Steel Wire Scratch Hand Brush Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for steel wire scratch hand brush

In the dynamic landscape of industrial cleaning solutions, sourcing high-quality steel wire scratch hand brushes presents a significant challenge for B2B buyers globally. These essential tools are vital for effective surface preparation, de-burring, and cleaning across various sectors, including automotive, aerospace, and manufacturing. However, navigating the complexities of supplier options, material specifications, and pricing can be daunting, especially for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe.

This comprehensive guide aims to empower international B2B buyers by providing detailed insights into the types of steel wire scratch hand brushes available, their specific applications, and critical considerations for supplier vetting. From understanding the differences between stainless steel and carbon steel brushes to evaluating cost structures and bulk purchasing options, this resource equips decision-makers with the knowledge needed to make informed purchasing choices.

By addressing common pain points and offering actionable strategies, this guide serves as a valuable tool for businesses seeking reliable, effective cleaning solutions. Whether you’re in Brazil, Germany, or beyond, you will find the information necessary to enhance your procurement process and ensure that you select the right products to meet your operational needs.

Understanding steel wire scratch hand brush Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Wire Brush | Durable, corrosion-resistant, ideal for aggressive cleaning. | Automotive, aerospace, metal fabrication | Pros: Long-lasting, effective on tough grime. Cons: May scratch softer surfaces. |

| Carbon Steel Wire Brush | Cost-effective, suitable for general cleaning tasks. | Construction, manufacturing, welding | Pros: Economical, versatile. Cons: Prone to rust, less durable than stainless steel. |

| Conductive Wire Brush | Designed to dissipate static electricity, made with conductive materials. | Electronics, cleanrooms, ESD-sensitive environments | Pros: Prevents static discharge. Cons: Higher cost, specialized use. |

| Curved Handle Wire Brush | Ergonomic design for better grip and access to tight spaces. | Maintenance, automotive repair, intricate cleaning | Pros: Enhances user comfort, effective in hard-to-reach areas. Cons: May be bulkier to store. |

| Heavy-Duty Scratch Brush | Features a robust construction with thicker bristles for tough jobs. | Industrial cleaning, heavy machinery maintenance | Pros: Excellent for tough applications. Cons: Heavier, can be unwieldy for delicate tasks. |

What Are the Characteristics of Stainless Steel Wire Brushes?

Stainless steel wire brushes are renowned for their durability and resistance to corrosion. They excel in heavy-duty applications, making them ideal for industries like automotive and aerospace, where they are employed for cleaning metal surfaces and removing rust. When purchasing, consider the bristle diameter and brush configuration to ensure they meet specific cleaning requirements. Their longevity can offset higher initial costs, making them a smart investment for frequent use.

How Do Carbon Steel Wire Brushes Compare?

Carbon steel wire brushes are often favored for their cost-effectiveness and versatility. They are commonly used in construction and manufacturing settings where general cleaning is required. While they provide excellent performance, buyers should be aware that carbon steel is more susceptible to rust compared to stainless steel. When selecting a carbon steel brush, consider the environment in which it will be used to ensure it meets durability needs.

What Are the Benefits of Using Conductive Wire Brushes?

Conductive wire brushes are specifically designed to eliminate static electricity, making them essential in electronics and cleanroom applications. These brushes are made from materials that provide a path to ground, effectively preventing static buildup. When purchasing, businesses should evaluate the brush’s conductivity rating and compatibility with their specific static-sensitive processes. While they are generally more expensive, their specialized function can significantly enhance safety and efficiency in sensitive environments.

Illustrative image related to steel wire scratch hand brush

Why Choose a Curved Handle Wire Brush?

Curved handle wire brushes are ergonomically designed to improve grip and allow easier access to tight spaces. This makes them particularly useful in maintenance and automotive repair tasks where precision is key. Buyers should consider the brush’s overall length and the curvature of the handle to ensure it fits their cleaning needs. While they may take up more storage space, their user-friendly design can lead to better cleaning results and reduced fatigue during use.

When to Use Heavy-Duty Scratch Brushes?

Heavy-duty scratch brushes are built for rigorous applications, featuring thicker bristles that tackle the toughest jobs in industrial settings. They are ideal for cleaning heavy machinery and removing stubborn grime. Buyers should assess the specific material and bristle thickness to match their cleaning tasks. Although these brushes can be heavier and more challenging to maneuver, their effectiveness in demanding environments often justifies the investment.

Key Industrial Applications of steel wire scratch hand brush

| Industry/Sector | Specific Application of steel wire scratch hand brush | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Cleaning aircraft components and removing surface contaminants | Ensures safety and compliance with regulations | Need for high-quality, durable brushes that can withstand rigorous cleaning without damaging surfaces |

| Automotive | Deburring and cleaning engine parts before assembly | Improves product quality and reduces rework | Sourcing brushes with specific bristle types suited for various metals and alloys used in engines |

| Metal Fabrication | Preparing metal surfaces for welding or coating | Enhances adhesion and finish quality | Consideration for brush size, wire type, and handle design for ergonomic use in tight spaces |

| Electronics Manufacturing | Removing dust and debris from circuit boards | Prevents static discharge and ensures component reliability | Requirement for anti-static properties and compatibility with delicate electronic components |

| Construction and Maintenance | Cleaning tools and machinery from rust and debris | Extends tool life and improves efficiency | Need for brushes that can handle tough conditions and various debris types, including rust and paint |

How is the Steel Wire Scratch Hand Brush Used in Aerospace Applications?

In the aerospace industry, steel wire scratch hand brushes are essential for cleaning aircraft components, particularly in removing surface contaminants like grease, paint, and oxidation. These brushes help maintain safety and compliance with stringent regulations. Buyers in this sector require brushes made from durable materials that can endure rigorous cleaning processes without damaging sensitive surfaces. It’s crucial to source brushes that meet aerospace standards, ensuring they are capable of handling the specific materials used in aviation.

What Role Does the Steel Wire Scratch Hand Brush Play in Automotive Applications?

Automotive manufacturers utilize steel wire scratch hand brushes for deburring and cleaning engine parts prior to assembly. This process is vital for enhancing product quality and minimizing the chances of rework due to imperfections. Buyers in this industry need to consider the type of bristles that will work best with various metals and alloys commonly found in engines. Sourcing brushes that offer the right balance of stiffness and durability is essential for achieving optimal results in automotive applications.

How are Steel Wire Scratch Hand Brushes Used in Metal Fabrication?

In metal fabrication, steel wire scratch hand brushes are employed to prepare metal surfaces for welding or coating. By effectively removing rust, scale, and other contaminants, these brushes enhance adhesion and ensure a superior finish. Businesses must focus on sourcing brushes with the appropriate size, wire type, and handle design to facilitate ergonomic use, especially in tight spaces or complex assemblies. This attention to detail can significantly improve productivity and the quality of fabricated products.

Why are Steel Wire Scratch Hand Brushes Important in Electronics Manufacturing?

In the electronics manufacturing sector, steel wire scratch hand brushes are crucial for cleaning circuit boards and removing dust and debris. This cleaning process is vital to prevent static discharge, which can compromise the reliability of electronic components. Buyers in this field should prioritize sourcing brushes with anti-static properties and suitable bristle configurations that are gentle enough not to damage delicate electronic parts. Ensuring compatibility with various cleaning agents is also a key consideration.

What Benefits Do Steel Wire Scratch Hand Brushes Offer in Construction and Maintenance?

Steel wire scratch hand brushes are widely used in construction and maintenance for cleaning tools and machinery from rust and debris. This application not only extends the life of tools but also improves overall efficiency in operations. Businesses should consider sourcing brushes that are robust enough to handle tough conditions and capable of dealing with various types of debris, including rust, paint, and dirt. The selection of the right brush can significantly impact maintenance practices and equipment longevity.

3 Common User Pain Points for ‘steel wire scratch hand brush’ & Their Solutions

Scenario 1: Limited Durability Leading to Frequent Replacements

The Problem: B2B buyers often struggle with the longevity of steel wire scratch hand brushes, especially in demanding industrial environments. These brushes can wear down quickly, leading to frequent replacements, increased operational costs, and interruptions in workflow. Buyers in sectors like automotive manufacturing or metal fabrication may find themselves continually purchasing new brushes, affecting their budgets and efficiency.

Illustrative image related to steel wire scratch hand brush

The Solution: To mitigate this issue, buyers should focus on sourcing high-quality steel wire scratch brushes that are specifically designed for durability. Look for brushes made from stainless steel, as they tend to resist wear better than carbon steel options. Additionally, investing in brushes with a robust handle design can enhance longevity. It’s crucial to review product specifications, such as bristle thickness and row configuration, to ensure optimal performance for specific applications. When using these brushes, ensure that the pressure applied during cleaning is consistent and appropriate for the task at hand to prolong the brush’s lifespan.

Scenario 2: Inadequate Brush Selection for Specific Applications

The Problem: Another common challenge for B2B buyers is selecting the right type of steel wire scratch brush for their specific applications. For example, a buyer may need a brush for delicate cleaning tasks in the aerospace industry, where damage to surfaces is a concern. Choosing a brush that is too aggressive can lead to surface scratches or damage, ultimately resulting in costly repairs or rework.

The Solution: Buyers can overcome this challenge by conducting a thorough analysis of their cleaning needs and the surfaces they are working on. It is essential to understand the material being cleaned and the type of debris to be removed. For sensitive applications, consider brushes with finer bristles or specialized materials like brass or nylon that provide a gentler touch. Creating a checklist of requirements—such as bristle material, stiffness, and handle type—can help streamline the selection process. Collaborating with manufacturers or suppliers to obtain samples and testing them in real-world scenarios can also provide valuable insights into the best fit for specific applications.

Scenario 3: Static Buildup Concerns in Sensitive Environments

The Problem: In industries such as electronics or pharmaceuticals, the buildup of static electricity can pose significant risks during cleaning processes. Steel wire brushes that do not have anti-static properties can lead to electrostatic discharge (ESD), potentially damaging sensitive components or compromising sterile environments. This can create a major headache for B2B buyers who need to ensure compliance with safety and operational standards.

The Solution: To address static buildup concerns, B2B buyers should prioritize sourcing ESD-safe steel wire scratch brushes. These brushes are specifically designed with conductive materials that help dissipate static electricity during use. When selecting brushes, verify that they meet relevant ESD standards and have been tested for effectiveness in static control. Additionally, implementing a static control program that includes using wrist straps or grounding mats while cleaning can further mitigate risks. Providing training for employees on the proper handling and use of ESD-safe tools will enhance compliance and operational safety across the organization.

Strategic Material Selection Guide for steel wire scratch hand brush

What Are the Key Materials Used in Steel Wire Scratch Hand Brushes?

When selecting materials for steel wire scratch hand brushes, it’s essential to consider the properties and performance characteristics that align with specific applications. Below is an analysis of four common materials used in these brushes, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its corrosion resistance, durability, and ability to withstand high temperatures. It typically has a tensile strength that allows it to maintain structural integrity under pressure.

Pros & Cons:

The primary advantage of stainless steel is its resistance to rust and corrosion, making it ideal for applications in humid or corrosive environments. However, it is generally more expensive than other materials, which may impact cost-sensitive projects. Manufacturing complexity is moderate due to the need for specialized equipment.

Impact on Application:

Stainless steel brushes are suitable for cleaning and surface preparation in industries like food processing, pharmaceuticals, and marine applications, where hygiene and corrosion resistance are critical.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and ISO for corrosion resistance. Countries like Germany may have specific regulations regarding food safety that necessitate the use of stainless steel brushes.

2. Carbon Steel

Key Properties:

Carbon steel is characterized by its high strength and hardness, making it effective for aggressive scrubbing and cleaning tasks. However, it is more susceptible to rust and corrosion compared to stainless steel.

Pros & Cons:

The main advantage of carbon steel is its cost-effectiveness, as it is generally less expensive than stainless steel. However, its susceptibility to corrosion limits its use in wet or corrosive environments, requiring additional maintenance or protective coatings.

Impact on Application:

Carbon steel brushes are often used in metalworking and automotive applications where aggressive cleaning is required, but they may not be suitable for environments where moisture is prevalent.

Considerations for International Buyers:

Buyers in regions with high humidity should consider the potential for rust and may need to invest in additional coatings or treatments. Compliance with local standards for material safety and performance is also essential.

3. Brass

Key Properties:

Brass is known for its moderate strength and good corrosion resistance, particularly in marine environments. It has a lower density than steel, which can be beneficial in lightweight applications.

Pros & Cons:

Brass brushes provide a softer scrubbing action, making them suitable for delicate surfaces. However, they are generally more expensive than carbon steel and may not be as durable under heavy use.

Impact on Application:

Brass brushes are ideal for cleaning non-ferrous metals and delicate surfaces, making them popular in the electronics and jewelry industries.

Considerations for International Buyers:

Buyers should verify compliance with environmental regulations regarding the use of brass, especially in Europe, where there may be restrictions on certain metals.

Illustrative image related to steel wire scratch hand brush

4. Synthetic Fill Materials

Key Properties:

Synthetic materials can be engineered for specific applications, offering properties like chemical resistance and flexibility. They are also non-corrosive and can be designed to withstand various temperatures.

Pros & Cons:

The primary advantage of synthetic brushes is their versatility and ability to be customized for specific applications. However, they may not provide the same level of scrubbing power as metal brushes and can be more expensive to produce.

Impact on Application:

Synthetic brushes are often used in applications involving sensitive surfaces or where chemical exposure is a concern, such as in the pharmaceutical or electronics industries.

Considerations for International Buyers:

Buyers should ensure that synthetic materials meet relevant safety and performance standards, particularly in industries with stringent regulations.

Illustrative image related to steel wire scratch hand brush

Summary Table of Material Selection for Steel Wire Scratch Hand Brushes

| Material | Typical Use Case for steel wire scratch hand brush | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost than other materials | High |

| Carbon Steel | Metalworking, automotive | Cost-effective for aggressive cleaning | Prone to rust, requires maintenance | Low |

| Brass | Electronics, jewelry | Softer scrubbing action for delicate surfaces | More expensive, less durable under heavy use | Medium |

| Synthetic Fill | Pharmaceuticals, electronics | Versatile and customizable for specific needs | May lack scrubbing power compared to metals | Medium to High |

This guide provides B2B buyers with a comprehensive overview of material options for steel wire scratch hand brushes, aiding in informed decision-making for various applications across different regions.

In-depth Look: Manufacturing Processes and Quality Assurance for steel wire scratch hand brush

What Are the Main Stages in the Manufacturing Process of Steel Wire Scratch Hand Brushes?

The manufacturing of steel wire scratch hand brushes involves several critical stages that ensure the final product meets the required standards for durability and performance. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is the careful selection and preparation of materials. For steel wire scratch brushes, manufacturers primarily use stainless steel or carbon steel. The wire is sourced from suppliers who adhere to international standards for quality and composition. Once the raw materials are procured, they undergo a series of tests to assess their tensile strength, corrosion resistance, and other mechanical properties. This step is crucial because the performance and longevity of the brushes are directly linked to the quality of the raw materials.

Forming Techniques

After material preparation, the next stage is forming. The steel wire is cut to specific lengths and then shaped into bristles. Common techniques include twisting and lacing the wire into the brush handle. This process can involve advanced machinery that ensures uniformity in the bristle arrangement, which is vital for achieving optimal cleaning performance. Manufacturers often employ automated systems for precision, but skilled labor is also essential to maintain high-quality standards during this phase.

Assembly of Components

The assembly stage involves attaching the bristles to the handle, which can be made from various materials like wood, aluminum, or plastic. The choice of handle material affects the overall ergonomics and usability of the brush. Once the bristles are secured, additional components, such as scrapers or protective coatings, may be added. The assembly process is designed to ensure that each brush is robust and capable of withstanding rigorous cleaning tasks.

Finishing Touches

The final stage of manufacturing is finishing, which may include surface treatments to enhance durability and aesthetics. This can involve processes like polishing, coating, or painting. Additionally, brushes may undergo a quality control inspection at this stage to identify any defects or inconsistencies. Manufacturers may also apply anti-corrosive coatings to extend the life of brushes, especially those intended for use in harsh environments.

How Is Quality Assurance Ensured During the Manufacturing of Steel Wire Scratch Brushes?

Quality assurance (QA) is a pivotal aspect of the manufacturing process, particularly for B2B buyers who demand reliability and performance in their products. Manufacturers typically adhere to several international and industry-specific standards to ensure that their products meet the necessary quality benchmarks.

What International Standards Are Relevant for Manufacturing Steel Wire Scratch Brushes?

One of the most recognized standards is ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has established a systematic approach to managing its processes and improving customer satisfaction. This certification is particularly valuable for international B2B buyers as it assures them of consistent quality across products.

In addition to ISO 9001, manufacturers may also comply with industry-specific standards such as CE marking for safety and environmental compliance or API standards for products used in the oil and gas sector. These certifications help to build trust and credibility among buyers in diverse markets, including Africa, South America, the Middle East, and Europe.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral to the manufacturing process, ensuring that each brush meets the established quality criteria. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection occurs as raw materials arrive at the manufacturing facility. Materials are tested for compliance with specifications before they are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, random sampling and inspections are conducted to monitor production quality and detect any deviations from the standard.

-

Final Quality Control (FQC): Once the brushes are assembled, a thorough inspection is carried out. This includes testing for bristle retention, handle integrity, and overall functionality.

What Common Testing Methods Are Used for Steel Wire Scratch Brushes?

Manufacturers employ various testing methods to ensure that steel wire scratch brushes meet performance standards. Common methods include:

-

Tensile Testing: This assesses the strength of the wire and its ability to withstand pulling forces without breaking.

-

Corrosion Resistance Testing: Brushes may be subjected to accelerated aging tests to evaluate how well they resist rust and deterioration over time.

-

Bristle Retention Tests: These tests measure how well the bristles stay in place under stress, which is critical for effective cleaning.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying a supplier’s quality control practices is essential to mitigate risks and ensure product reliability. Here are several strategies B2B buyers can adopt:

Conducting Supplier Audits

Buyers can conduct on-site audits to review the manufacturer’s processes, quality control measures, and compliance with international standards. This direct engagement allows buyers to gain insights into the operational practices and quality assurance protocols in place.

Requesting Quality Assurance Reports

Manufacturers should provide detailed quality assurance reports that outline their compliance with relevant standards, testing results, and any certifications obtained. These documents serve as evidence of the manufacturer’s commitment to quality.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process. Independent inspectors can verify compliance with industry standards and conduct random sampling of products for quality testing.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers from different regions must be aware of specific nuances related to quality control and certification. For instance, buyers in Europe may prioritize CE marking due to stringent safety regulations, while those in Africa may focus on local certifications that align with regional standards. Understanding these regional differences is crucial for successful procurement.

Illustrative image related to steel wire scratch hand brush

Additionally, international trade agreements and tariffs can influence the choice of suppliers. Buyers should consider manufacturers who are familiar with export regulations and can provide necessary documentation to facilitate smooth transactions.

In summary, the manufacturing processes and quality assurance practices for steel wire scratch hand brushes are complex yet vital for ensuring product performance and reliability. B2B buyers must take proactive steps to verify the quality of their suppliers to make informed purchasing decisions that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel wire scratch hand brush’

This guide aims to assist international B2B buyers in effectively sourcing steel wire scratch hand brushes. By following these steps, you can ensure that you procure high-quality brushes that meet your specific needs while establishing a reliable supplier relationship.

Step 1: Define Your Technical Specifications

Clearly defining your technical specifications is vital to ensure that the products meet your operational needs. Consider factors such as the type of wire (stainless steel vs. carbon steel), bristle diameter, handle material, and brush size. This clarity will help suppliers understand your requirements and provide appropriate options.

Illustrative image related to steel wire scratch hand brush

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing can provide insights into what to expect and help you budget accordingly. Analyze competitor pricing, product features, and material quality to gauge the market landscape. This knowledge can also strengthen your negotiation position with suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request company profiles, product catalogs, and references from buyers in similar industries or regions. Look for suppliers with a proven track record and positive reviews to ensure reliability and product quality.

Step 4: Verify Supplier Certifications

Certifications can be an indicator of quality and compliance with industry standards. Verify that potential suppliers have relevant certifications such as ISO 9001:2015 or others specific to your industry. This step is crucial, especially if your operations are subject to strict quality control or safety regulations.

Step 5: Request Samples

Always request samples before placing a bulk order. Testing samples allows you to evaluate the quality and performance of the brushes in real applications. Ensure that the samples align with your specifications and perform as expected under operational conditions.

Step 6: Negotiate Terms and Conditions

Effective negotiation can lead to more favorable terms and conditions, impacting your overall procurement costs. Discuss pricing, payment terms, delivery schedules, and return policies. Having clear agreements in place can prevent misunderstandings and ensure a smooth transaction.

Step 7: Establish a Communication Plan

Maintaining open lines of communication with your supplier is critical for addressing any concerns or changes. Establish regular check-ins and updates throughout the sourcing process. This proactive approach helps build a strong partnership and ensures that both parties are aligned on expectations.

By following this checklist, you can streamline your procurement process for steel wire scratch hand brushes, ensuring that you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for steel wire scratch hand brush Sourcing

What Are the Key Cost Components for Steel Wire Scratch Hand Brushes?

When sourcing steel wire scratch hand brushes, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The type of wire used (stainless steel versus carbon steel) significantly impacts cost. Stainless steel brushes tend to be more expensive due to their durability and resistance to corrosion. Additional materials, such as the handle (wood, plastic, or aluminum), also factor into the overall cost.

-

Labor: Labor costs can vary based on the manufacturing location and the complexity of the brush design. Regions with higher labor costs, like Western Europe, may see increased prices compared to manufacturers in Southeast Asia or Eastern Europe.

-

Manufacturing Overhead: This encompasses costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing practices can help lower these costs, which can be passed on to buyers.

-

Tooling: Custom designs or specific brush configurations may require specialized tooling, contributing to the overall expense. Investment in tooling is crucial for long-term production efficiency.

-

Quality Control (QC): Ensuring product consistency and meeting international standards (like ISO certifications) necessitates quality control measures, which add to the production costs.

-

Logistics: Shipping costs can fluctuate based on distance, volume, and chosen shipping methods. International buyers must consider import tariffs and customs duties as part of their logistics expenses.

-

Margin: Suppliers typically apply a profit margin, which can vary based on competition, demand, and market conditions.

How Do Price Influencers Affect Steel Wire Scratch Hand Brush Sourcing?

Several factors influence pricing, particularly in international B2B transactions:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often yield better pricing due to economies of scale. Negotiating MOQs can lead to significant savings.

-

Specifications and Customization: Customized brushes with specific dimensions or materials can cost more. Understanding the balance between customization and standard options can help buyers optimize costs.

-

Materials and Quality Certifications: Brushes made from higher-quality materials or those that meet specific certifications (like ESD compliance) will generally be priced higher. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can affect pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: The terms of shipping can significantly impact total costs. Understanding Incoterms (like FOB, CIF) will help buyers estimate their total landed costs accurately.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing?

To maximize value while sourcing steel wire scratch hand brushes, international buyers should consider the following strategies:

-

Negotiation: Always negotiate pricing, especially when dealing with larger orders. Suppliers may offer discounts for bulk purchases or longer-term contracts.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the longevity and performance of the brushes. A slightly higher upfront cost may lead to lower replacement rates and overall savings.

-

Pricing Nuances for International Buyers: Buyers in Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and import regulations that may affect costs. Engaging local suppliers or distributors can mitigate some of these challenges.

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and gather quotes from multiple suppliers. This can provide leverage in negotiations and ensure competitive pricing.

Conclusion

Sourcing steel wire scratch hand brushes involves a comprehensive understanding of cost components, pricing influencers, and effective buying strategies. By being informed, B2B buyers can make better purchasing decisions that align with their operational needs and budget constraints. Always remember that prices can vary widely; thus, it is essential to gather multiple quotes and consider the total cost of ownership when making sourcing decisions.

Illustrative image related to steel wire scratch hand brush

Alternatives Analysis: Comparing steel wire scratch hand brush With Other Solutions

Introduction to Alternative Solutions for Surface Cleaning

When evaluating the best tools for surface preparation and cleaning, B2B buyers must consider various alternatives to the traditional steel wire scratch hand brush. While these brushes are effective for heavy-duty cleaning and surface conditioning, there are other solutions that may better suit specific applications or operational needs. This analysis compares the steel wire scratch hand brush with two viable alternatives: abrasive pads and pneumatic wire brushes. Each option has unique benefits and drawbacks that can influence purchasing decisions.

Comparison Table

| Comparison Aspect | Steel Wire Scratch Hand Brush | Abrasive Pads | Pneumatic Wire Brushes |

|---|---|---|---|

| Performance | Excellent for aggressive scrubbing and cleaning tight spaces | Good for surface preparation, but less aggressive | High-speed cleaning, suitable for large areas |

| Cost | Moderate initial cost | Low to moderate cost | Higher initial investment |

| Ease of Implementation | Simple manual operation | Easy to use, requires no special training | Requires air compressor and training |

| Maintenance | Low maintenance, replace as needed | Disposable, minimal maintenance | Regular maintenance needed for compressor and tools |

| Best Use Case | Tight spaces and heavy debris | General cleaning and surface prep | Large-scale industrial cleaning |

Detailed Breakdown of Alternatives

Abrasive Pads

Abrasive pads are versatile tools made from materials like nylon or polyester, often infused with abrasive particles. They are effective for various cleaning tasks, including surface preparation and finishing. Their low cost and ease of use make them ideal for light to moderate applications, especially in environments where aggressive scrubbing is not required. However, abrasive pads may not perform well on heavily soiled surfaces or in tight spaces, where steel wire brushes excel.

Pneumatic Wire Brushes

Pneumatic wire brushes utilize compressed air to drive a rotating brush, delivering high-speed cleaning for large surface areas. This method is particularly advantageous in industrial settings where efficiency is paramount. Pneumatic brushes reduce the physical strain on workers and can significantly speed up cleaning processes. However, they require a higher initial investment for equipment and ongoing maintenance for air compressors. Additionally, they may not be suitable for delicate surfaces due to the aggressive nature of their operation.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate cleaning solution, B2B buyers should carefully assess their specific needs, including the type of surface being cleaned, the level of grime, and the operational scale. Steel wire scratch hand brushes are optimal for heavy-duty applications in tight spaces, while abrasive pads offer a cost-effective and user-friendly option for general cleaning tasks. Pneumatic wire brushes provide the speed and efficiency needed for large-scale operations but require a more significant investment and maintenance. By weighing these factors, buyers can make informed decisions that align with their operational requirements and budget constraints.

Illustrative image related to steel wire scratch hand brush

Essential Technical Properties and Trade Terminology for steel wire scratch hand brush

What Are the Key Technical Properties of Steel Wire Scratch Hand Brushes?

When selecting steel wire scratch hand brushes for industrial applications, understanding the essential technical properties is crucial. Here are some key specifications that buyers should consider:

-

Material Composition

The material used for the bristles significantly affects the brush’s performance. Common materials include stainless steel and carbon steel. Stainless steel brushes are more resistant to corrosion and are ideal for applications involving moisture, while carbon steel brushes are often used for heavy-duty cleaning and rust removal. Choosing the right material based on the application ensures durability and effectiveness. -

Bristle Diameter

Bristle diameter typically ranges from 0.006 inches to 0.012 inches. A smaller diameter is suitable for delicate tasks requiring precision, while a larger diameter is better for heavy-duty applications that involve aggressive scrubbing. Understanding bristle diameter helps in selecting the right brush for specific cleaning needs. -

Handle Material and Design

Handles are often made from materials like aluminum or wood, each offering different benefits. Aluminum handles are lightweight and resistant to rust, while wooden handles provide a traditional grip and comfort during extended use. The design, whether straight or curved, can influence ease of use in various applications, particularly in hard-to-reach areas. -

Brush Configuration (Row and Trim)

Brush configuration refers to the arrangement of bristles, typically noted as rows (e.g., 1 x 11) and trim height (e.g., 7/16 inches). A higher row count can provide denser bristle coverage, making it more effective for scrubbing and cleaning larger surfaces. Understanding these configurations allows buyers to choose brushes that align with their operational requirements. -

Conductivity for ESD Applications

For applications sensitive to static electricity, brushes can be designed to be conductive. These brushes help remove static buildup, protecting electronic components and sensitive materials. Buyers in the electronics and aerospace industries should consider conductivity as a critical property to ensure compliance with ESD standards. -

Cleaning and Maintenance Recommendations

Each type of brush may have specific cleaning and maintenance requirements to prolong its lifespan. For instance, brushes with stainless steel bristles may require different care than those with carbon steel. Understanding these recommendations can help buyers maintain their equipment effectively.

What Common Trade Terms Should B2B Buyers Know?

Familiarizing oneself with industry terminology is vital for effective communication and negotiation. Here are some common trade terms relevant to steel wire scratch hand brushes:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure they are sourcing high-quality products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, particularly for businesses that require large quantities of brushes for ongoing projects. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to obtain price quotes for specific products. It’s a critical step in the procurement process, allowing buyers to compare prices and negotiate terms effectively. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of sellers and buyers in international transactions. Understanding Incoterms helps buyers manage shipping costs and responsibilities, ensuring clarity in logistics. -

Lead Time

This term describes the time it takes from placing an order to receiving the product. Knowing the lead time is essential for project planning and ensuring that supplies are available when needed. -

Certification Standards

Certifications like ISO 9001 indicate that a manufacturer adheres to quality management principles. Buyers should look for these certifications to ensure that they are partnering with reputable suppliers who prioritize quality and reliability in their products.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing steel wire scratch hand brushes, ultimately enhancing operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the steel wire scratch hand brush Sector

What Are the Current Market Dynamics and Key Trends in the Steel Wire Scratch Hand Brush Sector?

The global steel wire scratch hand brush market is experiencing notable growth driven by increased demand across various industries, including automotive, aerospace, and construction. The rise in manufacturing activities, particularly in developing regions such as Africa and South America, is propelling the need for efficient surface cleaning and preparation tools. Furthermore, the surge in infrastructure projects in the Middle East and Europe has heightened the demand for robust cleaning solutions, with steel wire brushes being essential for removing rust, paint, and debris.

Illustrative image related to steel wire scratch hand brush

Emerging technologies are reshaping sourcing strategies in this sector. The integration of digital platforms for procurement is streamlining the buying process, allowing international B2B buyers to access a broader range of products and suppliers. Additionally, the use of data analytics is enabling companies to make informed decisions regarding inventory management and supplier selection, enhancing operational efficiency.

Sustainability is another critical trend influencing market dynamics. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to eco-friendly practices, including the use of recyclable materials and energy-efficient manufacturing processes. This shift is particularly evident in regions like Europe, where regulations around environmental impact are stringent. Overall, the market is becoming more competitive, with suppliers needing to adapt to these evolving preferences and technological advancements to meet the demands of international buyers.

How Is Sustainability and Ethical Sourcing Shaping the Steel Wire Scratch Hand Brush Market?

Sustainability and ethical sourcing are integral to the steel wire scratch hand brush market, reflecting a growing awareness of environmental impact among B2B buyers. The production of these brushes often involves the use of materials that can have significant ecological consequences if not managed responsibly. For instance, sourcing steel from suppliers that adhere to sustainable practices ensures that the environmental footprint is minimized, aligning with global efforts to combat climate change.

The importance of ethical supply chains cannot be overstated. B2B buyers are increasingly scrutinizing their suppliers’ sourcing practices, looking for transparency and adherence to labor standards. Certifications such as ISO 14001 for environmental management systems and ISO 9001 for quality management are becoming crucial benchmarks for evaluating potential suppliers. Furthermore, buyers are gravitating toward companies that use ‘green’ materials, such as recycled metals or sustainably sourced wood for handles, which not only reduce waste but also appeal to environmentally conscious consumers.

Incorporating sustainability into procurement strategies not only fulfills corporate social responsibility goals but also enhances brand reputation. As markets in Africa, South America, the Middle East, and Europe evolve, the emphasis on sustainable practices will likely influence purchasing decisions, making it essential for suppliers to embrace ethical sourcing initiatives.

What Is the Historical Context of the Steel Wire Scratch Hand Brush Sector?

The steel wire scratch hand brush has a rich history rooted in industrial cleaning and maintenance. Initially developed for heavy-duty applications in workshops and manufacturing plants, these brushes have evolved significantly over the decades. The introduction of stainless steel wires improved durability and effectiveness, making them suitable for a broader range of applications, including delicate tasks in electronics and aerospace.

As industries expanded, so did the variety of brushes available, with innovations in handle materials and brush configurations to meet specific cleaning needs. Today, these brushes are not just tools; they represent a vital component in the production and maintenance processes across various sectors. The ongoing evolution reflects not only advancements in materials and technology but also changing buyer preferences towards efficiency and sustainability in industrial cleaning solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of steel wire scratch hand brush

-

How do I choose the right steel wire scratch hand brush for my application?

Selecting the appropriate steel wire scratch brush depends on the specific application and material being cleaned or finished. Consider the wire diameter, bristle material (stainless steel vs. carbon steel), and handle type (wood, plastic, or aluminum). For heavy-duty applications requiring aggressive cleaning, a brush with a thicker wire diameter and a sturdy handle is ideal. Additionally, evaluate whether you need a conductive brush for static-sensitive environments, especially in electronics or aerospace industries. -

What factors should I consider when sourcing steel wire scratch hand brushes internationally?

When sourcing steel wire scratch brushes from international suppliers, prioritize quality, compliance with industry standards, and supplier reliability. Check for certifications such as ISO 9001 to ensure consistent product quality. Additionally, assess the supplier’s experience in your industry, customer reviews, and their ability to meet your specific requirements. Understanding local regulations and tariffs in your region is also essential to avoid unexpected costs. -

What are the minimum order quantities (MOQ) for steel wire scratch brushes?

Minimum order quantities for steel wire scratch brushes can vary significantly depending on the manufacturer and your specific requirements. Typically, MOQs range from 100 to 500 units for standard products, while custom orders may have higher MOQs. It’s advisable to communicate your needs directly with suppliers to negotiate terms that suit your purchasing strategy, especially if you’re testing a new product line. -

How can I customize my steel wire scratch brushes?

Customization options for steel wire scratch brushes often include variations in wire material, diameter, handle type, and overall brush size. Many manufacturers offer bespoke solutions tailored to specific applications or branding requirements. To initiate the customization process, provide detailed specifications and drawings to the supplier. Always request samples before finalizing large orders to ensure the product meets your expectations. -

What payment terms are typically offered by suppliers of steel wire scratch brushes?

Payment terms can vary widely among suppliers, but common options include upfront payment, a 30% deposit with the balance upon delivery, or net 30/60 terms after receipt of goods. When negotiating payment terms, consider your financial capabilities and the supplier’s policies. Establishing a good relationship with suppliers may also open up more favorable payment options over time. -

How do I ensure quality assurance for the steel wire scratch brushes I order?

To ensure quality assurance, request product samples and review specifications before placing a bulk order. Ask suppliers about their quality control processes, including testing for durability and compliance with relevant standards. Additionally, consider third-party inspections for large orders, especially if sourcing from a new supplier. Maintaining open communication with the supplier during production can also help address any quality concerns promptly. -

What logistics considerations should I keep in mind when importing steel wire scratch brushes?

Logistics considerations include shipping methods, lead times, and customs clearance processes. Choose a shipping method that balances cost and delivery speed—air freight is faster but more expensive, while sea freight is economical for larger shipments. Ensure you understand the import regulations and duties applicable in your country to avoid delays. Partnering with a reliable freight forwarder can streamline the logistics process and help navigate complex customs requirements. -

What are the common applications for steel wire scratch hand brushes in various industries?

Steel wire scratch brushes are widely used across various industries, including automotive, aerospace, manufacturing, and construction. They are effective for removing rust, paint, and debris from metal surfaces, as well as for preparing surfaces for welding or coating. In the food processing industry, these brushes are utilized for equipment cleaning to ensure hygiene standards. Understanding the specific applications in your industry can help you select the right brush type for optimal performance.

Top 9 Steel Wire Scratch Hand Brush Manufacturers & Suppliers List

1. Weiler – Small Hand Wire Scratch Brush

Domain: weilerabrasives.com

Registered: 1999 (26 years)

Introduction: This company, Weiler – Small Hand Wire Scratch Brush, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

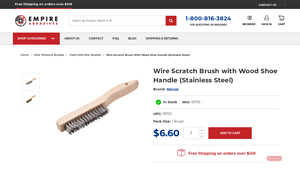

2. Mercer – Wire Scratch Brush with Wood Shoe Handle

Domain: empireabrasives.com

Registered: 2014 (11 years)

Introduction: {“Product Name”: “Wire Scratch Brush with Wood Shoe Handle (Stainless Steel)”, “Brand”: “Mercer”, “SKU”: “191110”, “UPC”: “191110”, “Pack Size”: “1 Brush”, “Material”: “Stainless Steel”, “Tool Type”: “Hand Tool”, “MSRP”: “$6.60”, “Length”: “10-1/4 inches”, “Bristle Dimensions”: “5 Columns x 16 Rows”, “Features”: [“Containment Free”, “Corrosion Resistant Stainless Steel Wire Bristles”, “Extra Thick…

3. Benchmark Abrasives – Wire Scratch Brush with Curved Handle

Domain: benchmarkabrasives.com

Registered: 2009 (16 years)

Introduction: {“Product Name”: “Wire Scratch Brush with Curved Handle – Carbon Steel”, “SKU”: “14CURVE-C_1”, “Rating”: “4.8 / 5.0”, “Price”: “$4.19”, “Quantity”: “1 piece”, “Dimensions”: {“Length”: “13-3/4 inches”, “Wire Gauge”: “0.012 inches”}, “Bristle Configuration”: “3 x 19”, “Wire Style”: “straight”, “Type”: “Scratch brush (Shoe Handle)”, “Material”: “Carbon Steel”, “Applications”: {“Ferrous Materials”: [“…

4. JAZ USA, Inc – Hand Wire Scratch Brush

Domain: sparkyabrasives.com

Registered: 2006 (19 years)

Introduction: {“Product Name”: “Hand Wire Scratch Brush, Stainless Steel w/Plastic Handle”, “Brand”: “JAZ USA, Inc”, “SKU”: “WB85130”, “Price”: “$205.58”, “Quantity per Box”: “24”, “Face Width”: “5/8 inch”, “Wire Size”: “.012 inch”, “Trim Length”: “1-1/8 inch”, “Crimped Wire Usable Length”: “5 inch”, “Total Length”: “10 inch”, “Made in”: “USA”, “Unit Price”: “$8.57/ea”, “Applications”: “General maintenance appl…

5. Gornell Brush – Steel Wire Hand Scratch Brushes

Domain: gornellbrush.com

Registered: 1999 (26 years)

Introduction: Steel Wire Hand Scratch Brushes – Various types including Curved Handle, Shoe Handle, Straight Back, Scraper, V-Groove Curved Handle, Rocker Back, and Duster Wire. Item numbers for Curved Handle: 192, 192-SS, 193, 193-SC, 193-SS, 193-B, E193, E193-SS, F193, F193-SS, 194, 194-SC, 194-SS, 194-BZ, 194-B, E194, E194-SS. Item numbers for Shoe Handle: 161, 161-SS, 161-SS 3/4, 162, 162-SS, 164, 164-SC, 1…

6. Anchor Brand – Utility Brush

Domain: awisco.com

Registered: 1998 (27 years)

Introduction: [{‘name’: ‘Anchor Brand Utility Brush’, ‘size’: ‘3×7 Rows’, ‘bristles’: ‘Stainless Steel’, ‘handle’: ‘Wood Block/Handle, Hand Tied’, ‘item_code’: ‘ORS102-15SS’, ‘locations’: ’11 Locations’, ‘price’: ‘$3.10 / EA’}, {‘name’: ‘Anchor Brand Hand Scratch Brush’, ‘size’: ‘4 X 16 Rows’, ‘bristles’: ‘Carbon Steel’, ‘handle’: ‘Shoe Wood Handle’, ‘item_code’: ‘ORS102-387’, ‘locations’: ’11 Locations’, ‘pric…

7. JAZ USA – Hand Stainless Steel Wire Scratch Brush

Domain: jag10tools.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “JAZ USA Hand Stainless Steel Wire Scratch Brush”, “sku”: “85130”, “price”: “$8.57”, “handle_material”: “Plastic”, “brush_face_diameter”: “5/8 inch”, “wire_diameter”: “.012 inch”, “corrosion_resistance”: “Highly corrosion-resistant”, “heat_tolerance”: “Higher heat tolerance than steel”, “trim_length”: “1-1/8 inch”, “brush_length”: “5 inch”, “overall_length”: “10 inch”, “applicatio…

8. Orsnasco – Small Hand Scratch Brushes

Domain: orsnasco.com

Registered: 2002 (23 years)

Introduction: This company, Orsnasco – Small Hand Scratch Brushes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

9. Inlineco – West Coast Brush 319-CS

Domain: inlineco.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “West Coast Brush 319-CS Carbon Steel Wire Scratch Hand Brush with Wood Handle”, “packaging”: “12/Box”, “SKU”: “280019”, “dimensions”: {“height”: “4 in”, “width”: “0.33333 in”, “length”: “20.5 in”}, “features”: [“General-duty use”, “Recommended for removing paint, rust, scale, solder chips, and dirt”, “Excellent for cleaning files, threads, castings, and metal parts”], “brush_spec…

Strategic Sourcing Conclusion and Outlook for steel wire scratch hand brush

In the rapidly evolving landscape of industrial tools, strategic sourcing of steel wire scratch hand brushes is essential for businesses aiming to enhance operational efficiency and product quality. By leveraging partnerships with reputable manufacturers, international B2B buyers can secure high-quality products that meet specific cleaning and finishing needs, while also benefiting from competitive pricing and reliable supply chains.

Illustrative image related to steel wire scratch hand brush

Investing in durable and effective scratch brushes can significantly improve productivity in various sectors, including automotive, aerospace, and facility management. Moreover, understanding the diverse range of materials and configurations available—such as stainless steel and aluminum handles—allows buyers to select the right tools for their unique applications.

As markets in Africa, South America, the Middle East, and Europe continue to grow, the demand for effective surface conditioning solutions will rise. Now is the time for buyers to engage with trusted suppliers to explore innovative products and solutions that can drive success in their operations. Embrace the opportunity to enhance your sourcing strategy today and position your business for a prosperous future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.