conditions, which is crucial for the success of breeding initiatives. For international buyers, especially from Europe, sourcing high-quality materials that can withstand varying climates and are easy to maintain is vital. This ensures the longevity of the equipment and the health of the birds.

How Do Research Facilities Benefit from Breeding Benches?

Research and development labs employ breeding benches for genetic research, where controlled breeding experiments are conducted. These benches facilitate precise monitoring and management of breeding conditions, which is essential for accurate research outcomes. Buyers in this sector should prioritize customization options and compliance with safety standards when sourcing breeding benches, ensuring they can accommodate various research needs and species.

Why Are Breeding Benches Important for Educational Institutions?

Educational institutions leverage breeding benches in agricultural training programs to provide students with practical experience in breeding techniques. These benches allow for hands-on learning, which is critical for developing the next generation of agricultural professionals. When sourcing these benches, institutions should look for cost-effective solutions that can be scaled and adapted to different species, ensuring a comprehensive educational experience.

What is the Significance of Breeding Benches in Horticulture?

In horticulture, breeding benches are crucial for plant breeding nurseries, supporting the efficient development of new plant varieties. These benches can be designed to optimize space and provide the ideal conditions for plant growth and breeding. Buyers in this field should consider environmental sustainability and the sourcing of materials that meet local regulations, ensuring that their operations are both efficient and compliant with industry standards.

3 Common User Pain Points for ‘breeding bench’ & Their Solutions

Scenario 1: Sourcing Quality Breeding Benches for Diverse Species

The Problem:

B2B buyers in the breeding industry often face challenges when sourcing breeding benches that cater to various species, such as birds, reptiles, or small mammals. Many suppliers provide generic solutions that lack the specific features needed for different species’ comfort and breeding success. This can lead to inadequate environments that may hinder breeding activities, resulting in financial losses and reduced productivity. Additionally, international buyers may encounter difficulties in understanding local regulations regarding materials and animal welfare standards.

The Solution:

To overcome this challenge, buyers should prioritize working with suppliers who specialize in species-specific breeding solutions. Conduct thorough research to identify manufacturers that offer customizable breeding benches tailored to the needs of particular species. When sourcing, ask for specifications regarding the materials used, ensuring they comply with local regulations and welfare standards. Establish partnerships with suppliers who provide detailed product descriptions and can offer insights into the best practices for each species. Furthermore, consider attending international trade shows or conferences where specialized vendors showcase their products. This direct interaction can help buyers assess the quality and suitability of breeding benches before making a purchase.

Scenario 2: Ensuring Durability and Longevity of Breeding Benches

The Problem:

Another significant pain point for B2B buyers is the durability of breeding benches, especially in environments that experience variable temperatures and humidity levels. Many buyers invest in breeding equipment only to find that subpar materials lead to rapid wear and tear. This not only results in frequent replacements but also disrupts breeding operations, causing potential losses in productivity and profitability.

The Solution:

To ensure the longevity of breeding benches, buyers should focus on sourcing products made from high-quality, weather-resistant materials such as stainless steel, treated wood, or specialized plastics. Request samples or conduct material tests to evaluate their resistance to moisture, temperature fluctuations, and wear. Additionally, consider vendors that provide warranties or guarantees on their products, indicating confidence in the durability of their offerings. Implementing a regular maintenance schedule for the benches can also extend their life—this includes routine cleaning and inspection for any signs of damage. By investing in high-quality materials and establishing a proactive maintenance approach, buyers can significantly reduce long-term costs associated with replacements.

Scenario 3: Optimizing Space Utilization with Breeding Benches

The Problem:

In breeding facilities, space optimization is crucial, particularly for businesses operating in urban environments where square footage is limited. B2B buyers often struggle with selecting breeding benches that maximize space while still providing the necessary functionalities for breeding and care. Poorly designed benches can result in overcrowding or inefficient workflows, ultimately affecting the overall productivity of the breeding operation.

The Solution:

To effectively optimize space with breeding benches, buyers should consider modular or multifunctional designs that can be reconfigured as needed. Look for benches that can be easily stacked, moved, or adjusted in height to accommodate different breeding activities. Engage with suppliers who offer design consultations to help visualize how different configurations could work within the available space. Additionally, incorporating mobile benches with wheels can enhance flexibility, allowing for quick adjustments based on operational demands. Before purchasing, create a detailed layout of the breeding facility, marking out areas for benches and other equipment to ensure efficient use of space. By carefully selecting the right bench designs, buyers can enhance both the functionality and efficiency of their breeding operations.

Strategic Material Selection Guide for breeding bench

What Are the Key Materials for Breeding Benches?

When selecting materials for breeding benches, it is essential to consider various properties that affect performance, durability, and cost. This analysis will focus on four common materials: wood, metal, plastic, and composite materials. Each material presents unique advantages and disadvantages that can significantly impact the end product’s suitability for specific applications.

How Does Wood Perform in Breeding Bench Applications?

Wood is a traditional choice for breeding benches due to its natural aesthetics and structural integrity. Key properties include excellent load-bearing capabilities and natural insulation against temperature fluctuations. However, wood is susceptible to moisture and pests, which can lead to decay over time.

Pros: Wood is durable, offers good thermal insulation, and is often cost-effective. It is also widely available and can be sourced sustainably, aligning with eco-friendly practices.

Cons: The primary limitations include its vulnerability to environmental factors like humidity and pests, which may necessitate regular maintenance. Additionally, wood can be more expensive than some synthetic alternatives depending on the type used.

For international buyers, especially in regions like Africa and South America, sourcing sustainably harvested wood can meet compliance with environmental standards. In Europe, adherence to certifications like FSC (Forest Stewardship Council) is crucial.

What Are the Advantages of Metal Breeding Benches?

Metal, particularly stainless steel and aluminum, is increasingly used for breeding benches due to its strength and resistance to corrosion. Key properties include high tensile strength and excellent durability, making metal benches suitable for heavy loads and harsh environments.

Pros: Metal benches are highly durable, resistant to pests, and easy to clean, which is vital in breeding applications where hygiene is a priority. They also have a longer lifespan compared to wood.

Cons: The primary drawback is the higher cost of materials and manufacturing processes. Metal benches can also conduct heat, which may be a concern in extreme temperature conditions.

For B2B buyers in the Middle East and Europe, compliance with standards such as ASTM for metals is essential. Additionally, understanding local regulations regarding metal sourcing and manufacturing can impact procurement strategies.

How Do Plastic Materials Compare for Breeding Benches?

Plastic materials, such as high-density polyethylene (HDPE) and polypropylene, are increasingly popular due to their lightweight and corrosion-resistant properties. They are also impervious to moisture, making them ideal for breeding environments.

Pros: Plastics are cost-effective, lightweight, and resistant to chemicals and moisture. They require minimal maintenance and can be easily molded into various shapes.

Cons: The main limitations include lower load-bearing capacity compared to wood and metal, and potential environmental concerns regarding plastic waste.

For international buyers, particularly in regions like Africa and South America, the availability of recycled plastics can be an attractive option. Compliance with local environmental regulations regarding plastic use is also an important consideration.

What Role Do Composite Materials Play in Breeding Bench Design?

Composite materials, which combine fibers (like fiberglass) with resins, offer a balance between the benefits of wood and plastic. They provide excellent durability and resistance to environmental factors.

Pros: Composites are lightweight, resistant to moisture, and do not warp or decay like wood. They also offer design flexibility and can mimic the appearance of wood.

Cons: The cost of composite materials can be higher than both wood and plastic, and their manufacturing process may involve complex techniques.

For buyers in Europe and South America, understanding the specific composite standards and certifications can enhance product quality assurance. Compliance with local regulations regarding material sourcing is also crucial.

Summary of Material Selection for Breeding Benches

| Material | Typical Use Case for breeding bench | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | General breeding applications | Durable and aesthetically pleasing | Vulnerable to moisture and pests | Medium |

| Metal | Heavy-duty breeding environments | Highly durable and easy to clean | Higher cost and heat conductivity | High |

| Plastic | Moisture-prone breeding settings | Lightweight and corrosion-resistant | Lower load-bearing capacity | Low |

| Composite | Versatile breeding applications | Resistant to moisture and decay | Higher manufacturing complexity | Medium to High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for breeding bench

What Are the Key Stages in the Manufacturing Process of a Breeding Bench?

The manufacturing of a breeding bench involves several critical stages, each designed to ensure that the final product meets the required standards of quality and functionality. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing a breeding bench is selecting the right materials. High-quality wood, such as hardwoods (e.g., oak, maple), is often preferred for its durability and aesthetic appeal. Suppliers may also consider alternative materials such as metal or composite materials, depending on the intended use and market demands.

Once selected, the raw materials undergo processing, which includes cutting, drying, and treating to enhance their durability and resistance to environmental factors. This phase is crucial as it sets the foundation for the bench’s longevity and structural integrity.

What Forming Techniques Are Used in Breeding Bench Manufacturing?

In the forming stage, the processed materials are shaped into the components required for the breeding bench. Common techniques include:

- CNC Machining: This technology allows for precise cutting and shaping of materials, ensuring uniformity across production batches.

- Lamination: In some cases, layers of materials are bonded together to create a more robust structure. This is particularly common with composite materials.

- Pressing: For wooden benches, pressing techniques may be used to achieve specific contours or designs.

These forming techniques are essential in creating components that not only fit together well but also meet the aesthetic demands of the market.

How Is the Assembly Process Conducted for Breeding Benches?

The assembly stage involves bringing together all the components created in the previous stages. Skilled workers or automated systems assemble the benches, ensuring that each part is correctly aligned and securely fastened.

Quality control during assembly is critical. Manufacturers often employ techniques such as:

- Jigs and Fixtures: These tools help maintain precision during assembly, minimizing errors.

- Dry Fitting: Before final assembly, components may be dry-fitted to ensure proper alignment and fit.

This attention to detail helps in reducing the likelihood of defects and enhances the overall quality of the finished product.

What Finishing Techniques Are Commonly Used for Breeding Benches?

Finishing is the final stage of manufacturing and significantly influences the bench’s appearance and durability. Common finishing techniques include:

- Sanding and Smoothing: This process enhances the tactile quality of the bench and prepares it for the application of finishes.

- Staining and Sealing: Applying stains can enhance the wood’s natural beauty, while sealants protect against moisture and wear.

- Painting: In some instances, benches may be painted for aesthetic purposes or to provide additional protection.

Each finishing technique is selected based on the desired outcome, whether it be aesthetic appeal, durability, or both.

What International Quality Standards Are Relevant to Breeding Bench Manufacturing?

Quality assurance is a fundamental aspect of manufacturing breeding benches, particularly for B2B buyers who require consistency and reliability. Several international standards are pertinent:

- ISO 9001: This standard focuses on quality management systems and is applicable across various manufacturing sectors, ensuring that organizations consistently meet customer and regulatory requirements.

- CE Marking: Particularly relevant in the European market, CE marking indicates that products meet EU safety, health, and environmental protection standards.

- API Standards: Although primarily associated with the oil and gas industry, certain API standards can apply to manufacturing practices, particularly in material quality and testing procedures.

Adhering to these standards not only enhances product quality but also builds trust with international buyers.

What Are the Key Quality Control Checkpoints in Breeding Bench Manufacturing?

Quality control (QC) is an ongoing process throughout the manufacturing stages, with specific checkpoints established to ensure compliance with standards:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet the specified quality criteria.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor adherence to specifications and identify any deviations early.

- Final Quality Control (FQC): Before shipping, a comprehensive inspection is performed on the finished product, checking for defects, functionality, and compliance with standards.

These checkpoints are critical for minimizing defects and ensuring that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial to ensure they are partnering with reliable manufacturers. Here are some effective strategies:

- Supplier Audits: Conducting regular audits allows buyers to assess the manufacturing processes, quality control systems, and overall compliance with international standards.

- Quality Reports: Requesting detailed quality reports, including data on defect rates and compliance with standards, can provide insights into a supplier’s performance.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and product quality.

These strategies enable buyers to mitigate risks associated with quality and ensure that their investments are protected.

What Testing Methods Are Commonly Used for Breeding Benches?

Various testing methods are employed to ensure that breeding benches meet quality and safety standards:

- Mechanical Testing: This includes testing for strength, durability, and load-bearing capacity, ensuring that the benches can withstand expected usage.

- Environmental Testing: Assessing how materials react to environmental factors like humidity and temperature can help predict the longevity of the product.

- Safety Testing: Ensuring that the finished benches are free from sharp edges, toxic materials, or any other safety hazards is critical for consumer safety.

These testing methods provide additional assurance that the breeding benches will perform as expected in real-world conditions.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, may encounter specific quality control nuances. These can include:

- Regulatory Differences: Understanding the local regulations and standards applicable to their region is vital for compliance.

- Cultural Expectations: Different markets may have varying expectations regarding product quality and durability, necessitating tailored quality assurance practices.

- Logistical Considerations: International shipping can introduce risks such as damage during transit, making it essential to ensure that packaging and handling meet quality standards.

By recognizing these nuances, buyers can better navigate the complexities of international sourcing and enhance their procurement strategies.

In conclusion, the manufacturing processes and quality assurance practices for breeding benches are integral to delivering high-quality products to the market. By understanding these processes, international B2B buyers can make informed decisions and establish successful partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘breeding bench’

To assist B2B buyers in procuring a breeding bench effectively, this guide outlines a step-by-step checklist that ensures a thorough and informed purchasing process. This checklist is tailored for international buyers, especially those from Africa, South America, the Middle East, and Europe, focusing on key considerations that enhance the procurement experience.

Step 1: Identify Your Specific Requirements

Before engaging with suppliers, outline the specific functionalities and dimensions needed for your breeding bench. Consider factors such as the type of animals or plants you intend to breed, the bench’s size, and material requirements. This clarity will enable you to communicate effectively with potential suppliers and ensure that the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in breeding benches. Utilize online marketplaces, industry directories, and local trade shows to gather a list of potential vendors. Pay attention to their reputation, product offerings, and customer reviews, as these can provide valuable insights into their reliability and quality.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that your shortlisted suppliers comply with industry standards and regulations. Certifications such as ISO or specific agricultural compliance can indicate a commitment to quality and safety. Additionally, understanding regional regulations regarding breeding equipment can help avoid legal issues later.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the breeding benches to evaluate their quality and suitability. Assess the materials used, sturdiness, and overall design. Testing the product firsthand can help you gauge whether it meets your expectations and requirements, reducing the risk of dissatisfaction post-purchase.

Step 5: Discuss Pricing and Payment Terms

Once you have identified a supplier that meets your requirements, engage in discussions about pricing and payment terms. Compare quotes from multiple suppliers to ensure you receive a competitive rate. Be clear about your budget constraints and inquire about bulk purchase discounts or financing options that may be available.

Step 6: Establish a Delivery Timeline

Clarify the expected delivery timeline with your chosen supplier. Establishing a clear timeline is crucial, particularly if you have specific project deadlines or breeding cycles to adhere to. Ensure that the supplier can meet your time frames and discuss penalties or contingencies if delays occur.

Step 7: Finalize and Document Your Agreement

Before concluding the transaction, ensure that all agreements are documented in a formal contract. Include details such as product specifications, pricing, delivery timelines, and warranty terms. This documentation will serve as a safeguard for both parties, helping to resolve any disputes that may arise in the future.

By following this checklist, B2B buyers can streamline their procurement process for breeding benches, ensuring they make informed decisions that align with their operational needs and expectations.

Comprehensive Cost and Pricing Analysis for breeding bench Sourcing

What Are the Key Cost Components in Breeding Bench Manufacturing?

When analyzing the cost structure for breeding bench sourcing, several key components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the margin applied by suppliers.

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for breeding benches include wood, metal, and various upholstery fabrics. High-quality materials may raise costs but can enhance durability and performance, which is essential for long-term use.

-

Labor: Labor costs vary based on the region and skill level required for production. Countries with lower labor costs can offer more competitive pricing, but this may come at the expense of craftsmanship or quality.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs, allowing suppliers to offer better pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. These costs are typically amortized over larger production runs, which can lower the per-unit price for bulk orders.

-

Quality Control: Investing in quality control processes is vital to ensure product reliability. QC costs can vary but are crucial for maintaining standards, especially when exporting to international markets that may have specific compliance requirements.

-

Logistics: Transportation and shipping costs play a critical role, particularly for international buyers. Factors such as distance, shipping method, and customs duties must be factored into the total cost.

-

Margin: Supplier profit margins can vary widely. Understanding the margin expectations of different suppliers can help buyers negotiate more effectively.

How Do Pricing Influencers Impact Breeding Bench Costs?

Several factors influence the pricing of breeding benches, including volume or minimum order quantity (MOQ), specifications and customization, materials quality and certifications, supplier reliability, and Incoterms.

-

Volume/MOQ: Larger orders typically result in lower per-unit costs. Suppliers are often willing to negotiate better pricing with higher volume commitments, making it beneficial for buyers to consolidate their orders.

-

Specifications/Customization: Custom designs or specific features can increase costs. Buyers should weigh the benefits of customization against the additional expense, especially if standard models meet their needs.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO, CE) can elevate costs. Buyers should assess whether these certifications are necessary for their market or if they can opt for lower-cost alternatives.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers with a track record of quality may charge higher prices but can save buyers costs related to returns and replacements.

-

Incoterms: Understanding the chosen Incoterms is essential for calculating total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will affect the final price and delivery responsibilities.

What Buyer Tips Can Enhance Cost Efficiency in Breeding Bench Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiation: Always enter negotiations with a clear understanding of your budget and the competitive landscape. Leverage quotes from multiple suppliers to negotiate better terms.

-

Total Cost of Ownership: Evaluate the total cost of ownership rather than just the purchase price. Consider long-term factors such as maintenance, durability, and potential resale value.

-

Pricing Nuances for International Transactions: Be mindful of currency fluctuations, tariffs, and local taxes that can impact final costs. Understanding local market conditions can also provide leverage in negotiations.

-

Supplier Relationship Management: Building strong relationships with suppliers can lead to better pricing and favorable terms over time. Regular communication can help anticipate market changes and adjust strategies accordingly.

In conclusion, a thorough understanding of the cost structure, pricing influencers, and strategic negotiation tactics can significantly enhance the sourcing process for breeding benches, allowing buyers to optimize their procurement strategies effectively.

Alternatives Analysis: Comparing breeding bench With Other Solutions

Exploring Alternatives to Breeding Bench Solutions

In the ever-evolving landscape of breeding solutions, businesses are often confronted with various options that can achieve similar objectives. Breeding benches are designed to facilitate controlled breeding environments, but other technologies and methods may also serve this purpose effectively. Understanding the comparative advantages and disadvantages of these alternatives is crucial for informed decision-making.

Comparison Table

| Comparison Aspect | Breeding Bench | Automated Breeding Systems | Traditional Breeding Methods |

|---|---|---|---|

| Performance | High efficiency in controlled environments | Very high; precision in breeding cycles | Variable; depends on expertise and conditions |

| Cost | Moderate initial investment | High initial and operational costs | Low initial costs, but high in time and labor |

| Ease of Implementation | Requires setup and calibration | Complex installation and training | Simple to implement, no special equipment needed |

| Maintenance | Regular checks and cleaning | High maintenance; requires technical support | Minimal, but labor-intensive |

| Best Use Case | Ideal for specialized breeding projects | Large-scale commercial breeding | Small-scale or hobbyist breeding |

Detailed Breakdown of Alternatives

Automated Breeding Systems

Automated breeding systems utilize advanced technology to create optimal breeding conditions, including climate control, feeding, and monitoring systems. These solutions excel in performance, providing precise control over breeding cycles, which can significantly enhance productivity. However, the initial investment and ongoing operational costs can be substantial, making them less accessible for smaller operations. Additionally, the complexity of installation and the need for technical training can pose challenges for some users.

Traditional Breeding Methods

Traditional breeding methods rely on manual processes and natural conditions to facilitate breeding. This approach is often the most cost-effective, requiring minimal upfront investment and no specialized equipment. However, the performance can be inconsistent and heavily dependent on the breeder’s expertise and the prevailing environmental conditions. While easy to implement, these methods can be labor-intensive and may not yield the same efficiency or success rates as more modern solutions.

Conclusion: Choosing the Right Breeding Solution

Selecting the appropriate breeding solution requires careful consideration of specific business needs, budget constraints, and operational capabilities. For businesses focused on high efficiency and productivity, investing in breeding benches or automated systems may provide significant advantages. Conversely, organizations operating on a smaller scale or with limited resources might find traditional methods more feasible. Ultimately, a thorough analysis of the intended use case, along with a clear understanding of the pros and cons of each option, will empower B2B buyers to make the best choice for their breeding initiatives.

Essential Technical Properties and Trade Terminology for breeding bench

What Are the Key Technical Properties of a Breeding Bench?

When sourcing a breeding bench for commercial use, understanding its technical properties is crucial to ensure it meets operational needs. Here are some essential specifications to consider:

1. Material Grade

The material grade of a breeding bench significantly affects its durability and functionality. Common materials include stainless steel, aluminum, or high-density polyethylene (HDPE). Stainless steel is favored for its corrosion resistance and ease of cleaning, making it ideal for environments requiring high hygiene standards. In contrast, HDPE is lightweight and resistant to chemicals, which is beneficial for outdoor or harsh environments. Buyers must assess the specific material properties to match their operational demands.

2. Load Capacity

Load capacity refers to the maximum weight the bench can support safely. This specification is critical, especially in breeding operations where multiple animals may be housed simultaneously. A breeding bench should have a load capacity that exceeds the combined weight of the animals it will accommodate. Ensuring adequate load capacity prevents structural failures and enhances safety.

3. Tolerance Levels

Tolerance levels indicate the permissible deviation from specified dimensions during manufacturing. For breeding benches, precise tolerances are vital to ensure proper fit and function, particularly in modular or adjustable systems. A tighter tolerance can lead to better assembly and longevity of the bench, thus reducing maintenance costs over time.

4. Surface Finish

The surface finish of a breeding bench impacts its hygiene and cleaning efficiency. Options include powder coating, electro-polishing, or a smooth, non-porous surface. A smooth finish reduces bacterial growth and makes cleaning more efficient, which is crucial in breeding environments where cleanliness is paramount. Buyers should consider the surface finish in relation to their specific cleaning protocols.

5. Dimensions and Configurability

Understanding the dimensions and configurability of a breeding bench is essential for space optimization. Buyers should assess the available space in their facilities and choose a bench that can fit appropriately while allowing for necessary movement and access. Configurable options allow for flexibility in breeding setups, accommodating various species or breeding practices.

What Common Trade Terms Should B2B Buyers Know Regarding Breeding Benches?

Familiarity with industry jargon can enhance communication and negotiation with suppliers. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of breeding benches, understanding OEM relationships can help buyers identify reputable sources for high-quality components and ensure that they are purchasing from reliable manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it affects purchasing decisions and inventory management. Buyers should negotiate MOQs based on their needs to avoid excess inventory or increased costs.

3. RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Issuing an RFQ allows buyers to compare offers and select the best supplier based on price, quality, and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers clarify shipping costs, risks, and insurance responsibilities, which are crucial for managing logistics effectively.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. For breeding benches, understanding lead times is essential for project planning and ensuring that operations can proceed without delays. Buyers should inquire about lead times during the procurement process to align with their operational timelines.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions, ensuring that their investments in breeding benches are sound and strategically aligned with their operational goals.

Navigating Market Dynamics and Sourcing Trends in the breeding bench Sector

What are the Current Market Dynamics and Key Trends in the Breeding Bench Sector?

The breeding bench sector is experiencing a transformative phase, driven by globalization, technological advancements, and changing consumer preferences. International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for specialized breeding benches that cater to both functional and aesthetic needs. Key trends include the integration of smart technology, which enhances breeding efficiency and monitoring, and a shift towards customizable solutions that align with specific breeding practices, whether for agricultural or ornamental purposes.

In addition, the rise of e-commerce platforms has streamlined sourcing processes, allowing buyers to easily access a diverse range of products and suppliers. This shift is particularly beneficial for buyers in emerging markets who may have previously struggled with limited local options. Furthermore, the growing emphasis on quality and durability means that suppliers are increasingly focusing on premium materials and craftsmanship, ensuring that their breeding benches meet the rigorous demands of both professional and hobbyist breeders.

Another significant trend is the increasing collaboration between manufacturers and breeders, fostering innovation in product design. This collaborative approach not only addresses specific market needs but also helps in creating benches that are more efficient in terms of space utilization and breeding outcomes. As these dynamics evolve, international buyers must stay informed and adaptable to capitalize on emerging opportunities within the breeding bench market.

How is Sustainability and Ethical Sourcing Impacting the Breeding Bench Sector?

Sustainability and ethical sourcing are becoming paramount in the breeding bench sector, reflecting broader environmental concerns and consumer expectations. The production of breeding benches often involves materials such as wood and metal, which can have significant environmental impacts if sourced irresponsibly. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using reclaimed or certified wood, reducing waste during production, and implementing energy-efficient manufacturing processes.

Moreover, the demand for ‘green’ certifications is on the rise. Certifications such as FSC (Forest Stewardship Council) for wood products and ISO 14001 for environmental management are becoming essential for suppliers aiming to attract international buyers. These certifications not only signify a commitment to sustainability but also enhance the credibility of suppliers in competitive markets.

Incorporating sustainable materials and practices into the breeding bench production process is not just an ethical choice but also a strategic business move. Buyers who prioritize sustainability are likely to enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers. By fostering ethical supply chains, businesses can contribute to a more sustainable future while meeting the evolving expectations of their customers.

What is the Historical Evolution of the Breeding Bench Sector?

The breeding bench sector has evolved significantly over the years, transitioning from rudimentary designs to sophisticated, purpose-built solutions. Historically, breeding benches were simple structures used primarily in agricultural settings. However, as animal husbandry and horticulture practices advanced, the need for specialized benches that catered to various breeding needs became apparent.

The introduction of innovative materials and technology in the late 20th century marked a turning point for the sector. Manufacturers began to experiment with different designs that not only improved functionality but also addressed aesthetic considerations. Today, breeding benches are available in various styles and materials, reflecting both traditional craftsmanship and modern design principles.

This evolution has been driven by a growing understanding of breeding requirements and the need for efficiency in breeding practices. As global demand for quality breeding solutions continues to rise, the breeding bench sector is poised for further innovation, ensuring it meets the needs of both professional breeders and hobbyists alike.

Frequently Asked Questions (FAQs) for B2B Buyers of breeding bench

-

How do I choose the right breeding bench for my needs?

Selecting the right breeding bench involves evaluating several factors, including size, material, and functionality. Consider the specific requirements of your breeding operation, such as the species being bred and the available space. Look for benches made from durable materials that can withstand environmental factors. Additionally, check for features like adjustable height and easy cleaning options. Consulting with suppliers about their product specifications and previous customer experiences can also help you make an informed decision. -

What are the key features to look for in a breeding bench?

When sourcing a breeding bench, essential features to consider include sturdy construction, ease of maintenance, and size options. A bench should be made from high-quality materials that resist wear and tear. Other desirable attributes might include adjustable height settings for versatility, removable trays for easy cleaning, and surfaces that minimize stress for breeding animals. Ensure that the bench design aligns with the specific needs of the species you are working with to enhance the breeding process. -

What customization options are available for breeding benches?

Many manufacturers offer customization options for breeding benches, allowing you to tailor them to your specific operational needs. Customization may include dimensions, materials, colors, and additional features such as integrated storage or specialized surfaces. When discussing customization with suppliers, clearly outline your requirements and ask for samples or prototypes if possible. This ensures the final product meets your expectations and operational demands. -

What is the minimum order quantity (MOQ) for breeding benches?

Minimum order quantities for breeding benches can vary significantly depending on the manufacturer and product specifications. Some suppliers may allow orders for single units, while others may require bulk orders of 10 or more. It’s essential to clarify MOQ terms during initial discussions to avoid misunderstandings. If you are a smaller business, inquire about potential flexibility in order sizes or options for combined shipments to meet MOQ requirements. -

What payment terms should I expect when ordering breeding benches internationally?

Payment terms for international orders can vary widely based on the supplier and the buyer’s relationship. Common terms include advance payment, partial upfront payment with the balance due upon delivery, or payment through letters of credit. It’s advisable to negotiate terms that provide security for both parties. Ensure you understand any additional costs, such as shipping, customs duties, and taxes, which can affect the overall price. -

How can I ensure the quality of breeding benches from suppliers?

To ensure quality, conduct thorough due diligence on potential suppliers. Request product samples, review quality certifications, and read customer testimonials. Additionally, consider visiting the manufacturing facility or asking for third-party inspections before shipment. Establishing a clear quality assurance process, including specifications and testing requirements, can help mitigate risks associated with product quality. -

What logistics considerations should I keep in mind when importing breeding benches?

Logistics play a crucial role in the successful import of breeding benches. Key considerations include shipping methods, transit times, and customs clearance processes. Work closely with your suppliers to understand packaging requirements and ensure that the benches are protected during transit. Additionally, collaborate with experienced freight forwarders who can navigate the complexities of international shipping and provide timely updates throughout the shipping process. -

What are the common challenges faced when sourcing breeding benches internationally?

Sourcing breeding benches internationally can present challenges such as language barriers, cultural differences, and varying regulations. Additionally, differences in product standards and quality expectations can complicate the purchasing process. To mitigate these challenges, invest time in building strong relationships with suppliers, utilizing clear communication, and understanding the local market conditions. Being proactive in addressing these factors will help ensure a smoother transaction and better outcomes for your breeding operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Breeding Bench Manufacturers & Suppliers List

1. Etsy – Breeding Benches

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Breeding Benches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Reddit – Comfortable Foam Bench

Domain: reddit.com

Introduction: This company, Reddit – Comfortable Foam Bench, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Tumblr – Breeding Bench

Domain: tumblr.com

Registered: 2006 (19 years)

Introduction: This company, Tumblr – Breeding Bench, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Wayfair – Breeding Upholstered Bench

Domain: havenly.com

Registered: 2012 (13 years)

Introduction: {“name”: “Breeding Upholstered Bench”, “brand”: “Wayfair”, “color”: “Brown”, “dimensions”: “19’H x 72’W”, “shipping”: “Typically ships within 7-10 business days.”, “return_policy”: “Returns accepted within 30 days of delivery if in original, undamaged condition and disassembled if originally delivered that way.”, “price_verification”: “Price Verification Guarantee”, “availability”: “Out of stock”,…

5. Black Velvet Room – Breeding Bench 1

Domain: blackvelvetroom.com

Registered: 2021 (4 years)

Introduction: {“Category”:”Decorations: Sculptures”,”Search Phrase”:”breeding”,”Swatches”:[“Black”,”Red”,”White”,”Pink”],”Functionality”:”Standard”,”Latest Version”:”[Kritical]BreedingBench1″,”Mesh Compatibility”:{“Female”:”Any (female)”,”Male”:”Partial (male)”},”Time Exclusive”:”Public”,”Support”:”Full”,”Required Packages”:”Wicked Whims”}

6. Frankie Arts – Breeding Bench

Domain: patreon.com

Registered: 2013 (12 years)

Introduction: Breeding Bench [WIP] | Frankie Arts | Digital furry art | Patreon | Join to unlock

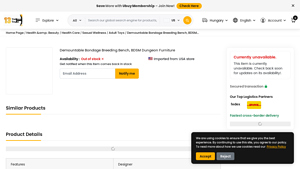

7. Ubuy – Demountable Bondage Breeding Bench

Domain: ubuy.hu

Introduction: {“product_name”: “Demountable Bondage Breeding Bench”, “category”: “BDSM Dungeon Furniture”, “item_number”: “80477669”, “price”: “KWD 21”, “availability”: “In stock”, “imported_from”: “USA store”, “size”: “11.5 x 5.5 inches”, “color”: “Black/White-001”, “shipping_info”: {“free_shipping_eligibility”: “Add an additional item worth KWD 60”, “shipping_cost”: “KWD 11.84”, “delivery_exclusions”: “Exclud…

Strategic Sourcing Conclusion and Outlook for breeding bench

What Are the Key Benefits of Strategic Sourcing for Breeding Benches?

In summary, strategic sourcing for breeding benches presents a significant opportunity for international buyers to enhance operational efficiency and product quality. By leveraging global suppliers, businesses can access a diverse range of high-quality materials and innovative designs tailored to their specific needs. This approach not only reduces costs but also fosters stronger supplier relationships, ensuring reliable delivery and support.

How Can International Buyers Leverage Market Trends?

As markets in Africa, South America, the Middle East, and Europe continue to evolve, staying ahead of trends in design, sustainability, and functionality is crucial. Buyers are encouraged to explore partnerships with suppliers who prioritize sustainable practices and can provide customizable solutions. This proactive approach will enhance competitiveness and align with the growing consumer demand for environmentally friendly products.

What Is the Future Outlook for Breeding Benches?

Looking ahead, the demand for breeding benches is poised to grow, driven by an increasing focus on quality and innovation. International B2B buyers should seize this moment to invest in strategic sourcing partnerships that can adapt to market changes. By doing so, they not only secure their supply chains but also position themselves as leaders in their respective markets. Engage with suppliers today to unlock the full potential of your business and meet the evolving needs of your customers.