Stickers En 3D: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for stickers en 3d

In the ever-evolving landscape of consumer goods, sourcing high-quality 3D stickers presents a unique challenge for international B2B buyers. These dynamic products, known for their vibrant designs and dimensional appeal, are increasingly sought after across various markets, including Africa, South America, the Middle East, and Europe. This comprehensive guide aims to empower buyers by providing essential insights into the diverse types of 3D stickers available, their myriad applications in industries such as crafts, marketing, and product branding, and effective strategies for supplier vetting.

Understanding the nuances of 3D sticker production is crucial for making informed purchasing decisions. This guide covers key aspects such as material choices, printing techniques, and the importance of quality assurance. Additionally, we delve into cost considerations, enabling buyers to navigate price variations influenced by regional manufacturing practices and import regulations.

By equipping B2B buyers with actionable knowledge and best practices, this guide serves as a valuable resource for those looking to enhance their product offerings with eye-catching 3D stickers. Whether you’re based in Nigeria, Vietnam, or elsewhere, the insights provided will help streamline your sourcing process and ensure that you select the right suppliers to meet your business needs effectively.

Understanding stickers en 3d Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dome Stickers | Raised design with a glossy finish, often made from vinyl. | Branding, promotional materials, product labels. | Pros: Durable, eye-catching. Cons: Can be more expensive than flat stickers. |

| Puffy Stickers | Soft, flexible material that adds a tactile element. | Scrapbooking, children’s products, event branding. | Pros: Lightweight, fun designs. Cons: May not adhere well to all surfaces. |

| Foam Stickers | Made from foam, providing a thick, three-dimensional look. | Crafting, educational tools, packaging. | Pros: Versatile, easy to apply. Cons: Limited durability outdoors. |

| 3D Embellishments | Incorporate various materials (glitter, fabric) for depth. | Arts and crafts, gift packaging, scrapbooking. | Pros: Highly decorative, unique designs. Cons: Can increase production costs. |

| Custom Printed Stickers | Tailored designs with specific branding elements. | Marketing campaigns, corporate branding. | Pros: Brand-specific, professional appearance. Cons: Minimum order quantities may apply. |

What are Dome Stickers and How Can They Benefit B2B Buyers?

Dome stickers feature a raised, glossy finish that enhances their visibility and aesthetic appeal. Typically made from durable vinyl, they are ideal for branding and promotional materials. B2B buyers should consider their application in product labels or marketing campaigns, as their eye-catching design can significantly enhance brand recognition. However, the cost may be higher compared to flat stickers, which is an important factor for budget-conscious buyers.

How Do Puffy Stickers Stand Out in the Market?

Puffy stickers are characterized by their soft and flexible material, creating a playful and tactile experience. These stickers are commonly used in scrapbooking, children’s products, and event branding due to their lightweight nature and fun designs. B2B buyers should evaluate their suitability for specific projects, especially those targeting younger demographics. However, it’s essential to note that puffy stickers may not adhere well to all surfaces, which could limit their applications.

What Makes Foam Stickers a Good Choice for Crafting?

Foam stickers are crafted from thick foam, providing a unique three-dimensional look that adds depth to any project. They are widely used in crafting, educational tools, and packaging, making them versatile for various applications. B2B buyers should consider their ease of application and the ability to customize shapes and sizes. However, their limited durability outdoors may restrict their use in certain environments, which is a crucial consideration for outdoor promotional activities.

How Can 3D Embellishments Enhance Arts and Crafts?

3D embellishments incorporate various materials like glitter and fabric, offering a highly decorative option for arts and crafts. They are particularly useful in gift packaging and scrapbooking, allowing for creative expression. B2B buyers can benefit from their unique designs, which can differentiate products in a competitive market. However, the potential increase in production costs should be weighed against the value added by these embellishments.

Why Consider Custom Printed Stickers for Branding?

Custom printed stickers allow businesses to tailor designs with specific branding elements, ensuring a professional appearance in marketing campaigns. They are vital for corporate branding and promotional efforts, helping to create a cohesive brand identity. B2B buyers should assess the minimum order quantities and the cost implications of custom designs, as these factors can influence overall marketing budgets. The ability to produce unique stickers can significantly enhance brand visibility in the marketplace.

Key Industrial Applications of stickers en 3d

| Industry/Sector | Specific Application of stickers en 3d | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Product Labeling and Branding | Enhances product visibility and shelf appeal | Quality of materials, customization options, and lead time |

| Advertising | Promotional Materials and Giveaways | Increases brand engagement and customer attraction | Design flexibility, pricing, and production speed |

| Manufacturing | Equipment and Safety Labels | Improves workplace safety and compliance | Durability, weather resistance, and regulatory compliance |

| Education | Educational Tools and Resources | Facilitates interactive learning and engagement | Educational relevance, safety standards, and cost-effectiveness |

| Event Management | Event Branding and Signage | Creates a memorable experience and enhances visibility | Customization capabilities, turnaround time, and pricing |

How Are 3D Stickers Used in Retail for Product Labeling and Branding?

In the retail sector, 3D stickers are increasingly utilized for product labeling and branding. They enhance the visual appeal of products, making them stand out on shelves and attracting consumer attention. This is particularly beneficial in competitive markets across Africa, South America, and Europe, where differentiation is key. Retailers should consider sourcing high-quality materials that can withstand different environmental conditions and offer customization options to align with brand identities.

What Role Do 3D Stickers Play in Advertising and Promotional Materials?

3D stickers serve as effective promotional materials in advertising campaigns, often used in giveaways and as part of marketing collateral. Their dimensionality makes them more engaging, which can lead to higher customer interaction and retention rates. For businesses targeting international markets, it’s crucial to consider the design flexibility and pricing structures of suppliers, ensuring that promotional materials resonate with diverse cultural contexts.

Why Are 3D Stickers Important for Manufacturing Equipment and Safety Labels?

In manufacturing, 3D stickers are vital for labeling equipment and ensuring safety compliance. These stickers help communicate important information, such as operating instructions and safety warnings, effectively reducing workplace accidents. Buyers in this sector should prioritize sourcing stickers that are durable and weather-resistant, as they need to withstand various environmental factors while remaining legible and intact.

How Do 3D Stickers Enhance Educational Tools and Resources?

The education sector benefits from 3D stickers by using them in educational tools and resources to create interactive learning experiences. They can be applied to books, classroom decorations, and educational kits, making learning more engaging for students. Buyers should focus on safety standards and cost-effectiveness when sourcing these stickers, especially for schools in developing regions like Nigeria and Vietnam, where budgets may be limited.

In What Ways Do 3D Stickers Contribute to Event Branding and Signage?

Event management companies utilize 3D stickers for branding and signage at events, creating immersive experiences that leave lasting impressions on attendees. They can be used for everything from directional signs to promotional materials, enhancing the overall visibility of the event. Key considerations for international buyers include the customization capabilities of suppliers and the turnaround time for production, ensuring that materials arrive in time for the event.

Illustrative image related to stickers en 3d

3 Common User Pain Points for ‘stickers en 3d’ & Their Solutions

Scenario 1: Sourcing Quality 3D Stickers for Diverse Markets

The Problem: B2B buyers often face the challenge of sourcing high-quality 3D stickers that resonate with their target demographic, particularly in diverse markets like Africa, South America, the Middle East, and Europe. Each region has unique cultural preferences, which means that a one-size-fits-all approach can lead to poor sales and customer dissatisfaction. Buyers may struggle to find suppliers who offer a variety of designs that cater to local tastes while maintaining quality standards. Additionally, language barriers and different production specifications can complicate sourcing efforts.

The Solution: To overcome these challenges, B2B buyers should establish partnerships with manufacturers that specialize in localized production. Conduct thorough market research to identify popular themes and designs in your target regions, such as cultural motifs or trending aesthetics. Engage with suppliers who can provide customization options, allowing you to tailor stickers to meet specific market demands. Additionally, consider using online marketplaces or trade shows to discover new suppliers who understand regional preferences. Ensuring clear communication with suppliers about quality standards and design expectations will help mitigate sourcing issues and enhance customer satisfaction.

Scenario 2: Managing Inventory and Stock Levels for Seasonal Demand

The Problem: Many B2B buyers encounter difficulties in managing inventory levels, especially with 3D stickers that may have seasonal appeal. For instance, stickers related to holidays, events, or popular culture can see spikes in demand, leading to either stockouts or excess inventory that ties up capital. Buyers often struggle to predict which designs will be popular during certain seasons, leading to lost sales opportunities or unnecessary markdowns on unsold stock.

The Solution: Implement a data-driven inventory management system that uses historical sales data and market trends to forecast demand accurately. Collaborate with suppliers who can offer flexible production capabilities, allowing for smaller, more frequent orders to meet fluctuating demand without overcommitting resources. Utilizing just-in-time (JIT) inventory practices can also help manage stock levels effectively. Additionally, consider creating a diversified product line that includes evergreen designs alongside seasonal items to ensure consistent sales throughout the year. Regularly review inventory performance and adjust purchasing strategies based on real-time sales data to stay responsive to market changes.

Scenario 3: Ensuring Adhesive Quality and Longevity of 3D Stickers

The Problem: B2B buyers often grapple with the issue of adhesive quality in 3D stickers. Poor adhesion can lead to customer complaints, product returns, and damage to brand reputation. This is especially critical in regions with varying climates, where humidity and temperature fluctuations can affect the performance of adhesives. Buyers must ensure that the stickers not only look appealing but also adhere well to a range of surfaces over time.

The Solution: When sourcing 3D stickers, prioritize suppliers that use high-quality, climate-resistant adhesives. Request samples to test the adhesive performance across different environmental conditions. Additionally, look for suppliers who provide detailed specifications about the types of adhesives used and their durability under various circumstances. Educate your customers on proper application techniques, such as cleaning surfaces before application, to enhance adhesion. Establish a feedback loop with your customers to monitor the performance of the stickers in the field, allowing you to make informed decisions about future purchases and supplier selections. By ensuring adhesive quality, you can enhance customer satisfaction and reduce the risk of returns.

Strategic Material Selection Guide for stickers en 3d

What Are the Key Materials Used for 3D Stickers?

When selecting materials for 3D stickers, understanding the properties and suitability of each option is crucial for B2B buyers. The choice of material not only affects the performance and durability of the stickers but also impacts compliance with international standards and regional preferences.

What Are the Key Properties of Vinyl for 3D Stickers?

Vinyl is one of the most popular materials for 3D stickers due to its versatility and durability. Key properties include excellent resistance to moisture, UV radiation, and temperature fluctuations, making it suitable for both indoor and outdoor applications. Vinyl can be produced in various finishes, such as matte, glossy, or transparent, allowing for creative designs.

Pros: Vinyl is highly durable, cost-effective, and easy to print on. It adheres well to a variety of surfaces, including metal, plastic, and glass, making it ideal for promotional materials.

Illustrative image related to stickers en 3d

Cons: While vinyl is generally robust, it can become brittle over time if exposed to extreme temperatures. Additionally, the manufacturing process can be complex, especially for intricate designs.

Impact on Application: Vinyl stickers are compatible with various printing technologies, including digital and screen printing, which allows for high-quality graphics.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the vinyl used complies with local environmental regulations, as some countries have restrictions on PVC materials.

How Does Paper Perform as a Material for 3D Stickers?

Paper is another common material for 3D stickers, particularly for applications where cost is a primary concern. It offers a lightweight option that can be easily cut and printed.

Pros: Paper is generally less expensive than vinyl and can be produced with a range of textures and finishes. It is also biodegradable, making it an environmentally friendly choice.

Illustrative image related to stickers en 3d

Cons: Paper is less durable than vinyl and is susceptible to moisture and wear. It may not be suitable for outdoor applications unless treated with a protective coating.

Impact on Application: Paper stickers are best suited for short-term use, such as promotional events or temporary labeling.

Considerations for International Buyers: Buyers should be aware of the paper quality and its compliance with international standards like ISO 9706 for permanence, especially in markets that prioritize sustainability.

What Are the Benefits of Using Polyethylene for 3D Stickers?

Polyethylene is a strong, flexible plastic that is increasingly used for 3D stickers. Its key properties include chemical resistance and durability against environmental factors.

Pros: Polyethylene is highly resistant to moisture and chemicals, making it ideal for industrial applications. It is also lightweight and can be produced in various thicknesses.

Illustrative image related to stickers en 3d

Cons: The cost of polyethylene can be higher than paper, and it may require specialized printing techniques, which can complicate the manufacturing process.

Impact on Application: This material is suitable for stickers used in harsh environments, such as those found in the automotive or chemical industries.

Considerations for International Buyers: Buyers should ensure that the polyethylene used meets local safety and environmental standards, particularly in regions with stringent regulations.

Illustrative image related to stickers en 3d

Why Choose Foam as a Material for 3D Stickers?

Foam stickers are a unique option that adds a tactile dimension to products. They are often used in crafts and educational materials.

Pros: Foam stickers are lightweight, easy to apply, and provide a three-dimensional effect without the need for complex printing techniques. They are also available in various colors and shapes.

Cons: Foam may not adhere well to all surfaces and can be less durable than vinyl or polyethylene, particularly in outdoor conditions.

Impact on Application: Foam stickers are often used in creative projects, children’s crafts, and promotional items where a playful appearance is desired.

Considerations for International Buyers: Buyers should consider the foam’s compliance with safety standards, especially in markets focused on children’s products.

Summary Table of Material Selection for 3D Stickers

| Material | Typical Use Case for stickers en 3d | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | Outdoor promotional stickers | Excellent durability and versatility | Can become brittle over time | Medium |

| Paper | Short-term promotional events | Cost-effective and biodegradable | Less durable, susceptible to moisture | Low |

| Polyethylene | Industrial applications | High chemical and moisture resistance | Higher cost, requires special printing | High |

| Foam | Crafts and educational materials | Lightweight and easy to apply | Poor adhesion on some surfaces | Medium |

This strategic material selection guide provides actionable insights for B2B buyers in diverse markets, helping them make informed decisions based on specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for stickers en 3d

What Are the Key Stages in the Manufacturing Process of 3D Stickers?

The manufacturing of 3D stickers involves several critical stages, each designed to ensure high-quality output that meets the specific needs of B2B buyers. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for 3D Sticker Production?

Material preparation is the foundation of the manufacturing process. High-quality vinyl or paper is typically selected based on the desired end-use of the stickers. For instance, vinyl is often chosen for outdoor durability, while paper might be preferred for indoor applications. This stage involves cutting the material into appropriate sizes and shapes, ensuring that all necessary colors and textures are ready for production. Suppliers may also treat materials with coatings or adhesives that enhance performance and adhesion.

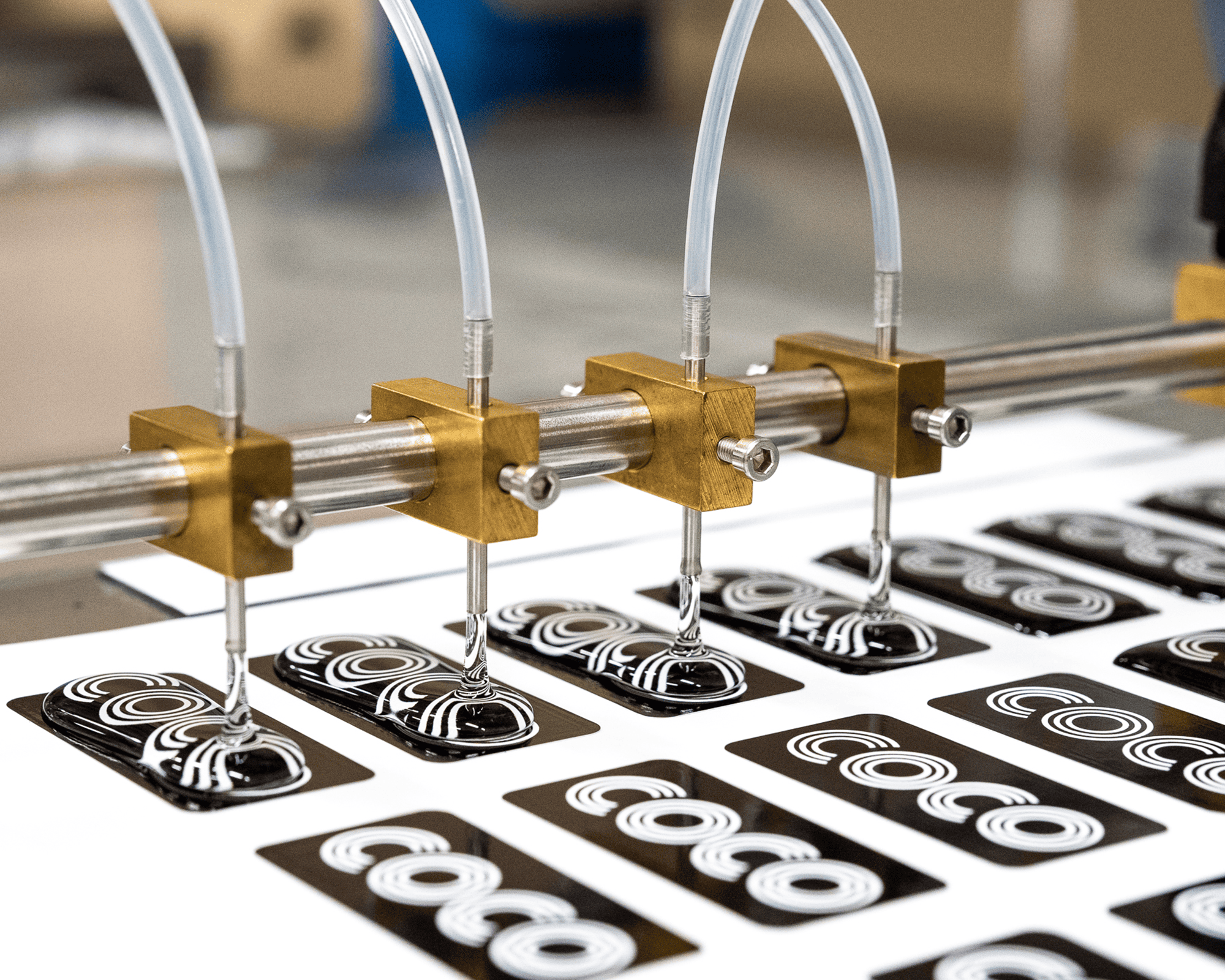

What Techniques Are Used in Forming 3D Stickers?

The forming stage employs various techniques to create the three-dimensional effect. Common methods include:

- Foam Layering: This involves applying a foam layer between two printed materials to create depth. The foam acts as a cushion, giving the stickers a tactile quality.

- Dome Coating: A clear epoxy resin is applied over printed designs to produce a glossy, rounded finish. This not only enhances visual appeal but also protects the print from wear and tear.

- Die-Cutting: Precision die-cutting machines are used to shape stickers into intricate designs, ensuring that they maintain their intended form during handling and application.

How Are 3D Stickers Assembled and Finished?

Once the forming process is complete, the assembly stage begins. This may involve combining multiple components, such as layering different materials or integrating embellishments like glitter or rhinestones.

Finishing techniques include:

- Quality Control Checks: Each batch undergoes inspection to ensure consistency in color, shape, and adhesion.

- Packaging: Proper packaging is essential for protecting stickers during transit. This might involve using blister packs or flat envelopes, depending on the product type.

What Quality Assurance Standards Are Relevant for 3D Stickers?

Quality assurance (QA) is crucial in the manufacturing of 3D stickers, particularly for B2B buyers who require reliable and consistent products. International standards like ISO 9001 provide a framework for quality management systems, ensuring that manufacturers adhere to best practices throughout their production processes.

Illustrative image related to stickers en 3d

Which Industry-Specific Standards Should B2B Buyers Consider?

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, especially for stickers used in specific applications, such as industrial or safety environments. These certifications indicate compliance with safety and performance standards.

What Are the Key Quality Control Checkpoints in 3D Sticker Manufacturing?

Quality control (QC) checkpoints are integral to the production process, ensuring that defects are identified and rectified promptly. The typical QC checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to verify that they meet specified quality standards before being used in production.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps detect issues early, allowing for immediate corrective actions.

- Final Quality Control (FQC): The finished products are inspected to ensure they meet the established quality criteria before shipment.

What Common Testing Methods Are Used to Ensure Quality in 3D Stickers?

Common testing methods include:

- Adhesion Testing: Evaluates how well stickers adhere to various surfaces, crucial for ensuring customer satisfaction.

- Durability Testing: Assesses how well stickers withstand environmental factors such as UV light, moisture, and abrasion.

- Visual Inspection: A thorough visual check for any defects in print quality, color accuracy, and overall appearance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are several actionable steps:

Illustrative image related to stickers en 3d

-

Conduct Supplier Audits: Regular audits can help assess a supplier’s adherence to quality standards and their manufacturing capabilities. This process can involve on-site visits or remote assessments.

-

Request Quality Reports: Suppliers should provide detailed quality reports, including data on defect rates, inspection results, and corrective actions taken.

-

Utilize Third-Party Inspection Services: Engaging third-party inspectors can offer an unbiased evaluation of a supplier’s quality control processes, providing additional assurance for B2B buyers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Cultural Differences: Understanding local manufacturing practices and quality expectations can help facilitate better communication with suppliers.

- Regulatory Compliance: Different regions may have varying regulations regarding materials and safety standards. Buyers should ensure that their suppliers comply with local and international regulations.

- Logistics and Supply Chain Considerations: Delays in shipping or customs clearance can affect the quality of products upon arrival. It’s essential to have contingency plans in place.

Conclusion

The manufacturing process and quality assurance for 3D stickers are multi-faceted and crucial for meeting the demands of B2B buyers. By understanding these processes, standards, and verification methods, buyers can make informed decisions when selecting suppliers, ensuring high-quality products that meet their specifications. This knowledge not only enhances procurement efficiency but also strengthens business relationships across international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stickers en 3d’

To assist B2B buyers in effectively procuring 3D stickers, this guide outlines essential steps to ensure a successful sourcing process. By following this checklist, businesses can identify the right suppliers and products that meet their specific needs while maximizing value.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clarify what types of 3D stickers you need. Consider the size, material (e.g., vinyl, paper), and design elements (e.g., puffy, holographic) that align with your branding or product requirements. Having a clear specification helps streamline the sourcing process and ensures that suppliers can meet your expectations.

Step 2: Identify Your Target Market

Understanding your target audience is crucial for selecting the right stickers. Different regions may have varying preferences, such as vibrant colors or specific themes. For instance, buyers in Africa may prefer culturally relevant designs, while those in Europe might lean towards minimalistic aesthetics. Tailoring your selection to your audience can enhance customer engagement and sales.

Step 3: Research and Shortlist Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for manufacturers that specialize in 3D stickers and have a proven track record. Utilize online platforms, trade shows, and industry directories to find reputable suppliers. Pay attention to reviews and testimonials from other B2B buyers to gauge reliability.

Illustrative image related to stickers en 3d

Step 4: Request Samples for Evaluation

Once you have a shortlist, request samples of the 3D stickers you are interested in. This step is critical for assessing the quality, durability, and visual appeal of the products. Make sure to evaluate the stickers in real-world applications to see how they perform under different conditions, such as exposure to sunlight or moisture.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers comply with relevant industry standards and regulations. Look for certifications that demonstrate their commitment to quality and safety, such as ISO certification or compliance with specific materials regulations. This verification protects your business from potential risks associated with subpar products.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations regarding pricing, minimum order quantities, and payment terms. Be clear about your budget and expectations to avoid misunderstandings later. Establishing favorable terms can lead to long-term partnerships and better pricing on future orders.

Step 7: Plan for Logistics and Delivery

Finally, outline the logistics of your order, including shipping methods, delivery timelines, and potential customs regulations, especially if you’re importing from international suppliers. Effective planning in this stage ensures timely delivery, which is essential for maintaining inventory levels and meeting customer demand.

By following this checklist, B2B buyers can navigate the sourcing process for 3D stickers with confidence, ensuring they select the best products and suppliers for their business needs.

Illustrative image related to stickers en 3d

Comprehensive Cost and Pricing Analysis for stickers en 3d Sourcing

When considering the procurement of 3D stickers, a comprehensive understanding of the cost structure and pricing dynamics is essential for international B2B buyers. This analysis delves into the key components that influence costs and provides actionable insights for effective sourcing strategies.

What Are the Key Cost Components in 3D Sticker Production?

Materials: The choice of materials significantly impacts the overall cost of 3D stickers. Common materials include vinyl, paper, and specialty substrates like holographic or textured finishes. Higher-quality materials not only enhance the sticker’s appearance but also increase durability, which can justify a higher price point.

Labor: Labor costs vary widely depending on the region and the complexity of the sticker designs. Customization or intricate designs often require more skilled labor, which can raise production costs. Understanding local labor markets is crucial, especially when sourcing from diverse regions such as Africa or South America.

Illustrative image related to stickers en 3d

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these costs. Buyers should consider suppliers with streamlined operations to achieve better pricing.

Tooling: For custom designs, tooling costs can be significant. This involves the creation of molds or dies specific to the sticker designs. Buyers should inquire about these costs upfront, as they can be a substantial part of the initial investment.

Quality Control (QC): Ensuring product quality through rigorous QC processes is vital. However, these processes add to the overall cost. Suppliers with robust QC measures may charge higher prices, but this often results in better product consistency and fewer defects.

Illustrative image related to stickers en 3d

Logistics: Shipping and handling costs can vary based on the destination and the chosen Incoterms. International buyers must factor in these costs, especially when sourcing from regions with high shipping fees or longer transit times.

Margin: Suppliers typically apply a margin to their costs to ensure profitability. Understanding the standard margins in the industry can help buyers negotiate more effectively.

How Do Price Influencers Affect 3D Sticker Sourcing?

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Suppliers often provide tiered pricing, where larger orders result in lower per-unit costs. Buyers should assess their needs and negotiate MOQs that align with their budget.

Specifications and Customization: Customized stickers often come at a premium. Buyers should clarify the extent of customization required and explore options for standard designs that may reduce costs.

Material Choices: The selection of materials directly influences pricing. For example, eco-friendly materials may cost more but can appeal to environmentally-conscious consumers.

Quality and Certifications: Stickers that meet specific quality standards or certifications (e.g., food-safe, non-toxic) may command higher prices. Buyers should evaluate the necessity of these certifications based on their target markets.

Supplier Factors: The reputation, reliability, and production capabilities of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer competitive prices to gain market share.

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Clarity on Incoterms can prevent unexpected costs and aid in budgeting.

What Are the Best Negotiation and Sourcing Strategies for International Buyers?

Negotiation Tips: Buyers should approach negotiations with a clear understanding of their requirements and the market landscape. Leverage competitive quotes from multiple suppliers to strengthen negotiating positions.

Illustrative image related to stickers en 3d

Cost-Efficiency Strategies: Consider long-term partnerships with suppliers for better pricing. Engaging in bulk purchasing or seasonal contracts can also lead to more favorable terms.

Total Cost of Ownership: Assess the total cost of ownership, including initial purchase price, shipping, and potential wastage or returns. This holistic view ensures that buyers make informed decisions based on overall costs rather than just sticker prices.

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and import duties that can affect pricing. Establishing relationships with local distributors can mitigate some of these challenges.

Illustrative image related to stickers en 3d

By understanding these cost components and pricing influencers, international B2B buyers can make informed decisions when sourcing 3D stickers, ensuring they achieve both quality and value in their purchases.

Alternatives Analysis: Comparing stickers en 3d With Other Solutions

Exploring Alternative Solutions to Stickers en 3D

In the competitive landscape of product embellishments and branding, businesses often seek innovative ways to enhance their offerings. While stickers en 3D serve as a popular choice for adding visual appeal and personalization, it is crucial for B2B buyers to consider alternative solutions that may better fit their specific requirements. This section will compare stickers en 3D with two viable alternatives: custom printed labels and digital printing on products.

Comparison Table

| Comparison Aspect | Stickers en 3D | Custom Printed Labels | Digital Printing on Products |

|---|---|---|---|

| Performance | High visual impact; adds dimension | Versatile; suitable for various surfaces | Direct application; often integrated into the product |

| Cost | Moderate; varies by design and quantity | Generally lower; depends on size and materials | Higher initial costs; varies based on product type |

| Ease of Implementation | Simple application; requires clean surface | Easy to apply; requires adhesive | Requires specialized equipment; may need design software |

| Maintenance | Minimal; durable but can peel if not applied correctly | Low; can be replaced easily | Low; permanent once printed |

| Best Use Case | Scrapbooking, crafts, promotional items | Branding, product packaging, labeling | Custom merchandise, promotional products, or packaging |

In-Depth Look at Alternatives

What Are the Benefits and Drawbacks of Custom Printed Labels?

Custom printed labels offer a versatile alternative to stickers en 3D. They can be designed for various applications, including branding, product packaging, and labeling. Labels generally have a lower cost, making them attractive for businesses looking to manage expenses. However, they may lack the visual impact and tactile appeal of 3D stickers, which can be a disadvantage for businesses aiming for standout marketing materials. Labels also require precise application to ensure they adhere well, which may complicate the process for some users.

How Does Digital Printing on Products Compare?

Digital printing on products represents another innovative approach. This method allows designs to be printed directly onto items, such as textiles, ceramics, or packaging. The primary advantage of digital printing is its ability to create a seamless integration of design and product, eliminating the need for secondary application processes. However, this method can incur higher initial costs due to the need for specialized equipment and materials. Additionally, not all surfaces are suitable for digital printing, which can limit its applicability in certain scenarios.

How Should B2B Buyers Decide on the Right Solution?

When considering the right solution, B2B buyers should assess their specific needs, including budget constraints, desired aesthetic, and application environment. Stickers en 3D are ideal for businesses looking to create impactful and engaging products, especially in the craft and promotional sectors. Alternatively, custom printed labels offer a cost-effective and versatile solution for branding and packaging, while digital printing provides a modern, integrated approach for customized merchandise. Ultimately, the choice depends on the desired outcome and the context in which the solution will be applied. By evaluating these factors, buyers can make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for stickers en 3d

What Are the Key Technical Properties of 3D Stickers?

Understanding the technical properties of 3D stickers is essential for B2B buyers aiming to make informed purchasing decisions. Here are some critical specifications to consider:

1. Material Composition

3D stickers can be made from various materials, including vinyl, paper, and specialty plastics. Vinyl stickers are known for their durability and weather resistance, making them ideal for outdoor applications. Paper stickers, while often less expensive, may not hold up as well in harsh conditions. Choosing the right material affects the sticker’s longevity and suitability for specific uses, such as promotional events or product packaging.

2. Adhesive Strength

The adhesive used on 3D stickers varies in strength, which is crucial for their application. High-tack adhesives are designed for permanent bonding, while removable adhesives allow for easy repositioning. Understanding adhesive properties helps buyers select stickers that meet their intended use, whether for temporary promotions or long-term branding.

3. Thickness and Dimension

The thickness of 3D stickers contributes to their tactile appeal and visual impact. Standard thickness ranges from 0.5 mm to 2 mm. Greater thickness often results in a more pronounced 3D effect, enhancing the sticker’s visibility. B2B buyers should consider how thickness influences the application surface and the desired aesthetic.

4. Finish and Coating

3D stickers can feature various finishes, including matte, gloss, and UV coating. A gloss finish can enhance colors and provide a shiny appearance, while matte finishes offer a more subdued look. UV coating adds an extra layer of protection against fading and scratches, which is particularly valuable for outdoor applications. Selecting the appropriate finish can significantly affect the sticker’s visual appeal and durability.

5. Customization Options

Customization capabilities, such as shape, size, and printing techniques (e.g., digital, screen printing), play a vital role in meeting specific branding needs. Customization allows businesses to create unique designs that resonate with their target audience, making it a crucial factor for B2B buyers focused on brand differentiation.

What Are Common Trade Terminology and Concepts in the 3D Sticker Industry?

Navigating the 3D sticker market requires familiarity with industry jargon. Here are some essential terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the sticker industry, this could relate to manufacturers who produce stickers for brands that sell them under their own labels. Understanding OEM dynamics is essential for buyers looking to collaborate with manufacturers for custom products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory levels and initial investment costs. Understanding MOQs helps businesses plan their purchasing strategy and manage cash flow effectively.

Illustrative image related to stickers en 3d

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. In the context of 3D stickers, an RFQ can help buyers gather competitive pricing and terms, ensuring they make informed decisions when selecting suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is vital for B2B buyers engaging in cross-border transactions to clarify shipping responsibilities and costs.

5. Die-Cut

Die-cut refers to a manufacturing process that allows stickers to be cut into specific shapes or designs. This term is essential for buyers seeking unique sticker designs that stand out. Understanding die-cut options enables businesses to enhance their branding through distinctive shapes.

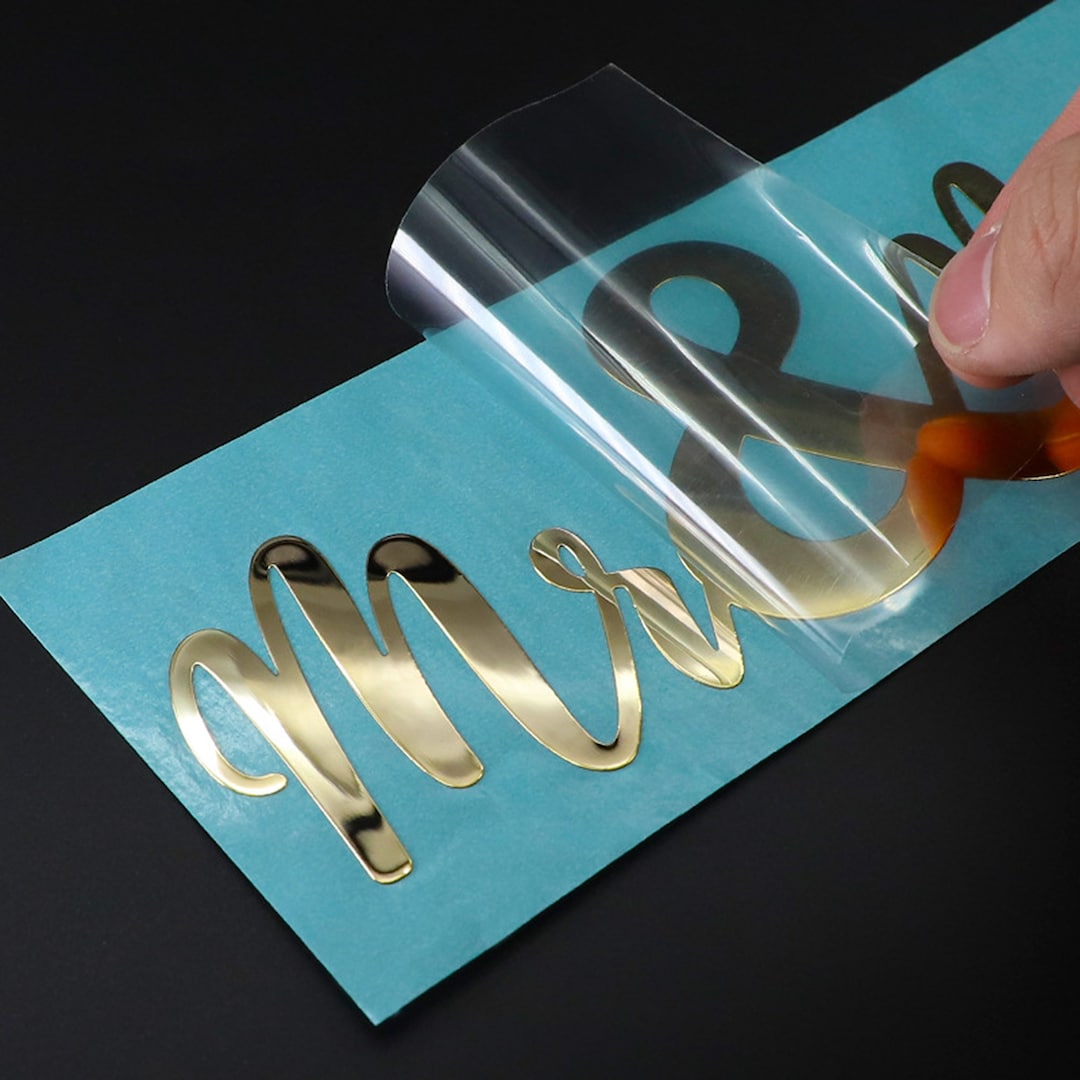

6. Custom Dome

Custom dome stickers involve a 3D effect achieved by applying a clear resin coating over the printed design, creating a glossy, raised surface. This term is relevant for buyers looking for high-impact visual appeal in their branding efforts.

In conclusion, understanding the technical properties and trade terminology associated with 3D stickers equips B2B buyers with the knowledge needed to make informed purchasing decisions. By considering material composition, adhesive strength, and customization options, along with familiarizing themselves with industry jargon, buyers can effectively navigate the sticker market.

Navigating Market Dynamics and Sourcing Trends in the stickers en 3d Sector

What Are the Current Market Dynamics and Key Trends Influencing the 3D Stickers Sector?

The global market for 3D stickers is experiencing robust growth, driven by factors such as the rising popularity of scrapbooking, card-making, and personalized gifts. The demand for unique and visually appealing products has surged, particularly among younger demographics, which is influencing B2B sourcing strategies. International buyers from regions like Africa, South America, the Middle East, and Europe are increasingly looking for innovative suppliers who can offer diverse product lines, including themed and customizable options.

Emerging technologies are also reshaping the industry landscape. The integration of digital printing technology allows for quicker production times and lower minimum order quantities, appealing to businesses that prefer on-demand production. Additionally, the rise of e-commerce platforms has made it easier for buyers to access a wider range of suppliers and products, fostering a competitive marketplace.

Key trends include the increasing demand for thematic stickers that cater to specific events or hobbies, such as holidays, travel, and popular culture icons. Furthermore, the use of social media platforms for marketing and showcasing products is becoming essential, as visually-driven content captures consumer attention and influences purchasing decisions.

How Does Sustainability Impact Sourcing in the 3D Stickers Market?

Sustainability is a critical consideration for B2B buyers in the 3D stickers sector. The environmental impact of sticker production, including waste generated and the materials used, is under scrutiny. Buyers are increasingly prioritizing suppliers who adopt eco-friendly practices, such as using recycled materials and non-toxic inks. This shift is not only about compliance but also about meeting the growing consumer demand for sustainable products.

Ethical sourcing is another vital aspect that businesses must consider. Companies are expected to provide transparency in their supply chains, ensuring that labor practices are fair and environmentally responsible. Certifications like FSC (Forest Stewardship Council) for paper products and eco-labels for inks can help buyers identify suppliers that align with their sustainability goals.

Moreover, the introduction of biodegradable and compostable materials in sticker production is gaining traction. This not only minimizes environmental impact but also appeals to environmentally conscious consumers. As sustainability becomes a core business principle, companies that embrace these practices are likely to gain a competitive edge in the marketplace.

What Is the Evolution of the 3D Stickers Market and Its Relevance to B2B Buyers?

The evolution of 3D stickers can be traced back to their origins in the early scrapbooking movement, where crafters sought ways to add dimension and personalization to their projects. Over the years, advancements in technology have allowed for the creation of more intricate designs, such as puffy stickers and dome stickers, which enhance the tactile experience.

In the B2B context, this evolution has led to a more diverse product offering, catering to various markets, including education, marketing, and event planning. As businesses recognize the value of creative branding and product differentiation, the demand for unique 3D sticker solutions continues to grow.

Understanding the historical context of 3D stickers not only informs current trends but also helps B2B buyers appreciate the evolving nature of consumer preferences, allowing them to make informed sourcing decisions that align with market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of stickers en 3d

-

How do I choose the right supplier for 3D stickers?

Selecting the right supplier involves evaluating their product quality, production capacity, and reliability. Start by requesting samples to assess the quality of their 3D stickers. Verify their manufacturing capabilities to ensure they can meet your order volumes and timelines. Additionally, check reviews or testimonials from other businesses, and consider their responsiveness and communication throughout the sourcing process. Lastly, ensure the supplier complies with international trade regulations and has experience shipping to your target markets. -

What customization options are available for 3D stickers?

Most suppliers offer a variety of customization options for 3D stickers, including size, shape, color, and design. You can often choose between different materials, such as vinyl or paper, and even select special finishes like gloss or matte. Some manufacturers provide the option to add your branding or logo, which can enhance your marketing efforts. It’s crucial to communicate your specific requirements and request a prototype or digital proof before finalizing the order to ensure your expectations are met. -

What is the minimum order quantity (MOQ) for 3D stickers?

The MOQ for 3D stickers can vary widely depending on the supplier and the complexity of the design. Generally, MOQs can range from as low as 100 units to several thousand. It’s essential to discuss your needs with potential suppliers, as many are willing to accommodate smaller orders, especially for custom designs. Keep in mind that lower MOQs may come with higher per-unit costs, so evaluate your budget and inventory needs accordingly. -

What payment terms should I expect when ordering 3D stickers?

Payment terms can differ based on the supplier’s policies, but common practices include a deposit upfront (usually 30-50%) with the balance due upon completion or prior to shipping. Some suppliers may offer credit terms for established businesses. Always clarify payment methods accepted (e.g., bank transfers, PayPal) and any additional fees associated with international transactions. Ensuring clear terms can help prevent misunderstandings and foster a positive business relationship. -

How can I ensure quality assurance for my 3D sticker orders?

To ensure quality assurance, request detailed specifications and sample products before placing a large order. Establishing a clear quality control process with your supplier is essential; this may include inspecting the materials and designs at various production stages. Some businesses choose to conduct third-party inspections to verify product quality before shipment. Additionally, familiarize yourself with the supplier’s return policy in case the delivered products do not meet your specifications. -

What shipping options are available for international orders of 3D stickers?

International shipping options typically include air freight, sea freight, and express courier services. Air freight is faster but more expensive, while sea freight is more economical for larger shipments but takes longer. When selecting a shipping method, consider delivery timelines, costs, and your target market’s location. Ensure that your supplier provides tracking information, and be aware of any customs duties or taxes that may apply upon arrival in your country. -

What are the common applications for 3D stickers in B2B markets?

3D stickers are versatile and can be used in various B2B applications, including product labeling, promotional materials, and branding. They are popular in packaging, scrapbooking, and crafting industries. Businesses often use them for events, trade shows, or as part of marketing campaigns to create eye-catching visuals. Understanding your target market’s preferences can help tailor your product offerings and maximize the impact of your stickers in promotional efforts. -

How do I handle potential issues with my 3D sticker order?

If issues arise with your order, such as delays or quality concerns, it’s crucial to communicate promptly with your supplier. Document your concerns clearly and provide evidence, such as photographs of defective products. Most reputable suppliers will work with you to resolve issues, whether through replacements or refunds. Establishing a good relationship with your supplier can facilitate smoother resolutions and help prevent future problems in your orders.

Top 3 Stickers En 3D Manufacturers & Suppliers List

1. FastPrinting – Dome 3D Stickers

Domain: fastprinting.com

Registered: 1999 (26 years)

Introduction: Dome (3D) Stickers, also known as 3D stickers, feature a dynamic three-dimensional or bubble-like appearance. They are popular for use on machinery, car windows, and special products, offering a unique tactile quality. Suitable for both indoor and outdoor use, they are favored by brands like Westfield and David Jones. Small quantity printing is available, and options for outdoor use include strong…

2. Hobby Lobby – Dimensional Stickers

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: Dimensional Stickers from Hobby Lobby include various designs and themes for scrapbook and paper crafts. Key products listed are: 1. Hunting 3D Stickers – Current price: $2.09, Original price: $3.49 2. Thanksgiving Greetings 3D Stickers – Current price: $1.49, Original price: $2.49 3. Happy Thanksgiving 3D Stickers – Current price: $2.09, Original price: $3.49 4. Country Fall 3D Stickers – Current…

3. Homeford – 3D Stickers Collection

Domain: homeford.com

Registered: 2015 (10 years)

Introduction: 3D Stickers collection from Homeford features eye-catching designs that add dimension to belongings. The stickers are playful and fun, suitable for decorating various surfaces. There are 84 products available, with sorting options by best selling, alphabetically, and price. Discounts are available for bulk purchases: 2% off for 6-11 items, 5% off for 12-23 items, and 10% off for 24 or more items. …

Strategic Sourcing Conclusion and Outlook for stickers en 3d

In today’s competitive landscape, strategic sourcing of 3D stickers presents a unique opportunity for international buyers. These dimensional embellishments not only enhance product appeal but also cater to diverse markets across Africa, South America, the Middle East, and Europe. As noted, the growing demand for customizable and thematic stickers—ranging from event-specific designs to everyday decor—underscores the importance of sourcing partners who can provide quality, variety, and innovation.

B2B buyers should prioritize suppliers that offer a robust selection and flexible ordering options, ensuring they can meet fluctuating market demands. Emphasizing sustainability and ethical sourcing practices will also resonate with increasingly conscientious consumers. Establishing long-term partnerships with reliable manufacturers can lead to improved pricing strategies and exclusive product lines, thereby enhancing your competitive edge.

As we look ahead, the integration of technology in sticker production and distribution will likely reshape the market. Now is the time for businesses to assess their sourcing strategies and explore new suppliers who can provide cutting-edge solutions. Embrace this opportunity to elevate your brand with distinctive 3D stickers that captivate your audience and drive sales.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.