The Definitive Guide to Best Burn Barrels: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for best burn barrels

In today’s global market, sourcing the best burn barrels can pose a significant challenge for businesses, particularly those in regions like Africa, South America, the Middle East, and Europe. Buyers face a myriad of options and must navigate factors such as material quality, efficiency, safety standards, and environmental regulations. This comprehensive guide serves as a vital resource, addressing the diverse types of burn barrels available, their various applications, and essential criteria for supplier vetting.

From understanding the advantages of stainless steel incinerators to exploring cost-effective solutions for waste management, this guide empowers international B2B buyers with the knowledge needed to make informed purchasing decisions. With insights into the latest technology and best practices for burning waste, businesses can optimize their operations while adhering to local and international compliance standards.

Whether you’re based in Brazil, Vietnam, or elsewhere, this guide aims to simplify the complexities of sourcing burn barrels, ensuring that you select the right solution for your unique requirements. By leveraging our expert insights, buyers can confidently navigate the global market, enhance waste disposal efficiency, and contribute to sustainable practices within their communities.

Understanding best burn barrels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Burn Barrels | High durability, warp-resistant design, and patented airflow system | Waste management, agricultural waste disposal | Pros: Long-lasting, efficient burn, cleaner emissions. Cons: Higher initial investment. |

| Standard Steel Drums | Typically made from carbon steel, often modified for burning | General waste disposal, construction sites | Pros: Cost-effective, widely available. Cons: May warp or rust over time. |

| Incinerator Barrels | Designed for higher temperatures, often with enhanced airflow | Industrial waste disposal, hazardous material incineration | Pros: Effective for complete waste destruction, cleaner emissions. Cons: More complex setup and maintenance. |

| Fire Pit Burn Barrels | Dual-purpose for burning waste and recreational use | Landscaping, backyard maintenance | Pros: Versatile use, aesthetic appeal. Cons: Less efficient for large waste volumes. |

| Vortex Burn Barrels | Engineered for maximum airflow, promoting complete combustion | Municipal waste management, forestry practices | Pros: Extremely efficient, reduces smoke emissions. Cons: May require more frequent maintenance. |

What Are the Key Characteristics of Stainless Steel Burn Barrels?

Stainless steel burn barrels are renowned for their durability and resistance to warping, making them suitable for long-term use. They feature a patented airflow system that enhances combustion efficiency, achieving burn temperatures exceeding 1800°F. These barrels are particularly useful for businesses needing reliable waste management solutions. When considering a purchase, B2B buyers should evaluate the upfront investment against the long-term savings on maintenance and replacement costs.

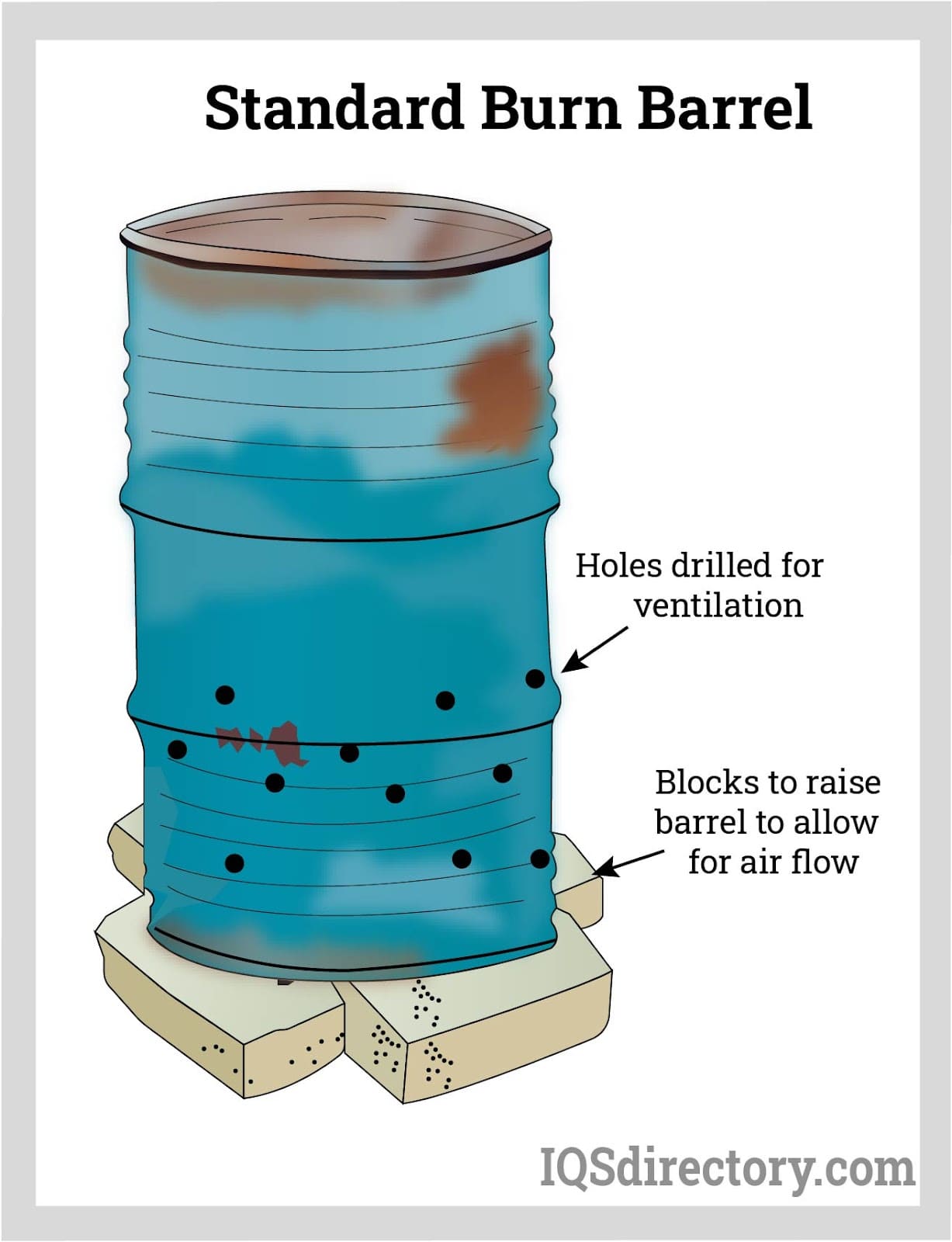

How Do Standard Steel Drums Compare in Functionality?

Standard steel drums are often modified for burning and are widely available, making them a cost-effective option for businesses. They are commonly used in construction sites and for general waste disposal. However, their susceptibility to rust and warping can limit their lifespan. Buyers should weigh the lower initial cost against the potential need for frequent replacements or repairs.

Illustrative image related to best burn barrels

What Advantages Do Incinerator Barrels Offer for Industrial Applications?

Incinerator barrels are specifically designed for high-temperature waste disposal, making them ideal for industrial applications where hazardous materials are involved. Their enhanced airflow systems allow for complete waste destruction, leading to cleaner emissions. While they provide significant benefits in terms of waste management, buyers must consider the complexity of setup and the potential for higher maintenance needs.

In What Situations Are Fire Pit Burn Barrels Most Effective?

Fire pit burn barrels serve a dual purpose, allowing businesses to manage waste while also providing a recreational fire pit for landscaping and backyard maintenance. Their versatility makes them appealing to various sectors, especially in residential landscaping. However, they may not be as efficient for large volumes of waste, prompting buyers to consider their specific needs before purchasing.

Why Choose Vortex Burn Barrels for Waste Management?

Vortex burn barrels are engineered to maximize airflow, promoting complete combustion and significantly reducing smoke emissions. They are particularly effective in municipal waste management and forestry practices. Although they may require more frequent maintenance due to their complex design, the efficiency gains can lead to substantial long-term benefits for businesses focused on sustainability and compliance with environmental regulations.

Illustrative image related to best burn barrels

Key Industrial Applications of best burn barrels

| Industry/Sector | Specific Application of best burn barrels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Waste Management | Incineration of non-recyclable waste materials | Reduces landfill use, minimizes environmental impact | Compliance with local regulations and emissions standards |

| Agriculture | Disposal of agricultural waste and debris | Enhances land cleanliness, reduces pest issues | Durability and resistance to corrosion in outdoor settings |

| Construction | Burning of construction waste and debris | Efficient waste management, cost savings on disposal | Size and capacity to handle large volumes of waste |

| Chemical Industry | Safe incineration of hazardous materials | Ensures safe disposal, mitigates environmental risks | Material specifications to handle specific waste types |

| Forestry | Burning of forest debris and slash | Reduces fire hazards, promotes land management practices | Temperature control features for effective burning |

How Are Best Burn Barrels Used in Waste Management?

In the waste management sector, best burn barrels are utilized for the incineration of non-recyclable waste materials. This application is crucial for businesses aiming to minimize landfill usage while adhering to environmental regulations. By converting waste into ash and gases, companies can significantly reduce their environmental footprint. Buyers in this sector must consider compliance with local emissions standards and the burn barrel’s ability to handle various waste types, ensuring efficient and safe operations.

What Role Do Best Burn Barrels Play in Agriculture?

Agricultural businesses leverage best burn barrels for the disposal of waste and debris, such as crop residues and damaged plants. This process not only promotes cleanliness on farms but also helps mitigate pest issues that can arise from decaying organic matter. For international buyers, especially in regions with diverse agricultural practices, it is essential to select burn barrels that are durable and resistant to corrosion, given the outdoor conditions and potential exposure to chemicals.

How Are Best Burn Barrels Applied in the Construction Industry?

In the construction sector, best burn barrels serve as a practical solution for burning construction waste, including wood scraps, paper, and other debris. This application streamlines waste management processes and can lead to substantial cost savings by reducing the need for traditional waste disposal methods. Buyers should focus on the barrel’s size and capacity to ensure it can accommodate large volumes of waste, as well as its durability to withstand harsh working conditions.

Why Are Best Burn Barrels Important in the Chemical Industry?

The chemical industry requires stringent waste disposal methods, particularly for hazardous materials. Best burn barrels are designed for the safe incineration of such substances, ensuring compliance with environmental safety standards and reducing the risk of contamination. Companies looking to purchase these barrels must pay close attention to material specifications that can handle specific waste types, as well as features that ensure safe operation and emissions control.

How Do Best Burn Barrels Contribute to Forestry Management?

In forestry applications, best burn barrels are employed to incinerate forest debris and slash, which can pose fire hazards if left unmanaged. This practice not only aids in land management but also contributes to the prevention of wildfires, particularly in regions prone to dry conditions. Buyers in the forestry sector should prioritize burn barrels with effective temperature control features to ensure complete combustion and minimize smoke emissions, addressing environmental concerns while promoting safety.

3 Common User Pain Points for ‘best burn barrels’ & Their Solutions

Scenario 1: Inconsistent Burning Efficiency in Varied Conditions

The Problem: B2B buyers often face challenges with burn barrels that do not perform consistently across different environmental conditions. For example, a buyer may purchase a burn barrel expecting it to efficiently incinerate waste, but factors such as humidity, wind, or the moisture content of the waste can hinder performance. This inconsistency can lead to incomplete burns, excessive smoke production, and ultimately, increased operational costs due to the need for additional burning cycles or alternative waste disposal methods.

Illustrative image related to best burn barrels

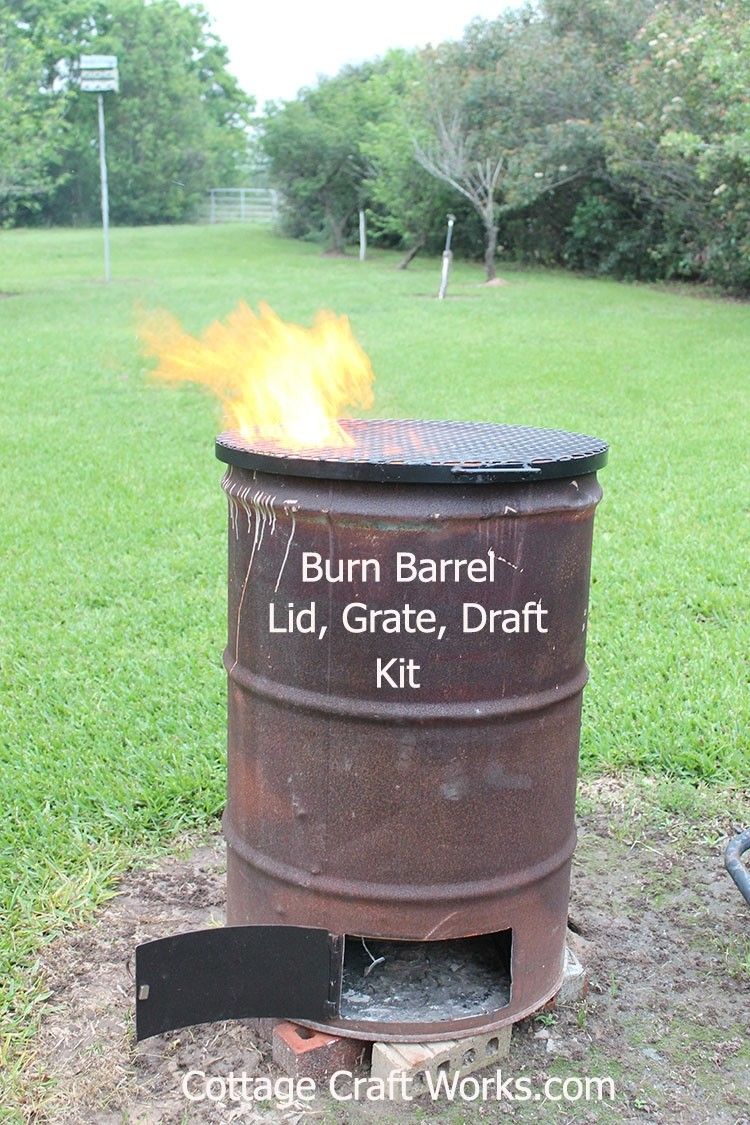

The Solution: To address these issues, buyers should consider investing in burn barrels specifically designed with advanced airflow systems and temperature controls. Products that feature adjustable air intake, such as those with enhanced ventilation systems, can significantly improve combustion efficiency. When sourcing burn barrels, look for those made from high-quality materials like stainless steel, which not only resist warping but also maintain optimal burn temperatures. Furthermore, educating users on the importance of preparing waste—such as drying wet materials and breaking down large items—can also mitigate performance issues. Including a guide for proper use and maintenance can ensure that all users understand how to maximize efficiency regardless of environmental factors.

Scenario 2: Safety Concerns with Traditional Burn Barrels

The Problem: Safety is a primary concern for B2B buyers when it comes to burn barrels, particularly in regions prone to wildfires or where fire regulations are stringent. Traditional burn barrels can pose risks, including uncontrolled flames, flying embers, and smoke emissions that can lead to health issues. Buyers may be hesitant to utilize burn barrels due to the fear of liability or regulatory penalties associated with unsafe practices.

The Solution: Buyers should seek burn barrels that are engineered with safety features, such as a patented flame containment system or a smoke-reduction design. Products that incorporate a lid or cover can help contain embers and reduce smoke emissions, making them compliant with local regulations. Additionally, providing comprehensive training for employees on safe burning practices and the correct setup of the burn barrel can further enhance safety. It’s beneficial to establish a clear protocol for monitoring weather conditions and ensuring that burning activities are conducted during safe periods. By prioritizing safety in sourcing and training, businesses can effectively mitigate risks associated with burn barrels.

Scenario 3: High Operational Costs Due to Poor Durability

The Problem: Many B2B buyers experience high operational costs stemming from the frequent replacement of subpar burn barrels. Traditional models may corrode, warp, or fail under high temperatures, leading to a shorter lifespan and increased expenditure on replacements. This not only strains budgets but also disrupts waste management operations, leading to inefficiencies.

Illustrative image related to best burn barrels

The Solution: To combat durability issues, buyers should focus on sourcing burn barrels made from high-grade, corrosion-resistant materials such as stainless steel. Investing in products with a proven track record of durability can save money in the long run. Additionally, buyers should consider barrels that come with warranties or guarantees, as these often reflect the manufacturer’s confidence in their product’s longevity. Regular maintenance and inspection routines should also be established to identify potential wear and tear early, ensuring that the barrels remain in optimal condition. By prioritizing quality over price and implementing proactive maintenance, companies can significantly reduce operational costs associated with burn barrels.

Strategic Material Selection Guide for best burn barrels

What Are the Key Properties of Common Materials Used in Burn Barrels?

When selecting materials for burn barrels, it is essential to consider their properties, durability, and suitability for specific applications. The most common materials include steel, stainless steel, aluminum, and plastic. Each material has distinct characteristics that influence performance and longevity.

How Does Steel Perform in Burn Barrel Applications?

Steel is a widely used material for burn barrels due to its strength and heat resistance. It can withstand high temperatures, typically up to 1,200°F (650°C), making it suitable for incinerating waste. However, steel is prone to corrosion, particularly when exposed to moisture and chemicals, which can lead to premature failure.

Pros: Steel is relatively inexpensive and easy to manufacture, making it a cost-effective option for mass production. Its durability allows for heavy-duty use in various environments.

Cons: The primary limitation is its susceptibility to rust and corrosion, which can significantly reduce its lifespan. Regular maintenance, such as painting or coating, is often necessary to prolong its use.

Illustrative image related to best burn barrels

What Advantages Does Stainless Steel Offer for Burn Barrels?

Stainless steel is a premium choice for burn barrels, known for its excellent corrosion resistance and ability to maintain structural integrity at high temperatures (up to 1,800°F or 982°C). This material is particularly beneficial in humid or chemically aggressive environments.

Pros: The durability of stainless steel translates to a longer lifespan, reducing the need for frequent replacements. Its resistance to rust and staining makes it ideal for outdoor applications.

Cons: The higher manufacturing costs associated with stainless steel can be a barrier for some buyers. Additionally, its weight may pose challenges during transportation and installation.

Why Choose Aluminum for Burn Barrels?

Aluminum is lightweight and resistant to corrosion, making it an attractive option for burn barrels, especially in regions with high humidity. It can handle temperatures up to 1,000°F (538°C), but its performance may degrade at higher temperatures compared to steel and stainless steel.

Pros: The lightweight nature of aluminum facilitates easy handling and transportation. It is also resistant to rust, which is advantageous for longevity.

Cons: Aluminum’s lower melting point compared to steel means it may not be suitable for all burning applications, particularly those involving high heat. Additionally, it can be more expensive than traditional steel options.

Illustrative image related to best burn barrels

How Do Plastic Burn Barrels Compare?

Plastic burn barrels, typically made from high-density polyethylene (HDPE), are gaining popularity due to their resistance to corrosion and chemicals. They can withstand temperatures up to 180°F (82°C), making them suitable for specific applications but limiting their use for high-temperature incineration.

Pros: Plastic barrels are lightweight, resistant to rust, and often more affordable than metal options. They are also less likely to require maintenance over time.

Cons: The major limitation is their inability to handle high temperatures, which restricts their use to lower-heat applications. Additionally, they may not be as durable as metal options in harsh environments.

Summary of Material Selection for Burn Barrels

| Material | Typical Use Case for best burn barrels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General waste incineration | Cost-effective and durable | Prone to rust and corrosion | Low |

| Stainless Steel | High-temperature waste incineration | Excellent corrosion resistance | Higher cost and weight | High |

| Aluminum | Lightweight applications | Lightweight and corrosion-resistant | Lower melting point limits applications | Medium |

| Plastic | Low-temperature waste disposal | Affordable and rust-free | Limited temperature tolerance | Low |

In conclusion, B2B buyers should evaluate these materials based on their specific needs, considering factors such as application, environmental conditions, and budget. Each material has its unique strengths and weaknesses, making it crucial to align material selection with operational requirements and compliance standards in their respective regions.

Illustrative image related to best burn barrels

In-depth Look: Manufacturing Processes and Quality Assurance for best burn barrels

What Are the Key Stages in the Manufacturing Process of Burn Barrels?

The manufacturing of burn barrels involves several critical stages that ensure the final product meets both functional and quality standards.

Material Preparation: What Materials Are Used in Burn Barrel Manufacturing?

The primary materials used for burn barrels are high-quality steel or stainless steel, chosen for their durability and resistance to warping under high temperatures. Manufacturers typically source raw materials from reputable suppliers who comply with international standards for quality. The preparation phase involves cutting the metal sheets into specific dimensions, depending on the design of the burn barrel, and ensuring that all materials are free from defects.

How Are Burn Barrels Formed and Assembled?

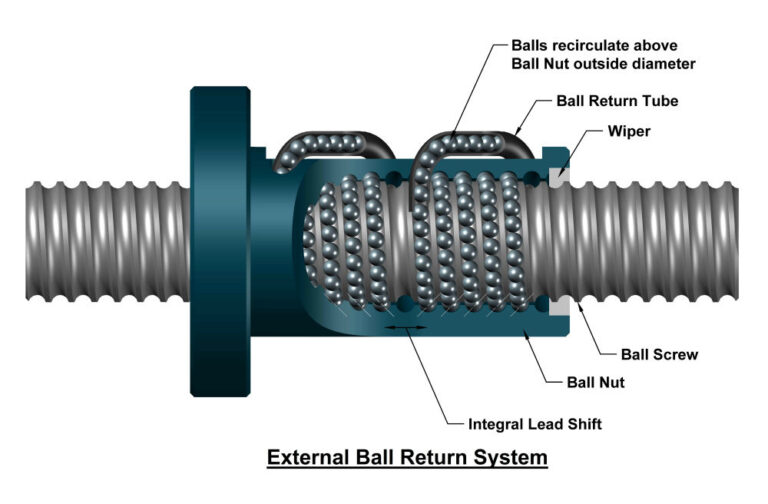

The forming stage utilizes techniques such as rolling and welding to create the cylindrical shape of the burn barrel. Advanced machinery is employed to ensure precision in shaping, which is crucial for maintaining structural integrity during use. The assembly process may include the installation of components such as air vents, handles, and lids. Each part must fit seamlessly to ensure optimal performance, particularly in airflow management, which is vital for efficient combustion.

Illustrative image related to best burn barrels

What Finishing Techniques Are Commonly Used for Burn Barrels?

Finishing processes typically involve surface treatment to enhance corrosion resistance and durability. Common techniques include powder coating, galvanizing, or applying high-temperature resistant paint. These treatments not only improve the aesthetic appeal but also extend the lifespan of the burn barrel, making it more suitable for long-term outdoor use.

What Quality Assurance Measures Are Essential for Burn Barrel Manufacturers?

Quality assurance is a crucial aspect of the manufacturing process, ensuring that the burn barrels meet international safety and performance standards.

Which International Standards Should B2B Buyers Be Aware Of?

For international buyers, it is essential to verify that manufacturers adhere to recognized quality standards such as ISO 9001, which emphasizes quality management systems. Compliance with European standards (CE) is also critical for products marketed in Europe. Furthermore, certifications from industry-specific bodies such as the American Petroleum Institute (API) may be relevant, particularly for barrels intended for industrial applications.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control (QC) is typically integrated at several checkpoints throughout the manufacturing process:

Illustrative image related to best burn barrels

- Incoming Quality Control (IQC): At this stage, incoming materials are inspected for defects and conformity to specifications.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process to identify any deviations from quality standards.

- Final Quality Control (FQC): Once the burn barrels are fully assembled, they undergo a final inspection to ensure they meet all safety and performance criteria.

What Testing Methods Are Commonly Used in Burn Barrel Quality Assurance?

To ensure that burn barrels perform as expected, various testing methods are employed. These may include:

- Pressure Testing: Assessing the structural integrity of the barrel under simulated conditions.

- Heat Resistance Testing: Measuring how well the materials withstand high temperatures during operation.

- Airflow Efficiency Testing: Evaluating the design for optimal combustion efficiency, which is vital for reducing smoke emissions and enhancing performance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Conducting Audits: Arranging on-site audits allows buyers to assess the manufacturing environment, quality control processes, and adherence to standards firsthand.

- Requesting Quality Reports: Suppliers should be willing to provide documentation that details their quality assurance practices, test results, and any certifications obtained.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing practices and product quality.

What Are the Specific QC and Certification Nuances for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Different countries may have varying requirements for product safety, environmental impact, and manufacturing practices.

- Regional Compliance: Buyers should familiarize themselves with local regulations that may affect the import and use of burn barrels, such as environmental protection laws.

- Documentation Requirements: Ensuring that all necessary documentation is in order, including compliance certificates and test reports, can facilitate smoother customs processes and reduce the risk of delays.

Conclusion: Why Understanding Manufacturing and Quality Assurance is Critical for Sourcing Burn Barrels

A thorough understanding of the manufacturing processes and quality assurance measures in place for burn barrels is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they source reliable, durable, and compliant products that meet their specific needs. This knowledge not only aids in selecting the right supplier but also fosters long-term partnerships built on quality and trust.

Illustrative image related to best burn barrels

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best burn barrels’

In today’s competitive landscape, sourcing the best burn barrels is essential for businesses that rely on efficient waste management and incineration. This guide provides a comprehensive checklist to assist B2B buyers in making informed decisions when procuring burn barrels, ensuring compliance with safety standards, and optimizing operational efficiency.

1. Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure that the burn barrels meet your specific operational needs. Consider factors such as capacity, material (e.g., steel or plastic), and design (e.g., airflow systems). This clarity will help you avoid miscommunications and ensure that the barrels perform optimally in your waste management processes.

2. Research Regulatory Compliance Requirements

Before purchasing, verify the regulatory standards applicable in your region. Different countries may have varying guidelines concerning emissions, safety, and waste disposal. Ensure that your chosen burn barrels comply with local regulations to avoid potential fines and legal issues, especially in regions like Africa and South America where environmental regulations may be stringent.

Illustrative image related to best burn barrels

3. Evaluate Potential Suppliers

Vetting suppliers is a critical step in the sourcing process. Investigate their reputation in the industry by requesting company profiles, case studies, and testimonials from other businesses in similar markets. A reliable supplier should be able to demonstrate their experience and commitment to quality, which is essential for long-term partnerships.

4. Check for Certifications and Quality Standards

Look for burn barrels that come with relevant certifications, such as ISO or CE markings. These certifications indicate that the products have met specific safety and quality standards. Ensuring that your supplier adheres to these standards minimizes the risk of receiving subpar products that could compromise safety or efficiency.

5. Assess Product Features and Innovations

When choosing burn barrels, examine the features that enhance their functionality, such as airflow designs that promote efficient burning and reduce smoke emissions. Innovative designs, like those that prevent warping or incorporate ash catchers, can significantly improve performance and longevity. Evaluate how these features align with your operational goals.

6. Request Samples or Demonstrations

Before finalizing your purchase, it’s beneficial to request samples or demonstrations of the burn barrels. This hands-on approach allows you to assess the quality and functionality of the product firsthand. Observing the burning process can also help you understand how well the barrel meets your waste disposal needs in practice.

7. Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations regarding pricing, delivery schedules, and warranty terms. Establish clear terms that protect your investment, including after-sales support and maintenance options. This step is essential for ensuring a smooth procurement process and building a solid working relationship with your supplier.

By following this checklist, B2B buyers can confidently navigate the procurement of burn barrels, ensuring they select products that align with their operational needs while adhering to regulatory standards.

Comprehensive Cost and Pricing Analysis for best burn barrels Sourcing

What Are the Key Cost Components in Burn Barrel Manufacturing?

Understanding the cost structure of burn barrels is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of materials used, such as stainless steel or high-density plastics, significantly impacts the cost. Stainless steel, for instance, is more durable and resistant to warping, leading to higher initial costs but potentially lower replacement costs over time.

-

Labor: Labor costs vary by region, influenced by local wage standards and workforce availability. Skilled labor is necessary for high-quality manufacturing processes, particularly in crafting custom designs.

-

Manufacturing Overhead: This includes utilities, rent, and other indirect costs associated with production. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer competitive pricing.

-

Tooling: Initial tooling costs for molds and production equipment can be substantial, especially for custom designs. Buyers should consider these costs when negotiating prices.

-

Quality Control (QC): Ensuring that burn barrels meet safety and efficiency standards incurs additional costs. Rigorous QC processes can enhance product reliability but also increase overall costs.

-

Logistics: Shipping and handling costs can vary widely based on the distance and method of transport. Buyers should factor in these logistics costs, especially for international shipments.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. The margin can fluctuate based on market competition and demand.

How Do Price Influencers Affect Burn Barrel Costs?

Several factors influence the pricing of burn barrels, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing, especially when planning to order for multiple sites or projects.

-

Specifications and Customization: Custom features, such as additional air holes for improved burning efficiency or specific dimensions, can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, CE) typically result in higher prices. However, investing in quality can yield long-term savings through reduced maintenance and longer product life.

-

Supplier Factors: The reputation and experience of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: The terms of sale can significantly impact the final price. Buyers should clarify who is responsible for shipping, insurance, and customs duties to avoid unexpected costs.

What Buyer Tips Should Be Considered for Cost-Efficiency?

B2B buyers can enhance their cost-efficiency by considering the following strategies:

-

Negotiation: Establishing a strong relationship with suppliers can lead to better negotiation outcomes. Discussing long-term partnerships or larger order volumes can also incentivize suppliers to provide favorable terms.

-

Total Cost of Ownership (TCO): Buyers should evaluate the TCO, which includes not just the initial purchase price but also maintenance, operational efficiency, and potential replacement costs. Investing more upfront in a high-quality burn barrel can lead to savings in the long run.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of additional costs such as tariffs, taxes, and customs duties. Understanding local regulations can prevent unexpected expenses.

-

Market Research: Conducting thorough market research can help buyers identify competitive pricing and suitable suppliers. Participating in trade shows and industry forums can provide insights into emerging suppliers and new technologies.

In conclusion, navigating the cost and pricing landscape for burn barrels requires a comprehensive understanding of the various cost components and price influencers. By leveraging negotiation strategies and considering the total cost of ownership, international B2B buyers can make informed purchasing decisions that align with their operational needs and budget constraints.

Disclaimer: The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier agreements, and specific order requirements. Always consult with suppliers for the most accurate pricing information.

Illustrative image related to best burn barrels

Alternatives Analysis: Comparing best burn barrels With Other Solutions

In the realm of waste management and disposal, burn barrels have long been a preferred solution for many businesses. However, as environmental regulations tighten and the need for efficiency increases, exploring alternatives becomes crucial. This section examines how best burn barrels stack up against other viable waste disposal methods, providing B2B buyers with a comprehensive understanding of their options.

| Comparison Aspect | Best Burn Barrels | Incinerators | Composting Systems |

|---|---|---|---|

| Performance | Efficient burn, high temperatures (up to 1800°F) ensure complete waste incineration. | Very high efficiency with complete destruction of waste, minimal emissions. | Converts organic waste into nutrient-rich compost; slower process. |

| Cost | Moderate initial investment (e.g., $429 – $699). | Higher upfront costs (typically $1,000+), but lower operational costs over time. | Low initial cost, but can require more land and labor. |

| Ease of Implementation | Simple setup; requires minimal space and can be used in various locations. | More complex installation; often requires permits and specific site conditions. | Requires space for composting, may need additional materials for effective composting. |

| Maintenance | Low maintenance; periodic cleaning and monitoring of airflow. | Requires regular maintenance and monitoring to ensure safety and compliance. | Requires ongoing management, including turning and monitoring moisture levels. |

| Best Use Case | Suitable for small-scale waste disposal, particularly in rural areas. | Ideal for larger operations needing to dispose of hazardous or large volumes of waste. | Best for organic waste management and sustainable practices in landscaping or agriculture. |

What Are the Benefits and Drawbacks of Incinerators Compared to Burn Barrels?

Incinerators represent a significant advancement over traditional burn barrels, offering higher efficiency and lower emissions. Their ability to handle various waste types while maintaining compliance with stringent environmental regulations makes them a strong contender. However, the initial investment can be substantial, and operational complexities might deter smaller businesses. For those with larger waste volumes or hazardous materials, incinerators present a viable long-term solution, though they require careful management and maintenance.

How Do Composting Systems Compare to Burn Barrels?

Composting systems provide an eco-friendly alternative, focusing on organic waste conversion into compost. This method not only reduces waste but also enhances soil quality, making it an attractive option for agricultural businesses. However, composting is slower and requires more space and labor compared to burn barrels. While it is cost-effective in the long run, organizations must consider their capacity for ongoing management and the type of waste they generate. Composting may not be suitable for all waste types, particularly non-organic materials.

How Should B2B Buyers Decide Between Burn Barrels and Alternatives?

Choosing the right waste disposal method hinges on several factors, including the nature of the waste, volume, budget, and compliance with local regulations. Businesses in rural areas with limited waste types may find burn barrels an efficient and cost-effective choice. In contrast, larger enterprises or those dealing with hazardous materials may benefit from investing in incinerators despite their higher costs. For companies prioritizing sustainability, composting systems may be the best fit, although they require a commitment to management and maintenance. Ultimately, B2B buyers should assess their specific needs, environmental impact goals, and operational capabilities to make the most informed decision.

Essential Technical Properties and Trade Terminology for best burn barrels

What Are the Key Technical Properties of the Best Burn Barrels?

When evaluating burn barrels for commercial use, several technical properties are critical for ensuring efficiency, durability, and safety. Below are some of the essential specifications that B2B buyers should consider:

-

Material Grade

The material from which a burn barrel is made significantly impacts its performance and lifespan. High-quality burn barrels are typically constructed from 100% stainless steel, which offers superior resistance to warping, rust, and corrosion. This material choice is crucial for buyers in regions with high humidity or fluctuating temperatures, as it ensures longevity and reliability under various conditions. -

Burn Temperature

The burn temperature is a vital specification that affects the efficiency of waste incineration. High-performance burn barrels can achieve temperatures exceeding 1800°F, which facilitates complete combustion and minimizes smoke emissions. This is particularly important for businesses aiming to comply with environmental regulations and reduce their carbon footprint. -

Airflow Design

An effective airflow design, such as patented ventilation systems, enhances combustion efficiency by allowing adequate oxygen flow. This feature prevents smoldering and ensures a cleaner burn, which is vital for waste management operations. Buyers should look for designs that incorporate multiple air intake points, as these can significantly improve burn performance. -

Capacity

The capacity of a burn barrel, often measured in gallons, is a practical consideration for B2B buyers. Common sizes include 30-gallon and 55-gallon models, with larger barrels suitable for industrial applications that generate significant waste. Understanding the capacity needed for specific operations helps businesses optimize their waste disposal strategies. -

Safety Features

Safety features such as flame arrestors and sturdy construction are essential for preventing accidents and ensuring compliance with safety standards. Buyers should prioritize burn barrels that include these features to protect personnel and property, especially in environments where flammable materials are present.

What Are Common Trade Terms Related to Burn Barrels?

Navigating the procurement process for burn barrels involves understanding specific industry terminology. Below are some common trade terms that are relevant for international B2B transactions:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of burn barrels, an OEM may create custom designs or specifications tailored to a buyer’s unique requirements, enhancing the product’s functionality and performance. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially when managing inventory and costs. Suppliers might set MOQs based on production capabilities, which can impact pricing and availability. -

RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to solicit price quotes from multiple suppliers. Including detailed specifications in an RFQ for burn barrels can help ensure that suppliers provide comparable bids, facilitating more informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for international transactions involving burn barrels, as they define who bears the risk and cost at each stage of the shipping process. -

Certification Standards

Certification standards, such as ISO 9001, indicate that a product meets specific quality management criteria. For burn barrels, certifications can assure buyers of product reliability and compliance with safety regulations, making them a key consideration in the procurement process.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding the procurement of burn barrels, ensuring they select products that meet their operational needs while adhering to safety and environmental standards.

Navigating Market Dynamics and Sourcing Trends in the best burn barrels Sector

What Are the Key Trends Driving the Best Burn Barrels Market?

The global burn barrels market is witnessing a transformation driven by several factors, including regulatory changes, technological advancements, and shifting consumer preferences. In regions such as Africa and South America, the need for efficient waste management solutions is propelling demand for burn barrels. These products are increasingly being recognized for their role in facilitating environmentally responsible waste disposal, especially in rural areas where traditional waste management systems are lacking.

Emerging technologies are reshaping sourcing strategies within the sector. International B2B buyers are now prioritizing suppliers that offer innovative designs and advanced materials, such as stainless steel, which enhances durability and efficiency. The integration of smart technology in burn barrels, such as temperature control and airflow management systems, is becoming a key differentiator, appealing to environmentally conscious buyers across Europe and the Middle East.

Illustrative image related to best burn barrels

Furthermore, as global environmental regulations tighten, companies are adapting their sourcing strategies to comply with stricter emissions standards. This trend is particularly relevant in Europe, where sustainability is a critical purchasing factor. B2B buyers are increasingly looking for suppliers who can demonstrate compliance with these regulations while also offering cost-effective solutions.

How Is Sustainability and Ethical Sourcing Shaping the Burn Barrel Industry?

Sustainability is no longer a peripheral concern for B2B buyers; it is a central pillar influencing procurement decisions in the burn barrel sector. The environmental impact of burn barrels, particularly concerning emissions and material waste, has prompted buyers to seek solutions that minimize their carbon footprint. Ethical sourcing is becoming increasingly important as companies strive to ensure their supply chains are transparent and responsible.

Burn barrels that utilize ‘green’ materials, such as recycled metals or sustainably sourced wood, are gaining traction in the market. Certifications such as ISO 14001 (Environmental Management) and other eco-labels are becoming critical factors in supplier selection. International buyers are increasingly inclined to partner with manufacturers that can provide evidence of sustainable practices and materials, as these certifications not only enhance brand reputation but also align with consumer demand for responsible products.

Moreover, the shift towards circular economy principles is influencing product design and lifecycle management in the burn barrel industry. B2B buyers are encouraged to consider the entire lifecycle of the product, from sourcing raw materials to end-of-life disposal, promoting a more sustainable approach to waste management.

Illustrative image related to best burn barrels

What Is the Historical Context of Burn Barrels in B2B Sourcing?

The evolution of burn barrels dates back to the early 20th century when they were primarily used for waste disposal in industrial settings. Traditionally made from metal drums, their design has undergone significant improvements to enhance efficiency and safety. The introduction of features like airflow management and heat-resistant materials has transformed burn barrels from basic waste disposal tools into sophisticated incineration systems.

In recent decades, the rise of environmental awareness has led to a reevaluation of burn barrels’ role in waste management. As global awareness of pollution and waste management challenges has grown, so too has the demand for more sustainable and effective solutions. This historical context is essential for B2B buyers to understand, as it informs current trends and shapes future innovations in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of best burn barrels

-

How do I choose the right burn barrel for my needs?

When selecting a burn barrel, consider factors such as material, size, and design. Stainless steel options offer durability and resistance to warping, while larger barrels can handle greater volumes of waste. Additionally, look for features like improved airflow systems, which facilitate efficient burning and minimize smoke. Evaluate your specific burning requirements, such as the types of waste you’ll incinerate and local regulations, to make an informed choice that meets both safety and operational needs. -

What is the best material for a burn barrel?

Stainless steel is widely regarded as the best material for burn barrels due to its durability and resistance to corrosion and warping. This material can withstand high temperatures, ensuring a longer lifespan compared to traditional steel or plastic barrels. When sourcing burn barrels, prioritize those with a design that enhances airflow and combustion efficiency, as this will result in cleaner burns and reduced emissions, aligning with environmental standards. -

What are the common uses for burn barrels in various industries?

Burn barrels are versatile and commonly used in waste management across various sectors, including agriculture, construction, and manufacturing. They efficiently incinerate yard debris, industrial waste, and other materials that cannot be recycled. Additionally, they serve as effective solutions for disposing of hazardous materials, provided they meet regulatory compliance. Understanding your industry’s specific waste disposal needs will help in selecting the most suitable burn barrel design. -

What should I consider when vetting suppliers for burn barrels?

When vetting suppliers, assess their reputation, product quality, and compliance with international standards. Look for certifications that demonstrate adherence to safety and environmental regulations. Request samples or conduct factory visits to evaluate the manufacturing process and quality control measures. Additionally, consider their experience in your target market, as local knowledge can enhance communication and logistics efficiency. -

What are the minimum order quantities (MOQs) for burn barrels?

Minimum order quantities can vary significantly between suppliers, often depending on production capacity and customization options. It’s common for manufacturers to have MOQs ranging from a few units to several hundred. When negotiating, clarify your needs and explore whether suppliers can accommodate smaller orders, especially if you are testing the market or have fluctuating demand. Bulk orders may also provide cost savings, so consider your long-term plans. -

What payment terms should I expect when purchasing burn barrels internationally?

Payment terms can vary widely among suppliers but typically include options such as letters of credit, advance payments, or net payment terms (e.g., 30, 60, or 90 days after delivery). Ensure you understand the payment structure, including any upfront deposits required. It’s advisable to negotiate terms that protect both parties, such as escrow services for larger transactions, to mitigate risks associated with international trade. -

How do I ensure quality assurance (QA) for burn barrels?

To ensure quality assurance, request detailed specifications and certifications from suppliers, including compliance with relevant industry standards. Consider implementing a quality control process that includes pre-shipment inspections and testing for durability and performance. Establish a clear communication channel with the supplier for addressing any quality issues post-delivery. Collaborating with third-party inspection agencies can provide additional assurance of product integrity. -

What logistics considerations should I keep in mind when importing burn barrels?

When importing burn barrels, consider shipping methods, customs regulations, and potential tariffs in your target market. Assess the dimensions and weight of the barrels to optimize shipping costs, and choose a reliable freight forwarder experienced in handling bulk industrial goods. Ensure compliance with local regulations regarding waste disposal and burning practices to avoid legal complications. Effective logistics planning will streamline the import process and ensure timely delivery.

Top 1 Best Burn Barrels Manufacturers & Suppliers List

1. Burn Right® Products – Small Incinerator

Domain: burnrightproducts.com

Registered: 2003 (22 years)

Introduction: Burn Right® Products offers a range of incinerators and burn barrels, including the following key products:

1. **Small Incinerator** – Price: $429.00

– Designed for backyard use and burning yard debris.

– Made from 100% stainless steel for durability.

– Patented airflow system for efficient burning.

– Rated 5.00 out of 5.

2. **XL Burn Barrel Incinerator** – Price: $699.00

-…

Strategic Sourcing Conclusion and Outlook for best burn barrels

Why Should International Buyers Prioritize Strategic Sourcing for Burn Barrels?

In conclusion, strategic sourcing of burn barrels is crucial for international B2B buyers looking to optimize waste management and incineration practices. The key takeaways emphasize the importance of selecting high-quality, durable products that meet specific operational needs while complying with environmental regulations. Understanding the differences in materials—such as stainless steel versus traditional steel—can lead to better choices that enhance efficiency and safety.

Illustrative image related to best burn barrels

Furthermore, the design features that promote airflow and temperature control are vital for achieving effective waste incineration. Buyers should consider suppliers that offer innovative solutions, such as patented designs that minimize smoke emissions and improve combustion efficiency.

As the global market continues to evolve, especially in regions like Africa, South America, the Middle East, and Europe, there is a growing demand for reliable burn barrels that align with sustainable practices. Now is the time for international buyers to engage with trusted manufacturers and suppliers, ensuring a strategic approach to sourcing that not only meets immediate needs but also anticipates future challenges. Explore the options available to elevate your waste management processes and contribute to a cleaner, more efficient environment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.