Specialty Liquid Gas Filter Materials Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for specialty liquid gas filter materials

In an increasingly interconnected world, sourcing specialty liquid gas filter materials poses significant challenges for international B2B buyers. The complexity of selecting the right filters, tailored to specific applications and stringent industry standards, can be daunting. This guide serves as a comprehensive resource, addressing critical aspects such as the diverse types of filter materials, their applications across various industries, and strategies for supplier vetting. It also delves into cost considerations, enabling buyers to make informed decisions that align with their operational requirements and budget constraints.

For businesses operating in regions like Africa, South America, the Middle East, and Europe—especially in key markets such as Germany and Brazil—understanding the nuances of specialty liquid gas filter materials is essential. The guide empowers decision-makers by offering insights into the latest advancements in filtration technology, helping them navigate the global market with confidence. By equipping buyers with actionable knowledge about sourcing, compliance, and quality assurance, this resource aims to streamline the procurement process and enhance operational efficiency. Whether you are seeking high-purity filters for semiconductor manufacturing or robust solutions for oil and gas applications, this guide will help you identify the right products and partners to meet your unique needs.

Understanding specialty liquid gas filter materials Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pleated Filters | Increased filtration area, customizable end caps | Air intake systems, HVAC applications | Pros: High efficiency; Cons: Limited to specific configurations. |

| Resin-Treated Felt Filters | Enhanced strength and porosity, chemical resistance | Chemical processing, oil & gas industries | Pros: Versatile; Cons: May require custom orders. |

| High Purity Metal Filters | All-metal construction, ultra-high purity filtration capabilities | Semiconductor manufacturing, pharmaceuticals | Pros: Exceptional purity; Cons: Higher initial costs. |

| Specialty Process Filters | Designed for extreme conditions, tailored geometries | Aerospace, marine, and subsea applications | Pros: Custom solutions; Cons: Longer lead times. |

| Porous Ceramics | Dual-density designs, varying pore sizes | Water treatment, gas purification | Pros: High durability; Cons: May be less flexible in applications. |

What Are Pleated Filters and Their Key Features?

Pleated filters are designed to maximize the filtration area within a compact space, making them ideal for applications like air intake systems in small engines and HVAC systems. The pleating increases surface area, allowing for higher dirt-holding capacity and longer service life. When purchasing pleated filters, buyers should consider the specific end cap requirements and whether they need custom configurations to fit existing systems.

How Do Resin-Treated Felt Filters Enhance Performance?

Resin-treated felt filters offer enhanced strength and porosity, making them suitable for filtering various chemicals and gases. The resin treatment provides a level of chemical resistance that is essential in industries like oil and gas, where exposure to harsh substances is common. Buyers should evaluate the specific chemical compatibility and service temperature ranges when selecting these filters, as customization may be necessary for unique applications.

Why Choose High Purity Metal Filters for Critical Applications?

High purity metal filters are constructed from materials like nickel and stainless steel, ensuring they meet stringent purity requirements in sensitive industries, such as semiconductor manufacturing and pharmaceuticals. Their all-metal design minimizes contamination risks, making them indispensable for processes where even minor impurities can compromise product quality. Buyers should assess the filtration efficiency and compatibility with their specific gas or fluid systems to ensure optimal performance.

What Advantages Do Specialty Process Filters Offer?

Specialty process filters are engineered to perform under extreme conditions, accommodating high temperatures, corrosive environments, and high-viscosity fluids. These filters are commonly used in aerospace, marine, and subsea applications, where reliability is paramount. When considering specialty filters, buyers should focus on the specific performance requirements and potential lead times for custom designs, as these can impact project timelines.

How Do Porous Ceramics Benefit Filtration Processes?

Porous ceramics provide a robust solution for filtration needs, particularly in water treatment and gas purification applications. With dual-density designs and customizable pore sizes, they offer high durability and efficiency in capturing contaminants. Buyers should consider the specific application requirements, including flow rates and contaminant types, to determine the most suitable porous ceramic filter for their needs.

Key Industrial Applications of specialty liquid gas filter materials

| Industry/Sector | Specific Application of specialty liquid gas filter materials | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Semiconductor Manufacturing | Ultra-high purity gas filtration for process gases | Ensures contamination-free environment, enhancing yield and quality | Customization for specific gas types, compliance with industry standards |

| Oil & Gas Exploration | Filtration of high-viscosity fluids and gases | Protects equipment from corrosion and prolongs service life | Durability under extreme conditions, compatibility with various fluids |

| Aerospace | Specialty filters for liquid oxygen and hydrogen | Critical for safety and performance in high-stakes environments | Certification for aerospace standards, ability to withstand high pressures |

| Water Treatment | Removal of contaminants from water sources | Improves water quality and compliance with health regulations | Material compatibility with various contaminants, maintenance ease |

| Pharmaceutical Production | Filtration of solvents and active ingredients | Guarantees product safety and efficacy, adhering to regulatory requirements | High purity standards, validation of filtration efficiency |

How Are Specialty Liquid Gas Filter Materials Used in Semiconductor Manufacturing?

In semiconductor manufacturing, specialty liquid gas filter materials are essential for ultra-high purity filtration of process gases. These filters prevent contamination from even the smallest particles, which is critical in maintaining product quality and yield. International buyers must ensure that their suppliers offer customization options to meet specific gas types and comply with stringent industry standards, particularly in regions like Europe and the Middle East where regulations are strict.

What Role Do Specialty Filters Play in Oil & Gas Exploration?

In the oil and gas sector, specialty filters are used to manage high-viscosity fluids and gases that can cause significant damage to equipment. These filters protect against corrosion and extend the lifespan of machinery, leading to cost savings and enhanced operational efficiency. Buyers from South America and Africa should consider the durability of materials under extreme conditions and their compatibility with a wide range of fluids to ensure reliable performance in diverse environments.

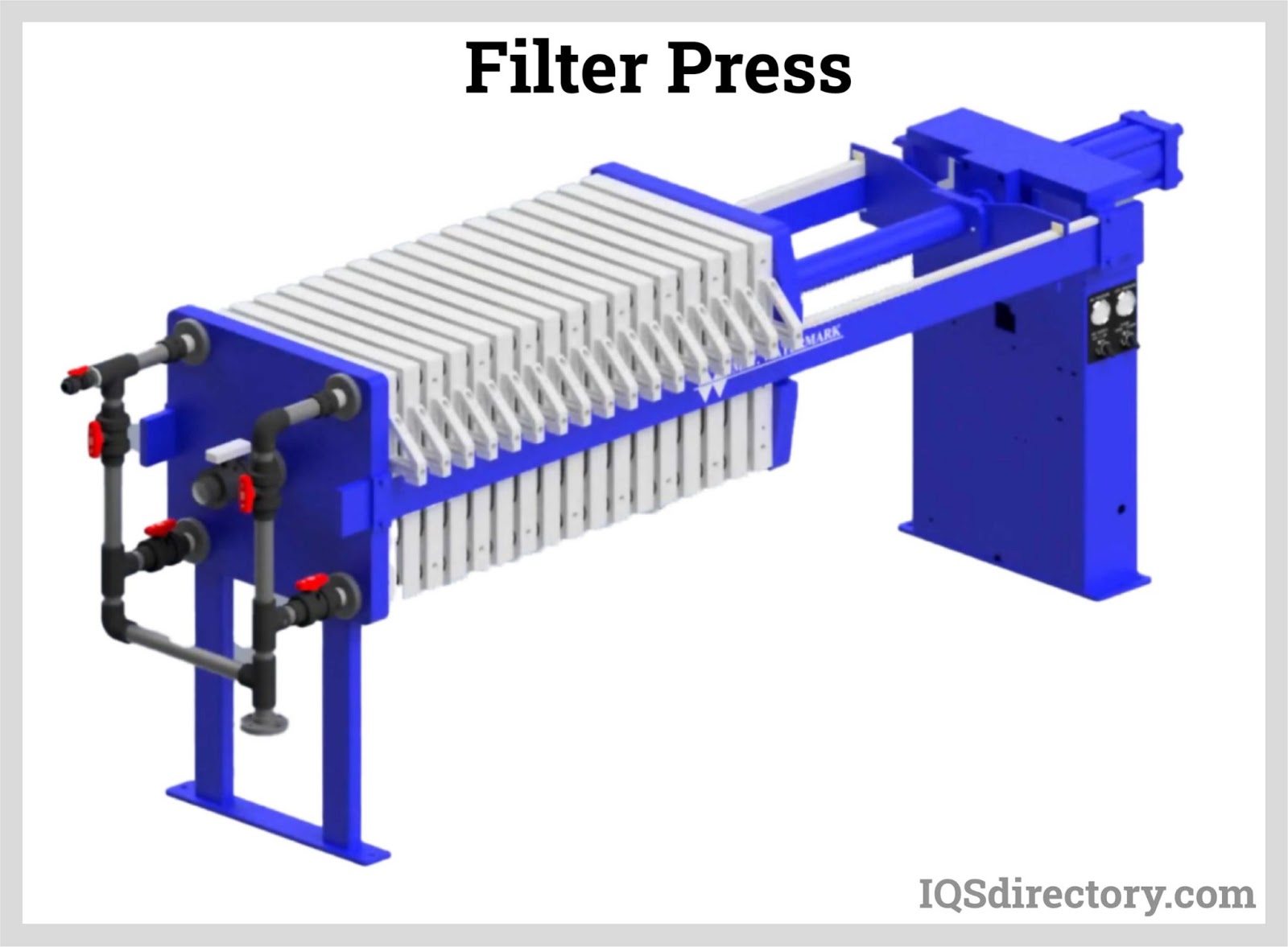

Illustrative image related to specialty liquid gas filter materials

Why Are Specialty Filters Critical in Aerospace Applications?

Aerospace applications require specialty filters for handling liquid oxygen and hydrogen, which are critical for propulsion systems. These filters must meet rigorous safety and performance standards, as any failure can lead to catastrophic consequences. B2B buyers in this sector, particularly in Europe, should prioritize suppliers that offer certified products and can demonstrate the ability to withstand high pressures and extreme temperatures, ensuring reliability in challenging environments.

How Do Specialty Liquid Gas Filters Improve Water Treatment Processes?

In water treatment, specialty liquid gas filter materials are utilized to remove contaminants from various water sources, ensuring compliance with health regulations. These filters enhance water quality, making them essential for municipalities and industries that rely on clean water. Buyers should focus on the material compatibility with different contaminants and ease of maintenance to optimize operational efficiency, particularly in regions like Africa where water quality is a critical issue.

What Benefits Do Specialty Filters Provide in Pharmaceutical Production?

Specialty filters in pharmaceutical production are crucial for filtering solvents and active ingredients, ensuring that products are safe and effective. Compliance with high purity standards is mandatory, as any contamination can result in serious health risks and regulatory penalties. International buyers, especially from Brazil and other emerging markets, should seek suppliers that can validate filtration efficiency and meet specific regulatory requirements to ensure product integrity and safety.

3 Common User Pain Points for ‘specialty liquid gas filter materials’ & Their Solutions

Scenario 1: Navigating Quality Standards in Specialty Liquid Gas Filtration

The Problem: B2B buyers, particularly those in highly regulated industries such as pharmaceuticals and semiconductor manufacturing, often face challenges ensuring that the specialty liquid gas filter materials they procure meet stringent quality and purity standards. This can lead to costly delays if filters do not perform as expected, resulting in production downtime and potential compliance issues. The pressure to maintain operational efficiency while adhering to these regulations can be overwhelming.

The Solution: To address this challenge, buyers should prioritize sourcing from manufacturers with established certifications, such as ISO 9001 or AS9100, which indicate a commitment to quality management standards. Additionally, it is crucial to request detailed product specifications, including data sheets that outline filter material composition, performance metrics, and compliance with industry standards. Collaborating closely with the supplier’s engineering team can also yield tailored solutions that meet specific requirements. Engaging in regular quality audits and establishing a robust feedback loop with suppliers can help maintain high standards over time, ensuring that the filters perform reliably in critical applications.

Scenario 2: Managing High-Volume Demand with Custom Solutions

The Problem: A sudden spike in demand can catch B2B buyers off guard, especially in industries such as oil and gas or food processing, where specialty liquid gas filters are critical for maintaining production efficiency. Many manufacturers do not have the capacity for rapid scale-up, leading to delays that can negatively impact supply chains and customer satisfaction. This situation is exacerbated when standard filter solutions are not suitable for the unique requirements of the application.

The Solution: Buyers should develop strong relationships with specialty filter manufacturers who offer custom solutions and can scale production quickly. Engaging in advance planning and forecasting can help identify potential demand surges, allowing buyers to negotiate flexible contracts with suppliers. It is also beneficial to discuss the potential for inventory management solutions, where suppliers can hold safety stock of critical filter materials to ensure quick turnaround times. Additionally, investing in modular filter designs that can be adapted to various applications can streamline the procurement process and enhance responsiveness to market fluctuations.

Scenario 3: Overcoming Performance Issues with Filter Efficiency

The Problem: Many B2B buyers encounter performance issues with specialty liquid gas filters that do not meet efficiency expectations, leading to increased operational costs and compromised product quality. Filters may clog more quickly than anticipated or fail to remove contaminants effectively, which can result in equipment malfunctions and increased maintenance costs. This challenge is particularly pronounced in industries dealing with high-viscosity fluids or corrosive gases.

The Solution: To mitigate these performance issues, buyers should conduct thorough evaluations of filter specifications before purchase. This includes assessing the filter’s porosity, material compatibility, and operational limits, such as temperature and pressure ratings. Engaging in a pilot testing phase can provide valuable insights into how the filters perform under actual working conditions. Collaborating with filter manufacturers to develop bespoke solutions tailored to specific applications can also enhance efficiency. Furthermore, implementing a maintenance schedule that includes regular filter inspections and replacements can prevent unexpected downtime and ensure optimal performance over the filter’s lifespan.

Strategic Material Selection Guide for specialty liquid gas filter materials

What Are the Key Properties of Common Materials Used in Specialty Liquid Gas Filters?

When selecting materials for specialty liquid gas filters, it is essential to consider their properties, performance characteristics, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of these filters, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel (316L)

Key Properties: Stainless steel 316L is known for its excellent corrosion resistance, particularly against chlorides, and can withstand temperatures up to 1,600°F (870°C). It also exhibits good mechanical strength and can handle high pressures.

Pros & Cons: The durability and strength of 316L make it ideal for harsh environments, including chemical processing and oil and gas applications. However, the cost of stainless steel is relatively high compared to other materials, and manufacturing complexities can arise during welding and fabrication.

Impact on Application: This material is particularly suitable for applications involving aggressive chemicals and high-temperature gases, ensuring longevity and reliability.

Illustrative image related to specialty liquid gas filter materials

Considerations for International Buyers: Compliance with ASTM standards is crucial, especially for buyers in Europe and the Middle East. Buyers should also be aware of local regulations regarding material sourcing and environmental impact.

2. Polypropylene

Key Properties: Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight nature. It can typically withstand temperatures up to 200°F (93°C) and is resistant to many acids and bases.

Pros & Cons: The low cost and ease of manufacturing make polypropylene a popular choice for many applications. However, its temperature and pressure ratings are lower than metals, which may limit its use in high-stress environments.

Impact on Application: This material is ideal for applications involving non-aggressive liquids and gases, such as water filtration and certain food processing scenarios.

Considerations for International Buyers: Buyers should ensure compliance with food safety standards (e.g., FDA regulations) and local environmental standards, particularly in regions like Africa and South America, where regulations may vary significantly.

3. Teflon (PTFE)

Key Properties: Teflon, or PTFE, is renowned for its exceptional chemical resistance and can operate effectively in temperatures ranging from -450°F to 500°F (-268°C to 260°C). It is also non-stick, which aids in preventing clogging.

Pros & Cons: The chemical inertness and high-temperature resistance make Teflon ideal for aggressive chemical applications. However, it can be more expensive than other materials and may require specialized manufacturing techniques.

Impact on Application: Teflon is particularly useful in applications involving corrosive gases and liquids, such as in the pharmaceutical and semiconductor industries.

Considerations for International Buyers: Buyers should verify compliance with international standards for chemical handling and safety, especially in regions with stringent regulations like Germany.

4. Resin-Treated Felt

Key Properties: Resin-treated felt filters offer excellent porosity control and can withstand temperatures from -40°F to 250°F (-40°C to 121°C). The resin treatment enhances durability and chemical resistance.

Pros & Cons: The ability to customize porosity and thickness makes this material versatile for various applications. However, the manufacturing process can be complex, impacting lead times.

Impact on Application: This material is suitable for applications requiring high filtration efficiency, such as in HVAC systems and industrial liquid filtration.

Considerations for International Buyers: Buyers should look for manufacturers that comply with local standards (e.g., DIN in Germany) and ensure that the materials meet specific industry requirements.

Summary Table of Material Selection for Specialty Liquid Gas Filters

| Material | Typical Use Case for specialty liquid gas filter materials | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (316L) | Chemical processing, oil and gas | Excellent corrosion resistance and durability | Higher cost and manufacturing complexity | High |

| Polypropylene | Water filtration, food processing | Low cost and easy to manufacture | Limited temperature and pressure ratings | Low |

| Teflon (PTFE) | Pharmaceutical, semiconductor applications | Exceptional chemical resistance | Higher cost and specialized manufacturing needed | High |

| Resin-Treated Felt | HVAC systems, industrial liquid filtration | Customizable porosity and thickness | Complex manufacturing process | Medium |

This strategic material selection guide provides essential insights for B2B buyers seeking to optimize their filter material choices based on performance, application requirements, and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for specialty liquid gas filter materials

What Are the Main Stages of Manufacturing Specialty Liquid Gas Filter Materials?

The manufacturing process for specialty liquid gas filter materials involves several critical stages, ensuring that the final product meets stringent industry standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step involves sourcing high-quality raw materials suitable for filtration applications. Common materials include resin-treated felt, metal alloys, and high-purity ceramics. Suppliers often conduct rigorous assessments of the raw materials, ensuring they meet the required specifications for porosity, chemical resistance, and temperature tolerance. This stage is crucial, as the material’s characteristics significantly influence the filter’s performance.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. For instance, pleated filters are created by folding the filter media in a manner that maximizes the filtration area while minimizing space. Techniques such as injection molding are employed for creating filter ends and other components, ensuring that the filters fit perfectly into their designated applications. Advanced methods like 3D printing may also be utilized for custom components, allowing for innovative designs that meet specific customer requirements.

Assembly Process

The assembly stage involves integrating different components of the filter system. This may include attaching gaskets, end caps, and other necessary fittings. Precision is critical during this stage to ensure that all parts fit seamlessly, preventing leaks and ensuring optimal performance. Automated assembly lines are often employed, especially for high-volume production, to enhance efficiency and consistency.

Finishing Touches

The final stage of manufacturing involves finishing processes that may include cleaning, surface treatment, and packaging. These steps ensure that the filters are free from contaminants and ready for deployment. For specialty applications, additional treatments may be applied to enhance durability and performance, such as passivation for metal components or heat treatment for high-temperature applications.

How Is Quality Assurance Integrated Into the Manufacturing Process?

Quality assurance (QA) is vital for ensuring that specialty liquid gas filters meet both international standards and customer expectations. This process is typically integrated into every stage of manufacturing.

What International Standards Should B2B Buyers Look For?

Many manufacturers adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with these standards indicates that the manufacturer has established processes for continuous improvement and customer satisfaction. In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for oil and gas applications may also be crucial depending on the filter’s intended use.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to monitor quality consistently. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the required specifications before they enter production.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process and ensure that each stage adheres to quality standards. This can include checks on dimensions, filtration efficiency, and material integrity.

- Final Quality Control (FQC): Once production is complete, the finished filters undergo comprehensive testing to verify their performance against established criteria. This may include flow rate tests, pressure tests, and filtration efficiency assessments.

What Testing Methods Are Commonly Used in Quality Assurance?

A variety of testing methods are employed to ensure the quality and reliability of specialty liquid gas filters:

- Flow Rate Testing: Measures the filter’s ability to allow fluid or gas to pass through at specified pressures, ensuring it meets performance requirements.

- Filtration Efficiency Tests: Determine the filter’s capability to remove particles of certain sizes, which is crucial for applications requiring high purity.

- Pressure Testing: Assesses the filter’s structural integrity under varying pressure conditions, ensuring it can withstand operational demands.

- Material Compatibility Testing: Evaluates how the filter materials interact with different gases or liquids, confirming they can handle the intended applications without degradation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are actionable steps buyers can take:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This is an excellent way to gauge a supplier’s commitment to quality.

- Requesting Quality Reports: Buyers should ask suppliers for detailed quality control reports, including results from IQC, IPQC, and FQC stages. This documentation can provide insights into the supplier’s reliability and adherence to standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and quality assurance measures in place. This is particularly useful for buyers in regions where local inspections may not be feasible.

What Quality Control Nuances Should International Buyers Consider?

When sourcing specialty liquid gas filters globally, buyers should be aware of certain quality control nuances:

- Regulatory Compliance: Different regions may have varying regulatory requirements. Understanding these can help buyers ensure that the filters meet local laws and industry standards.

- Cultural Differences in Quality Expectations: Buyers should consider that quality perceptions may differ across cultures. Clear communication about specifications and standards is vital to align expectations.

- Logistical Challenges: International shipping can introduce risks to product integrity. Buyers should ensure that suppliers have robust packaging and handling procedures to minimize damage during transit.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions and secure reliable specialty liquid gas filter materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘specialty liquid gas filter materials’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring specialty liquid gas filter materials effectively. As the demand for high-quality filtration solutions grows across various industries, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the sourcing process is critical. This checklist outlines essential steps to ensure that you find the right materials and suppliers to meet your specific filtration needs.

Step 1: Define Your Technical Specifications

Clearly outline the specific technical requirements for your filtration needs, including material types, porosity levels, and operational conditions. This step is crucial because it helps you communicate your needs effectively to potential suppliers and ensures that the filters you source will perform optimally in your application.

- Considerations: Identify the types of contaminants you need to filter out, as well as the operating temperatures and pressures involved in your processes.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers specializing in specialty liquid gas filter materials. This step is vital to ensure that you have access to a range of options that can meet your specifications.

- Sources: Utilize industry directories, trade shows, and online platforms to gather supplier information. Look for manufacturers with a proven track record in your sector.

Step 3: Evaluate Supplier Certifications

Verify the certifications of potential suppliers, such as ISO, AS9100, or industry-specific standards. This is essential to ensure that the suppliers adhere to quality management systems that guarantee product reliability and compliance with international standards.

- Key Certifications: Check for certifications relevant to your industry, as they reflect a supplier’s commitment to quality and safety.

Step 4: Request Product Samples

Before making a bulk order, request samples of the specialty liquid gas filter materials. Testing samples in your operational environment allows you to assess their performance and compatibility.

- Evaluation Criteria: Pay attention to filtration efficiency, durability, and any chemical compatibility issues that may arise during use.

Step 5: Inquire About Customization Capabilities

Discuss with suppliers their ability to customize products to meet your specific requirements. Customization can be crucial for specialized applications, especially in industries like semiconductor manufacturing or oil and gas.

- Customization Options: Ask about their design capabilities, material choices, and how they handle unique geometries or performance specifications.

Step 6: Review Lead Times and Delivery Options

Understand the lead times for production and delivery from your shortlisted suppliers. This information is critical for planning your procurement cycle and ensuring that you do not face delays in your operations.

- Logistics Considerations: Evaluate their shipping capabilities and any potential customs implications if sourcing internationally.

Step 7: Establish Clear Communication Channels

Ensure that there are clear lines of communication with your chosen suppliers. Effective communication helps to address any issues quickly and ensures that all parties are aligned throughout the sourcing process.

- Best Practices: Set up regular check-ins and establish points of contact for quick resolution of queries and updates on order statuses.

By following this checklist, B2B buyers can streamline their sourcing process for specialty liquid gas filter materials, ensuring they find the right products to meet their operational needs efficiently.

Comprehensive Cost and Pricing Analysis for specialty liquid gas filter materials Sourcing

What Are the Key Cost Components for Specialty Liquid Gas Filter Materials?

When sourcing specialty liquid gas filter materials, understanding the cost structure is essential. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. Specialty filters often use advanced materials like nickel or 316L stainless steel, which are more expensive than standard options but necessary for high-purity applications.

-

Labor: Skilled labor is required for the manufacturing and assembly of filters, especially for custom solutions. Labor costs may vary based on the complexity of the filters and the location of the manufacturing facility.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and equipment depreciation. Facilities that focus on high-purity or specialized filters may have higher overhead due to the need for advanced machinery and cleanroom environments.

-

Tooling: Custom tooling can be a significant upfront cost, particularly for unique filter geometries or specifications. Buyers should consider the amortization of these costs over the expected production volume.

-

Quality Control (QC): Stringent quality assurance processes are essential, especially in industries like semiconductor manufacturing where contamination can have dire consequences. QC processes may involve rigorous testing and certification, adding to the overall cost.

-

Logistics: Shipping costs can vary widely based on the destination and the size of the order. International shipping may also involve customs duties and tariffs that affect the total landed cost.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. This margin can vary based on market conditions, competition, and the supplier’s positioning.

How Do Price Influencers Affect the Cost of Specialty Liquid Gas Filters?

Several factors can influence the pricing of specialty liquid gas filters:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for higher volumes, making it advantageous for buyers to consolidate orders when possible.

-

Specifications and Customization: Custom filters tailored to specific applications will incur higher costs due to the additional engineering and manufacturing processes involved. Buyers should clearly define their needs to avoid unnecessary customization that can inflate prices.

-

Material Quality and Certifications: Filters designed for high-purity applications require certified materials, which can increase costs. Buyers should verify certifications to ensure compliance with industry standards.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers with a proven track record may charge a premium but offer better quality assurance and customer support.

-

Incoterms: The terms of trade can impact pricing significantly. Understanding Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can help buyers calculate total costs accurately, including shipping and insurance.

What Are the Best Negotiation Strategies for B2B Buyers in Specialty Liquid Gas Filters?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and terms:

-

Research and Benchmarking: Before negotiations, conduct market research to understand prevailing prices and trends. This knowledge will empower you to negotiate more effectively.

-

Total Cost of Ownership (TCO): Emphasize the importance of TCO rather than just upfront costs. Consider factors such as durability, maintenance, and efficiency, which can save costs over the product lifecycle.

-

Leverage Volume: If possible, consolidate orders to increase volume, thereby securing better pricing. Suppliers are often more willing to negotiate on larger contracts.

-

Build Relationships: Establishing strong relationships with suppliers can lead to more favorable terms and potential long-term partnerships. Trust can be a crucial factor in negotiations.

-

Be Aware of Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and local market conditions that may affect pricing. Incorporating these factors into your negotiation strategy can yield better outcomes.

Disclaimer on Indicative Prices

Prices for specialty liquid gas filters can vary widely based on numerous factors outlined above. It is advisable for buyers to request detailed quotes from suppliers, taking into account their specific requirements and desired specifications.

Alternatives Analysis: Comparing specialty liquid gas filter materials With Other Solutions

Understanding Alternatives for Specialty Liquid Gas Filter Materials

In the quest for efficient filtration solutions, it’s essential to evaluate various alternatives to specialty liquid gas filter materials. This analysis provides a comparison with other viable solutions, helping B2B buyers make informed decisions tailored to their specific industry needs.

Comparison Table

| Comparison Aspect | Specialty Liquid Gas Filter Materials | Membrane Filtration Systems | Cyclone Separators |

|---|---|---|---|

| Performance | High filtration efficiency, tailored porosity | Excellent for small particles, but less effective for larger solids | Good for larger particulate matter, but lower efficiency for fine particles |

| Cost | Moderate initial investment, custom solutions may increase price | Higher upfront cost due to complex technology | Low initial cost, but may incur higher operational costs |

| Ease of Implementation | Customizable, but requires technical knowledge for installation | Requires specialized knowledge and equipment | Easy to install and maintain with standard setups |

| Maintenance | Regular checks needed, but generally low maintenance | Requires periodic membrane replacement and cleaning | Minimal maintenance; however, periodic cleaning is needed |

| Best Use Case | Ideal for high-purity applications (e.g., semiconductor, pharmaceuticals) | Suitable for water treatment and food processing | Effective in dust collection and large particle removal in industrial applications |

What Are the Pros and Cons of Membrane Filtration Systems?

Membrane filtration systems utilize semi-permeable membranes to separate particles from fluids. They provide excellent filtration for small particles, making them a preferred choice in water treatment and food processing. However, their higher upfront costs and maintenance needs, such as regular membrane replacements, can be a drawback for some industries. Additionally, they require specialized installation and operational knowledge, which may not be feasible for all businesses.

How Do Cyclone Separators Compare?

Cyclone separators are mechanical devices that utilize centrifugal force to remove larger particulate matter from gases or liquids. They are relatively low-cost solutions that are easy to implement and maintain. However, their efficiency diminishes when dealing with fine particles, making them less suitable for high-purity applications. Cyclone separators are often favored in industrial settings where large debris is prevalent, but they may not meet the stringent purity standards required in sectors like semiconductor manufacturing.

Conclusion: How to Choose the Right Filtration Solution for Your Needs

When selecting the right filtration solution, B2B buyers should consider several factors, including the specific application, budget constraints, and maintenance capabilities. Specialty liquid gas filter materials excel in high-purity environments but may come at a higher cost and require technical expertise. On the other hand, membrane filtration systems offer advanced filtration capabilities but demand significant investment and maintenance. Cyclone separators provide a cost-effective alternative for less stringent applications, although they may not meet all purity requirements. Ultimately, a thorough assessment of your operational needs and long-term goals will guide you to the most suitable filtration solution.

Essential Technical Properties and Trade Terminology for specialty liquid gas filter materials

What Are the Key Technical Properties of Specialty Liquid Gas Filter Materials?

In the B2B landscape, understanding the technical properties of specialty liquid gas filter materials is essential for making informed purchasing decisions. Here are some critical specifications that buyers should consider:

1. Material Grade

The material grade refers to the specific composition and quality of the filter material, often denoted by industry standards such as ASTM or ISO classifications. Common materials include stainless steel, nickel alloys, and polymer composites. The grade influences the filter’s durability, resistance to corrosion, and overall performance in various environments. Buyers should prioritize material grades that match their operational conditions to ensure reliability and longevity.

2. Filtration Efficiency

Filtration efficiency is a measure of a filter’s ability to remove contaminants from gases or liquids, often expressed as a percentage (e.g., 99.9% efficiency). This metric is crucial for applications requiring high purity, such as semiconductor manufacturing or pharmaceutical processes. Understanding the filtration efficiency helps buyers select filters that meet their specific cleanliness standards, thus safeguarding product quality.

3. Temperature and Pressure Ratings

Every filter has defined operating temperature and pressure limits, which determine its suitability for specific applications. Filters designed for high-temperature or high-pressure environments must be constructed from appropriate materials to withstand these conditions without compromising performance. Buyers should assess their operational requirements to select filters that can endure the expected extremes.

4. Flow Rate

Flow rate indicates the volume of gas or liquid that can pass through a filter over a specific period, typically measured in liters per minute (L/min) or standard liters per minute (slpm). Selecting a filter with the appropriate flow rate is critical for maintaining system efficiency and performance. A filter that cannot handle the required flow may cause system bottlenecks, while one that exceeds the necessary capacity may lead to unnecessary costs.

5. Porosity

Porosity refers to the size and distribution of pores within the filter material, which directly impacts its filtration capabilities. Filters with varying porosity levels can be tailored for different applications, from coarse filtration to sub-micron filtration. Buyers should consider the specific contaminants they need to filter out and select materials with the appropriate porosity for optimal performance.

What Are Common Trade Terms Related to Specialty Liquid Gas Filters?

Familiarity with industry jargon can facilitate smoother negotiations and procurement processes. Here are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of filters, buyers may need to source components from OEMs to ensure compatibility with existing systems. Understanding OEM specifications can help buyers make informed choices about quality and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, particularly in industries where large volumes are not needed. Knowing the MOQ helps in budgeting and inventory planning, ensuring that buyers do not overcommit to products they may not use.

Illustrative image related to specialty liquid gas filter materials

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers for specific goods or services. For specialty liquid gas filters, an RFQ should include details such as specifications, quantities, and delivery timelines. Utilizing RFQs can streamline the procurement process and help buyers compare options effectively.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for negotiating shipping, insurance, and liability clauses in contracts. Familiarity with Incoterms helps buyers minimize risks and ensure smooth logistics.

5. Custom Filters

Custom filters are tailored solutions designed to meet specific customer requirements, including unique dimensions, materials, or performance characteristics. Buyers often require custom filters for specialized applications, and understanding the customization process can aid in effective communication with suppliers.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies and ensure they select the most suitable specialty liquid gas filter materials for their applications.

Navigating Market Dynamics and Sourcing Trends in the specialty liquid gas filter materials Sector

What Are the Current Market Dynamics and Key Trends Influencing Specialty Liquid Gas Filter Materials?

The specialty liquid gas filter materials sector is experiencing significant growth driven by various global factors. Increasing industrialization and urbanization across emerging markets in Africa, South America, and the Middle East are propelling demand for efficient filtration solutions. In Europe, particularly in countries like Germany, stringent environmental regulations and a shift towards sustainable manufacturing processes are influencing sourcing decisions. Notably, the semiconductor and aerospace industries are increasingly adopting high-purity filters to ensure compliance with rigorous quality standards, highlighting a trend toward specialized and customized filtration solutions.

Emerging technologies such as advanced materials engineering and 3D printing are reshaping the manufacturing landscape. For instance, companies are investing in custom filter designs that meet specific application requirements while enhancing efficiency. Additionally, the integration of IoT (Internet of Things) technology in filtration systems is gaining traction, allowing for real-time monitoring and predictive maintenance, which can significantly reduce downtime and operational costs for B2B buyers.

Buyers from international markets must navigate these dynamics by aligning their sourcing strategies with technological advancements and regulatory requirements. The ability to adapt to these trends will be crucial for optimizing supply chains and ensuring product quality in a competitive landscape.

How Are Sustainability and Ethical Sourcing Shaping the Specialty Liquid Gas Filter Materials Market?

Sustainability has become a cornerstone of sourcing strategies in the specialty liquid gas filter materials sector. With growing awareness of environmental impacts, companies are increasingly prioritizing the use of eco-friendly materials and processes. B2B buyers are now seeking suppliers who can demonstrate a commitment to reducing their carbon footprint through sustainable manufacturing practices.

Illustrative image related to specialty liquid gas filter materials

Ethical sourcing is equally important as businesses recognize the value of transparent supply chains. Buyers should look for suppliers who provide certifications indicating adherence to environmental standards, such as ISO 14001 or similar green certifications. These not only ensure compliance but also enhance brand reputation in increasingly eco-conscious markets.

Furthermore, innovative materials such as bio-based or recyclable filter media are emerging as viable alternatives to traditional materials. Implementing these alternatives can not only reduce environmental impact but also meet regulatory requirements, thus enhancing the overall sustainability profile of products in the supply chain.

What Is the Brief Evolution and History of Specialty Liquid Gas Filter Materials?

The specialty liquid gas filter materials sector has evolved significantly over the past few decades. Initially, filtration solutions were predominantly standard and generalized, catering to broad industrial needs. However, as industries began to adopt more sophisticated technologies and stringent quality standards, the demand for specialized filtration solutions surged.

The development of high-purity filters in the semiconductor industry marked a pivotal moment, as it necessitated advanced materials and engineering capabilities. Manufacturers began to innovate, creating tailored filter solutions capable of withstanding extreme conditions, such as high temperatures and corrosive environments. Today, the sector is characterized by a diverse range of products designed for specific applications, reflecting the ongoing evolution toward customization and precision in filtration technology. This historical context highlights the importance of understanding industry trends and adapting sourcing strategies accordingly for B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of specialty liquid gas filter materials

-

How do I choose the right specialty liquid gas filter materials for my application?

Choosing the right specialty liquid gas filter materials involves understanding your specific filtration requirements, including the type of contaminants, flow rates, and operating conditions. Start by assessing the chemical compatibility of the filter material with the substances it will encounter. Consider factors such as temperature ranges and pressure levels. Consulting with manufacturers who offer customization can help you identify the best solution tailored to your unique needs, ensuring optimal performance and longevity. -

What are the key performance characteristics to look for in liquid gas filters?

Key performance characteristics include filtration efficiency, flow rate, pressure drop, and material compatibility. Filtration efficiency indicates the filter’s ability to remove specific contaminants, while flow rate assesses how much fluid can pass through without significant resistance. Additionally, consider the pressure drop, as lower resistance can lead to energy savings. Ensure the filter material is compatible with the fluids and gases involved to prevent degradation and maintain effectiveness over time. -

What customization options are available for specialty liquid gas filters?

Many manufacturers offer customization options to meet specific application requirements. Customization can include size, shape, filtration media, and end connections. Some suppliers also provide specialized treatments, such as resin impregnation or pleating, to enhance performance. Discuss your unique needs with potential suppliers to explore available options, ensuring the final product aligns with your operational demands. -

What is the minimum order quantity (MOQ) for specialty liquid gas filters?

Minimum order quantities (MOQ) can vary widely among manufacturers and depend on the complexity of the filter design and the materials used. Some suppliers may have a low MOQ for standard products, while custom filters might require a higher MOQ due to the specific manufacturing processes involved. It is advisable to discuss MOQ with potential suppliers early in the procurement process to align your purchasing strategy with their production capabilities. -

What payment terms are typically offered by suppliers of liquid gas filters?

Payment terms can vary significantly between suppliers and may include options such as net 30, net 60, or even upfront payments for custom orders. Some suppliers may offer discounts for early payments or bulk orders. It’s essential to clarify payment terms during negotiations to avoid misunderstandings. Additionally, consider the impact of international trade regulations and currency exchange rates, especially when dealing with suppliers from different regions. -

How can I ensure quality assurance (QA) in my specialty filter purchases?

To ensure quality assurance, look for suppliers with recognized certifications such as ISO 9001 or industry-specific standards like AS9100 for aerospace applications. Request documentation of their QA processes, including testing methods and compliance with international standards. Additionally, consider requesting samples or trial orders to evaluate the performance of the filters before committing to larger purchases. -

What logistics considerations should I keep in mind when sourcing liquid gas filters internationally?

Logistics considerations include shipping methods, lead times, and customs regulations. Understand the supplier’s shipping options and estimated delivery times to ensure they align with your project timelines. Additionally, familiarize yourself with the customs requirements for importing filters into your country, including any tariffs or duties. Collaborating with a logistics provider experienced in international trade can help streamline the process and mitigate potential delays. -

How do I vet suppliers for specialty liquid gas filters?

Vetting suppliers involves researching their reputation, experience, and customer reviews. Check for industry certifications and their compliance with quality standards. Engaging in direct communication with potential suppliers can provide insight into their customer service and responsiveness. Consider requesting references from previous clients to gauge their reliability and performance. Attending trade shows or industry conferences can also provide opportunities to meet suppliers face-to-face and assess their capabilities.

Top 2 Specialty Liquid Gas Filter Materials Manufacturers & Suppliers List

1. STDSpecialtyFilters – Specialty Air, Gas, and Liquid Filters

Domain: stdspecialtyfilters.com

Registered: 2013 (12 years)

Introduction: Specialty Air Filters, Gas Filters, and Liquid Filters; Pleated Filters; Cylinder Molded Felt; Felt Gaskets; Roll Goods; Resin treated felt filters and gaskets; Custom manufacturing capabilities including pleating, molding, and cutting; Resin treated felt fabric available in roll form; Filters with injection molded, epoxy, plastisol, or plastic ends; Filters with rubber gaskets and grommets; Stamp…

2. East Coast Filter – JFG Series Gas Coalescing Depth Filters

Domain: eastcoastfilter.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “JFG Series Gas Coalescing Depth Filters”, “Overview”: “The JFG Series Filter Elements are designed for demanding applications with high contamination loading. They feature a large diameter with inside flow direction, specifically for gas filtration. The design combines specialized glass fibers with varying fiber diameters for optimal solid contaminant holding and liquid particle …

Strategic Sourcing Conclusion and Outlook for specialty liquid gas filter materials

In navigating the complexities of sourcing specialty liquid gas filter materials, international B2B buyers must prioritize strategic partnerships that enhance operational efficiency and product quality. Emphasizing customization and high purity standards is vital, particularly in sectors such as semiconductor manufacturing and oil exploration, where the integrity of filtration solutions directly impacts performance and profitability.

The diverse offerings from manufacturers, including pleated filters and high-purity components, highlight the importance of selecting suppliers who can meet specific application requirements while ensuring compliance with industry standards such as AS9100 and ISO certifications. As demand for advanced filtration solutions continues to grow across regions like Africa, South America, the Middle East, and Europe, companies are encouraged to leverage these innovations to enhance their competitive edge.

Looking ahead, the landscape for specialty liquid gas filter materials promises ongoing advancements in technology and materials science. Buyers are urged to remain proactive in their sourcing strategies, fostering collaborations that align with future market trends. By prioritizing quality, reliability, and innovation, organizations can secure their place at the forefront of their respective industries. Engage with trusted suppliers today to explore tailored solutions that meet your unique filtration needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.