The Definitive Guide to Aircraft Wire: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for aircraft wire

In the fast-evolving landscape of aviation, sourcing high-quality aircraft wire is a critical challenge that international B2B buyers face. Whether you are operating in the dynamic markets of Africa, South America, the Middle East, or Europe, ensuring the reliability and safety of your aircraft’s electrical systems hinges on selecting the right wiring solutions. This comprehensive guide delves into the various types of aircraft wire, including insulated, shielded, and multi-conductor options, as well as their applications in both commercial and military aviation contexts.

Moreover, we provide essential insights into the supplier vetting process, helping you identify reputable manufacturers and distributors that meet international standards. You’ll also find a detailed analysis of cost factors, enabling you to make informed purchasing decisions that align with your budgetary constraints and operational needs.

By empowering B2B buyers with actionable information, this guide serves as a vital resource to navigate the complexities of sourcing aircraft wire. We aim to equip you with the knowledge necessary to enhance your procurement strategies and improve the performance and safety of your aviation operations. As you explore the intricacies of this global market, you can confidently position your business for success in an increasingly competitive landscape.

Understanding aircraft wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tefzel Wire | High resistance to corrosion, temperature extremes | Avionics, internal wiring, harsh environments | Pros: Durable, versatile; Cons: Higher cost compared to standard wire. |

| Aircraft Ground Strapping | Essential for grounding circuits, prevents interference | Engine components, electrical systems | Pros: Critical for safety; Cons: Often overlooked, leading to potential issues. |

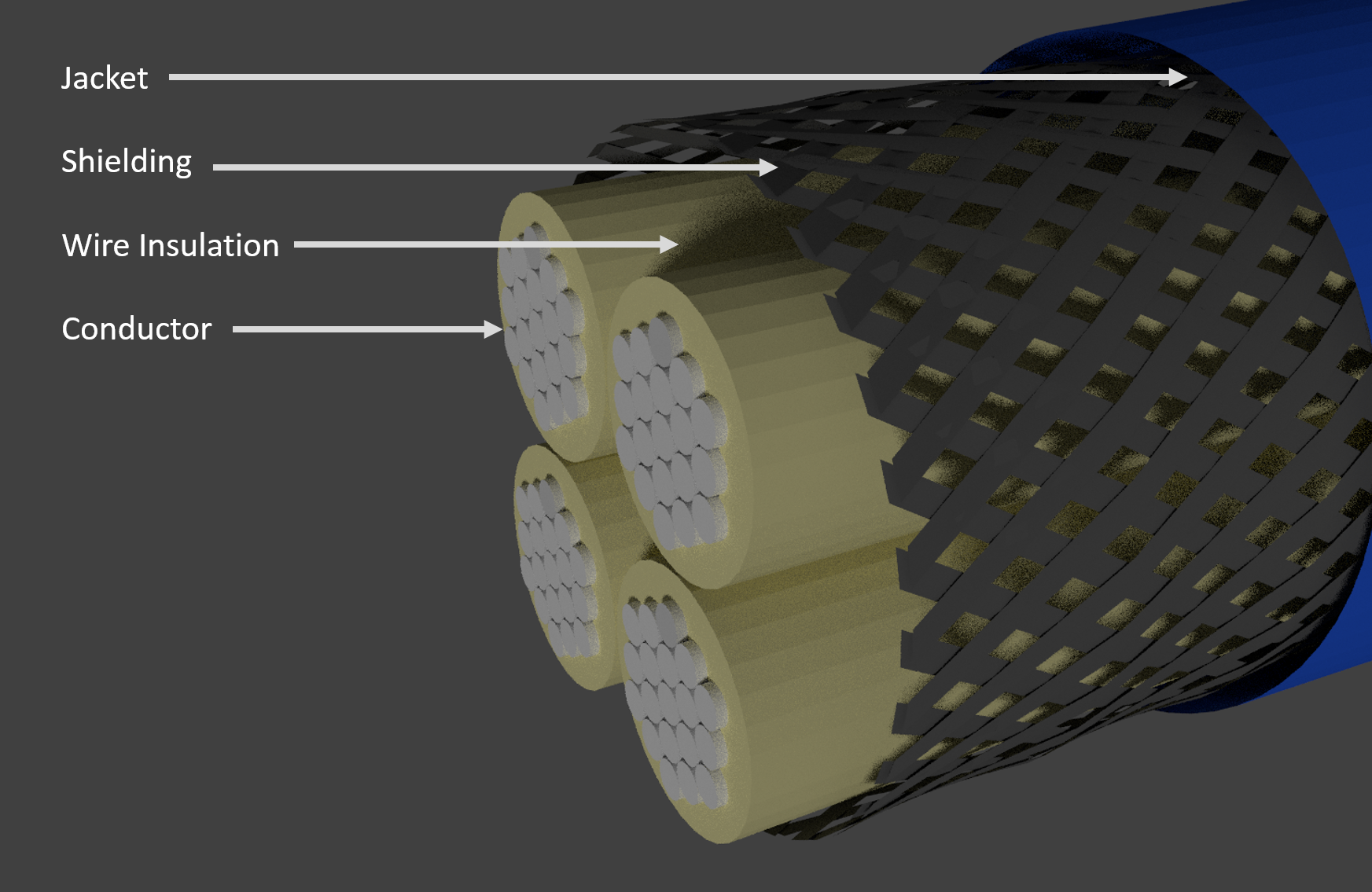

| Shielded Wire | Provides protection from electromagnetic interference | Sensitive avionics, communication systems | Pros: Enhances signal integrity; Cons: More complex installation. |

| Multi-Conductor Cable | Multiple conductors within a single cable | Control systems, signal transmission | Pros: Space-saving, efficient; Cons: Can be expensive and complex. |

| High-Performance Wires | Chemically inert, high durability in extreme conditions | Defense aircraft, high-stakes aviation applications | Pros: Long-lasting, reliable; Cons: Premium pricing may deter budget-conscious buyers. |

What Are the Characteristics of Tefzel Wire for Aircraft Applications?

Tefzel wire is notable for its exceptional resistance to both corrosion and extreme temperatures, making it an ideal choice for aviation applications. Its insulation maintains integrity in harsh conditions, thus ensuring reliable performance. B2B buyers should consider Tefzel wire for avionics and internal wiring, particularly in environments where exposure to chemicals or temperature fluctuations is common. The initial investment is higher, but the long-term durability can lead to lower maintenance costs.

Why Is Aircraft Ground Strapping Essential for Safety?

Aircraft ground strapping is crucial for grounding circuits and preventing electrical interference, which can lead to malfunctions in engine and electrical systems. This wire type is often used in critical areas where safety is paramount. B2B buyers must recognize the importance of including ground strapping in their procurement lists, as neglecting it can lead to severe operational risks. Its cost-effectiveness becomes evident when considering the potential costs associated with electrical failures.

How Does Shielded Wire Enhance Aircraft Communication Systems?

Shielded wire is specifically designed to protect sensitive electrical signals from electromagnetic interference, making it indispensable for avionics and communication systems. This type of wire ensures that data integrity is maintained, especially in crowded electromagnetic environments. For B2B buyers, investing in shielded wire can significantly enhance the reliability of communication systems, though it may require more complex installation processes.

What Advantages Does Multi-Conductor Cable Offer in Aircraft Wiring?

Multi-conductor cables bundle several conductors into a single cable, providing significant space-saving advantages. They are widely used in control systems and signal transmission applications within aircraft. B2B buyers should weigh the benefits of efficiency and reduced installation complexity against the higher costs and potential complications associated with multi-conductor systems. Choosing the right type will depend on the specific wiring requirements of the aircraft.

What Makes High-Performance Wires Suitable for Defense Aircraft?

High-performance wires are engineered to withstand extreme environmental conditions, making them ideal for defense and high-stakes aviation applications. Their chemically inert properties and resistance to chafing and abrasion ensure long-term reliability. B2B buyers focusing on defense contracts should prioritize these wires for their durability and performance under stress, although the premium pricing may be a consideration for budget constraints.

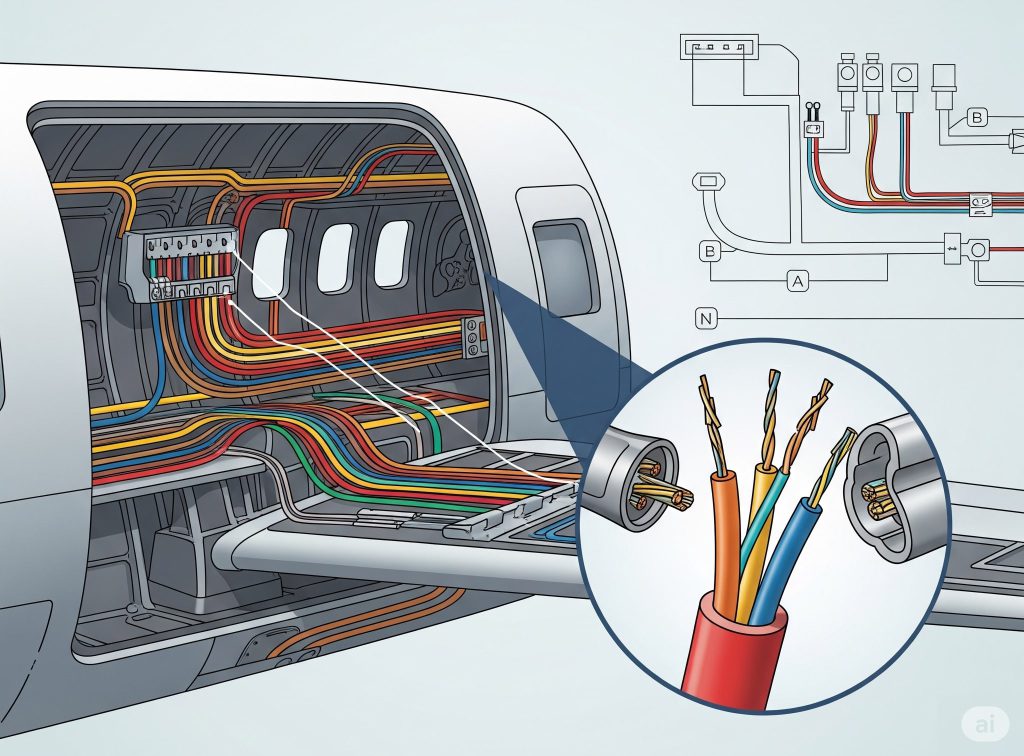

Illustrative image related to aircraft wire

Key Industrial Applications of aircraft wire

| Industry/Sector | Specific Application of aircraft wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace Manufacturing | Wiring for avionics and control systems | Ensures reliable performance and safety in flight | Compliance with international standards and certifications |

| Military Aviation | High-performance wiring for defense aircraft | Enhances durability and operational readiness | Resistance to harsh environments and materials |

| Commercial Aviation | Electrical systems for passenger aircraft | Improves passenger safety and comfort | Lightweight materials with high tensile strength |

| General Aviation | Wiring for small aircraft and UAVs | Reduces maintenance costs and increases efficiency | Cost-effective solutions with high reliability |

| Space Exploration | Specialized wiring for spacecraft systems | Supports advanced technologies and mission success | Extreme temperature and radiation resistance |

How is Aircraft Wire Used in Aerospace Manufacturing?

In aerospace manufacturing, aircraft wire is critical for wiring avionics and control systems. These wires connect essential instruments and systems, ensuring reliable performance and safety during flight. Buyers need to prioritize sourcing wires that comply with international standards, such as ASTM and SAE, to guarantee quality and reliability. The aviation sector often demands high-temperature resistance, lightweight materials, and durability to withstand the rigors of flight, making it essential for international B2B buyers to choose suppliers with proven track records.

What Role Does Aircraft Wire Play in Military Aviation?

Military aviation relies heavily on high-performance wiring for defense aircraft. These wires are designed to endure extreme conditions, ensuring durability and operational readiness. The use of specialized materials that resist chafing, abrasion, and harsh environmental factors is vital. Buyers in this sector must consider the wires’ resistance to chemicals and moisture, as well as their compliance with military specifications. Establishing relationships with suppliers who understand the unique needs of military applications is critical for international buyers.

How is Aircraft Wire Integrated into Commercial Aviation?

In commercial aviation, aircraft wire is primarily used for electrical systems in passenger aircraft. This includes wiring for lighting, communication, and navigation systems, all of which enhance passenger safety and comfort. The demand for lightweight yet strong materials is paramount to improve fuel efficiency and overall performance. B2B buyers should focus on sourcing wires that meet rigorous safety standards while also being cost-effective. Establishing a consistent supply chain for these critical components is essential for maintaining operational efficiency.

Illustrative image related to aircraft wire

Why is Aircraft Wire Important for General Aviation?

General aviation, including small aircraft and UAVs, utilizes aircraft wire for various electrical and control systems. The choice of wire can significantly reduce maintenance costs and improve operational efficiency. Buyers should seek cost-effective solutions that do not compromise on quality or reliability. Furthermore, sourcing from suppliers that offer a range of wire types, such as Tefzel and shielded wires, ensures that buyers can meet specific requirements for different aircraft models and operational needs.

How is Aircraft Wire Essential for Space Exploration?

In space exploration, specialized wiring is crucial for spacecraft systems. These wires must withstand extreme temperatures, radiation, and other harsh conditions encountered in space. The performance of these wires directly impacts mission success and the safety of astronauts. International B2B buyers need to source wires that meet stringent aerospace standards, focusing on suppliers with expertise in high-performance materials. Understanding the unique challenges of space applications is vital for making informed purchasing decisions in this highly specialized sector.

3 Common User Pain Points for ‘aircraft wire’ & Their Solutions

Scenario 1: The Challenge of Compliance with International Aviation Standards

The Problem: B2B buyers often struggle with ensuring that the aircraft wire they purchase complies with stringent international aviation safety standards. This challenge is especially significant for companies in regions such as Africa and South America, where regulatory updates may not be as readily available. Buyers may find themselves with wire products that do not meet the necessary certifications, leading to costly delays and potential safety hazards.

The Solution: To mitigate this problem, buyers should prioritize sourcing aircraft wire from reputable suppliers who provide clear documentation of compliance with standards such as ASTM, FAA, or EASA. Establishing a checklist of required certifications can streamline the procurement process. Additionally, buyers should consider forming partnerships with local distributors or representatives who are familiar with regional regulations and can provide guidance on compliant products. Regular training sessions on the latest standards can also equip procurement teams with the knowledge needed to make informed decisions.

Scenario 2: Difficulty in Selecting the Right Type of Aircraft Wire

The Problem: With a variety of aircraft wire types available, B2B buyers frequently face confusion over which wire best suits their specific aircraft applications. This can lead to the selection of unsuitable materials, resulting in performance issues, increased maintenance costs, and safety concerns. For instance, choosing the wrong insulation type can lead to wire degradation in extreme temperature variations, which is common in regions like the Middle East.

The Solution: Buyers should invest time in understanding the specific requirements of their aircraft and the environments in which they operate. It is beneficial to engage with technical experts or manufacturers who can offer detailed specifications and performance comparisons of different wire types. Creating a matrix of applications against wire properties—such as temperature resistance, weight, and chemical exposure—can guide buyers in making informed choices. Utilizing application guides and consulting case studies from similar operational contexts can also provide invaluable insights into wire selection.

Scenario 3: Managing Supply Chain Disruptions

The Problem: Global supply chain disruptions have become a significant concern for B2B buyers, particularly in the aviation sector. Delays in wire shipments can halt aircraft maintenance and manufacturing processes, leading to financial losses and operational setbacks. Buyers in regions with less robust logistical infrastructures, such as parts of Africa and South America, may feel this impact even more acutely.

The Solution: To counteract supply chain issues, buyers should develop a diversified sourcing strategy that includes multiple suppliers across different geographical regions. Building strong relationships with both local and international suppliers can enhance flexibility and responsiveness. Additionally, implementing a just-in-time inventory system can help manage stock levels and reduce the risk of over-reliance on a single source. Regularly reviewing supply chain performance metrics and maintaining open lines of communication with suppliers can enable quicker adjustments to unforeseen disruptions, ensuring continuity in operations.

Strategic Material Selection Guide for aircraft wire

What Are the Key Properties of Common Aircraft Wire Materials?

When selecting aircraft wire materials, understanding their properties is crucial for ensuring optimal performance in aviation applications. Below are analyses of four common materials used in aircraft wiring, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Copper

Key Properties:

Copper is renowned for its excellent electrical conductivity, making it a preferred choice for wiring applications. It typically operates effectively within a temperature range of -40°C to 150°C and has a high tensile strength. However, it is susceptible to corrosion, particularly in saline environments.

Pros & Cons:

Copper wires are highly durable and have a long lifespan when properly maintained. They are relatively easy to manufacture and terminate. However, their susceptibility to corrosion can lead to increased maintenance costs and potential failures in harsh environments. Additionally, copper is more expensive than aluminum, which may impact budget considerations.

Impact on Application:

Copper wires are suitable for applications requiring high conductivity, such as power distribution and avionics. However, in humid or saline environments, additional protective coatings or treatments may be necessary.

Considerations for International Buyers:

Compliance with international standards such as ASTM B3 (for copper wire) is critical. Buyers from regions like Africa and the Middle East should be aware of local corrosion risks and may need to consider additional protective measures.

2. Aluminum

Key Properties:

Aluminum offers a good balance of conductivity and weight, making it an attractive alternative to copper. It typically operates within a temperature range of -65°C to 150°C and has a lower density, which is advantageous for weight-sensitive applications.

Pros & Cons:

Aluminum is less expensive than copper and is resistant to corrosion due to its natural oxide layer. However, it has lower conductivity, requiring larger diameters to achieve equivalent performance. Manufacturing can be more complex, particularly in terms of terminations.

Impact on Application:

Aluminum wires are commonly used in high-voltage applications and in aircraft where weight savings are critical. However, they may require specialized connectors to ensure reliable performance.

Considerations for International Buyers:

Buyers should ensure compliance with standards like ASTM B800 for aluminum wire. In regions with high humidity, additional protective measures may be necessary to mitigate corrosion risks.

3. Tefzel (ETFE)

Key Properties:

Tefzel is a fluoropolymer known for its excellent chemical resistance and thermal stability, with operating temperatures ranging from -70°C to 150°C. It provides superior insulation and is resistant to abrasion and chafing.

Pros & Cons:

The primary advantage of Tefzel is its durability in extreme environments, making it suitable for military and aerospace applications. However, it is more expensive than traditional materials and can be more challenging to work with during installation.

Impact on Application:

Tefzel is ideal for applications exposed to harsh chemicals or extreme temperatures, such as in military aircraft. Its superior insulation properties enhance safety and reliability.

Illustrative image related to aircraft wire

Considerations for International Buyers:

Compliance with standards such as MIL-W-22759 is essential. Buyers in regions with stringent aviation regulations, like Europe, should ensure that Tefzel wiring meets all necessary certifications.

4. GORE® High Performance Wires

Key Properties:

GORE® wires are designed for extreme durability, with resistance to chemicals, humidity, and high temperatures. They maintain performance in a wide temperature range and are lightweight.

Pros & Cons:

These wires offer exceptional reliability and longevity, reducing the need for frequent replacements. However, they come at a premium price point, which may not be feasible for all budgets.

Impact on Application:

GORE® wires are particularly suited for defense and high-performance aircraft applications where reliability is critical. Their unique properties make them ideal for environments that challenge conventional materials.

Illustrative image related to aircraft wire

Considerations for International Buyers:

Buyers should verify compliance with international standards and certifications relevant to their specific region, especially in defense-related applications.

Summary Table of Aircraft Wire Materials

| Material | Typical Use Case for aircraft wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Power distribution, avionics | Excellent electrical conductivity | Susceptible to corrosion | High |

| Aluminum | High-voltage applications | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Tefzel (ETFE) | Military and aerospace applications | Superior chemical and thermal resistance | Higher cost and installation complexity | High |

| GORE® High Performance Wires | Defense and high-performance aircraft | Exceptional durability and reliability | Premium price point | High |

This guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding aircraft wire materials, ensuring compliance with regional standards and suitability for specific applications.

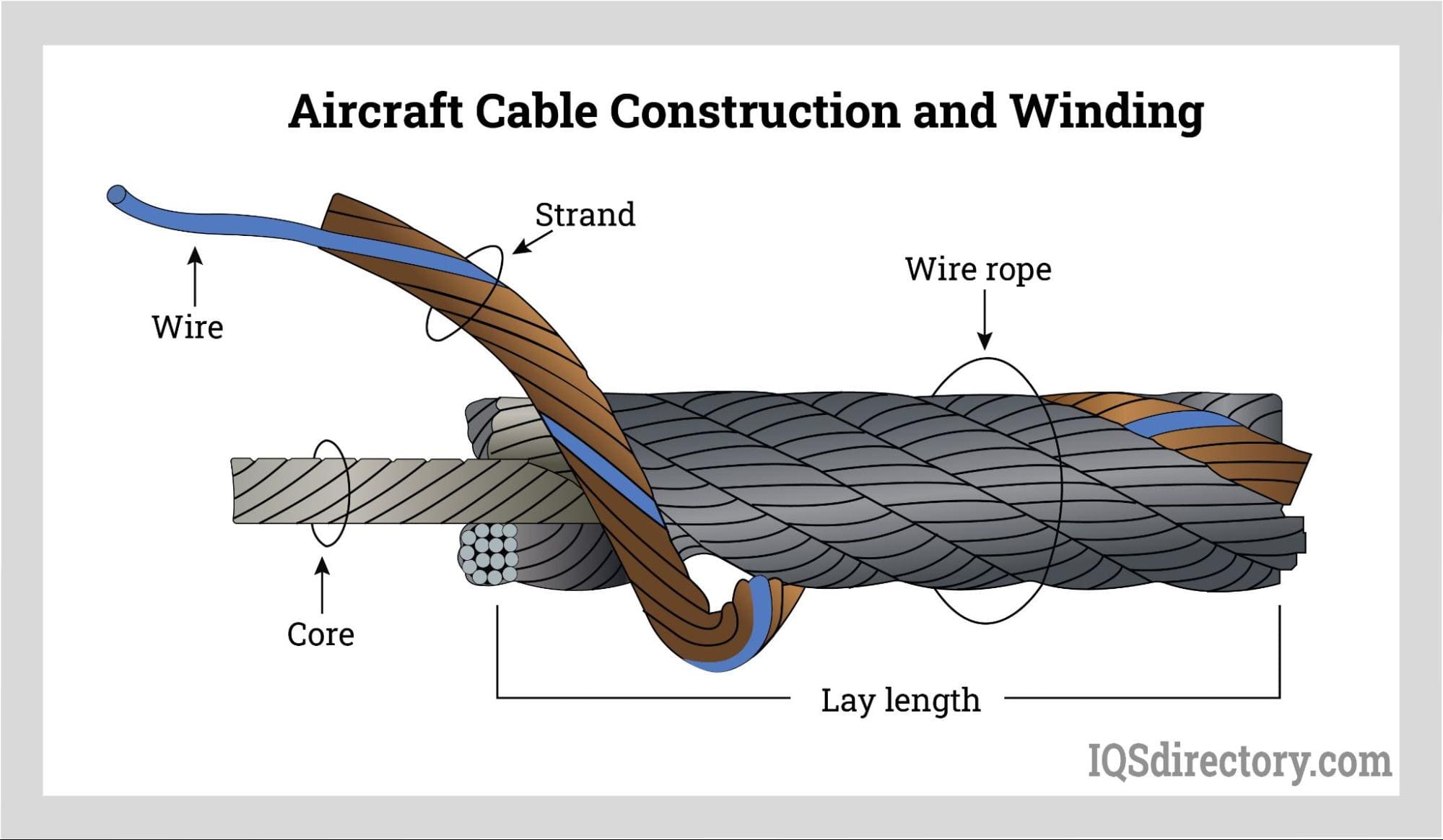

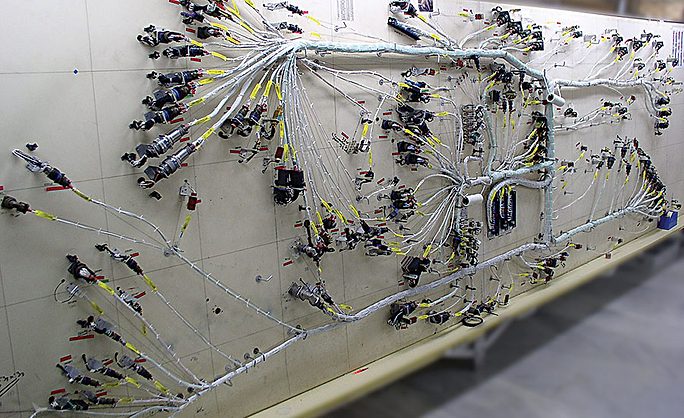

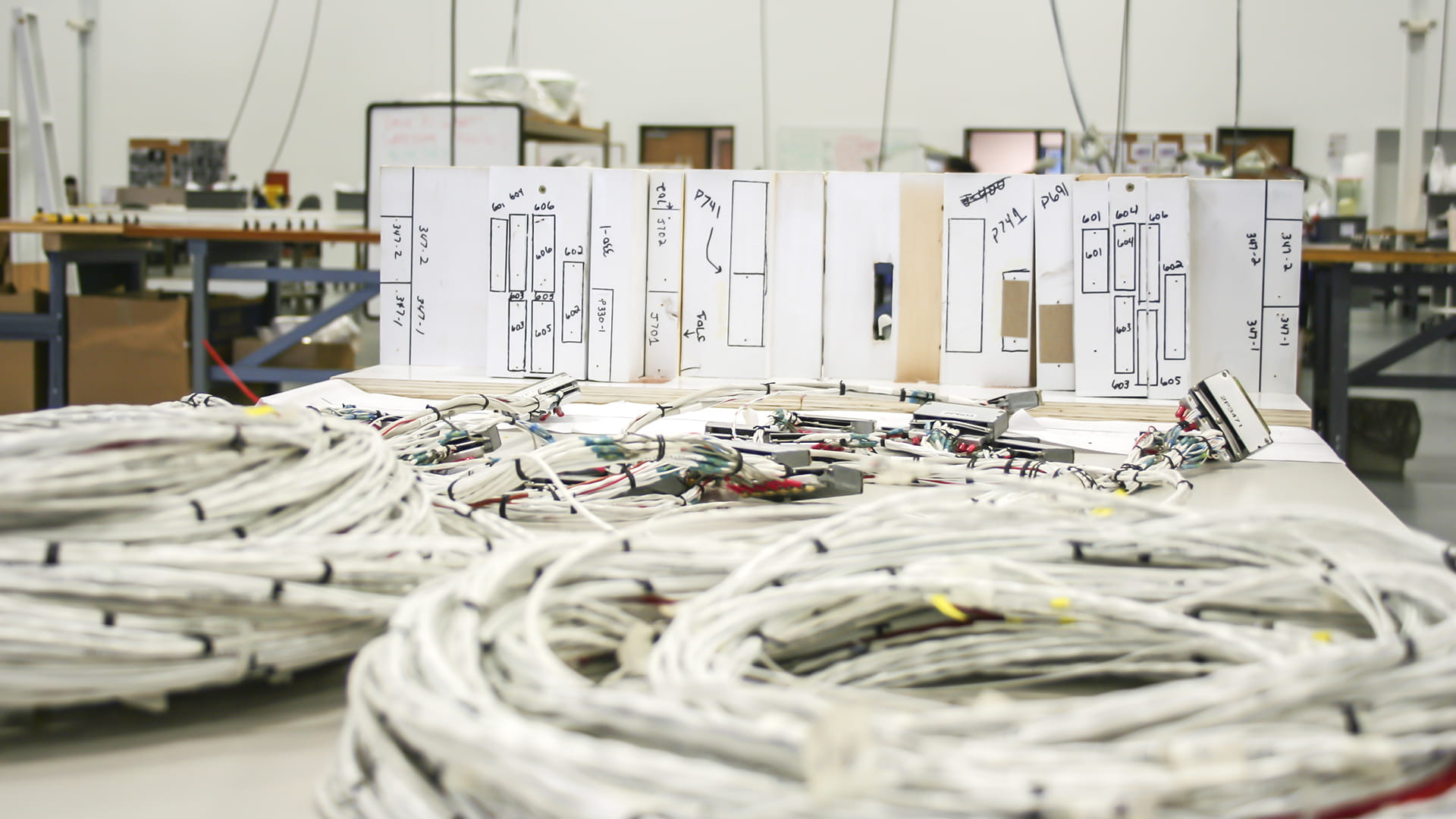

In-depth Look: Manufacturing Processes and Quality Assurance for aircraft wire

What Are the Key Stages in Aircraft Wire Manufacturing Processes?

The manufacturing of aircraft wire involves several critical stages that ensure the final product meets the stringent safety and performance requirements of the aviation industry. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

-

Material Preparation: The process begins with selecting the appropriate raw materials, typically copper or aluminum, which are known for their excellent electrical conductivity. The materials undergo treatment to remove impurities, ensuring high-quality wire. In many cases, specialized coatings are applied to enhance durability and resistance to environmental factors, such as corrosion and extreme temperatures.

-

Forming: During this stage, the prepared materials are drawn into wire of specific diameters. This is achieved through a series of dies that gradually reduce the wire’s thickness while maintaining its structural integrity. Advanced techniques such as cold drawing may be employed to achieve tighter tolerances and improved mechanical properties.

-

Assembly: Depending on the application, wires may be bundled or twisted together to form multi-conductor cables. This assembly process often includes the installation of connectors, insulation, and protective sheathing. The choice of insulation material, such as Tefzel or silicone, is crucial for providing the necessary thermal and chemical resistance.

-

Finishing: The final stage includes processes such as annealing, which helps to relieve stress in the wire and improve flexibility. Additional finishing treatments may involve applying surface coatings or markings for identification and traceability. Quality checks are conducted throughout this stage to ensure compliance with specifications.

How Is Quality Assurance Implemented in Aircraft Wire Manufacturing?

Quality assurance in aircraft wire manufacturing is paramount to ensuring safety and reliability. Various international and industry-specific standards guide this process, and buyers should familiarize themselves with these standards to evaluate suppliers effectively.

-

International Standards: Compliance with ISO 9001 is a fundamental requirement for manufacturers. This standard outlines a framework for a quality management system (QMS) that emphasizes customer satisfaction and continuous improvement. B2B buyers should inquire about a supplier’s ISO certification and their adherence to documented quality processes.

-

Industry-Specific Standards: Beyond ISO, suppliers may also comply with specific aviation standards such as AS9100, which focuses on quality management systems in aerospace manufacturing. Additional certifications, such as CE marking for products sold in Europe or API standards for oil and gas applications, can further assure buyers of quality.

What Are the Key Quality Control Checkpoints in Aircraft Wire Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with several key checkpoints established to maintain product integrity.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt. It ensures that all materials meet specified requirements before production begins. Testing may include verifying material certifications and conducting physical inspections.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, IPQC checkpoints are established to monitor production. This may include measuring wire diameter, tensile strength, and conductivity at various stages. Non-conformance issues are documented and addressed promptly to prevent defects from progressing.

-

Final Quality Control (FQC): Before products are shipped, FQC involves comprehensive testing of finished wires. This may include electrical testing for continuity, insulation resistance, and durability assessments. Certifications and test reports are generated, providing transparency to B2B buyers.

What Testing Methods Are Commonly Used for Aircraft Wire Quality Assurance?

Various testing methods are employed to ensure the safety and reliability of aircraft wire. Understanding these methods can help buyers assess the credibility of their suppliers.

-

Electrical Testing: This includes tests for continuity and insulation resistance, ensuring that the wire can conduct electricity without leakage. Suppliers may also conduct high-voltage tests to verify insulation integrity under extreme conditions.

-

Mechanical Testing: Tensile strength tests assess the wire’s ability to withstand pulling forces without breaking. Additionally, flexibility tests evaluate how well the wire can bend without damage, which is critical for installation in confined spaces.

-

Environmental Testing: Wires are subjected to temperature cycling, humidity exposure, and chemical resistance tests to simulate real-world conditions. This helps ensure that the wire will perform reliably in various environments, particularly in regions with extreme climates, such as Africa and the Middle East.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several proactive steps.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should evaluate the supplier’s adherence to quality standards and their commitment to continuous improvement.

-

Requesting Documentation: Buyers should ask for quality assurance documentation, including certificates of compliance, test reports, and details on the supplier’s QMS. This information can help verify that the supplier meets industry standards.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These organizations can perform independent assessments of the supplier’s processes and products, providing unbiased evaluations of quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control.

-

Regulatory Compliance: Different regions may have varying regulations regarding aviation safety and product standards. Buyers should ensure that their suppliers comply with both local and international regulations relevant to their market.

-

Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother communication and negotiation with suppliers. Building relationships based on trust can enhance the buyer-supplier partnership, which is crucial for long-term success.

-

Logistical Challenges: International shipping and logistics can introduce risks to product quality. Buyers should work with suppliers who have robust logistics management systems in place to mitigate potential issues during transportation.

In conclusion, understanding the manufacturing processes and quality assurance practices for aircraft wire is essential for B2B buyers seeking reliable suppliers. By familiarizing themselves with these processes, testing methods, and quality control measures, buyers can make informed decisions that enhance safety and performance in their aviation applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aircraft wire’

Introduction

Sourcing aircraft wire is a critical task for businesses involved in aviation, whether for manufacturing, maintenance, or repair. This guide provides a step-by-step checklist to help B2B buyers make informed decisions when procuring aircraft wire, ensuring safety, compliance, and quality in their operations.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for the aircraft wire you need is paramount. Consider factors such as diameter, insulation type (e.g., Tefzel for high durability), and environmental conditions (temperature ranges, exposure to chemicals). Clear specifications will help you communicate your needs effectively to suppliers and ensure the wire meets aviation standards.

Step 2: Research Applicable Standards and Regulations

Familiarize yourself with the industry standards and regulations governing aircraft wire. Look for compliance with organizations such as the American Society for Testing and Materials (ASTM) or the Federal Aviation Administration (FAA). Ensuring that the wire adheres to these standards is crucial for safety and performance in aviation applications.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, product catalogs, and certifications. Seek references from other businesses in similar regions or industries to gauge reliability and service quality. A well-vetted supplier will not only provide quality products but also support your long-term operational needs.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the aircraft wire. Testing these samples in real-world conditions will help determine their suitability for your specific applications. Pay attention to factors such as flexibility, resistance to abrasion, and overall durability under operating conditions.

Illustrative image related to aircraft wire

Step 5: Verify Supplier Certifications

Ensure that your selected suppliers possess the necessary certifications for the wires they offer. Look for certifications from recognized bodies, such as ISO or specific aviation-related certifications. These validations provide assurance of the wire’s quality and compliance with industry standards.

Step 6: Assess Pricing and Payment Terms

Compare pricing structures across different suppliers but remember that the lowest price does not always equate to the best value. Evaluate the total cost of ownership, including shipping, handling, and any potential tariffs. Additionally, clarify payment terms to avoid any future misunderstandings that could disrupt your supply chain.

Step 7: Establish a Clear Supply Agreement

Once you have chosen a supplier, draft a supply agreement that outlines all terms of the transaction. Include details such as delivery schedules, warranty terms, and procedures for handling defective products. A well-defined agreement protects both parties and helps ensure a smooth procurement process.

By following this checklist, B2B buyers can navigate the complexities of sourcing aircraft wire, ensuring they acquire high-quality products that meet their operational needs while adhering to industry standards.

Comprehensive Cost and Pricing Analysis for aircraft wire Sourcing

What Are the Key Cost Components in Aircraft Wire Sourcing?

When sourcing aircraft wire, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

Illustrative image related to aircraft wire

-

Materials: The type of materials used in aircraft wire significantly influences pricing. Options such as copper, aluminum, or high-performance polymers like Tefzel come with varying costs due to their properties and performance characteristics. High-performance wires, for example, offer better durability and resistance to harsh conditions, thus commanding a premium price.

-

Labor: Labor costs include the workforce involved in manufacturing, assembling, and quality assurance processes. Skilled labor, especially in specialized manufacturing settings, can be a significant cost driver.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Custom tooling for specific wire types or specifications can add to upfront costs. The need for specialized molds or machinery often arises when producing custom or high-spec wire.

-

Quality Control (QC): Given the critical nature of aircraft wiring, rigorous quality control measures are mandatory. The costs associated with testing and certification can impact overall pricing, especially for wires that require specific certifications (e.g., FAA or ASTM).

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. The distance from the supplier and chosen shipping methods can dramatically affect overall costs.

-

Margin: Suppliers typically apply a profit margin to cover their operational costs and risks. This margin can vary based on market conditions and the supplier’s positioning.

What Influences Pricing in Aircraft Wire Sourcing?

Several factors influence the pricing of aircraft wire:

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes often lead to lower per-unit costs due to economies of scale. Negotiating for bulk purchases can yield significant savings.

-

Specifications and Customization: Custom specifications for wire, such as length, gauge, and insulation type, can lead to increased costs. Standardized products tend to be less expensive.

-

Materials: The choice of materials impacts not only the initial cost but also the long-term performance and maintenance costs. Higher-quality materials may have a higher upfront cost but can lead to savings through reduced maintenance and increased lifespan.

-

Quality and Certifications: Wires that meet stringent quality standards and possess necessary certifications (e.g., for aerospace applications) typically command higher prices. Buyers should weigh these costs against the potential risks of using lower-quality alternatives.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, Freight) can significantly affect the total landed cost of the wire.

How Can Buyers Negotiate Effectively for Aircraft Wire?

To achieve cost efficiency in sourcing aircraft wire, buyers should consider the following tips:

-

Leverage Volume Discounts: When possible, consolidate orders to meet minimum order quantities and negotiate volume discounts.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also long-term costs associated with maintenance, durability, and performance. This approach can justify higher upfront costs for superior products.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import duties, and taxes that can affect the final cost. Establishing clear terms and conditions upfront can help mitigate unexpected expenses.

-

Build Relationships with Suppliers: Cultivating strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming changes in pricing or availability.

Disclaimer on Pricing Information

The prices for aircraft wire can vary widely based on market conditions, material availability, and specific requirements. It is advisable to obtain current quotes from multiple suppliers to ensure a competitive pricing structure. Always consider the total cost of ownership rather than just the initial purchase price when making sourcing decisions.

Alternatives Analysis: Comparing aircraft wire With Other Solutions

Exploring Alternatives to Aircraft Wire: What Are Your Options?

In the aerospace industry, selecting the right materials for wiring is crucial for ensuring safety, reliability, and efficiency. While aircraft wire has long been the standard for electrical connections in aviation, several alternative solutions exist that may better suit specific applications or operational environments. This section provides a comparative analysis of aircraft wire against two viable alternatives: High-Performance Aerospace Wires and Fiber Optic Cables.

| Comparison Aspect | Aircraft Wire | High-Performance Aerospace Wires | Fiber Optic Cables |

|---|---|---|---|

| Performance | Reliable under standard conditions; may degrade in extreme environments | Superior durability; resistant to chemicals and extreme temperatures | High-speed data transmission; immune to electromagnetic interference |

| Cost | Moderate cost; widely available | Higher initial investment; longer lifespan may offset costs | Generally high cost; installation can be expensive |

| Ease of Implementation | Easy to install; established practices in the industry | Requires specialized knowledge for installation | Complex installation; requires skilled technicians |

| Maintenance | Regular inspections needed; can wear over time | Low maintenance; designed for longevity | Minimal maintenance, but may require specialized tools |

| Best Use Case | General aircraft wiring needs | Military and high-performance aircraft applications | Advanced communication systems in aviation |

High-Performance Aerospace Wires: Are They Worth the Investment?

High-performance aerospace wires offer advanced features, such as resistance to abrasion, humidity, and harsh chemicals, making them ideal for military and high-performance aircraft applications. These wires maintain integrity under extreme environmental conditions, ensuring long-term reliability. However, the initial investment can be significantly higher than traditional aircraft wire. For operations that demand the utmost safety and reliability, the long-term benefits may justify the cost, especially when considering reduced maintenance and replacement frequency.

Fiber Optic Cables: Can They Replace Traditional Wiring?

Fiber optic cables represent a cutting-edge alternative, particularly for data transmission in modern aircraft systems. They are capable of transmitting large amounts of data at high speeds while being immune to electromagnetic interference. This makes them particularly advantageous for advanced communication systems and integrated avionics. However, their installation can be complex and costly, often requiring specialized technicians. While fiber optics can significantly enhance data capabilities, they may not be suitable for all wiring needs, particularly in applications where traditional power transmission is required.

Conclusion: How to Choose the Right Solution for Your Needs?

When selecting wiring solutions for aircraft, it’s essential for B2B buyers to assess their specific operational requirements, budget constraints, and the environments in which the aircraft will operate. Traditional aircraft wire may suffice for standard applications, while high-performance aerospace wires could be necessary for extreme conditions. Fiber optic cables may be the best choice for advanced communication needs but come with higher installation costs. Ultimately, understanding the unique demands of your aircraft and operational context will guide you toward the most effective wiring solution.

Illustrative image related to aircraft wire

Essential Technical Properties and Trade Terminology for aircraft wire

What Are the Key Technical Properties of Aircraft Wire?

When sourcing aircraft wire, understanding its technical specifications is essential for ensuring safety and performance. Here are several critical properties that B2B buyers should consider:

-

Material Grade: Aircraft wire is typically constructed from high-grade materials such as copper or aluminum. Copper wires are known for their superior conductivity, while aluminum wires offer a lighter option with decent conductivity. The choice of material affects weight, cost, and overall performance, making it crucial for aircraft applications where every gram counts.

-

Wire Gauge (AWG): The American Wire Gauge (AWG) system specifies the diameter of the wire. A lower AWG number indicates a thicker wire, which can carry more current. Understanding wire gauge is vital for ensuring compatibility with electrical systems and preventing overheating, which can lead to failures or safety hazards.

-

Insulation Type: The insulation surrounding aircraft wire is designed to withstand extreme conditions, including temperature variations and exposure to chemicals. Common insulation materials include Tefzel and PTFE, which offer excellent resistance to abrasion and corrosion. Selecting the right insulation is crucial for maintaining wire integrity and ensuring safety in demanding environments.

-

Temperature Rating: Each type of aircraft wire comes with a specified temperature rating, indicating the maximum operating temperature it can withstand. This is particularly important for wires used in engines or areas with high heat exposure. Ensuring the wire meets the necessary temperature ratings can prevent premature failure and enhance overall aircraft reliability.

-

Voltage Rating: This property indicates the maximum voltage that the wire can safely carry. Choosing a wire with an appropriate voltage rating is essential for preventing electrical shorts and ensuring the safe operation of onboard systems.

What Are Common Trade Terms Used in Aircraft Wire Procurement?

Familiarity with industry jargon can streamline communication and improve procurement efficiency. Here are some commonly used terms in the aircraft wire sector:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts that may be marketed by another manufacturer. Understanding OEM specifications is vital for buyers looking for compatible replacement parts or upgrades to existing aircraft systems.

-

MOQ (Minimum Order Quantity): MOQ defines the smallest quantity of an item that a supplier is willing to sell. It is crucial for B2B buyers to know MOQs to manage inventory effectively and avoid overstocking or stockouts.

-

RFQ (Request for Quotation): An RFQ is a document issued when an organization wants to purchase a product or service. It invites suppliers to provide pricing and terms for the required items, making it a key step in the procurement process.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Understanding Incoterms helps buyers manage logistics and shipping costs effectively, ensuring timely delivery of aircraft wire.

-

EWIS (Electrical Wiring Interconnection Systems): This term refers to the comprehensive wiring systems used in aircraft, encompassing all electrical connections. Knowledge of EWIS is essential for buyers to ensure compliance with safety regulations and standards in aircraft design and maintenance.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they procure the right aircraft wire that meets their operational requirements and safety standards.

Illustrative image related to aircraft wire

Navigating Market Dynamics and Sourcing Trends in the aircraft wire Sector

What Are the Current Market Dynamics and Key Trends in the Aircraft Wire Sector?

The global aircraft wire market is experiencing robust growth, driven by increasing air travel demand, advancements in aviation technology, and a surge in aircraft manufacturing. Key regions like Africa, South America, the Middle East, and Europe are witnessing significant investments in aviation infrastructure, which amplifies the demand for high-quality aircraft wiring solutions. International B2B buyers should note the trend towards lightweight materials, such as Tefzel and other high-performance polymers, which enhance fuel efficiency and reduce operational costs. Furthermore, the integration of digital technologies in supply chain management is becoming pivotal. Platforms that facilitate real-time tracking, inventory management, and predictive analytics are gaining traction, allowing buyers to make informed purchasing decisions.

Emerging trends also highlight a shift toward customization and modularity in wire and wiring systems to cater to specific aircraft models and operational needs. The adoption of advanced materials that provide durability in extreme conditions is essential for maintaining safety and compliance with rigorous aviation standards. For international buyers, understanding the regional dynamics, such as regulatory frameworks and local supplier capabilities, is crucial for successful sourcing and procurement strategies.

How Is Sustainability and Ethical Sourcing Reshaping the Aircraft Wire Industry?

Sustainability has become a cornerstone in the aircraft wire sector, with increasing emphasis on reducing the environmental footprint of manufacturing processes. B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainable practices, such as using recycled materials and minimizing waste. The importance of ethical sourcing is underscored by the need for transparency in supply chains, ensuring that materials are sourced responsibly and do not contribute to environmental degradation or human rights abuses.

Illustrative image related to aircraft wire

Certifications such as ISO 14001 for environmental management systems and specific ‘green’ labels for materials signal a supplier’s commitment to sustainability. Buyers should actively seek out manufacturers who utilize environmentally friendly wire insulation materials and coatings that comply with international regulations on harmful substances. By aligning purchasing decisions with sustainability goals, companies can enhance their brand reputation and meet the growing consumer demand for responsible business practices.

What Is the Historical Context of Aircraft Wire Development Relevant to B2B Buyers?

The development of aircraft wire has evolved significantly since the early days of aviation. Initially, basic copper wires were the standard; however, as aircraft technology advanced, the need for lighter, more durable materials became evident. The introduction of insulated wires, such as Tefzel, marked a turning point, providing resistance to heat and corrosion—key factors in aviation safety.

Over the decades, regulatory bodies have established stringent standards for aircraft wiring, leading to innovations in materials and manufacturing processes. Today’s aircraft wires are engineered to withstand extreme environmental conditions, ensuring reliability and performance. For B2B buyers, understanding this evolution is crucial, as it informs the selection of suppliers and products that meet contemporary safety and performance standards, ultimately influencing operational efficiency and safety in aviation.

Illustrative image related to aircraft wire

Frequently Asked Questions (FAQs) for B2B Buyers of aircraft wire

-

How do I determine the right type of aircraft wire for my needs?

Selecting the appropriate aircraft wire involves considering various factors, including the wire’s insulation material, gauge, and specific application. For high-performance applications, Tefzel wire is often recommended due to its resistance to extreme temperatures and corrosion. It’s crucial to evaluate the operating conditions, such as exposure to chemicals or mechanical stress, to ensure you choose a wire that meets industry standards and safety requirements. Consulting with suppliers who have expertise in aviation can also provide valuable insights into selecting the best wire for your specific aircraft model. -

What is the best insulation material for aircraft wire?

The best insulation material for aircraft wire largely depends on the operating environment and application. Tefzel and PTFE (Polytetrafluoroethylene) are popular choices due to their excellent thermal stability and chemical resistance. Tefzel wire, for instance, is preferred for its durability in extreme conditions, making it suitable for both general aviation and military applications. When sourcing wire, consider the specific environmental challenges your aircraft may face to ensure optimal performance and longevity. -

What are the minimum order quantities (MOQs) for aircraft wire?

Minimum order quantities for aircraft wire can vary significantly between suppliers and depend on the type and specifications of the wire. Typically, MOQs may range from 100 meters to several kilometers, particularly for specialized products. It is advisable to communicate directly with potential suppliers to understand their MOQs and whether they can accommodate smaller orders if needed. This flexibility can be particularly beneficial for smaller maintenance facilities or those just starting to stock up on aircraft parts. -

How can I vet suppliers of aircraft wire effectively?

Vetting suppliers is critical to ensuring quality and reliability. Start by checking their certifications, such as AS9100 or ISO 9001, which demonstrate adherence to industry standards. Request samples to evaluate wire quality and performance. Additionally, seek customer references and reviews to gauge their reliability and service quality. Engaging in direct communication can also provide insights into their responsiveness and willingness to support international shipping, which is particularly important for buyers from regions like Africa and South America. -

What payment terms are typically offered for B2B purchases of aircraft wire?

Payment terms can vary widely among suppliers, but common practices include net 30, net 60, or even net 90 days after invoicing. Some suppliers may offer discounts for upfront payments or larger orders. It’s essential to clarify payment terms before finalizing any agreements to avoid misunderstandings. Additionally, consider using secure payment methods or escrow services to protect your investment, especially when dealing with international transactions. -

What quality assurance processes should I expect from aircraft wire suppliers?

Reputable aircraft wire suppliers will have stringent quality assurance processes in place, including testing for conductivity, insulation integrity, and resistance to environmental factors. Look for suppliers that provide detailed documentation of their quality control measures, such as inspection reports and compliance certifications. Some suppliers may also offer warranties or guarantees on their products, which can serve as an additional layer of assurance regarding their reliability and performance. -

What logistics considerations should I keep in mind when sourcing aircraft wire internationally?

When sourcing aircraft wire internationally, consider shipping times, customs regulations, and potential tariffs or duties. Work with suppliers who have experience in international shipping and can provide clarity on packaging, labeling, and required documentation to facilitate smooth customs clearance. Additionally, factor in the reliability of logistics partners and consider options for tracking shipments to ensure timely delivery, especially given the critical nature of aircraft maintenance. -

Can I customize aircraft wire to meet specific requirements?

Yes, many suppliers offer customization options for aircraft wire, including variations in gauge, insulation type, and length. Customization can be particularly useful for meeting specific regulatory standards or unique operational needs. When discussing customization, provide detailed specifications and requirements to ensure the supplier can meet your needs effectively. Be aware that custom orders may have longer lead times and potentially higher costs, so plan accordingly.

Top 7 Aircraft Wire Manufacturers & Suppliers List

1. Aircraft Spruce – Wiring Systems

Domain: aircraftspruce.com

Registered: 1999 (26 years)

Introduction: Wire & Wiring Systems available at Aircraft Spruce. Options to add filters for sorting by price and category. Categories include Electrical, Avionics, and Instruments. Products include alternators, batteries, battery accessories, cables and connectors, circuit breakers, dimming systems, LED lighting, relays/solenoids, and more. Customer service contact: 877-477-7823. Free shipping on orders over $…

2. Brown Aircraft – Ground Strapping and Tefzel Insulated Wire

Domain: brownaircraft.com

Registered: 2003 (22 years)

Introduction: Electrical Insulated Aircraft Wire, Ground Strapping, and Battery Cables. Key products include: BA-6-G 3/8″ wide braided Ground Strapping ($5.91), BA-8-B 1/2″ wide braided Ground Strapping ($5.96), BA-4-G 1/4″ wide braided Ground Strapping ($4.98), NO-24 100 Ft spool Tefzel Insulated Aircraft Wire ($73.20), NO-22 100 Ft spool Tefzel Insulated Aircraft Wire ($60.74), NO-20 100 Ft spool Tefzel Insul…

3. Chief Aircraft Inc. – Shielded Wire & COAX Solutions

Domain: chiefaircraft.com

Registered: 1996 (29 years)

Introduction: Aircraft Shielded Wire, COAX, Single Conductor & Multi-Conductor – Chief Aircraft Inc.

4. GORE® – High Performance Wires for Aerospace & Defense

Domain: gore.com

Registered: 1998 (27 years)

Introduction: GORE® High Performance Wires for Aerospace & Defense deliver long-term stability, increase EV readiness and aircraft availability, improve safety, and reduce total costs without adding size or weight. They meet higher durability levels for electrical wires operating in extreme environments, are chemically inert and non-flammable, and resist chafing, abrasion, and cut-through over wide temperatures…

5. Pelican Wire – Copper, Stranded & Teflon Coated Wires

Domain: pelicanwire.com

Registered: 1998 (27 years)

Introduction: Types of Wires: 1. Copper Wires – Highly conductive, used in power transmission; includes tin-plated copper for corrosion resistance. 2. Stranded Wires – Flexible, consists of multiple smaller wires, used in tight spaces and vibration-prone areas. 3. Teflon Coated Wire – High-temperature resistance, durable, non-reactive, used near engines. 4. Aluminum Wires – Lightweight, lower conductivity, used…

6. Rose Brand – Aircraft Cable & Fittings

Domain: rosebrand.com

Registered: 1995 (30 years)

Introduction: Aircraft Cable / Wire Rope, Fittings and Accessories from Rose Brand. Call for Sales Support 1-800-223-1624. Categories include: ADC Winches & Theatrical Automation, Caster, Chain Hoists, Chains and Slings, Curtain Track, Fiber Rope, Pulleys and Blocks, Kabuki Drop Systems, Personal Protective Equipment (PPE), Pipe & Base, Rigging Accessories, Rope-Rigging, Scenic, Shop & Studio Supplies, and more…

7. Murphy Lift – Stainless Steel Aircraft Cables

Domain: murphylift.com

Registered: 2021 (4 years)

Introduction: Stainless Steel Aircraft Cables, Wires, Cords. Free FedEx/UPS ground shipping to the 48 contiguous U.S. on all online orders of $50 or more. Various types of cables available including galvanized, vinyl coated, and stainless steel options. Includes accessories such as cable sleeves, wire rope clips, thimbles, and installation tools. Offers a range of wire rope configurations including 6×19, 6×36, …

Strategic Sourcing Conclusion and Outlook for aircraft wire

In navigating the complexities of sourcing aircraft wire, international buyers must prioritize quality, reliability, and compliance with aviation standards. Strategic sourcing is essential for mitigating risks associated with supply chain disruptions and ensuring the safety and performance of aircraft systems. By selecting suppliers with proven track records and certifications, such as those recognized by the American Society for Testing and Materials, buyers can enhance operational efficiency while reducing long-term costs.

Investing in high-performance wires, such as those resistant to extreme temperatures and harsh chemicals, not only improves aircraft reliability but also supports sustainability initiatives by minimizing maintenance needs. As the aviation market continues to expand in regions like Africa, South America, and the Middle East, the demand for superior aircraft components will rise.

Looking ahead, buyers should actively seek partnerships with innovative suppliers who can provide advanced materials and technologies. Engaging with a diverse range of manufacturers will enable organizations to leverage competitive pricing and exceptional service. Now is the time to enhance your procurement strategies, ensuring your fleet remains competitive and ready for the challenges of tomorrow’s aviation landscape.

Illustrative image related to aircraft wire

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.