The Definitive Guide to Battery Test Chambers: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for battery test chambers

Navigating the global market for battery test chambers presents a significant challenge for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. As the demand for reliable and safe battery technologies surges—driven by the increasing reliance on electric vehicles and portable electronic devices—sourcing the right battery test chambers becomes critical. These chambers are essential for simulating extreme environmental conditions to ensure that batteries perform safely and effectively, thereby minimizing risks associated with battery failure.

This guide comprehensively explores the landscape of battery test chambers, detailing various types, applications, and industry standards. It will empower international buyers by providing insights into supplier vetting processes, cost considerations, and the latest innovations in battery testing technology. From understanding the safety features that protect against thermal runaway to selecting chambers that meet specific testing requirements, this guide serves as a valuable resource for making informed purchasing decisions.

With a focus on delivering actionable insights tailored to diverse markets, this guide is designed to help you navigate the complexities of battery test chamber procurement. By equipping you with the knowledge to assess your options and align your needs with the right solutions, we aim to enhance your operational efficiency and drive your success in the competitive battery technology sector.

Understanding battery test chambers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Environmental Test Chambers | Simulates extreme temperature and humidity conditions | R&D for consumer electronics, automotive | Pros: Accurate simulation; Cons: Higher initial investment. |

| Safety Test Chambers | Equipped with advanced safety features to prevent thermal runaway | Electric vehicle battery testing, aerospace | Pros: Enhanced safety; Cons: May require specialized training. |

| High-Throughput Test Chambers | Allows simultaneous testing of multiple cells | Mass production of batteries, energy storage | Pros: Increased efficiency; Cons: Higher maintenance costs. |

| Compact Test Chambers | Space-saving designs ideal for small labs | Startups and small-scale R&D | Pros: Cost-effective; Cons: Limited capacity. |

| Customizable Test Chambers | Tailored configurations for specific testing needs | Specialized applications, research institutions | Pros: Flexibility in testing; Cons: Longer lead time for delivery. |

What Are Environmental Test Chambers and Their Benefits for B2B Buyers?

Environmental test chambers are designed to replicate extreme temperature and humidity conditions that batteries may encounter in real-world applications. These chambers are essential for research and development in sectors such as consumer electronics and automotive, where understanding battery performance under stress is critical. Buyers should consider the chamber’s temperature range, humidity control capabilities, and overall build quality to ensure they meet their testing requirements.

How Do Safety Test Chambers Enhance Battery Testing?

Safety test chambers are specifically engineered with advanced safety features to mitigate risks such as thermal runaway and explosions during testing. These chambers are particularly vital for industries focused on electric vehicle battery testing and aerospace applications. When selecting a safety test chamber, B2B buyers should prioritize features like gas monitoring systems and fire suppression mechanisms, which can significantly enhance operational safety.

Why Choose High-Throughput Test Chambers?

High-throughput test chambers allow for the simultaneous testing of multiple battery cells, making them ideal for mass production environments and energy storage applications. These chambers are designed for efficiency, enabling companies to accelerate their testing processes and reduce time-to-market for new products. Buyers should evaluate the chamber’s capacity and compatibility with existing testing equipment to optimize their production lines.

What Advantages Do Compact Test Chambers Offer?

Compact test chambers are designed for space efficiency, making them suitable for smaller laboratories or organizations with limited floor space. They are particularly beneficial for startups and small-scale R&D operations that require reliable testing solutions without a significant capital investment. When considering a compact chamber, buyers should assess the chamber’s performance specifications to ensure it meets their testing needs despite its smaller size.

How Can Customizable Test Chambers Meet Unique Testing Needs?

Customizable test chambers offer tailored configurations to address specific testing requirements, making them suitable for specialized applications in research institutions and innovative projects. These chambers can be adapted to meet unique environmental conditions or testing protocols. B2B buyers should consider the flexibility of the design and the lead time for customization when selecting a chamber, as this can impact project timelines and costs.

Key Industrial Applications of battery test chambers

| Industry/Sector | Specific Application of Battery Test Chambers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Testing lithium-ion batteries for electric vehicles (EVs) | Ensures battery reliability and safety under various conditions | Compliance with international safety standards and regulations |

| Consumer Electronics | Evaluating performance of batteries in portable devices | Enhances product safety and consumer trust | Size and capacity to accommodate diverse battery types |

| Renewable Energy | Testing energy storage systems for solar and wind applications | Optimizes performance and longevity of storage solutions | Environmental controls for temperature and humidity |

| Aerospace | Assessing battery performance under extreme conditions | Guarantees reliability in critical applications | High safety standards and advanced monitoring systems |

| Telecommunications | Testing backup power systems for telecom infrastructure | Ensures uninterrupted service and operational reliability | Integration with existing testing equipment |

How Are Battery Test Chambers Used in the Automotive Industry?

In the automotive sector, battery test chambers are essential for testing lithium-ion batteries used in electric vehicles (EVs). These chambers simulate extreme temperatures and cycling conditions, allowing manufacturers to assess the reliability and safety of their batteries. By ensuring compliance with international safety standards, businesses can mitigate risks associated with battery failure, ultimately enhancing consumer confidence and driving sales. International buyers should prioritize chambers that meet regulatory requirements specific to their region, such as UL and IEC standards.

What Role Do Battery Test Chambers Play in Consumer Electronics?

For the consumer electronics industry, battery test chambers are vital for evaluating the performance of batteries used in portable devices. These chambers help manufacturers test the batteries under various environmental conditions, ensuring they can withstand fluctuations in temperature and humidity. Enhanced safety features in testing processes increase consumer trust in products. Buyers should consider the size and capacity of the chambers to accommodate different battery types, ensuring flexibility in testing protocols.

How Are Battery Test Chambers Beneficial for Renewable Energy Applications?

In renewable energy, battery test chambers are crucial for testing energy storage systems that support solar and wind applications. These chambers simulate real-world conditions to optimize the performance and longevity of batteries, ensuring they can handle the demands of energy storage. The ability to conduct precise testing helps businesses innovate and improve their products. Buyers should focus on sourcing chambers with advanced environmental controls that can maintain specific temperature and humidity levels, which are critical for accurate testing.

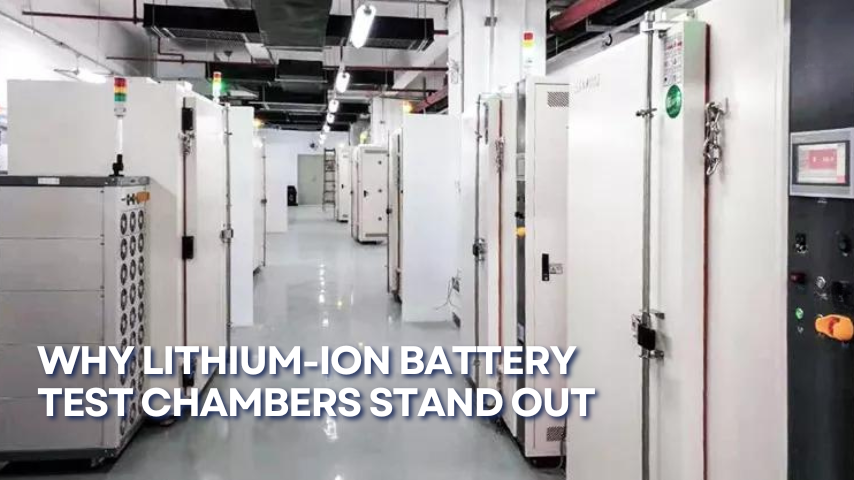

Illustrative image related to battery test chambers

What Is the Importance of Battery Test Chambers in the Aerospace Sector?

In the aerospace industry, battery test chambers are employed to assess battery performance under extreme conditions, including high altitudes and temperature variations. The reliability of battery systems in this sector is paramount, as failures can have catastrophic consequences. These chambers enable thorough testing to ensure that batteries meet rigorous safety standards. Buyers should prioritize chambers equipped with advanced monitoring systems and safety features to protect both personnel and equipment during testing.

How Do Battery Test Chambers Support Telecommunications Reliability?

Battery test chambers are utilized in the telecommunications sector to test backup power systems that ensure uninterrupted service. By simulating various environmental conditions, these chambers help verify that batteries can perform reliably during outages or peak usage times. This testing is crucial for maintaining operational reliability and customer satisfaction. Buyers should consider sourcing chambers that can integrate seamlessly with existing testing equipment, facilitating a streamlined testing process.

3 Common User Pain Points for ‘battery test chambers’ & Their Solutions

Scenario 1: Inconsistent Testing Conditions Compromise Results

The Problem: Many companies face challenges with inconsistent environmental conditions when using battery test chambers. Variability in temperature and humidity can lead to unreliable test results, which may compromise product safety and performance. For B2B buyers in industries like electric vehicles or consumer electronics, this inconsistency can hinder compliance with stringent safety regulations and testing standards, causing delays in product launches and increased costs due to re-testing.

The Solution: To ensure consistency, it is crucial to select a battery test chamber equipped with advanced environmental controls. Look for chambers that feature precise temperature and humidity control systems, allowing for detailed monitoring and adjustments during testing. When specifying your requirements, consider chambers with integrated data logging capabilities that document environmental conditions throughout the test cycle. This not only facilitates better compliance with industry standards but also provides a historical record to troubleshoot any anomalies. Collaborating with a reputable manufacturer who offers customizable solutions can help you tailor the chamber to your specific testing needs, ensuring reliable and repeatable results.

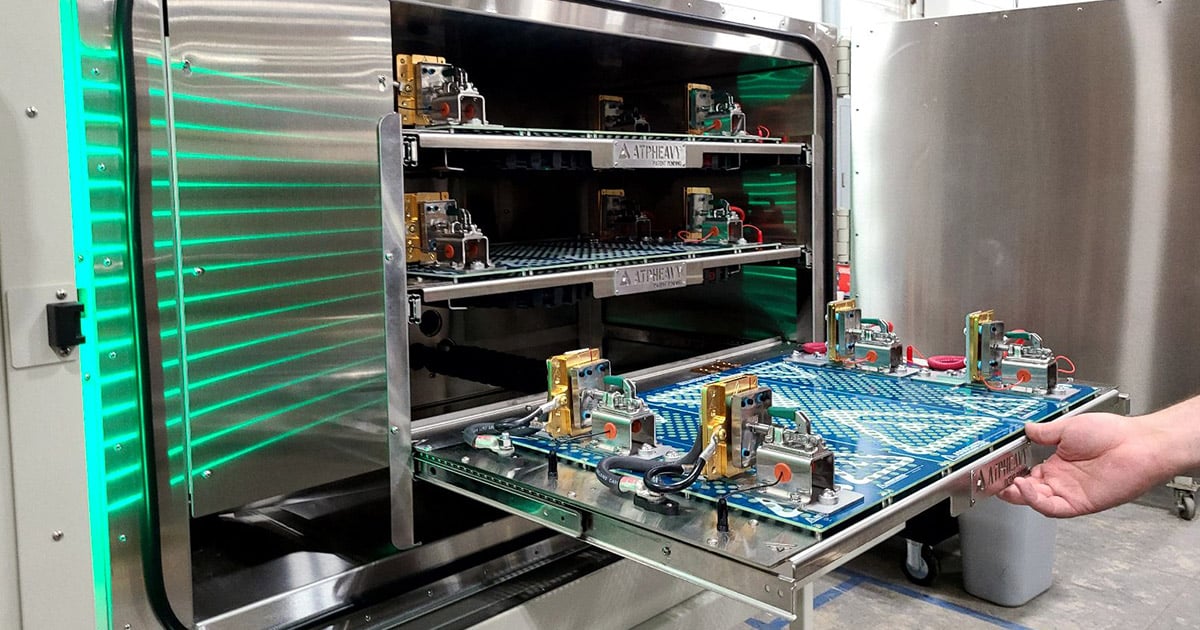

Illustrative image related to battery test chambers

Scenario 2: Safety Concerns During High-Pressure Tests

The Problem: Safety is a paramount concern when testing high-energy batteries, particularly lithium-ion cells, which can pose risks of thermal runaway or explosion if not handled properly. B2B buyers, especially those in industries such as aerospace or automotive, may worry about the safety of their personnel and facilities during rigorous testing processes. The potential for hazardous incidents can lead to increased insurance costs and reputational damage.

The Solution: Investing in battery test chambers that come equipped with comprehensive safety features is essential. Look for chambers that include gas monitoring systems, pressure relief ports, and fire suppression mechanisms. It is advisable to conduct a thorough risk assessment and choose chambers that offer customizable safety options based on your specific testing scenarios. Additionally, training your personnel on proper operational procedures and emergency protocols can significantly mitigate risks. Regular maintenance checks and adherence to safety standards will further enhance the safety of your testing environment, ensuring peace of mind for both employees and stakeholders.

Scenario 3: High Operational Costs Due to Inefficient Systems

The Problem: B2B buyers often encounter high operational costs associated with inefficient battery testing systems. This can stem from outdated equipment that requires frequent repairs, excessive energy consumption, or a lack of integration with battery testing protocols. These inefficiencies not only drain resources but can also slow down product development timelines, leading to missed market opportunities.

The Solution: To combat high operational costs, consider investing in fully integrated battery testing solutions that combine testing chambers with advanced monitoring and control systems. Seek out manufacturers that offer modular designs, allowing for scalability as your testing needs grow. Implementing energy-efficient chambers can also significantly reduce utility costs; look for models with optimized airflow and insulation to minimize energy waste. Furthermore, establishing a maintenance schedule can prevent costly breakdowns and extend the lifespan of your equipment. By streamlining operations and investing in modern technology, your company can enhance productivity while managing costs effectively.

Strategic Material Selection Guide for battery test chambers

What Are the Key Properties of Common Materials Used in Battery Test Chambers?

When selecting materials for battery test chambers, several factors determine their suitability, including temperature and pressure ratings, corrosion resistance, and mechanical strength. Understanding these properties is crucial for ensuring optimal performance and safety during testing processes.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and high-temperature tolerance, making it ideal for environments where battery testing may involve chemical exposure or extreme temperatures.

Pros & Cons:

– Pros: Highly durable and resistant to rust, stainless steel also provides structural integrity under pressure. Its surface can be easily cleaned, which is essential for maintaining hygiene in testing environments.

– Cons: The primary drawback is its cost, which can be higher than other materials. Additionally, the manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with various media, including corrosive chemicals, making it suitable for diverse battery testing scenarios.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local and international standards such as ASTM and ISO, which often specify material requirements for safety and performance.

2. Aluminum

Key Properties: Aluminum is lightweight, has good thermal conductivity, and offers moderate corrosion resistance. It can withstand a range of temperatures, making it versatile for different testing conditions.

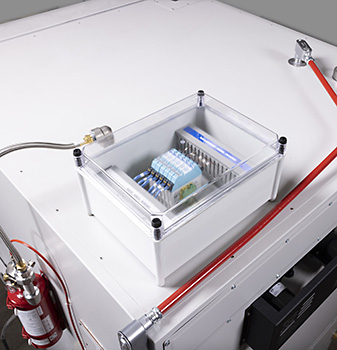

Illustrative image related to battery test chambers

Pros & Cons:

– Pros: The lightweight nature of aluminum allows for easier handling and installation. It is generally less expensive than stainless steel, making it a cost-effective choice for many applications.

– Cons: While it has decent corrosion resistance, aluminum can oxidize in certain environments, potentially leading to structural weaknesses over time.

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as portable battery test chambers. However, care must be taken regarding its exposure to harsh chemicals.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of specific regulations regarding aluminum use in manufacturing, particularly concerning environmental impact and recycling.

3. Polycarbonate

Key Properties: Polycarbonate is a strong, impact-resistant thermoplastic that can withstand a wide temperature range. It is also transparent, allowing for visual monitoring of tests.

Pros & Cons:

– Pros: This material is lightweight and offers excellent impact resistance, making it ideal for safety in environments where battery failure may occur. Its transparency aids in monitoring without opening the chamber.

– Cons: Polycarbonate can be susceptible to scratching and may degrade under prolonged exposure to UV light, which could limit its lifespan in outdoor or high-UV environments.

Impact on Application: Ideal for applications requiring visibility, polycarbonate is often used in test chambers designed for safety assessments.

Considerations for International Buyers: Compliance with safety standards is critical, particularly in regions like Europe, where stringent regulations govern materials used in testing environments.

4. Fiberglass Reinforced Plastic (FRP)

Key Properties: FRP combines plastic with glass fibers to enhance strength and durability while remaining lightweight. It is resistant to corrosion and can withstand a variety of chemicals.

Illustrative image related to battery test chambers

Pros & Cons:

– Pros: FRP is highly resistant to chemical attacks, making it suitable for environments where battery tests may involve corrosive substances. Its lightweight nature also aids in installation and mobility.

– Cons: The initial cost can be moderate to high, and the manufacturing process may be complex, requiring specialized techniques.

Impact on Application: FRP is particularly beneficial for battery test chambers that need to endure harsh chemical environments without compromising structural integrity.

Considerations for International Buyers: Buyers should check for compliance with local standards, especially in regions like Brazil, where specific regulations may dictate material properties for safety and environmental considerations.

Summary Table of Material Selection for Battery Test Chambers

| Material | Typical Use Case for battery test chambers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-temperature and chemical exposure | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Lightweight portable chambers | Cost-effective and easy to handle | Can oxidize in harsh environments | Medium |

| Polycarbonate | Chambers requiring visibility | Impact-resistant and lightweight | Susceptible to UV degradation | Medium |

| Fiberglass Reinforced Plastic (FRP) | Chemical-resistant environments | Highly resistant to chemicals | Moderate to high cost | Medium |

This material selection guide provides a comprehensive overview for international B2B buyers to make informed decisions when sourcing battery test chambers, ensuring safety, compliance, and optimal performance in various testing scenarios.

In-depth Look: Manufacturing Processes and Quality Assurance for battery test chambers

What Are the Main Stages in the Manufacturing Process of Battery Test Chambers?

The manufacturing of battery test chambers involves several key stages that ensure both performance and safety standards are met. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation:

The first step is sourcing high-quality materials such as aluminum, stainless steel, and specialized insulation that can withstand extreme temperatures and pressures. Suppliers often provide certifications to ensure compliance with international standards, which is crucial for B2B buyers concerned about quality.

Forming:

Once materials are prepared, they undergo forming processes that can include cutting, bending, and welding. Precision is critical in this stage, as any deviation can affect the chamber’s performance. Advanced techniques like CNC machining are often employed to ensure that components meet exact specifications.

Assembly:

After forming, the components are assembled into the final product. This stage often involves integrating various safety features like gas monitoring systems, fire suppression systems, and pressure relief ports. Technicians must follow detailed assembly protocols to ensure that every unit is built to specification, reducing the risk of operational failures during testing.

Finishing:

The final stage includes surface treatment, painting, and installation of electronic controls. Finishing processes not only enhance aesthetics but also protect against corrosion and wear. Quality checks are integral at this stage to ensure that all parts function correctly and meet environmental standards.

Which Key Techniques Are Used in the Manufacturing of Battery Test Chambers?

Various techniques are employed throughout the manufacturing process to enhance the reliability and safety of battery test chambers.

Precision Engineering:

Manufacturers use precision engineering techniques to create components that fit together seamlessly. This reduces air leaks and enhances temperature control, which is critical for accurate testing.

Modular Design:

Many manufacturers utilize a modular design approach, allowing for easy upgrades and maintenance. This flexibility is particularly valuable for B2B clients who may need to scale their testing capabilities over time.

Automation and Robotics:

Automation plays a significant role in the assembly process, minimizing human error and increasing efficiency. Robotics are often used for repetitive tasks, ensuring a consistent quality across all units produced.

What Quality Control Measures Are Relevant for Battery Test Chambers?

Quality control (QC) is paramount in the manufacturing of battery test chambers, especially given the potential hazards associated with battery testing. Several international standards and industry-specific certifications guide QC measures.

Illustrative image related to battery test chambers

International Standards:

ISO 9001 is widely recognized as a benchmark for quality management systems. Manufacturers often pursue this certification to demonstrate their commitment to quality. Compliance with ISO standards assures B2B buyers of consistent production quality and effective management processes.

Industry-Specific Certifications:

Certifications such as CE (Conformité Européenne) indicate compliance with European safety standards, while others like API (American Petroleum Institute) may apply depending on the application. These certifications are crucial for international buyers who must navigate varying regulations across regions.

What Are the Key QC Checkpoints During Manufacturing?

Quality assurance involves multiple checkpoints throughout the manufacturing process.

Incoming Quality Control (IQC):

This initial stage involves inspecting raw materials and components upon arrival. Suppliers must provide certifications and test results to confirm the quality of the materials used in manufacturing.

In-Process Quality Control (IPQC):

During the manufacturing process, regular checks are conducted to ensure that each stage meets predefined quality standards. This includes measuring tolerances, inspecting welds, and ensuring that assembly processes adhere to specifications.

Illustrative image related to battery test chambers

Final Quality Control (FQC):

Once assembly is complete, the final product undergoes rigorous testing to ensure it meets all operational and safety standards. This includes performance testing under simulated environmental conditions, as well as safety checks for features such as gas monitoring and fire suppression systems.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive measures to verify the quality control processes of suppliers to ensure they meet their needs.

Audits and Inspections:

Conducting regular audits of suppliers can reveal insights into their QC practices. Buyers can request to see audit reports, which should cover aspects like compliance with ISO standards and any industry-specific certifications.

Third-Party Inspections:

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s manufacturing processes. These agencies can conduct on-site inspections and test products to verify quality claims.

Documentation and Reporting:

Requesting detailed documentation, including QC reports, test results, and compliance certificates, can help buyers assess the reliability of a supplier. This is particularly important for international transactions, where regulatory compliance can vary significantly.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance.

Regulatory Compliance:

Different countries have varying regulations that can impact product acceptance. Understanding these regulations is crucial for ensuring that battery test chambers meet local safety and performance standards.

Cultural Considerations:

Cultural differences can affect communication and expectations regarding quality. It’s vital for international buyers to establish clear lines of communication with suppliers to address any potential misunderstandings.

Logistics and Supply Chain Transparency:

International shipping can introduce additional risks, such as damage during transit. Buyers should work closely with suppliers to ensure that logistics are handled with care and that adequate insurance is in place.

By understanding these manufacturing and quality assurance processes, B2B buyers can make informed decisions when selecting battery test chambers, ensuring they meet both their operational needs and compliance standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘battery test chambers’

Introduction

In the evolving landscape of battery technology, selecting the right battery test chamber is crucial for ensuring the reliability and safety of battery systems. This guide offers a practical checklist to aid B2B buyers in evaluating their options, considering critical factors such as technical specifications, safety features, and supplier reliability. By following these steps, organizations can make informed decisions that align with their testing requirements and operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing a battery test chamber. Consider factors such as temperature range, humidity control, and the chamber’s size to accommodate your battery types and testing procedures.

- Temperature and Humidity: Identify the extremes your batteries will face to ensure the chamber can replicate these conditions accurately.

- Capacity: Determine the number of cells you need to test simultaneously, as this will influence the size and configuration of the chamber.

Step 2: Assess Compliance with Industry Standards

Battery test chambers must comply with relevant safety and testing standards to ensure reliability and safety in testing procedures. Familiarize yourself with standards such as UL 1642, IEC 62133, and SAE J2464.

- Certification Verification: Ensure that the chamber meets the necessary certifications for your specific applications. This will help mitigate risks associated with battery testing.

- Documentation: Request documentation demonstrating compliance with these standards from potential suppliers.

Step 3: Evaluate Safety Features

Safety is paramount when testing batteries due to the inherent risks, such as thermal runaway or gas emissions. Assess the safety features integrated into the chambers.

- Ventilation and Monitoring Systems: Look for chambers with gas monitoring systems and ventilation blowers to handle potential hazardous gases effectively.

- Emergency Protocols: Ensure the chamber includes fire suppression systems and pressure relief ports for added protection during testing.

Step 4: Research Supplier Track Record

Before making a purchase, thoroughly research potential suppliers to gauge their reputation and reliability. Supplier experience can significantly impact the performance and longevity of your testing equipment.

- Case Studies and References: Request case studies or references from clients in similar industries or regions to understand their experiences with the supplier.

- Industry Experience: Evaluate the supplier’s history in the battery testing sector to ensure they are knowledgeable about the latest technologies and testing methodologies.

Step 5: Request Demonstrations and Samples

Seeing the equipment in action can provide valuable insights into its performance and suitability for your needs. Request demonstrations or sample tests to evaluate the chamber’s capabilities firsthand.

Illustrative image related to battery test chambers

- Testing Procedures: Inquire about the testing protocols used during demonstrations to ensure they align with your requirements.

- User Interface: Assess the ease of use and functionality of the chamber’s controls and interfaces during the demonstration.

Step 6: Evaluate After-Sales Support and Maintenance

Post-purchase support is critical for ensuring the longevity and optimal performance of your battery test chamber. Investigate the supplier’s after-sales service offerings.

- Maintenance Plans: Inquire about regular maintenance schedules and support services to address any potential issues that may arise.

- Training: Confirm if the supplier offers training for your staff on how to operate and maintain the chamber effectively.

Step 7: Compare Pricing and Warranty Options

Finally, while price shouldn’t be the sole deciding factor, it is essential to compare pricing structures and warranty options among different suppliers.

- Total Cost of Ownership: Consider not just the upfront costs but also the long-term expenses associated with maintenance and operation.

- Warranty Terms: Evaluate warranty coverage to understand the extent of protection against defects and failures, which can significantly impact your overall investment.

By following these steps, B2B buyers can ensure they select a battery test chamber that meets their specific needs while providing safety, reliability, and value.

Illustrative image related to battery test chambers

Comprehensive Cost and Pricing Analysis for battery test chambers Sourcing

What Are the Key Cost Components for Battery Test Chambers?

When considering the procurement of battery test chambers, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: High-quality materials are essential for constructing battery test chambers that can withstand extreme conditions. This includes specialized insulation, durable metals, and advanced electronic components, which collectively contribute significantly to the overall cost.

-

Labor: Skilled labor is required for both assembly and quality assurance. The labor costs vary by region, with countries that have a higher wage standard impacting the total price.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial costs for tooling can be substantial, especially for customized chambers. Advanced manufacturing techniques may require specialized tools, which can affect the pricing structure.

-

Quality Control (QC): Rigorous QC processes are critical, particularly for safety-sensitive applications like battery testing. The costs associated with testing and certification add to the overall expenditure but are necessary for ensuring compliance with industry standards.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and weight. International buyers should factor in potential tariffs and import duties, which can significantly affect the total cost.

-

Margin: Suppliers typically include a profit margin that reflects the value of their offerings, expertise, and market conditions. Understanding the margin can provide insight into pricing flexibility during negotiations.

How Do Volume and Specifications Influence Pricing?

Several factors can significantly affect the pricing of battery test chambers:

-

Volume/MOQ: The volume of purchase directly impacts pricing. Larger orders often qualify for bulk discounts, which can lead to substantial cost savings for buyers.

-

Specifications and Customization: Custom features and specifications can increase costs. Buyers should clearly outline their requirements to avoid unexpected price hikes. Chambers designed for specific applications or with advanced safety features typically come at a premium.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO, UL standards) can also influence price. Chambers made with superior materials and certified for safety will command higher prices but offer greater reliability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may offer higher-quality products backed by better service but at a premium.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect the final cost, as they define who is responsible for shipping and insurance costs.

What Are Effective Buyer Tips for Cost-Efficiency?

To optimize procurement strategies for battery test chambers, consider the following tips:

-

Negotiate Wisely: Leverage the information on costs and specifications to negotiate better terms. Be clear about your budget constraints and explore options for discounts on bulk orders.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term operational costs, including maintenance, energy consumption, and potential downtime. A lower initial price may lead to higher TCO if the equipment is not reliable.

-

Pricing Nuances for International Buyers: For buyers in regions such as Africa, South America, the Middle East, and Europe, be aware of currency fluctuations and economic conditions that may impact pricing. Engaging local representatives can help navigate these complexities.

-

Seek Multiple Quotes: Always obtain multiple quotes from different suppliers to compare costs and features. This not only helps in finding the best price but also in assessing the market range for similar products.

-

Plan for Future Needs: Consider your long-term requirements when purchasing. Investing in a chamber that can accommodate future testing needs can save costs associated with upgrades or replacements.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific requirements of the buyer. It is advisable to conduct thorough research and obtain quotes for precise budgeting.

Alternatives Analysis: Comparing battery test chambers With Other Solutions

Understanding Alternatives to Battery Test Chambers in Testing Solutions

When it comes to testing batteries, particularly in the context of electric vehicles and portable electronics, battery test chambers have established themselves as a critical tool. However, there are alternative solutions available that also aim to ensure battery performance, safety, and reliability. In this analysis, we will compare battery test chambers with two viable alternatives: thermal shock testing systems and battery simulation software.

Comparison Table

| Comparison Aspect | Battery Test Chambers | Thermal Shock Testing Systems | Battery Simulation Software |

|---|---|---|---|

| Performance | High precision in temperature and humidity control; simulates real-world conditions effectively. | Good for rapid temperature cycling but may lack environmental control. | Offers predictive analytics and modeling but cannot physically test batteries. |

| Cost | Higher initial investment; ongoing maintenance costs. | Moderate cost; lower than chambers but may require additional equipment. | Generally lower cost; software licensing fees apply. |

| Ease of Implementation | Requires installation and calibration; operator training necessary. | Easier to implement; often portable and requires less setup. | Quick to deploy; requires software installation and system compatibility checks. |

| Maintenance | Regular maintenance needed; requires specialized knowledge. | Lower maintenance; less complexity in equipment. | Minimal maintenance; software updates needed. |

| Best Use Case | Ideal for comprehensive testing of battery safety and performance under extreme conditions. | Suitable for rapid testing of thermal performance but not comprehensive. | Best for early-stage design and development testing; useful in predictive analysis. |

Detailed Breakdown of Alternatives

Thermal Shock Testing Systems

Thermal shock testing systems are designed to subject batteries to rapid temperature changes, helping to identify potential failures due to thermal stress. These systems are generally easier to implement and often more cost-effective than battery test chambers. However, they primarily focus on temperature fluctuations and may lack the comprehensive environmental controls that chambers provide, limiting their effectiveness in simulating real-world conditions.

Battery Simulation Software

Battery simulation software allows for the modeling and analysis of battery performance through predictive analytics. This solution is often the most cost-effective, requiring only a computer and compatible software. While it excels in early-stage design and can help anticipate battery behavior, it lacks the ability to physically test batteries under extreme conditions. Therefore, while it is beneficial for theoretical analysis, it cannot replace the detailed safety and performance testing offered by battery test chambers.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate testing solution for batteries, B2B buyers should consider their specific testing requirements, budget constraints, and the criticality of performance and safety in their applications. Battery test chambers provide an unmatched level of detail and safety for testing, making them ideal for high-stakes environments like electric vehicle production. However, for companies in the early design stages or those needing rapid temperature assessments, thermal shock testing systems or battery simulation software may offer more efficient, cost-effective alternatives. Ultimately, aligning the choice with the operational goals and testing requirements will lead to the most effective solution.

Essential Technical Properties and Trade Terminology for battery test chambers

When evaluating battery test chambers, understanding the essential technical properties and industry terminology is crucial for making informed purchasing decisions. This guide outlines the key specifications that define the performance and reliability of these chambers, as well as common terms that will help facilitate effective communication with suppliers and manufacturers.

What Are the Key Technical Specifications for Battery Test Chambers?

-

Temperature Range

The temperature range of a battery test chamber indicates the extremes it can simulate, typically ranging from -40°C to +100°C. This is vital for testing batteries under various environmental conditions they might face in real-world applications, such as in electric vehicles or consumer electronics. A wider temperature range allows for more comprehensive testing, ensuring product safety and performance. -

Humidity Control

Humidity control is an essential feature that allows chambers to maintain specific moisture levels during testing. This specification is particularly important for applications where battery performance may be influenced by humidity, such as in tropical climates. Precise humidity control helps in evaluating the long-term reliability of batteries, which can be crucial for markets in regions with high humidity levels. -

Chamber Size and Capacity

The size and capacity of the chamber dictate how many batteries can be tested simultaneously. This specification is especially important for manufacturers that need to conduct high-volume testing. A larger capacity can streamline operations and reduce time-to-market by enabling concurrent testing of multiple battery cells or packs. -

Safety Features

Safety is paramount in battery testing due to the risk of thermal runaway, explosions, or gas emissions. Key safety features may include gas monitoring systems, fire suppression mechanisms, and pressure relief ports. Understanding these features is crucial for buyers, as they ensure compliance with safety regulations and protect personnel and equipment. -

Integration Capabilities

Integration capabilities refer to how well the test chamber can work with other testing equipment, such as cyclers and data acquisition systems. Chambers that offer seamless integration can save time and reduce the complexity of testing setups, making them more efficient for manufacturers looking to optimize their processes.

Which Trade Terms Should B2B Buyers Know?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers who want to ensure that they are sourcing high-quality components that meet their specifications and standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for budget-conscious buyers, as it can affect inventory costs and the feasibility of testing multiple battery types or configurations. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. Crafting a clear RFQ can help buyers compare costs effectively and ensure they are getting the best value for their investment in battery test chambers. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is essential for buyers involved in cross-border procurement, as they dictate shipping responsibilities, risk transfer, and cost allocation. -

Calibration

Calibration refers to the process of adjusting the accuracy of the test chamber’s measurement instruments. Regular calibration is essential for ensuring the reliability of test results, which can have significant implications for product development and compliance with industry standards.

By understanding these technical specifications and trade terms, B2B buyers can navigate the complex landscape of battery test chambers more effectively, ensuring they make informed decisions that align with their operational needs and safety standards.

Navigating Market Dynamics and Sourcing Trends in the battery test chambers Sector

What Are the Current Market Dynamics and Trends Affecting Battery Test Chambers?

The global market for battery test chambers is experiencing robust growth, driven by the increasing demand for batteries in electric vehicles (EVs), consumer electronics, and renewable energy storage solutions. This demand is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where governments are implementing stricter regulations and incentives to promote electric mobility and sustainable energy practices. Key trends include the integration of advanced technologies such as automation and data analytics in testing processes, which enhance accuracy and efficiency.

Emerging B2B sourcing trends also highlight a shift towards integrated testing solutions that combine chambers with battery testing equipment, allowing for streamlined operations. This is particularly beneficial for manufacturers seeking to optimize their R&D and production processes. Additionally, the adoption of modular and scalable testing systems is gaining traction, enabling businesses to adapt their testing capabilities as battery technologies evolve. Buyers are increasingly looking for suppliers that offer comprehensive support, including installation and maintenance services, to ensure operational efficiency and minimize downtime.

Illustrative image related to battery test chambers

How Are Sustainability and Ethical Sourcing Practices Shaping the Battery Test Chamber Market?

Sustainability is becoming a critical focus in the battery test chamber sector. Manufacturers are increasingly aware of the environmental impact of their operations, prompting a shift toward ethical sourcing practices. This includes the use of eco-friendly materials and processes in the production of test chambers, which helps reduce carbon footprints and promote sustainability.

B2B buyers are encouraged to prioritize suppliers that hold ‘green’ certifications, such as ISO 14001, which ensures that companies adhere to rigorous environmental management standards. These certifications can serve as a benchmark for assessing a supplier’s commitment to sustainability. Furthermore, ethical supply chains are gaining importance, as buyers look to ensure that their suppliers maintain fair labor practices and responsible sourcing of materials. By investing in sustainable testing solutions, companies can not only comply with regulatory demands but also enhance their brand reputation and appeal to environmentally-conscious consumers and stakeholders.

What Is the Historical Context of Battery Test Chambers in the B2B Landscape?

The evolution of battery test chambers has been significantly influenced by advancements in battery technology and the growing need for safety and reliability in battery performance. Initially, testing was limited to basic environmental simulations. However, as the demand for high-capacity batteries surged—especially with the advent of electric vehicles—test chambers evolved to incorporate complex features that simulate extreme conditions.

Today’s battery test chambers are equipped with sophisticated monitoring systems that provide real-time data on battery performance under various stress conditions. This evolution has not only improved the safety of testing processes but has also contributed to the development of more efficient and reliable battery technologies. For B2B buyers, understanding this historical context is crucial as it highlights the importance of selecting advanced testing solutions that can accommodate future technological advancements in battery design and application.

Frequently Asked Questions (FAQs) for B2B Buyers of battery test chambers

-

How do I solve battery safety concerns during testing?

Ensuring battery safety during testing is crucial, especially for lithium-ion batteries prone to thermal runaway. Utilize battery test chambers equipped with safety features such as gas monitoring systems, ventilation blowers, and fire suppression systems. Regularly train personnel on safety protocols and conduct routine maintenance checks on the equipment. Selecting chambers that comply with international safety standards, such as IEC 62133 and UL 2054, will also help mitigate risks associated with battery testing. -

What is the best battery test chamber for electric vehicle applications?

For electric vehicle applications, opt for battery test chambers that can handle high capacity and multiple testing scenarios, including extreme temperature conditions and cycling processes. Look for models with integrated cooling and heating systems, precise humidity control, and robust safety features. Chambers like those from AES, designed specifically for high-volume production and R&D, are excellent choices due to their proven track record in the industry. -

What are the key specifications to consider when sourcing a battery test chamber?

When sourcing a battery test chamber, consider specifications such as temperature range, humidity control, chamber size, and load capacity. Additionally, evaluate the safety features, such as pressure relief systems and gas monitoring. Ensure compatibility with your testing equipment and confirm the chamber meets relevant international testing standards. It’s also wise to assess the manufacturer’s reputation and customer support services to ensure a reliable partnership. -

How can I customize a battery test chamber to meet my specific testing needs?

Customization options for battery test chambers typically include adjusting chamber size, incorporating additional safety features, or integrating specific testing equipment. Engage directly with manufacturers to discuss your requirements, such as unique environmental conditions or testing protocols. Many suppliers offer tailored solutions, ensuring that the chamber aligns with your operational goals and enhances testing efficiency. -

What are the minimum order quantities (MOQ) for battery test chambers?

Minimum order quantities (MOQ) for battery test chambers can vary significantly by manufacturer and model. Generally, larger manufacturers may have lower MOQs due to their production capabilities. However, smaller or specialized suppliers might require higher MOQs for customized solutions. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms that align with your budget and project timelines. -

What payment terms should I expect when purchasing battery test chambers internationally?

Payment terms for international purchases of battery test chambers can vary widely. Common terms include a deposit upfront (often 30-50%), with the balance due before shipment or upon delivery. Some suppliers may offer financing options or payment plans for larger purchases. Always clarify terms during negotiations, including acceptable payment methods, currency considerations, and any potential duties or taxes that may apply to international transactions. -

How do I vet suppliers for battery test chambers to ensure quality and reliability?

Vetting suppliers for battery test chambers involves several steps: review their industry reputation, request references from previous clients, and assess their compliance with international standards. Investigate their manufacturing processes and quality control measures, including certifications like ISO 9001. Additionally, consider visiting their facilities or requesting product samples to evaluate quality firsthand. Establishing a strong communication line can also provide insights into their reliability and customer service. -

What logistics considerations should I keep in mind when importing battery test chambers?

When importing battery test chambers, consider logistics factors such as shipping methods, lead times, and customs regulations. Ensure that your supplier can provide all necessary documentation for customs clearance, including certificates of origin and compliance. Factor in shipping costs and potential duties, and consider using a freight forwarder familiar with international shipping of specialized equipment. Proper planning can help mitigate delays and additional expenses during the import process.

Top 4 Battery Test Chambers Manufacturers & Suppliers List

1. Associated Environmental Systems – Battery Test Chambers

Domain: associatedenvironmentalsystems.com

Registered: 2004 (21 years)

Introduction: Battery Test Chambers simulate real-world conditions for battery testing, including extreme temperature fluctuations, humidity levels, and cycling processes. They enable precise testing of battery performance, safety, and reliability with controlled charging and discharging cycles. Key models include: SD-501-3RS (compact, triple-stack, 1-cubic-foot chambers for small-batch testing), SD-508-SAFE (8…

2. Weiss Technik – Battery Test Chambers

Domain: weiss-na.com

Registered: 2013 (12 years)

Introduction: Weiss Technik offers battery test chambers designed for testing various types of batteries, including Lithium Ion, lead acid, Battery Management Systems (BMS), battery packs, modules, and battery cells. These chambers can simulate a range of environmental conditions such as low or high temperatures, humidity changes, vibration changes, and altitude changes. They conform to IEC, UL, and EUCAR testi…

3. Thermotron – Battery Chamber

Domain: thermotron.com

Registered: 1996 (29 years)

Introduction: Battery Chamber by Thermotron is designed for testing cells, battery packs, or modules. It features high-performance and high-reliability testing equipment that exceeds industry standard specifications. The chambers are available in various sizes and configurations for different battery types and are fully customizable to meet specific test requirements. Safety features include automatic door lock…

4. Total Shield – Battery Test Chambers & Enclosures

Domain: totalshield.com

Registered: 2002 (23 years)

Introduction: Battery Test Chambers & Enclosures designed to contain thermal runaway events, overpressurization, and explosions. Features include:

– Engineered for energy impact threat levels

– Available as mobile enclosures and walk-in safety chambers

– Thermally isolated flame and heat shields

– Clear panels for procedure observance

– Vent holes for combustion gas release

– No building permits required …

Strategic Sourcing Conclusion and Outlook for battery test chambers

How Can Strategic Sourcing Enhance Your Battery Testing Capabilities?

In the evolving landscape of battery technology, the strategic sourcing of battery test chambers is critical for businesses aiming to enhance product reliability and safety. By investing in advanced testing solutions, companies can ensure compliance with international safety standards and improve their R&D processes. Key takeaways include the importance of selecting chambers that accommodate various testing scenarios, from extreme temperature conditions to abuse testing, ensuring comprehensive evaluation of battery performance.

Moreover, strategic sourcing not only streamlines operations by integrating testing equipment but also significantly reduces time and costs associated with installation and maintenance. As the demand for electric vehicles and portable electronics surges, the need for reliable battery testing becomes paramount, making informed procurement decisions vital for competitive advantage.

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe—particularly in emerging markets like Brazil and Saudi Arabia—should prioritize partnerships with manufacturers that offer innovative, integrated solutions tailored to their specific needs. This proactive approach will not only enhance product quality but also foster long-term growth in the rapidly expanding battery sector. Engage with industry experts today to explore the optimal testing solutions for your unique requirements and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to battery test chambers

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.