The Definitive Guide to Best Power Cable For Office: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for best power cable for office

In the fast-paced world of international business, selecting the best power cable for office environments can pose significant challenges. B2B buyers often grapple with the complexities of sourcing reliable and efficient power solutions that meet diverse operational needs while adhering to local standards and regulations. This guide aims to demystify the process of identifying the most suitable power cables by exploring various types, applications, and the nuances of supplier vetting.

From understanding wire gauges and plug types to evaluating cost-effectiveness and safety standards, this comprehensive resource equips decision-makers with the knowledge needed to make informed purchasing choices. For businesses operating in regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Germany—this guide addresses unique market considerations and offers insights into navigating local supply chains.

By fostering a deeper understanding of power cable specifications and their practical applications, this guide empowers international B2B buyers to confidently select high-quality products that enhance operational efficiency and safety. Whether you are outfitting a new office or upgrading existing equipment, the insights provided here will help you avoid common pitfalls and optimize your power sourcing strategy.

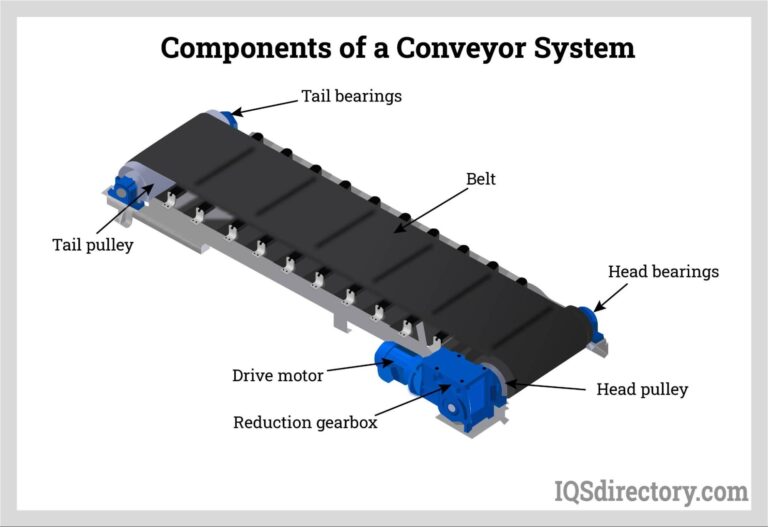

Understanding best power cable for office Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Two-Prong Cables | Non-grounded, lightweight, ideal for low-power devices | Small electronics, lamps, and chargers | Pros: Cost-effective, lightweight. Cons: Not suitable for high-power devices. |

| Three-Prong Cables | Grounded, suitable for high-power appliances | Computers, printers, and power tools | Pros: Enhanced safety, versatile. Cons: Slightly more expensive than two-prong. |

| Heavy-Duty Extension Cords | Thicker gauge, supports higher amperage (up to 15A) | Construction sites, workshops, and outdoor events | Pros: Durable, safe for high-power tools. Cons: Bulkier and more expensive. |

| Medium-Duty Cables | Grounded, supports moderate power (up to 10A) | Office equipment, TVs, and small appliances | Pros: Balance of power and flexibility. Cons: Limited to medium applications. |

| Outdoor Rated Cables | Weather-resistant, designed for outdoor use | Outdoor events, landscaping equipment, and construction | Pros: Durable, safe for outdoor use. Cons: Generally higher cost due to special materials. |

What Are Two-Prong Cables and When Should They Be Used?

Two-prong cables are non-grounded and primarily designed for low-power devices. They are ideal for everyday electronics such as lamps, phone chargers, and smaller appliances. When purchasing, B2B buyers should consider the power requirements of the devices they intend to use these cables with. While they are cost-effective and lightweight, they lack the safety features required for high-power applications, making them unsuitable for more demanding environments.

How Do Three-Prong Cables Enhance Safety in Office Settings?

Three-prong cables include a grounding pin, making them suitable for higher-power appliances like computers and printers. They are essential for environments where electrical safety is paramount. B2B buyers should ensure that their equipment requires grounding before purchasing these cables. The added safety feature justifies the slightly higher cost, as it helps prevent electrical shocks and equipment damage.

Why Choose Heavy-Duty Extension Cords for Industrial Use?

Heavy-duty extension cords are designed to handle higher amperage, making them ideal for construction sites and workshops where power tools are frequently used. These cables have thicker gauge wires that allow them to carry more power safely over longer distances. B2B buyers should prioritize durability and safety when selecting these cords, as their robust construction can withstand harsh conditions. However, their bulkiness and higher cost may be a consideration for budget-conscious buyers.

What Are the Benefits of Medium-Duty Cables for Office Equipment?

Medium-duty cables are grounded and can support moderate power needs, making them suitable for office equipment like computers and televisions. They offer a good balance between power capacity and flexibility, which is essential in a dynamic office environment. B2B buyers should assess the power requirements of their devices to ensure compatibility. While they are versatile, their limitations in power capacity may not meet the needs of more demanding equipment.

How Do Outdoor Rated Cables Ensure Safety in External Environments?

Outdoor rated cables are specially designed to resist weather conditions, making them ideal for outdoor events and landscaping equipment. These cables are made from durable materials that protect against moisture and UV rays. B2B buyers should consider the specific outdoor applications they require, as these cables often come at a premium price due to their specialized construction. While the investment is higher, the safety and longevity they provide in outdoor settings make them a worthwhile purchase.

Key Industrial Applications of best power cable for office

| Industry/Sector | Specific Application of best power cable for office | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Information Technology | Powering servers and networking equipment | Ensures reliable uptime and data integrity | Voltage compatibility, gauge for power load |

| Healthcare | Connecting medical devices and equipment | Supports critical operations and patient safety | Compliance with safety standards, durability |

| Manufacturing | Powering machinery and tools in production | Enhances efficiency and minimizes downtime | Heavy-duty specifications, environmental resistance |

| Education | Supplying power to computers and AV equipment | Facilitates effective learning and teaching | Length and gauge for classroom layouts |

| Construction | Powering tools and temporary lighting on-site | Improves productivity and safety on job sites | Weather resistance, flexibility in usage |

How is the Best Power Cable Used in Information Technology?

In the information technology sector, the best power cables are crucial for powering servers, routers, and other networking equipment. These cables must meet specific voltage and current ratings to ensure reliable performance and prevent downtime. International buyers, particularly from regions like Africa and South America, should prioritize cables with robust insulation and appropriate gauge to handle high power loads. A common issue faced is voltage drop, which can lead to equipment failure; thus, selecting the right cable can mitigate such risks effectively.

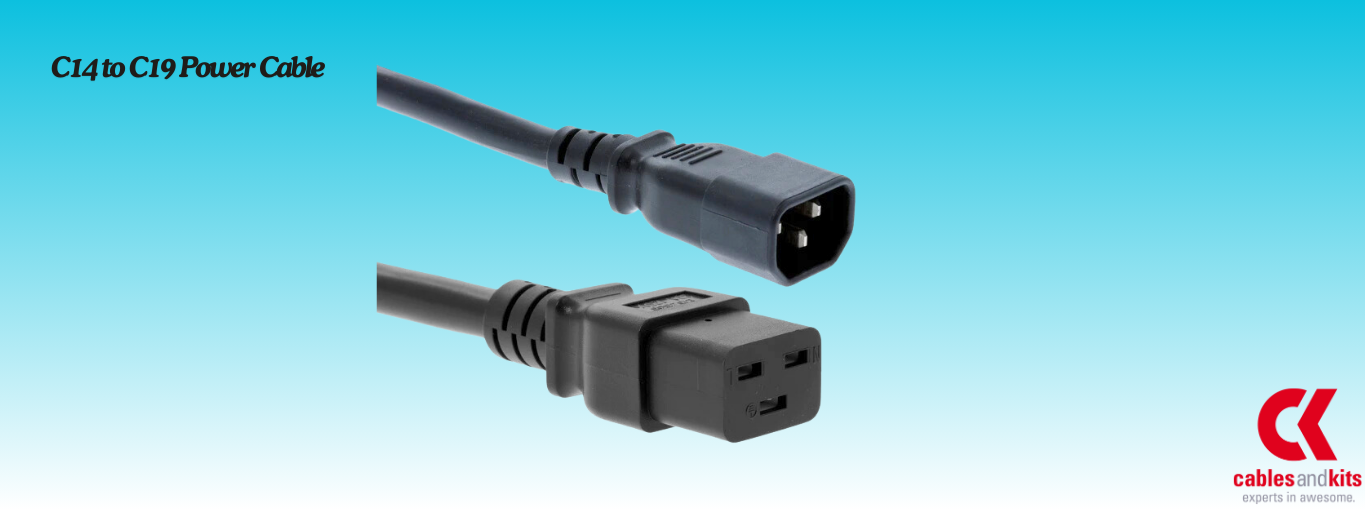

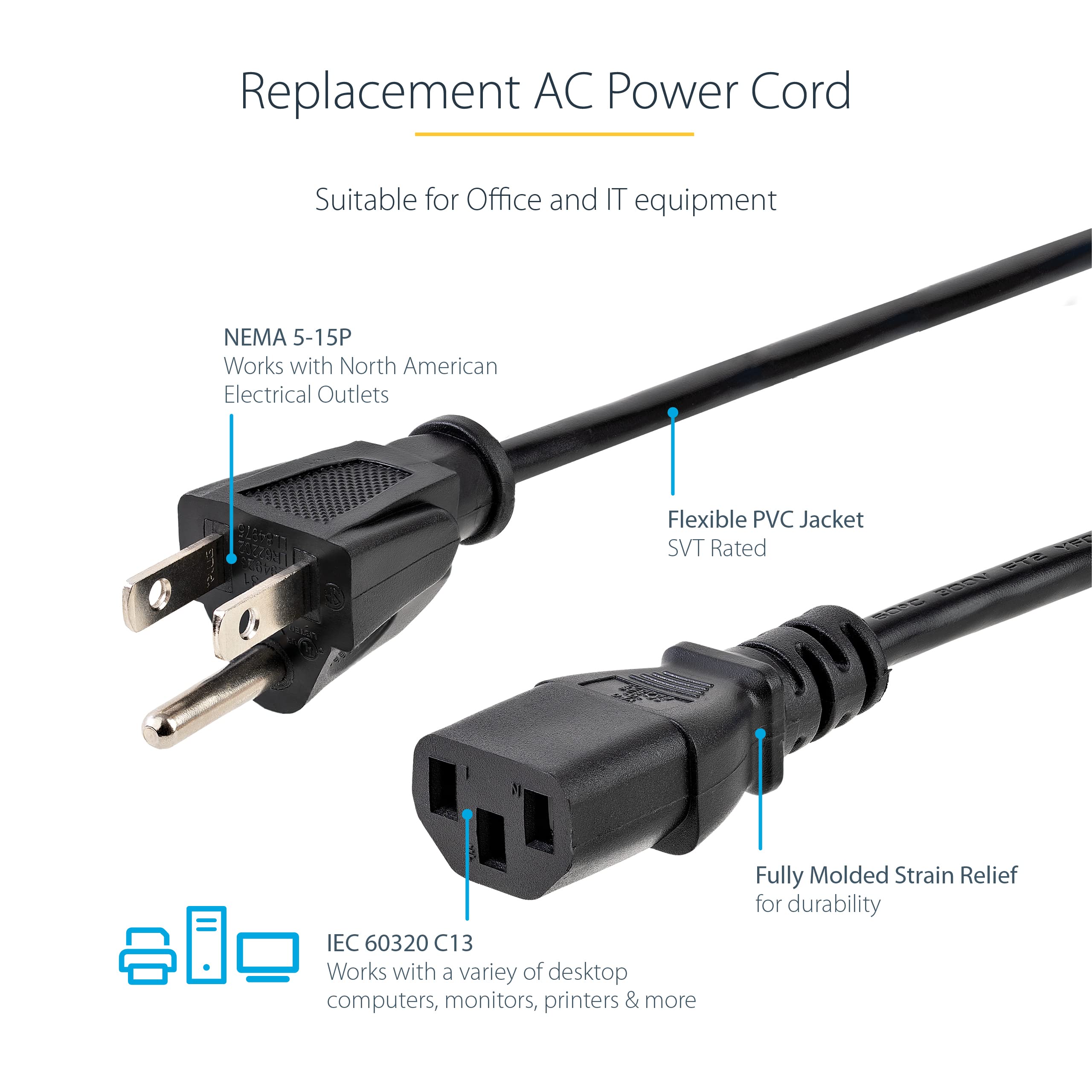

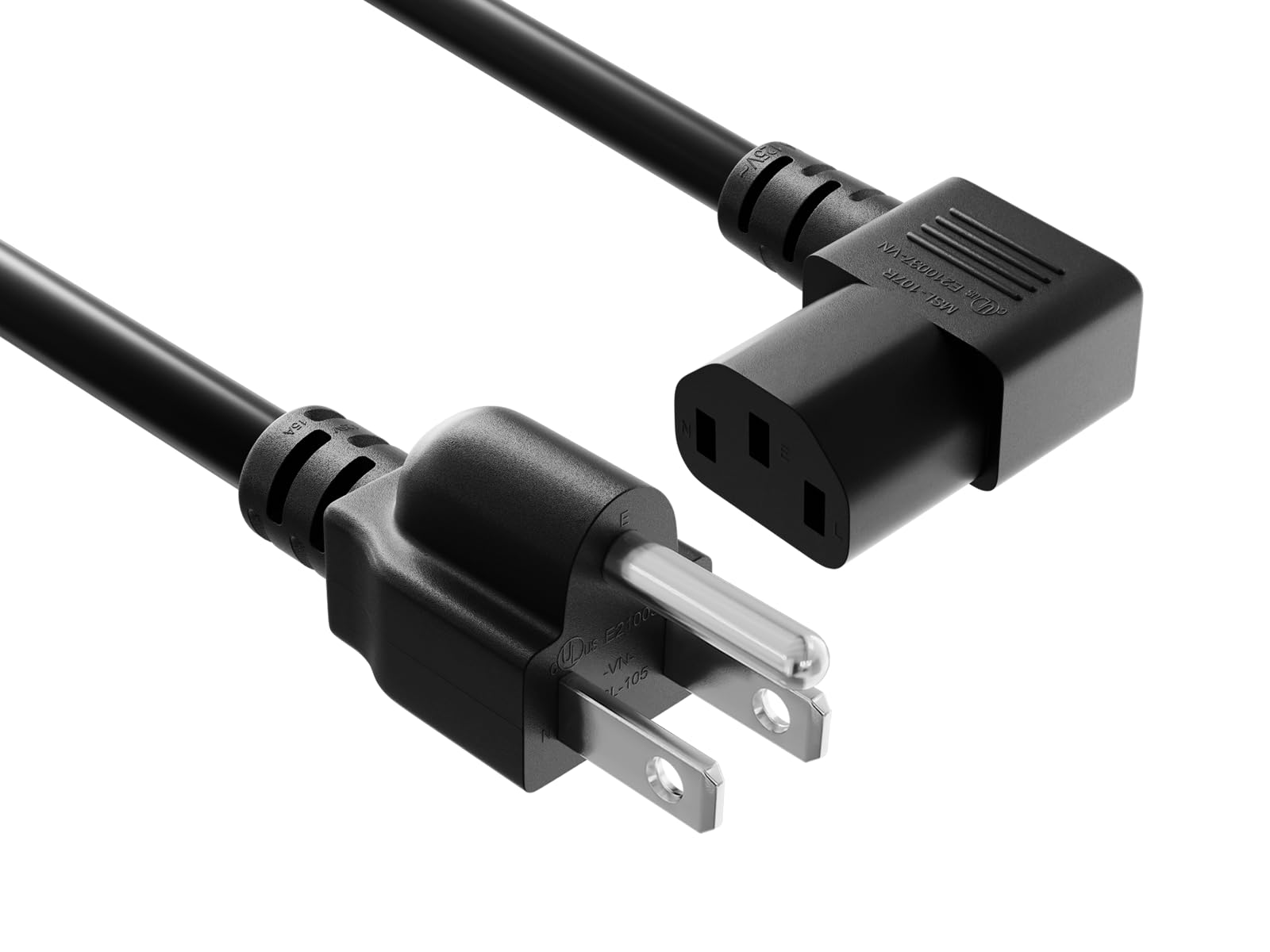

Illustrative image related to best power cable for office

What Role Does Power Cable Play in Healthcare Applications?

In healthcare, reliable power supply is paramount for medical devices, from imaging machines to patient monitoring systems. The best power cables used in this sector must comply with stringent safety standards to ensure patient safety and operational reliability. Buyers from Europe and the Middle East should consider cables that are resistant to electromagnetic interference and have proper certifications. The failure of power supply in medical settings can have dire consequences, making it essential to choose high-quality cables that meet industry requirements.

How Does Manufacturing Benefit from Quality Power Cables?

In manufacturing environments, the best power cables are essential for powering heavy machinery and tools. These cables need to withstand harsh conditions, including exposure to oils, chemicals, and extreme temperatures. B2B buyers in this sector should look for heavy-duty cables that offer durability and flexibility, allowing for easy movement and installation. A frequent challenge is maintaining continuous operations; thus, investing in high-quality cables minimizes downtime and enhances overall productivity.

Why are Power Cables Important in Educational Settings?

Educational institutions rely heavily on power cables to supply energy to computers, projectors, and other AV equipment. The best power cables facilitate effective learning environments by ensuring that all devices function without interruptions. Buyers, especially in developing regions, should focus on the length and gauge of the cables to accommodate classroom layouts effectively. Issues such as inadequate power supply can hinder educational experiences, making it essential for schools to invest in reliable power solutions.

How are Power Cables Utilized on Construction Sites?

In the construction industry, power cables are vital for powering tools and temporary lighting. The best power cables must be rugged and weather-resistant to withstand outdoor conditions. Buyers from regions with extreme weather, such as the Middle East, should prioritize cables that offer flexibility and durability. Safety is a significant concern on construction sites; therefore, selecting high-quality cables can prevent accidents and ensure that operations run smoothly.

Illustrative image related to best power cable for office

3 Common User Pain Points for ‘best power cable for office’ & Their Solutions

Scenario 1: Inadequate Power Supply for High-Powered Office Equipment

The Problem: Many B2B buyers often encounter challenges when trying to power high-demand office equipment like printers, copiers, or servers. These devices typically require more power than standard office outlets can provide, and using an inadequate power cable can lead to malfunctions, damage, or even fire hazards. Buyers may mistakenly choose lighter gauge cables, assuming they can handle the load, which can result in significant operational disruptions and increased costs.

The Solution: To address this issue, buyers should first identify the power requirements of their office equipment, typically indicated in watts or amps. For high-powered devices, it’s advisable to choose cables with a thicker gauge (12 AWG or 10 AWG) that can safely handle up to 15 amps or more. When sourcing power cables, consider options that meet or exceed the power specifications of the equipment. It’s also essential to ensure that the cables are grounded, as this adds an extra layer of safety. Additionally, consider implementing a power management system to monitor and manage power distribution effectively, which can prevent overloads and enhance safety in the office environment.

Scenario 2: Frequent Voltage Drops and Equipment Malfunction

The Problem: Voltage drops can frequently affect performance in an office setting, especially in larger spaces where power must travel longer distances. This issue can lead to equipment malfunction, causing downtime and impacting productivity. Buyers often overlook the importance of cable length and gauge, resulting in the selection of cables that cannot maintain voltage over extended distances.

The Solution: To mitigate voltage drop issues, buyers should select power cables based on the distance from the outlet to the equipment. As a rule of thumb, thicker cables (lower AWG numbers) should be used for longer runs. For distances exceeding 50 feet, a 12 AWG or even a 10 AWG cable is recommended to ensure adequate power delivery without significant loss. Additionally, consider using power conditioners or voltage regulators to stabilize the voltage supplied to sensitive equipment. Regularly reviewing and upgrading the existing power infrastructure can prevent voltage drop issues and enhance overall office efficiency.

Illustrative image related to best power cable for office

Scenario 3: Weather-Related Cable Damage in Outdoor Office Spaces

The Problem: For offices that utilize outdoor spaces or have equipment that needs to be powered outside, the risk of cable damage due to weather conditions is a common concern. Standard indoor cables are often not designed to withstand outdoor elements, leading to frayed wires, reduced functionality, and safety hazards. This issue can be particularly pressing for businesses in regions with harsh weather conditions.

The Solution: Buyers should invest in weather-resistant power cables specifically designed for outdoor use. Look for cables that comply with the SJEOW standard, which indicates they are built to withstand various environmental factors, including moisture and temperature extremes. When selecting these cables, ensure they have adequate insulation and are rated for outdoor use. Additionally, using GFCI (Ground Fault Circuit Interrupter) outlets can enhance safety by preventing electrical shocks. Regular inspections of outdoor cables should also be conducted to identify any signs of wear or damage early, allowing for timely replacements and minimizing risks associated with outdoor power supply.

Strategic Material Selection Guide for best power cable for office

What Are the Key Materials for Power Cables Used in Office Environments?

When selecting power cables for office environments, the choice of materials is crucial for ensuring performance, safety, and compliance with international standards. Below are analyses of four common materials used in power cables, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Copper Influence Power Cable Performance?

Key Properties: Copper is renowned for its excellent electrical conductivity, with a conductivity rating of 100% IACS (International Annealed Copper Standard). It also has a high melting point (approximately 1,984°F or 1,085°C), making it suitable for high-temperature applications.

Pros & Cons: Copper cables are highly durable and resistant to corrosion, which extends their lifespan. However, they are more expensive than alternatives like aluminum, which can be a significant consideration for budget-conscious buyers. The manufacturing complexity is moderate, as copper is readily available and widely used.

Illustrative image related to best power cable for office

Impact on Application: Copper is compatible with a wide range of media and is often used in high-power applications, making it ideal for office environments where devices require stable and efficient power.

Considerations for International Buyers: Buyers from regions like Africa or South America should ensure compliance with local electrical standards, such as IEC or ANSI, which often favor copper for its reliability. In Europe, compliance with DIN standards is crucial.

What Advantages Does Aluminum Offer for Power Cables?

Key Properties: Aluminum has a lower conductivity than copper (approximately 61% IACS) but is lightweight and has a melting point of around 1,221°F (660°C). It is also resistant to corrosion, especially when treated with protective coatings.

Pros & Cons: The primary advantage of aluminum is its cost-effectiveness, making it a popular choice for large-scale installations. However, its lower conductivity means that aluminum cables need to be thicker than copper cables to carry the same current, which can increase installation complexity.

Impact on Application: Aluminum is suitable for medium-power applications and can be used in office settings, particularly in environments where weight is a concern. However, it may not be the best choice for high-demand devices.

Illustrative image related to best power cable for office

Considerations for International Buyers: Buyers should be aware of local regulations regarding aluminum usage. In regions like the Middle East, where high temperatures are common, ensuring that aluminum cables meet local standards for thermal performance is essential.

How Do PVC and TPE Insulations Affect Power Cable Suitability?

Key Properties: Polyvinyl chloride (PVC) and thermoplastic elastomer (TPE) are commonly used for insulation. PVC is durable and resistant to chemicals, while TPE offers flexibility and better performance at low temperatures.

Pros & Cons: PVC is cost-effective and widely used, but it can become brittle over time, especially in colder climates. TPE, while more expensive, provides superior flexibility and is less prone to cracking, making it suitable for dynamic environments.

Impact on Application: Both materials are compatible with various office equipment, but TPE is particularly advantageous in environments with fluctuating temperatures, such as regions in Africa or Europe with seasonal variations.

Considerations for International Buyers: Compliance with international standards like RoHS and REACH is crucial for both materials. Buyers should ensure that their selected insulation meets local safety regulations, particularly in countries with stringent environmental laws.

What Is the Summary of Material Selection for Power Cables?

Below is a summary table that encapsulates the key insights regarding material selection for power cables in office environments.

| Material | Typical Use Case for best power cable for office | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-power devices, servers | Excellent conductivity and durability | Higher cost compared to aluminum | High |

| Aluminum | Medium-power applications, overhead lines | Cost-effective and lightweight | Lower conductivity requires thicker cables | Medium |

| PVC | General office equipment | Cost-effective and resistant to chemicals | Can become brittle in cold climates | Low |

| TPE | Flexible applications, dynamic environments | Superior flexibility and low-temperature performance | More expensive than PVC | Medium |

This strategic material selection guide provides valuable insights for B2B buyers, ensuring informed decisions that align with performance needs and compliance standards across various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for best power cable for office

What Are the Key Manufacturing Processes for High-Quality Power Cables?

The production of power cables suitable for office environments involves several critical stages that ensure the final product meets the performance, safety, and durability standards expected by B2B buyers. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Power Cable Manufacturing?

The manufacturing process begins with the careful selection of raw materials. Copper or aluminum is typically used for the conductors due to their excellent electrical conductivity. Insulation materials, such as PVC (polyvinyl chloride) or XLPE (cross-linked polyethylene), are chosen based on their thermal stability and environmental resistance.

In preparation, these materials undergo quality checks to ensure they meet the necessary specifications. For instance, copper wire must be free from impurities and have the correct gauge size, which is crucial for the cable’s performance. Additionally, insulation materials are evaluated for flexibility and resistance to environmental factors.

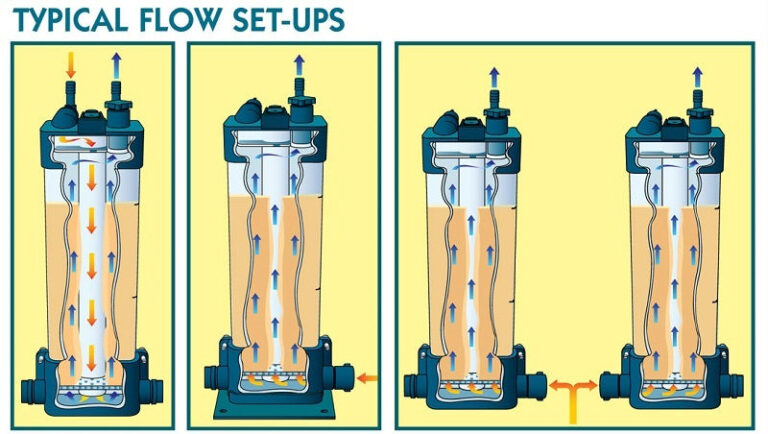

Illustrative image related to best power cable for office

How Are Power Cables Formed?

Once materials are prepared, the next step is forming. This process involves drawing the metal conductors to the required diameter, ensuring they meet the specified wire gauge. The drawn conductors are then coated with insulation material. This can be achieved through various methods, including extrusion, where the insulation is heated and forced over the conductor.

During this stage, precision is key. Any inconsistencies in the insulation thickness can lead to performance issues, such as overheating or electrical shorts. Manufacturers often utilize advanced machinery that allows for tight tolerances, ensuring uniformity across the production batch.

What Does the Assembly Process Involve?

After forming, the assembly process begins. This includes twisting together multiple conductors to create multi-core cables, which are commonly required for office power applications. Connectors are also attached during this phase, which may involve soldering or crimping to ensure a secure electrical connection.

To enhance safety, grounding wires are integrated into the cable assembly. This is particularly important for three-prong configurations, which are standard in office environments. Each assembly is subjected to visual inspections to identify any defects before moving on to the next stage.

How Is the Finishing Stage Executed?

The finishing stage involves several steps, including the application of an outer jacket and labeling. The outer jacket provides additional protection against physical damage and environmental conditions. Manufacturers often use materials that are resistant to oil, moisture, and UV radiation, particularly for cables intended for outdoor use.

Labeling is also crucial, as it provides essential information about the cable’s specifications, such as voltage rating, amperage, and compliance with international standards. This step not only aids in proper usage but also assists in regulatory compliance.

What Quality Assurance Processes Are Essential for Power Cables?

Quality assurance (QA) is a fundamental component of the manufacturing process, ensuring that power cables meet both international and industry-specific standards.

Which International Standards Should B2B Buyers Consider?

For power cable manufacturing, compliance with international standards such as ISO 9001 is essential. This standard focuses on quality management systems and helps ensure consistent quality in production processes. Additionally, certifications such as CE (Conformité Européenne) indicate compliance with EU safety standards, while others like UL (Underwriters Laboratories) provide assurance regarding safety and performance.

B2B buyers should prioritize suppliers that demonstrate adherence to these standards, as they signify a commitment to quality and safety in manufacturing.

What Are the Key QC Checkpoints in Power Cable Production?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. Key stages include:

-

Incoming Quality Control (IQC): Here, raw materials undergo initial inspections to verify their compliance with specifications. This includes checking the electrical conductivity of copper or aluminum and the mechanical properties of insulation materials.

-

In-Process Quality Control (IPQC): During the forming and assembly stages, continuous monitoring ensures that production processes remain within acceptable tolerances. This often involves real-time testing of insulation thickness and conductor diameter.

-

Final Quality Control (FQC): Before shipping, the finished cables are subjected to comprehensive testing. Common tests include electrical resistance, insulation resistance, and dielectric strength. These tests ensure that the cables can safely handle their rated loads without failure.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure quality and reliability, B2B buyers should engage in thorough due diligence when selecting suppliers. This can include:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, equipment, and overall quality management systems of potential suppliers.

-

Quality Reports: Requesting detailed quality control reports can provide insights into the supplier’s testing methodologies, failure rates, and compliance with industry standards.

-

Third-Party Inspections: Engaging independent third-party inspectors can further validate the quality claims made by suppliers. These inspections can be particularly beneficial for B2B buyers from regions with varying regulatory standards, ensuring that products meet their specific requirements.

What Nuances Should International Buyers Be Aware of?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different regions may have varying standards and regulatory requirements, which can impact product safety and performance.

Buyers should be aware of the specific certifications required in their region, such as the SANS (South African National Standards) in South Africa or the IEC (International Electrotechnical Commission) standards applicable in Europe. Ensuring that suppliers are compliant with these region-specific standards can mitigate risks and enhance product reliability.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for power cables is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as adhering to international standards and rigorous QC practices, suppliers can deliver high-quality power cables that meet the diverse needs of office environments worldwide.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best power cable for office’

Introduction

Selecting the right power cable for your office is essential to ensure efficient operation and safety of your electronic devices. This guide provides a practical checklist for B2B buyers to make informed sourcing decisions, focusing on key specifications and supplier evaluation criteria that cater to your specific needs.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your devices is the first step in selecting the best power cable. Assess the voltage, amperage, and power needs of each piece of equipment, as different devices have varying power requirements.

– Voltage and Amperage Ratings: Ensure the cable matches or exceeds the voltage and amperage ratings required by your devices to prevent overheating and potential failures.

– Device Type: Identify whether you need cords for light-duty, medium-duty, or heavy-duty applications based on the devices you will be using.

Step 2: Determine the Appropriate Wire Gauge

Choosing the right wire gauge is critical for the safety and efficiency of power delivery. Thicker wires can handle more power and are less prone to overheating, especially over longer distances.

– Common Gauges: For office equipment, 14 AWG is typically suitable for up to 15 amps, while 12 AWG is recommended for more power-hungry devices.

– Length Considerations: Always consider the length of the cable as longer distances may require a thicker gauge to minimize voltage drop.

Step 3: Evaluate Cable Types and Features

Different types of power cables serve various purposes; selecting the right type is crucial for functionality and safety. Assess whether you need indoor, outdoor, or specialized cables.

– Indoor vs. Outdoor: Indoor cables are generally less robust, while outdoor cables must be weather-resistant and flexible.

– Special Features: Look for features like grounding, GFCI protection, and temperature ratings that suit your operational environment.

Step 4: Verify Supplier Certifications

Before proceeding with a supplier, ensure they meet industry standards and certifications. This step is vital for ensuring product quality and safety.

– Safety Standards: Check for certifications such as UL, CE, or IEC that indicate compliance with international safety standards.

– Quality Assurance: Inquire about the supplier’s quality assurance processes and warranties to safeguard your investment.

Step 5: Request Samples and Testing

Before making a bulk purchase, request samples to evaluate the quality and compatibility of the cables with your devices. Testing the cables can prevent potential issues down the line.

– Compatibility Testing: Ensure the samples work with your existing equipment and meet the required performance benchmarks.

– Real-World Use Cases: Consider testing in actual office scenarios to assess durability and functionality under operational conditions.

Step 6: Assess Pricing and Value

Pricing is a crucial factor in sourcing decisions, but it should not be the only consideration. Evaluate the overall value offered by the supplier in terms of quality, service, and support.

– Total Cost of Ownership: Consider not just the initial purchase price but also potential long-term costs related to maintenance and replacements.

– Bulk Discounts: Inquire about discounts for bulk orders, which can significantly reduce overall costs.

Step 7: Establish a Reliable Supply Chain

Finally, ensure that your supplier can consistently meet your demands. A reliable supply chain is essential for uninterrupted operations.

– Delivery Timelines: Discuss lead times and ensure they align with your operational needs.

– Supplier Reliability: Research the supplier’s reputation for timely deliveries and responsiveness to inquiries and issues.

By following this checklist, B2B buyers can confidently source the best power cables for their office needs, ensuring both safety and efficiency in their operations.

Comprehensive Cost and Pricing Analysis for best power cable for office Sourcing

What Are the Key Cost Components of Power Cables for Office Use?

When sourcing power cables for office applications, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. High-quality copper wires, durable insulation, and robust outer jackets are essential for safety and longevity. Cables designed for heavy-duty use often require more expensive materials, such as thermoplastic elastomers for outdoor applications.

-

Labor: Labor costs can vary based on the region of production. Skilled labor is necessary for quality assurance, particularly in countries with stringent safety regulations. Additionally, manufacturers may incur higher labor costs for custom cable solutions.

-

Manufacturing Overhead: This encompasses the costs associated with running production facilities, including utilities, equipment maintenance, and depreciation. Factories that meet international quality standards often have higher overhead costs, which can influence pricing.

-

Tooling: Initial tooling costs for custom or specialized cables can be significant. For buyers requiring specific configurations or unique features, understanding these costs is essential to gauge overall pricing.

-

Quality Control (QC): Rigorous QC processes ensure that cables meet safety and performance standards. However, extensive testing protocols can add to overall costs. Buyers should seek suppliers who balance quality with cost-effectiveness.

-

Logistics: Shipping and handling costs vary widely based on the distance, mode of transport, and destination. For international buyers, understanding logistics costs is vital, especially when factoring in tariffs and customs duties.

-

Margin: Manufacturers and suppliers typically add a profit margin to their costs. This margin varies based on market demand, competition, and the supplier’s reputation.

How Do Price Influencers Impact Power Cable Sourcing Decisions?

Several factors can influence the price of power cables, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchasing often leads to significant discounts. Establishing a minimum order quantity (MOQ) with suppliers can optimize pricing for larger-scale operations.

-

Specifications and Customization: Custom cables tailored to specific applications or regulatory requirements tend to be more expensive. Buyers should weigh the necessity of customization against potential cost savings from standard products.

-

Materials: As mentioned, the choice of materials affects pricing. Buyers should consider the long-term benefits of investing in higher-quality materials that enhance durability and performance.

-

Quality and Certifications: Cables that meet international safety and performance certifications, such as UL or CE, may come at a premium. However, they provide assurance of reliability and compliance, which can mitigate risks.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge more, but they often provide better service and assurance of compliance with safety standards.

-

Incoterms: Understanding the terms of trade (Incoterms) is essential for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, impacting the total landed cost.

What Buyer Tips Can Enhance Cost-Efficiency in Power Cable Procurement?

To optimize procurement processes and achieve better pricing, consider these strategies:

-

Negotiate Wisely: Engage in discussions with suppliers to explore volume discounts or long-term contracts. Building a strong relationship can lead to more favorable terms.

-

Focus on Total Cost of Ownership (TCO): Consider not just the upfront costs but also the long-term implications of maintenance, durability, and energy efficiency. Investing in higher-quality cables can reduce replacement and repair costs over time.

-

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, be aware of regional market variations, currency fluctuations, and import regulations. Understanding local market dynamics can lead to more informed purchasing decisions.

-

Seek Multiple Quotes: Obtaining quotes from multiple suppliers can provide leverage in negotiations and help identify competitive pricing.

-

Evaluate Supplier Reliability: Research potential suppliers to ensure they have a history of delivering quality products on time. This can minimize delays and unforeseen costs in the supply chain.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and regional factors. Buyers are encouraged to conduct thorough market research to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing best power cable for office With Other Solutions

Introduction to Alternatives for Power Supply in Office Settings

When considering power supply solutions for office environments, the ‘best power cable for office’ serves as a critical component. However, businesses often overlook viable alternatives that may offer enhanced performance, cost-efficiency, or convenience. This section evaluates the leading power cable options against alternative solutions, including power strips and wireless charging systems, to help B2B buyers make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Best Power Cable For Office | Power Strip | Wireless Charging System |

|---|---|---|---|

| Performance | High, stable power delivery | Moderate, limited by outlet capacity | Variable, dependent on device compatibility |

| Cost | Moderate to high | Low to moderate | High initial investment |

| Ease of Implementation | Straightforward installation | Easy to set up | Requires compatible devices |

| Maintenance | Minimal, check for wear | Regular inspection needed | Low, but dependent on technology updates |

| Best Use Case | High-powered devices, stationary setups | General office appliances, multiple devices | Mobile devices, flexible workspaces |

Detailed Breakdown of Alternatives

Power Strip

Power strips offer a convenient way to connect multiple devices to a single outlet, making them a popular choice for office environments. They are cost-effective and easy to implement, requiring minimal setup. However, their performance can be limited, particularly if too many high-powered devices are connected simultaneously, potentially leading to overloads. Additionally, users must regularly inspect power strips for wear and tear to ensure safety. They are best suited for general office use where multiple lower-powered devices like computers and printers need to be powered.

Wireless Charging System

Wireless charging systems represent a modern alternative that provides convenience, especially in mobile device-heavy environments. Users can charge their smartphones and other compatible devices without needing cables, which enhances workspace flexibility and reduces clutter. However, the initial investment can be high, and performance can be inconsistent depending on the device’s compatibility with the charging pad. Furthermore, this method is limited to mobile devices and may not be suitable for powering larger office equipment. It’s best used in dynamic workspaces where mobility is prioritized.

Conclusion: Choosing the Right Power Solution for Your Office

In conclusion, selecting the right power supply solution involves evaluating the specific needs of your office environment. While the best power cable for office scenarios provides robust power delivery for high-demand devices, alternatives like power strips and wireless charging systems can offer practical benefits in terms of cost and convenience. B2B buyers should consider factors such as device compatibility, workspace layout, and the nature of their operations when deciding on the most suitable power solution. By carefully assessing these aspects, businesses can optimize their power supply strategy to enhance productivity and ensure safety in the workplace.

Essential Technical Properties and Trade Terminology for best power cable for office

What Are the Key Technical Properties of Power Cables for Office Use?

When selecting the best power cables for office environments, understanding the essential technical properties is crucial for ensuring safety, reliability, and efficiency. Here are some critical specifications to consider:

1. Wire Gauge (AWG)

The wire gauge, measured in American Wire Gauge (AWG), indicates the thickness of the wire. Thicker wires (lower AWG numbers) can carry more current and are essential for high-power devices. For example, a 10 AWG wire is suitable for heavy-duty applications, while a 16 AWG wire is adequate for light-duty devices. Selecting the correct gauge ensures that the cable can handle the necessary load without overheating or failing.

2. Amperage Rating

The amperage rating specifies the maximum current the cable can safely carry without overheating. For office settings, cables rated for 15 amps are typically recommended. This rating is crucial for ensuring that the power supply meets the needs of various devices, from computers to printers, without risking electrical hazards.

3. Voltage Rating

Voltage rating denotes the maximum voltage the cable can handle. In commercial applications, cables are often rated for 125V or 250V, depending on the region and specific use case. Understanding voltage ratings is vital for compliance with local electrical codes and ensuring that devices operate efficiently without damage.

4. Outer Jacket Material

The outer jacket material affects the cable’s durability and suitability for different environments. For instance, PVC is common for indoor use, while thermoplastic elastomer (TPE) is preferred for outdoor cables due to its flexibility and resistance to extreme temperatures. Choosing the right material ensures the longevity and performance of the cable in various settings.

5. Temperature Rating

The temperature rating indicates the range of temperatures in which the cable can operate safely. Cables designed for high temperatures or extreme cold are essential for maintaining functionality in diverse climates. This property is particularly important for international buyers from regions with varying environmental conditions.

6. Flexibility and Bend Radius

The flexibility of a power cable affects its usability in tight spaces and its ease of storage. Cables with a smaller bend radius can be maneuvered easily around corners without risking damage. This characteristic is particularly important in office environments where space may be limited.

What Are Common Trade Terms in Power Cable Procurement?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that may be marketed by another company under its brand name. In the context of power cables, understanding the OEM can help buyers ensure they are sourcing high-quality products that meet specific standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan their procurement strategies and budget effectively, especially for large-scale projects.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific product or service. For power cables, issuing an RFQ allows buyers to compare offers and negotiate better deals based on their requirements.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international shipping to define the responsibilities of buyers and sellers. Understanding Incoterms is critical for B2B buyers engaged in cross-border transactions, as they clarify aspects like shipping costs, risks, and delivery points.

5. Certification Standards

Certification standards refer to the regulations and benchmarks that products must meet to ensure safety and performance. Common standards for power cables include UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission). Compliance with these standards is crucial for ensuring product reliability and safety.

By understanding these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing the best power cables for their office needs.

Navigating Market Dynamics and Sourcing Trends in the best power cable for office Sector

What Are the Key Market Trends Influencing the Best Power Cable for Office Sector?

The power cable market is undergoing significant transformation driven by technological advancements and changing business needs. As global digitalization accelerates, the demand for reliable, high-quality power cables has surged, particularly in emerging markets across Africa, South America, the Middle East, and Europe. International B2B buyers are increasingly seeking cables that not only meet their operational requirements but also align with evolving industry standards. For instance, the adoption of smart office solutions is pushing companies to invest in power cables that can support higher voltages and data transmission capabilities.

Moreover, the emphasis on sustainability is reshaping sourcing strategies. Businesses are now prioritizing suppliers that offer environmentally friendly options and adhere to ethical sourcing practices. Key trends such as the integration of renewable energy sources and the rise of electric vehicles are also influencing the specifications required for power cables. This shift is particularly relevant in regions like Nigeria, where there is a growing focus on energy efficiency and sustainability in infrastructure development.

Additionally, the regulatory landscape is evolving. In Europe, for example, strict compliance with safety standards such as the CE marking is crucial for market entry. Buyers from different regions need to be aware of these regulations as they can affect sourcing decisions. Understanding these market dynamics will empower international buyers to make informed decisions that not only fulfill their immediate needs but also position them favorably for future growth.

How Important Is Sustainability and Ethical Sourcing for Power Cable Suppliers?

Sustainability and ethical sourcing are no longer optional considerations in the power cable sector; they have become essential criteria for B2B buyers. The environmental impact of power cables is significant, given that traditional manufacturing processes can contribute to pollution and resource depletion. International buyers are increasingly scrutinizing the supply chain to ensure that the materials used are sourced responsibly and that production processes minimize environmental harm.

The importance of certifications such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) cannot be overstated. These certifications indicate that the power cables are manufactured without hazardous substances, thereby reducing their environmental footprint. Additionally, buyers are looking for suppliers who use recycled materials and sustainable practices, such as energy-efficient manufacturing processes.

Illustrative image related to best power cable for office

Incorporating sustainability into sourcing strategies not only enhances a company’s reputation but also opens up new market opportunities. As consumers and businesses alike become more environmentally conscious, suppliers who prioritize green certifications and sustainable materials will likely enjoy a competitive advantage. This focus on ethical sourcing is particularly relevant in regions such as Europe, where consumers are increasingly demanding transparency and sustainability in the products they purchase.

What Is the Historical Context Behind Power Cable Evolution in the B2B Sector?

The evolution of power cables has been shaped by technological advancements and changing industrial needs. Initially, power cables were primarily designed for basic electrical transmission, with limited considerations for safety and efficiency. However, as industries began to expand and diversify, the demand for more specialized cables grew.

The introduction of standards such as NEMA (National Electrical Manufacturers Association) and IEC (International Electrotechnical Commission) marked a significant turning point. These standards established guidelines for safety, performance, and compatibility, enabling businesses to select cables that met specific operational requirements. Over the years, innovations such as improved insulation materials, enhanced conductivity, and the development of multi-conductor cables have transformed the landscape.

Today, the focus is not just on functionality but also on sustainability and compliance with stringent regulatory frameworks. This historical context highlights the ongoing need for B2B buyers to stay informed about technological developments and regulatory changes to ensure they are sourcing the best power cables for their office needs. Understanding this evolution provides valuable insights into how to navigate current market dynamics effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of best power cable for office

-

How do I choose the right power cable for my office equipment?

Choosing the right power cable involves understanding the power requirements of your devices. Start by identifying whether your equipment needs a two-prong or three-prong plug. Consider the wire gauge; thicker cables (lower AWG numbers) can handle more power and are better for longer distances. Additionally, evaluate the cable’s outer jacket for durability, especially if it will be used in varying temperatures or outdoor settings. Always opt for a cable that exceeds your device’s power needs to prevent overheating and potential hazards. -

What is the best type of power cable for high-powered office devices?

For high-powered office devices, the best choice is a three-prong NEMA 5-15 power cable, ideally with a 12 AWG or 10 AWG wire gauge. These cables are designed to handle up to 15 amps of current, making them suitable for equipment like computers, printers, and heavy machinery. Ensure that the cable is also rated for the appropriate voltage, typically 125V to 130V for most office applications. This will provide a safe and reliable power source while minimizing the risk of electrical issues. -

What should I consider when sourcing power cables from international suppliers?

When sourcing power cables internationally, consider the supplier’s compliance with international safety standards and certifications (like UL, CE, or ISO). Evaluate their manufacturing processes and material quality to ensure reliability. Also, assess the supplier’s experience in your specific market region, as this can affect logistics and customer support. Request samples and documentation of previous projects to gauge their capability. Lastly, review their payment terms and minimum order quantities to ensure they align with your budget and purchasing strategy. -

How can I customize power cables for my specific office needs?

Customization options for power cables may include adjusting the length, wire gauge, plug type, and outer jacket material to suit specific applications. When discussing customization with suppliers, provide clear specifications and requirements for your office equipment. Some manufacturers can accommodate unique branding or color coding for easy identification. Be prepared to discuss minimum order quantities (MOQs) as custom cables often require larger production runs. Ensure that any changes meet safety standards applicable in your region. -

What are the typical payment terms for international power cable orders?

Payment terms for international power cable orders can vary widely among suppliers. Common terms include payment in advance, partial payment upfront with the balance due upon shipment, or payment against documents upon delivery. It’s essential to negotiate terms that protect your interests, such as using letters of credit for larger orders. Additionally, ensure clarity on currency exchange rates and any additional fees that may apply. Always review the supplier’s payment policies to avoid unexpected costs. -

How do I ensure quality assurance for power cables sourced internationally?

To ensure quality assurance for international power cables, request detailed quality control documentation from your supplier, including test reports and certifications. Consider conducting factory audits to assess manufacturing processes and compliance with safety standards. Establish a quality assurance protocol that includes receiving inspections and testing of samples upon delivery. Collaborating with a third-party inspection service can also help verify product quality before shipment, minimizing the risk of defects or non-compliance. -

What logistics considerations should I keep in mind when importing power cables?

Logistics considerations for importing power cables include understanding shipping methods (air vs. sea), estimated transit times, and customs regulations in your destination country. Ensure that the supplier provides accurate shipping documents, including invoices, packing lists, and certificates of origin. Factor in potential delays due to customs inspections or clearance processes. Working with a reliable freight forwarder can streamline the logistics process and help navigate any challenges related to international shipping and compliance. -

How can I assess the reliability of a power cable supplier?

Assessing the reliability of a power cable supplier involves researching their reputation in the industry. Look for customer reviews, testimonials, and case studies that demonstrate their experience and reliability. Check their certifications and compliance with international safety standards. Engage in direct communication to gauge their responsiveness and willingness to address your concerns. Additionally, inquire about their production capacity and lead times to ensure they can meet your demands consistently. A solid track record and open communication are key indicators of a trustworthy supplier.

Top 3 Best Power Cable For Office Manufacturers & Suppliers List

1. Reddit – 10A Power Cable

2. Newegg – Best-Selling Computer Power Cords

Domain: newegg.com

Registered: 2000 (25 years)

Introduction: This company, Newegg – Best-Selling Computer Power Cords, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. PS Audio – Audio Quality Power Cables

Domain: forum.psaudio.com

Registered: 1998 (27 years)

Introduction: 1. Audio Quality Power Cables: Users report significant improvements in sound quality when upgrading to audio quality power cables. 2. Dynavector Amp: Mentioned as a device that benefits from an upgraded power cable. 3. dCS Network Bridge: Suggested as a potential device for power cable upgrade. 4. PS Audio Mk1 DAC: Another device considered for power cable improvement. 5. Furutech IEC + Shunyata …

Strategic Sourcing Conclusion and Outlook for best power cable for office

In navigating the complexities of sourcing the best power cables for your office, it is imperative to prioritize quality, compatibility, and safety. Understanding the specific requirements of your devices, including factors like wire gauge and plug type, ensures that your organization avoids costly mistakes and potential hazards. Thicker cables not only support higher power loads but also enhance the longevity of your electrical systems.

Strategic sourcing is vital for international B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. By fostering relationships with reliable suppliers and leveraging local knowledge, businesses can secure the right products that meet regulatory standards and environmental conditions unique to their regions.

As you plan for future electrical needs, consider investing in durable, flexible cables designed for your specific operational demands. This proactive approach will not only improve efficiency but also mitigate risks associated with electrical failures. Engage with trusted suppliers and make informed purchasing decisions today to empower your office with the best power cable solutions for tomorrow’s challenges.

Illustrative image related to best power cable for office

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.