The Definitive Guide to Bedside Locker Metal: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for bedside locker metal

In today’s competitive landscape, international B2B buyers face the significant challenge of sourcing high-quality bedside locker metal that aligns with both functionality and aesthetic appeal. Whether you’re a retailer in Africa, a distributor in South America, or an interior designer in Europe, understanding the diverse range of bedside lockers available is crucial. This guide delves into the various types of bedside locker metal, their applications in residential and commercial settings, and essential factors to consider when selecting suppliers.

Navigating the global market requires a strategic approach to sourcing. This comprehensive resource covers key aspects such as material quality, design trends, price ranges, and supplier vetting processes. By providing insights into the manufacturing standards and certifications relevant to different regions—including the Middle East and Europe—this guide empowers B2B buyers to make informed purchasing decisions that enhance their offerings.

Additionally, we explore the cost implications of bedside lockers, helping buyers understand how to balance budget constraints with quality requirements. With actionable advice and a focus on practical solutions, this guide is designed to support your journey in sourcing the right bedside locker metal for your business needs. Equip yourself with the knowledge necessary to thrive in the evolving marketplace and meet the demands of your clientele effectively.

Understanding bedside locker metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Powder-Coated Metal Lockers | Durable finish, resistant to scratches and rust, available in various colors | Hospitality, Education, Residential | Pros: Attractive, easy to clean. Cons: Color may fade over time. |

| Industrial-Style Metal Lockers | Rugged design, often with exposed hardware, vintage aesthetics | Offices, Studios, Home Decor | Pros: Durable, unique look. Cons: May not fit all decor styles. |

| Modular Metal Lockers | Customizable sizes and configurations, often stackable | Retail, Warehousing, Schools | Pros: Versatile, space-saving. Cons: Assembly may be required. |

| Lockable Metal Nightstands | Security features, compact design, often with shelves or drawers | Residential, Small Apartments | Pros: Safe storage, stylish. Cons: Limited storage capacity. |

| Multi-Functional Metal Lockers | Combines storage with additional features like charging ports | Modern Offices, Co-Working Spaces | Pros: Practical, modern conveniences. Cons: Higher price point. |

What Are the Characteristics of Powder-Coated Metal Lockers?

Powder-coated metal lockers are characterized by their durable finish that provides resistance against scratches, rust, and corrosion. This type of locker is available in a variety of colors, making it suitable for various design aesthetics in environments such as hotels, schools, and residential spaces. B2B buyers should consider the longevity and maintenance ease of powder-coated lockers, as they are designed to withstand heavy use while maintaining their visual appeal.

How Do Industrial-Style Metal Lockers Stand Out?

Industrial-style metal lockers feature a rugged design often highlighted by exposed hardware, giving them a vintage aesthetic that appeals to modern decor sensibilities. These lockers are particularly popular in office settings, studios, and residential spaces where a unique style is desired. Buyers should evaluate the durability and aesthetic compatibility with existing furnishings, as these lockers may not suit every environment but offer a distinctive charm.

What Benefits Do Modular Metal Lockers Provide?

Modular metal lockers offer customizable sizes and configurations, allowing businesses to tailor their storage solutions according to specific needs. Their stackable design makes them ideal for maximizing space in retail environments, warehouses, and educational institutions. When considering modular lockers, B2B buyers should assess the flexibility of configurations and the potential for future expansion to accommodate changing storage demands.

Why Choose Lockable Metal Nightstands for Security?

Lockable metal nightstands combine security features with a compact design, making them ideal for residential settings and small apartments. They often include shelves or drawers for organized storage, allowing users to keep personal items secure. B2B buyers should weigh the benefits of safety and style against the potential limitations in storage capacity, ensuring that the product meets their specific requirements.

What Are the Advantages of Multi-Functional Metal Lockers?

Multi-functional metal lockers integrate additional features such as charging ports, making them suitable for modern offices and co-working spaces. Their practical design caters to the needs of tech-savvy users who require accessible storage and device charging capabilities. When purchasing multi-functional lockers, B2B buyers should consider the investment cost relative to the conveniences offered, ensuring that the features align with user needs and workspace demands.

Key Industrial Applications of bedside locker metal

| Industry/Sector | Specific Application of bedside locker metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Patient Room Storage | Enhances patient care by organizing personal items | Durability, hygiene standards, and easy cleaning |

| Hospitality | Guest Room Furniture | Provides secure storage for guests’ belongings | Aesthetic appeal, customization options, and cost |

| Education | Dormitory and School Storage | Offers secure storage for students’ personal items | Space efficiency, lockable features, and mobility |

| Residential Furniture | Home Organization | Serves as stylish storage for everyday essentials | Design variety, material quality, and pricing |

| Office/Workspace | Employee Lockers | Improves organization and security in the workplace | Size, lock mechanisms, and integration with decor |

How is Bedside Locker Metal Utilized in Healthcare Settings?

In healthcare facilities, bedside lockers made of metal serve as essential storage solutions in patient rooms. They provide a secure place for patients to keep personal items, medications, and other essentials within reach. This organization enhances patient care by reducing clutter and promoting hygiene. For international B2B buyers, sourcing lockers that meet specific durability and hygiene standards is crucial, particularly in regions where healthcare regulations may vary.

What Role Do Bedside Lockers Play in Hospitality?

In the hospitality sector, bedside lockers are increasingly used in guest rooms to offer secure storage for personal belongings. This application not only enhances the guest experience by providing peace of mind but also allows hotels to differentiate themselves through stylish and functional furniture. Buyers in regions like Africa and the Middle East should consider aesthetic appeal and customization options when sourcing these products to align with local design preferences.

How Are Bedside Lockers Applied in Educational Institutions?

Educational institutions utilize bedside lockers in dormitories and schools to provide students with secure storage for their personal items. This application is vital in promoting a sense of safety and organization among students. For B2B buyers in South America, sourcing lockers that are space-efficient and feature lockable compartments is essential, especially in crowded living conditions typical in urban areas.

What Benefits Do Bedside Lockers Offer for Residential Use?

In residential settings, bedside lockers made of metal serve as stylish and functional storage solutions for everyday essentials. They help keep spaces organized while adding an industrial aesthetic to home décor. Buyers from Europe and beyond should focus on design variety and material quality to ensure that the lockers complement their interior design while being durable enough for daily use.

How Do Bedside Lockers Enhance Office Environments?

In office environments, bedside lockers can be adapted as employee lockers, providing secure storage for personal belongings and work-related materials. This promotes organization and security in the workplace, helping to create a more efficient working environment. Key considerations for B2B buyers include size, lock mechanisms, and the ability to integrate these lockers seamlessly into existing office decor, which is especially important for companies in competitive markets.

3 Common User Pain Points for ‘bedside locker metal’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Size and Style for Diverse Spaces

The Problem: B2B buyers often struggle with selecting bedside lockers that fit various room dimensions and aesthetic requirements. In environments such as hospitals, hotels, or residential complexes, the need for uniformity in design while accommodating different room layouts can lead to frustration. Buyers may find themselves overwhelmed by the range of styles, sizes, and colors available, leading to potential mismatches that can affect the overall aesthetic and functionality of the space.

The Solution: To streamline the selection process, buyers should first conduct a thorough space assessment. Measure the dimensions of the intended location and create a visual layout to determine the optimal size for each locker. When sourcing bedside lockers, prioritize suppliers who offer customizable options, allowing for tailored sizes and finishes to suit specific environments. Additionally, consider selecting a versatile design that can seamlessly integrate into various decor themes. This can help maintain a cohesive look throughout the space while meeting functional needs. Engaging with manufacturers that provide samples or 3D modeling can also aid in visualizing how different lockers will work in your intended spaces, ultimately leading to more informed purchasing decisions.

Scenario 2: Ensuring Durability in High-Traffic Environments

The Problem: Metal bedside lockers are often exposed to heavy use in settings such as hospitals, schools, or hotels. Buyers may face challenges related to the durability of the materials, as low-quality finishes can lead to rust, scratches, or dents over time. This not only impacts the visual appeal of the lockers but also necessitates more frequent replacements, increasing overall costs and operational disruptions.

The Solution: To address durability concerns, buyers should prioritize sourcing metal lockers made from high-quality, powder-coated steel that offers enhanced resistance to scratches and corrosion. Seek out manufacturers that provide warranties or guarantee long-term performance, as this indicates confidence in the product’s durability. Additionally, consider investing in lockers with reinforced hinges and lock mechanisms, which can withstand daily wear and tear more effectively. Regular maintenance, such as cleaning and inspection for any signs of damage, can also prolong the lifespan of the lockers, making it essential for facilities to implement a routine upkeep strategy.

Scenario 3: Security Concerns in Shared Living Spaces

The Problem: In shared living environments like dormitories or multi-tenant housing, security is a paramount concern for B2B buyers. Users often require a safe place to store personal items, and inadequate security features can lead to theft or loss, undermining tenant satisfaction and trust. Buyers may struggle to find lockers that offer both functionality and robust security measures, leaving them hesitant to make a purchase.

The Solution: To enhance security, buyers should prioritize bedside lockers that feature built-in locking systems, preferably with keyless options such as combination locks or electronic keypads. This not only provides enhanced security but also eliminates the risk of lost keys. When sourcing these products, consider suppliers who offer lockers designed specifically for high-density living environments, ensuring that they include features such as wall anchoring kits to prevent tipping and additional security measures. Furthermore, educating users on proper usage of locking systems and implementing access policies can further enhance the security of shared storage spaces. By addressing these concerns proactively, buyers can ensure that their investments in bedside lockers provide peace of mind for all users.

Strategic Material Selection Guide for bedside locker metal

What Are the Key Materials Used in Bedside Locker Metal Production?

When selecting materials for bedside lockers, particularly in international markets, it is crucial to consider properties that affect performance, durability, and compliance with industry standards. Below are analyses of four common materials used in the manufacture of bedside lockers, focusing on their properties, advantages, limitations, and considerations for international buyers.

How Does Steel Perform as a Material for Bedside Lockers?

Key Properties: Steel, particularly carbon steel, offers excellent strength and durability. It has a high resistance to deformation under pressure and can withstand varying temperatures. However, it is susceptible to corrosion if not properly treated.

Pros & Cons: Steel is relatively cost-effective and widely available, making it a popular choice. Its durability ensures a long lifespan, which is essential for high-traffic areas. On the downside, untreated steel can rust, necessitating additional coatings or treatments, which can increase manufacturing complexity and costs.

Impact on Application: Steel is compatible with various environments, but its susceptibility to corrosion means it may not be ideal for humid or salty conditions without proper treatment.

International Considerations: Buyers from regions like Africa and South America should ensure that the steel used complies with local standards, such as ASTM or ISO certifications, to guarantee quality and safety.

What Role Does Aluminum Play in Bedside Locker Manufacturing?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It is non-magnetic and can withstand a wide range of temperatures, making it suitable for various applications.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which simplifies transport and assembly. Additionally, it offers good corrosion resistance, reducing maintenance needs. However, aluminum can be more expensive than steel and may not provide the same level of structural strength, making it less suitable for heavy-duty applications.

Impact on Application: Aluminum is particularly well-suited for environments where weight is a concern, such as in mobile healthcare units. However, its lower strength might limit its use in high-load situations.

International Considerations: Compliance with standards such as DIN or JIS is vital for buyers in Europe and Asia. Additionally, the availability of aluminum may vary by region, affecting supply chain logistics.

Why Is Stainless Steel a Preferred Choice for Bedside Lockers?

Key Properties: Stainless steel is known for its exceptional corrosion resistance, strength, and aesthetic appeal. It can withstand high temperatures and is easy to clean, making it ideal for healthcare settings.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and staining, which is crucial in environments that require high hygiene standards. However, it is generally more expensive than both carbon steel and aluminum, which can impact overall project budgets.

Impact on Application: Stainless steel lockers are particularly suited for hospitals and clinics where cleanliness is paramount. They can handle exposure to various chemicals without degrading.

International Considerations: Buyers should look for compliance with specific health and safety regulations in their region, ensuring that the stainless steel used meets standards like ASTM A240.

What Benefits Does Galvanized Steel Offer for Bedside Lockers?

Key Properties: Galvanized steel is coated with a layer of zinc to enhance its corrosion resistance. This makes it suitable for outdoor use and in humid environments.

Pros & Cons: The galvanization process provides a cost-effective solution for durability against rust. However, it can be less aesthetically pleasing compared to stainless steel, and the coating can wear off over time if subjected to harsh conditions.

Impact on Application: Galvanized steel is ideal for applications where lockers may be exposed to moisture, such as in coastal regions or outdoor settings.

International Considerations: Buyers should ensure that the galvanization process meets local standards to guarantee the longevity of the product, particularly in regions with high humidity or salt exposure.

Summary Table of Material Selection for Bedside Lockers

| Material | Typical Use Case for bedside locker metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General-purpose lockers | High strength and durability | Susceptible to rust without treatment | Medium |

| Aluminum | Lightweight, mobile applications | Lightweight and corrosion-resistant | Higher cost and lower structural strength | High |

| Stainless Steel | Healthcare and high-hygiene environments | Exceptional corrosion resistance | Higher cost compared to other metals | High |

| Galvanized Steel | Outdoor and humid environments | Cost-effective corrosion resistance | Aesthetic limitations and wear over time | Medium |

This guide aims to provide B2B buyers with the insights necessary to make informed decisions regarding material selection for bedside lockers, ensuring compliance with local standards and suitability for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for bedside locker metal

What Are the Key Stages in the Manufacturing Process of Bedside Lockers Made of Metal?

The manufacturing of bedside lockers involves several critical stages that ensure the final product meets durability, functionality, and aesthetic standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used and How Are They Prepared?

The primary materials used in the production of metal bedside lockers are typically steel or aluminum, chosen for their strength and durability. The material preparation phase includes sourcing high-quality sheets or coils of metal, which are then subjected to processes like cutting, shearing, and deburring to achieve the desired dimensions and remove sharp edges.

In many facilities, automated machines are employed for precision cutting, ensuring uniformity in the components. The materials may also undergo pre-treatment processes such as galvanization or powder coating, which not only enhance corrosion resistance but also allow for a variety of finishes and colors.

What Forming Techniques Are Commonly Used in Manufacturing Metal Lockers?

Once the materials are prepared, the next step is forming. This involves shaping the metal into the locker components, such as the body, doors, and shelves. The most common techniques include:

- Stamping: This process uses a die to press metal sheets into specific shapes. It’s efficient for producing large quantities of identical parts.

- Bending: Metal sheets are bent using hydraulic or mechanical presses to create angles and contours needed for the locker design.

- Welding: Components are joined using welding techniques such as MIG or TIG welding, ensuring structural integrity and durability.

These forming techniques are crucial for creating a robust product that can withstand daily use in various environments, including hospitals, schools, and homes.

How Are Bedside Lockers Assembled and Finished?

The assembly stage involves combining all formed components into a complete bedside locker. This may include attaching doors with hinges, installing locking mechanisms, and adding shelves. Quality assembly is vital; any misalignment can lead to functional issues and affect the aesthetic appeal of the product.

After assembly, the finishing process begins. This can involve additional powder coating or painting to provide an attractive finish and further protect against wear and tear. Final touches may include the installation of accessories like drawer pulls and locking systems, ensuring that the product is not only functional but also visually appealing.

What Quality Assurance Measures Are Essential for Metal Bedside Lockers?

Quality assurance (QA) is critical in the manufacturing of metal bedside lockers, ensuring that products meet international standards and customer expectations. Several QA measures are commonly implemented throughout the production process.

Which International Standards Should B2B Buyers Consider?

For B2B buyers, understanding relevant international standards is crucial. ISO 9001 is the most recognized quality management standard, focusing on consistent quality and continuous improvement. Compliance with ISO 9001 indicates that the manufacturer has established a quality management system that meets international benchmarks.

In addition to ISO standards, specific product certifications such as CE marking may be relevant, especially for products sold within the European Union. CE marking signifies that the product meets health, safety, and environmental protection standards.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure product integrity. The primary checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility. Materials are assessed for quality and compliance with specifications before being used in production.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process. This includes checking dimensions, alignment, and weld quality to catch any deviations early.

-

Final Quality Control (FQC): Once the lockers are assembled, a comprehensive inspection is performed. This includes functional tests, aesthetic evaluations, and ensuring that all components meet specified standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers maintain rigorous quality control practices. Here are some strategies for verification:

What Steps Can Buyers Take to Audit Suppliers Effectively?

-

Supplier Audits: Conduct on-site audits to review the manufacturing process, quality control measures, and compliance with international standards. This allows buyers to assess the supplier’s capabilities firsthand.

-

Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, including inspection reports and compliance certificates. Reviewing these documents can give buyers confidence in the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s products and processes. These agencies can conduct inspections at various stages, from material sourcing to final product delivery.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from different regions may face unique challenges regarding quality control. For instance, buyers in Africa or South America might encounter difficulties in accessing reliable suppliers or verifying certifications due to varying regulatory environments.

To navigate these challenges, buyers should:

-

Understand Regional Regulations: Familiarize themselves with local standards and regulations applicable to metal products in their region. This knowledge can help in selecting suppliers who comply with relevant laws.

-

Build Relationships with Trusted Suppliers: Establishing long-term partnerships with reputable suppliers can facilitate better communication and ensure consistent quality over time.

-

Leverage Technology: Utilizing digital tools for supply chain management and quality control can enhance transparency and tracking, allowing buyers to monitor product quality effectively.

In conclusion, understanding the manufacturing processes and quality assurance measures associated with metal bedside lockers equips B2B buyers to make informed decisions. By focusing on material preparation, forming techniques, assembly, finishing, and rigorous quality control, buyers can ensure they procure durable and reliable products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bedside locker metal’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring metal bedside lockers efficiently. Given the diverse markets in regions such as Africa, South America, the Middle East, and Europe, it is essential to follow a structured approach to ensure you choose the right products and suppliers. This checklist will help you navigate the complexities of sourcing metal bedside lockers, focusing on quality, compliance, and supplier reliability.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is crucial for meeting your operational needs. Consider factors such as dimensions, materials, color options, and locking mechanisms. This step will help ensure that the lockers not only fit your aesthetic requirements but also comply with safety standards relevant to your industry.

- Dimensions: Specify the height, width, and depth based on intended use.

- Material: Decide on the type of metal, such as steel or aluminum, for durability.

- Features: Include any additional features like adjustable shelves or cable management systems.

Step 2: Research Market Trends

Understanding current market trends can inform your purchasing decisions and help you negotiate better. Stay updated on popular designs, materials, and functionalities that are in demand in your target regions. This knowledge will enhance your sourcing strategy and ensure your offerings remain competitive.

- Color Trends: Identify popular colors that resonate with your customer base.

- Design Preferences: Consider whether customers prefer minimalist designs or more robust, industrial looks.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet potential suppliers thoroughly. Request company profiles, case studies, and references from other businesses within your industry or region. This step helps ensure you choose a supplier with a solid reputation and reliable delivery timelines.

- Supplier Background: Look for suppliers with experience in manufacturing metal furniture.

- References: Ask for customer testimonials or case studies that reflect the supplier’s reliability and product quality.

Step 4: Verify Compliance and Certifications

Ensure that your selected suppliers comply with international quality standards and regulations. Certifications such as ISO 9001 for quality management and ISO 14001 for environmental management can indicate a supplier’s commitment to quality and sustainability.

- Safety Standards: Confirm that the products meet safety regulations relevant to your industry.

- Environmental Compliance: Inquire about the supplier’s practices regarding sustainable sourcing and manufacturing.

Step 5: Request Samples

Before finalizing your order, request samples of the metal bedside lockers. This allows you to assess the quality, finish, and functionality first-hand. Evaluating samples can prevent costly mistakes and ensure the product meets your expectations.

- Quality Check: Inspect the durability and overall craftsmanship of the sample.

- Functionality Test: Ensure locking mechanisms and hinges operate smoothly.

Step 6: Negotiate Terms and Pricing

Once you are satisfied with the samples, engage in negotiations regarding pricing, payment terms, and delivery schedules. Building a good relationship with your supplier can lead to better deals and more flexible terms in the future.

- Bulk Discounts: Inquire about pricing breaks for larger orders.

- Payment Terms: Discuss payment methods that align with your cash flow needs.

Step 7: Plan for Logistics and Delivery

Finally, establish a comprehensive logistics plan that outlines shipping methods, delivery timelines, and potential customs requirements. Effective logistics management ensures timely delivery and minimizes the risk of disruptions.

- Shipping Options: Evaluate air freight versus sea freight based on urgency and cost.

- Customs Clearance: Ensure all necessary documentation is prepared to facilitate smooth customs processing.

By following this checklist, B2B buyers can streamline their sourcing process for metal bedside lockers, ensuring they meet both quality standards and market demands.

Comprehensive Cost and Pricing Analysis for bedside locker metal Sourcing

What Are the Key Cost Components in Bedside Locker Metal Sourcing?

When evaluating the cost structure for sourcing bedside lockers made from metal, several components contribute to the overall pricing. Materials typically encompass the type of metal used, such as steel or aluminum, which can vary significantly in price based on quality and availability. Labor costs are influenced by the manufacturing location; regions with lower labor costs can offer competitive pricing, but this often comes at the expense of quality or compliance with international standards.

Manufacturing overhead includes expenses related to factory operations, utilities, and administrative support. Additionally, tooling costs for specialized equipment can be substantial, especially if custom designs are requested. Quality control (QC) measures are essential to ensure the final product meets specified standards, and these costs should not be overlooked. Finally, logistics—including shipping, customs, and handling—play a critical role in the total cost, particularly for international transactions.

How Do Price Influencers Affect Bedside Locker Metal Costs?

Several factors can significantly influence the pricing of bedside lockers. Volume and minimum order quantities (MOQ) can create price breaks; larger orders typically yield lower per-unit costs. Specifications and customization also impact pricing; bespoke designs or unique finishes may lead to higher costs due to additional labor and materials required.

The choice of materials directly affects the price; premium metals or finishes will naturally increase costs. Furthermore, the quality certifications (e.g., ISO, CE) that a supplier holds can be a deciding factor for buyers focused on compliance and safety, potentially affecting the cost structure. Supplier factors, such as reputation, reliability, and historical performance, can also lead to variances in pricing. Lastly, understanding Incoterms is crucial; these terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can substantially affect the final price.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings. Start by gathering multiple quotes to understand the market rate and leverage this data during negotiations. Total Cost of Ownership (TCO) is another critical consideration; beyond the purchase price, factor in logistics, potential tariffs, maintenance, and the product’s lifespan.

When dealing with suppliers, inquire about potential discounts for bulk purchases or long-term contracts, which can provide additional cost savings. Be mindful of pricing nuances that can arise from fluctuations in metal prices and currency exchange rates, which are particularly relevant for international transactions. Establishing a strong relationship with suppliers can also lead to better pricing, improved service, and priority in production schedules.

What Should Buyers Know About Indicative Pricing for Bedside Lockers?

While indicative prices for bedside lockers can range widely based on the factors discussed, it is essential to understand that these figures are not fixed. For instance, basic metal bedside lockers may start around $75 to $125 for standard models, while customized or designer options can exceed $400.

Buyers should approach pricing with the understanding that numerous variables are at play, including market demand, economic conditions, and shipping logistics. Always seek clarity from suppliers on what the quoted price includes and any potential additional costs that may arise during production or shipping.

Alternatives Analysis: Comparing bedside locker metal With Other Solutions

Understanding the Alternatives to Bedside Locker Metal

When selecting storage solutions for bedrooms, hospitals, or offices, understanding the available alternatives to bedside locker metal can empower buyers to make informed decisions. Bedside locker metal offers durability and design, but there are several other options that may suit specific needs or preferences. This analysis compares bedside locker metal against two viable alternatives: wooden nightstands and plastic storage cabinets.

Comparison Table

| Comparison Aspect | Bedside Locker Metal | Wooden Nightstand | Plastic Storage Cabinet |

|---|---|---|---|

| Performance | Highly durable, resistant to wear and tear; ideal for high-traffic areas. | Good durability; susceptible to scratches and water damage. | Generally durable but can crack under stress; lightweight. |

| Cost | Moderate to high cost, typically $100 – $300. | Varies widely, from $50 to over $500 depending on quality and craftsmanship. | Generally lower cost, ranging from $30 to $150. |

| Ease of Implementation | Requires assembly; can be heavier and more challenging to move. | Typically pre-assembled or easy to assemble; lightweight options available. | Usually lightweight and easy to set up; may require minimal assembly. |

| Maintenance | Low maintenance; easy to clean with damp cloth. | Moderate maintenance; needs periodic polishing and care to avoid damage. | Low maintenance; easy to wipe clean but may stain over time. |

| Best Use Case | Ideal for modern, industrial settings or areas needing secure storage. | Best for traditional or rustic decor; suitable for personal items. | Excellent for temporary or casual storage needs; versatile for various settings. |

Pros and Cons of Alternatives

Wooden Nightstands

Wooden nightstands offer a classic and aesthetic appeal, fitting seamlessly into traditional or rustic-themed interiors. They provide a warm, inviting look and can be crafted from various types of wood, enhancing their uniqueness. However, they may require more maintenance to avoid wear from moisture or scratches, and their price can vary significantly based on craftsmanship and materials. For buyers in humid climates or high-traffic areas, wooden options may not be as durable as metal alternatives.

Plastic Storage Cabinets

Plastic storage cabinets present a cost-effective solution for those needing lightweight and versatile storage. They are particularly useful in environments where mobility is key, such as schools or temporary setups. These cabinets can handle a variety of items, from toys to office supplies, and require minimal maintenance. However, they may not offer the same level of durability as metal or wood, making them less suitable for high-stress environments. Additionally, their aesthetic appeal may be lower, limiting their use in more design-focused settings.

Conclusion: How to Choose the Right Solution

Selecting the right storage solution depends on the specific requirements of the user. Buyers should consider factors such as the intended use, environmental conditions, and aesthetic preferences. For environments requiring robust, secure storage, bedside locker metal may be the best choice. Conversely, for a more traditional look or cost-effective solution, wooden nightstands could be preferable. For casual or temporary storage needs, plastic cabinets offer flexibility and ease. By carefully weighing these alternatives against their unique needs, B2B buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for bedside locker metal

What Are the Key Technical Properties of Bedside Locker Metal?

When sourcing bedside lockers, understanding their technical specifications is crucial for making informed purchasing decisions. Here are several essential properties to consider:

-

Material Composition

Bedside lockers are typically constructed from various grades of metal, with steel and aluminum being the most common. Steel lockers offer durability and strength, making them suitable for heavy-use environments, while aluminum lockers are lightweight and resistant to rust, ideal for humid conditions. Buyers should consider the specific application and choose a material that meets their durability and aesthetic requirements. -

Finish Type

The finish of the metal, such as powder coating or anodizing, greatly influences both appearance and longevity. Powder-coated finishes provide a vibrant color palette and excellent resistance to scratches and corrosion, making them ideal for environments where aesthetics are essential. Anodized finishes enhance corrosion resistance and are often used for aluminum lockers, adding to their lifespan. -

Dimensions and Tolerance

Standard dimensions for bedside lockers typically range in height, width, and depth, but custom sizes can be specified to fit unique spaces. Tolerance refers to the allowable deviation in these dimensions, which is critical for ensuring that the lockers fit seamlessly into designated areas. Precision in dimensions is essential for ease of installation and optimal functionality. -

Locking Mechanism

Security features are vital, especially in environments like hospitals or educational institutions. Bedside lockers may come with various locking mechanisms, including padlocks, key locks, or electronic locks. Understanding the security requirements of the end-users will guide the choice of locking mechanism, balancing accessibility and security. -

Weight Capacity

The weight capacity of a bedside locker determines how much it can safely hold without compromising its structural integrity. This specification is particularly important in environments where lockers may be used to store heavy items like books or medical supplies. Buyers should evaluate the expected load to ensure the chosen model meets these needs. -

Mobility Features

Some bedside lockers come with wheels or casters for easy relocation. This feature is especially beneficial in dynamic environments like hospitals where furniture arrangements may frequently change. Understanding the mobility options can enhance the utility of the locker in various settings.

Which Trade Terminology Should B2B Buyers Understand for Bedside Locker Metal?

Familiarity with industry terminology can streamline procurement processes and improve negotiations. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bedside lockers, sourcing from an OEM can lead to better quality assurance and customization options. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs can help buyers plan their purchases effectively, ensuring they meet supplier requirements while avoiding excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specified products. For bedside lockers, an RFQ can help buyers compare costs and negotiate better terms, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Familiarity with these terms can help buyers understand shipping responsibilities, costs, and risk management when importing bedside lockers from overseas. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. Knowing the lead time is crucial for planning inventory and ensuring that delivery aligns with operational needs. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of a product. Understanding warranty terms can help buyers assess the reliability of bedside lockers and plan for potential replacements or repairs.

By grasping these technical properties and trade terminologies, B2B buyers can make more strategic decisions when sourcing bedside lockers, ensuring they select products that meet their specific needs and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the bedside locker metal Sector

What Are the Current Market Dynamics and Key Trends in the Bedside Locker Metal Sector?

The bedside locker metal market is experiencing a notable evolution driven by several global factors. Urbanization and the increasing demand for multifunctional furniture are propelling growth, particularly in regions like Africa, South America, the Middle East, and Europe. As cities expand, compact living spaces necessitate innovative storage solutions that combine style and utility. Furthermore, the rise of e-commerce has transformed sourcing dynamics, enabling international B2B buyers to access a broader range of products and suppliers from diverse geographical locations, such as Vietnam and Germany.

Technological advancements in manufacturing processes are also reshaping the market. Automation and smart technologies are making production more efficient, allowing for quicker turnaround times and customization options that cater to varying consumer preferences. For instance, the integration of smart features, such as charging ports and built-in lighting, is becoming increasingly popular in bedside lockers, enhancing their functionality and appeal.

Emerging trends such as industrial design aesthetics are gaining traction, with many buyers favoring rugged, minimalist styles that reflect contemporary tastes. Color options and finishes are expanding, allowing for personalization that meets the demands of different markets. Additionally, there is a growing focus on collaboration between manufacturers and designers to create unique, market-specific products, which is crucial for international buyers looking to differentiate their offerings.

How Is Sustainability and Ethical Sourcing Influencing the Bedside Locker Metal Market?

Sustainability and ethical sourcing are becoming paramount in the bedside locker metal sector as consumers and businesses increasingly prioritize environmental responsibility. The production of metal furniture can have significant environmental impacts, including carbon emissions and resource depletion. As a result, many manufacturers are adopting eco-friendly practices, such as using recycled materials and implementing energy-efficient production methods.

B2B buyers are encouraged to seek suppliers that offer ‘green’ certifications and materials, which signify adherence to sustainability standards. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can help buyers identify environmentally responsible manufacturers. Moreover, ethical supply chains are crucial; transparency in sourcing materials and labor practices can enhance brand reputation and consumer trust.

As awareness of environmental issues rises, products that combine style with sustainability are gaining a competitive edge. Buyers should consider the lifecycle of products, including durability and recyclability, which can significantly impact long-term value. By prioritizing sustainability, businesses not only contribute to environmental conservation but also appeal to a growing demographic of eco-conscious consumers.

How Has the Bedside Locker Metal Sector Evolved Over Time?

The bedside locker metal sector has a rich history that reflects broader societal changes and technological advancements. Initially designed for practical use in schools and industrial settings, metal lockers evolved into more versatile pieces of furniture that cater to modern living spaces. In the mid-20th century, as urbanization increased, the demand for compact and multifunctional furniture surged, giving rise to bedside lockers that blend storage with aesthetic appeal.

Over time, materials and design philosophies have shifted significantly. The introduction of powder-coated finishes not only improved durability but also opened up a spectrum of color options, aligning with contemporary interior design trends. Today, bedside lockers are crafted to meet diverse consumer needs, ranging from children’s rooms to sophisticated adult spaces, showcasing the sector’s adaptability and innovation.

This evolution underscores the importance of understanding market dynamics and sourcing trends, enabling international B2B buyers to make informed decisions that align with current consumer preferences and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of bedside locker metal

-

How do I choose the right supplier for bedside locker metal?

When selecting a supplier for bedside locker metal, consider their experience, reputation, and production capabilities. Request samples to assess the quality of their products, and check for certifications that demonstrate compliance with international standards. It’s also beneficial to read reviews and testimonials from other B2B clients. Establish clear communication channels to ensure that the supplier can meet your specific needs, including customization options and delivery timelines. Engaging with multiple suppliers can help you compare pricing and service levels. -

What customization options are available for bedside locker metal?

Most manufacturers offer a range of customization options for bedside lockers, including size, color, and design features like lock mechanisms or shelving configurations. It’s essential to communicate your specific requirements early in the negotiation process. Some suppliers may also provide bespoke designs to match your branding or specific functional needs. Inquire about the minimum order quantities (MOQs) for customized items, as this can affect your purchasing strategy. -

What are the typical minimum order quantities (MOQs) for bedside locker metal?

Minimum order quantities can vary significantly between suppliers and depend on factors such as material costs and production capacity. Generally, MOQs for bedside locker metal may range from 50 to 200 units. It’s advisable to clarify these terms upfront to align your inventory needs with the supplier’s capabilities. Some manufacturers may be willing to negotiate MOQs, particularly for first-time buyers or larger orders. -

What payment terms should I expect when sourcing bedside locker metal?

Payment terms can differ widely among suppliers. Standard practices often include a deposit (typically 30% to 50%) upfront, with the balance due upon delivery or prior to shipment. It’s crucial to negotiate terms that suit your cash flow requirements. Also, consider using secure payment methods such as letters of credit or escrow services, especially for large transactions, to mitigate risks associated with international trade. -

How can I ensure quality assurance for bedside lockers?

To ensure quality assurance, request detailed product specifications and quality control processes from your supplier. Many manufacturers perform inspections at various stages of production, including raw material sourcing, in-process checks, and final inspections. Consider conducting third-party quality audits or inspections, especially for larger orders. Establish clear return policies and warranty agreements to protect your investment. -

What logistics considerations should I keep in mind when importing bedside lockers?

Logistics is a critical aspect of international sourcing. Assess the shipping options available, including air and sea freight, and factor in transit times and costs. Understand the customs regulations in your country to avoid delays and additional fees. Collaborate with a freight forwarder who has experience in handling furniture imports to streamline the shipping process and ensure compliance with import regulations. -

What are the advantages of using metal bedside lockers compared to other materials?

Metal bedside lockers offer numerous advantages, including durability, security, and ease of maintenance. They are resistant to wear and tear, making them ideal for high-traffic environments like hotels or hospitals. Metal is also less susceptible to damage from moisture or pests compared to wood or plastic options. Additionally, many metal designs incorporate locking mechanisms for added security, which is particularly beneficial in shared living spaces. -

How do I assess the market demand for bedside locker metal in my region?

To assess market demand, conduct thorough market research, including competitor analysis and customer surveys. Utilize industry reports and trade publications to gauge trends and preferences in your target markets, particularly in regions like Africa, South America, and Europe. Engaging with local distributors or retailers can provide insights into consumer behavior and pricing strategies. Additionally, consider attending trade shows or exhibitions to network and gather firsthand information on emerging trends in the furniture sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Bedside Locker Metal Manufacturers & Suppliers List

1. Mustard Made – Shorty Locker

Domain: mustardmade.com

Registered: 2017 (8 years)

Introduction: The Shorty Locker is available in multiple colors including Blush, Berry, Poppy, Mustard, Butter, Sage, Olive, Navy, Ocean, Lilac, Chalk, and Slate. Each color option is priced at $229. The locker comes in right and left opening options, making it suitable for various placements such as beside a bed, desk, or couch. Mustard Made focuses on creating practical and aesthetically pleasing storage solu…

2. Teksi – Light Blue Metal Bedside Table

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Light Blue Metal Bedside Table with Door – Teksi – Industrial Metal Locker Style Cabinet – Internal Shelf For 2 Tiers – Suitable for Bedroom Storage and Living Room End Table – Modern Design

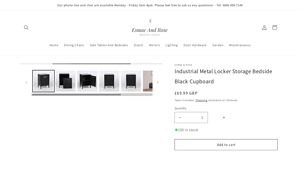

3. Esmae and Rose – Industrial Metal Locker Storage Bedside Black Cupboard

Domain: esmaeandrose.com

Registered: 2024 (1 years)

Introduction: {“product_name”: “Industrial Metal Locker Storage Bedside Black Cupboard”, “price”: “£69.99 GBP”, “product_id”: “ER”, “sku”: “ID735”, “dimensions”: {“height”: “58 cm”, “width”: “41 cm”, “depth”: “31.5 cm”}, “assembly_required”: true, “material”: “Metal”, “delivery_info”: “FREE delivery to UK mainland. Orders usually processed and shipped within 1 working day, aiming for same day dispatch if ordere…

Strategic Sourcing Conclusion and Outlook for bedside locker metal

In conclusion, the strategic sourcing of metal bedside lockers offers significant opportunities for international B2B buyers. As highlighted, the diverse range of styles, sizes, and functionalities available caters to various market needs, from residential settings to commercial environments. The emphasis on durable materials, such as powder-coated metal, enhances product longevity while also providing aesthetic appeal, which is crucial in competitive markets.

Effective sourcing strategies not only ensure quality and reliability but also allow businesses to leverage cost advantages. By tapping into emerging markets in Africa, South America, the Middle East, and Europe, companies can access innovative designs and manufacturing capabilities that align with current consumer trends.

Looking forward, the demand for stylish and functional storage solutions will continue to grow. B2B buyers are encouraged to explore partnerships with manufacturers that offer customization options and sustainable practices. By doing so, they can enhance their product offerings and meet the evolving preferences of their clientele. Embrace the potential of metal bedside lockers today to stay ahead in this dynamic market.