Stainless Steel Hardware Cloth: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for stainless steel hardware cloth

In today’s global marketplace, sourcing high-quality stainless steel hardware cloth presents a significant challenge for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. With varying specifications, applications, and quality standards, making informed purchasing decisions is crucial. This comprehensive guide delves into the intricacies of stainless steel hardware cloth, covering essential topics such as types of materials, common applications, supplier vetting processes, and cost considerations.

By providing actionable insights and expert advice, this guide empowers international buyers to navigate the complexities of sourcing stainless steel hardware cloth effectively. Whether you are looking to enhance security measures in commercial settings, create durable fencing solutions, or implement innovative designs in agricultural applications, understanding the nuances of this versatile product is key to achieving optimal results.

Furthermore, we address critical factors such as supplier reliability and product certification, ensuring that buyers can confidently select partners who meet their quality and service expectations. With this knowledge, B2B buyers will be well-equipped to make strategic decisions that align with their operational needs and budget constraints, ultimately driving success in their respective markets.

Understanding stainless steel hardware cloth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 304 Stainless Steel Cloth | Good corrosion resistance, versatile in applications | Construction, agriculture, DIY projects | Pros: Cost-effective, easy to work with. Cons: Less corrosion-resistant than 316. |

| 316 Stainless Steel Cloth | Superior corrosion resistance, ideal for harsh environments | Marine applications, chemical processing | Pros: Excellent durability, long lifespan. Cons: Higher cost compared to 304. |

| Welded Wire Mesh | Uniform grid pattern, strong welds | Security fencing, animal enclosures | Pros: Strong, stable structure. Cons: Limited flexibility in applications. |

| PVC Coated Stainless Steel | Additional layer of protection against corrosion | Garden fencing, industrial applications | Pros: Enhanced durability, aesthetic appeal. Cons: Slightly higher cost due to coating. |

| Heavy-Duty Stainless Steel Mesh | Thicker wire gauge for enhanced strength | Heavy industrial use, construction | Pros: Exceptional strength, long-lasting. Cons: More difficult to cut and handle. |

What are the characteristics of 304 Stainless Steel Cloth?

304 stainless steel cloth is the most commonly used type of hardware cloth due to its balance of cost and performance. It offers good corrosion resistance and is suitable for a wide range of applications, including construction, agriculture, and various DIY projects. When purchasing, consider the mesh size and gauge to ensure it meets your specific project needs. This type is often favored for its affordability, but buyers should be aware that it may not hold up as well in extremely corrosive environments compared to other grades.

How does 316 Stainless Steel Cloth outperform other types?

316 stainless steel cloth is known for its superior corrosion resistance, making it ideal for applications in marine environments and chemical processing. This type of hardware cloth is more expensive than 304 due to its enhanced durability, but it is essential for projects that require longevity in harsh conditions. B2B buyers should evaluate the specific environmental factors their products will face to determine if the investment in 316 is justified, particularly for industries dealing with saltwater or aggressive chemicals.

What are the benefits of using Welded Wire Mesh?

Welded wire mesh features a uniform grid pattern and strong welds, providing a stable structure ideal for security fencing and animal enclosures. Its design allows for easy installation and can be customized in terms of size and gauge. Buyers should consider the intended use and whether the mesh will need to be cut or shaped, as welded wire can be less flexible than other types. This type is particularly appealing for those needing a reliable and robust solution for fencing needs.

Why choose PVC Coated Stainless Steel for your projects?

PVC coated stainless steel offers an extra layer of protection against corrosion while also providing an aesthetic appeal. This type is commonly used in garden fencing and industrial applications where both durability and appearance matter. The coating can enhance the lifespan of the material, but buyers should weigh the additional cost against the benefits of increased durability and reduced maintenance needs. It’s an excellent option for projects that require both functionality and visual appeal.

What makes Heavy-Duty Stainless Steel Mesh suitable for industrial use?

Heavy-duty stainless steel mesh is characterized by its thicker wire gauge, which provides exceptional strength and is designed for demanding industrial applications. It is ideal for construction projects or any environment where heavy-duty materials are necessary. Buyers should consider the mesh size and gauge to ensure it meets their specific load requirements. While it offers remarkable durability, it may be more challenging to cut and handle, which could impact installation time and costs.

Key Industrial Applications of stainless steel hardware cloth

| Industry/Sector | Specific Application of stainless steel hardware cloth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Animal housing and fencing | Durable and rust-resistant solutions for livestock | Gauge, mesh size, and local availability |

| Construction | Reinforcement for concrete and masonry | Enhances structural integrity and safety | Compliance with local building codes |

| Food and Beverage | Filtration systems in processing plants | Ensures hygiene and prevents contamination | Grade of stainless steel and mesh size |

| Environmental Management | Erosion control and landscaping | Effective barrier against soil loss and wildlife | Durability and resistance to environmental factors |

| Security | Fencing for commercial properties | Provides a secure perimeter against intruders | Thickness, mesh size, and ease of installation |

How is Stainless Steel Hardware Cloth Used in Agriculture?

In the agricultural sector, stainless steel hardware cloth is commonly utilized for constructing animal housing and fencing. Its durability and resistance to rust and corrosion make it an ideal choice for protecting livestock from predators while ensuring proper ventilation. Buyers in this sector need to consider the gauge and mesh size to ensure it meets the specific needs of the animals they are housing. Local availability is also crucial, especially in regions like Africa and South America, where logistics may impact sourcing.

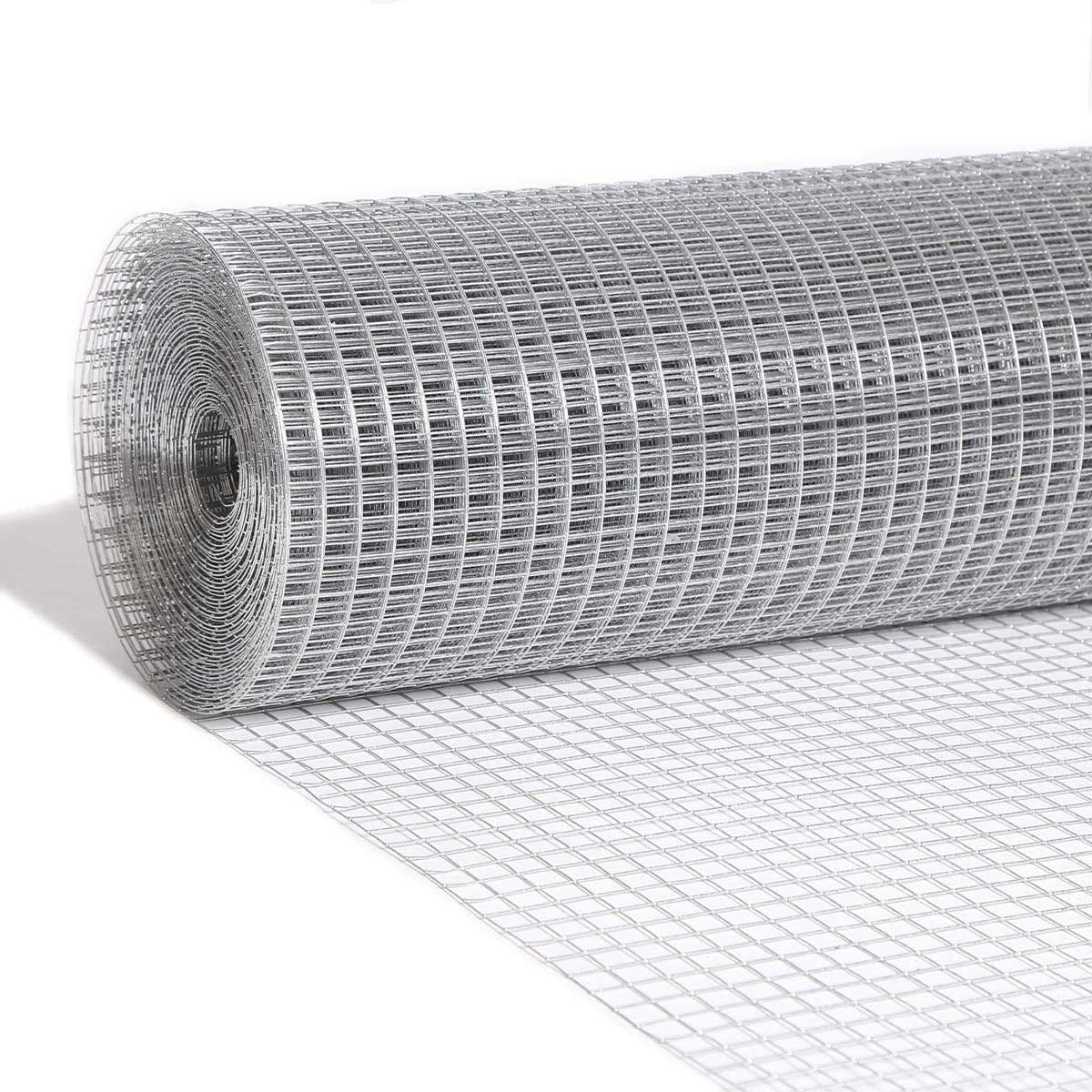

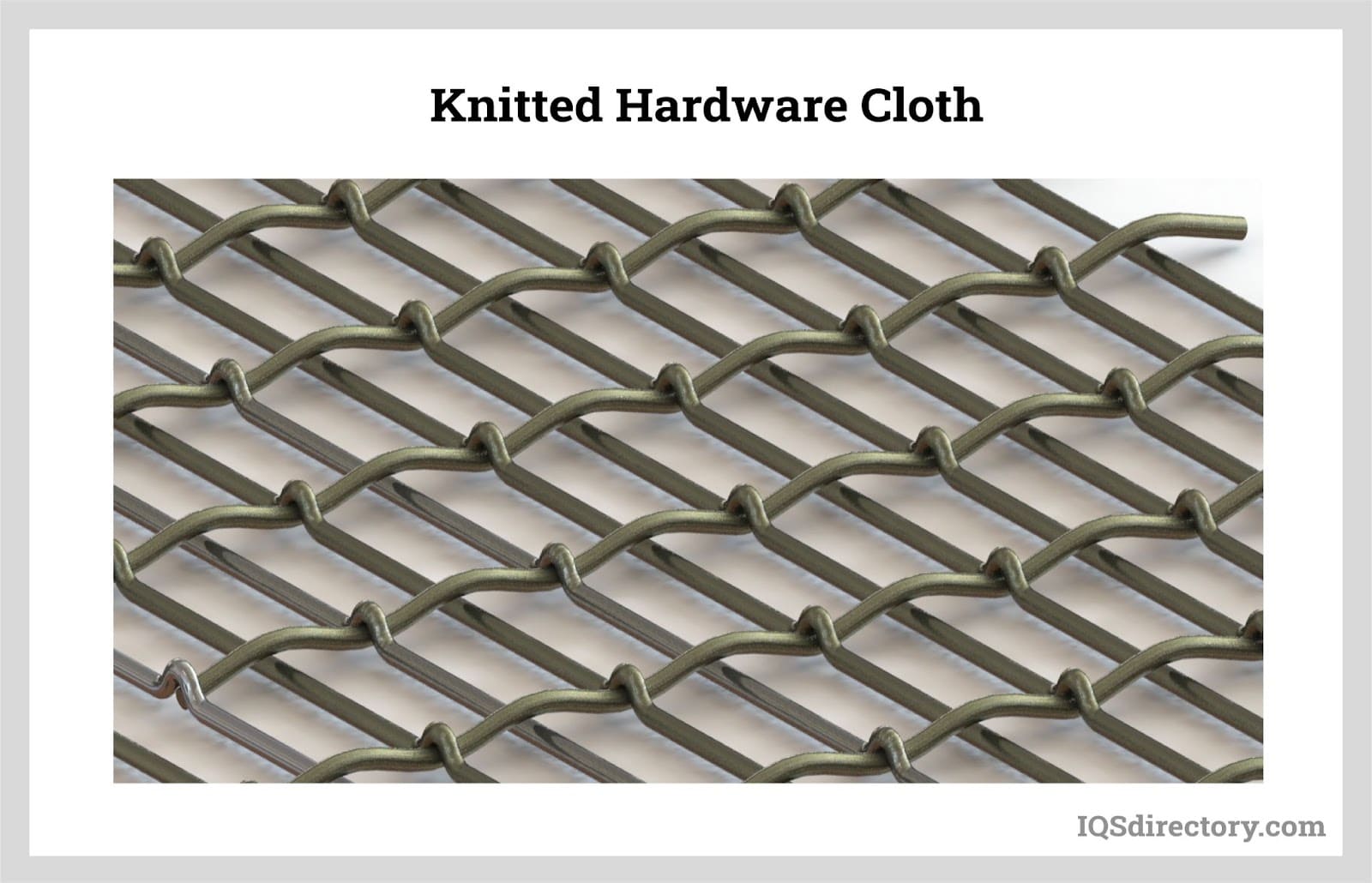

Illustrative image related to stainless steel hardware cloth

What Role Does Stainless Steel Hardware Cloth Play in Construction?

Within the construction industry, stainless steel hardware cloth serves as reinforcement for concrete and masonry applications. It enhances structural integrity by preventing cracking and increasing load-bearing capacity. For international B2B buyers, compliance with local building codes is essential, as different regions may have varying standards for materials used in construction. Additionally, understanding the specific requirements for gauge and mesh size can optimize performance in diverse construction environments.

How is Stainless Steel Hardware Cloth Essential in Food and Beverage Processing?

In food and beverage processing, stainless steel hardware cloth is critical for filtration systems, ensuring hygiene and preventing contamination during production. Its non-corrosive nature allows it to withstand harsh cleaning chemicals, making it suitable for high-standards environments. Buyers must focus on the grade of stainless steel, as it directly impacts food safety compliance. Moreover, mesh size is crucial to filter out unwanted particles effectively, especially in regions with diverse food processing needs, such as the Middle East and Europe.

How Does Stainless Steel Hardware Cloth Aid in Environmental Management?

Stainless steel hardware cloth is also employed in environmental management for erosion control and landscaping applications. It acts as an effective barrier against soil loss while allowing water to pass through, thus supporting vegetation growth. For businesses involved in environmental projects, durability against harsh weather conditions and resistance to environmental factors are key considerations. Buyers should ensure they select a product that meets local environmental regulations, particularly in areas prone to erosion, such as parts of South America and Africa.

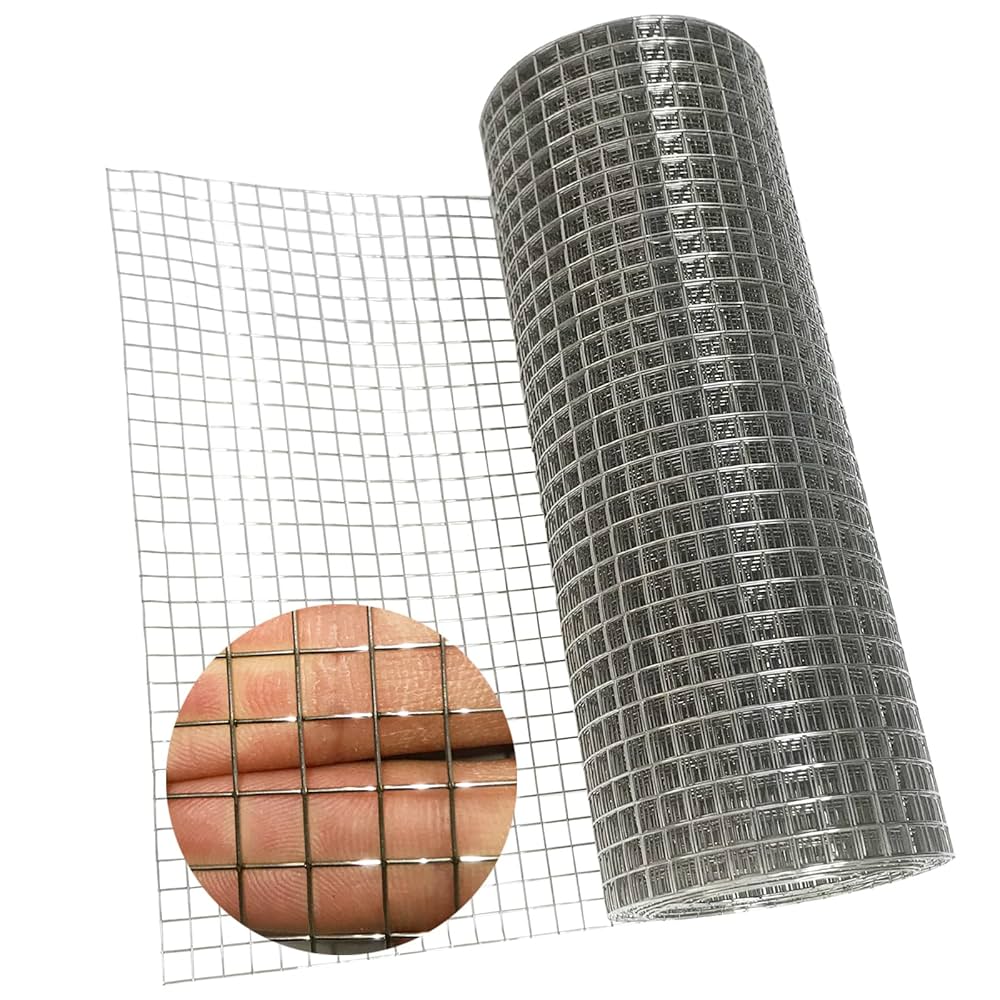

Illustrative image related to stainless steel hardware cloth

What Security Benefits Does Stainless Steel Hardware Cloth Provide?

In the security sector, stainless steel hardware cloth is used extensively for fencing around commercial properties. It provides a robust barrier against intruders while maintaining visibility and airflow. For B2B buyers, factors such as thickness, mesh size, and ease of installation are critical for ensuring that the fencing meets both security and aesthetic requirements. Understanding the local crime rates and security needs in different regions, including Europe and the Middle East, can also influence purchasing decisions.

3 Common User Pain Points for ‘stainless steel hardware cloth’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Stainless Steel Hardware Cloth

The Problem: B2B buyers often face significant challenges when sourcing stainless steel hardware cloth, especially when quality standards vary widely among suppliers. In regions like Africa and South America, where infrastructure may not support consistent supply chains, buyers can be left with inferior products that rust or degrade quickly. This not only impacts the immediate project at hand but can also lead to long-term financial losses due to increased maintenance costs or project delays.

The Solution: To effectively source high-quality stainless steel hardware cloth, buyers should prioritize suppliers that provide detailed product specifications, including material grade (such as 304 or 316 stainless steel), wire gauge, and mesh size. Establishing relationships with reputable manufacturers who offer certifications and quality assurance can further mitigate risks. Additionally, utilizing local suppliers or distributors who understand regional requirements can streamline the sourcing process. Implementing a thorough vetting process that includes reviewing samples and conducting quality checks before placing bulk orders will ensure that the material meets the necessary standards for durability and application.

Scenario 2: Installation Challenges with Stainless Steel Hardware Cloth

The Problem: Another common pain point for B2B buyers is the installation process of stainless steel hardware cloth. Many users underestimate the complexity of working with this material, particularly when it comes to cutting and securing the cloth. The rigidity of stainless steel can lead to difficulties in achieving a proper fit, especially in custom applications like fencing or animal enclosures. This can result in wasted materials and increased labor costs.

The Solution: To overcome installation challenges, it’s crucial for buyers to invest in the right tools and techniques. Utilizing tin snips or specialized wire cutters can make the cutting process more manageable. Additionally, providing training for installation teams on best practices for handling and securing stainless steel hardware cloth can enhance efficiency. Detailed installation guides or videos from suppliers can serve as valuable resources. Buyers should also consider pre-fabricated solutions that can save time and labor, such as ready-to-install panels or kits that come with all necessary hardware and instructions.

Scenario 3: Cost Concerns Compared to Alternative Materials

The Problem: B2B buyers frequently express concern over the upfront cost of stainless steel hardware cloth compared to alternative materials, such as plastic or galvanized steel. In regions with budget constraints, the initial investment in higher-quality stainless steel can be a tough sell, particularly when cheaper options appear to offer immediate savings. However, these alternatives often lack the durability and longevity of stainless steel, leading to increased replacement costs and potential project failures down the line.

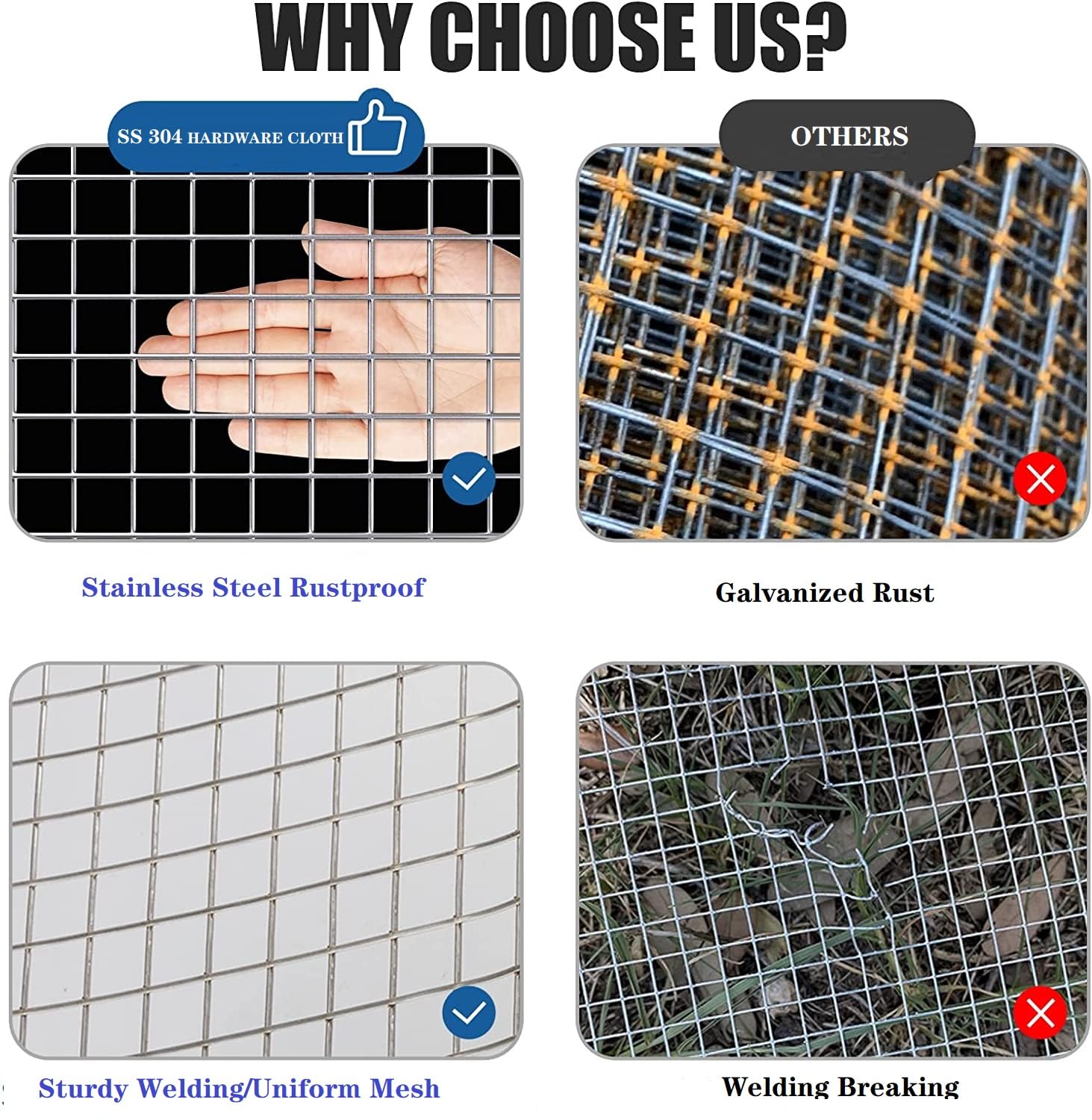

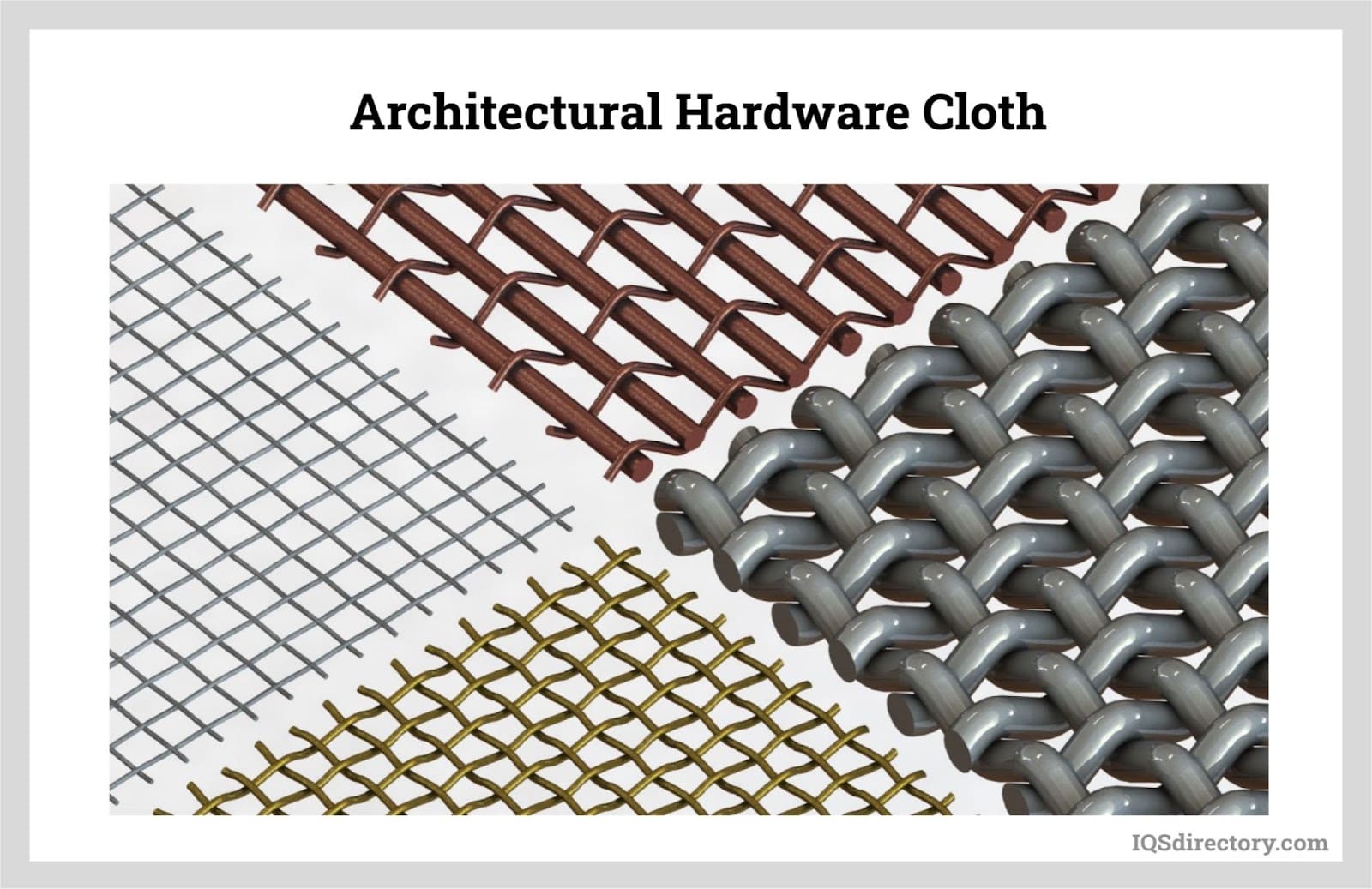

Illustrative image related to stainless steel hardware cloth

The Solution: To address cost concerns, buyers should conduct a total cost of ownership analysis that considers not just the initial purchase price, but also factors in longevity, maintenance, and replacement frequency. Educating stakeholders on the benefits of stainless steel—such as resistance to rust, corrosion, and pests—can help justify the investment. Furthermore, negotiating bulk pricing or exploring volume discounts with suppliers can significantly reduce costs. Buyers might also explore financing options or payment plans that allow for the initial investment to be spread over time, making it easier to opt for higher-quality materials without straining budgets.

Strategic Material Selection Guide for stainless steel hardware cloth

What Are the Key Properties of Different Stainless Steel Grades for Hardware Cloth?

When selecting stainless steel hardware cloth, understanding the properties of various materials is crucial for ensuring optimal performance in specific applications. The most common grades used in hardware cloth are 304 and 316 stainless steel, each offering unique advantages and disadvantages.

What Are the Advantages and Disadvantages of 304 Stainless Steel Hardware Cloth?

304 stainless steel is the most widely used grade for hardware cloth due to its excellent balance of strength, corrosion resistance, and affordability. It performs well in a variety of environments, making it suitable for applications ranging from gardening to industrial use.

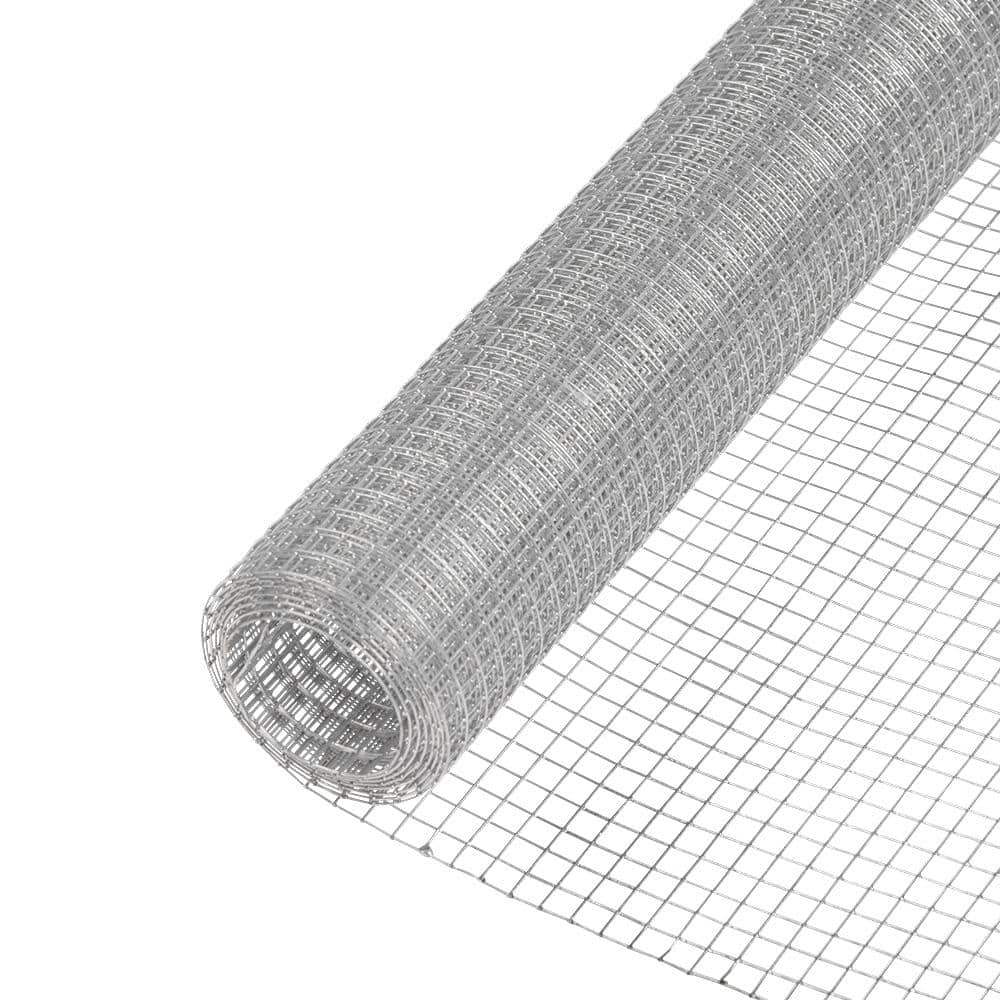

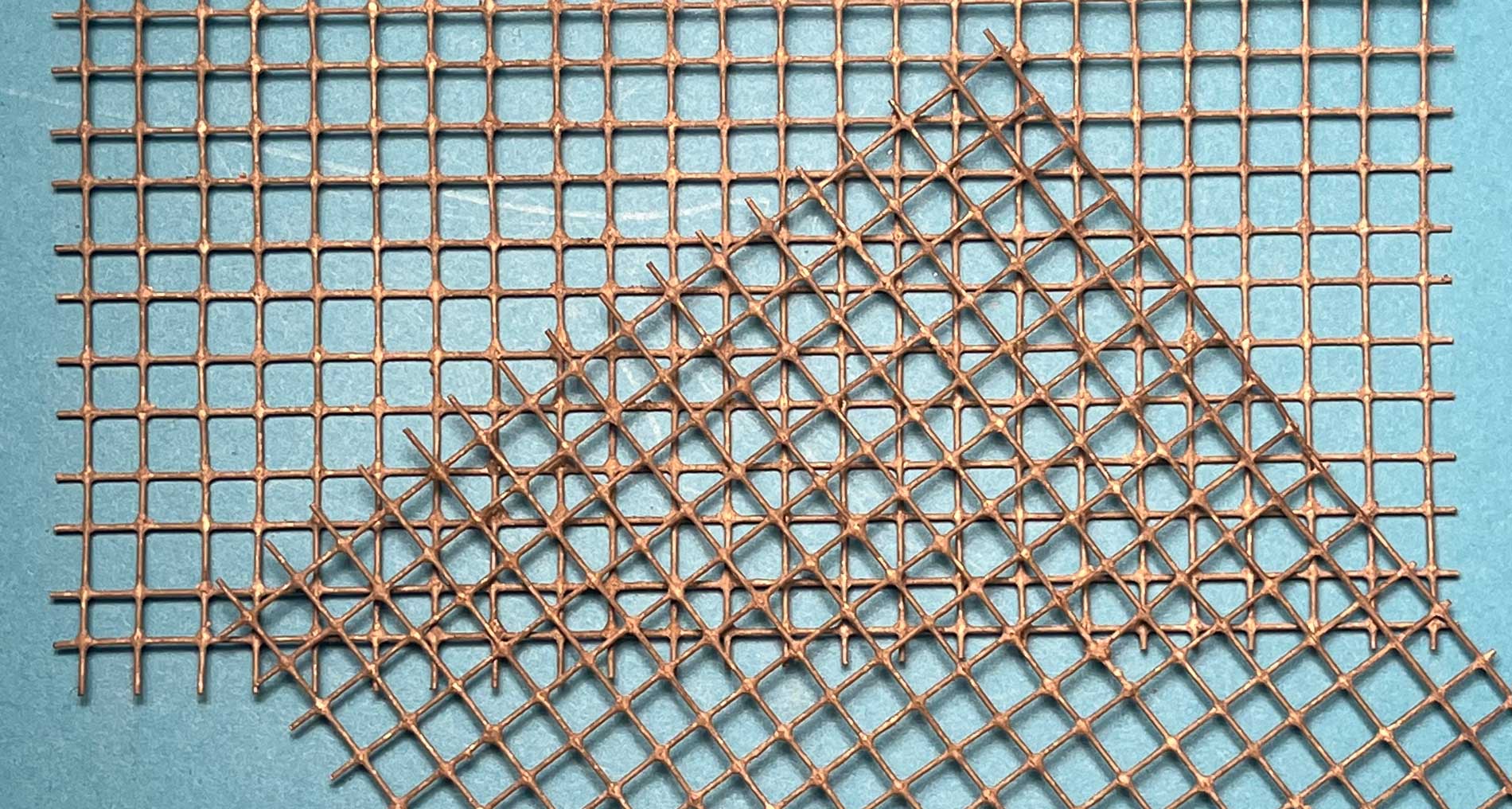

Illustrative image related to stainless steel hardware cloth

Key Properties:

– Corrosion Resistance: Good, but not suitable for highly corrosive environments (e.g., marine applications).

– Temperature Rating: Can withstand temperatures up to 870°C (1600°F).

Pros:

– Cost-effective compared to other stainless steel grades.

– Easy to work with and cut, making it suitable for DIY projects.

– Versatile for various applications, including fencing and ventilation.

Cons:

– Less resistant to chlorides compared to 316 grade, limiting its use in coastal regions.

– May require additional protective coatings in harsh environments.

How Does 316 Stainless Steel Compare for Hardware Cloth Applications?

316 stainless steel is often preferred for applications requiring superior corrosion resistance, particularly in marine or chemical environments.

Key Properties:

– Corrosion Resistance: Excellent, especially against chlorides and acidic environments.

– Temperature Rating: Similar to 304, withstanding high temperatures up to 870°C (1600°F).

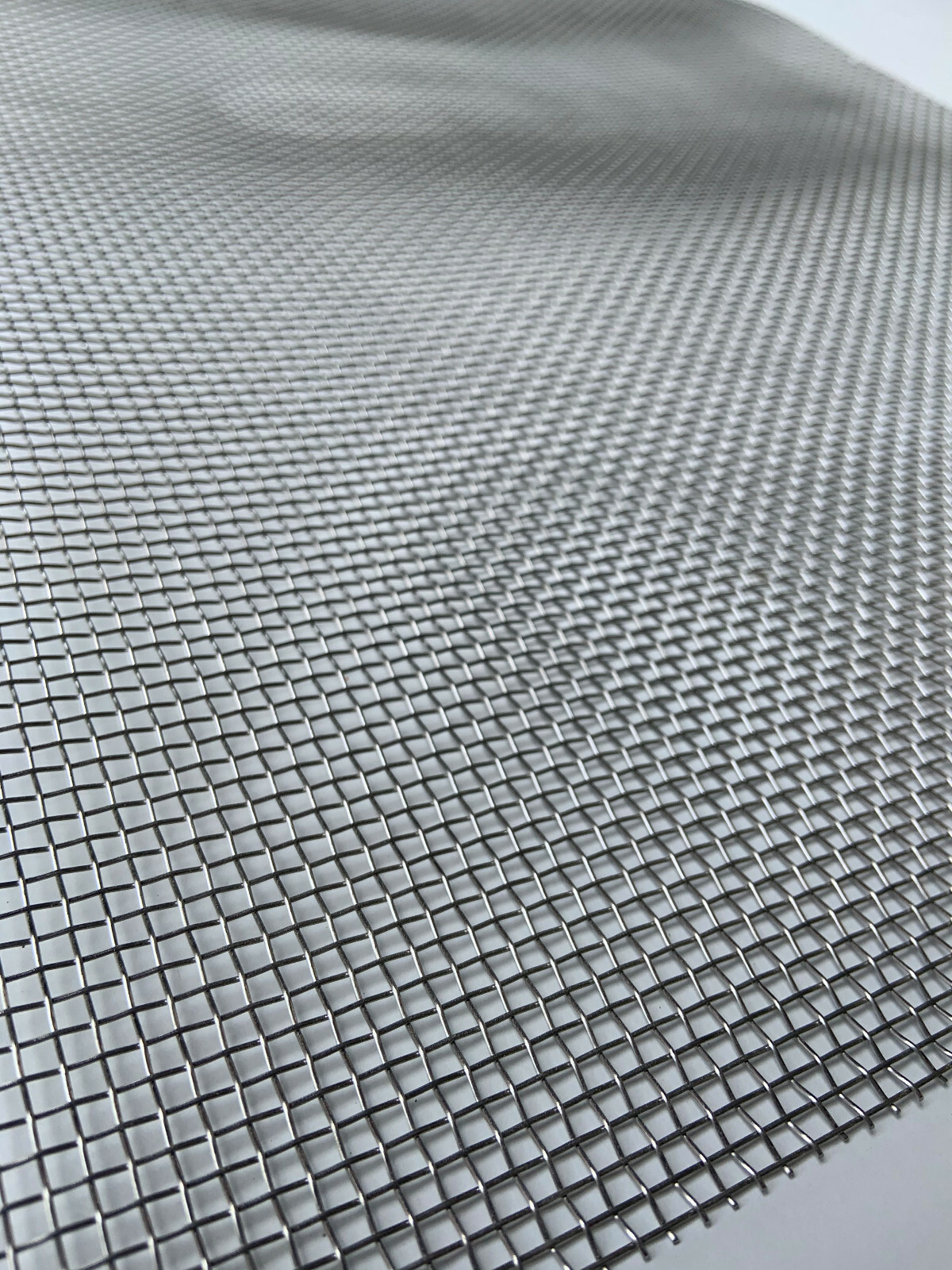

Illustrative image related to stainless steel hardware cloth

Pros:

– Ideal for coastal and industrial applications where exposure to saltwater or chemicals is common.

– Longer lifespan due to enhanced corrosion resistance, reducing replacement costs over time.

Cons:

– Generally more expensive than 304 stainless steel.

– Heavier and may be more challenging to work with due to its durability.

What Are the Specific Considerations for International Buyers?

When sourcing stainless steel hardware cloth, international buyers from regions like Africa, South America, the Middle East, and Europe should consider compliance with local standards such as ASTM, DIN, or JIS. These standards ensure quality and safety in various applications.

Key Considerations:

– Regulatory Compliance: Ensure that the selected material meets local regulations for construction and safety.

– Supply Chain Logistics: Consider shipping costs and availability of materials in specific regions.

– Cultural Preferences: Some regions may prefer specific grades based on local environmental conditions or industry practices.

Illustrative image related to stainless steel hardware cloth

Summary Table of Stainless Steel Grades for Hardware Cloth

| Material | Typical Use Case for stainless steel hardware cloth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 Stainless Steel | General fencing, garden applications | Cost-effective and versatile | Limited corrosion resistance in harsh environments | Medium |

| 316 Stainless Steel | Marine applications, chemical processing environments | Superior corrosion resistance | Higher cost and heavier weight | High |

This strategic material selection guide provides a comprehensive overview of the key properties, advantages, and considerations for choosing the right stainless steel hardware cloth. By understanding these factors, B2B buyers can make informed decisions that align with their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel hardware cloth

What Are the Main Stages in the Manufacturing Process of Stainless Steel Hardware Cloth?

The production of stainless steel hardware cloth involves several key stages, each crucial for ensuring the final product meets durability and functionality standards. The main stages include:

-

Material Preparation: High-quality stainless steel, typically 304 or 316 grade, is selected for its corrosion resistance and strength. The steel is often sourced from reputable suppliers who provide mill certificates, ensuring traceability and compliance with international standards.

-

Forming: The stainless steel wire is drawn to the required gauge, which can vary based on the intended use of the hardware cloth. Once drawn, the wire is cut into specified lengths. The forming process may involve weaving or welding techniques, depending on the desired mesh pattern. Welded wire cloth is particularly common due to its structural integrity and uniformity.

-

Assembly: After forming, the hardware cloth may undergo additional processes such as cutting into rolls or sheets. This step is crucial for meeting customer specifications regarding dimensions. The assembly phase may also include the application of protective coatings to enhance corrosion resistance and longevity, particularly for outdoor applications.

-

Finishing: The final finishing touches involve cleaning and inspecting the product for defects. This may include processes like passivation, which enhances the corrosion resistance of stainless steel by removing free iron and other contaminants from the surface.

How Are Quality Assurance Measures Integrated into the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process for stainless steel hardware cloth, ensuring that products meet established standards and customer expectations. The following are key aspects of QA:

-

International Standards Compliance: Manufacturers typically adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards demonstrates a commitment to quality and continuous improvement.

-

Quality Control Checkpoints: The manufacturing process includes several checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for compliance with specifications. Certificates of compliance from suppliers are verified.

– In-Process Quality Control (IPQC): During production, continuous monitoring is conducted to ensure processes are followed correctly, and any deviations are addressed immediately.

– Final Quality Control (FQC): After production, the finished products undergo thorough inspections to identify any defects or non-conformities before shipment. -

Testing Methods: Common testing methods include tensile strength tests, mesh size verification, and corrosion resistance assessments. Non-destructive testing methods may also be employed to evaluate the integrity of welded joints.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers play a vital role in ensuring the quality of stainless steel hardware cloth they source. Here are actionable steps to verify supplier QC processes:

Illustrative image related to stainless steel hardware cloth

-

Conduct Supplier Audits: Buyers should perform regular audits of potential suppliers to assess their manufacturing processes, equipment, and quality control measures. This on-site evaluation can provide insights into the supplier’s commitment to quality.

-

Request Quality Reports: Buyers can request documentation that outlines the supplier’s quality management practices, including results from IQC, IPQC, and FQC. These reports can highlight adherence to international standards and internal QC protocols.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality before shipment. These inspections can verify compliance with specifications and standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control and certification. Here are some nuances to consider:

-

Understanding Local Regulations: Different countries have varying regulations regarding materials and product standards. Buyers should familiarize themselves with local compliance requirements and ensure that their suppliers can meet these standards.

-

Navigating Certification Requirements: Certifications such as CE marking (Europe) or API (American Petroleum Institute) may be required depending on the application of the hardware cloth. Buyers should ensure that their suppliers possess the necessary certifications and that these are current and valid.

-

Cultural Considerations in Quality Assurance: Different regions may have distinct approaches to quality assurance. Understanding these cultural differences can facilitate better communication and expectations between buyers and suppliers.

-

Building Long-term Relationships: Establishing long-term relationships with suppliers can enhance trust and transparency. Regular communication regarding quality expectations can lead to improved product consistency and responsiveness to any quality concerns.

Conclusion

The manufacturing processes and quality assurance measures for stainless steel hardware cloth are pivotal in ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions, verify supplier capabilities, and ultimately source high-quality materials that meet their specific needs. Investing time in due diligence regarding manufacturing and QC practices is essential for fostering successful international business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel hardware cloth’

In the competitive landscape of B2B procurement, sourcing stainless steel hardware cloth requires careful planning and thorough evaluation. This step-by-step checklist is designed to guide international buyers through the sourcing process, ensuring that they make informed decisions that align with their specific needs.

Illustrative image related to stainless steel hardware cloth

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the stainless steel hardware cloth you need. Consider factors such as mesh size, wire gauge, and material grade (e.g., 304 or 316 stainless steel). A well-defined specification helps ensure that the product meets your application needs, whether for industrial, agricultural, or construction purposes.

Step 2: Research Market Trends and Pricing

Before reaching out to suppliers, conduct thorough market research to understand current pricing trends and availability. This insight will help you set a budget and identify competitive pricing ranges. Look for fluctuations in material costs, especially in regions like Africa and South America, where sourcing may be influenced by local economic conditions.

Step 3: Evaluate Potential Suppliers

It’s crucial to vet suppliers thoroughly before committing to a purchase. Request detailed company profiles, product samples, and references from other buyers within your industry. This step is vital for assessing the supplier’s reliability and quality of product, ensuring that you can trust them to meet your delivery schedules and quality standards.

- Check Certifications: Ensure suppliers have relevant industry certifications, such as ISO standards or compliance with local regulations.

- Assess Production Capacity: Verify that the supplier can handle your order volume and timeline.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of the hardware cloth. Evaluating samples allows you to assess the material’s quality, durability, and suitability for your specific application. Pay attention to aspects like weave uniformity, rust resistance, and ease of handling during installation.

Step 5: Negotiate Terms and Conditions

After selecting a preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear communication during this phase is essential to avoid misunderstandings later. Aim for mutually beneficial terms that protect your interests while allowing the supplier to maintain profitability.

- Consider Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Clarify Shipping Arrangements: Discuss who will bear shipping costs and the logistics involved, especially for international shipments.

Step 6: Finalize Purchase Agreement

Once all terms are agreed upon, finalize the purchase agreement. Ensure that all specifications, pricing, and delivery details are documented to prevent discrepancies. A well-structured agreement protects both parties and provides a reference point should issues arise.

Step 7: Monitor Order Progress and Quality Control

After placing your order, maintain communication with the supplier to monitor the progress of your shipment. Implement quality control measures upon receipt to ensure that the product meets your specifications. This step is crucial for maintaining operational efficiency and minimizing disruptions in your projects.

By following this checklist, B2B buyers can streamline their sourcing process for stainless steel hardware cloth, ensuring they secure high-quality materials that meet their operational needs effectively.

Comprehensive Cost and Pricing Analysis for stainless steel hardware cloth Sourcing

What Are the Key Cost Components in Stainless Steel Hardware Cloth Sourcing?

When sourcing stainless steel hardware cloth, several cost components contribute to the overall pricing. The primary elements include:

-

Materials: The type of stainless steel used significantly impacts costs. For instance, 304 stainless steel is generally less expensive than 316 stainless steel due to its lower corrosion resistance. The gauge of the wire also affects the price; thicker wires (lower gauge numbers) typically cost more.

-

Labor: Labor costs can vary based on the manufacturing region. Countries with lower labor costs may provide a competitive edge, but this should be weighed against quality and reliability.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Facilities that employ advanced manufacturing techniques may incur higher overhead but can produce superior products more efficiently.

-

Tooling: Custom tooling for specific applications or unique mesh sizes can add to initial costs. Buyers should consider if the added expense justifies the potential benefits of tailored products.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, which may add to costs but ultimately reduces the risk of defects and returns, enhancing long-term value.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and local tariffs. Import duties and taxes must also be factored in for international transactions.

-

Margin: Supplier profit margins influence final pricing. Larger suppliers may offer lower margins due to economies of scale, while smaller, niche manufacturers may charge higher prices for specialized products.

What Factors Influence Pricing of Stainless Steel Hardware Cloth?

Several factors can influence the pricing of stainless steel hardware cloth, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for volume discounts, making it crucial for buyers to consolidate orders where possible.

-

Specifications and Customization: Customized products generally command higher prices. Buyers should assess whether the added cost aligns with their specific needs.

-

Material Quality and Certifications: Products that meet specific industry standards or certifications (e.g., ISO, ASTM) may be priced higher. Buyers should verify the certifications to ensure they meet regulatory requirements.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a history of quality may charge a premium.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) is essential for calculating total costs. Buyers must ensure they are clear on who bears responsibility for shipping, insurance, and tariffs.

How Can Buyers Negotiate Better Prices for Stainless Steel Hardware Cloth?

B2B buyers can employ several strategies to negotiate better pricing on stainless steel hardware cloth:

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can foster trust.

-

Benchmark Pricing: Research and compare prices from multiple suppliers to establish a baseline. This knowledge can provide leverage during negotiations.

-

Focus on Total Cost of Ownership: Evaluate the total cost of ownership rather than just the upfront price. Consider factors like durability, maintenance, and potential replacements over time.

-

Be Flexible with Specifications: If possible, be open to alternative specifications that may be more cost-effective. Discussing alternative materials or standard sizes can lead to lower prices.

-

Plan Orders Strategically: Timing purchases to align with supplier production cycles can yield savings. Suppliers may offer discounts during slower periods.

What Should International B2B Buyers from Africa, South America, the Middle East, and Europe Consider?

International buyers must navigate unique challenges when sourcing stainless steel hardware cloth. Understanding local market conditions, currency fluctuations, and import regulations is essential. Additionally, buyers should be aware of potential additional costs, such as customs duties, which can significantly impact overall pricing.

Disclaimer: The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific order requirements. Always conduct thorough due diligence and request quotes tailored to your needs.

Illustrative image related to stainless steel hardware cloth

Alternatives Analysis: Comparing stainless steel hardware cloth With Other Solutions

When considering solutions for applications requiring durable and versatile mesh materials, stainless steel hardware cloth stands out. However, various alternatives exist that may cater to specific needs or preferences. This analysis will compare stainless steel hardware cloth with two viable alternatives: galvanized wire mesh and PVC-coated wire mesh. Each option has unique characteristics that can influence a buyer’s decision based on their specific requirements.

| Comparison Aspect | Stainless Steel Hardware Cloth | Galvanized Wire Mesh | PVC-Coated Wire Mesh |

|---|---|---|---|

| Performance | High corrosion resistance; withstands high temperatures and wear | Moderate corrosion resistance; suitable for outdoor use | Good resistance to corrosion; softer than stainless steel |

| Cost | Higher initial investment; long-term durability justifies expense | Lower cost; budget-friendly option | Mid-range pricing; cost-effective for many applications |

| Ease of Implementation | Requires cutting tools; relatively easy to install | Simple to cut and install; widely available | Easy to install; flexible and lightweight |

| Maintenance | Low maintenance; does not rust or corrode | Moderate maintenance; can rust over time | Low maintenance; durable and long-lasting |

| Best Use Case | Ideal for high-stress applications (e.g., security, animal enclosures) | Great for general fencing and garden use | Suitable for decorative applications and light-duty fencing |

What Are the Advantages and Disadvantages of Galvanized Wire Mesh Compared to Stainless Steel Hardware Cloth?

Galvanized wire mesh is a cost-effective alternative that provides moderate corrosion resistance, making it suitable for various outdoor applications. While it is significantly cheaper than stainless steel hardware cloth, it can rust over time, particularly in humid or corrosive environments. Galvanized mesh is easy to cut and install, making it an appealing choice for general fencing or garden use. However, its longevity and strength do not match that of stainless steel, which may be a critical factor for high-stress applications.

How Does PVC-Coated Wire Mesh Stack Up Against Stainless Steel Hardware Cloth?

PVC-coated wire mesh offers a balance between aesthetics and functionality. It provides good corrosion resistance and is softer than stainless steel, making it easier to handle and install. This type of mesh is often used in decorative applications or for light-duty fencing, where the visual appeal is as important as the functional aspect. The PVC coating adds an extra layer of protection against the elements; however, it may not withstand high-stress applications as effectively as stainless steel. The pricing is typically mid-range, which can be attractive for projects where budget constraints are a factor.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate mesh material, B2B buyers should evaluate their specific requirements, including environmental conditions, budget constraints, and the intended application. Stainless steel hardware cloth, while more expensive, provides unmatched durability and corrosion resistance, making it ideal for critical applications. On the other hand, galvanized and PVC-coated wire meshes may serve well in less demanding situations where cost savings and ease of installation are priorities. Ultimately, understanding the trade-offs between performance, cost, and application suitability will guide buyers in making informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for stainless steel hardware cloth

What Are the Key Technical Properties of Stainless Steel Hardware Cloth?

When sourcing stainless steel hardware cloth, understanding its technical specifications is crucial for ensuring that the product meets your specific application needs. Here are some of the most critical properties:

Illustrative image related to stainless steel hardware cloth

1. Material Grade: Why Is It Important?

The most common grades of stainless steel used in hardware cloth are 304 and 316. Grade 304 offers good corrosion resistance and is often sufficient for indoor applications or areas with minimal exposure to harsh environments. In contrast, Grade 316 contains molybdenum, enhancing its resistance to saltwater and chlorides, making it ideal for marine or coastal applications. Selecting the right grade is vital for durability and performance, particularly in industries such as agriculture, construction, and aquaculture.

2. Wire Gauge: How Does It Affect Strength?

Wire gauge refers to the thickness of the wire used in the cloth. A lower gauge number indicates a thicker wire, which generally translates to greater strength and durability. For instance, a 22-gauge wire is sturdier than a 24-gauge wire, making it more suitable for high-stress applications like fencing or animal enclosures. Understanding wire gauge helps in selecting the right product based on the required tensile strength and application.

3. Mesh Size: What Does It Mean for Functionality?

Mesh size refers to the openings between the wires in the cloth, typically measured in inches. For example, a 1/4″ mesh size means that each square opening measures 1/4″ by 1/4″. Smaller mesh sizes can keep out smaller animals and insects, while larger mesh sizes may allow for better airflow or visibility. Choosing the appropriate mesh size is essential for the intended use, whether for pest control, security, or ventilation.

4. Tolerance: Why Is It Critical in Manufacturing?

Tolerance in hardware cloth refers to the allowable variation in the dimensions of the product. A tighter tolerance means the dimensions are more precise, which is crucial for applications requiring exact fits or where multiple sheets need to align perfectly. This is particularly important in industries like construction and manufacturing, where precision can affect overall project quality and safety.

Illustrative image related to stainless steel hardware cloth

5. Roll Size: How Does It Impact Shipping and Handling?

Stainless steel hardware cloth is often sold in rolls of various sizes, such as 24″ x 100′ or 36″ x 100′. The size of the roll can affect shipping costs and ease of handling. Larger rolls may provide cost savings for bulk purchases but can be cumbersome to manage. Understanding roll sizes is vital for planning logistics and determining the quantity needed for specific projects.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with trade terminology can streamline communication and negotiations in the procurement process. Here are some common terms that buyers should be aware of:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for ensuring compatibility and quality in your sourcing strategy.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers assess their purchasing power and budget constraints while negotiating with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products. It is essential for comparing offers and ensuring that all vendors provide consistent information, making it easier to evaluate options.

Illustrative image related to stainless steel hardware cloth

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They are used in international transactions to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help mitigate risks and misunderstandings in cross-border transactions.

5. Lead Time: Why Is It a Key Consideration?

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is crucial for project planning and ensuring timely delivery, especially in sectors where delays can incur significant costs.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing stainless steel hardware cloth, ensuring that they select the right products for their specific needs while navigating international procurement efficiently.

Illustrative image related to stainless steel hardware cloth

Navigating Market Dynamics and Sourcing Trends in the stainless steel hardware cloth Sector

What Are the Current Market Dynamics and Key Trends in the Stainless Steel Hardware Cloth Sector?

The stainless steel hardware cloth market is witnessing significant growth, driven by increasing demand across various sectors such as construction, agriculture, and industrial applications. Global drivers include the rising need for durable and corrosion-resistant materials, particularly in harsh environmental conditions. The 304 and 316 grades of stainless steel are gaining traction due to their superior properties, making them preferred choices for applications ranging from garden fencing to security screening.

Emerging B2B tech trends, such as digital marketplaces and e-commerce platforms, are reshaping sourcing strategies. Buyers from Africa, South America, the Middle East, and Europe are increasingly leveraging these platforms to access a wider range of suppliers and products, thereby enhancing competitive pricing and availability. Additionally, advancements in logistics and supply chain management technologies are improving delivery times and reducing costs, further incentivizing international buyers to source materials online.

Market dynamics are influenced by fluctuating raw material prices, trade policies, and evolving regulatory standards regarding product quality and safety. For international B2B buyers, understanding local market conditions and compliance requirements is essential for successful procurement. Moreover, the trend towards customization and tailored solutions is becoming more pronounced, as businesses seek specific mesh sizes, gauges, and finishes to meet their unique operational needs.

How Can Sustainability and Ethical Sourcing Impact B2B Procurement in the Stainless Steel Hardware Cloth Sector?

Sustainability is increasingly becoming a priority for B2B buyers in the stainless steel hardware cloth sector. The environmental impact of sourcing practices, including the carbon footprint of transportation and manufacturing, is under scrutiny. Buyers are now more inclined to engage with suppliers who demonstrate responsible sourcing and production processes, emphasizing the importance of transparency and traceability in the supply chain.

Illustrative image related to stainless steel hardware cloth

Ethical sourcing is crucial, as it not only aligns with corporate social responsibility goals but also resonates with end consumers who are increasingly eco-conscious. Buyers are encouraged to seek suppliers that hold certifications, such as ISO 14001 (Environmental Management) or those that utilize recycled materials in their production processes. Utilizing ‘green’ certifications can enhance a company’s reputation and marketability, particularly in regions where environmental regulations are stringent.

Additionally, the shift towards circular economy principles is fostering innovation in the stainless steel hardware cloth market. Suppliers that adopt sustainable practices, such as reducing waste and optimizing resource use, are likely to gain a competitive edge. For B2B buyers, investing in sustainably sourced materials not only fulfills ethical obligations but can also lead to long-term cost savings and improved supplier relationships.

How Has the Stainless Steel Hardware Cloth Sector Evolved Over Time?

The evolution of the stainless steel hardware cloth sector can be traced back to the increasing industrialization of the early 20th century, when the demand for durable and versatile materials surged. Initially used primarily in agricultural settings for fencing and pest control, advancements in manufacturing techniques and material science have broadened the applications of stainless steel hardware cloth.

Over the decades, the introduction of various grades of stainless steel, such as 304 and 316, has allowed for enhanced performance characteristics, making these materials suitable for a wider array of environments, including marine and industrial applications. The rise of globalization has further transformed the market, enabling international trade and the entry of diverse suppliers, which has led to increased competition and innovation.

Today, the sector is characterized by a blend of traditional applications and emerging uses in high-tech industries, such as aerospace and pharmaceuticals. As sustainability and ethical sourcing become more critical, the market continues to adapt, focusing on quality, durability, and environmental responsibility, ensuring that stainless steel hardware cloth remains a vital component across various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel hardware cloth

-

1. How do I choose the right stainless steel hardware cloth for my application?

Choosing the right stainless steel hardware cloth involves considering factors such as mesh size, wire gauge, and the specific application. For instance, a finer mesh (like 1/4″) is ideal for preventing small pests, while a coarser mesh (like 1/2″) may be more suitable for larger animals or structural applications. Additionally, wire gauge affects strength and durability; a lower gauge indicates thicker wire, which provides better resistance to wear and tear. Assess your project’s requirements and consult with suppliers for recommendations tailored to your needs. -

2. What is the best type of stainless steel hardware cloth for outdoor use?

The best type of stainless steel hardware cloth for outdoor applications is typically made from 304 or 316 stainless steel. While 304 offers good resistance to corrosion, 316 stainless steel provides enhanced protection against rust, especially in coastal areas or humid environments. If your project involves exposure to harsh conditions, opt for 316 stainless steel. Ensure the mesh is welded securely to maintain integrity against environmental factors, ensuring long-lasting performance. -

3. What are the typical minimum order quantities (MOQs) for stainless steel hardware cloth?

Minimum order quantities for stainless steel hardware cloth can vary significantly depending on the supplier and the specific product. Generally, MOQs can range from a few rolls (for smaller suppliers) to several tons (for larger manufacturers). When sourcing internationally, consider suppliers that offer flexibility in MOQs, especially if you’re testing the market. Always inquire about bulk purchasing discounts, as higher quantities may lead to reduced pricing per unit. -

4. How can I vet suppliers of stainless steel hardware cloth for quality and reliability?

Vetting suppliers involves several steps: checking their certifications (ISO, CE, etc.), reviewing customer feedback, and requesting product samples for quality assessment. Additionally, look for suppliers with a strong track record in international trade, as they are more likely to understand the complexities of shipping and customs. Utilize platforms like Alibaba or ThomasNet to find reputable suppliers, and consider reaching out to other businesses in your network for recommendations based on their experiences. -

5. What payment terms should I expect when sourcing stainless steel hardware cloth internationally?

Payment terms can vary, but common practices include advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit (usually 30%) before production, with the balance due upon completion. It’s essential to discuss and agree upon payment terms upfront to avoid misunderstandings. Consider using secure payment methods that offer buyer protection, especially for larger transactions, to mitigate risks associated with international trade. -

6. How do I ensure quality assurance (QA) for my stainless steel hardware cloth order?

To ensure quality assurance, establish clear specifications and standards before placing your order. Request a detailed quality control plan from the supplier, including inspection procedures and testing methods. Conduct pre-shipment inspections, either through third-party services or by visiting the supplier, to verify that the products meet your specifications. Additionally, consider requesting certifications for materials used, such as ASTM standards, to confirm compliance with industry norms. -

7. What are the logistics considerations for importing stainless steel hardware cloth?

Logistics considerations include selecting a reliable freight forwarder, understanding customs regulations, and planning for potential delays. Ensure you have all necessary documentation, such as commercial invoices and packing lists, to facilitate smooth customs clearance. Additionally, consider the shipping method (air vs. sea) based on urgency and cost. Evaluate your total landed cost, including tariffs and duties, to ensure your pricing remains competitive in your market. -

8. Can stainless steel hardware cloth be customized for specific applications?

Yes, many suppliers offer customization options for stainless steel hardware cloth, including specific mesh sizes, wire gauges, and dimensions. If you have unique requirements, such as specific coatings or treatments (e.g., PVC coating for added corrosion resistance), communicate these needs to your supplier. Discuss lead times and any additional costs associated with customization to ensure your project remains on schedule and within budget.

Top 6 Stainless Steel Hardware Cloth Manufacturers & Suppliers List

1. McNICHOLS – Wire Mesh Solutions

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: Product Line: Wire Mesh; Online Order Available: Yes; Mesh Types: Square (226), Rectangular (10), ECO-MESH® (1), Designer Mesh (192); Construction Types: Woven (357), Welded (71), Standard-Duty Welded (1); Series Names: ASHLAND™, AURA™, CHATEAU™, CREMONA™, HALO™, HW & IND CLTH, INSECT SCREEN, SHIRE™, TALICA™, TECHNA™, VINYLMESH™; Primary Materials: Aluminum (AL), Brass (BRS), Bronze (BNZ), Bronze/…

2. McMaster – 316 Stainless Steel Wire Cloth

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – 316 Stainless Steel Wire Cloth, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Argus Steel – Stainless Steel Woven Wire Mesh

Domain: argussteel.com

Registered: 2003 (22 years)

Introduction: Argus Steel offers a variety of stainless steel woven wire mesh and wire cloth products suitable for industrial applications. Key features include:

– Material Options: T304 and T316 stainless steel, high tensile carbon steel, galvanized steel, aluminum, brass, bronze, copper, titanium, and other high-temperature alloys.

– Durability: Superior chemical resistance and anti-corrosive properties for…

4. Online Metals – Stainless Steel Wire Mesh

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: Stainless Steel Wire Mesh available in various sizes and alloys, including 304 and 316 stainless steel. Common applications include animal housing, security solutions, farm and garden fencing, and DIY projects. Custom cutting options are available. Example product: 500×500 Mesh with 0.0010″ wire diameter, part # mp-00002013, sold by Universal Wire Cloth Co. Custom sizes range from 12″ x 12″ to 36″…

5. Newark Wire – Customized Stainless Steel Wire Mesh Solutions

Domain: newarkwire.com

Registered: 1996 (29 years)

Introduction: Newark Wire Cloth specializes in customized stainless steel wire mesh solutions and offers a wide range of wire cloth products including: Wire Cloth, US Standard Sieve Cloth, Filter Cloth, Hardware Cloth, Industrial Wire Cloth, Market Grade Wire Cloth, Mill Grade Wire Cloth, Space Cloth, Strainer Grade Wire Cloth, Tensile Bolting Cloth, Welded Wire Cloth, Fabricated Parts, Test Sieves, Strainers (…

6. Stainless Steel Wire Mesh – Durable Hardware Cloth

Domain: stainlesssteelwiremesh.us

Registered: 2009 (16 years)

Introduction: Stainless steel hardware cloth is a type of wire mesh made from either woven or welded wires in a square or rectangular grid. It is available in galvanized, stainless steel, and bare steel, and is typically used for outdoor applications. The mesh openings range from 1/8″ x 1/8″ to 2″ x 2″ for square openings and 1/2″ x 1″ to 2″ x 4″ for rectangular openings. The product comes in rolls that are 24″…

Strategic Sourcing Conclusion and Outlook for stainless steel hardware cloth

In the evolving landscape of industrial materials, stainless steel hardware cloth stands out due to its durability, corrosion resistance, and versatility across various applications. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, strategic sourcing of this material can lead to significant advantages. Sourcing high-quality stainless steel hardware cloth from reputable suppliers ensures not only superior product performance but also long-term cost savings by reducing maintenance and replacement needs.

Engaging with suppliers who offer a range of specifications, such as different grades of stainless steel and mesh sizes, allows businesses to tailor their purchases to specific project requirements. Additionally, understanding local market dynamics and shipping logistics can enhance procurement efficiency and cost-effectiveness.

As you consider your next sourcing decisions, prioritize partnerships that align with your operational goals and sustainability practices. The future of stainless steel hardware cloth looks promising, driven by increased demand in construction, agriculture, and security applications. By making informed decisions today, you can position your business for growth and success in this competitive market. Explore your options now and leverage the full potential of stainless steel hardware cloth to enhance your projects and operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.