Southern Tool Steel: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for southern tool steel

In today’s competitive manufacturing landscape, sourcing high-quality southern tool steel can be a daunting challenge for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, the stakes are high when it comes to selecting the right materials that ensure durability and precision in production. This comprehensive guide is designed to demystify the complexities of sourcing southern tool steel, covering essential aspects such as types, applications, and supplier vetting processes.

With a focus on actionable insights, we will explore the various grades and specifications of tool steel, discuss their applications across different industries, and provide strategies for evaluating suppliers effectively. Additionally, this guide will delve into cost considerations, helping you make informed purchasing decisions that align with your budget and quality requirements.

By equipping you with the knowledge to navigate the global market for southern tool steel, this resource empowers you to optimize your supply chain, enhance product quality, and ultimately drive business growth. You’ll find that making informed choices about sourcing tool steel not only mitigates risks but also positions your business for long-term success in an increasingly interconnected world.

Understanding southern tool steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| D2 Tool Steel | High wear resistance, excellent toughness | Dies, cutting tools, stamping dies | Pros: Long life, good wear resistance. Cons: Difficult to machine, can be brittle. |

| A2 Tool Steel | Air-hardening, good dimensional stability | Blades, punches, shear blades | Pros: Easy to machine, good toughness. Cons: Lower wear resistance than D2. |

| O1 Tool Steel | Oil-hardening, good machinability | Tooling, jigs, fixtures | Pros: Excellent edge retention, easy to heat treat. Cons: Lower toughness compared to others. |

| M2 Tool Steel | High-speed steel, retains hardness at high temps | Cutting tools, drill bits | Pros: High wear resistance, suitable for high-speed applications. Cons: More expensive, requires careful heat treatment. |

| S7 Tool Steel | Shock-resistant, tough at high temperatures | Striking tools, punches, chisels | Pros: Excellent shock resistance, versatile. Cons: Limited wear resistance compared to other tool steels. |

What Are the Characteristics of D2 Tool Steel and Its B2B Suitability?

D2 tool steel is known for its high wear resistance and excellent toughness, making it a popular choice for applications requiring durability, such as dies and cutting tools. Its ability to maintain hardness at elevated temperatures enhances its performance in stamping and forming processes. However, it can be challenging to machine and may exhibit brittleness if not properly heat-treated, which is a critical consideration for B2B buyers looking for reliable performance in demanding applications.

Why Choose A2 Tool Steel for Your Manufacturing Needs?

A2 tool steel is an air-hardening variant that offers good dimensional stability and ease of machining. This makes it suitable for manufacturing blades, punches, and shear blades. Its balance of toughness and wear resistance allows for efficient production without excessive tool wear. While it does not match the wear resistance of D2, its machinability and toughness make it an attractive option for manufacturers needing versatile tooling solutions.

How Does O1 Tool Steel Stand Out for Tooling Applications?

O1 tool steel, an oil-hardening steel, is favored for its excellent edge retention and ease of heat treatment. This quality makes it ideal for tooling applications such as jigs and fixtures. While it provides lower toughness compared to other tool steels, its machinability and ability to achieve a fine finish make it suitable for precision applications. Buyers should consider its performance characteristics and heat treatment requirements to ensure optimal results.

What Makes M2 Tool Steel a Preferred Choice for High-Speed Applications?

M2 tool steel is classified as high-speed steel, known for its ability to retain hardness at elevated temperatures. This property makes it particularly effective for cutting tools and drill bits used in high-speed machining operations. Although it tends to be more expensive and requires careful heat treatment, its high wear resistance justifies its cost for businesses seeking longevity and performance in their tools.

In What Scenarios Is S7 Tool Steel the Best Option?

S7 tool steel is characterized by its shock resistance, making it an ideal choice for striking tools, punches, and chisels. Its toughness at high temperatures provides versatility across various applications. However, while it excels in shock resistance, it has limited wear resistance compared to other tool steels. B2B buyers should assess their specific application needs to determine if the shock-resistant properties of S7 align with their operational requirements.

Key Industrial Applications of southern tool steel

| Industry/Sector | Specific Application of Southern Tool Steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of precision tooling and components | High strength and durability for safety-critical parts | Certification standards (e.g., AS9100), material traceability, and fast delivery times |

| Automotive | Production of cutting tools and dies | Enhanced productivity and reduced downtime | Specific grade requirements, heat treatment specifications, and compatibility with existing machinery |

| Oil and Gas | Drilling and exploration tools | Resistance to wear and corrosion in harsh environments | Compliance with industry standards, custom sizes, and rapid prototyping capabilities |

| Medical Devices | Surgical instruments and implants | Biocompatibility and precision engineering | Regulatory compliance (e.g., FDA), material certifications, and custom machining services |

| Manufacturing Equipment | Tooling for CNC machines and fabrication | Improved efficiency and lower operational costs | Inventory availability, custom cutting services, and logistics for timely delivery |

How is Southern Tool Steel Used in the Aerospace Industry?

In the aerospace sector, southern tool steel is crucial for producing precision tooling and components such as landing gear, engine parts, and structural elements. The high strength and durability of tool steel ensure that these critical components can withstand extreme operational conditions. International buyers must ensure compliance with stringent certification standards, such as AS9100, and demand for material traceability. Fast delivery is also essential to meet tight production schedules.

What Role Does Southern Tool Steel Play in Automotive Production?

Southern tool steel is extensively utilized in the automotive industry for manufacturing cutting tools, dies, and molds. These tools are essential for shaping parts with high precision, thereby enhancing productivity and reducing downtime in assembly lines. Buyers should consider specific grade requirements and heat treatment specifications to ensure compatibility with their existing machinery. Timely sourcing is vital to maintain production flow and meet market demands.

How is Southern Tool Steel Beneficial in Oil and Gas Applications?

In the oil and gas sector, southern tool steel is employed in the fabrication of drilling and exploration tools that require exceptional wear resistance and corrosion protection. The harsh environments these tools operate in demand materials that can endure extreme stress and exposure to corrosive substances. When sourcing, companies must ensure compliance with industry standards and may require custom sizes and rapid prototyping capabilities to meet unique project specifications.

Why is Southern Tool Steel Essential for Medical Devices?

Southern tool steel is integral in the medical device industry for crafting surgical instruments and implants that require high precision and biocompatibility. The reliability of tool steel ensures that these instruments can perform effectively in delicate medical procedures. Buyers in this sector must navigate regulatory compliance, such as FDA approval, and seek out suppliers who can provide necessary material certifications and custom machining services to meet specific design needs.

How Does Southern Tool Steel Enhance Manufacturing Equipment?

In manufacturing, southern tool steel is used to create tooling for CNC machines and fabrication processes. The durability and efficiency of tool steel contribute to lower operational costs and improved production rates. B2B buyers should focus on inventory availability and the ability to provide custom cutting services. Additionally, logistics for timely delivery are critical, as delays can significantly impact production schedules and overall business operations.

3 Common User Pain Points for ‘southern tool steel’ & Their Solutions

Scenario 1: Delays in Material Delivery Impacting Production Schedules

The Problem: In the competitive landscape of manufacturing, timely access to high-quality materials is crucial. B2B buyers often face significant challenges when suppliers cannot deliver the required southern tool steel on time. Delays in material delivery can halt production lines, leading to missed deadlines and financial penalties. Buyers may find themselves in a bind, needing specific grades or sizes of tool steel urgently, but encountering backorders or extended lead times.

The Solution: To mitigate delivery delays, buyers should establish clear communication channels with their suppliers, specifically Southern Tool Steel. Begin by discussing your expected timelines and the critical nature of your projects. Inquire about their inventory levels and the availability of specific grades of tool steel. Additionally, consider leveraging Southern Tool Steel’s fast delivery options, which include same-day shipping on many items. By forming a strategic partnership and utilizing their cutting services, you can order precisely what you need without minimum order requirements, ensuring that you receive materials on time and in the right quantities.

Scenario 2: Uncertainty Over Material Specifications and Quality

The Problem: B2B buyers often struggle with understanding the specific properties and applications of various grades of southern tool steel. The risk of sourcing materials that do not meet the required specifications can lead to poor product performance and increased production costs. This is particularly pertinent when dealing with specialized applications that demand specific qualities, such as hardness, wear resistance, or machinability.

The Solution: To overcome this challenge, buyers should engage with the technical support team at Southern Tool Steel. Take advantage of their expertise by requesting detailed material datasheets and application guidance. Before placing an order, conduct a thorough analysis of your project requirements and ask for recommendations based on your specific application. Consider requesting samples of different grades to evaluate their performance in your manufacturing processes. Utilizing the knowledge of Southern Tool Steel’s representatives can lead to better-informed decisions, ensuring that you select the right material that meets both quality and performance standards.

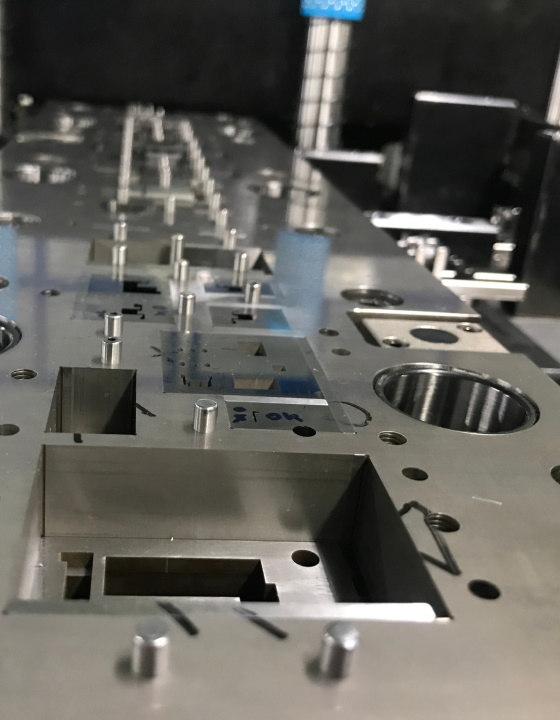

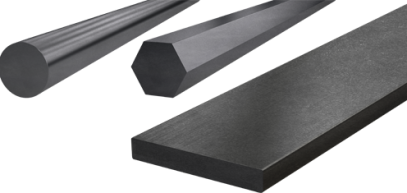

Illustrative image related to southern tool steel

Scenario 3: Difficulty in Customizing Tool Steel for Unique Applications

The Problem: Many B2B buyers require customized sizes or finishes of southern tool steel to meet unique project specifications. However, the challenge often lies in finding a supplier that can accommodate these custom requests without excessive lead times or additional costs. Buyers may feel frustrated when faced with rigid inventory options that do not align with their production needs.

The Solution: Southern Tool Steel offers a range of customization options, including cutting, machining, and finishing services. To leverage these capabilities, buyers should clearly outline their specifications, including dimensions, grades, and desired finishes, before initiating an order. Communicate your project requirements directly with Southern Tool Steel’s sales representatives, who can guide you on the available customization options and expected turnaround times. By taking advantage of their advanced processing services, you can receive tailored solutions that fit your exact needs, ultimately enhancing your production efficiency and product quality.

Strategic Material Selection Guide for southern tool steel

What Are the Key Properties of Tool Steel for B2B Applications?

Tool steel is a crucial material in manufacturing, particularly for producing tools and dies. It is known for its hardness, resistance to abrasion, and ability to withstand high temperatures. Common grades of tool steel include D2, A2, O1, and M2, each offering unique properties that cater to different applications.

D2 Tool Steel

D2 is a high-carbon, high-chromium tool steel known for its excellent wear resistance and ability to retain hardness at elevated temperatures. It is often used in applications such as stamping dies, shear blades, and other tooling applications where durability is critical. However, D2 is prone to chipping, which can be a disadvantage in high-impact applications. For international buyers, compliance with ASTM A681 is essential, as it ensures the quality and performance of D2 steel.

A2 Tool Steel

A2 is an air-hardening tool steel that offers a balance between toughness and wear resistance. It is less prone to chipping compared to D2, making it suitable for applications like cutting tools and dies. A2 also provides good dimensional stability during heat treatment. However, it may not perform as well in extremely high-temperature environments. International buyers should consider compliance with ASTM A681 and JIS G4403 standards when sourcing A2 steel to ensure compatibility with their manufacturing processes.

O1 Tool Steel

O1 is an oil-hardening tool steel that is known for its ease of machining and good wear resistance. It is commonly used in applications such as knives, punches, and dies. O1 offers good toughness and can be heat-treated to achieve high hardness levels. However, it has lower wear resistance compared to D2 and A2. For B2B buyers, ensuring compliance with ASTM A681 is vital, as it guarantees the material meets specific performance criteria.

M2 Tool Steel

M2 is a high-speed steel that is designed for high-performance applications, such as cutting tools and drill bits. It maintains its hardness at elevated temperatures, making it ideal for high-speed machining. M2 offers excellent wear resistance and toughness, but it can be more expensive than other tool steels. Buyers from regions like Europe may need to ensure compliance with DIN standards, which may differ from ASTM specifications.

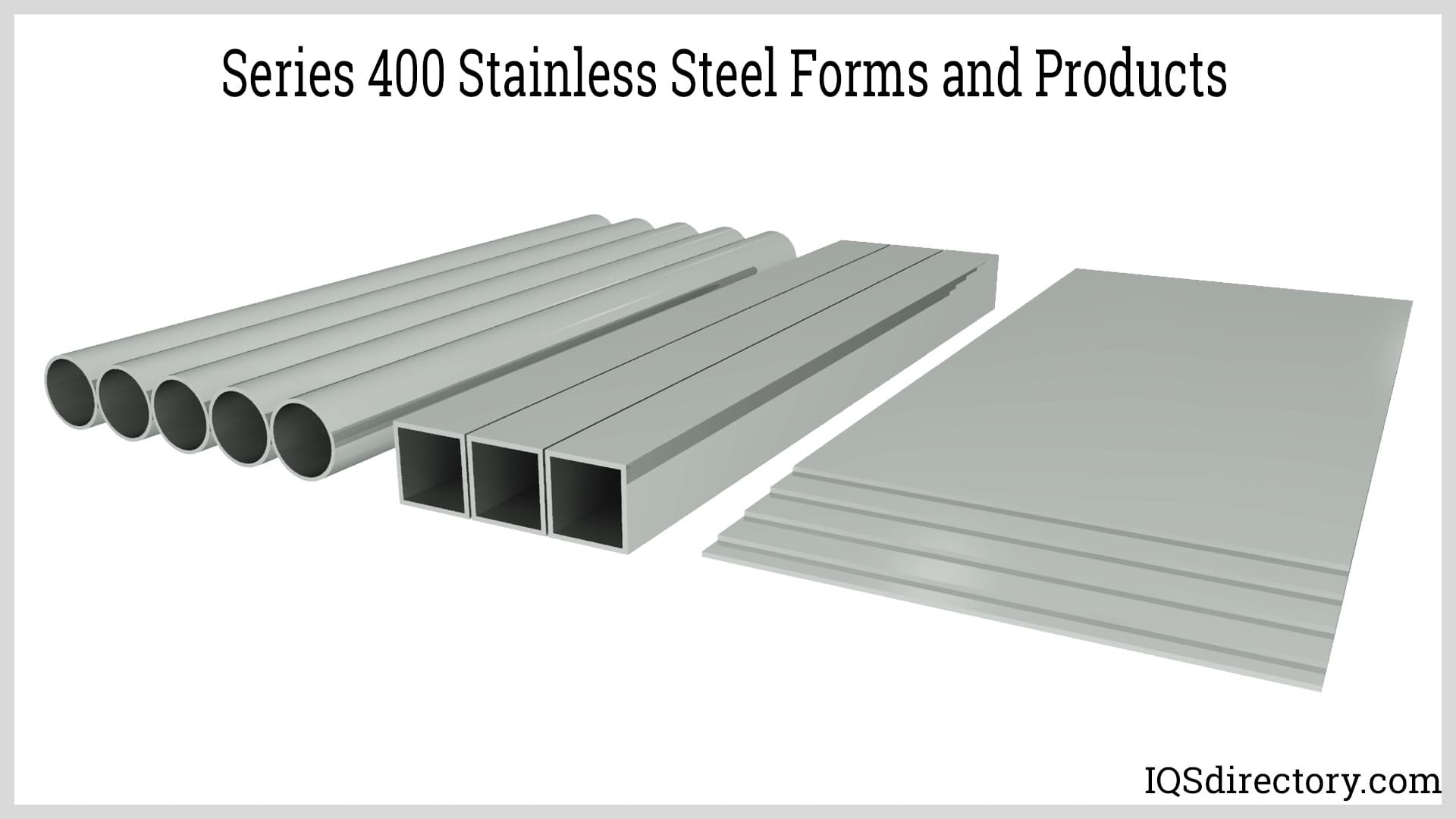

Illustrative image related to southern tool steel

Summary Table of Material Comparisons

| Material | Typical Use Case for southern tool steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| D2 Tool Steel | Stamping dies, shear blades | Excellent wear resistance | Prone to chipping under impact | High |

| A2 Tool Steel | Cutting tools, dies | Good toughness and wear resistance | Less effective at extreme temperatures | Medium |

| O1 Tool Steel | Knives, punches, dies | Easy to machine | Lower wear resistance than D2 and A2 | Medium |

| M2 Tool Steel | High-speed cutting tools | Maintains hardness at high temperatures | Higher cost compared to other tool steels | High |

This strategic material selection guide provides B2B buyers with critical insights into the properties, advantages, and limitations of various tool steels. Understanding these factors can help manufacturers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for southern tool steel

What Are the Key Stages in the Manufacturing Process of Southern Tool Steel?

The manufacturing of southern tool steel involves several critical stages to ensure the final product meets the high standards required by various industries. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The process begins with the selection of high-quality raw materials. Southern tool steel typically utilizes premium grades of steel, which are sourced based on specific mechanical properties and applications. The raw materials undergo rigorous inspection to ensure they meet the required chemical compositions and physical properties. This is often done through chemical analysis and mechanical testing of sample batches to confirm conformity to industry standards. -

Forming:

The forming stage involves processes such as forging, casting, or rolling, depending on the final shape and properties desired. Forging is particularly prominent as it enhances the steel’s strength and toughness by aligning the grain structure. Advanced techniques like hot rolling and cold working may be employed to achieve precise dimensions and surface finishes. During this phase, precise control of temperature and pressure is crucial to maintain the material’s integrity. -

Assembly:

While assembly may not be a direct process for tool steel itself, it becomes relevant when steel components are being integrated into larger systems or tools. This stage may involve machining, where components are cut, shaped, or drilled to fit specific applications. CNC (Computer Numerical Control) machining ensures high precision, allowing for complex geometries that are often required in tooling applications. -

Finishing:

The finishing stage encompasses processes such as grinding, polishing, and coating. Southern Tool Steel employs techniques like blanchard grinding to achieve a smooth and uniform surface finish. Additional treatments, such as heat treatment, may be applied to enhance hardness and wear resistance. The finishing process is vital for ensuring that the tool steel can perform effectively under the rigorous demands of its intended applications.

How is Quality Assurance Implemented in the Production of Southern Tool Steel?

Quality assurance is paramount in the production of southern tool steel, ensuring that every batch meets international standards and customer expectations. The following outlines the key components of the quality assurance process.

-

Adherence to International Standards:

Southern Tool Steel adheres to various international quality management standards, such as ISO 9001. This certification demonstrates a commitment to continuous improvement and customer satisfaction. In addition, compliance with industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for the oil and gas sector ensures that products meet stringent safety and quality requirements. -

Quality Control Checkpoints:

The quality control process is structured around several key checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for compliance with specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing ensures adherence to process parameters and product specifications.

– Final Quality Control (FQC): The finished product undergoes comprehensive testing to verify that it meets all specified requirements before shipment. -

Common Testing Methods:

Various testing methods are employed to verify the quality of southern tool steel. These may include:

– Tensile Testing: To assess the strength and ductility of the steel.

– Hardness Testing: To measure the resistance to deformation.

– Non-destructive Testing (NDT): Techniques like ultrasonic testing or X-ray inspection are used to detect internal flaws without damaging the material.

How Can B2B Buyers Verify the Quality Control Processes of Southern Tool Steel Suppliers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial for ensuring reliability. Here are actionable steps buyers can take:

-

Conduct Supplier Audits:

Regular audits allow buyers to assess the supplier’s quality management systems and processes. This includes reviewing documentation related to their ISO certifications, quality control procedures, and production practices. -

Request Quality Assurance Reports:

Suppliers should be able to provide detailed quality assurance reports that include results from various testing methods, compliance certifications, and inspection records. These documents should outline how the supplier meets international standards and customer requirements. -

Engage Third-Party Inspection Services:

Utilizing independent third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. Such services can conduct on-site inspections, review manufacturing processes, and validate compliance with specified standards. -

Understand QC Nuances for International Markets:

Buyers should be aware of specific regulations and quality standards that may differ by region. For instance, CE marking is essential for products entering the European market, while other certifications may be relevant in African or South American countries. Understanding these nuances can help buyers make informed decisions when selecting suppliers.

Conclusion

The manufacturing processes and quality assurance practices for southern tool steel are integral to delivering high-quality products that meet the diverse needs of various industries. By understanding these processes and implementing thorough verification methods, B2B buyers can ensure they partner with reliable suppliers that uphold the highest standards of quality and performance. This not only enhances operational efficiency but also strengthens the overall value chain in manufacturing applications across the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘southern tool steel’

This guide serves as a practical checklist for B2B buyers seeking to procure southern tool steel. By following these structured steps, you can ensure that your sourcing process is efficient, effective, and tailored to your specific needs.

Step 1: Define Your Technical Specifications

Understanding your specific requirements for southern tool steel is essential. This includes determining the grade, size, shape, and any special properties needed for your application. Clearly defined specifications help streamline the procurement process and ensure you receive materials that meet your operational standards.

- Grade Selection: Identify the appropriate grade of tool steel based on hardness, toughness, and wear resistance.

- Dimensions: Specify the required dimensions and tolerances, as custom orders can incur additional costs and lead times.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of southern tool steel. This step is crucial for ensuring quality and reliability in your sourcing decisions. Use online directories, industry publications, and trade shows to compile a list of potential vendors.

Illustrative image related to southern tool steel

- Industry Reputation: Look for suppliers with positive reviews and testimonials from other B2B clients.

- Product Range: Ensure the supplier offers a comprehensive selection of tool steels and related services.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify the certifications of potential suppliers. This ensures that they comply with industry standards and regulations, which is particularly important when sourcing materials for critical applications.

- Quality Management Systems: Check for ISO certifications or equivalent quality management systems that indicate adherence to quality standards.

- Material Certifications: Request mill test reports or certificates of compliance for the specific grades of steel you intend to purchase.

Step 4: Request Samples for Testing

Obtaining samples from shortlisted suppliers allows you to assess the quality and suitability of the tool steel before making a bulk purchase. This step is vital for ensuring that the material meets your technical specifications and performance expectations.

- Testing Methods: Utilize standardized testing methods to evaluate hardness, tensile strength, and microstructure.

- Comparison: Compare samples from different suppliers to make an informed decision based on performance metrics.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable terms that align with your budget and operational timelines.

- Volume Discounts: Inquire about bulk purchase discounts or loyalty programs for repeat orders.

- Delivery Options: Discuss shipping methods and timelines, particularly if you require expedited delivery.

Step 6: Finalize the Purchase Agreement

After negotiations, ensure that all terms and conditions are documented in a purchase agreement. This agreement should detail the specifications, pricing, delivery schedules, and any warranties or return policies.

- Clarity: Ensure that the agreement is clear and comprehensive to avoid potential disputes later.

- Legal Review: Consider having the contract reviewed by legal counsel, especially for large orders or long-term agreements.

Step 7: Plan for Quality Control Upon Delivery

Upon receiving your order, implement a quality control process to verify that the delivered tool steel meets your specifications. This final step is critical for maintaining operational integrity and ensuring that the materials perform as expected.

- Inspection Protocols: Develop protocols for inspecting the material upon arrival, focusing on dimensions, surface quality, and certifications.

- Documentation: Keep detailed records of all transactions and inspections for future reference and compliance purposes.

By following this checklist, you can navigate the complexities of sourcing southern tool steel with greater confidence and efficiency.

Comprehensive Cost and Pricing Analysis for southern tool steel Sourcing

What Are the Key Cost Components in Sourcing Southern Tool Steel?

When sourcing southern tool steel, several cost components play a critical role in determining the overall pricing structure. The primary elements include:

Illustrative image related to southern tool steel

-

Materials: The base material cost is influenced by the quality and type of steel. High-grade tool steels such as D2 or A2 can command higher prices due to their superior properties and applications in demanding environments.

-

Labor: Labor costs vary based on the complexity of the processing required. Operations like CNC machining or specialized cutting will incur higher labor expenses due to skilled labor requirements.

-

Manufacturing Overhead: This encompasses costs associated with facility maintenance, utilities, and equipment depreciation. Efficient operations can minimize overhead, impacting the final price.

-

Tooling: Custom tooling for specific applications can significantly add to costs. Buyers should consider whether standard tooling suffices or if investment in custom solutions is warranted for their production needs.

-

Quality Control (QC): Rigorous quality assurance processes ensure the steel meets industry standards. This includes testing for tensile strength, hardness, and other specifications, which contributes to the overall cost.

-

Logistics: Shipping costs can vary greatly depending on distance, method of transport, and the weight of the materials. For international buyers, understanding logistics can help mitigate unforeseen expenses.

-

Margin: Suppliers typically include a profit margin on top of their costs. This margin can vary based on competition and market demand.

What Influences the Pricing of Southern Tool Steel?

Several factors can influence pricing, particularly for international B2B buyers:

-

Volume and Minimum Order Quantities (MOQ): Purchasing in bulk often leads to lower per-unit costs. Negotiating MOQs can be beneficial for larger orders.

-

Specifications and Customization: Customized grades or specific dimensions can lead to higher costs. Buyers should assess whether such specifications are necessary for their applications.

-

Materials and Quality Certifications: Steel with specific certifications (like ASTM or ISO) may be priced higher due to the assurance of quality and compliance with industry standards.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can impact pricing. Established suppliers may charge more but offer added value through superior service and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They dictate responsibilities for shipping, insurance, and tariffs, which can significantly affect total costs.

How Can Buyers Negotiate Effectively for Southern Tool Steel?

Negotiation is a critical skill in securing favorable pricing for southern tool steel. Here are some strategies for B2B buyers:

-

Research Market Prices: Familiarize yourself with current market rates and trends in tool steel pricing. This knowledge empowers you to negotiate from a position of strength.

-

Build Long-term Relationships: Establishing a good rapport with suppliers can lead to better pricing, as suppliers may be more willing to offer discounts or favorable terms to reliable partners.

-

Consider Total Cost of Ownership (TCO): Evaluate the complete costs associated with sourcing, including maintenance, logistics, and potential downtime. A lower initial price may not always lead to the best value if it results in higher long-term costs.

-

Be Aware of Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and import duties can affect final costs. Factor these into your negotiations to avoid surprises.

What Should International Buyers Keep in Mind When Sourcing Southern Tool Steel?

For buyers from regions like Africa, South America, the Middle East, and Europe, several additional considerations are essential:

-

Cultural and Communication Differences: Be aware of potential language barriers and cultural differences that can affect negotiations and transaction processes.

-

Regulatory Compliance: Ensure that the tool steel sourced complies with local regulations in your country, as non-compliance can lead to costly delays or penalties.

-

Shipping and Customs: Understand the logistics involved in international shipping, including customs clearance procedures, to prevent delays in receiving your materials.

Disclaimer

Pricing information provided in this analysis is indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing tailored to your needs.

Alternatives Analysis: Comparing southern tool steel With Other Solutions

Understanding Alternatives to Southern Tool Steel

In the world of industrial manufacturing, selecting the right material is crucial for achieving optimal performance, cost-efficiency, and durability. Southern tool steel, renowned for its high-quality properties, is often compared against other materials and methods. This analysis will highlight key alternatives, enabling B2B buyers to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Southern Tool Steel | High-Speed Steel (HSS) | Carbide Tooling |

|---|---|---|---|

| Performance | Excellent toughness and wear resistance | Good hardness and wear resistance | Superior hardness and heat resistance |

| Cost | Moderate to high cost | Generally lower than tool steel | High initial investment |

| Ease of Implementation | Readily available, customizable dimensions | Requires specialized tooling | Complex machining setup required |

| Maintenance | Low maintenance with proper use | Moderate maintenance | Very low maintenance |

| Best Use Case | Precision machining, high-stress applications | General machining, drilling | Heavy-duty machining, high-speed applications |

Detailed Breakdown of Alternatives

High-Speed Steel (HSS)

High-speed steel is widely used for cutting tools and drills due to its ability to withstand high temperatures without losing hardness. It is typically less expensive than tool steel, making it an attractive option for many manufacturers. However, while HSS offers good wear resistance and hardness, it does not match the toughness of southern tool steel. As a result, HSS is better suited for general machining tasks and applications where precision is less critical.

Carbide Tooling

Carbide tooling is known for its exceptional hardness and ability to maintain sharp edges even under extreme conditions. This material is ideal for high-speed machining and heavy-duty applications, providing longer tool life and reduced downtime. However, carbide tools come with a higher upfront cost, which can be a barrier for smaller operations. Additionally, they require more complex setups and specialized machinery for effective use, making them less accessible than southern tool steel for some manufacturers.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating alternatives to southern tool steel, it’s vital for B2B buyers to consider their specific application requirements, budget constraints, and operational capabilities. Southern tool steel excels in applications requiring toughness and precision, while alternatives like high-speed steel and carbide tooling offer distinct advantages in cost and performance under certain conditions. By carefully assessing these factors, buyers can select the most suitable material to enhance their manufacturing processes and achieve their business objectives.

Essential Technical Properties and Trade Terminology for southern tool steel

What Are the Key Technical Properties of Southern Tool Steel?

When sourcing southern tool steel, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade

Southern tool steel is classified into various grades, such as A2, D2, and O1, each offering unique characteristics like hardness, wear resistance, and toughness. For instance, D2 is known for its high wear resistance, making it ideal for cutting tools. Selecting the appropriate grade ensures that the tool steel meets specific application requirements, ultimately affecting performance and longevity. -

Tensile Strength

This property measures the maximum amount of tensile (pulling) stress a material can withstand before failure. Southern tool steels typically exhibit high tensile strength, which is vital for applications requiring durable tools that can endure heavy loads without deforming. Understanding tensile strength helps buyers assess the suitability of the steel for their manufacturing processes. -

Hardness

Hardness is a critical factor in determining the wear resistance of tool steel. It is often measured on the Rockwell scale (HRC), with higher values indicating greater hardness. For example, southern tool steel can achieve hardness levels ranging from 58 to 65 HRC. Knowing the hardness is essential for buyers as it directly impacts tool performance and the frequency of replacements. -

Tolerances

Tolerance specifications define the allowable limits of variation in dimensions. For tool steel, tight tolerances (±0.001 inches, for example) are crucial in precision applications where exact measurements are needed for proper fitting and function. Understanding tolerances can help buyers ensure their components fit seamlessly, reducing the risk of operational issues. -

Heat Treatment

Southern tool steel often undergoes heat treatment processes to enhance its properties, such as hardness and toughness. Different treatments, like quenching and tempering, are applied depending on the desired final characteristics. Buyers should be familiar with the heat treatment processes to specify their requirements accurately, ensuring they receive material tailored to their needs.

What Are Common Trade Terms Related to Southern Tool Steel?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand name. In the context of tool steel, an OEM may require specific grades and specifications to meet their product standards. Understanding OEM needs can help suppliers tailor their offerings to meet market demands. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is particularly important for B2B buyers, as it affects inventory management and cash flow. Knowing the MOQ helps buyers plan their purchases to avoid overstocking or frequent reordering. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products or services. For southern tool steel, submitting an RFQ allows buyers to compare prices and terms from different suppliers, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. They clarify aspects such as shipping, insurance, and delivery. Understanding Incoterms helps buyers manage logistics and costs associated with importing southern tool steel from suppliers in different countries. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. In the context of tool steel, understanding lead times is essential for project planning and ensuring that production schedules are met without delays. -

Customs Clearance

This term describes the process of passing goods through customs so they can enter a country. For international buyers, understanding customs clearance is critical to avoid delays and additional costs when importing southern tool steel.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they source the right materials for their manufacturing needs while optimizing their supply chain processes.

Illustrative image related to southern tool steel

Navigating Market Dynamics and Sourcing Trends in the southern tool steel Sector

What Are the Current Market Dynamics and Sourcing Trends in the Southern Tool Steel Sector?

The southern tool steel sector is witnessing significant transformation driven by global demand, technological advancements, and shifting buyer preferences. As industries across Africa, South America, the Middle East, and Europe increasingly emphasize quality and customization, B2B buyers are seeking suppliers that can provide tailored solutions. Key trends include the rise of just-in-time inventory practices, which allow companies to minimize holding costs while ensuring they receive the necessary materials promptly. This demand for efficiency has prompted suppliers to invest in advanced logistics and inventory management systems, enhancing their capacity for same-day shipping and customized orders.

Moreover, digital transformation is reshaping the sourcing landscape. B2B buyers are utilizing online platforms to assess suppliers, compare prices, and streamline procurement processes. The adoption of AI and machine learning is also emerging as a game-changer, enabling suppliers to predict market trends, optimize pricing strategies, and improve customer service through personalized interactions. For international buyers, particularly from regions like Brazil and Germany, this shift towards digital solutions not only facilitates better procurement decisions but also fosters stronger supplier partnerships.

How Is Sustainability and Ethical Sourcing Influencing the Southern Tool Steel Industry?

In today’s market, sustainability and ethical sourcing are paramount considerations for B2B buyers. The environmental impact of steel production is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. This includes sourcing materials from manufacturers that utilize recycled content and employ energy-efficient production methods. Certifications such as ISO 14001 for environmental management are becoming critical indicators of a supplier’s commitment to sustainability.

Ethical supply chains are also gaining traction, with buyers increasingly interested in the labor practices of their suppliers. Transparency regarding the sourcing of raw materials, particularly concerning labor conditions in regions like Africa and South America, is essential. Suppliers who can demonstrate compliance with ethical standards and provide traceability in their supply chains are likely to be favored by conscientious buyers.

Furthermore, the demand for ‘green’ materials is on the rise. This includes tool steels with lower carbon footprints and those produced using sustainable methods. By aligning with suppliers who prioritize sustainability, B2B buyers can not only enhance their corporate social responsibility profiles but also appeal to an increasingly environmentally conscious customer base.

What Is the Historical Context of the Southern Tool Steel Sector?

The southern tool steel sector has evolved significantly over the past few decades. Initially dominated by traditional manufacturing methods, the industry has embraced innovation and technological advancements to meet the growing demands of modern manufacturing. The establishment of specialized service centers like Southern Tool Steel has transformed the landscape, providing a wide array of high-quality metals and services tailored to diverse industrial applications.

As global markets expanded, the need for reliable and efficient suppliers became critical. Southern Tool Steel and similar distributors have risen to the occasion, offering rapid delivery, customized solutions, and extensive inventories. This evolution reflects broader trends in manufacturing, where agility, quality, and sustainability are increasingly essential for success in the competitive global marketplace. As the industry continues to adapt, international B2B buyers can expect ongoing improvements in service, product offerings, and supply chain transparency.

Frequently Asked Questions (FAQs) for B2B Buyers of southern tool steel

-

How can I ensure the quality of southern tool steel products?

To ensure the quality of southern tool steel products, request certifications and specifications from suppliers. Look for compliance with international standards such as ASTM or ISO, as these indicate adherence to quality benchmarks. Additionally, consider suppliers that provide material test reports (MTRs) and offer samples for evaluation. Engaging in a site visit or third-party inspection can also help verify the supplier’s production processes and capabilities, ensuring that the tool steel meets your exact requirements. -

What are the customization options available for southern tool steel?

Southern tool steel suppliers often provide various customization options, including specific sizes, shapes, and grades tailored to your project needs. Services such as cutting, grinding, and heat treatment can also be offered to meet precise specifications. When placing an order, communicate your requirements clearly, including dimensions, tolerances, and any special finishes required. It’s advisable to work closely with the supplier’s technical team to ensure all aspects of customization are accurately addressed. -

What are the minimum order quantities (MOQs) for southern tool steel?

Minimum order quantities (MOQs) for southern tool steel can vary by supplier and specific product. Many distributors, like Southern Tool Steel, offer flexibility with no minimum order requirements, allowing you to purchase exactly what you need. However, larger orders may benefit from discounts or better pricing. It’s best to inquire directly with the supplier about their policies and any potential benefits for bulk purchasing to optimize your sourcing strategy. -

What payment terms are typically offered for international orders?

Payment terms for international orders of southern tool steel can vary by supplier but generally include options such as advance payment, letters of credit, and net payment terms (e.g., net 30 or net 60). It’s crucial to clarify these terms upfront to avoid misunderstandings. Additionally, consider discussing currency exchange rates and any transaction fees that may apply. Establishing a clear agreement on payment terms helps streamline the procurement process and fosters a trustworthy supplier relationship. -

How do I vet potential suppliers of southern tool steel?

Vetting potential suppliers involves several steps. Start by researching their reputation in the industry through reviews, testimonials, and case studies. Verify their certifications and compliance with international standards. Request references from previous clients to assess their reliability and service quality. Additionally, evaluate their logistics capabilities, including shipping times and delivery options, to ensure they can meet your demands efficiently. Engaging with suppliers in preliminary discussions can also provide insights into their customer service and responsiveness. -

What logistics considerations should I keep in mind when sourcing southern tool steel?

When sourcing southern tool steel internationally, consider logistics aspects such as shipping methods, lead times, and customs regulations. Understand the import duties and taxes that may apply in your country, as these can significantly affect overall costs. Collaborate with suppliers that have a robust logistics network, ensuring timely and efficient delivery. Additionally, clarify packaging requirements to protect the steel during transit and inquire about tracking systems for real-time shipment updates. -

What industries commonly use southern tool steel?

Southern tool steel is utilized across various industries, including aerospace, automotive, medical, and manufacturing. Each of these sectors demands high-quality materials for precision tools, molds, and parts. Understanding the specific applications within your industry can guide your selection of the right tool steel grade and type. Engaging with suppliers who have experience in your industry can also provide insights into the best materials for your specific applications and needs. -

How can I stay informed about the latest developments in southern tool steel?

To stay informed about the latest developments in southern tool steel, consider subscribing to industry newsletters, trade publications, and webinars. Joining professional organizations and attending trade shows can also provide networking opportunities and access to the latest innovations. Engage with suppliers and industry experts on platforms like LinkedIn for real-time insights and updates. Additionally, following relevant blogs and forums can help you remain current on market trends and technological advancements in tool steel applications.

Top 2 Southern Tool Steel Manufacturers & Suppliers List

1. Southern Tool Steel – High-Quality Metals

Domain: southerntoolsteel.com

Registered: 1996 (29 years)

Introduction: Southern Tool Steel offers a wide range of high-quality metals including Tool Steel (A2, D2, H13, S7, Decarb Free Drill Rod, O1), Aluminum (6061, 2024, 3003, 7075, 5052, 6063), Stainless Steel (303, 304, 316), Carbon Steel (1018, A36), and Alloy Steel (4140). The products are available in various forms such as plates, bars, round bars, square bars, flat bars, sheets, expanded metal, pipes, and str…

2. Southern Tool Steel – High-Quality Metals Distributor

Domain: thefabricator.com

Registered: 1999 (26 years)

Introduction: Southern Tool Steel, LLC is a Metals Service Center and Distributor of High-Quality Tool Steels, Carbon Steels, Alloy Steels, Aluminum, Stainless Steel, Brass, Bronze, Copper, Flat Ground & Drill Rod, Metric Sized Steels, and Specialty Metals. They offer fast delivery of the metals cut to size without a minimum order requirement.

Strategic Sourcing Conclusion and Outlook for southern tool steel

In conclusion, the strategic sourcing of southern tool steel presents a unique opportunity for international B2B buyers seeking high-quality materials tailored to diverse manufacturing needs. By partnering with reliable suppliers like Southern Tool Steel, companies can benefit from a vast inventory that includes tool steels, carbon steels, and specialty metals, all available with rapid delivery options. This flexibility allows businesses to minimize lead times and reduce inventory costs, which is crucial in today’s competitive landscape.

Moreover, the emphasis on exceptional customer service and technical support ensures that buyers receive not only products but also valuable insights and solutions that enhance their operations. As industries continue to evolve, the demand for specialized materials will only grow, making strategic sourcing a vital component of procurement strategies.

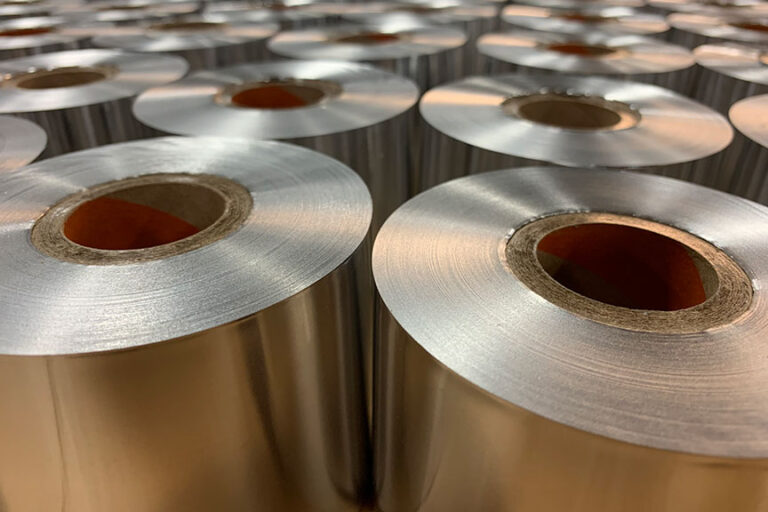

Illustrative image related to southern tool steel

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should leverage these insights to foster partnerships that drive innovation and efficiency. By prioritizing quality and service in their sourcing decisions, companies can position themselves for long-term success in the global marketplace. Engage with suppliers today to explore tailored solutions that meet your manufacturing needs and elevate your business to new heights.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.