Spring Latch: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for spring latch

In today’s competitive landscape, sourcing the right spring latch can present a significant challenge for international B2B buyers. With an array of options available, understanding the nuances of spring latches—including their types, materials, and applications—becomes crucial for making informed purchasing decisions. This comprehensive guide aims to demystify the global market for spring latches, offering insights into various styles ranging from heavy-duty options to specialized industrial designs.

We will explore the diverse applications of spring latches across industries, including shipping, agriculture, automotive, and construction, helping you identify the best fit for your needs. Additionally, the guide will provide valuable tips on supplier vetting, ensuring that you choose reliable manufacturers capable of delivering quality products that meet your specifications.

Cost considerations will also be addressed, enabling you to balance quality and budget effectively. By equipping international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe (e.g., Brazil, Saudi Arabia)—with the knowledge to navigate the complexities of the spring latch market, this guide empowers you to make strategic purchasing decisions that enhance operational efficiency and product reliability. Dive in to discover how to streamline your sourcing process and secure the best spring latch solutions for your business.

Understanding spring latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Spring Latch | Simple design, spring-loaded pin, available in various sizes | General industrial use, gates, and doors | Pros: Easy to install, cost-effective. Cons: Limited load capacity. |

| Heavy-Duty Spring Latch | Reinforced construction, capable of holding heavier weights | Shipping containers, agricultural equipment, trailers | Pros: High durability, suitable for heavy applications. Cons: Higher cost. |

| Slam Latch | Automatically locks upon closure, quick-release mechanism | Automotive shipping, storage containers, gates | Pros: Fast operation, secure locking. Cons: May wear over time with frequent use. |

| Weld-On Spring Latch | Designed for permanent attachment via welding | Metal fabrication, trailers, industrial machinery | Pros: Strong and secure, custom-fit solutions. Cons: Installation requires welding expertise. |

| Retractable Pin Latch | Features a pin that retracts for easy access, customizable options | Automotive, machinery, and equipment manufacturing | Pros: Versatile, customizable for specific needs. Cons: More complex design can lead to maintenance issues. |

What are the characteristics of Standard Spring Latches and their suitability for B2B buyers?

Standard spring latches are characterized by their straightforward design, featuring a spring-loaded pin that retracts to secure or release doors and gates. These latches are available in various lengths and materials, making them adaptable to many applications. They are particularly suitable for general industrial use, where cost-effectiveness and ease of installation are priorities. B2B buyers should consider the operational environment, as these latches may not withstand high-stress conditions or heavy loads.

How do Heavy-Duty Spring Latches differ from standard options in terms of usage?

Heavy-duty spring latches are built with reinforced materials and designs that allow them to hold significantly heavier weights compared to standard latches. They are ideal for applications in shipping containers, agricultural equipment, and trailers, where strength and reliability are crucial. When purchasing, buyers should assess the specific load requirements of their applications, as well as the latch’s durability and resistance to environmental factors, such as corrosion.

What advantages do Slam Latches offer for B2B applications?

Slam latches are designed to automatically lock when a door or lid is closed, providing a quick-release mechanism that enhances operational efficiency. They are commonly used in automotive shipping, storage containers, and gates, where speed and security are essential. Buyers should weigh the benefits of fast operation against potential wear and tear; frequent use may lead to maintenance needs, which should be factored into total cost considerations.

In what scenarios are Weld-On Spring Latches the best choice for industrial applications?

Weld-on spring latches are specifically engineered for permanent attachment, providing a robust solution for applications requiring high security and strength. They are frequently used in metal fabrication and on trailers, where a custom-fit is necessary. B2B buyers should ensure they have the appropriate welding capabilities and expertise, as installation may require specialized skills. The long-term durability of these latches makes them a worthwhile investment for heavy-duty applications.

What makes Retractable Pin Latches a versatile choice for various industries?

Retractable pin latches feature a pin that retracts to allow for easy access, making them highly versatile for different applications, including automotive and machinery manufacturing. Their customizable options allow businesses to tailor solutions to specific operational needs. When considering these latches, buyers should evaluate the complexity of the design, as it may lead to increased maintenance requirements over time. However, their adaptability often justifies the investment for many industrial applications.

Key Industrial Applications of spring latch

| Industry/Sector | Specific Application of spring latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Used in equipment enclosures for quick access | Enhances operational efficiency and safety | Ensure durability, resistance to corrosion, and compliance with safety standards. |

| Transportation | Securing doors and compartments in trailers and containers | Protects cargo, reduces theft, and ensures safety | Evaluate load capacity and ease of use under various conditions. |

| Agriculture | Latching gates and equipment covers | Provides reliable access control and safety for livestock | Consider environmental resistance and customization options for different applications. |

| Construction | Locking mechanisms for heavy machinery and tools | Improves security and operational efficiency | Focus on heavy-duty options and compatibility with existing systems. |

| Automotive | Used in vehicle assembly for quick-release mechanisms | Streamlines assembly processes and improves safety | Assess compatibility with various automotive designs and regulatory compliance. |

In the manufacturing sector, spring latches are commonly employed in equipment enclosures, allowing for quick access to machinery while maintaining safety standards. These latches help streamline operations by enabling swift maintenance, reducing downtime. Buyers should prioritize durability, resistance to corrosion, and compliance with industry safety regulations to ensure the longevity and effectiveness of the latches in their applications.

In transportation, spring latches are vital for securing doors and compartments in trailers and shipping containers. They provide a reliable locking mechanism that protects cargo from theft and ensures safety during transit. When sourcing, businesses should consider the load capacity of the latches and their performance under various environmental conditions, especially in regions prone to harsh weather.

The agriculture industry benefits from spring latches for securing gates and equipment covers, enhancing both safety and access control for livestock. These latches ensure that gates remain securely closed while allowing for easy access when needed. Buyers should look for options that are resistant to environmental factors, such as moisture and rust, and consider customization to meet specific operational needs.

In the construction sector, spring latches serve as locking mechanisms for heavy machinery and tools, improving security and operational efficiency on job sites. They prevent unauthorized access and ensure that equipment is safely stored when not in use. Sourcing considerations should include heavy-duty options that can withstand the rigors of construction environments and compatibility with existing systems.

In the automotive industry, spring latches are utilized in vehicle assembly for quick-release mechanisms, facilitating a more efficient assembly process. They enhance safety by ensuring that components are securely fastened during operation. Buyers should assess the compatibility of these latches with various automotive designs and ensure compliance with regulatory standards to maintain safety and performance.

3 Common User Pain Points for ‘spring latch’ & Their Solutions

Scenario 1: Inconsistent Locking Performance in Heavy-Duty Applications

The Problem: B2B buyers often face challenges when using spring latches in heavy-duty applications, such as securing industrial equipment or shipping containers. The problem arises when the latch fails to engage properly due to the weight or stress of the door or lid, leading to inconsistent locking performance. This can cause operational disruptions, safety hazards, and potential damage to valuable equipment. For buyers in sectors like manufacturing or logistics, this inconsistency can lead to costly downtime and increased liability.

The Solution: To overcome this issue, it’s essential to select a heavy-duty spring latch designed specifically for the weight and demands of your application. Look for latches that feature a reinforced construction with robust materials such as stainless steel, which offers higher strength and durability. Additionally, consider latches with adjustable tension settings that allow you to customize the locking force according to the specific load requirements. Sourcing from reputable suppliers who offer customization options can also ensure that you receive a product that meets your exact specifications, thereby enhancing the reliability of the locking mechanism.

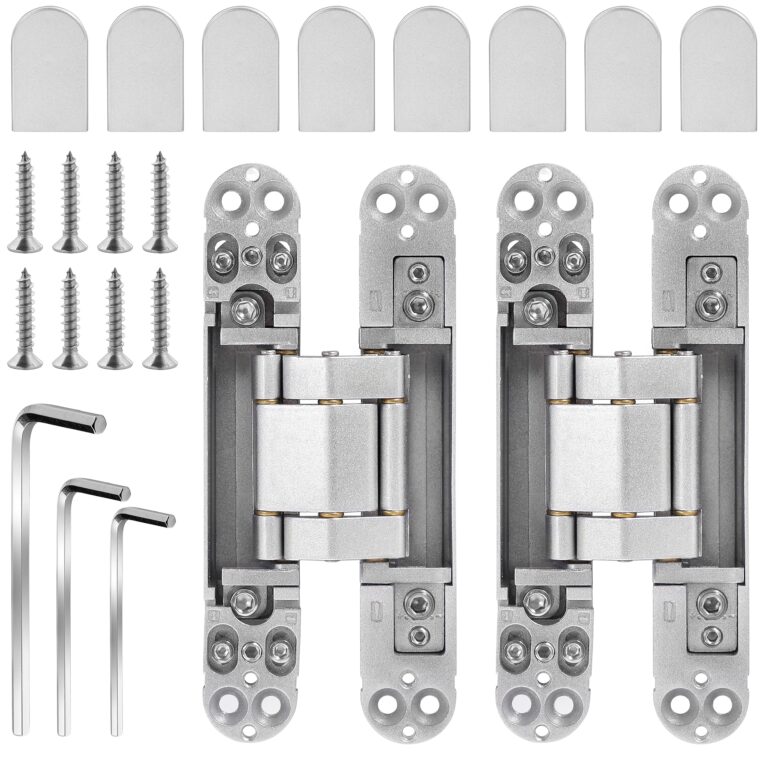

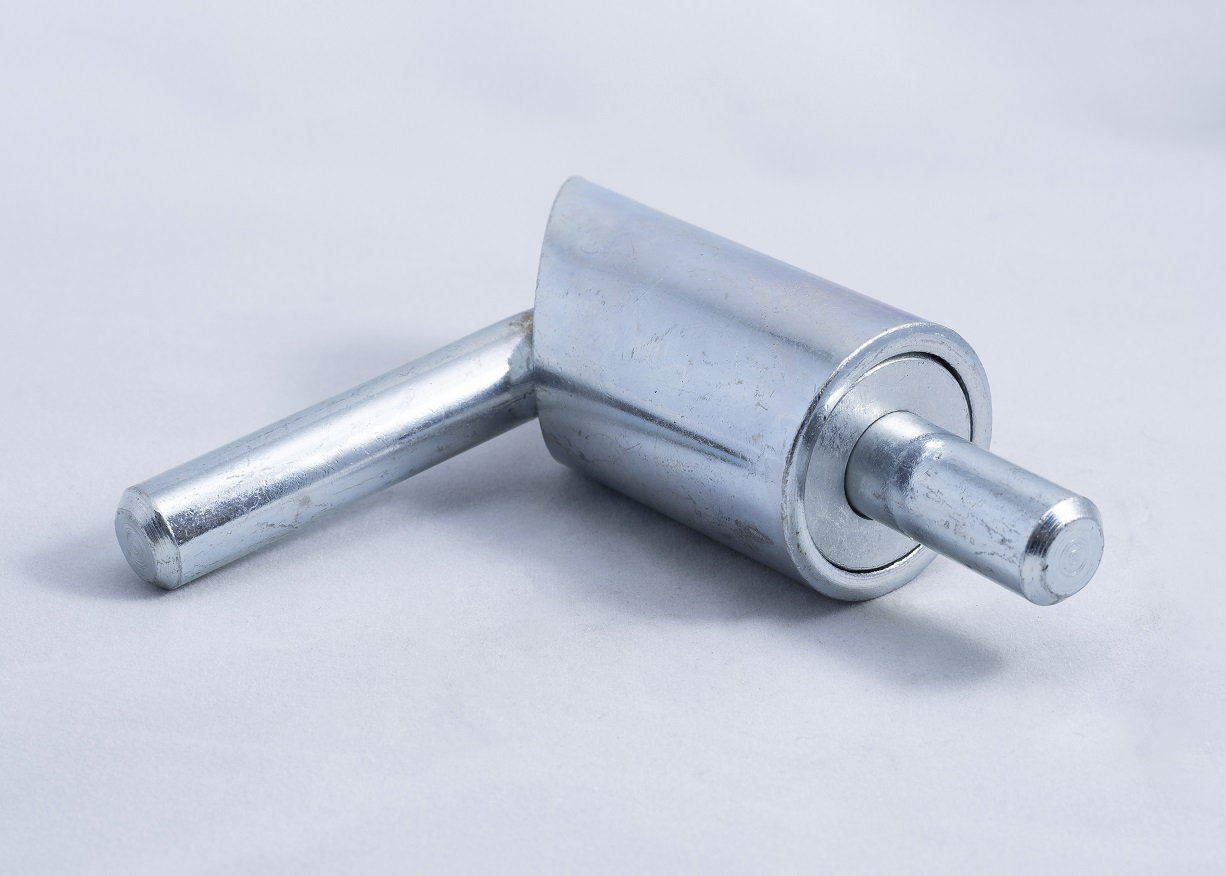

Illustrative image related to spring latch

Scenario 2: Difficulty in Installation and Compatibility with Existing Hardware

The Problem: Another common pain point for B2B buyers is the complexity of installing spring latches, especially when integrating them with existing hardware. Many businesses find that the latches they purchase do not fit well with their current setups, leading to frustrating installation processes that can waste time and resources. This issue is particularly prevalent among companies in sectors such as construction and automotive manufacturing, where precise fit and functionality are crucial.

The Solution: To address installation difficulties, it’s vital to conduct thorough compatibility assessments before purchasing spring latches. Begin by measuring the dimensions of your existing hardware and comparing them with the specifications of potential latches. Many suppliers offer CAD drawings and detailed product specifications, which can help visualize how the latch will fit into your existing system. Furthermore, consider latches that come with comprehensive installation guides or even technical support from the manufacturer. If necessary, opt for latches that allow for easy retrofitting or those designed with adjustable mounting options, which can simplify the installation process significantly.

Scenario 3: Corrosion and Environmental Damage Affecting Latch Longevity

The Problem: In many industries, particularly in regions with harsh environmental conditions, spring latches are susceptible to corrosion and wear. This degradation can compromise the functionality of the latch, leading to premature failure and increased maintenance costs. For companies involved in outdoor operations or those located in humid or saline environments, this issue is not only a matter of performance but also impacts overall operational efficiency.

The Solution: To mitigate the effects of environmental damage, it’s crucial to select spring latches that are specifically engineered for corrosion resistance. Stainless steel or latches with specialized coatings (like zinc plating or powder coating) can significantly enhance durability against environmental factors. Additionally, regular maintenance, including periodic cleaning and lubrication, can extend the life of your latches. Consider sourcing latches from suppliers who provide detailed information about their materials and protective finishes. This proactive approach will not only ensure a longer lifespan for the latches but also reduce the total cost of ownership by minimizing the need for replacements.

Strategic Material Selection Guide for spring latch

What Are the Key Properties of Common Materials Used in Spring Latches?

When selecting materials for spring latches, several options are prevalent in the market, each with distinct properties that influence performance, durability, and suitability for various applications. Here, we analyze four common materials: plain steel, stainless steel, aluminum, and plastic.

Illustrative image related to spring latch

How Does Plain Steel Perform in Spring Latch Applications?

Plain steel is a widely used material for spring latches due to its strength and cost-effectiveness. It typically has a high tensile strength, making it suitable for applications requiring robust locking mechanisms. However, plain steel lacks corrosion resistance, which can be a significant drawback in humid or saline environments.

Pros: Cost-effective, high strength, easy to machine and fabricate.

Cons: Prone to rusting and corrosion, limited temperature resistance.

Plain steel latches are ideal for indoor applications or environments where exposure to moisture is minimal. International buyers, especially from regions with high humidity like parts of Africa and South America, should consider protective coatings or finishes to enhance durability.

Why Choose Stainless Steel for Spring Latches?

Stainless steel is another popular choice for spring latches, known for its excellent corrosion resistance and aesthetic appeal. It can withstand a wide range of temperatures and is less likely to deform under stress compared to other materials.

Pros: Corrosion-resistant, durable, maintains appearance over time.

Cons: Higher cost than plain steel, more complex manufacturing processes.

Stainless steel latches are particularly suitable for outdoor applications or environments exposed to chemicals or saline conditions, making them a preferred choice for buyers in coastal regions or industries such as marine and food processing. Compliance with international standards such as ASTM or DIN is crucial when sourcing stainless steel components.

What Are the Advantages of Using Aluminum in Spring Latches?

Aluminum is lightweight and offers good corrosion resistance, making it an excellent option for applications where weight is a concern. It is easy to machine and can be anodized for additional protection against wear and corrosion.

Pros: Lightweight, good corrosion resistance, easy to fabricate.

Cons: Lower tensile strength compared to steel, may deform under heavy loads.

Aluminum spring latches are ideal for applications in the automotive and aerospace industries, where reducing weight is critical. Buyers from Europe and the Middle East should consider the specific load requirements of their applications, as aluminum may not be suitable for heavy-duty uses.

When Is Plastic a Viable Material for Spring Latches?

Plastic spring latches are becoming increasingly popular due to their lightweight nature and resistance to corrosion. They are often used in applications where electrical insulation is required or where the latch will not be subjected to heavy loads.

Pros: Lightweight, corrosion-resistant, good electrical insulator.

Cons: Limited strength, can degrade under UV exposure.

Plastic latches are suitable for indoor applications, particularly in electronics and consumer goods. Buyers should be aware of the specific type of plastic used, as some may not meet international standards for durability or heat resistance.

Summary Table of Material Selection for Spring Latches

| Material | Typical Use Case for spring latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plain Steel | Indoor applications | Cost-effective, high strength | Prone to rusting | Low |

| Stainless Steel | Outdoor, marine applications | Corrosion-resistant, durable | Higher cost | High |

| Aluminum | Automotive, aerospace applications | Lightweight, good corrosion resistance | Lower tensile strength | Medium |

| Plastic | Electronics, consumer goods | Lightweight, good electrical insulator | Limited strength, UV degradation | Low |

This guide provides an overview of the key materials used in spring latch manufacturing, highlighting their properties and suitability for various applications. International B2B buyers should consider these factors carefully to ensure compliance with relevant standards and to meet the specific needs of their projects.

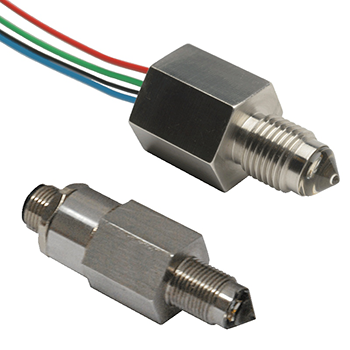

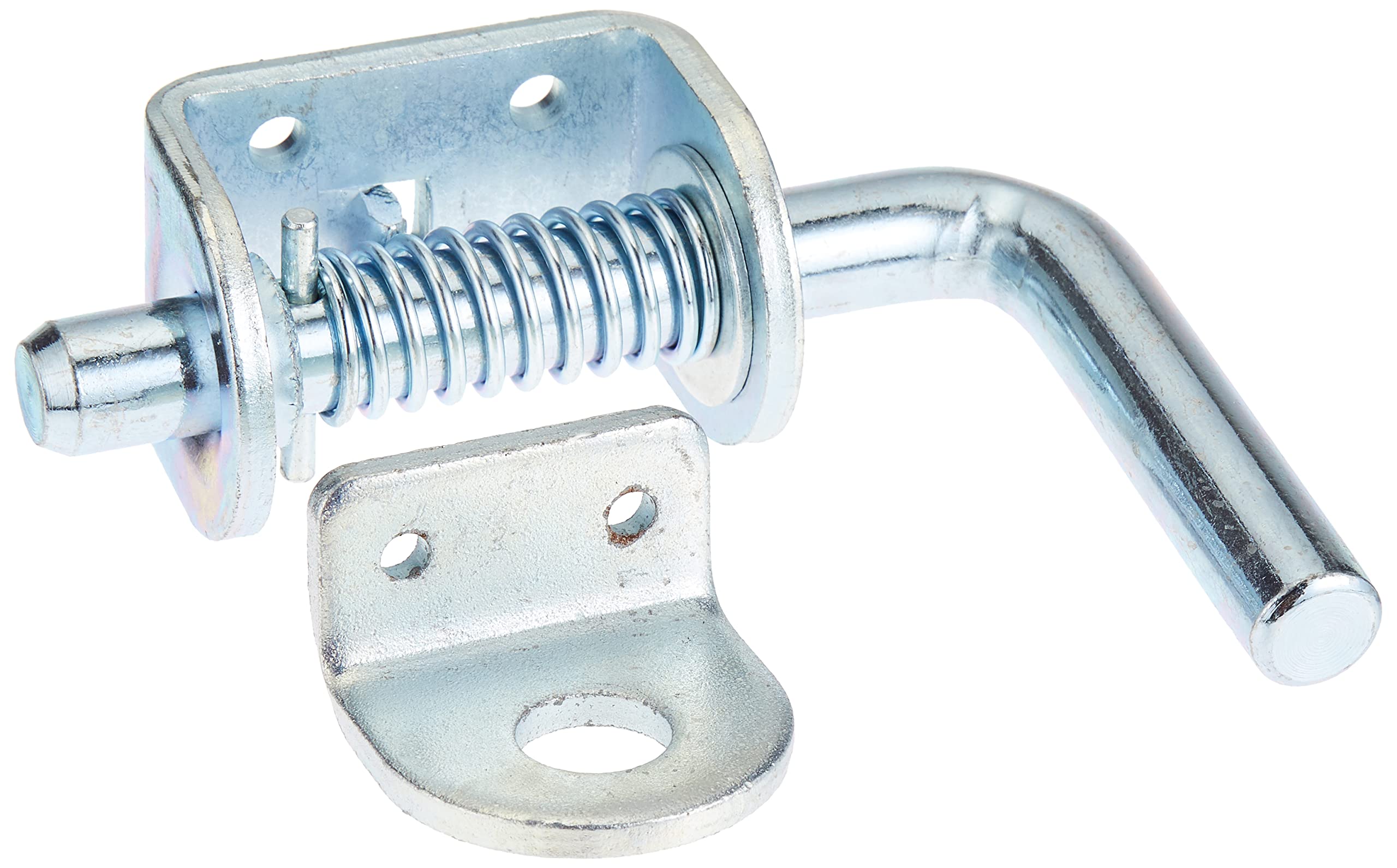

Illustrative image related to spring latch

In-depth Look: Manufacturing Processes and Quality Assurance for spring latch

What Are the Main Stages in the Manufacturing Process of Spring Latches?

The manufacturing of spring latches involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages can help B2B buyers assess potential suppliers effectively.

Material Preparation: What Materials Are Commonly Used?

The first step in the manufacturing process is material selection and preparation. Common materials for spring latches include plain steel and stainless steel, chosen for their strength, durability, and resistance to corrosion. Manufacturers typically source raw materials from certified suppliers to ensure consistency and quality. Once the material is selected, it undergoes processes such as cutting and shaping to prepare it for forming. This stage may include the use of CNC machines or laser cutting to achieve precise dimensions.

How Are Spring Latches Formed?

Forming is a crucial stage where the prepared materials are shaped into the desired latch components. Techniques such as stamping, bending, and molding are commonly employed. Stamping is particularly popular due to its efficiency in producing high volumes of parts with consistent quality. During this process, dies are used to cut and shape the metal into components like pins, springs, and latch bodies. Advanced technologies such as hydraulic presses may also be utilized to ensure that components maintain their structural integrity under stress.

What Is Involved in the Assembly of Spring Latches?

After forming, the individual components are assembled. This stage can involve manual labor or automated assembly lines, depending on the scale of production. Key techniques include inserting the spring into the latch body and attaching the pin. For heavy-duty spring latches, additional reinforcement may be added to ensure they can handle increased loads. Quality control checkpoints are established during assembly to catch defects early, such as misalignment or improper fitting.

What Finishing Techniques Are Commonly Used?

The final stage in manufacturing spring latches involves finishing processes that enhance durability and appearance. Common techniques include surface treatments such as plating, powder coating, or anodizing. For example, zinc plating is frequently applied to steel latches to prevent rusting. Each finishing process requires careful monitoring to ensure that the coating adheres properly and meets industry standards.

What Quality Assurance Processes Are In Place for Spring Latches?

Quality assurance (QA) is vital in the manufacturing of spring latches to ensure they meet safety and performance standards. B2B buyers should look for suppliers that adhere to international quality standards, such as ISO 9001, which outlines criteria for a quality management system.

How Do International Standards Impact Quality Control?

ISO 9001 is a globally recognized standard that helps organizations ensure their products meet customer and regulatory requirements consistently. Compliance with such standards indicates that the manufacturer has established a systematic approach to quality management, which can enhance trust among international buyers. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in the European market or API (American Petroleum Institute) for latches used in oil and gas applications may also apply.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control in the manufacturing of spring latches typically includes several critical checkpoints:

Illustrative image related to spring latch

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process allows for immediate detection of defects or deviations from specifications.

- Final Quality Control (FQC): A thorough inspection of the finished product is conducted to ensure it meets all design and quality standards before shipping.

Common testing methods include tensile strength tests, corrosion resistance evaluations, and dimensional inspections to ensure that each latch performs as intended.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing spring latches, B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting audits is an effective way to assess a supplier’s manufacturing capabilities and quality control processes. Buyers can request on-site visits to review the manufacturing facilities, quality management systems, and compliance with international standards. During these audits, buyers should inquire about the supplier’s quality assurance processes and any certifications they hold.

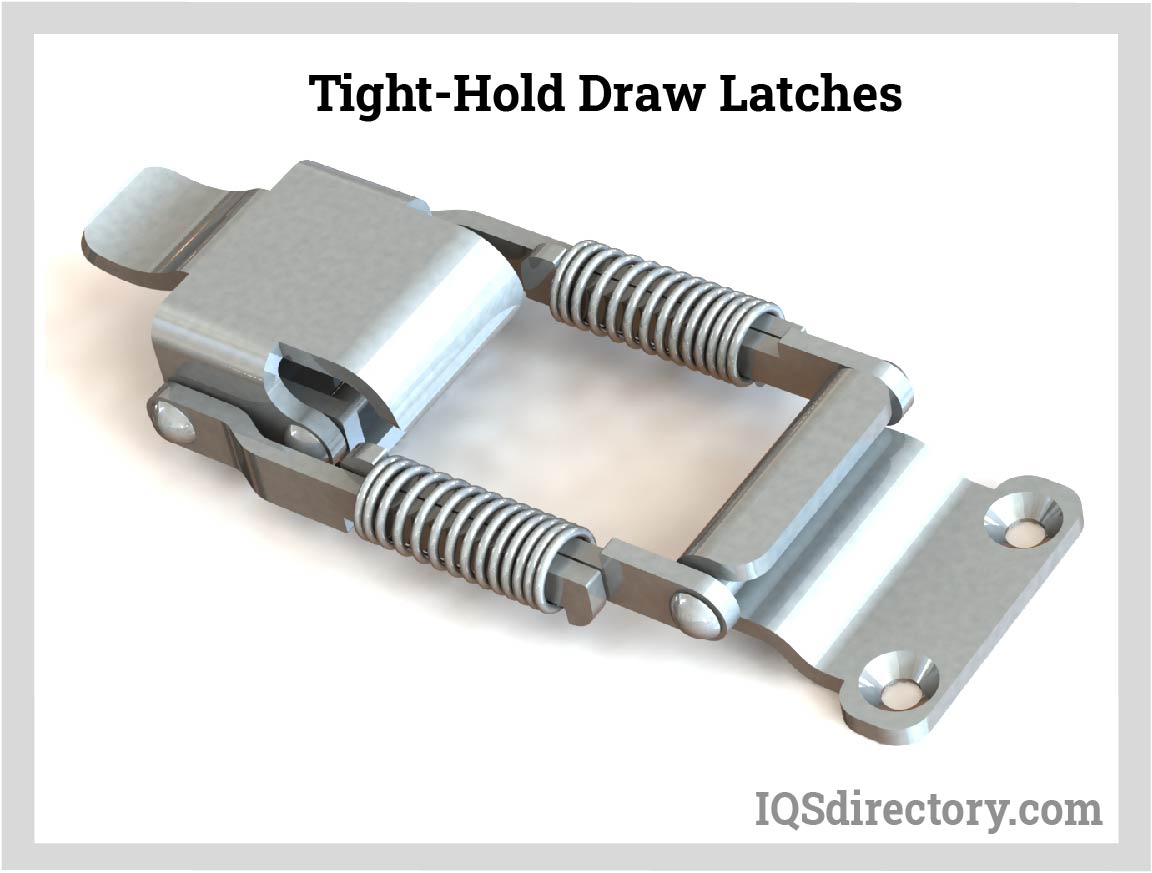

Illustrative image related to spring latch

How Can Buyers Access Quality Control Reports?

Buyers should request access to quality control reports, which detail the results of inspections and tests conducted during production. Regular reports can provide insights into the supplier’s consistency in maintaining quality standards. Additionally, third-party inspections can serve as an impartial verification of a supplier’s quality control measures.

What Are the Specific Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control that may affect their procurement processes. These include:

- Regulatory Compliance: Different regions may have varying regulations regarding product safety and environmental standards. Understanding these regulations is crucial for ensuring compliance and avoiding legal issues.

- Cultural Considerations: Communication styles and expectations regarding quality may differ across cultures. Establishing clear lines of communication and understanding local practices can facilitate smoother transactions.

- Logistics and Supply Chain Risks: International shipping can introduce risks related to quality, such as damage during transport. Buyers should work closely with suppliers to establish robust logistics plans and consider insurance options for high-value shipments.

By gaining a comprehensive understanding of the manufacturing processes and quality assurance measures for spring latches, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality and performance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spring latch’

Introduction

Sourcing spring latches requires a strategic approach to ensure you select products that meet your specific needs and quality standards. This checklist serves as a practical guide for B2B buyers, helping you navigate the procurement process effectively, from defining technical specifications to evaluating suppliers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for selecting the right spring latch. Consider factors such as the dimensions, material (plain steel vs. stainless steel), load capacity, and finish. Additionally, think about the application—whether it’s for heavy-duty industrial use or lighter applications will significantly influence your choice.

Step 2: Research Market Trends and Applications

Understanding current market trends and applications for spring latches can provide insight into the most suitable products for your needs. Investigate industries that frequently utilize these components, such as automotive, agriculture, or construction. This knowledge can help you identify innovative latch designs or materials that enhance performance and durability.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Look for suppliers with a solid reputation and extensive experience in manufacturing spring latches. Request company profiles, product catalogs, and customer references to assess their reliability and quality standards.

- Check certifications: Ensure that suppliers adhere to international quality standards, such as ISO certifications, which can indicate their commitment to excellence.

Step 4: Request Samples for Testing

Obtaining samples allows you to assess the quality and functionality of the spring latches firsthand. Testing samples ensures that the products meet your specifications and perform as expected in real-world applications. Pay attention to the latch’s ease of use, durability, and any unique features that may benefit your operation.

Step 5: Compare Pricing and Terms of Sale

Once you’ve narrowed down your options, compare pricing and terms of sale among different suppliers. Consider not just the unit price, but also the total cost of ownership, including shipping, warranties, and return policies. This comprehensive assessment will help you identify the most cost-effective solution while ensuring quality.

Illustrative image related to spring latch

Step 6: Verify Supplier Support and Customization Options

Ensure that your chosen supplier offers adequate support and customization options. Effective communication can streamline the procurement process and address any specific requirements you may have. Ask about their capabilities for custom designs or modifications to existing products, as this flexibility can be crucial for unique applications.

Step 7: Finalize Your Order and Monitor Delivery

Once you’ve selected a supplier and agreed on terms, finalize your order with a clear contract that outlines all details, including delivery timelines. Monitor the shipment to ensure it arrives on time and matches the specifications agreed upon. Establishing a reliable delivery process is vital for maintaining your project’s schedule and efficiency.

By following this checklist, B2B buyers can make informed decisions when sourcing spring latches, ensuring they select the right products for their specific applications while fostering strong supplier relationships.

Illustrative image related to spring latch

Comprehensive Cost and Pricing Analysis for spring latch Sourcing

What Are the Key Cost Components for Sourcing Spring Latches?

When sourcing spring latches, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials, such as plain or stainless steel, significantly impacts the cost. Stainless steel options tend to be more expensive due to their corrosion resistance and durability, which is particularly important for applications in harsh environments.

-

Labor: Labor costs vary based on the manufacturing location. Regions with higher labor costs may result in increased pricing, while areas with lower labor costs can offer more competitive pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Manufacturers often pass these costs onto buyers, making it essential to consider them in the total cost.

-

Tooling: Custom tooling for specialized spring latches can add to initial costs. However, investing in quality tooling can enhance production efficiency and reduce long-term costs.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. While this can add to the cost, it significantly reduces the risk of defects and failures, which can be far more costly in the long run.

-

Logistics: Shipping and handling costs are vital in the pricing equation, particularly for international buyers. Factors such as distance, shipping method, and Incoterms can influence overall logistics costs.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on their market positioning, competition, and demand.

How Do Price Influencers Affect Spring Latch Costs?

Several factors influence the pricing of spring latches, making it essential for buyers to consider them carefully:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts. Understanding the MOQ policies of suppliers can help buyers negotiate better pricing.

-

Specifications and Customization: Customized latches tailored to specific applications may incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected price increases.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO standards) can increase costs but also enhance product reliability. Buyers should weigh these factors against their specific application needs.

-

Supplier Factors: The reputation and reliability of a supplier can influence pricing. Established suppliers may charge a premium, but their quality assurance and service can justify the higher costs.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They determine the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can significantly affect the total landed cost.

What Buyer Tips Can Help Optimize Spring Latch Sourcing Costs?

To navigate the complexities of spring latch sourcing, buyers can employ several strategies:

-

Effective Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Highlighting long-term partnership potential can encourage suppliers to offer better rates.

-

Focus on Cost-Efficiency: Rather than solely chasing the lowest price, consider the Total Cost of Ownership (TCO). This includes initial purchase price, maintenance, and potential replacement costs, ensuring a comprehensive evaluation.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa and South America should be aware of currency fluctuations, import tariffs, and local market conditions that can affect pricing. Establishing relationships with local distributors can also aid in navigating these complexities.

-

Stay Informed on Market Trends: Keeping abreast of market trends and pricing fluctuations in the spring latch industry can empower buyers to make informed purchasing decisions and negotiate effectively.

Disclaimer

Prices for spring latches can vary widely based on the aforementioned factors. It is advisable for buyers to request quotes from multiple suppliers and conduct thorough due diligence to ensure they receive competitive pricing aligned with their requirements.

Alternatives Analysis: Comparing spring latch With Other Solutions

Understanding Alternatives to Spring Latches in B2B Applications

When evaluating locking mechanisms, particularly in the context of doors, gates, and equipment access, spring latches are a popular choice due to their reliability and ease of use. However, it’s crucial for B2B buyers to consider various alternatives that might better suit specific applications or operational needs. Below, we compare spring latches against two viable alternatives: bolt latches and magnetic locks. This analysis will help buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Spring Latch | Bolt Latch | Magnetic Lock |

|---|---|---|---|

| Performance | Quick release, reliable locking | High strength, secure closure | Instant locking, no physical wear |

| Cost | Moderate | Low to moderate | Higher upfront cost |

| Ease of Implementation | Simple installation | Requires more precise installation | Moderate complexity, needs power |

| Maintenance | Low maintenance | Low maintenance | Higher maintenance (power issues) |

| Best Use Case | Light to medium weight applications | Heavy doors, gates | High-security areas, glass doors |

How Do Bolt Latches Compare to Spring Latches?

Bolt latches are an alternative that provides a more robust locking solution, particularly for heavy-duty applications. They use a sliding bolt mechanism to secure doors or gates and can withstand significant force, making them suitable for industrial settings or outdoor environments where security is paramount. The main advantage of bolt latches is their strength and reliability under stress. However, they can be slower to operate compared to spring latches, which may hinder efficiency in high-traffic areas.

What Are the Advantages of Magnetic Locks Over Spring Latches?

Magnetic locks offer a different approach by using electromagnetic force to secure doors. They are particularly effective in high-security environments, such as banks and data centers, where unauthorized access must be strictly controlled. The primary benefits of magnetic locks include their ability to provide a seamless appearance and instant locking without physical wear. However, they require a constant power supply, which can lead to higher maintenance costs and potential failures during power outages. Additionally, installation can be more complex than spring latches, necessitating careful planning and electrical considerations.

Making the Right Choice: How Should B2B Buyers Decide on Locking Solutions?

When selecting the right locking mechanism, B2B buyers should consider the specific requirements of their applications. For environments where rapid access is necessary and moderate security is sufficient, spring latches may be ideal. In contrast, for heavy-duty applications or where maximum security is required, bolt latches or magnetic locks may be more appropriate. It’s essential to weigh factors such as cost, installation complexity, and maintenance needs against the operational demands of the business. Ultimately, understanding the unique characteristics of each locking solution will empower buyers to make informed decisions that enhance security and efficiency in their operations.

Essential Technical Properties and Trade Terminology for spring latch

What Are the Key Technical Properties of a Spring Latch?

When sourcing spring latches, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade

Spring latches are commonly made from materials such as plain steel, stainless steel, or zinc-plated steel. The material grade significantly affects the latch’s durability, corrosion resistance, and suitability for specific environments. For example, stainless steel is ideal for outdoor applications due to its resistance to rust, making it a preferred choice in humid regions like parts of Africa and South America. -

Load Capacity

The load capacity indicates the maximum weight a spring latch can securely hold. For B2B buyers, knowing this specification is vital when using latches for heavy doors, gates, or industrial equipment. Heavy-duty spring latches can support substantial weights, providing safety and reliability in various applications, including agricultural equipment and shipping containers. -

Pin Diameter

The pin diameter is a critical dimension that affects the latch’s compatibility with other components. A standard pin diameter can range from 0.125 inches to 0.500 inches. Buyers must ensure that the pin size aligns with the intended application, as this can impact the ease of operation and security. -

Tolerance Levels

Tolerance levels refer to the permissible limits of variation in the dimensions of the latch components. For precision applications, tighter tolerances are essential to ensure proper fit and function. Understanding tolerance is particularly important in industries like automotive and heavy machinery, where component alignment is critical. -

Finish Type

The finish type not only affects the aesthetic appeal but also the functionality and longevity of the latch. Common finishes include no finish, zinc plating, or clear trivalent chromate. A suitable finish can provide additional corrosion resistance, making it an important consideration for outdoor or industrial applications.

What Are Common Trade Terms Related to Spring Latches?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of spring latches, understanding whether a supplier is an OEM can help buyers assess the quality and reliability of the products they are sourcing. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units that a supplier is willing to sell. This is crucial for B2B buyers as it affects inventory management and cost efficiency. Understanding MOQ can help businesses avoid overcommitting to a large order that may not align with their needs. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price bids from suppliers for specific quantities of goods or services. Issuing an RFQ for spring latches can help businesses compare pricing and terms from different suppliers, ultimately aiding in the selection of the best value. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Knowing the applicable Incoterms for spring latch shipments can clarify shipping costs, delivery responsibilities, and risk management, which is especially relevant for international buyers in regions like the Middle East and Europe. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For businesses relying on timely deliveries, understanding lead times for spring latches is vital for effective project planning and inventory management.

By grasping these technical specifications and trade terms, B2B buyers can make more informed decisions, ensuring they select the right spring latches for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the spring latch Sector

What Are the Current Market Dynamics and Key Trends Influencing the Spring Latch Sector?

The global spring latch market is experiencing robust growth, driven by increasing demand across various sectors, including automotive, industrial, and construction. The expansion of e-commerce and logistics has further accelerated the need for reliable and secure fastening solutions, particularly in packaging and shipping applications. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly sourcing spring latches that not only meet functional requirements but also align with specific regional standards and preferences.

Emerging technologies are reshaping the sourcing landscape. The integration of automation and IoT in manufacturing processes is leading to the development of smart latches that enhance security and ease of use. Additionally, online platforms are facilitating direct access to suppliers, allowing buyers to compare products and prices efficiently. As a result, companies are prioritizing partnerships with manufacturers that offer customization options, rapid prototyping, and fast shipping capabilities.

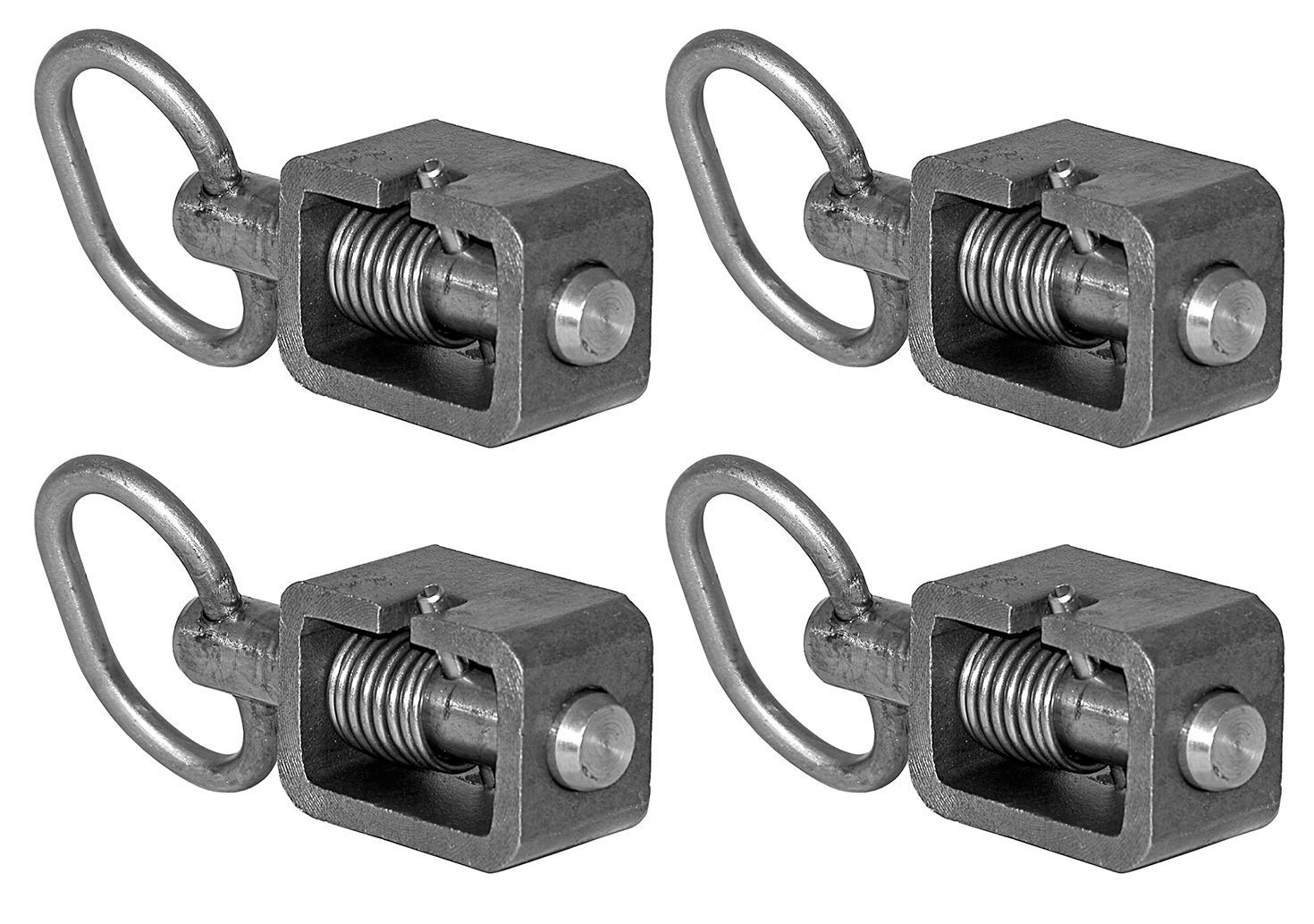

Illustrative image related to spring latch

Sourcing trends indicate a shift towards heavier-duty and versatile spring latches capable of withstanding demanding conditions. For instance, the popularity of heavy-duty latches is increasing, particularly in industries like construction and agriculture, where durability and reliability are paramount. Furthermore, as international trade continues to expand, ensuring compliance with regional regulations and standards is becoming increasingly important for B2B buyers.

How Does Sustainability and Ethical Sourcing Impact the Spring Latch Market?

Sustainability is no longer a peripheral concern for B2B buyers in the spring latch sector; it is a central consideration in sourcing decisions. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting companies to seek suppliers committed to sustainable practices. This includes the use of recycled materials and eco-friendly coatings, which are becoming increasingly prevalent in the production of spring latches.

Ethical sourcing is also gaining traction, with buyers prioritizing suppliers that uphold fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade standards are becoming essential criteria for selecting partners. International buyers, particularly in regions like Europe and North America, are scrutinizing their supply chains to ensure that their products align with sustainability goals, reflecting a broader shift toward responsible business practices.

Moreover, the demand for ‘green’ materials is influencing product development. Manufacturers are responding by offering spring latches made from recyclable metals and sustainable composites, addressing both performance and environmental concerns. This trend not only meets consumer expectations but also helps companies mitigate risks associated with regulatory compliance and reputational damage.

What Is the Historical Context of Spring Latch Development for B2B Buyers?

The evolution of spring latches dates back several centuries, initially designed for simplicity and reliability in locking mechanisms. Over time, advancements in materials science and manufacturing processes have transformed these latches into robust components suitable for a wide array of applications. Early versions were predominantly crafted from wood and simple metal alloys, but modern iterations utilize high-strength stainless steel and other durable materials, enhancing their performance and lifespan.

Illustrative image related to spring latch

The introduction of automation in manufacturing has significantly impacted the production of spring latches, allowing for greater precision and customization. This evolution has made it possible for B2B buyers to access a diverse range of products tailored to specific needs, from lightweight options for consumer goods to heavy-duty variants for industrial applications. As the market continues to evolve, understanding this historical context can help buyers make informed decisions about the best sourcing strategies and product choices for their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of spring latch

-

How do I solve compatibility issues with spring latches in my application?

To address compatibility issues, first, ensure that the spring latch dimensions (length, width, and pin diameter) match the specifications of your application. Consider the material requirements as well; stainless steel offers corrosion resistance, while plain steel is more cost-effective but less durable. If you encounter specific challenges, consult with your supplier for customization options. They can provide tailored solutions to meet unique application needs, including adjustments in design or specifications. -

What is the best type of spring latch for outdoor applications?

For outdoor applications, stainless steel spring latches are recommended due to their superior resistance to rust and corrosion compared to plain steel. Additionally, consider heavy-duty options that can withstand extreme weather conditions and heavy usage. Ensure the latch has a secure locking mechanism to prevent accidental openings. Discuss your specific environmental conditions with your supplier to select the most suitable latch for your application. -

How can I verify the quality of spring latches from international suppliers?

To ensure the quality of spring latches, request certifications such as ISO 9001 for quality management systems. Ask for samples to conduct physical inspections and tests for durability and functionality. Furthermore, review customer feedback and case studies to gauge supplier reliability. Establishing a clear communication channel with the supplier will also help clarify any quality concerns before placing a bulk order. -

What are the minimum order quantities (MOQs) for spring latches?

Minimum order quantities can vary significantly by supplier and product type. Typically, MOQs for spring latches range from 100 to 1,000 units, depending on customization and material specifications. Always confirm the MOQ before finalizing your order to avoid unexpected costs. If your needs are lower than the MOQ, discuss potential options with the supplier, such as combining orders with other buyers or sourcing standard products. -

What payment terms should I expect when sourcing spring latches internationally?

Payment terms can differ based on the supplier and the buyer’s negotiation leverage. Common practices include partial upfront payments (20-50%) with the balance due upon shipment or delivery. Some suppliers may offer net 30 or net 60 terms for established relationships. Always clarify payment methods accepted (e.g., bank transfers, letters of credit) and ensure that terms are documented in the purchase agreement to avoid misunderstandings. -

How can I customize spring latches for my specific needs?

Customization of spring latches typically involves specifying dimensions, materials, finishes, and locking mechanisms. Many suppliers offer tailored solutions to meet unique application requirements. To begin the customization process, provide detailed specifications and any necessary drawings or CAD files. Collaborate closely with your supplier to ensure that the final product meets your exact needs and complies with industry standards. -

What logistics considerations should I keep in mind when importing spring latches?

When importing spring latches, consider shipping methods, costs, and delivery times. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but takes longer. Ensure that your supplier provides all necessary shipping documents, including commercial invoices and packing lists. Be aware of customs duties and tariffs applicable in your region, as these can impact overall costs. Coordination with a freight forwarder can streamline the logistics process. -

What industries commonly use spring latches, and what are their applications?

Spring latches are widely used across various industries, including automotive, marine, agriculture, and manufacturing. Common applications include securing doors on trailers, shipping containers, agricultural equipment, and industrial machinery. Their versatility makes them suitable for both light and heavy-duty applications. When sourcing, consider the specific requirements of your industry to select the appropriate latch type that meets safety and performance standards.

Top 6 Spring Latch Manufacturers & Suppliers List

1. Guden – Spring Latches

Domain: guden.com

Introduction: Guden offers a variety of Spring Latches ranging from .875 inches to 3.00 inches long, available in plain steel and stainless steel. All parts are customizable and in stock for same day shipments. Spring latches feature a spring-loaded retractable pin with a bent end for easy operation, allowing for the quick release of doors, lids, covers, or gates. Guden’s spring latches are also referred to as …

2. Maxum Hardware – Latches and Fasteners

Domain: maxumhardware.com

Registered: 2007 (18 years)

Introduction: This company, Maxum Hardware – Latches and Fasteners, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. McMaster-Carr – Key Product Details for Spring Latches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: Key product details for Spring Latches from McMaster-Carr include: 1. Product Categories: Push-to-Close Latches (322 products), Slide-Bolt Latches (20 products), Draw Latches (119 products), Rotary Latches (37 products), Cam Latches (80 products), Multipoint Latches (19 products), Swinging Latches (3 products), Cabinet Locking Bars (5 products), Drawer and Cabinet Deadbolt Locks (4 products), Hing…

4. Spring Creek Products – Vinyl End Cap

Domain: springcreekproducts.com

Registered: 2008 (17 years)

Introduction: This company, Spring Creek Products – Vinyl End Cap, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. IQS Directory – Spring Latches

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Spring latches are mechanical devices designed to securely fasten two parts, preventing unintentional movement or opening. They operate using spring compression and are resistant to vibrations. Key types include deadbolts and slam latches. Deadbolts feature solid rods, while slam latches use an angled load bolt. Common materials include brass, aluminum, bronze, stainless steel, and iron, each offe…

6. Buyers Products – Heavy Duty Spring Latch

Domain: buyersproducts.com

Registered: 1997 (28 years)

Introduction: This company, Buyers Products – Heavy Duty Spring Latch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for spring latch

What Are the Key Insights for Sourcing Spring Latches?

In summary, strategic sourcing of spring latches is essential for businesses aiming to enhance operational efficiency and ensure product reliability. By understanding the diverse applications and materials available, such as stainless steel and plain steel, buyers can select the optimal latch for their specific needs. Additionally, the availability of customization options allows for tailored solutions that meet unique operational requirements, reinforcing the importance of working closely with suppliers.

How Can International Buyers Leverage Strategic Sourcing?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, embracing strategic sourcing practices can lead to significant cost savings and improved supply chain resilience. It is crucial to assess suppliers not just on price, but also on their capacity for innovation, quality assurance, and delivery reliability.

Illustrative image related to spring latch

What’s Next for Your Sourcing Strategy?

As you move forward, consider establishing long-term partnerships with reputable suppliers who offer comprehensive support and customization. By doing so, you position your business to adapt to changing market demands and technological advancements. Begin your strategic sourcing journey today by engaging with suppliers that can provide the quality and reliability your operations require.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to spring latch