Steel Mezzanine Floor: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for steel mezzanine floor

In today’s competitive landscape, sourcing a reliable steel mezzanine floor solution is critical for businesses looking to optimize their warehouse and operational efficiency. As companies expand globally, particularly in dynamic markets across Africa, South America, the Middle East, and Europe, the challenge of finding the right mezzanine system can become overwhelming. This comprehensive guide serves as an essential resource for international B2B buyers, addressing key factors such as types of steel mezzanine systems, their diverse applications, and best practices for supplier vetting.

We delve into the intricacies of customization options, load capacities, and modular designs, ensuring you understand how to align your business needs with the right mezzanine solution. Additionally, we provide insights into cost considerations and logistics that will help you make informed purchasing decisions. By equipping you with actionable knowledge, this guide empowers you to navigate the complexities of the global market effectively. Whether you are based in Nigeria, Vietnam, or any other country, the information within these pages will enhance your understanding and confidence in selecting the optimal steel mezzanine floor for your operations, ultimately leading to improved productivity and growth.

Understanding steel mezzanine floor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Structural Steel Mezzanine | High load capacity, customizable design, independent frame | Warehousing, manufacturing | Pros: Durable, flexible, high load-bearing. Cons: Higher upfront cost. |

| Modular Mezzanine | Pre-manufactured components, quick assembly | Retail, logistics | Pros: Fast installation, easy expansion. Cons: Less customization than structural. |

| Heavy-Duty Mezzanine | Reinforced for extreme loads, robust materials | Industrial manufacturing, automotive | Pros: Suitable for heavy machinery, reliable. Cons: Requires significant space and planning. |

| Mezzanine with Office Space | Integrated office areas, enhanced functionality | Corporate settings, distribution | Pros: Maximizes space utility, improves workflow. Cons: Higher design complexity. |

| Open Deck Mezzanine | Grated flooring for visibility and ventilation | Warehousing, assembly areas | Pros: Lightweight, allows for airflow. Cons: Limited load capacity compared to solid flooring. |

What Are the Key Characteristics of Structural Steel Mezzanines?

Structural steel mezzanines are characterized by their high load capacity and customizable design, making them suitable for various industrial applications. They consist of a robust steel frame that provides independent support, allowing for flexibility in size and layout. These mezzanines are ideal for warehousing and manufacturing sectors where heavy equipment and storage are prevalent. Buyers should consider the upfront investment, as these systems may require a higher initial cost but offer long-term durability and adaptability.

How Does a Modular Mezzanine Differ from Traditional Options?

Modular mezzanines utilize pre-manufactured components that allow for rapid installation and easy reconfiguration. This type is particularly advantageous for businesses with fluctuating space requirements, such as retail and logistics operations. While they offer quick assembly and the potential for expansion, buyers should note that modular options may provide less customization compared to structural alternatives. This trade-off can impact the overall design and functionality of the space.

Why Choose a Heavy-Duty Mezzanine for Industrial Applications?

Heavy-duty mezzanines are engineered to support extreme loads, making them essential in industries that handle substantial machinery or materials, such as automotive and industrial manufacturing. The robust materials used in their construction ensure reliability and longevity under rigorous conditions. Buyers must consider the space requirements and structural planning necessary for these systems, as their installation can be more complex than standard mezzanines.

What Advantages Do Mezzanines with Office Space Offer?

Integrating office space into mezzanine designs enhances functionality and workflow in corporate settings and distribution centers. These mezzanines maximize vertical space utilization, allowing businesses to efficiently manage operations without expanding their footprint. However, the increased design complexity can lead to higher costs and longer installation times, so it is crucial for buyers to evaluate their specific needs and budget constraints.

When Should You Consider Open Deck Mezzanines?

Open deck mezzanines feature grated flooring that promotes visibility and ventilation, making them suitable for assembly areas and warehousing. They are lightweight and easy to install but may not support heavy loads as effectively as solid flooring options. Buyers should assess their operational requirements, including airflow needs and load capacities, when considering open deck designs to ensure they meet safety and functionality standards.

Key Industrial Applications of steel mezzanine floor

| Industry/Sector | Specific Application of steel mezzanine floor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Warehousing | Additional storage space for inventory management | Maximizes vertical space, improving storage capacity | Load capacity, modular design, and compliance with safety standards |

| Manufacturing | Elevated work platforms for assembly lines | Enhances workflow efficiency and organization | Customization options, access solutions, and durability of materials |

| Retail | Creating office spaces or display areas above sales floors | Optimizes floor space utilization and enhances customer experience | Aesthetic appeal, ease of installation, and flexibility for future changes |

| Logistics | Sorting and packing areas for distribution centers | Streamlines operations and improves logistics efficiency | Accessibility, integration with existing systems, and load specifications |

| Automotive | Storage solutions for parts and equipment | Increases operational efficiency and reduces clutter | Heavy load capacity, safety features, and adaptability to changing needs |

How are Steel Mezzanine Floors Used in Warehousing?

In warehousing, steel mezzanine floors serve as an efficient solution for maximizing vertical space. By creating additional levels for inventory storage, businesses can increase their storage capacity without expanding their physical footprint. This is particularly beneficial for international B2B buyers in regions like Africa or South America, where space may be limited or costly. Buyers should focus on load capacity and modular design to ensure the mezzanine can accommodate varying inventory sizes and weights while adhering to local safety regulations.

What Role Do Steel Mezzanine Floors Play in Manufacturing?

In manufacturing environments, steel mezzanine floors are often used to create elevated work platforms for assembly lines. This setup enhances workflow efficiency by allowing for better organization of tools and materials. For buyers in the Middle East or Europe, it is essential to consider customization options that meet specific operational needs, including access solutions like staircases or lifts. Durability is also a key factor, as these platforms must withstand heavy machinery and constant use.

Illustrative image related to steel mezzanine floor

How Can Retailers Benefit from Steel Mezzanine Floors?

Retailers utilize steel mezzanine floors to create additional office spaces or display areas above sales floors, optimizing the use of valuable ground space. This not only increases the store’s functionality but also enhances the customer experience by providing a more organized shopping environment. For B2B buyers in regions like Nigeria or Vietnam, sourcing mezzanines that offer aesthetic appeal and ease of installation can significantly impact the overall store design and customer engagement.

Why are Steel Mezzanine Floors Important in Logistics?

In logistics, steel mezzanine floors are essential for creating sorting and packing areas within distribution centers. They help streamline operations by providing dedicated spaces for different logistics processes, thus improving efficiency and workflow. Buyers should prioritize accessibility and integration with existing systems when sourcing these mezzanines, ensuring they can accommodate various operational demands and comply with safety standards.

How Do Steel Mezzanine Floors Enhance Automotive Operations?

In the automotive industry, steel mezzanine floors provide critical storage solutions for parts and equipment, helping to reduce clutter and improve operational efficiency. This is particularly vital for businesses looking to optimize their workspace while managing a large inventory of components. Buyers should consider heavy load capacities and safety features when sourcing mezzanines, as these factors are crucial for maintaining a safe and efficient working environment.

Illustrative image related to steel mezzanine floor

3 Common User Pain Points for ‘steel mezzanine floor’ & Their Solutions

Scenario 1: Navigating Customization Challenges for Steel Mezzanine Floors

The Problem:

B2B buyers often face significant challenges when it comes to customizing steel mezzanine floors to meet specific operational needs. Many businesses require unique configurations to optimize space, accommodate heavy machinery, or integrate office environments within their warehouses. This need for customization can lead to frustration, as standard products may not suffice, and miscommunication with suppliers about load capacities or design specifications can result in costly delays or unsafe installations.

The Solution:

To effectively navigate these customization challenges, buyers should engage with manufacturers who prioritize bespoke solutions. Begin by conducting a thorough needs assessment of your facility. Document the specific dimensions, load requirements, and intended use of the mezzanine. Open communication with suppliers is crucial; provide them with detailed information and ask for consultations that involve site visits if possible. This collaboration will help ensure that the design aligns with your operational goals. Additionally, consider suppliers who offer modular designs that can be easily adapted or expanded over time, allowing for future modifications without major overhauls.

Scenario 2: Ensuring Compliance with Safety Standards

The Problem:

Another common pain point for B2B buyers is ensuring that their steel mezzanine floors comply with local safety regulations and building codes. Non-compliance can lead to serious liabilities, including fines or, worse, accidents that jeopardize employee safety. Many buyers, especially those new to mezzanine installations, may not be fully aware of the various codes that apply, which can lead to oversight and significant financial repercussions.

Illustrative image related to steel mezzanine floor

The Solution:

To mitigate compliance risks, buyers should proactively educate themselves on the relevant local and international safety standards that pertain to mezzanine installations. This includes understanding load limits, guardrail requirements, and stairway specifications. Collaborating with a knowledgeable supplier is essential; choose manufacturers who provide detailed documentation on compliance and can assist in navigating local regulations. Some manufacturers offer pre-approval services, where they ensure that the proposed mezzanine design meets all necessary codes before installation. Furthermore, consider engaging third-party safety inspectors to review the mezzanine setup post-installation, ensuring all safety standards are met.

Scenario 3: Managing Installation and Downtime Concerns

The Problem:

Installation of a steel mezzanine floor often requires considerable downtime, which can disrupt business operations and affect productivity. B2B buyers may struggle with balancing the need for additional storage or operational space with the potential impact on their workflow. The fear of prolonged installation periods can deter companies from pursuing necessary upgrades, leading to inefficiencies and lost revenue.

The Solution:

To effectively manage installation and minimize downtime, buyers should opt for suppliers who specialize in modular mezzanine systems that allow for rapid assembly. These systems are designed with standardized components, facilitating quicker on-site installation and often requiring fewer labor resources. Buyers should also plan the installation during off-peak hours or scheduled downtimes to further mitigate disruptions. Prior to installation, ensure that all components are delivered on-site and ready to go, which can streamline the process. Communication with the installation team is critical; establish clear timelines and milestones to monitor progress and make adjustments as necessary. By taking these proactive steps, businesses can enhance operational efficiency while seamlessly integrating new mezzanine solutions into their existing infrastructure.

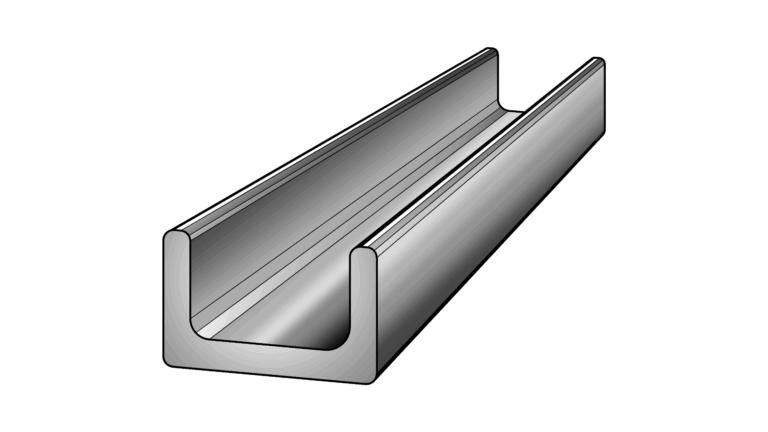

Strategic Material Selection Guide for steel mezzanine floor

What Are the Key Materials for Steel Mezzanine Floors?

When selecting materials for steel mezzanine floors, several options stand out based on their performance characteristics, suitability for specific applications, and compliance with international standards. Below, we analyze four common materials used in the construction of steel mezzanine floors: galvanized steel, carbon steel, stainless steel, and composite decking.

Illustrative image related to steel mezzanine floor

How Does Galvanized Steel Perform in Mezzanine Applications?

Key Properties: Galvanized steel is coated with a layer of zinc to enhance its corrosion resistance, making it suitable for environments with high humidity or exposure to chemicals. It typically withstands temperatures up to 200°C and offers good structural integrity under pressure.

Pros & Cons: One of the primary advantages of galvanized steel is its durability and long lifespan, often exceeding 30 years with minimal maintenance. However, it can be more expensive than standard carbon steel due to the galvanization process. Additionally, while it is resistant to rust, it may not be suitable for highly corrosive environments without additional protective coatings.

Impact on Application: Galvanized steel is ideal for industrial settings where moisture and chemical exposure are prevalent, such as food processing and pharmaceutical industries.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM A123 for hot-dip galvanizing. Understanding the specific environmental conditions can help in selecting the right grade of galvanized steel.

What Are the Advantages of Carbon Steel for Mezzanine Floors?

Key Properties: Carbon steel is known for its high tensile strength and affordability. It is generally suitable for applications requiring structural integrity but may require additional treatments for corrosion resistance.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-conscious projects. However, it is prone to rusting if not properly treated, which can lead to increased maintenance costs over time. Its manufacturing complexity is moderate, as it can be easily fabricated into various shapes.

Impact on Application: Carbon steel is often used in warehouses and distribution centers where load-bearing capacity is crucial but environmental conditions are not excessively corrosive.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings in humid climates. Compliance with standards like ASTM A36 for structural steel is essential for ensuring quality and safety.

How Does Stainless Steel Compare for Steel Mezzanine Floors?

Key Properties: Stainless steel offers excellent corrosion resistance due to its chromium content, making it suitable for harsh environments. It can withstand high temperatures and is also non-reactive, which is beneficial in food and pharmaceutical applications.

Pros & Cons: The key advantage of stainless steel is its longevity and minimal maintenance requirements, as it does not rust or corrode easily. However, it is significantly more expensive than both carbon and galvanized steel, which can be a deterrent for some projects. The complexity of manufacturing stainless steel components can also lead to longer lead times.

Impact on Application: Stainless steel is particularly advantageous in applications where hygiene is critical, such as in food processing, healthcare, and cleanroom environments.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM A240 for stainless steel. In regions with stringent health regulations, such as Europe, stainless steel may be the preferred choice.

What Role Does Composite Decking Play in Mezzanine Floors?

Key Properties: Composite decking combines materials such as wood fibers and plastic, offering a lightweight yet strong alternative to traditional steel decking. It is resistant to moisture and UV rays, making it suitable for outdoor applications.

Illustrative image related to steel mezzanine floor

Pros & Cons: The main advantage of composite decking is its resistance to rot and decay, making it ideal for environments with fluctuating temperatures. However, it may not support as heavy a load as steel options, which can limit its use in certain industrial applications. The manufacturing process can also be more complex and costly.

Impact on Application: Composite decking is often used in retail and commercial spaces where aesthetic appeal and comfort are important, such as in showrooms or offices.

Considerations for International Buyers: Buyers should check for compliance with local building codes and standards, as well as the material’s load-bearing capabilities.

Summary Table of Material Selection for Steel Mezzanine Floors

| Material | Typical Use Case for Steel Mezzanine Floor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Food processing, pharmaceutical industries | Excellent corrosion resistance | Higher cost compared to carbon steel | High |

| Carbon Steel | Warehouses, distribution centers | Cost-effective and strong | Prone to rust without treatment | Low |

| Stainless Steel | Healthcare, cleanrooms | Long-lasting and low maintenance | High cost and longer lead times | High |

| Composite Decking | Retail spaces, commercial environments | Resistant to moisture and UV rays | Limited load capacity compared to steel | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions based on specific application needs and regional considerations.

Illustrative image related to steel mezzanine floor

In-depth Look: Manufacturing Processes and Quality Assurance for steel mezzanine floor

What Are the Main Stages in the Manufacturing Process of Steel Mezzanine Floors?

The manufacturing process of steel mezzanine floors involves several critical stages, each designed to ensure structural integrity, safety, and compliance with international standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Steel Mezzanine Floors?

Material preparation is the first step in the manufacturing process. High-quality steel is sourced, often conforming to specifications such as ASTM A36 or S235, which determine the steel’s mechanical properties. The raw steel is cut into appropriate dimensions using advanced cutting techniques like plasma or laser cutting. This precision ensures that the components fit together seamlessly during assembly.

Moreover, the steel may undergo surface treatment to remove impurities and enhance corrosion resistance, essential for environments with high humidity or exposure to chemicals. The preparation stage sets the foundation for subsequent manufacturing processes, ensuring that all materials meet the required quality standards.

What Forming Techniques Are Used in Steel Mezzanine Production?

Once the materials are prepared, they proceed to the forming stage. This involves shaping the steel into beams, columns, and decking panels using techniques such as bending, rolling, and welding.

Illustrative image related to steel mezzanine floor

- Bending and Rolling: Steel sheets are shaped into the desired profiles using hydraulic or mechanical presses. This process is critical for creating structural components that can bear significant loads.

- Welding: Various components are joined together using welding techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding. This creates strong, permanent joints essential for structural integrity.

Precision in forming ensures that all components meet the required load capacities and dimensional tolerances, which is crucial for the safety and functionality of the mezzanine.

How Does the Assembly Process Work for Steel Mezzanines?

The assembly stage involves the construction of the mezzanine structure itself. This is where the prepared and formed components are brought together. Skilled workers or automated systems will erect the steel framework, ensuring that columns, beams, and decking are installed correctly.

- Installation of Support Columns: Vertical steel columns are anchored to the ground or building foundation, providing essential load-bearing support.

- Connecting Beams and Joists: Main beams are attached to the columns, followed by secondary joists, which distribute the load evenly across the structure.

- Decking Installation: The final surface, made from materials such as steel grating or plywood, is laid over the joists. This choice of decking material will depend on the intended load and usage of the mezzanine.

During assembly, it is vital to adhere to architectural and engineering plans to ensure compliance with safety standards.

What Finishing Processes Are Applied to Steel Mezzanine Floors?

After assembly, the finishing stage includes applying protective coatings and conducting final inspections. Finishing processes may involve:

- Surface Coating: Steel surfaces are often coated with paint or galvanized finishes to prevent rust and corrosion. This is particularly important for mezzanines used in industrial or outdoor environments.

- Quality Inspections: Final inspections are conducted to ensure that the assembled mezzanine meets all design specifications and safety standards.

Finishing not only enhances the aesthetic appeal of the mezzanine but also significantly extends its lifespan.

What Quality Assurance Measures Are Standard in Steel Mezzanine Manufacturing?

Quality assurance (QA) is integral to the manufacturing of steel mezzanines, ensuring that the final product meets international safety and quality standards. Various QA measures are implemented throughout the manufacturing process.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001, which outlines requirements for quality management systems, are crucial in the manufacturing process. Compliance with these standards indicates that the manufacturer has established effective processes to ensure product quality.

Additionally, industry-specific certifications such as CE marking (for products sold in the European Economic Area) and API (American Petroleum Institute) specifications for structural integrity may also apply, depending on the intended use of the mezzanine. These certifications help buyers assess the reliability and safety of the mezzanine floors.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure adherence to quality standards. Common QC checkpoints include:

- Incoming Quality Control (IQC): This initial inspection verifies that raw materials meet specified standards before they are used in production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages ensures that any defects are identified and corrected promptly. This may involve dimensional checks and material tests.

- Final Quality Control (FQC): A thorough inspection of the finished product is conducted to ensure it meets all specifications and safety requirements.

These checkpoints are critical in minimizing defects and ensuring that the final product is reliable and safe for use.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers looking to ensure quality in their steel mezzanine purchases can take several proactive steps:

- Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to evaluate their manufacturing processes, quality control measures, and adherence to industry standards.

- Requesting Quality Reports: Buyers can ask for documentation of quality tests and certifications. This includes material test reports, inspection records, and compliance certificates.

- Third-Party Inspections: Engaging independent inspection agencies can provide unbiased assessments of the manufacturer’s quality control processes and product reliability.

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these QC nuances is vital for making informed purchasing decisions.

What Testing Methods Are Commonly Used in Quality Assurance for Steel Mezzanines?

Testing methods play a crucial role in the quality assurance of steel mezzanines. Common testing techniques include:

Illustrative image related to steel mezzanine floor

- Load Testing: This assesses the load-bearing capacity of the mezzanine to ensure it meets specified requirements.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle inspection are used to detect internal and surface defects without damaging the material.

- Visual Inspections: Regular visual checks can identify issues such as weld defects, surface imperfections, and misalignments.

Utilizing a combination of these testing methods helps manufacturers ensure that their steel mezzanine products are safe, reliable, and compliant with industry standards.

Conclusion: Ensuring Quality in Steel Mezzanine Floors

For B2B buyers, understanding the manufacturing processes and quality assurance measures associated with steel mezzanine floors is essential for making informed decisions. By focusing on the details of manufacturing stages, international standards, QC checkpoints, and testing methods, buyers can ensure they select a reliable supplier that meets their specific needs. This knowledge not only enhances safety and performance but also contributes to long-term operational efficiency in various industrial applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel mezzanine floor’

Introduction

When sourcing a steel mezzanine floor, understanding the essential steps can significantly streamline the procurement process and ensure that you meet your operational needs. This checklist is designed for B2B buyers looking to invest in steel mezzanine systems, particularly in diverse markets across Africa, South America, the Middle East, and Europe. By following these steps, you will not only enhance your buying decision but also ensure that the installation meets safety and functionality standards.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clarify your specific requirements. This includes load capacity, dimensions, and intended use (e.g., storage, office space, or production). Understanding these details is crucial for ensuring that the mezzanine can handle the operational demands of your facility.

- Load Capacity: Determine the maximum weight the mezzanine will need to support.

- Dimensions: Measure the available space to ensure a proper fit.

- Usage Requirements: Identify whether you need features like access points, safety rails, or electrical integration.

Step 2: Research and Identify Reputable Suppliers

Finding reliable suppliers is essential to ensure quality and safety. Conduct thorough research to identify suppliers with a strong reputation in the industry. Look for reviews, case studies, and references from businesses similar to yours.

- Supplier Experience: Prioritize companies with a proven track record in manufacturing and installing mezzanine systems.

- Certifications: Check for relevant industry certifications, which can indicate compliance with safety standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; engage directly with current or past clients to gauge satisfaction and performance.

- Case Studies: Ask for examples of past projects that align with your needs.

- Client References: Speak with previous clients to understand their experience with the supplier’s products and services.

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request comprehensive quotes. Ensure these quotes include all necessary components such as materials, labor, shipping, and installation costs.

- Breakdown of Costs: Ensure the quote provides a clear breakdown to help you compare options effectively.

- Lead Times: Inquire about estimated delivery and installation timelines to align with your project schedule.

Step 5: Review Safety and Compliance Standards

Safety is paramount when it comes to mezzanine installations. Review the safety features offered by the supplier and ensure they comply with local building codes and regulations.

- Safety Features: Confirm the presence of guardrails, handrails, and emergency access routes.

- Compliance Documentation: Request documentation that proves adherence to safety standards and regulations.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate the terms of the contract. This includes payment terms, warranties, and support services after installation.

Illustrative image related to steel mezzanine floor

- Warranties: Ensure there are clear warranties on materials and workmanship.

- Post-Installation Support: Clarify what kind of support will be provided after installation to address any potential issues.

Step 7: Finalize Your Order and Confirm Delivery

After agreeing on terms, finalize your order and confirm delivery dates. Maintain open communication with the supplier throughout this process to avoid any misunderstandings.

- Order Confirmation: Ensure you receive written confirmation of your order details.

- Delivery Coordination: Discuss delivery logistics to ensure smooth access to your facility on the scheduled date.

By following this checklist, you can make informed decisions when sourcing a steel mezzanine floor, ultimately enhancing operational efficiency and safety in your business environment.

Comprehensive Cost and Pricing Analysis for steel mezzanine floor Sourcing

What Are the Key Cost Components of Steel Mezzanine Floors?

When sourcing steel mezzanine floors, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Structural steel, for example, is commonly used for its strength and durability, but prices can vary based on market conditions. Additional materials for flooring, such as steel grating or concrete, also contribute to the total cost.

-

Labor: Labor costs encompass installation, which can vary depending on the complexity of the design and the expertise required. Skilled labor is often necessary for precise assembly and adherence to safety standards.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Custom designs may require specialized tooling, which can add to the upfront costs. However, investing in the right tools can lead to better quality and efficiency in production.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the mezzanine meets safety and performance standards. This can involve additional testing and inspections, contributing to overall costs.

-

Logistics: Transportation costs for delivering the mezzanine to the site can vary based on distance, mode of transport, and local regulations. It’s crucial to consider these factors when budgeting.

-

Margin: Suppliers typically apply a markup to cover their costs and profit. Understanding the supplier’s pricing strategy can help in negotiations.

How Do Price Influencers Affect Steel Mezzanine Floor Costs?

Several factors can influence the pricing of steel mezzanine floors:

-

Volume/MOQ: Purchasing in larger volumes often leads to lower per-unit costs due to economies of scale. Buyers should inquire about minimum order quantities (MOQ) that may affect pricing.

-

Specifications and Customization: Custom designs tailored to specific operational needs may incur additional costs. It’s essential to balance the benefits of customization with budget constraints.

-

Materials and Quality Certifications: Higher-quality materials or those with specific certifications (e.g., ISO) can lead to increased costs. Buyers should evaluate the long-term benefits of investing in certified products against the initial price.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more for their reliability and expertise, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding the shipping terms agreed upon can impact the total landed cost. Different Incoterms can shift responsibility for costs and risks between buyers and sellers, affecting overall pricing.

What Buyer Tips Can Help in Sourcing Steel Mezzanine Floors?

To ensure cost-efficiency and informed decision-making, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Negotiate Wisely: Engage in discussions with suppliers to negotiate prices, especially for bulk orders. Leveraging competitive quotes from multiple suppliers can strengthen your negotiating position.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider ongoing costs such as maintenance, potential repairs, and operational efficiencies. A higher upfront investment may result in lower long-term costs if the mezzanine is more durable and requires less maintenance.

-

Understand Pricing Nuances for International Purchases: Be aware of additional costs such as tariffs, taxes, and currency fluctuations that can affect pricing when importing from different regions. Collaborating with local experts can provide insights into market conditions and potential hidden costs.

-

Request Detailed Quotes: Ensure that quotes provide a breakdown of all costs, including materials, labor, and logistics. This transparency helps in making informed comparisons between suppliers.

Disclaimer on Indicative Prices

Prices for steel mezzanine floors can vary widely based on numerous factors, including market fluctuations, supplier pricing strategies, and customization requirements. It is advisable for buyers to seek detailed quotations tailored to their specific needs and circumstances to obtain the most accurate pricing information.

Alternatives Analysis: Comparing steel mezzanine floor With Other Solutions

Exploring Alternative Solutions to Steel Mezzanine Floors

In the quest for maximizing space and improving operational efficiency, businesses often explore various structural solutions. Steel mezzanine floors are a popular choice due to their strength and versatility. However, it’s essential to consider alternative methods that may better suit specific operational needs, budget constraints, or space requirements. This analysis compares steel mezzanine floors with two viable alternatives: concrete mezzanine floors and rack-supported platforms.

| Comparison Aspect | Steel Mezzanine Floor | Concrete Mezzanine Floor | Rack-Supported Platforms |

|---|---|---|---|

| Performance | High load capacity, customizable | Very strong, good for heavy loads | Moderate load capacity, flexible |

| Cost | Higher initial investment | Generally lower than steel | Lower upfront cost |

| Ease of Implementation | Quick installation, modular design | Longer curing time, more complex | Simple installation, less labor |

| Maintenance | Low maintenance, durable | Higher due to cracking and wear | Low, but needs inspection |

| Best Use Case | Industrial storage, offices | Heavy-duty applications, manufacturing | Light to moderate storage needs |

What Are the Pros and Cons of Concrete Mezzanine Floors?

Concrete mezzanine floors provide a robust alternative, especially for applications requiring significant load-bearing capabilities. The primary advantage of concrete is its strength and durability, making it suitable for heavy industrial environments. However, the installation process can be lengthy due to the curing time required for concrete. Additionally, while concrete can be cost-effective for large spans, the initial costs may not be as favorable as steel options when considering customization and flexibility. Maintenance can also be a concern, as concrete is prone to cracking, which necessitates periodic inspections and repairs.

How Do Rack-Supported Platforms Compare?

Rack-supported platforms are another alternative that offers a unique approach to maximizing vertical space. These platforms utilize existing racking systems to support the floor, which can significantly reduce the need for additional structural elements. This design allows for quicker installation and less upfront cost compared to a steel mezzanine. However, the load capacity is typically lower than that of steel or concrete options, making them less ideal for heavy-duty applications. Rack-supported platforms are best suited for light to moderate storage needs, particularly in environments where flexibility and rapid reconfiguration are essential.

How Should B2B Buyers Choose the Right Solution?

When selecting the right structural solution for your business, consider the specific requirements of your operations. Assess the load capacity needed, the available budget, and the time constraints for implementation. Steel mezzanine floors are excellent for businesses requiring high load capacities and customization options, while concrete floors might be more suitable for heavy-duty applications where longevity is paramount. Rack-supported platforms offer flexibility and cost savings for lighter loads but may not meet the needs of heavier operations. Ultimately, aligning the choice with your operational goals will ensure optimal space utilization and efficiency.

Essential Technical Properties and Trade Terminology for steel mezzanine floor

What Are the Key Technical Properties of Steel Mezzanine Floors?

When considering steel mezzanine floors, understanding their technical properties is crucial for ensuring safety, functionality, and compliance with industry standards. Here are several critical specifications that every B2B buyer should be aware of:

Illustrative image related to steel mezzanine floor

-

Material Grade

The material grade of steel used in mezzanine construction is essential for determining strength and durability. Commonly used grades include ASTM A36 and ASTM A992, which are known for their excellent weldability and tensile strength. Selecting the appropriate material grade ensures that the mezzanine can withstand the specified loads and environmental conditions, which is vital for industries such as warehousing and manufacturing. -

Load Capacity

Load capacity refers to the maximum weight a mezzanine can safely support, including live loads (people and equipment) and dead loads (the weight of the mezzanine itself). This specification is crucial for businesses that need to optimize their storage solutions without compromising safety. Understanding load capacity helps in planning for future expansions or modifications. -

Tolerance

Tolerance specifies the allowable deviation in dimensions during manufacturing. For example, a tolerance of ±1/16 inch in beam length ensures that all components fit together accurately during assembly. This property is important for maintaining structural integrity and facilitating smooth installation, which can save time and costs during the construction process. -

Finish Type

The finish type refers to the protective coating applied to the steel, such as galvanization or powder coating. These finishes enhance corrosion resistance and durability, making the mezzanine suitable for various environments. Choosing the right finish type can extend the lifespan of the mezzanine, especially in industries exposed to moisture or chemicals. -

Height and Span

The height and span of the mezzanine dictate its design and use cases. A taller mezzanine allows for more vertical storage, while the span between support columns affects the structural configuration. Understanding these measurements is crucial for B2B buyers to optimize space utilization in their facilities.

What Are Common Trade Terms Related to Steel Mezzanine Floors?

Familiarity with industry jargon can significantly streamline communication between buyers and suppliers. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of steel mezzanines, understanding OEM relationships can help buyers ensure they are sourcing high-quality components from reputable manufacturers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases and manage inventory effectively, particularly for custom mezzanine solutions. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and terms for specific products or services. Submitting an RFQ is a critical step in the procurement process, as it helps buyers compare offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs in international trade. Understanding these terms is vital for B2B buyers, especially when importing steel mezzanine systems from overseas, as they outline who is responsible for costs and risks at various stages of transportation. -

Lead Time

Lead time is the period between placing an order and receiving the goods. For customized mezzanine systems, understanding lead times can help businesses plan their projects and manage operational timelines effectively. -

Modular Design

Modular design refers to a construction approach that uses standardized components for easy assembly and reconfiguration. This term is particularly relevant for steel mezzanines, as it allows for quick installation and adaptability to changing business needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their steel mezzanine investments meet operational demands and safety standards.

Navigating Market Dynamics and Sourcing Trends in the steel mezzanine floor Sector

What Are the Current Market Dynamics and Key Trends in the Steel Mezzanine Floor Sector?

The global steel mezzanine floor market is experiencing significant growth driven by various factors, including the increasing demand for space optimization in warehouses and manufacturing facilities. As industries expand, the need for additional storage and operational areas without incurring the costs of new construction is becoming a priority, particularly in regions like Africa, South America, the Middle East, and Europe. International B2B buyers are increasingly looking for customizable solutions that can be adapted to their specific operational requirements.

Emerging technologies, such as advanced manufacturing processes and modular construction techniques, are reshaping how mezzanine floors are designed and produced. Modular manufacturing not only accelerates lead times but also allows for easier reconfiguration as business needs evolve. Additionally, digital platforms for sourcing and procurement are streamlining the buying process, enabling buyers to quickly compare options and make informed decisions.

Market dynamics are also influenced by regulatory changes and compliance requirements, especially concerning safety standards in construction. For B2B buyers, understanding local regulations is crucial when sourcing steel mezzanine systems, as compliance can vary significantly across different regions. The trend towards integrated solutions that combine structural components with advanced safety features is also gaining traction, reflecting an increased focus on workplace safety and efficiency.

How Is Sustainability and Ethical Sourcing Shaping the Steel Mezzanine Floor Market?

Sustainability has emerged as a critical consideration in the steel mezzanine floor sector, driven by heightened awareness of environmental impacts and the importance of ethical supply chains. The production of steel is energy-intensive, leading to significant carbon emissions; thus, buyers are increasingly seeking suppliers who demonstrate a commitment to reducing their environmental footprint.

Utilizing ‘green’ certifications and materials, such as recycled steel or sustainably sourced timber for decking, can enhance the appeal of mezzanine systems. Buyers can benefit from sourcing from manufacturers who prioritize sustainability, as this not only contributes to environmental goals but can also lead to cost savings through energy-efficient practices.

Moreover, ethical sourcing practices are gaining importance as companies look to build responsible supply chains. B2B buyers should assess their suppliers’ sourcing policies, ensuring they align with ethical labor practices and environmental standards. By prioritizing suppliers with transparent supply chains, buyers can mitigate risks associated with unethical practices and enhance their corporate social responsibility profiles.

What Is the Brief Evolution and History of Steel Mezzanine Floors?

The concept of mezzanine floors has evolved significantly over the decades. Initially used primarily in industrial settings, these structures have become increasingly versatile, adapting to various applications across sectors such as warehousing, retail, and logistics. The introduction of structural steel as a primary material for mezzanine floors revolutionized the industry, allowing for greater load-bearing capacities and design flexibility.

Historically, mezzanines were often constructed using traditional building materials, which limited their scalability and ease of installation. However, advancements in steel manufacturing and modular design techniques have transformed mezzanine solutions into customizable, efficient systems that can be rapidly deployed. This evolution reflects a broader trend within the construction and manufacturing sectors towards leaner operations and smarter space utilization, catering to the dynamic needs of international B2B buyers in diverse markets.

By understanding these market dynamics, sustainability considerations, and the historical context of steel mezzanine floors, B2B buyers can make informed decisions that align with their operational goals and ethical standards.

Illustrative image related to steel mezzanine floor

Frequently Asked Questions (FAQs) for B2B Buyers of steel mezzanine floor

-

How do I ensure the structural integrity of a steel mezzanine floor?

To guarantee the structural integrity of a steel mezzanine floor, it is crucial to work with certified engineers who can assess load requirements and design specifications based on your operational needs. Ensure that the supplier provides detailed engineering drawings and calculations that comply with local building codes and safety standards. Additionally, regular inspections during installation and after completion can help identify any potential issues early, thereby maintaining safety and performance. -

What are the key features to look for in a steel mezzanine floor?

When sourcing a steel mezzanine floor, focus on customizable load capacities, modular designs for future expansion, and a variety of access options such as stairs, ladders, or elevators. Ensure that the materials used, like steel grating or concrete decking, meet your specific operational requirements. Safety features such as guardrails and non-slip surfaces are also essential to consider, as they contribute significantly to worker safety and compliance with regulations. -

How do I customize a steel mezzanine floor for my specific needs?

Customization of a steel mezzanine floor typically involves discussions with your supplier regarding your unique requirements, such as load capacity, dimensions, and intended use. Many suppliers offer bespoke solutions, allowing you to specify features like flooring materials, access options, and additional accessories. To facilitate this process, prepare a detailed outline of your needs and operational constraints, which can help the supplier design an optimal solution. -

What are the minimum order quantities (MOQ) for steel mezzanine floors?

Minimum order quantities for steel mezzanine floors vary by supplier and can depend on the complexity of the design and customization. Many suppliers cater to both large and small businesses, offering flexibility in MOQs. It is advisable to directly inquire with potential suppliers to understand their policies and negotiate terms that suit your project needs, especially if you are starting with a smaller facility. -

What payment terms should I expect when ordering a steel mezzanine floor?

Payment terms can vary widely among suppliers, but common practices include a deposit upon order confirmation followed by a balance due before delivery. Some suppliers may offer financing options or staggered payments based on project milestones. Always clarify payment terms upfront to avoid any misunderstandings and ensure that they align with your budget and cash flow needs. -

How can I vet suppliers for steel mezzanine floors?

To vet suppliers, start by researching their experience in the industry and reviewing customer testimonials or case studies. Request references from similar projects and assess their capabilities in customization and compliance with international standards. Additionally, consider visiting their manufacturing facilities or asking for certifications that demonstrate their commitment to quality and safety. -

What logistics considerations should I keep in mind when sourcing steel mezzanine floors?

Logistics play a critical role in sourcing steel mezzanine floors. Ensure that the supplier has a reliable shipping process, including details on lead times, delivery methods, and any potential customs issues for international shipments. It’s also important to confirm that they can handle any necessary installation services or provide guidance for assembly, as this can impact project timelines and costs. -

What quality assurance measures should I look for in steel mezzanine floor suppliers?

Quality assurance measures can include certifications such as ISO or compliance with local building codes. Ask about the supplier’s testing procedures for materials and structural integrity before shipping. Additionally, inquire whether they provide warranties for their products and if they have a clear return policy for defective items. A strong commitment to quality assurance can significantly reduce risks associated with structural failures and safety issues.

Top 7 Steel Mezzanine Floor Manufacturers & Suppliers List

1. Speedrack West – Customizable Steel Frame Solutions

Domain: speedrackwest.com

Registered: 1999 (26 years)

Introduction: Key Features: Custom product—contact us today. Customizable steel frame for high load capacity and flexibility. Access options: stairs, ladders, or elevators. Modular design for quick setup and future expansion. Delivery Terms: Contact Us for lead times. Custom Options Available: Call us for a customized solution. Nation-wide Shipping: Great rates across the country. Description: Structural mezzan…

2. Steel Solutions – Mezzanine Floors

Domain: steelesolutions.com

Registered: 1999 (26 years)

Introduction: Mezzanine floors are industrial structures that create additional space between two floors within a building. They are used to increase floor space without requiring a building expansion and can support equipment, piping, conveyors, and storage. Common materials for mezzanine floors include wood, concrete, and steel, with steel being preferred for heavy-duty applications. Types of mezzanine floors…

3. Mid Florida Material Handling – Steel Mezzanine Floors

Domain: midfloridamaterialhandling.com

Registered: 2009 (16 years)

Introduction: New York Steel Mezzanine Floors are column-supported platforms built from the existing floor of a warehouse or large facility. Made from high-quality steel, they create a second or third floor for office space, production space, locker rooms, or storage. Benefits include increased warehouse space at a fraction of the cost, quick design, delivery and installation, modular expansion options, custom …

4. Mezzanines Online – Mezzanine Floor Kits

Domain: mezzaninesonline.com

Registered: 2014 (11 years)

Introduction: Mezzanines Floor Kits: Small (Height: 63″-92″, Area: 25ft²-78ft², Load: 123lb/ft²), Medium (Height: 68″-111″, Area: 31ft²-164ft², Load: 123lb/ft²), Large (Height: 82″-135″, Area: 88ft²-365ft², Load: 123lb/ft²), Industrial XL (Height: 92″-150″, Area: 67ft²-1231ft², Load: 245lb/ft²). Full kits include various configurations such as loft beds, mezzanines with different stair types (straight, spiral, …

5. Invicta Mezzanine Floors – Structural Steel Solutions

Domain: invictamezzaninefloors.co.uk

Registered: 2007 (18 years)

Introduction: Structural Steel Mezzanine Floors from Invicta Mezzanine Floors are high-quality, lightweight steel structures designed for various applications. Key components include: 1. Mezzanine Support Columns – fire-rated, designed for load requirements, discreet and cost-effective. 2. Mezzanine Floor Main Support Beams – customizable thickness based on loading requirements, bolted to plates on columns. 3. …

6. Racking Engineering – Warehouse Steel Mezzanine Systems

Domain: racking-engineering.com

Registered: 2021 (4 years)

Introduction: Product: Warehouse Steel Mezzanine Systems

Key Features:

– Cost-efficient steel mezzanine rack systems

– High spacing utilization

– High efficient space utility

– Doubling or tripling available warehouse areas

– Free-standing industrial steel mezzanine

– Mass customization available

– Load capacity as per client’s request, less than 1500 kg per square meter

– Suitable for general warehouse distrib…

7. Metal Deck – Structural Steel Mezzanine

Domain: blog.metaldeck.com

Registered: 1998 (27 years)

Introduction: Structural Steel Mezzanine: A partial level intermediate floor in a building, commonly between the ground floor and the roof, fabricated from structural steel beams and columns. Metal decking is used on the floor with concrete or plywood on top. Benefits include additional floor space at a low cost, ideal for heavy-duty settings, and common applications like second-story offices and storage decks….

Strategic Sourcing Conclusion and Outlook for steel mezzanine floor

In the ever-evolving landscape of industrial infrastructure, strategic sourcing of steel mezzanine floors presents a vital opportunity for businesses aiming to optimize space and enhance operational efficiency. As highlighted throughout this guide, the flexibility and high load-bearing capacity of structural steel mezzanines make them ideal for diverse applications across sectors such as warehousing, logistics, and manufacturing. By leveraging customizable solutions, international buyers can meet specific operational needs while ensuring compliance with safety standards.

For companies in Africa, South America, the Middle East, and Europe, engaging with reliable suppliers who understand regional demands and logistics is paramount. The ability to source modular systems that are easy to install and can be expanded as business needs change offers a significant advantage in maintaining competitiveness.

Looking ahead, the demand for versatile and efficient storage solutions will only increase. It is imperative for B2B buyers to act decisively—assess your current infrastructure needs, explore strategic partnerships, and invest in steel mezzanine solutions that align with your growth objectives. By doing so, you can position your business for success in an increasingly dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to steel mezzanine floor

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.