Specialty Bar Products Company Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for specialty bar products company

Navigating the global market for specialty bar products can be a daunting task for international B2B buyers, particularly when it comes to sourcing high-quality components that meet stringent industry standards. As industries evolve, the demand for precision-engineered steel bars and components—ranging from cold-headed parts to custom machined products—has surged. This guide is designed to demystify the complexities of sourcing specialty bar products, providing insights into the various types available, their diverse applications, and the essential factors to consider when vetting suppliers.

In this comprehensive resource, we will explore critical aspects of the specialty bar products market, including the intricacies of manufacturing processes such as cold forming, powder metallurgy, and deep-hole drilling. We will also delve into the specific needs of key sectors like aerospace, defense, and power generation, ensuring that buyers can make informed decisions tailored to their unique requirements. Additionally, we will address cost considerations, quality assurance practices, and supplier selection criteria, equipping you with the knowledge needed to navigate this competitive landscape.

By leveraging this guide, B2B buyers from Africa, South America, the Middle East, and Europe—including markets like Vietnam and Germany—will be empowered to make strategic purchasing decisions that drive efficiency and enhance operational performance. Whether you are seeking reliable fasteners or custom components, our insights will serve as a valuable tool in your procurement journey.

Understanding specialty bar products company Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cold Heading Parts Manufacturers | Specializes in forming metal into desired shapes without heat | Aerospace, Automotive, Defense, Manufacturing | Pros: High precision, cost-effective for bulk; Cons: Limited to specific shapes and sizes. |

| Screw Machined Parts Suppliers | Focus on producing threaded and cylindrical components | Machinery, Automotive, Construction | Pros: Customization options; Cons: Higher lead times for custom designs. |

| Fastener Manufacturers | Produces a variety of fastening solutions | Construction, Automotive, Electronics | Pros: Wide range of products; Cons: Quality may vary across suppliers. |

| Powder Metallurgy Providers | Uses powdered metals to create complex shapes | Aerospace, Defense, Medical Devices | Pros: High strength and precision; Cons: Higher costs and longer production times. |

| Forging and Machining Services | Offers both forging and precision machining capabilities | Heavy Machinery, Oil & Gas, Marine | Pros: Durable products; Cons: Requires larger initial investment. |

What are the Key Characteristics of Cold Heading Parts Manufacturers?

Cold heading parts manufacturers are known for their ability to shape metal into specific forms without the application of heat. This method is particularly advantageous for producing high-volume components with tight tolerances. Industries such as aerospace, automotive, and defense frequently rely on these manufacturers for their ability to deliver precision parts efficiently. When purchasing, buyers should consider the manufacturer’s capabilities in terms of material types and the complexity of shapes they can produce.

How Do Screw Machined Parts Suppliers Differ from Others?

Screw machined parts suppliers specialize in creating complex, threaded components using automated lathes. These parts are essential for various applications, including machinery and automotive industries. Buyers should evaluate the supplier’s machine capabilities, customization options, and lead times, as these factors can significantly impact project timelines. The ability to produce small to medium-sized components with high precision is a key selling point for these suppliers.

What Should Buyers Know About Fastener Manufacturers?

Fastener manufacturers produce a wide range of products designed to connect two or more components securely. These products are crucial in sectors such as construction, automotive, and electronics. Buyers should assess the diversity of products offered, as well as the manufacturer’s quality assurance processes. While fasteners are generally affordable, the quality can vary significantly, making it essential to select reputable suppliers to ensure reliability in applications.

Why Choose Powder Metallurgy Providers?

Powder metallurgy providers utilize a unique manufacturing process that involves pressing powdered metals into shapes and then sintering them. This method allows for the production of complex geometries that are difficult to achieve with traditional machining. Industries such as aerospace and medical devices benefit from the high strength and precision offered by these products. Buyers should consider the cost implications and production times, as these can be higher compared to conventional methods.

What Advantages Do Forging and Machining Services Offer?

Forging and machining services combine the durability of forged components with the precision of machining processes. This dual capability is particularly beneficial in industries such as heavy machinery and oil and gas, where reliability is paramount. Buyers should focus on the supplier’s experience and the range of materials they can work with. While the initial investment may be higher, the long-term benefits of durability and performance can justify the costs.

Key Industrial Applications of specialty bar products company

| Industry/Sector | Specific Application of Specialty Bar Products Company | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Custom components for turbines and generators | Enhanced efficiency and reliability in energy production | Quality certifications, lead times, and material specifications |

| Transportation Systems | Manufacturing high-strength fasteners for vehicles | Improved safety and performance in transport applications | Compliance with international standards and testing requirements |

| Defense and Aerospace | Precision machined parts for military equipment | Increased operational effectiveness and durability | Military specifications, traceability, and rapid prototyping capabilities |

| Marine Propulsion | Components for propulsion systems and vessels | Enhanced performance and longevity of marine operations | Corrosion resistance, weight specifications, and custom designs |

| Oil and Gas | Custom bolting solutions for drilling equipment | Improved safety and operational efficiency in extraction | Material strength, environmental resistance, and supply chain reliability |

How Does Specialty Bar Products Company Address Power Generation Needs?

In the power generation sector, Specialty Bar Products Company provides custom components for turbines and generators. These components are critical for ensuring efficiency and reliability in energy production. International buyers, particularly from Africa and South America, must consider quality certifications and material specifications when sourcing these products. The ability to meet stringent performance standards can significantly enhance operational efficiency and reduce downtime.

What Role Does Specialty Bar Products Play in Transportation Systems?

Specialty Bar Products Company manufactures high-strength fasteners specifically designed for transportation systems, including automotive and rail applications. These fasteners are essential for ensuring the safety and performance of vehicles. Buyers from Europe and the Middle East should prioritize compliance with international standards and testing requirements to ensure that components can withstand rigorous operational conditions. The right fasteners can lead to improved safety and reliability in transport applications.

Why Are Precision Machined Parts Crucial for Defense and Aerospace?

In the defense and aerospace industries, the need for precision machined parts is paramount. Specialty Bar Products Company specializes in producing components that meet military specifications, enhancing the operational effectiveness and durability of military equipment. International buyers must focus on traceability and rapid prototyping capabilities when sourcing these parts, as they are often subject to stringent regulatory requirements. This attention to detail can significantly impact mission success and equipment longevity.

How Does Specialty Bar Products Enhance Marine Propulsion Systems?

Specialty Bar Products Company provides components for propulsion systems used in marine vessels. These products are designed to enhance performance and longevity, which is crucial in the demanding marine environment. Buyers should consider factors such as corrosion resistance and weight specifications when sourcing these components, especially in regions with challenging maritime conditions. By ensuring the right specifications, companies can improve the operational efficiency and durability of their marine operations.

What Solutions Does Specialty Bar Products Offer for Oil and Gas Applications?

In the oil and gas sector, Specialty Bar Products Company supplies custom bolting solutions for drilling equipment. These solutions are vital for ensuring safety and operational efficiency during extraction processes. International buyers need to prioritize material strength and environmental resistance when sourcing these products, as they often operate under extreme conditions. Reliable supply chain capabilities are also essential to minimize downtime and enhance overall operational effectiveness.

3 Common User Pain Points for ‘specialty bar products company’ & Their Solutions

Scenario 1: Navigating Customization Challenges in Specialty Bar Products

The Problem: B2B buyers often face difficulties when it comes to sourcing specialty bar products that meet their unique specifications. Industries such as aerospace and defense require precise tolerances and specific material characteristics. A buyer might need a custom steel bar with particular dimensions, strength properties, or corrosion resistance. However, they may find that suppliers often offer limited options or standard products, leading to delays and potential project failures.

Illustrative image related to specialty bar products company

The Solution: To effectively navigate customization challenges, buyers should engage directly with suppliers like Specialty Bar Products Company to discuss their specific needs. Before initiating contact, it’s crucial to prepare detailed specifications, including dimensions, material requirements, and expected tolerances. Utilizing a collaborative approach can lead to tailored solutions. Buyers can also request prototypes or samples to validate the product before committing to larger orders. Additionally, leveraging the supplier’s expertise can lead to recommendations for materials or processes that might improve performance and reduce costs. Establishing a clear line of communication and being open to suggestions will help ensure that the final product aligns with project requirements.

Scenario 2: Overcoming Supply Chain Disruptions in International Procurement

The Problem: Global supply chain disruptions can significantly impact the availability of specialty bar products, causing delays and escalating costs. For buyers in regions like Africa or South America, the challenge is compounded by varying import regulations, tariffs, and logistics issues. A buyer may face unexpected lead times or increased shipping costs that threaten project deadlines and budgets.

The Solution: To mitigate supply chain risks, buyers should adopt a proactive sourcing strategy that includes diversifying their supplier base. Engaging with Specialty Bar Products Company, which has a strong international presence, allows buyers to explore multiple shipping options and logistics partners. Additionally, establishing a robust relationship with suppliers can provide insights into inventory levels and expected delivery times. Buyers should also consider placing orders well in advance and utilizing just-in-time inventory strategies to minimize disruptions. Collaborating with suppliers on logistics planning can lead to optimized shipping routes and cost-effective solutions. Finally, staying informed about global market conditions and potential disruptions can help buyers anticipate challenges and adjust their procurement strategies accordingly.

Scenario 3: Ensuring Compliance with Industry Standards and Regulations

The Problem: Compliance with industry standards and regulations is a significant concern for B2B buyers, particularly in sectors like aerospace, defense, and energy. Buyers must ensure that specialty bar products meet specific certifications and quality standards. However, navigating the complex landscape of regulations can be daunting, and non-compliance can result in costly penalties and reputational damage.

The Solution: Buyers should prioritize working with suppliers that are transparent about their compliance processes and certifications. Specialty Bar Products Company, for example, can provide documentation that demonstrates adherence to relevant industry standards, such as ISO certifications. It is essential for buyers to communicate their compliance requirements clearly when placing orders. Establishing a quality assurance protocol that includes third-party inspections or audits can further ensure that products meet required standards. Additionally, attending industry workshops or webinars can provide valuable insights into evolving regulations, helping buyers stay informed and compliant. By fostering a collaborative relationship with suppliers and continuously monitoring compliance requirements, buyers can effectively mitigate risks and ensure the quality of their specialty bar products.

Illustrative image related to specialty bar products company

Strategic Material Selection Guide for specialty bar products company

When selecting materials for specialty bar products, it is crucial to consider the unique properties and performance characteristics that influence product durability, application suitability, and cost-effectiveness. Here, we analyze four common materials used in the manufacturing of specialty bar products, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Carbon Steel for Specialty Bar Products?

Carbon steel is widely used in the specialty bar products industry due to its excellent mechanical properties. It offers high strength and hardness, making it suitable for applications that require durability under stress. Carbon steel typically has a temperature rating of up to 300°C and can withstand moderate pressures. However, its corrosion resistance is limited, often requiring protective coatings or treatments for applications in harsh environments.

Pros: Carbon steel is relatively inexpensive and easy to machine, making it a cost-effective choice for mass production. Its strength-to-weight ratio is favorable, which is advantageous for applications in transportation and structural components.

Cons: The primary drawback is its susceptibility to rust and corrosion, necessitating additional protective measures. Moreover, its performance in extreme environments may be inadequate without proper alloying or treatment.

How Does Stainless Steel Perform in Specialty Bar Applications?

Stainless steel is known for its exceptional corrosion resistance, which makes it ideal for applications exposed to moisture or corrosive substances. With a temperature rating that can exceed 800°C, stainless steel is suitable for high-temperature applications. It also maintains its strength and integrity under varying pressure conditions.

Pros: The durability and aesthetic appeal of stainless steel make it a preferred choice for industries such as aerospace, marine, and food processing. Its resistance to oxidation and staining enhances longevity and reduces maintenance costs.

Cons: The primary disadvantage is its higher cost compared to carbon steel. Additionally, stainless steel can be more challenging to machine, which may increase manufacturing complexity and time.

What Role Does Alloy Steel Play in Specialty Bar Products?

Alloy steel, which incorporates elements such as chromium, nickel, and molybdenum, provides enhanced properties for specific applications. It offers improved strength, toughness, and wear resistance, making it suitable for high-stress environments. Alloy steels can withstand temperatures up to 600°C and are often used in the automotive and aerospace sectors.

Illustrative image related to specialty bar products company

Pros: The versatility of alloy steel allows for customization based on application requirements. Its enhanced mechanical properties make it ideal for components that experience high wear or fatigue.

Cons: The complexity of manufacturing alloy steel products can lead to higher costs and longer lead times. Additionally, alloy steels may require specific heat treatment processes to achieve desired properties, adding to production complexity.

Why is Aluminum a Viable Option for Specialty Bar Products?

Aluminum is increasingly used in specialty bar products due to its lightweight nature and excellent corrosion resistance. It is suitable for applications requiring low weight without compromising strength, with a temperature rating of around 150°C.

Pros: The lightweight characteristic of aluminum makes it ideal for applications in the aerospace and automotive industries, where reducing weight is critical. Its natural corrosion resistance reduces the need for protective coatings, lowering overall maintenance costs.

Cons: Aluminum has a lower strength compared to steel, which may limit its use in high-stress applications. Additionally, it can be more expensive than carbon steel, impacting budget considerations for large-scale projects.

Illustrative image related to specialty bar products company

Summary of Material Selection for Specialty Bar Products

| Material | Typical Use Case for specialty bar products company | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components in transportation systems | Cost-effective and strong | Susceptible to corrosion | Low |

| Stainless Steel | Aerospace and marine applications | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Alloy Steel | High-stress automotive and aerospace components | Enhanced strength and wear resistance | Higher manufacturing costs and complexity | Medium |

| Aluminum | Lightweight components in aerospace and automotive | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

This guide provides a foundational understanding of material selection for specialty bar products, enabling international B2B buyers to make informed decisions based on performance requirements, cost considerations, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for specialty bar products company

What Are the Key Stages in the Manufacturing Process for Specialty Bar Products?

The manufacturing of specialty bar products involves several critical stages that ensure the production of high-quality components. These stages typically include material preparation, forming, assembly, and finishing. Each stage plays a vital role in achieving the desired specifications and performance characteristics required by various industries.

How is Material Prepared for Specialty Bar Production?

Material preparation is the first step in the manufacturing process. It involves selecting the appropriate raw materials, usually high-grade steel alloys, to meet specific industry requirements. The materials are then subjected to rigorous inspections to ensure they conform to established standards. This includes checks for chemical composition, mechanical properties, and surface quality.

Once the materials are approved, they are cut to size and may undergo processes such as annealing to relieve internal stresses. This preparation phase is crucial, as the quality of the raw material directly impacts the final product’s performance and durability.

What Forming Techniques Are Commonly Used in Specialty Bar Manufacturing?

The forming stage is where the raw materials are transformed into the desired shapes. Techniques such as cold heading and cold forming are prevalent in the production of specialty bar products. Cold heading involves shaping the metal at room temperature using dies and hammers, which enhances the material’s strength and structural integrity.

In addition to cold heading, processes like thread rolling and swaging are employed to create specific features on the bars, such as threads or other complex geometries. These techniques are executed with precision, ensuring that each component meets the tight tolerances required by industries such as aerospace, defense, and automotive.

How is Assembly Handled in Specialty Bar Manufacturing?

While many specialty bar products may not require extensive assembly, certain components may involve additional processes. For instance, some products may need to be joined or coupled with other parts, which can include welding or the use of fasteners. This stage ensures that all components fit together seamlessly and are capable of performing their intended functions in the final application.

What Finishing Processes Are Essential for Specialty Bar Products?

Finishing processes enhance the aesthetic and functional qualities of specialty bar products. Techniques such as machining, grinding, and polishing are commonly employed to achieve the desired surface finish. Additionally, heat treatment processes may be applied to improve hardness, strength, and resistance to wear.

Finishing is also crucial for preparing the products for further processing or for direct delivery to customers. It ensures that the products not only meet visual standards but also perform reliably under operational conditions.

What Quality Assurance Practices Are Critical for Specialty Bar Products?

Quality assurance (QA) is a cornerstone of the manufacturing process for specialty bar products. Implementing robust QA practices helps ensure that products meet both international standards and specific industry requirements. This is particularly important for B2B buyers who must rely on consistent quality and compliance.

Which International Standards Should B2B Buyers Consider?

International quality standards, such as ISO 9001, are essential benchmarks for any manufacturing operation. ISO 9001 focuses on quality management systems and emphasizes continuous improvement, customer satisfaction, and process efficiency. For specialty bar products, adhering to this standard indicates a commitment to producing high-quality goods.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe, and API (American Petroleum Institute) standards for oil and gas applications, may be relevant. These certifications demonstrate compliance with regulatory requirements and industry best practices.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure product integrity. These checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections and tests are conducted to monitor adherence to quality specifications.

- Final Quality Control (FQC): Before products are dispatched, a final inspection is performed to confirm that they meet all quality and specification requirements.

These checkpoints are vital for identifying and rectifying any issues early in the process, thus minimizing waste and ensuring the final product’s reliability.

What Testing Methods Are Commonly Used for Specialty Bar Products?

Testing methods vary depending on the product and its intended application. Common testing techniques include:

- Mechanical Testing: Assessing tensile strength, yield strength, and ductility to ensure materials can withstand operational stresses.

- Non-Destructive Testing (NDT): Methods such as ultrasonic testing or magnetic particle inspection help identify internal flaws without damaging the product.

- Chemical Analysis: Verifying the material composition to ensure compliance with required specifications.

These testing methods provide B2B buyers with confidence in the quality and reliability of the products they source.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should take proactive steps to verify the quality control measures of their suppliers. This can involve several strategies:

- Conducting Audits: Regular audits of suppliers can help assess their adherence to quality standards and operational practices. This provides insights into their manufacturing processes and QC measures.

- Requesting Quality Reports: Suppliers should be able to provide detailed quality reports, including inspection results and certifications. This documentation can be critical for compliance and assurance.

- Utilizing Third-Party Inspections: Engaging third-party inspection services can provide an objective assessment of a supplier’s quality control processes and product quality.

What Are the Nuances of QC and Certification for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is essential. Different regions may have varying regulatory requirements and standards. For instance, European buyers may prioritize CE marking, while those in the Middle East may focus on compliance with local industry standards.

Additionally, cultural differences in business practices can impact the way quality assurance is approached. Buyers should familiarize themselves with the specific requirements of their target markets and ensure that their suppliers can meet these expectations.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for specialty bar products is crucial for B2B buyers. By focusing on key stages of production, relevant quality standards, and effective verification methods, buyers can make informed decisions and ensure the reliability of their supply chains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘specialty bar products company’

Introduction

This practical sourcing guide is designed for B2B buyers looking to procure products from Specialty Bar Products Company, a leader in steel bar machining and manufacturing. By following this step-by-step checklist, you can streamline your sourcing process, ensuring you find reliable suppliers that meet your technical and business requirements.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your technical specifications. This includes the material types (e.g., nickel alloy, stainless steel), dimensions, tolerances, and any special finishes required. Having a well-defined specification helps avoid misunderstandings and ensures that suppliers can meet your needs accurately.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers within the specialty bar products market. Look for companies that have a proven track record in your specific industry, such as aerospace or defense. Utilize online directories, industry publications, and referrals from industry contacts to compile a list of reputable suppliers.

Step 3: Evaluate Supplier Capabilities

It’s crucial to assess the manufacturing capabilities of each supplier on your shortlist. Consider their production processes, such as cold heading, machining, and forging, as well as their technology and equipment. Ensure they can produce the specific components you need and check for any unique capabilities that may provide a competitive edge, like custom machining services.

Step 4: Request Certifications and Compliance Documents

Verify that potential suppliers hold the necessary certifications and comply with industry standards. This may include ISO certifications, compliance with safety regulations, and adherence to quality management systems. Certifications are indicators of a supplier’s commitment to quality and can significantly affect the reliability of the products you receive.

Step 5: Ask for Samples or Prototypes

Before finalizing any agreements, request samples or prototypes of the products you intend to purchase. This allows you to evaluate the quality and performance of the components firsthand. Assess the samples against your specifications, focusing on factors such as finish, tolerances, and overall craftsmanship.

Illustrative image related to specialty bar products company

Step 6: Negotiate Terms and Conditions

Once you have selected a preferred supplier, it’s time to negotiate the terms of the agreement. Discuss pricing, lead times, payment terms, and warranty conditions. Ensure that all aspects of the agreement are clearly defined to avoid potential disputes later on.

Step 7: Establish a Communication Plan

Finally, establish a clear communication plan with your chosen supplier. Regular communication is vital to ensure that the production process runs smoothly and that any issues are addressed promptly. Define points of contact, preferred communication channels, and frequency of updates to maintain an effective partnership.

By following these steps, B2B buyers can effectively source products from Specialty Bar Products Company, ensuring they make informed decisions that align with their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for specialty bar products company Sourcing

What Are the Key Cost Components for Specialty Bar Products?

When sourcing specialty bar products, understanding the cost structure is crucial for effective budgeting and negotiation. The primary components of cost include:

-

Materials: The choice of raw materials significantly influences pricing. Specialty bar products often utilize high-grade steel, nickel alloys, or stainless steel, which can vary in cost based on market conditions and availability.

-

Labor: Skilled labor is required for machining and manufacturing processes, particularly in high-tolerance industries such as aerospace and defense. Labor costs can fluctuate based on geographic location and the complexity of the parts being produced.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities, facility maintenance, and administrative expenses. Efficient operations can help manage these overhead costs.

-

Tooling: Specialized tooling is often necessary for producing custom components. The initial investment in tooling can be significant but is essential for maintaining quality and precision in manufacturing.

-

Quality Control (QC): Rigorous QC processes ensure that products meet industry standards and client specifications. This may involve additional testing and certification, which can affect overall costs.

-

Logistics: Shipping and handling are vital considerations, especially for international transactions. Costs can vary based on the shipping method, distance, and whether the goods are transported by air, sea, or land.

-

Margin: The profit margin included in the pricing will vary based on the company’s positioning in the market, competitive landscape, and the perceived value of the products.

How Do Price Influencers Affect Specialty Bar Product Sourcing?

Several factors influence the pricing of specialty bar products, and understanding these can aid in negotiations:

-

Volume and Minimum Order Quantity (MOQ): Ordering in larger quantities often reduces the per-unit cost due to economies of scale. Buyers should inquire about MOQs to optimize pricing.

-

Specifications and Customization: Customized products typically incur additional costs due to the need for specialized manufacturing processes. Clear communication of specifications can help minimize unexpected expenses.

-

Materials: The choice of material can impact price significantly. Buyers should assess the trade-offs between material costs and the performance characteristics required for their applications.

-

Quality and Certifications: Products that meet specific industry standards or possess certifications (e.g., ISO, AS9100) may command higher prices. However, these certifications can also provide assurance of quality and reliability.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is essential for calculating the total cost. Terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can improve cost-efficiency:

-

Negotiation: Always be prepared to negotiate terms and pricing. Establishing a long-term relationship with suppliers can lead to better pricing and service.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, operational costs, and disposal. A lower upfront cost may lead to higher long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and additional costs associated with importing goods, such as tariffs and customs fees. Request detailed quotes that include all potential expenses.

-

Supplier Diversification: Relying on a single supplier can be risky. Explore multiple suppliers to compare pricing, quality, and service levels, which can provide leverage during negotiations.

-

Market Research: Conduct thorough research on market prices for similar products to ensure competitive pricing. Understanding regional market trends can also provide insights into potential cost fluctuations.

Disclaimer

Pricing for specialty bar products can vary widely based on the factors mentioned above. The information provided is intended for guidance only and does not reflect specific quotes or pricing from Specialty Bar Products or any other suppliers. Always seek updated quotes and engage in thorough discussions with suppliers to ensure accurate pricing based on current market conditions.

Illustrative image related to specialty bar products company

Alternatives Analysis: Comparing specialty bar products company With Other Solutions

Introduction to Alternatives in Specialty Bar Products

When evaluating options for specialty bar products, B2B buyers must consider various alternatives that can meet their specific operational needs. Different manufacturing methods and suppliers can significantly influence production efficiency, cost-effectiveness, and product quality. This analysis aims to compare Specialty Bar Products Company with other viable alternatives, providing insights into their strengths and weaknesses.

Comparison Table

| Comparison Aspect | Specialty Bar Products Company | Alternative 1: Chicago Rivet & Machine Co. | Alternative 2: Radax Industries, Inc. |

|---|---|---|---|

| Performance | High precision in machining and forging; suitable for tight tolerances. | Strong capabilities in rivet manufacturing and assembly. | Focused on cold heading with a diverse product range. |

| Cost | Competitive pricing with bulk orders; premium for custom solutions. | Generally lower cost due to high-volume production. | Similar pricing structure; cost-effective for standard products. |

| Ease of Implementation | Custom solutions may require longer lead times; skilled labor needed. | Streamlined processes for standard products; easy integration. | Moderate lead times; effective for standardization but less flexibility. |

| Maintenance | Requires regular maintenance for specialized machinery. | Lower maintenance due to simpler machinery. | Moderate maintenance; specialized equipment may require expert service. |

| Best Use Case | Ideal for aerospace, defense, and high-tolerance applications. | Best for high-volume manufacturing in automotive and general assembly. | Suitable for industries needing standardized components with quick turnaround. |

Detailed Breakdown of Alternatives

Alternative 1: Chicago Rivet & Machine Co.

Chicago Rivet & Machine Co. specializes in the production of rivets and fasteners, making it a strong alternative for industries focused on assembly processes. Its high-volume production capabilities can lead to lower costs for standard components, which is advantageous for manufacturers looking to minimize expenses. However, the trade-off is a potential lack of customization, which may not meet the specific requirements of sectors like aerospace or defense that require precision and tailored solutions.

Alternative 2: Radax Industries, Inc.

Radax Industries is known for its cold heading processes, providing a range of fasteners and components. This company is particularly effective for those seeking standardized parts with shorter lead times. While the cost structure is similar to Specialty Bar Products, Radax may not deliver the same level of precision for custom applications, making it less suitable for industries that require tight tolerances and specialized designs.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate supplier or manufacturing method for specialty bar products is critical for B2B buyers. It is essential to assess the specific requirements of your project, such as performance standards, budget constraints, and the level of customization needed. While Specialty Bar Products Company excels in delivering high-precision and tailored solutions, alternatives like Chicago Rivet & Machine Co. and Radax Industries offer cost-effective and efficient options for standard components. Ultimately, the decision should align with your operational goals and the long-term strategy of your business.

Essential Technical Properties and Trade Terminology for specialty bar products company

What Are the Essential Technical Properties for Specialty Bar Products?

When engaging with specialty bar products, understanding the technical properties is crucial for B2B buyers. Here are several key specifications that define the quality and suitability of these products for various applications:

Illustrative image related to specialty bar products company

1. Material Grade

Material grade is a classification that indicates the composition and properties of the steel used in manufacturing specialty bars. Common grades include stainless steel, alloy steel, and carbon steel. The choice of material grade directly impacts the product’s strength, corrosion resistance, and suitability for specific applications. For instance, aerospace components often require high-grade alloys to withstand extreme conditions.

2. Tolerance

Tolerance refers to the permissible limits of variation in a physical dimension of a part. In the specialty bar products industry, tight tolerances are essential for ensuring that components fit together correctly in assemblies. For example, a tolerance of ±0.001 inches can be critical in applications such as aerospace or military, where precision is paramount for safety and functionality.

3. Surface Finish

Surface finish indicates the texture of a material’s surface, which can affect its performance, especially in applications involving friction or wear. Common surface finishes include polished, sandblasted, or coated. A high-quality surface finish can enhance the durability and aesthetic appeal of products, making it an essential specification for buyers in industries such as automotive or consumer goods.

Illustrative image related to specialty bar products company

4. Mechanical Properties

Mechanical properties include tensile strength, yield strength, and hardness. These properties determine how a material behaves under various types of stress and are critical for ensuring that the specialty bars can perform reliably in their intended applications. For example, high tensile strength is vital for components subjected to heavy loads, such as those used in construction or machinery.

5. Heat Treatment

Heat treatment is a controlled process used to alter the physical and sometimes chemical properties of a material. This process can enhance toughness, hardness, and ductility, making it a vital aspect for buyers looking for specialty bars that can withstand demanding environments. Understanding the heat treatment process can help buyers specify products that meet their performance requirements.

What Are Common Trade Terms in the Specialty Bar Products Industry?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B space. Here are several important terms that you should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term helps buyers identify the original source of a product, which can be crucial for ensuring quality and compatibility with existing systems.

Illustrative image related to specialty bar products company

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of goods that a supplier is willing to sell. This term is vital for B2B buyers as it impacts inventory management and cost efficiency. Knowing the MOQ helps in budgeting and planning for production needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. It is a critical step in the procurement process, allowing buyers to compare offers and select the best supplier based on price, quality, and delivery terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and obligations, which is particularly important when sourcing specialty bar products from global suppliers.

5. Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. This term is crucial for supply chain management, as it affects production schedules and inventory levels. Understanding lead times helps buyers make informed decisions about order timing and stock management.

By grasping these essential technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the right specialty bar products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the specialty bar products company Sector

What Are the Current Market Dynamics and Key Trends in the Specialty Bar Products Sector?

The global specialty bar products market is witnessing significant transformation driven by various factors including technological advancements, increasing demand for high-precision components, and the need for enhanced supply chain efficiency. As industries such as aerospace, automotive, and defense continue to grow, international B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking suppliers that can deliver high-quality custom machined parts. Notably, the rise of Industry 4.0 technologies is reshaping sourcing strategies, with automation, AI, and IoT enabling manufacturers to streamline operations and improve product quality.

Emerging trends in sourcing include the integration of digital platforms that enhance visibility and collaboration between suppliers and buyers. These platforms facilitate real-time data exchange, helping companies to make informed decisions quickly. Additionally, the shift towards just-in-time (JIT) inventory practices is prompting buyers to partner with suppliers that can offer flexible production capabilities without compromising lead times. For B2B buyers, understanding these dynamics is crucial to identifying reliable partners that align with their operational needs.

Illustrative image related to specialty bar products company

How Is Sustainability Shaping Sourcing Practices in the Specialty Bar Products Industry?

Sustainability has become a cornerstone of strategic sourcing in the specialty bar products sector. As environmental regulations tighten and consumer preferences shift towards sustainable options, companies are increasingly focusing on ethical sourcing practices. This includes prioritizing suppliers that adhere to green certifications and utilize environmentally friendly materials, such as recycled metals or those sourced from sustainable operations.

The environmental impact of production processes, particularly in metallurgy, is significant. B2B buyers are now evaluating suppliers based not only on price and quality but also on their commitment to reducing carbon footprints and waste generation. By opting for suppliers that demonstrate responsible sourcing, buyers can enhance their corporate social responsibility (CSR) initiatives while also mitigating risks associated with supply chain disruptions. The emphasis on sustainability is not merely a trend; it is becoming a vital component of business strategy, as companies aim to meet both regulatory requirements and customer expectations.

What Is the Historical Context of the Specialty Bar Products Sector’s Development?

The specialty bar products sector has evolved significantly since its inception in the mid-20th century. Founded in 1945, companies like Specialty Bar Products Company have played a pivotal role in advancing manufacturing processes such as cold heading and precision machining. Initially focused on basic steel bar production, the industry has expanded its capabilities to include advanced technologies like computer numerical control (CNC) machining and powder metallurgy.

This evolution has been driven by the increasing demand for specialized components across diverse industries, including aerospace, defense, and energy. As the market has matured, the focus has shifted towards customization and high-tolerance manufacturing, catering to specific industry needs. For B2B buyers, understanding this historical context provides insights into the sector’s resilience and adaptability, emphasizing the importance of selecting suppliers with a proven track record in innovation and quality assurance.

In conclusion, the specialty bar products sector is characterized by dynamic market trends and a growing emphasis on sustainability. For international B2B buyers, aligning with forward-thinking suppliers who prioritize ethical sourcing and technological advancements is essential for maintaining a competitive edge in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of specialty bar products company

-

How do I ensure quality when sourcing specialty bar products?

To ensure quality, first, conduct thorough research on potential suppliers, focusing on their certifications (like ISO 9001) and industry reputation. Request samples of their products to evaluate the materials and craftsmanship. Additionally, inquire about their quality assurance processes, including testing and inspection methods. Establish clear communication regarding your quality standards and expectations, and consider visiting their facilities if feasible, as this can provide deeper insights into their operations and capabilities. -

What is the best way to customize specialty bar products for my specific needs?

The best way to customize specialty bar products is to engage directly with the manufacturer early in the design process. Provide detailed specifications, including dimensions, materials, and any unique features required. Discuss your application and performance expectations with their engineering team, as they can offer valuable insights and suggestions. A collaborative approach not only ensures that the end product meets your needs but also enhances the relationship with your supplier. -

What are the typical minimum order quantities (MOQs) for specialty bar products?

Minimum order quantities can vary significantly depending on the manufacturer and the complexity of the products. Generally, MOQs for specialty bar products can range from a few hundred to several thousand units. It’s important to discuss your specific needs with potential suppliers, as some may offer flexibility for smaller orders, especially for prototypes or initial runs. Understanding MOQs helps in budgeting and planning your inventory effectively. -

What payment terms should I expect when sourcing internationally?

Payment terms in international B2B transactions typically include options like advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, followed by the balance upon shipment. Be sure to clarify payment terms early in discussions to avoid misunderstandings. Additionally, consider currency fluctuations and transaction fees, and ensure that both parties agree on the payment method that provides security and convenience. -

How can I vet a supplier for international trade?

To vet a supplier for international trade, start by checking their business credentials, including registration and certifications. Look for reviews and testimonials from other clients, and consider reaching out to them for feedback. Additionally, utilize platforms that provide supplier ratings and performance metrics. Conducting a background check or using third-party verification services can also help ensure the legitimacy and reliability of the supplier before committing to a partnership. -

What logistics considerations should I keep in mind when importing specialty bar products?

When importing specialty bar products, logistics considerations include shipping methods, transit times, and customs regulations. Assess the best transportation mode (air, sea, or land) based on your budget and urgency. Ensure that you understand the customs duties and taxes applicable to your shipments, as well as any required documentation. Working with a reliable freight forwarder can simplify the logistics process and help navigate international shipping complexities. -

What industries commonly use specialty bar products?

Specialty bar products are widely used in various industries, including aerospace, defense, power generation, transportation, and marine applications. Their versatility and ability to be customized for specific engineering needs make them essential in these sectors. Understanding the specific requirements of your industry can guide your procurement process and ensure that the products you source align with industry standards and performance expectations. -

How can I establish a long-term partnership with a specialty bar products supplier?

To establish a long-term partnership with a specialty bar products supplier, focus on building trust and open communication. Regularly engage in discussions about your needs, provide feedback on products, and collaborate on improvements. Consider setting up performance reviews to assess the partnership’s effectiveness and address any concerns promptly. Additionally, showing commitment through consistent orders and prompt payments can foster loyalty and encourage the supplier to prioritize your business.

Top 5 Specialty Bar Products Company Manufacturers & Suppliers List

1. Cold Headed Parts – Specialty Bar Products

Domain: coldheadedparts.com

Registered: 2000 (25 years)

Introduction: Specialty Bar Products Company (SBP) specializes in international steel bar machining, drilling, and internal bolting. They offer forging, cold heading, and gun barrel production capabilities. Their product line includes cold headed fasteners, screw machined parts, self-drilling screws, and various types of bolts. SBP is committed to customer satisfaction and has been in operation since the mid-19…

2. Indeed – Workforce Challenges

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Indeed – Workforce Challenges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. PitchBook – Custom Machining Services

Domain: pitchbook.com

Registered: 2004 (21 years)

Introduction: Provider of custom machining services for the production of steel parts and components. The company manufactures custom steel bars for aerospace, military and defense, power generation, internal bolting, oil and gas, transportation systems, recreational firearms, pump and valve manufacturing and marine propulsion.

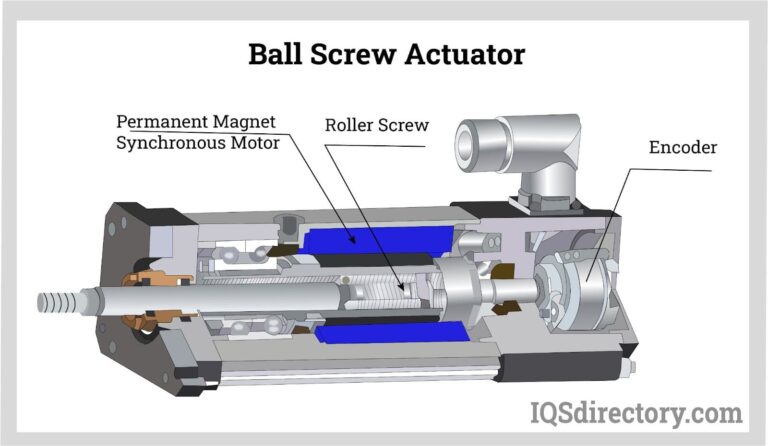

4. IQS Directory – Specialty Bar Products

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Specialty Bar Products Company specializes in cold headed parts, steel bar machining, drilling, internal bolting, and heat treatment services.

5. MFG – Specialty Bar Products

Domain: mfg.com

Registered: 1991 (34 years)

Introduction: Specialty Bar Products Company specializes in manufacturing processes including Machining, EDM, Milling, and Turning. The company is located in Beechtree Business Park, Greenville, South Carolina, United States, and has between 200-500 employees. They are an MFG member since September 19, 2002, and hold ISO 9002 certification.

Strategic Sourcing Conclusion and Outlook for specialty bar products company

How Can Strategic Sourcing Enhance Your Supply Chain for Specialty Bar Products?

In today’s competitive landscape, strategic sourcing plays a pivotal role in optimizing supply chains for specialty bar products. By establishing strong relationships with reputable manufacturers, such as Specialty Bar Products Company, international B2B buyers can access high-quality components tailored to their specific needs. The company’s expertise in steel bar machining, cold heading, and custom component production positions it as a key partner for industries such as aerospace, defense, and power generation.

Moreover, leveraging advanced manufacturing processes—like powder metallurgy and cold forming—can lead to enhanced product quality and operational efficiency. Buyers must prioritize suppliers that not only meet stringent quality standards but also demonstrate a commitment to innovation and customer satisfaction.

Illustrative image related to specialty bar products company

As you navigate your sourcing strategies, consider the long-term benefits of collaboration with established manufacturers. Now is the time to engage with suppliers who can support your growth objectives, ensuring you remain competitive in your respective markets. Embrace the opportunity to streamline your procurement processes and enhance your product offerings by partnering with industry leaders like Specialty Bar Products. Start your journey towards a more resilient supply chain today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.