The Definitive Guide to Application Of Mixing: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for application of mixing

In an increasingly interconnected global market, sourcing the right mixing solutions can pose significant challenges for businesses, especially in industries where precision and efficiency are paramount. The application of mixing is critical across various sectors, from food and beverage to pharmaceuticals and chemicals. This guide serves as an essential resource for international B2B buyers looking to navigate the complexities of mixing technologies, enabling them to identify the best equipment and practices tailored to their specific needs.

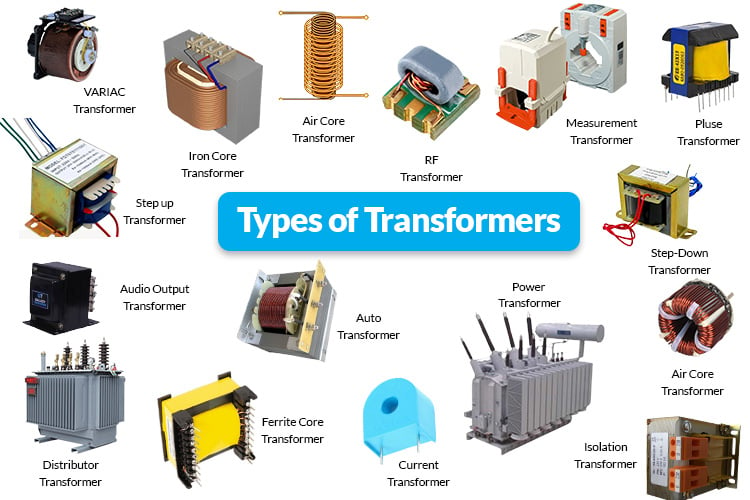

Within this comprehensive guide, we delve into the diverse types of mixers, such as agitator mixers, static mixers, and drum mixers, alongside their applications across different industries. Buyers will gain insights into the supplier vetting process, ensuring they choose reputable manufacturers capable of delivering quality and reliability. Additionally, we address key factors influencing costs, enabling informed financial planning and budgeting.

By equipping decision-makers from regions such as Africa, South America, the Middle East, and Europe—including markets like Saudi Arabia and Vietnam—with actionable insights, this guide empowers businesses to make strategic purchasing decisions. Understanding the nuances of mixing applications can lead to enhanced product quality, operational efficiency, and ultimately, a competitive edge in the global marketplace.

Understanding application of mixing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Agitator Mixers | Utilizes rotating impellers; suitable for high viscosity media. | Food processing, pharmaceuticals, chemical mixing. | Pros: Versatile; effective for various viscosities. Cons: May require maintenance due to moving parts. |

| Static Mixers | No moving parts; ideal for continuous flow applications. | Chemical processing, water treatment, cosmetics. | Pros: Low maintenance; efficient for low viscosity. Cons: Limited to specific flow conditions. |

| Drum Mixers | Rotating drums with internal blades; typically batch mixers. | Cement, adhesives, and slurries. | Pros: Portable; good for bulk mixing. Cons: Less precise mixing; may not suit all materials. |

| High-Shear Mixers | High-speed mixing for emulsification and homogenization. | Pharmaceuticals, cosmetics, food emulsions. | Pros: Excellent for creating stable emulsions. Cons: Higher energy consumption; may require specialized training. |

| Batch Mixers | Fixed amount of materials mixed over a set time. | Confectionery, sauces, and dressings. | Pros: Allows for precise control; customizable recipes. Cons: Time-consuming; not suitable for continuous production. |

What Are the Key Characteristics of Agitator Mixers?

Agitator mixers are designed with rotating impellers that facilitate the blending of solids, liquids, and gases. They excel in applications involving high-viscosity media, making them suitable for industries like food processing and pharmaceuticals. When considering an agitator mixer, B2B buyers should evaluate the specific viscosity and density of materials, as well as the required mixing speed. Maintenance is a crucial factor, as moving parts may necessitate regular servicing to ensure optimal performance.

Illustrative image related to application of mixing

How Do Static Mixers Function in Industrial Applications?

Static mixers operate without moving parts, utilizing a series of baffles to blend materials as they flow through a cylindrical housing. This design is particularly effective for low-viscosity liquids and continuous processes, making static mixers popular in chemical processing and water treatment applications. B2B buyers should consider the material compatibility and flow rate when selecting a static mixer, as these factors directly impact efficiency. The low maintenance requirement is a significant advantage, though the limitations in viscosity handling can restrict their use.

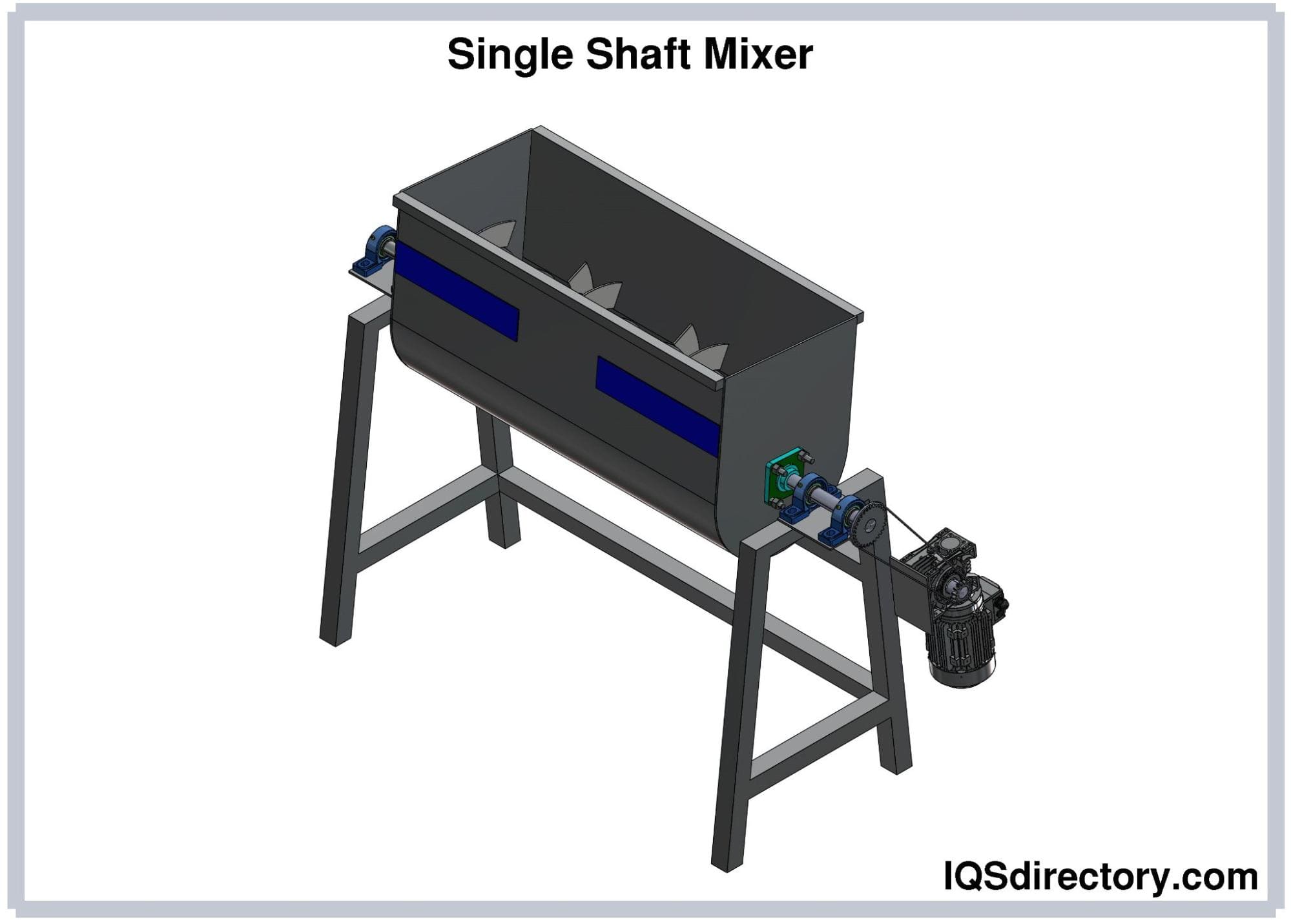

What Advantages Do Drum Mixers Offer for Bulk Materials?

Drum mixers feature a rotating drum with internal blades, allowing for the mixing of various materials, including slurries and adhesives. They are favored for their portability and ability to handle bulk quantities, making them ideal for industries like construction and manufacturing. Buyers should assess the specific mixing requirements, such as particle size and material consistency, since drum mixers may not achieve precise blending. While they provide a cost-effective solution, the batch mixing nature limits their suitability for continuous production processes.

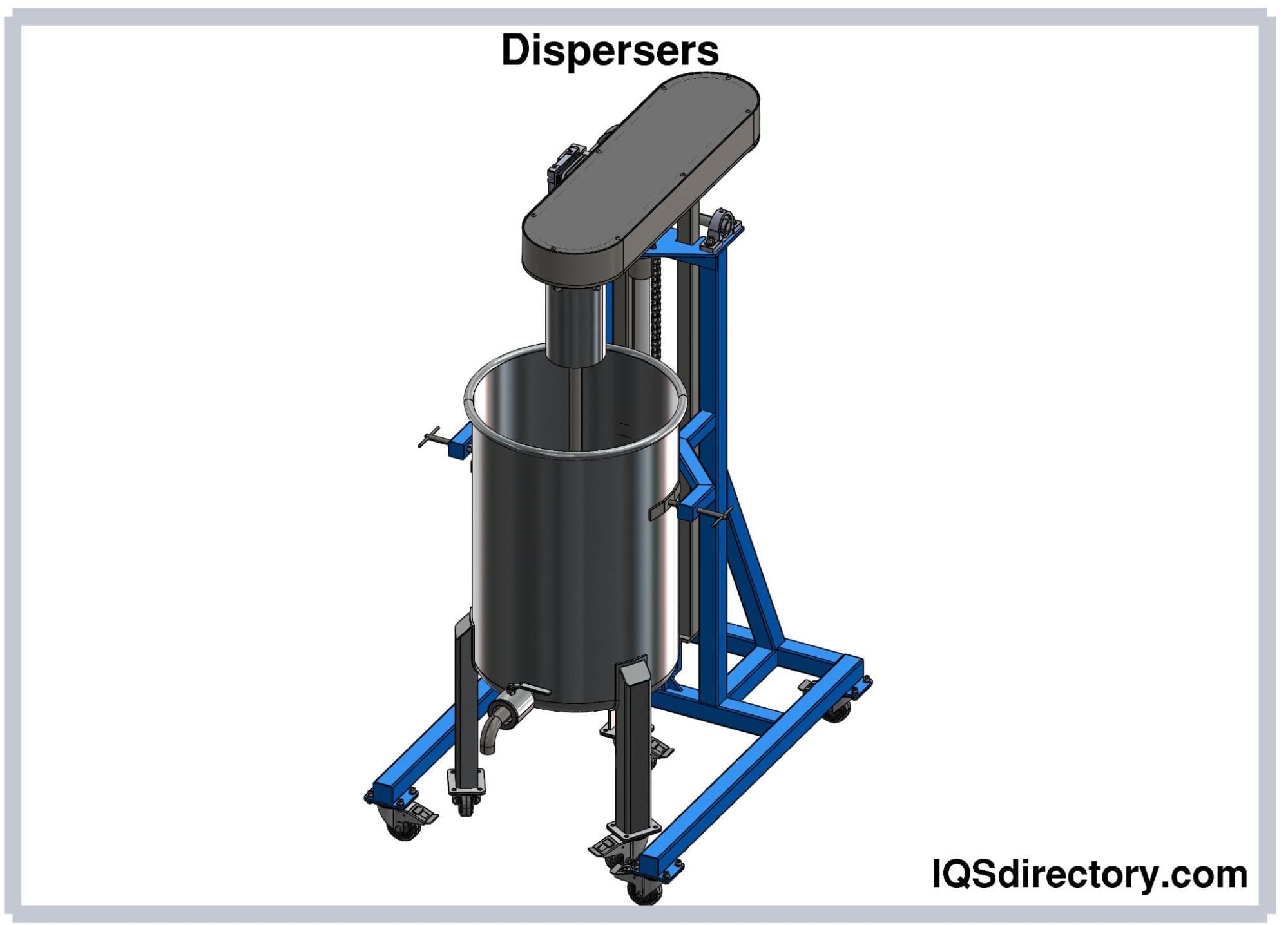

In What Scenarios Are High-Shear Mixers Essential?

High-shear mixers are designed for rapid mixing, emulsification, and homogenization, making them vital in pharmaceutical and cosmetic industries. Their ability to create stable emulsions and consistent particle sizes is a key advantage. B2B buyers should weigh the energy consumption and potential need for specialized training against the benefits of high-quality mixing. Understanding the specific application requirements, such as batch size and mixing duration, is critical for selecting the right high-shear mixer.

Why Choose Batch Mixers for Custom Recipes?

Batch mixers are ideal for applications that require precise control over mixing times and ingredient proportions, such as in the production of sauces and confectionery. They allow manufacturers to create customized recipes effectively. However, B2B buyers must consider the time constraints associated with batch mixing, as it can slow down production rates compared to continuous mixing systems. Evaluating the scale of production and flexibility in recipe adjustments will be essential when selecting batch mixers for specific applications.

Key Industrial Applications of application of mixing

| Industry/Sector | Specific Application of application of mixing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Production of Plant-Based Milk Alternatives | Enhances product quality and meets growing consumer demand for plant-based options. | Ensure mixers are capable of handling varying viscosities and maintaining hygiene standards. |

| Pharmaceuticals | Manufacture of Vaccines | Ensures uniformity and efficacy in vaccine formulations, critical for patient safety. | Look for ultra-sanitary mixing solutions that comply with stringent regulatory standards. |

| Chemicals | Production of Specialty Chemicals | Improves product consistency and performance, essential for market competitiveness. | Consider the mixer’s ability to handle aggressive chemicals and high shear mixing requirements. |

| Cosmetics | Manufacture of Creams & Lotions | Facilitates the creation of high-quality, stable products that meet consumer expectations. | Assess the mixer’s compatibility with various cosmetic ingredients and its ability to ensure product stability. |

| Agrochemicals | Manufacture of Pesticides | Enhances the effectiveness of agricultural products, vital for crop yield improvements. | Ensure mixers can handle varying particle sizes and provide uniform dispersion of active ingredients. |

How is Mixing Applied in the Food & Beverage Industry?

In the food and beverage sector, mixing is crucial for the production of plant-based milk alternatives. This application addresses the growing consumer demand for dairy-free options by ensuring a uniform blend of ingredients like nuts, grains, or legumes. Buyers must consider mixers that can manage varying viscosities while adhering to strict hygiene standards to prevent contamination. The ability to achieve consistent emulsion and flavor integration is key to maintaining product quality and consumer trust.

What Role Does Mixing Play in Pharmaceuticals?

The pharmaceutical industry relies on precise mixing for vaccine manufacture, where uniformity is essential for efficacy and safety. High-shear mixers are often employed to ensure that active ingredients are evenly distributed throughout the formulation. International buyers should prioritize ultra-sanitary mixing equipment that meets regulatory standards, as contamination can have serious implications. Additionally, the scalability of mixing solutions is important for adapting to changing production demands.

How is Mixing Utilized in Chemical Production?

In the chemicals sector, mixing is vital for producing specialty chemicals, enhancing product consistency and performance. This application often involves aggressive chemicals, requiring mixers that can withstand harsh conditions while providing high shear mixing capabilities. Buyers should evaluate the mixer’s materials of construction, ensuring compatibility with the specific chemicals being processed. Consistency in product quality can significantly impact market competitiveness, making the right mixing equipment a critical investment.

Why is Mixing Important in Cosmetics Manufacturing?

Mixing plays a significant role in the cosmetic industry, particularly in the manufacture of creams and lotions. This application ensures the stability and quality of products that consumers expect. Buyers must consider mixers that can handle a variety of ingredients, including emulsifiers and active compounds, while providing consistent results. The ability to maintain product integrity over time is essential for brand reputation and consumer satisfaction.

Illustrative image related to application of mixing

How Does Mixing Benefit Agrochemical Production?

In agrochemicals, mixing is integral to the manufacture of pesticides, where effective dispersion of active ingredients is crucial for agricultural success. This application enhances the performance of products designed to improve crop yields. Buyers need to ensure that mixers can accommodate varying particle sizes and provide uniform mixing to achieve optimal results. The right mixing solution can lead to significant improvements in product efficacy, ultimately benefiting agricultural productivity.

3 Common User Pain Points for ‘application of mixing’ & Their Solutions

Scenario 1: Inconsistent Product Quality in Food Processing

The Problem: B2B buyers in the food processing industry often face the challenge of inconsistent product quality. For instance, when manufacturing sauces or dressings, varying mixing speeds and times can lead to differences in texture and flavor. This inconsistency can result in customer dissatisfaction, increased waste, and potential financial losses. Moreover, the inability to achieve uniformity can complicate compliance with food safety regulations, which are stringent in many regions, including Europe and the Middle East.

The Solution: To combat this issue, B2B buyers should invest in high-shear mixers that can ensure consistent emulsification and homogenization of ingredients. It’s essential to work closely with mixer manufacturers to specify equipment that meets the specific viscosity and shear requirements of your products. Implementing a digital monitoring system can also provide real-time feedback on mixing parameters, allowing for adjustments on-the-fly. Additionally, establishing standard operating procedures (SOPs) for mixing processes will help maintain consistency across batches, ensuring that every product meets quality standards.

Illustrative image related to application of mixing

Scenario 2: Inefficient Mixing Processes Leading to Increased Production Costs

The Problem: Many manufacturers in the chemical and pharmaceutical sectors encounter inefficiencies in their mixing processes, which can lead to increased production costs. For example, when mixing high-viscosity substances, inadequate mixing can prolong processing times, requiring more energy and labor. This inefficiency not only raises operational costs but also affects the overall output, creating a bottleneck in production that can delay delivery times.

The Solution: To enhance mixing efficiency, buyers should consider transitioning to continuous mixing systems. These systems allow for the uninterrupted addition of materials, significantly reducing mixing times and improving throughput. Additionally, selecting the right type of mixer—such as an agitator or static mixer—based on the specific material properties is crucial. Conducting a thorough assessment of material flow rates and viscosity profiles can aid in selecting the most suitable mixing equipment. Moreover, investing in advanced mixer technology that includes automated controls can optimize mixing processes and reduce manual oversight, thereby cutting costs and improving productivity.

Scenario 3: Compliance and Safety Issues in Pharmaceutical Mixing

The Problem: In the pharmaceutical industry, compliance with stringent regulations is paramount, and any lapses in the mixing process can lead to serious safety issues. For instance, when preparing pharmaceutical creams or ointments, improper mixing can result in uneven distribution of active ingredients, leading to ineffective or unsafe products. This not only jeopardizes patient safety but can also result in costly recalls and damage to a company’s reputation.

The Solution: To ensure compliance and safety in mixing processes, B2B buyers should prioritize the acquisition of sanitary mixers that meet industry standards for cleanliness and sterility. Collaborating with manufacturers who specialize in pharmaceutical-grade mixing equipment is essential. Buyers should also implement rigorous validation protocols for their mixing processes, including routine testing of product samples to ensure uniformity and compliance with regulatory standards. Furthermore, training personnel on best practices in mixing and equipment handling can mitigate risks associated with contamination and ensure that safety protocols are consistently followed.

Strategic Material Selection Guide for application of mixing

What Are the Key Properties of Stainless Steel for Mixing Applications?

Stainless steel is a widely used material in mixing applications due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for various industrial processes. The most common grades used in mixing equipment are 304 and 316 stainless steel, with 316 offering superior resistance to chlorides and other corrosive agents. This property is particularly beneficial in food and pharmaceutical applications, where hygiene and safety are paramount.

Pros and Cons of Stainless Steel in Mixing

The advantages of stainless steel include its long lifespan, ease of cleaning, and resistance to rust and corrosion, which are critical for maintaining product quality. However, the initial cost can be high compared to other materials like carbon steel or plastic. Additionally, while stainless steel is durable, it can be susceptible to pitting in certain aggressive chemical environments, requiring careful selection based on the specific media being mixed.

How Does Polypropylene Perform in Mixing Applications?

Polypropylene (PP) is another popular material for mixing applications, especially in industries requiring a lightweight and chemically resistant solution. PP has a lower density than metals, making it easier to handle and install. Its temperature resistance typically ranges from -20°C to 100°C, which is adequate for many mixing processes but may not suffice for high-temperature applications.

Pros and Cons of Polypropylene in Mixing

The key advantages of polypropylene include its cost-effectiveness, resistance to a wide range of chemicals, and low weight. However, its lower mechanical strength compared to metals can limit its use in high-stress environments. Additionally, while it is suitable for many applications, it may not be appropriate for processes involving high pressures or extreme temperatures.

What Are the Benefits of Using Carbon Steel in Mixing?

Carbon steel is often chosen for mixing applications due to its strength and versatility. It is commonly used in industries such as construction and mining, where durability is essential. However, carbon steel is prone to corrosion, making it less suitable for applications involving moisture or corrosive substances unless properly coated or treated.

Pros and Cons of Carbon Steel in Mixing

The primary advantage of carbon steel is its affordability and strength, making it ideal for heavy-duty applications. However, its susceptibility to rust and corrosion can lead to increased maintenance costs and reduced lifespan if not adequately protected. This limitation is particularly important for international buyers in regions with high humidity or corrosive environments.

What Role Does Glass Play in Mixing Applications?

Glass is often utilized in mixing applications where visibility and chemical inertness are required. It is particularly favored in laboratory settings and for certain food applications due to its non-reactive nature. Glass can withstand a wide range of temperatures, but it is fragile and can break easily under mechanical stress.

Pros and Cons of Glass in Mixing

The advantages of glass include its excellent chemical resistance and the ability to visually monitor the mixing process. However, its fragility and higher cost compared to other materials can limit its use in industrial applications. Additionally, the weight of glass can pose handling challenges, particularly in large-scale operations.

Summary Table of Material Selection for Mixing Applications

| Material | Typical Use Case for application of mixing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and pharmaceutical mixing equipment | Excellent corrosion resistance and durability | High initial cost and pitting risk in aggressive environments | High |

| Polypropylene | Chemical mixing in low-stress applications | Cost-effective and lightweight | Lower mechanical strength and temperature limits | Medium |

| Carbon Steel | Heavy-duty mixing in construction and mining | Affordability and strength | Prone to corrosion without treatment | Low |

| Glass | Laboratory mixing and food applications | Chemical inertness and visibility | Fragility and higher handling costs | Medium |

This material selection guide provides B2B buyers with critical insights into the properties, advantages, and limitations of common materials used in mixing applications, ensuring informed decision-making tailored to their specific industry needs.

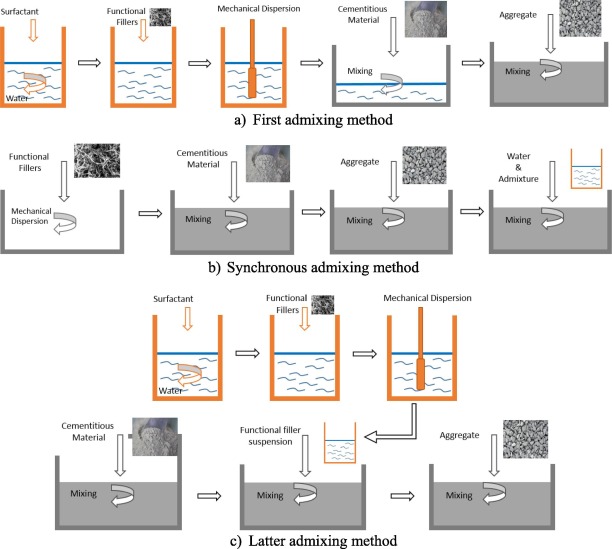

In-depth Look: Manufacturing Processes and Quality Assurance for application of mixing

In the realm of industrial mixing, understanding the manufacturing processes and quality assurance protocols is paramount for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This section delves into the stages of manufacturing and the critical quality assurance measures that ensure the reliability and effectiveness of mixing applications.

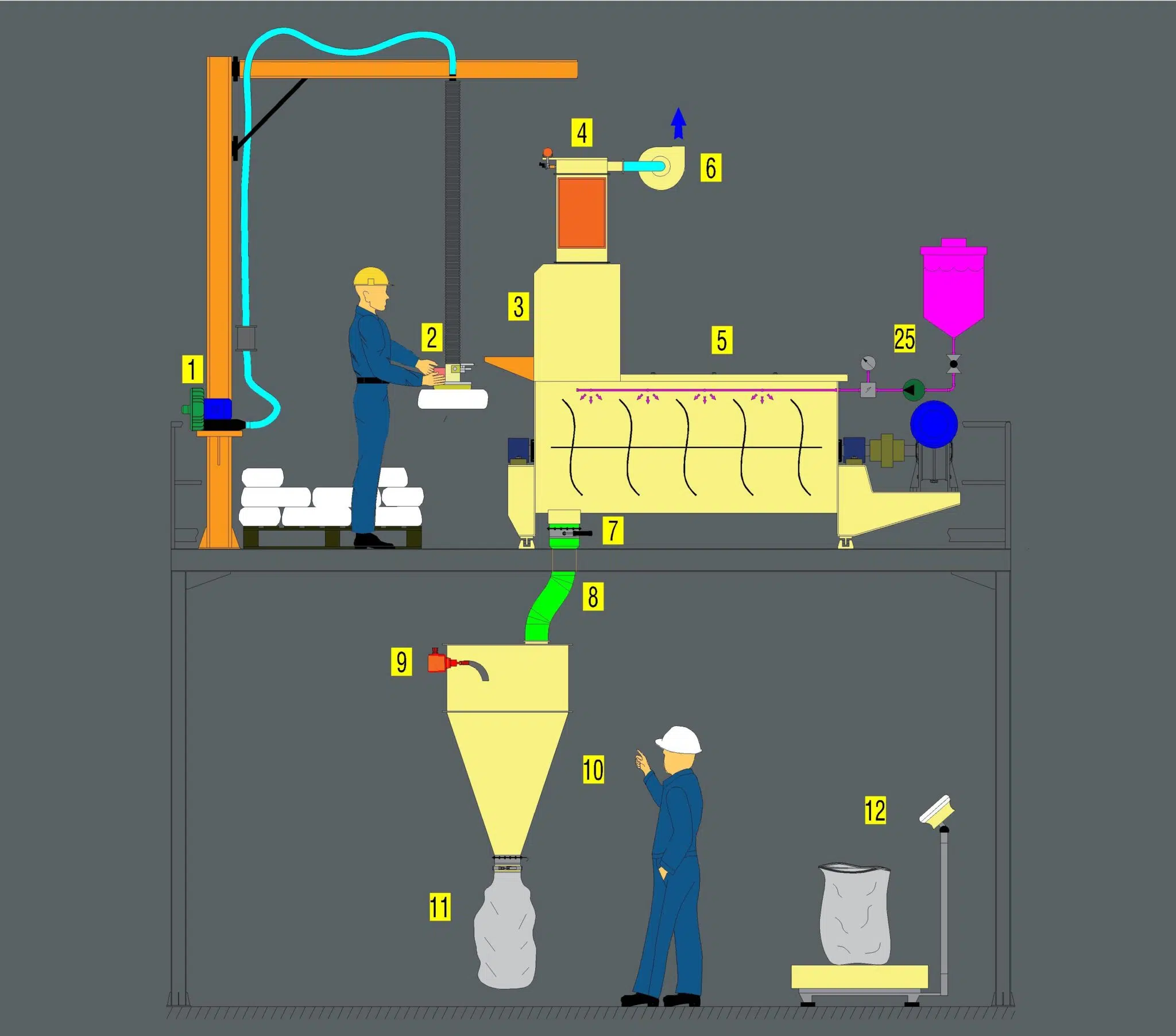

What Are the Main Stages of the Manufacturing Process for Mixing Equipment?

The manufacturing process for mixing equipment typically encompasses several key stages: material preparation, forming, assembly, and finishing. Each of these stages plays a crucial role in ensuring that the final product meets the required specifications and performance standards.

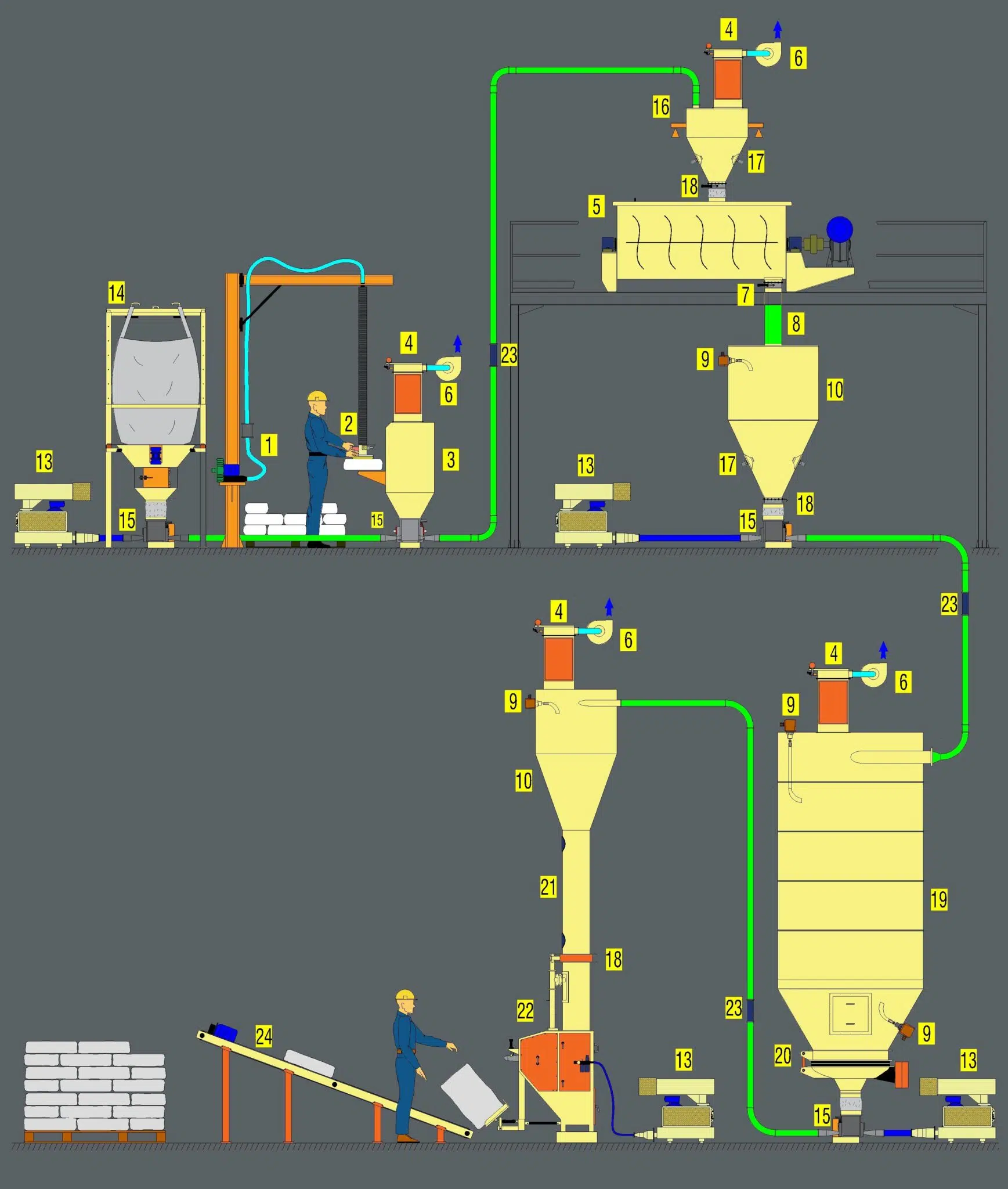

Illustrative image related to application of mixing

How Is Material Prepared for Mixing Equipment Production?

Material preparation is the initial phase where raw materials are sourced and processed. This involves selecting high-quality components such as metals, plastics, and elastomers, which are essential for the durability and functionality of the mixing equipment. Rigorous testing of these materials is often conducted to ensure they comply with industry standards. For instance, stainless steel is commonly used in food-grade applications due to its corrosion resistance and ease of cleaning.

What Techniques Are Used in Forming Mixing Equipment?

The forming stage involves shaping the prepared materials into the desired components using various techniques. Common methods include machining, casting, and welding. Machining is frequently employed for precision parts, while casting is used for creating complex shapes. Advanced techniques like 3D printing are also gaining traction, particularly for producing prototypes or custom parts. Each method must be executed with precision to ensure that the parts fit together seamlessly during assembly.

How Is the Assembly of Mixing Equipment Conducted?

In the assembly phase, individual components are brought together to create the final mixing equipment. This process often requires skilled labor and can involve both manual and automated assembly lines. Proper alignment and fitting of parts are critical to ensuring the equipment operates efficiently. Quality checks during assembly, such as torque testing and alignment verification, are essential to identify any potential issues before the equipment moves to the finishing stage.

What Finishing Techniques Are Applied to Enhance Mixing Equipment?

The finishing stage includes processes that enhance the appearance and functionality of the mixing equipment. This may involve surface treatments such as polishing, coating, or painting, which not only improve aesthetics but also provide additional protection against wear and corrosion. In industries like food and pharmaceuticals, finishing processes must meet stringent hygiene standards, often requiring the use of specific food-safe coatings.

What Are the Key Quality Assurance Measures in Mixing Equipment Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final products meet both international and industry-specific standards. B2B buyers should be well-versed in these measures to validate the credibility of their suppliers.

Illustrative image related to application of mixing

Which International Standards Are Relevant for Mixing Equipment Quality Assurance?

International standards, such as ISO 9001, provide a framework for quality management systems that manufacturers must adhere to. ISO 9001 focuses on continuous improvement and customer satisfaction, requiring companies to maintain comprehensive documentation and processes. In addition, industry-specific certifications, such as CE marking for European markets or API standards for the petroleum industry, signify compliance with safety and performance criteria.

What Are the Critical Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that each stage meets the required standards. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify their quality before production begins.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves monitoring production parameters and conducting tests to ensure that components are being produced correctly.

- Final Quality Control (FQC): This is the last line of defense where the finished product undergoes comprehensive testing to verify its functionality and compliance with specifications.

What Testing Methods Are Commonly Used to Ensure Quality?

Various testing methods are employed to ensure the quality of mixing equipment. These may include:

- Performance Testing: Assessing the equipment’s mixing efficiency, including flow rates and shear rates.

- Durability Testing: Evaluating how well the equipment withstands wear and tear under operating conditions.

- Safety Testing: Ensuring that the equipment meets safety standards to prevent accidents during operation.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For B2B buyers, verifying a supplier’s quality assurance practices is essential to mitigate risks associated with equipment failure or non-compliance. Here are some strategies to effectively assess supplier quality:

What Are Effective Audit Practices for Supplier Quality Verification?

Conducting audits is one of the most effective methods for assessing a supplier’s quality assurance practices. Buyers should consider both initial audits and ongoing evaluations to ensure compliance with required standards. An audit can include an examination of quality control processes, documentation, and equipment maintenance records.

Illustrative image related to application of mixing

How Can Buyers Utilize Quality Reports and Certifications?

Buyers should request detailed quality reports and certifications from suppliers to verify their adherence to international and industry standards. These documents serve as evidence of compliance and can provide insights into the supplier’s quality management practices.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality assurance practices. These inspections often involve comprehensive assessments of manufacturing processes, quality control measures, and product testing, offering buyers additional peace of mind.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those in diverse markets like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Variations in regulatory requirements, cultural expectations, and logistical challenges can impact the quality assurance process.

How Do Regional Regulations Affect Quality Standards?

Different regions may have specific regulations governing manufacturing practices and product safety. Buyers should familiarize themselves with local standards to ensure that the equipment complies with regional requirements. For example, the European Union has stringent regulations for food safety and equipment hygiene, which may not be as rigorous in other regions.

What Cultural Considerations Should Buyers Keep in Mind?

Cultural differences can influence communication and expectations around quality assurance. Buyers should engage in open dialogue with suppliers to clarify quality standards and expectations, ensuring alignment between both parties.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures in mixing equipment production is crucial for B2B buyers. By focusing on the main stages of manufacturing, relevant quality standards, and effective verification strategies, buyers can ensure they are making informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘application of mixing’

In this guide, we will outline a practical checklist for B2B buyers interested in procuring mixing solutions for various applications. This checklist will help streamline your sourcing process, ensuring that you select the right equipment and suppliers to meet your specific needs in industries such as food, chemicals, cosmetics, and pharmaceuticals.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for your mixing application. Consider factors such as viscosity, batch size, and the materials being mixed. This clarity will guide your search for mixers that can handle your unique specifications effectively.

- Viscosity and Density: Understand the viscosity of your materials, as this will influence the type of mixer required.

- Batch vs. Continuous Mixing: Decide whether you need batch mixing for smaller, varied quantities or continuous mixing for larger, ongoing production.

Step 2: Research Different Mixer Types

Familiarize yourself with the various types of mixers available, such as agitator mixers, static mixers, and drum mixers. Each type has its own advantages and is suited for different applications.

- Agitator Mixers: Ideal for blending solids and liquids; they can handle a wide range of viscosities.

- Static Mixers: Best for low-viscosity liquids, offering efficient inline mixing without moving parts.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers before making a commitment. Request detailed company profiles, case studies, and client references from businesses in similar industries or regions.

- Supplier Reputation: Look for suppliers with a proven track record in your specific application area.

- Certifications: Ensure suppliers comply with relevant quality and safety standards, which is crucial for industries like food and pharmaceuticals.

Step 4: Request Product Demonstrations

Before finalizing your purchase, request product demonstrations to see how the mixer performs in real-time. This step allows you to assess the machine’s efficiency and suitability for your needs.

- Performance Metrics: Pay attention to mixing speed, consistency, and ease of operation during the demonstration.

- Customization Options: Inquire about the ability to customize the mixer to fit your specific production requirements.

Step 5: Assess After-Sales Support and Service

Evaluate the after-sales support and service offered by suppliers. This is essential for ensuring long-term satisfaction and operational efficiency.

- Training and Maintenance: Check if the supplier provides training for your staff and ongoing maintenance support.

- Spare Parts Availability: Ensure that spare parts are readily available to minimize downtime in case of equipment failure.

Step 6: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare pricing structures and payment terms. Look for transparency in costs and any additional fees that may apply.

Illustrative image related to application of mixing

- Total Cost of Ownership: Consider not just the upfront cost but also maintenance, energy consumption, and potential operational efficiencies.

- Payment Flexibility: Look for suppliers offering flexible payment terms that align with your budget and cash flow.

Step 7: Finalize Your Purchase Agreement

Carefully review and finalize the purchase agreement with your chosen supplier. Ensure all terms are clearly outlined, including delivery timelines, warranty details, and service agreements.

- Clear Deliverables: Specify what is included in the purchase, such as installation services and training.

- Legal Compliance: Ensure the contract complies with local regulations and standards relevant to your industry.

By following this step-by-step checklist, B2B buyers can make informed decisions when sourcing mixing equipment, ultimately enhancing their production capabilities and product quality.

Comprehensive Cost and Pricing Analysis for application of mixing Sourcing

What Are the Key Cost Components for Mixing Applications?

When analyzing the cost structure of mixing applications, several components come into play. The primary cost components include:

-

Materials: The raw materials required for mixing can vary significantly depending on the industry and specific application. For example, food-grade emulsifiers may be more expensive than basic chemical components. Sourcing high-quality materials often results in a higher initial cost but can lead to improved product quality and lower long-term costs.

-

Labor: Labor costs can fluctuate based on the complexity of the mixing process and the expertise required. Highly skilled operators may command higher wages, but their expertise can enhance efficiency and reduce waste, ultimately benefiting the bottom line.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, maintenance, and facility costs. Effective management of overhead can help in achieving more competitive pricing.

-

Tooling: The initial investment in mixing equipment and tools can be substantial. Factors like the type of mixer (batch or continuous), the materials used for construction, and the customization required will influence the tooling costs.

-

Quality Control (QC): Ensuring the final product meets industry standards and regulations is critical, particularly in sectors such as food and pharmaceuticals. Investing in rigorous QC processes can prevent costly recalls and enhance customer satisfaction.

-

Logistics: Transportation costs, including shipping and handling, can significantly impact the overall cost structure. This is particularly relevant for international buyers who must consider customs duties, tariffs, and freight charges.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding the margin expectations can help buyers negotiate better deals.

How Do Price Influencers Impact Sourcing Decisions for Mixing Applications?

Several factors can influence pricing in the sourcing of mixing applications:

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing. Larger orders can lead to discounts, while smaller quantities may incur higher per-unit costs. Buyers should assess their needs and negotiate MOQs that align with their production schedules.

-

Specifications/Customization: Customizing mixers for specific applications can increase costs but may be necessary for optimal performance. Buyers should weigh the benefits of customization against potential cost increases.

-

Materials and Quality Certifications: The choice of materials and the presence of certifications (e.g., ISO, FDA) can significantly affect pricing. High-quality materials and compliance with regulatory standards usually come at a premium but can enhance product reliability and marketability.

-

Supplier Factors: The supplier’s reputation, reliability, and service levels can influence pricing. Established suppliers may charge more due to their track record and support services, but they may also offer better quality and assurance.

-

Incoterms: Understanding Incoterms is crucial for international transactions as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Choosing the right Incoterms can help manage costs and mitigate risks in global sourcing.

What Are Effective Buyer Tips for Negotiating Costs in Mixing Applications?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate for Total Cost of Ownership (TCO): Consider not only the upfront costs but also maintenance, operational efficiency, and potential downtime costs. A lower initial price may not always be the best value if it leads to higher long-term expenses.

-

Leverage Market Research: Understand the market trends and competitor pricing. Being informed allows buyers to negotiate from a position of strength.

-

Build Relationships with Suppliers: Establishing long-term partnerships can lead to better pricing and terms. Suppliers may be more willing to negotiate when they see a potential for repeat business.

-

Consider Payment Terms: Flexible payment terms can improve cash flow management. Buyers should negotiate terms that allow for better financial flexibility.

Conclusion: Understanding Pricing Nuances in the Mixing Sector

While the mixing industry presents various cost components and pricing influencers, a strategic approach can lead to significant savings and improved product quality. Buyers are encouraged to conduct thorough analyses, engage in informed negotiations, and foster strong supplier relationships to optimize their sourcing efforts. Note that prices can vary widely based on market conditions, so it is advisable to seek quotes and conduct comparative analyses regularly.

Alternatives Analysis: Comparing application of mixing With Other Solutions

Understanding Alternatives to Mixing Applications

In industrial processes, the application of mixing is a critical function, ensuring that components blend effectively to create a consistent final product. However, various alternatives exist that can achieve similar goals of blending, emulsifying, and homogenizing materials. Choosing the right solution involves evaluating performance, costs, implementation ease, maintenance requirements, and specific use cases.

Comparison of Mixing Applications and Alternatives

| Comparison Aspect | Application of Mixing | Alternative 1: Agitation | Alternative 2: Static Mixing |

|---|---|---|---|

| Performance | High efficiency in blending; suitable for various viscosities | Effective for slurries and suspensions; limited to specific applications | Best for low viscosity liquids; consistent performance in continuous flow |

| Cost | Moderate initial investment; operational costs vary | Generally lower initial costs; less expensive to operate | Low maintenance costs; moderate initial investment |

| Ease of Implementation | Requires skilled personnel for setup and operation | Easier to install; less technical expertise needed | Simple installation; minimal training required |

| Maintenance | Requires regular maintenance; parts may need frequent replacement | Low maintenance; fewer moving parts | Very low maintenance; no moving parts to service |

| Best Use Case | Ideal for food, pharmaceutical, and chemical industries | Suitable for mining, construction, and food processing | Best for water treatment, chemical blending, and low viscosity applications |

In-Depth Analysis of Alternatives

1. What Are the Advantages and Disadvantages of Agitation as an Alternative?

Agitation involves the use of mechanical devices, such as impellers or paddles, to mix materials. This method excels in applications involving slurries or highly viscous substances. The main advantage of agitation is its relatively lower initial cost and operational simplicity. However, it may not perform as well with low viscosity liquids and can require skilled personnel for optimal operation. Maintenance can also be a concern, as the moving parts can wear out over time.

2. How Does Static Mixing Compare in Terms of Performance and Cost?

Static mixing utilizes no moving parts, relying on fixed blades to blend materials as they flow through a cylindrical housing. This method is particularly effective for low viscosity liquids and is often used in industries such as water treatment and pharmaceuticals. The advantages of static mixing include low maintenance costs and consistent performance. However, it may not be suitable for all applications, particularly those requiring high shear or viscosity handling, limiting its versatility compared to traditional mixing methods.

Conclusion: How to Choose the Right Mixing Solution for Your Needs

When selecting between mixing applications and their alternatives, B2B buyers should carefully assess their specific operational requirements. Factors such as the type of materials being processed, production scale, budget constraints, and maintenance capabilities should all influence the decision. A thorough understanding of each method’s advantages and limitations will enable buyers to choose the most effective solution that aligns with their business objectives and operational efficiency.

Essential Technical Properties and Trade Terminology for application of mixing

What Are the Key Technical Properties in Mixing Applications?

In the realm of mixing applications, understanding the technical specifications is essential for effective decision-making. Here are several critical properties that B2B buyers should consider:

1. Material Grade

Material grade refers to the quality and type of materials used in manufacturing mixers and their components. For instance, stainless steel is commonly used for its corrosion resistance, making it ideal for food and pharmaceutical applications. Selecting the appropriate material grade ensures durability and compliance with industry standards, which is crucial for maintaining product integrity and safety.

2. Viscosity Range

Viscosity is a measure of a fluid’s resistance to flow. Different mixing applications require specific viscosity ranges to achieve optimal results. Understanding the viscosity of the materials being mixed helps in selecting the right mixer type, whether it’s an agitator for high-viscosity substances or a static mixer for low-viscosity liquids. This knowledge is vital for ensuring process efficiency and product consistency.

3. Mixing Speed

Mixing speed, often expressed in revolutions per minute (RPM), impacts the effectiveness of the mixing process. Different applications demand varying speeds; for example, high shear mixing is necessary for emulsifying delicate substances, while slower speeds may be adequate for blending solids. Choosing the correct mixing speed can improve product quality and reduce processing time.

Illustrative image related to application of mixing

4. Tolerance Levels

Tolerance levels indicate the permissible limits of variation in dimensions and performance of mixer components. High tolerance levels are critical in industries like pharmaceuticals, where precision is paramount to ensure consistent dosing. Understanding tolerance requirements aids in selecting equipment that meets operational standards, which can help avoid costly production errors.

5. Batch Size

Batch size refers to the quantity of materials processed in a single mixing operation. Different mixers are designed for specific batch sizes, and understanding these specifications allows businesses to optimize production scales. Selecting the right batch size helps in managing inventory and ensuring that production meets market demands efficiently.

What Are Common Trade Terms in Mixing Applications?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several common terms you should know:

Illustrative image related to application of mixing

1. OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products or components that are used in another company’s end products. In the mixing industry, buyers may source mixers from OEMs that specialize in specific applications. Understanding OEM relationships can help buyers ensure they are getting reliable, high-quality equipment.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their procurement strategies and manage costs effectively. It is particularly important for smaller businesses or those entering new markets where initial orders may be limited.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. In mixing applications, an RFQ can help buyers compare different suppliers’ offerings and negotiate better deals. Crafting a detailed RFQ is essential for ensuring that all necessary specifications are considered.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is crucial for international transactions, as they clarify who is responsible for shipping costs, insurance, and risks during transport. Understanding these terms can help buyers avoid disputes and ensure smooth logistics.

5. CIP (Carriage and Insurance Paid To)

CIP is an Incoterm that indicates the seller is responsible for paying transportation and insurance costs to a specified destination. For B2B buyers, understanding CIP helps in evaluating total landed costs and negotiating terms that align with their logistics strategies.

Illustrative image related to application of mixing

By mastering these technical properties and trade terminologies, B2B buyers can make informed decisions, optimize their procurement processes, and enhance their operational efficiency in mixing applications.

Navigating Market Dynamics and Sourcing Trends in the application of mixing Sector

What Are the Current Market Dynamics and Key Trends in the Application of Mixing?

The application of mixing technologies is witnessing transformative changes driven by globalization, technological advancements, and evolving consumer preferences. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize production efficiency, the demand for industrial mixers is surging. Key trends include the rise of automation and Industry 4.0, which integrate IoT and AI technologies into mixing processes, enhancing precision and reducing downtime. Furthermore, the shift towards sustainable practices is reshaping sourcing strategies, pushing manufacturers to adopt energy-efficient and environmentally friendly mixing solutions.

Emerging markets are particularly influenced by the demand for high-quality products in sectors such as food and beverage, pharmaceuticals, and cosmetics. Buyers in these regions are increasingly looking for suppliers that offer customized mixing solutions tailored to specific applications, such as the production of plant-based alternatives and advanced pharmaceutical formulations. Additionally, the focus on scalability allows manufacturers to adapt quickly to market changes, ensuring they remain competitive in a rapidly evolving landscape.

How Is Sustainability and Ethical Sourcing Impacting the Mixing Sector?

Sustainability has become a cornerstone of modern manufacturing practices, significantly impacting the application of mixing technologies. As global awareness of environmental issues grows, businesses are increasingly prioritizing ethical sourcing and reducing their ecological footprint. This shift not only appeals to environmentally conscious consumers but also aligns with regulatory requirements in many regions.

Illustrative image related to application of mixing

In the mixing sector, the use of sustainable materials and practices is gaining traction. B2B buyers are advised to seek suppliers who provide ‘green’ certifications, indicating compliance with environmental standards. This includes the use of biodegradable lubricants in mixers, energy-efficient equipment, and materials sourced from sustainable practices. By investing in sustainable mixing technologies, companies not only enhance their brand reputation but also mitigate risks associated with supply chain disruptions and regulatory non-compliance.

What Is the Historical Context of Mixing Technologies in B2B Applications?

The evolution of mixing technologies has its roots in early industrial processes where manual methods were predominant. Over the decades, advancements in mechanical engineering led to the development of various types of mixers, including agitators, static mixers, and drum mixers, each tailored to specific applications. The introduction of automation in the late 20th century marked a significant turning point, allowing for more consistent and efficient mixing processes.

Today, the application of mixing is integral to numerous industries, reflecting the ongoing evolution of technology and consumer demands. As B2B buyers continue to prioritize efficiency and sustainability, the mixing sector is poised for further innovations, driven by the need for high-quality products and environmentally responsible practices. Understanding this historical context can provide valuable insights into future trends and opportunities for buyers in diverse markets.

Frequently Asked Questions (FAQs) for B2B Buyers of application of mixing

-

How do I solve common mixing problems in my production process?

To address common mixing issues such as poor homogeneity, unwanted foam, or material settling, first assess your mixing equipment’s suitability for your specific application. Upgrading to high-shear mixers or employing specialized agitators can improve blending efficiency. Additionally, consider incorporating inline static mixers for continuous processes. Regular maintenance and calibration of your mixers also help to ensure consistent performance. Collaborating with experienced suppliers can provide tailored solutions that address your unique challenges. -

What is the best type of mixer for my specific application?

Choosing the right mixer depends on various factors including the viscosity of your materials, batch size, and desired mixing speed. For low-viscosity liquids, static mixers may be ideal, while high-viscosity substances might require high-shear or agitator mixers. In food applications, sanitary mixers are crucial to meet health standards. Conduct a thorough analysis of your production needs and consult with suppliers who can recommend mixers that align with your operational requirements. -

How can I ensure the quality of mixing equipment from international suppliers?

To ensure quality, start by conducting thorough supplier vetting. Look for manufacturers with certifications such as ISO or industry-specific quality standards. Request samples or case studies that demonstrate the effectiveness of their mixers in applications similar to yours. Additionally, verify customer testimonials and reviews to gauge reliability. Establish clear communication to discuss quality assurance processes, warranties, and after-sales support to safeguard your investment. -

What are the typical payment terms for sourcing mixing equipment internationally?

Payment terms can vary widely by supplier and region. Common terms include partial upfront payments, letters of credit, or net payment options after delivery. Always clarify payment schedules, currencies accepted, and any additional fees such as shipping or tariffs. It’s advisable to negotiate terms that are mutually beneficial while ensuring that they align with your company’s cash flow management practices. -

What is the minimum order quantity (MOQ) for mixing equipment?

Minimum order quantities for mixing equipment can differ based on the supplier and type of mixer. Some manufacturers may have flexible MOQs for standard equipment, while custom or specialized mixers typically require larger orders. Be upfront about your needs and ask suppliers about their MOQ policies. Negotiating terms can sometimes yield smaller order sizes, especially for first-time purchases or trial runs. -

How do I manage logistics when importing mixing equipment?

Effective logistics management begins with selecting a reliable freight forwarder familiar with international shipping regulations. Ensure you understand the customs requirements for your country, including tariffs and import duties. Plan for potential delays by allowing extra time for shipping and customs clearance. Maintain communication with your supplier throughout the process to track shipment progress and address any issues proactively. -

What customization options are available for mixing equipment?

Many manufacturers offer customization options to meet specific operational needs. Common customizations include size adjustments, material upgrades (e.g., corrosion-resistant materials), and tailored impeller designs for improved mixing efficiency. Discuss your requirements with potential suppliers early in the negotiation process to explore what modifications are feasible and how they can enhance your production capabilities. -

How can I ensure compliance with international regulations when sourcing mixing equipment?

Compliance with international regulations involves understanding the standards applicable to your industry and region. Research the relevant safety, environmental, and quality standards that your equipment must meet. Engage suppliers who can provide documentation proving compliance, such as CE markings or FDA approvals for food and pharmaceutical applications. Regularly update your knowledge of regulations to ensure ongoing compliance as laws evolve.

Top 6 Application Of Mixing Manufacturers & Suppliers List

1. Silverson – Key Mixers for Diverse Applications

Domain: silverson.com

Registered: 1996 (29 years)

Introduction: Silverson offers a range of mixers suitable for various applications across different industries. Key product details include:

1. **Lab Series**: Ideal for laboratory work and R&D, includes Laboratory Mixers, Laboratory In-Line Mixers, and Laboratory Powder/Liquid Mixers.

2. **Batch Series**: Designed to mix, emulsify, homogenize, disintegrate, and dissolve materials.

3. **Pilot Scale Batch Mi…

2. Paul Mueller – Industrial Mixing Processes

Domain: de.paulmueller.com

Registered: 1995 (30 years)

Introduction: The text outlines six common industrial mixing processes: 1. Miscible Liquids Blending – involves blending liquids that completely dissolve into one another, requiring light to moderate agitation. Examples include injectables and mouthwash. 2. Soluble Solid-Liquid Dissolution – involves dissolving solids in liquids, requiring less aggressive agitation, often using flow-driven mixing. 3. Chemical R…

3. ScienceDirect – Mixing Process Insights

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: A mixing process is a method aimed at creating a new homogeneous product by combining several substances, primarily utilizing electricity-based techniques. It is crucial for preparing raw materials, such as polymers, before shaping them into final products. The mixing process involves adding fillers, additional polymers, reinforcing agents, and chemical additives to improve the appearance and prop…

4. IQS Directory – Types of Mixers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Types of Mixers: Paddle Mixer (for viscous semi-solid substances), Horizontal Ribbon Mixer (for food, chemicals, powders), Tumbler Mixer (for bakery ingredients), Drum Mixer (for low and medium viscosity materials like slurry or cement), Emulsifier (for immiscible liquids like oils), Static Mixer (for gases and liquids). Capacity: Drum mixers typically have a capacity of 50 to 100 gallons (190 to …

5. Mixing Techniques – Types and Processes

Domain: slideshare.net

Registered: 2006 (19 years)

Introduction: This document discusses different types of mixers and mixing processes. It defines mixing as a unit operation that results in randomization of particles within a system. There are three types of mixtures – positive, negative, and neutral – based on how their components mix and separate. Mixing is commonly used in pharmaceutical formulations to prepare powders, liquids, semi-solids and other dosage…

6. Mixing Experts – Key Success Criteria

Domain: mixing-experts.com

Registered: 2020 (5 years)

Introduction: The mixing process involves several key criteria for success, including: 1. Identification of ingredients and raw materials. 2. Formulation development in the laboratory. 3. Objectivation through various tests (in vitro, ex vivo, tolerance, clinical trials, consumer tests). 4. Regulation for product conformity and registration, which can vary by country. 5. Distribution channels (importers, distri…

Strategic Sourcing Conclusion and Outlook for application of mixing

What Are the Key Takeaways from the Application of Mixing?

The application of mixing across various industries—ranging from food and beverages to pharmaceuticals and cosmetics—highlights its critical role in enhancing product quality and operational efficiency. As international B2B buyers, understanding the specific mixing requirements and challenges in your sector can lead to better sourcing decisions. For instance, high shear mixers are essential for achieving uniform emulsions in cosmetic formulations, while static mixers can streamline chemical processes in pharmaceuticals.

How Does Strategic Sourcing Enhance Your Mixing Operations?

Strategic sourcing is fundamental for optimizing the procurement of mixing equipment and materials. By identifying reliable suppliers and leveraging global networks, businesses can ensure access to advanced mixing technologies tailored to their unique needs. This not only reduces costs but also fosters innovation, enabling companies to stay competitive in rapidly evolving markets.

Illustrative image related to application of mixing

What’s Next for International Buyers in the Mixing Industry?

As you navigate the complexities of sourcing mixing solutions, consider the emerging trends such as sustainable practices and automation. Engaging with suppliers who prioritize eco-friendly materials and innovative technologies will prepare your business for future challenges. Embrace this opportunity to enhance your operations and drive growth. Reach out today to explore strategic partnerships that can elevate your mixing applications and ensure your business thrives on the global stage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to application of mixing

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.