The Definitive Guide to Adhesive Tape Roller: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for adhesive tape roller

In today’s competitive landscape, sourcing high-quality adhesive tape rollers presents a significant challenge for B2B buyers, particularly those operating in diverse international markets such as Africa, South America, the Middle East, and Europe. The adhesive tape roller is an essential tool across various industries, from packaging and manufacturing to arts and crafts, making it imperative for businesses to understand the nuances of this product category. This comprehensive guide will explore the different types of adhesive tape rollers available, their various applications, and the critical factors to consider when vetting suppliers.

By delving into aspects such as material quality, adhesive strength, and refill options, we aim to equip international buyers with the insights needed to make informed purchasing decisions. Additionally, this guide will address cost considerations and highlight emerging trends in the adhesive tape market, ensuring that buyers from regions like Germany and Brazil can navigate their sourcing challenges with confidence. Whether you are looking to streamline your production line or enhance your creative projects, understanding the global market for adhesive tape rollers is essential for optimizing your operations and achieving your business goals.

Understanding adhesive tape roller Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Permanent Adhesive Roller | Provides a strong, lasting bond; often acid-free and photo-safe. | Scrapbooking, card making, packaging. | Pros: Reliable adhesion; Cons: Not suitable for temporary applications. |

| Removable Adhesive Roller | Allows for repositioning; leaves no residue upon removal. | Temporary displays, prototyping. | Pros: Versatile and user-friendly; Cons: Weaker bond than permanent types. |

| Double-Sided Adhesive Roller | Adhesive on both sides; ideal for invisible bonding. | Mounting, crafting, product assembly. | Pros: Clean finish; Cons: Requires precise placement. |

| Dot Adhesive Roller | Applies adhesive in dot patterns; minimizes mess. | Arts and crafts, photo mounting. | Pros: Easy to use; Cons: May not cover larger areas effectively. |

| High-Strength Adhesive Roller | Designed for heavy-duty applications; strong and durable. | Industrial packaging, construction. | Pros: Exceptional holding power; Cons: May be overkill for lighter tasks. |

What are the Characteristics of Permanent Adhesive Rollers?

Permanent adhesive rollers are designed to create a strong, lasting bond suitable for various applications, such as scrapbooking, card making, and packaging. These rollers often feature acid-free adhesives, making them safe for archival materials and photographs. When purchasing, buyers should consider the roller’s ease of use, refill options, and the longevity of the bond, particularly for projects requiring durability.

How do Removable Adhesive Rollers Function?

Removable adhesive rollers allow users to reposition items without damaging surfaces or leaving residue. This feature makes them ideal for temporary displays and prototyping in design processes. Buyers should assess the adhesive’s strength and the ease of removal, as well as whether the roller can be refilled, which can enhance cost-effectiveness in a B2B context.

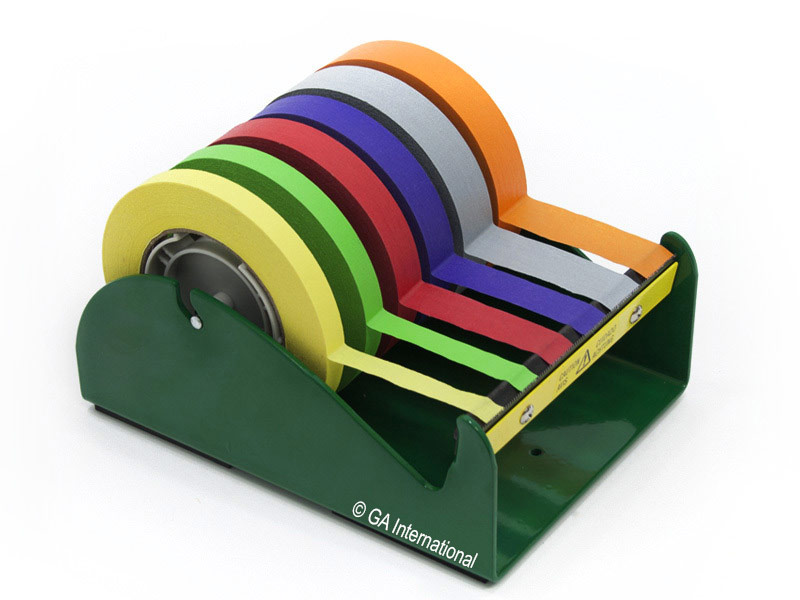

Illustrative image related to adhesive tape roller

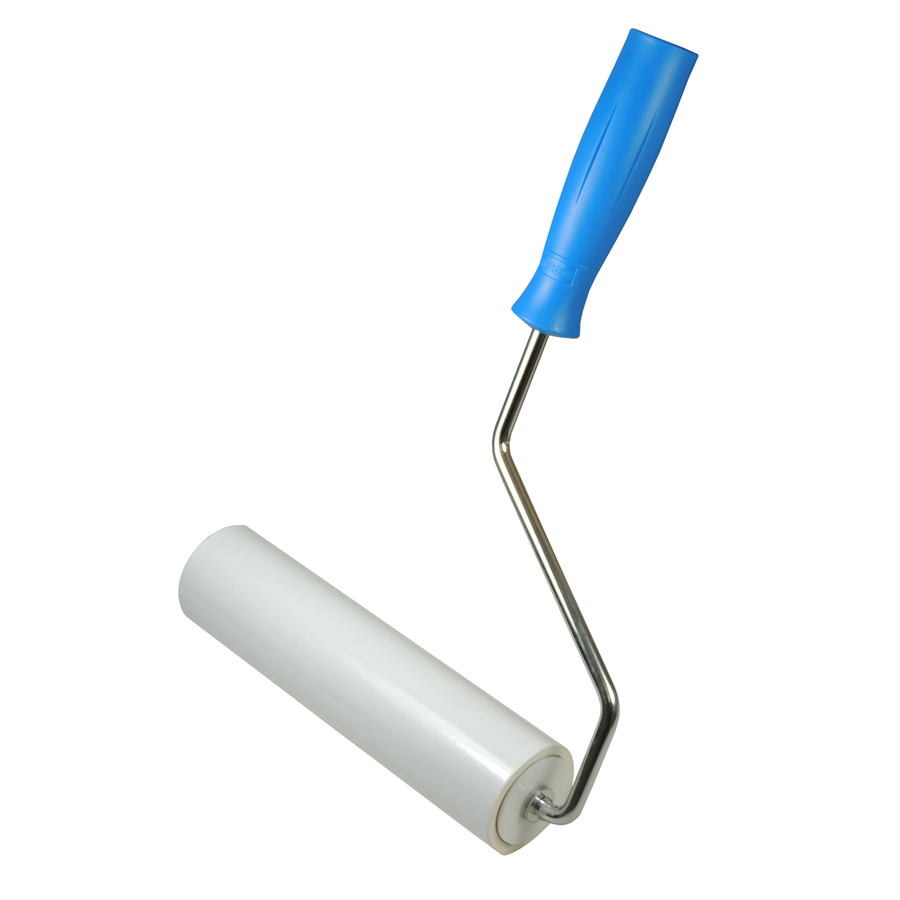

What are the Benefits of Double-Sided Adhesive Rollers?

Double-sided adhesive rollers apply adhesive to both sides of the tape, making them perfect for applications where invisible bonding is necessary, such as mounting photos or assembling products. These rollers provide a clean finish, which is essential in professional settings. Buyers should consider the precision of the application and whether the roller allows for easy repositioning to ensure optimal results.

When Should You Use Dot Adhesive Rollers?

Dot adhesive rollers dispense adhesive in small dot patterns, allowing for precise application while minimizing mess. They are particularly popular in arts and crafts, as well as photo mounting. B2B buyers should evaluate the coverage area and the roller’s compatibility with various materials to ensure it meets their specific project needs.

Why Choose High-Strength Adhesive Rollers for Industrial Applications?

High-strength adhesive rollers are engineered for heavy-duty applications, providing exceptional holding power for industrial packaging and construction tasks. These rollers are designed to withstand significant stress and are suitable for demanding environments. Buyers should weigh the benefits of strength against the potential overkill for lighter tasks, ensuring they select the right tool for their operational needs.

Key Industrial Applications of adhesive tape roller

| Industry/Sector | Specific Application of Adhesive Tape Roller | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Packaging and Shipping | Sealing packages and boxes for shipment | Ensures secure packaging, reduces damage during transit | Evaluate adhesive strength, temperature tolerance, and roll size. |

| Construction | Bonding materials in temporary installations | Facilitates quick setups, reduces labor costs | Consider weather resistance and adhesive durability under stress. |

| Arts and Crafts | Scrapbooking and card making | Provides clean, precise application for creative projects | Look for acid-free options and ease of use for various materials. |

| Automotive | Securing components during assembly | Enhances production efficiency and quality control | Assess heat resistance and compatibility with automotive materials. |

| Electronics | Insulating and securing wires and components | Improves safety and reliability in electronic devices | Focus on electrical insulation properties and adhesive longevity. |

How is Adhesive Tape Roller Used in Packaging and Shipping?

In the packaging and shipping sector, adhesive tape rollers are essential for sealing boxes and packages securely. They provide a quick and efficient way to ensure that products remain intact during transit, minimizing the risk of damage and loss. International B2B buyers in this sector should consider the adhesive’s strength and compatibility with various packaging materials, as well as the tape’s temperature tolerance, especially when shipping to regions with extreme climates.

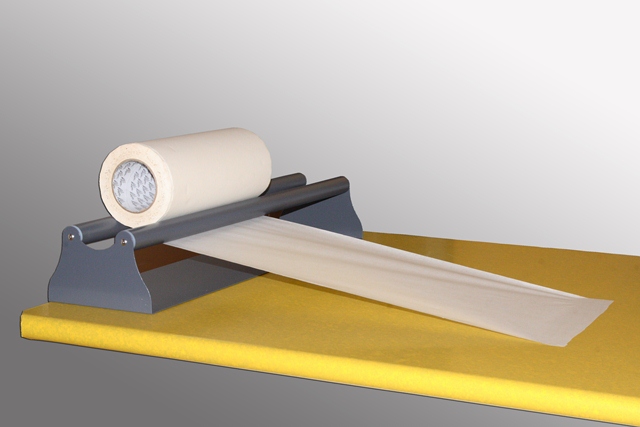

Illustrative image related to adhesive tape roller

What Role Does Adhesive Tape Roller Play in Construction?

In construction, adhesive tape rollers are utilized for bonding materials in temporary installations, such as weather barriers and insulation. They allow for rapid application, which can significantly reduce labor costs and time on-site. Buyers must evaluate the tape’s durability and weather resistance to ensure it performs well under various environmental conditions, particularly in regions with high humidity or temperature fluctuations.

How is Adhesive Tape Roller Beneficial for Arts and Crafts?

For arts and crafts, adhesive tape rollers are favored for scrapbooking and card-making due to their ability to deliver clean, precise lines of adhesive. This ensures that projects maintain a professional appearance without the mess associated with liquid adhesives. Buyers should look for acid-free options to protect photographs and other sensitive materials, as well as ease of use, especially for projects involving intricate designs.

In What Ways is Adhesive Tape Roller Used in the Automotive Industry?

In the automotive industry, adhesive tape rollers are crucial for securing components during assembly. They enhance production efficiency by providing a reliable bond that can withstand vibrations and stresses inherent in vehicle operation. Buyers should assess the tape’s heat resistance and compatibility with various automotive materials to ensure it meets the stringent demands of this sector.

Illustrative image related to adhesive tape roller

How Does Adhesive Tape Roller Enhance Electronics Manufacturing?

In electronics manufacturing, adhesive tape rollers are used for insulating and securing wires and components. This application is vital for enhancing the safety and reliability of electronic devices. International buyers should focus on sourcing tapes with excellent electrical insulation properties and a long-lasting adhesive to ensure their products meet industry standards and consumer expectations.

3 Common User Pain Points for ‘adhesive tape roller’ & Their Solutions

Scenario 1: Inconsistent Adhesion Leads to Production Delays

The Problem: In a bustling packaging facility, a B2B buyer responsible for sourcing adhesive tape rollers encounters a common yet critical issue: inconsistent adhesion during the application process. This inconsistency often results in products being inadequately secured, leading to delays in production and potential financial losses. Employees may need to reapply tape, slowing down the workflow and affecting overall productivity. Furthermore, the frustration can lead to decreased morale among staff who rely on reliable tools to perform their jobs efficiently.

The Solution: To tackle this issue, buyers should prioritize sourcing high-quality adhesive tape rollers known for their consistent performance. It is essential to evaluate specifications such as adhesive strength, application method, and suitability for various materials. For example, opting for a tape roller that features a smooth, skip-free application mechanism can significantly reduce the chances of adhesion failure. Buyers can also consider conducting trials with different products to find the one that best fits their operational needs. Additionally, investing in proper training for staff on the correct usage techniques can enhance adhesion quality and ultimately improve production efficiency.

Scenario 2: High Operational Costs Due to Frequent Replacements

The Problem: A purchasing manager for a manufacturing company faces escalating operational costs due to the frequent need to replace adhesive tape rollers. This situation arises from the use of low-quality products that wear out quickly, requiring constant replenishment and contributing to increased supply chain expenses. The purchasing manager is also challenged by the time and resources spent managing these frequent orders, disrupting budgeting and financial forecasting.

The Solution: To mitigate these costs, buyers should consider investing in premium adhesive tape rollers that offer durability and longevity. When selecting products, look for those that come with robust warranties or guarantees, which can provide insight into the manufacturer’s confidence in their product’s lifespan. Additionally, bulk purchasing agreements can help reduce costs per unit and minimize the frequency of orders. Establishing a reliable relationship with reputable suppliers who specialize in high-quality adhesive products can also ensure consistent supply and better pricing, ultimately leading to lower overall operational expenses.

Illustrative image related to adhesive tape roller

Scenario 3: Environmental Concerns Over Adhesive Tape Waste

The Problem: As sustainability becomes a priority in global business practices, a B2B buyer in the packaging industry is increasingly concerned about the environmental impact of adhesive tape waste generated from their operations. Traditional adhesive tape rollers often result in excessive waste due to non-recyclable materials and inefficient use of tape, which conflicts with the company’s sustainability goals and could tarnish its reputation among environmentally-conscious clients.

The Solution: To address these environmental concerns, buyers should explore eco-friendly adhesive tape roller options that utilize recyclable materials and are designed for minimal waste. Researching suppliers that focus on sustainable production practices can lead to finding products that align with the company’s values. Furthermore, implementing a waste reduction strategy, such as optimizing tape length during application, can help minimize excess waste. Collaborating with suppliers to create customized solutions that fit specific operational needs can also promote sustainability while maintaining efficiency in production processes. By prioritizing eco-friendly products, companies can enhance their corporate social responsibility efforts and appeal to a growing market of environmentally-conscious consumers.

Strategic Material Selection Guide for adhesive tape roller

What Are the Key Materials Used in Adhesive Tape Rollers?

Adhesive tape rollers are essential tools in various industries, and the choice of materials significantly influences their performance and suitability for specific applications. Below, we analyze four common materials used in adhesive tape rollers, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Properties and Suitability of Plastic in Adhesive Tape Rollers?

Key Properties: Plastic, particularly polypropylene and polyethylene, is widely used in adhesive tape rollers due to its lightweight nature and flexibility. These materials typically have good temperature resistance, allowing them to perform effectively in various environments.

Illustrative image related to adhesive tape roller

Pros & Cons: The primary advantage of plastic is its cost-effectiveness and ease of manufacturing, making it suitable for high-volume production. However, plastics may not offer the same durability as metal counterparts, particularly under high-stress conditions. They can be prone to warping or breaking under extreme temperatures or pressures.

Impact on Application: Plastic adhesive rollers are ideal for lightweight applications, such as crafting and office use. However, they may not be suitable for industrial applications requiring high strength or durability.

Considerations for International Buyers: Buyers should consider compliance with international standards such as ASTM and DIN, especially regarding the environmental impact of plastic materials. In regions like Europe, there is a growing preference for recyclable materials, which may influence purchasing decisions.

How Does Metal Compare as a Material for Adhesive Tape Rollers?

Key Properties: Metals like aluminum and stainless steel are valued for their strength and resistance to wear and corrosion. These materials can withstand higher temperatures and pressures compared to plastics.

Illustrative image related to adhesive tape roller

Pros & Cons: The durability of metal rollers makes them suitable for heavy-duty applications, ensuring a longer lifespan. However, they are generally more expensive and heavier, which can increase shipping costs. Manufacturing complexity is also higher due to the need for specialized equipment.

Impact on Application: Metal adhesive tape rollers are often used in industrial settings where strength and reliability are paramount. They are compatible with a wider range of adhesives, including those used in high-temperature applications.

Considerations for International Buyers: Compliance with safety and quality standards is crucial, especially in regions with strict regulations like Germany. Buyers should also consider the higher initial investment in metal rollers against their longer-term durability and performance.

What Role Do Rubber Components Play in Adhesive Tape Rollers?

Key Properties: Rubber is commonly used in the rollers’ grip or as a cushioning material. It provides excellent friction and shock absorption, enhancing user experience and control.

Pros & Cons: The primary advantage of rubber is its ability to provide a non-slip grip, making it easier to handle the roller. However, rubber can degrade over time, especially when exposed to certain chemicals or extreme temperatures, leading to a shorter lifespan.

Impact on Application: Rubber-enhanced rollers are particularly useful in applications requiring precision and control, such as crafting and detailed work. They are less suited for environments with harsh chemicals or extreme conditions.

Considerations for International Buyers: Buyers should ensure that the rubber used meets international safety standards, especially in regions with strict environmental regulations. Understanding the chemical compatibility of rubber with various adhesives is also essential.

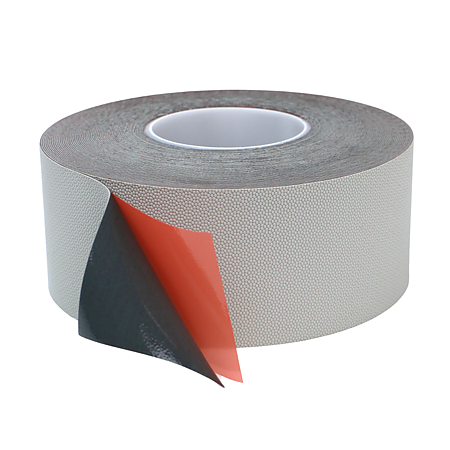

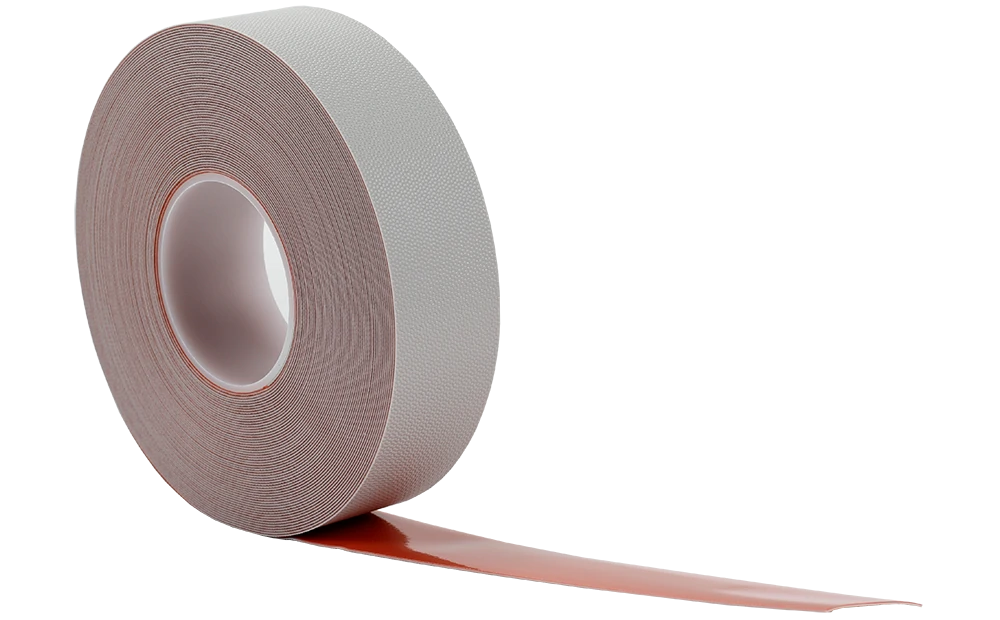

How Do Adhesives Themselves Influence the Performance of Tape Rollers?

Key Properties: The adhesive used in tape rollers can vary widely, with options including permanent, removable, and double-sided adhesives. Each type has unique properties affecting bond strength and application ease.

Pros & Cons: The right adhesive can significantly enhance performance, providing strong, reliable bonds. However, not all adhesives are suitable for all surfaces, which can limit versatility. Additionally, some adhesives may require specific storage conditions to maintain effectiveness.

Impact on Application: The choice of adhesive directly impacts the roller’s application range, from office tasks to industrial uses. Understanding the specific media compatibility is crucial for optimal performance.

Considerations for International Buyers: Buyers should be aware of regional preferences for specific adhesive types and any compliance requirements regarding chemical safety and environmental impact.

Illustrative image related to adhesive tape roller

Summary Table of Material Selection for Adhesive Tape Rollers

| Material | Typical Use Case for adhesive tape roller | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Office and crafting applications | Cost-effective and lightweight | Less durable under stress | Low |

| Metal | Industrial and heavy-duty applications | High strength and durability | Higher cost and manufacturing complexity | High |

| Rubber | Precision tasks requiring control | Non-slip grip and shock absorption | Degrades over time | Medium |

| Adhesives | Versatile applications across industries | Strong, reliable bonds | Limited surface compatibility | Varies by type |

This guide provides valuable insights for B2B buyers considering adhesive tape rollers, emphasizing the importance of material selection based on application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for adhesive tape roller

What Are the Main Stages in the Manufacturing Process of Adhesive Tape Rollers?

The manufacturing of adhesive tape rollers involves several key stages, each critical to ensuring the final product meets quality and performance standards.

Material Preparation

The first step in the manufacturing process is material preparation. This includes sourcing high-quality materials such as adhesive formulations, backing materials (like paper or plastic), and rollers. Suppliers often conduct rigorous material testing to ensure compatibility and performance. For adhesive formulations, the chemical properties must be optimized for specific applications, whether it’s permanent or removable adhesion.

Forming Techniques

Once the materials are prepared, the next stage is forming. This process involves the application of adhesive to the backing material, which is typically accomplished through techniques like extrusion or coating. Advanced technologies like slot-die coating or gravure printing can be used to ensure uniform adhesive distribution. This precision is vital to prevent issues like bubbling or uneven application, which could affect the product’s usability.

Assembly Process

Following forming, the adhesive tape roller components are assembled. This may involve integrating the adhesive-coated backing with a dispensing mechanism, which could be manual or automated. The assembly process must be conducted in a clean environment to avoid contamination, which could compromise the adhesive properties.

Finishing Touches

The final stage is finishing, which includes cutting the tape to specified lengths, packaging, and labeling. Quality checks are conducted throughout the process to ensure that each roller meets the required specifications. This stage also often involves applying protective coatings or treatments to enhance durability and performance.

How Is Quality Assurance Implemented in the Production of Adhesive Tape Rollers?

Quality assurance (QA) is paramount in the production of adhesive tape rollers, ensuring that products are reliable and meet international standards.

What International Standards Are Relevant to Adhesive Tape Roller Manufacturing?

Manufacturers typically adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with ISO standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, specific certifications like CE marking (for compliance with European health and safety standards) or API certifications (for products used in specific industrial applications) may apply depending on the product’s intended use.

Illustrative image related to adhesive tape roller

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to identify defects early. Common QC checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt. Materials that do not meet specified criteria are rejected.

- In-Process Quality Control (IPQC): During the manufacturing process, ongoing checks are conducted to monitor critical parameters such as adhesive thickness and application uniformity.

- Final Quality Control (FQC): Before products are packaged, a final inspection is performed to ensure all specifications are met, including adhesion strength and overall functionality.

What Testing Methods Are Commonly Used for Adhesive Tape Rollers?

Various testing methods are employed to ensure adhesive tape rollers perform as expected. These may include:

- Adhesion Testing: Measures the tape’s ability to bond to various surfaces under different conditions.

- Shear and Peel Testing: Evaluates the tape’s resistance to sliding and its ability to hold under stress.

- Environmental Testing: Assesses how the tape performs under extreme temperatures, humidity, and UV exposure.

- Durability Testing: Involves repeated application and removal to simulate real-world usage scenarios.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial. Here are several strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and compliance with international standards firsthand.

- Requesting Quality Reports: Suppliers should provide detailed quality assurance reports, including test results and compliance certifications.

- Third-party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the supplier’s quality practices and product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers face unique challenges in ensuring quality control. Different regions may have varying standards and certifications, which can complicate supplier selection. Buyers must be aware of:

- Regional Regulations: Understanding local regulations in markets like Germany or Brazil is essential, as they may have specific requirements for adhesive products.

- Cultural Differences: Communication barriers and cultural differences can impact quality assurance practices. Establishing clear expectations and maintaining open lines of communication is vital.

- Logistical Considerations: Transportation and storage conditions can affect product quality. Buyers should consider how products are handled during transit and whether suppliers have measures in place to maintain quality.

Conclusion

The manufacturing processes and quality assurance practices for adhesive tape rollers are complex and critical to the success of the product in the market. B2B buyers must understand these processes to make informed purchasing decisions. By focusing on supplier quality control, compliance with international standards, and effective testing methods, buyers can ensure they acquire high-quality adhesive tape rollers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘adhesive tape roller’

In the competitive landscape of B2B procurement, sourcing adhesive tape rollers requires a strategic approach to ensure quality, functionality, and cost-effectiveness. This guide provides a structured checklist to streamline your sourcing process, helping you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is critical before reaching out to suppliers. Determine the type of adhesive tape roller you need—permanent, removable, double-sided, or a specialized variant for particular applications. Consider factors such as:

– Size and dimensions: Ensure compatibility with your projects.

– Adhesive properties: Assess whether you need acid-free, photo-safe, or high-strength adhesives.

Step 2: Identify Potential Suppliers

Research and compile a list of suppliers known for manufacturing or distributing adhesive tape rollers. Consider both local and international options, especially those with a strong presence in your target markets, such as Africa, South America, the Middle East, and Europe. Look for:

– Industry reputation: Check online reviews and ratings.

– Product range: Ensure they offer a variety of adhesive rollers to meet diverse needs.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier list, verify that potential partners hold relevant certifications. Certifications can indicate compliance with international quality standards and safety regulations. Look for:

– ISO certifications: This shows a commitment to quality management.

– Environmental certifications: These may be important if sustainability is a key concern for your organization.

Step 4: Request Samples for Testing

Once you have narrowed down your options, request samples of the adhesive tape rollers. Testing samples allows you to evaluate the product’s performance in real-world applications. Pay attention to:

– Application ease: Ensure the roller provides a smooth, skip-free application.

– Adhesive strength: Check that the adhesive bonds effectively without warping or damaging materials.

Illustrative image related to adhesive tape roller

Step 5: Assess Pricing and Terms of Sale

Pricing is a crucial factor in your sourcing decision. Compare quotes from different suppliers but consider the overall value, including quality and service. In addition, clarify:

– Minimum order quantities (MOQs): Understand the supplier’s requirements.

– Payment terms: Ensure they align with your financial policies and capabilities.

Step 6: Check for After-Sales Support and Warranty

Reliable after-sales support can significantly affect your satisfaction with the product and the supplier. Inquire about:

– Return policies: Understand the process for defective products.

– Technical support: Confirm that the supplier offers assistance for product-related queries.

Step 7: Finalize Your Supplier Agreement

Once you’ve completed due diligence, it’s time to negotiate and finalize the supplier agreement. Ensure that the contract includes:

– Delivery timelines: Set clear expectations for lead times.

– Quality assurance clauses: Protect your interests in case the product does not meet specified standards.

By following this checklist, B2B buyers can navigate the sourcing process for adhesive tape rollers effectively, ensuring they select the right products and suppliers to meet their operational needs.

Comprehensive Cost and Pricing Analysis for adhesive tape roller Sourcing

What Are the Key Cost Components in Sourcing Adhesive Tape Rollers?

When sourcing adhesive tape rollers, several cost components must be considered to build a comprehensive cost structure. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to adhesive tape roller

-

Materials: The choice of adhesive and the roller mechanism significantly impact costs. High-quality adhesives and innovative designs, such as refillable systems, tend to be more expensive but offer superior performance and durability.

-

Labor: Labor costs vary by region and depend on the complexity of the production process. Automated production lines can reduce labor costs but may require a higher initial investment.

-

Manufacturing Overhead: This includes utilities, factory maintenance, and administrative expenses. Efficient manufacturing practices can help minimize these overheads.

-

Tooling: Initial tooling costs for specialized or custom designs can be substantial. However, these costs are often amortized over large production runs.

-

Quality Control: Ensuring the product meets quality standards incurs additional costs. This includes testing materials and final products, which is crucial for maintaining certification and customer satisfaction.

-

Logistics: Shipping costs can vary greatly depending on the distance from the supplier and the shipping method. Consideration of Incoterms is essential, as they define responsibilities for transportation costs and risks.

-

Margin: Finally, suppliers will add a profit margin based on their operational costs, market demand, and competitive positioning.

How Do Price Influencers Affect the Cost of Adhesive Tape Rollers?

Several price influencers can affect the final cost of adhesive tape rollers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically yield lower prices per unit due to economies of scale. Buyers should negotiate MOQs that align with their needs while ensuring they benefit from bulk pricing.

-

Specifications and Customization: Custom designs and specifications can increase costs. Buyers should balance the need for customization with the desire for cost efficiency.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as acid-free or environmentally friendly options) often come at a premium. Buyers should assess the value these certifications bring to their product offerings.

-

Supplier Factors: The reliability, reputation, and financial stability of suppliers can influence pricing. Establishing long-term relationships with suppliers can lead to better pricing and service.

-

Incoterms: Understanding Incoterms is crucial for determining who bears the costs and risks associated with transportation. Different terms can significantly impact the total landed cost.

What Tips Can Help Buyers Negotiate Better Pricing for Adhesive Tape Rollers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are essential.

-

Negotiation Strategies: Engage suppliers in discussions about pricing based on your specific requirements, order volumes, and potential for long-term partnerships. Be prepared to walk away if pricing does not meet your budget.

-

Cost-Efficiency Considerations: Look beyond the initial purchase price. Analyze the Total Cost of Ownership (TCO), which includes operational costs, maintenance, and disposal. A slightly higher upfront cost may result in lower long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local taxes that may affect overall pricing. Conduct thorough market research to understand regional pricing norms.

-

Supplier Diversification: Consider sourcing from multiple suppliers to foster competition and ensure better pricing. This strategy can also mitigate risks associated with supply chain disruptions.

Disclaimer on Pricing

Prices for adhesive tape rollers can vary widely based on the above factors. The figures provided are indicative and should be verified with suppliers for accurate and current pricing tailored to specific needs.

Alternatives Analysis: Comparing adhesive tape roller With Other Solutions

Understanding Alternatives to Adhesive Tape Rollers in B2B Solutions

When considering adhesive solutions for business applications, it is essential to explore various alternatives to adhesive tape rollers. This analysis will provide insights into how these alternatives stack up against adhesive tape rollers in terms of performance, cost, ease of implementation, maintenance, and best use cases. The goal is to enable B2B buyers to make informed decisions tailored to their specific needs.

| Comparison Aspect | Adhesive Tape Roller | Tombow MONO Adhesive Applicator | KOKUYO Dotliner Tape Runner |

|---|---|---|---|

| Performance | Provides a consistent, smooth application for various materials; ideal for crafts and light packaging. | Instant permanent bond with smooth, skip-free application; excels in arts and crafts. | Offers removable and permanent adhesive options; suitable for both crafts and office tasks. |

| Cost | Moderate price point; cost-effective for bulk purchasing. | Slightly higher cost per unit; offers good value for specific applications. | Generally lower cost; affordable for high-volume use. |

| Ease of Implementation | Simple to use; requires minimal training for effective application. | User-friendly design; intuitive for both professionals and hobbyists. | Straightforward operation; refillable design enhances usability. |

| Maintenance | Requires periodic refilling; low maintenance overall. | Easy to refill; requires occasional cleaning for optimal performance. | Low maintenance; designed for easy refills and consistent performance. |

| Best Use Case | Best for light-duty tasks, crafts, and scrapbooking. | Ideal for card making, scrapbooking, and photo projects. | Versatile; suitable for office use, crafts, and temporary applications. |

In-Depth Look at Alternatives

Tombow MONO Adhesive Applicator

The Tombow MONO is a compact and refillable adhesive applicator designed for precise applications in arts and crafts. Its standout feature is the instant bond it creates, ensuring a smooth, wrinkle-free finish. This applicator is particularly beneficial for users engaged in card making or scrapbooking. However, the cost may be slightly higher compared to bulk adhesive tape rollers, which could be a consideration for high-volume users.

Illustrative image related to adhesive tape roller

KOKUYO Dotliner Tape Runner

The KOKUYO Dotliner offers a unique advantage with its dual adhesive options: permanent and removable. This flexibility makes it an excellent choice for various applications, from crafting to office tasks. Its affordability and ease of use make it a popular choice among budget-conscious buyers. However, while it serves well for many applications, it may not provide the same strength as some heavier-duty adhesive tape rollers.

Making the Right Choice for Your Business Needs

When selecting an adhesive solution, B2B buyers should consider the specific requirements of their operations. Adhesive tape rollers are ideal for general applications and crafting, while alternatives like the Tombow MONO and KOKUYO Dotliner provide specialized features that may be better suited for specific tasks. Evaluating factors such as performance, cost, and ease of use will help organizations determine the best adhesive method for their unique circumstances, ensuring efficiency and effectiveness in their adhesive applications.

Essential Technical Properties and Trade Terminology for adhesive tape roller

What Are the Key Technical Properties of Adhesive Tape Rollers?

When evaluating adhesive tape rollers, understanding their technical properties is essential for making informed purchasing decisions. Below are critical specifications that should be considered:

-

Material Grade

The material used in the construction of adhesive tape rollers can vary, affecting durability and performance. Common materials include plastic and metal, with plastic offering lightweight portability while metal may provide enhanced durability. For B2B buyers, selecting the right material is crucial for ensuring that the roller can withstand the demands of specific applications, whether in packaging, crafting, or industrial use. -

Adhesive Type

The type of adhesive applied in tape rollers can vary significantly, including permanent, removable, or repositionable options. Permanent adhesives provide a strong, lasting bond ideal for permanent applications, while removable adhesives allow for adjustments without damaging surfaces. Understanding the adhesive type is vital for businesses to ensure compatibility with their intended materials and applications. -

Roller Width

The width of the adhesive tape roller impacts the type of tasks it can perform. Common widths range from 1/4 inch to 1 inch, with wider rollers providing coverage for larger surfaces. B2B buyers should assess the width based on their specific use cases, such as crafting, office tasks, or industrial applications, to maximize efficiency and effectiveness. -

Application Mechanism

Different adhesive tape rollers feature various application mechanisms, such as manual, automatic, or refillable systems. Manual rollers require physical pressure to dispense adhesive, while automatic models may offer easier operation for high-volume tasks. Understanding the application mechanism helps businesses choose a product that aligns with their workflow and user requirements. -

Refillability

Refillable adhesive tape rollers allow for the replacement of adhesive cartridges, making them more sustainable and cost-effective in the long run. This feature is particularly important for businesses looking to reduce waste and maintain consistent performance. B2B buyers should consider the ease of refilling when evaluating products to ensure minimal downtime.

What Are Common Trade Terms Related to Adhesive Tape Rollers?

Familiarity with industry-specific jargon is essential for effective communication and negotiation in the B2B adhesive tape market. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the adhesive tape roller industry, OEMs often provide customized solutions tailored to specific client needs, making them critical partners for businesses seeking specialized products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for businesses to ensure they can meet their production requirements without overcommitting to inventory. It also helps in negotiating better pricing based on bulk orders. -

RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers requesting a quote for specific products or services. In the context of adhesive tape rollers, submitting an RFQ allows businesses to compare prices and terms from different suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Understanding Incoterms is crucial for businesses engaged in international transactions, as they clarify who bears the risks and costs associated with shipping adhesive tape rollers. -

Lead Time

This term refers to the time it takes from placing an order until the product is delivered. For B2B buyers, understanding lead times is essential for planning production schedules and managing inventory effectively, especially when dealing with large orders or custom products. -

Customs Clearance

This is the process of passing goods through customs so they can enter or leave a country. For businesses importing adhesive tape rollers, understanding customs clearance is crucial to avoid delays and additional costs, ensuring a smooth supply chain operation.

By grasping these technical properties and trade terms, B2B buyers can navigate the adhesive tape roller market with greater confidence, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the adhesive tape roller Sector

What Are the Key Trends Driving the Adhesive Tape Roller Market?

The adhesive tape roller market is witnessing significant growth, driven by several global factors. The increasing demand for efficient packaging solutions across various industries, such as electronics, automotive, and consumer goods, is fueling the need for high-performance adhesive tape rollers. Additionally, the rise of e-commerce has led to a surge in packaging requirements, creating an opportunity for innovative adhesive solutions that offer convenience and reliability.

Emerging technologies, such as automation and smart manufacturing, are also influencing sourcing trends. Manufacturers are investing in advanced production techniques to enhance product quality and reduce lead times. This trend is particularly relevant for international B2B buyers looking for suppliers who can provide both speed and quality. Furthermore, the advent of digital platforms for sourcing and procurement is streamlining the buying process, allowing businesses to efficiently compare products and suppliers across global markets.

Regional dynamics play a crucial role as well. In Europe, particularly Germany, there is a strong emphasis on product quality and sustainability, while in South America and Africa, cost-effectiveness and accessibility are paramount. Understanding these regional preferences can aid buyers in making informed sourcing decisions tailored to their target markets.

How Is Sustainability Shaping Sourcing Practices in the Adhesive Tape Roller Sector?

Sustainability is becoming increasingly important in the adhesive tape roller industry, as businesses recognize the environmental impact of their products. Buyers are now prioritizing suppliers that adhere to sustainable practices, including the use of eco-friendly materials and processes. This shift is evident in the growing demand for adhesive tape rollers made from recycled or biodegradable materials, which not only reduce waste but also appeal to environmentally conscious consumers.

Moreover, ethical sourcing is gaining traction as companies aim to enhance their brand reputation and meet regulatory requirements. B2B buyers are encouraged to evaluate suppliers based on their commitment to ethical labor practices and transparent supply chains. Certifications such as FSC (Forest Stewardship Council) and ISO (International Organization for Standardization) can serve as indicators of a supplier’s dedication to sustainability and ethical sourcing.

Investing in sustainable adhesive tape rollers not only aligns with corporate social responsibility goals but can also lead to cost savings in the long run. Businesses that adopt green practices often benefit from tax incentives and improved operational efficiency, making sustainability a critical consideration for B2B buyers in this sector.

What Is the Evolution of Adhesive Tape Rollers in the B2B Market?

The adhesive tape roller has evolved significantly since its inception. Originally designed for basic applications, these tools have transformed into sophisticated devices capable of delivering precise and efficient adhesive solutions. Early models were primarily manual, requiring significant user input, while modern versions are often equipped with ergonomic designs and advanced dispensing mechanisms that enhance usability.

Over the years, technological advancements have contributed to the development of specialized adhesive formulations, allowing for improved performance on various substrates. The introduction of refillable models has also catered to the growing demand for sustainability in packaging and office supplies.

As businesses continue to seek innovative solutions to meet their operational needs, the adhesive tape roller market is expected to further adapt, integrating smart features and sustainable practices to stay competitive in a dynamic global landscape. Understanding this evolution can provide B2B buyers with valuable insights into the product offerings available and their potential applications across various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of adhesive tape roller

-

How do I choose the right adhesive tape roller for my business needs?

Selecting the appropriate adhesive tape roller depends on your specific applications. Consider factors such as the type of adhesive (permanent or removable), the width of the tape, and the volume of use. For high-volume applications, opt for rollers with larger tape capacities and faster application speeds. Additionally, assess the materials you’ll be working with; some rollers are designed for specific substrates like paper, fabric, or plastic. Request samples from suppliers to evaluate performance in your actual use case before making a bulk purchase. -

What are the advantages of using adhesive tape rollers in packaging?

Adhesive tape rollers provide numerous benefits in packaging processes. They enable a quick, clean, and precise application of adhesive, reducing the risk of wrinkles and misalignment that can occur with traditional tape. This efficiency can lead to significant time savings in high-volume environments. Furthermore, many adhesive rollers are designed to be portable and easy to refill, making them ideal for various packaging tasks across different locations. Their consistent application helps maintain product integrity during shipping and storage. -

What is the minimum order quantity (MOQ) for adhesive tape rollers?

Minimum order quantities (MOQ) for adhesive tape rollers can vary significantly between suppliers and depend on factors such as product type and customization options. Typically, MOQs can range from as low as 100 units to several thousand. When sourcing, clarify the MOQ with potential suppliers to ensure it aligns with your needs. If your order volume is low, consider negotiating terms or exploring suppliers that cater to smaller businesses, as many manufacturers are willing to accommodate diverse purchasing requirements. -

How can I ensure the quality of adhesive tape rollers from international suppliers?

To guarantee quality when sourcing adhesive tape rollers internationally, conduct thorough due diligence on potential suppliers. Request samples to evaluate adhesive performance and roller functionality. Additionally, inquire about their quality assurance processes, certifications, and compliance with international standards. Establishing clear communication regarding your quality expectations and specifications is crucial. Consider visiting the manufacturing site or employing third-party inspection services to verify product quality before shipment. -

What customization options are available for adhesive tape rollers?

Many manufacturers offer customization options for adhesive tape rollers, allowing businesses to tailor products to specific needs. Customization can include variations in tape width, adhesive types, and roller designs (e.g., ergonomic handles or specific dispensing mechanisms). Some suppliers may also offer branding options, such as printing your logo on the roller. Discuss your requirements with potential suppliers to explore available customization options, ensuring they can meet your unique operational demands. -

What payment terms should I expect when sourcing adhesive tape rollers internationally?

Payment terms for international purchases of adhesive tape rollers can vary widely depending on the supplier and the relationship established. Common terms include payment in advance, partial payment upon order confirmation, or net 30/60 days after delivery. It’s essential to clarify these terms upfront and consider using secure payment methods to mitigate risk. Establishing a trustworthy relationship with suppliers can often lead to more favorable payment conditions over time. -

How do I handle logistics and shipping for adhesive tape rollers?

When sourcing adhesive tape rollers internationally, logistics and shipping are critical considerations. Collaborate with your supplier to determine the best shipping method (air, sea, or land) based on cost, delivery time, and destination. Ensure you understand customs regulations in your country, including any duties or tariffs that may apply. Work with a reliable freight forwarder who can assist in managing shipping logistics and provide tracking information throughout the process. -

What are the best practices for storing adhesive tape rollers?

Proper storage of adhesive tape rollers is essential to maintain their functionality and adhesive quality. Store rollers in a cool, dry place away from direct sunlight and extreme temperatures, which can degrade the adhesive. Ensure that they are kept upright to prevent damage to the roller mechanism. Regularly check inventory for expiration dates, as adhesive properties may diminish over time. Implement a first-in, first-out (FIFO) system to ensure older stock is used before newer inventory.

Top 2 Adhesive Tape Roller Manufacturers & Suppliers List

1. Scotch – Extra Strength Tape Runner

Domain: target.com

Registered: 1997 (28 years)

Introduction: {“name”:”Scotch Create Extra Strength Tape Runner Double-Sided”,”type”:”Glue Tape Roller”,”use”:”Scrapbooking & Office”,”length”:”33 ft”,”color”:”Clear”,”rating”:”4 out of 5 stars”,”reviews”:”134 reviews”,”return_policy”:”Free & easy returns within 90 days for a full refund”,”eligibility”:”Eligible for registries and wish lists”}

2. XFasten – Double Sided Adhesive Roller

Domain: xfasten.com

Registered: 2015 (10 years)

Introduction: XFasten Double Sided Adhesive Roller | 0.3 Inch x 360 Inches | Clear | Available in 4-Pack, 8-Pack, and 24-Pack. Light-duty, crystal-clear scrapbooking tape suitable for home, office, and enterprise use.

Strategic Sourcing Conclusion and Outlook for adhesive tape roller

In the competitive landscape of adhesive tape rollers, strategic sourcing is paramount for international B2B buyers. By understanding the diverse product offerings—from double-sided to permanent adhesive solutions—companies can make informed purchasing decisions that align with their operational needs. Key insights reveal the importance of sourcing from reliable suppliers who prioritize quality, sustainability, and innovation.

Investing in high-quality adhesive tape rollers not only enhances product reliability but also reduces waste, ultimately leading to cost savings and improved efficiency in production processes. As markets across Africa, South America, the Middle East, and Europe continue to evolve, the demand for versatile and durable adhesive solutions is set to rise.

Illustrative image related to adhesive tape roller

Looking ahead, it is crucial for businesses to build strong relationships with manufacturers and suppliers who can adapt to changing market demands. By leveraging strategic sourcing practices, international buyers can secure competitive advantages and drive growth in their respective markets. Embrace this opportunity to enhance your procurement strategy and ensure your supply chain is equipped to meet future challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to adhesive tape roller