Sonotube Footings: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for sonotube footings

In the fast-evolving landscape of construction and infrastructure, sourcing reliable sonotube footings presents a formidable challenge for international B2B buyers. With the increasing demand for durable and efficient foundation solutions across diverse geographical regions—including Africa, South America, the Middle East, and Europe—understanding the nuances of sonotube footings is essential for making informed purchasing decisions. This guide is designed to equip you with a comprehensive understanding of various types of sonotubes, their applications in different construction projects, and the critical factors to consider when vetting suppliers.

From the intricacies of material selection to the implications of local soil conditions, this guide dives deep into the essential elements that dictate the performance and longevity of sonotube footings. We will explore the cost structures associated with different types of footings, enabling you to align your budget with your project requirements effectively. Additionally, our insights will cover best practices for supplier assessment, ensuring that you partner with reputable manufacturers who can meet your specific needs.

By empowering you with actionable insights and data-driven recommendations, this guide aims to streamline your sourcing process and enhance your project outcomes. Whether you are constructing residential decks, commercial buildings, or expansive infrastructures, understanding sonotube footings will enable you to navigate the global market with confidence and precision.

Understanding sonotube footings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Sonotube | Cardboard material, varying diameters (6″-24″) | Residential and light commercial builds | Pros: Cost-effective, easy to transport. Cons: Not suitable for heavy loads or wet conditions. |

| Plastic Sonotube | Durable, waterproof plastic construction | Heavy commercial structures | Pros: Long-lasting, resistant to moisture. Cons: Higher initial cost compared to cardboard. |

| Reinforced Sonotube | Includes additional steel or composite layers | Industrial applications | Pros: Superior strength and stability. Cons: More expensive, requires specialized installation. |

| Sonotube with Footing | Integrated footing base for added support | Foundations for larger structures | Pros: Enhanced stability, reduces settling. Cons: More complex installation process. |

| Custom Sonotube | Tailored dimensions and materials | Specialized projects | Pros: Meets specific project needs. Cons: Longer lead times and higher costs. |

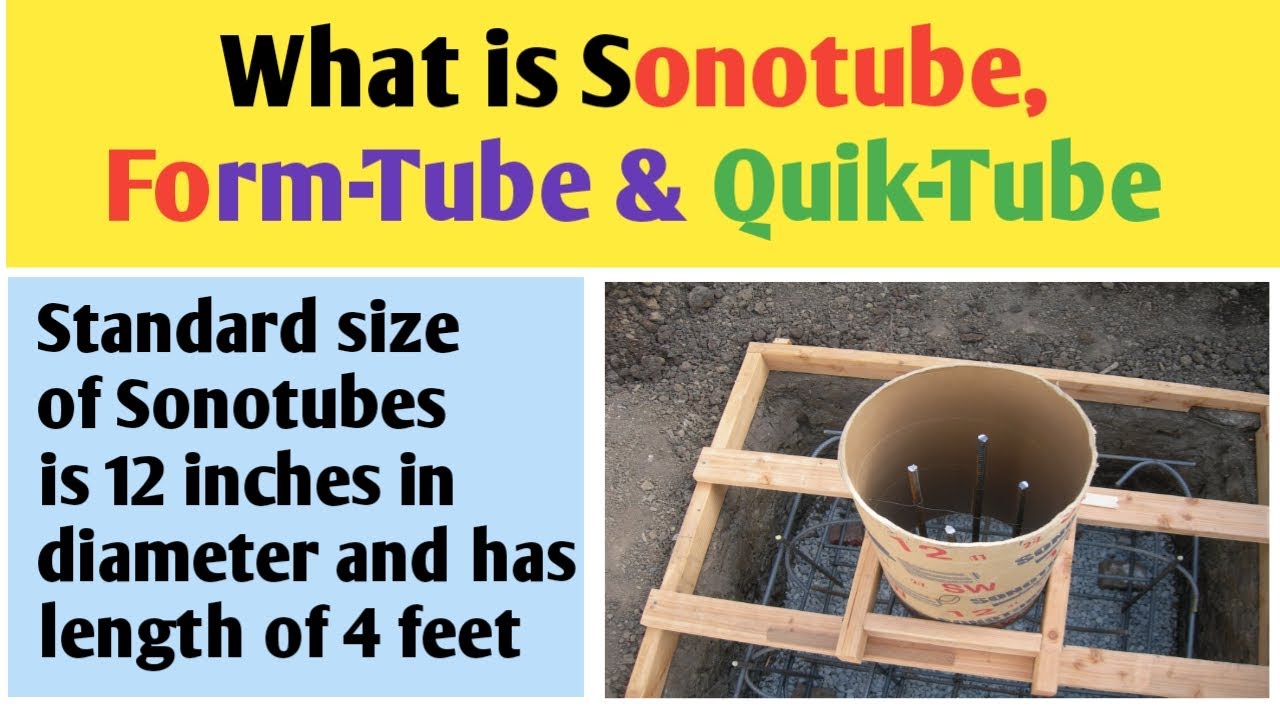

What are the characteristics of Standard Sonotubes?

Standard sonotubes are primarily made of cardboard and are available in a range of diameters, typically from 6 to 24 inches. These tubes are designed for pouring concrete footings and are ideal for residential and light commercial construction projects. Their lightweight nature makes them easy to handle and transport, which is a significant advantage for contractors looking to minimize labor costs. However, they are not suitable for heavy loads or wet environments, limiting their use in more demanding applications.

How do Plastic Sonotubes differ in performance?

Plastic sonotubes offer a more durable alternative to traditional cardboard versions, featuring waterproof construction that prevents degradation in moist conditions. They are particularly well-suited for heavy commercial projects where longevity and structural integrity are paramount. While they come with a higher upfront cost, the long-term benefits of reduced maintenance and replacement can justify the investment for many businesses. Buyers should consider their specific project requirements and budget when opting for plastic sonotubes.

What are the advantages of using Reinforced Sonotubes?

Reinforced sonotubes integrate additional materials, such as steel or composite layers, to enhance their structural capabilities. These tubes are ideal for industrial applications where exceptional strength and stability are required, such as in the foundations of large commercial buildings or heavy machinery. While they tend to be more expensive than standard options, their superior performance can result in lower risk of structural failure. B2B buyers should evaluate the load requirements of their projects to determine if the investment in reinforced sonotubes is warranted.

When should you consider using Sonotubes with Footings?

Sonotubes with integrated footings provide an extra layer of support, making them an excellent choice for larger structures that require enhanced stability. This design helps mitigate settling and shifting, which can be critical in areas with unstable soil conditions. Although the installation process is more complex and may require additional labor, the benefits of improved structural integrity often outweigh these challenges. For contractors working on significant commercial or residential projects, these sonotubes can be a valuable addition to their toolkit.

What are the benefits of Custom Sonotubes for specialized projects?

Custom sonotubes allow for tailored dimensions and materials to meet specific project needs, making them particularly useful for specialized applications. These tubes can be designed to fit unique requirements, such as varying soil conditions or specific load capacities. However, the trade-off is typically longer lead times and higher costs compared to standard options. Businesses looking to differentiate themselves in a competitive market may find that investing in custom sonotubes provides a distinct advantage in meeting client demands effectively.

Key Industrial Applications of sonotube footings

| Industry/Sector | Specific Application of sonotube footings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Foundation support for residential and commercial buildings | Provides stable support, reducing risk of structural failure | Local availability, compliance with building codes |

| Infrastructure | Support for utility poles and telecommunications towers | Enhances durability and longevity of infrastructure | Material quality, resistance to environmental factors |

| Landscaping and Outdoor Structures | Base for decks, pergolas, and outdoor structures | Ensures stability and level installation | Size and depth specifications, soil compatibility |

| Renewable Energy | Support for solar panel installations | Increases efficiency by providing a solid foundation | Load capacity, local regulations |

| Recreational Facilities | Footings for playground equipment and sports installations | Improves safety and longevity of recreational structures | Compliance with safety standards, installation ease |

How Are Sonotube Footings Applied in the Construction Industry?

In the construction sector, sonotube footings are primarily used to provide foundation support for both residential and commercial buildings. By facilitating a deep and stable base, they help mitigate risks associated with soil settlement and frost heave, which can lead to structural failures. For international buyers, especially in regions with varying soil conditions, understanding local building codes and soil compatibility is crucial when sourcing sonotube footings.

What Role Do Sonotube Footings Play in Infrastructure Development?

Sonotube footings are essential in the infrastructure sector, particularly for supporting utility poles and telecommunications towers. These applications require robust footing solutions that can withstand environmental stresses such as wind and seismic activity. Businesses need to consider the material quality and durability of sonotube footings, ensuring they meet local standards and can endure the specific environmental factors present in their region.

How Are Sonotube Footings Used in Landscaping and Outdoor Structures?

In landscaping, sonotube footings serve as the foundation for decks, pergolas, and other outdoor structures. They provide a level and stable base, which is vital for maintaining the integrity of these installations over time. For buyers in diverse regions, it’s important to evaluate the size and depth specifications of sonotubes based on local soil conditions to ensure optimal performance and longevity.

How Do Sonotube Footings Support Renewable Energy Projects?

The renewable energy sector often utilizes sonotube footings to support solar panel installations. A solid footing ensures that solar panels remain stable and optimally positioned, which can significantly enhance their efficiency. Buyers looking to source sonotube footings for renewable energy applications should focus on load capacity and adherence to local regulations to ensure compliance and performance.

What Are the Benefits of Using Sonotube Footings in Recreational Facilities?

In recreational facilities, sonotube footings are crucial for the installation of playground equipment and sports installations. They enhance safety by providing a secure and stable base, thereby extending the lifespan of these structures. When sourcing sonotube footings for recreational applications, businesses must ensure compliance with safety standards and consider the ease of installation to minimize downtime during projects.

3 Common User Pain Points for ‘sonotube footings’ & Their Solutions

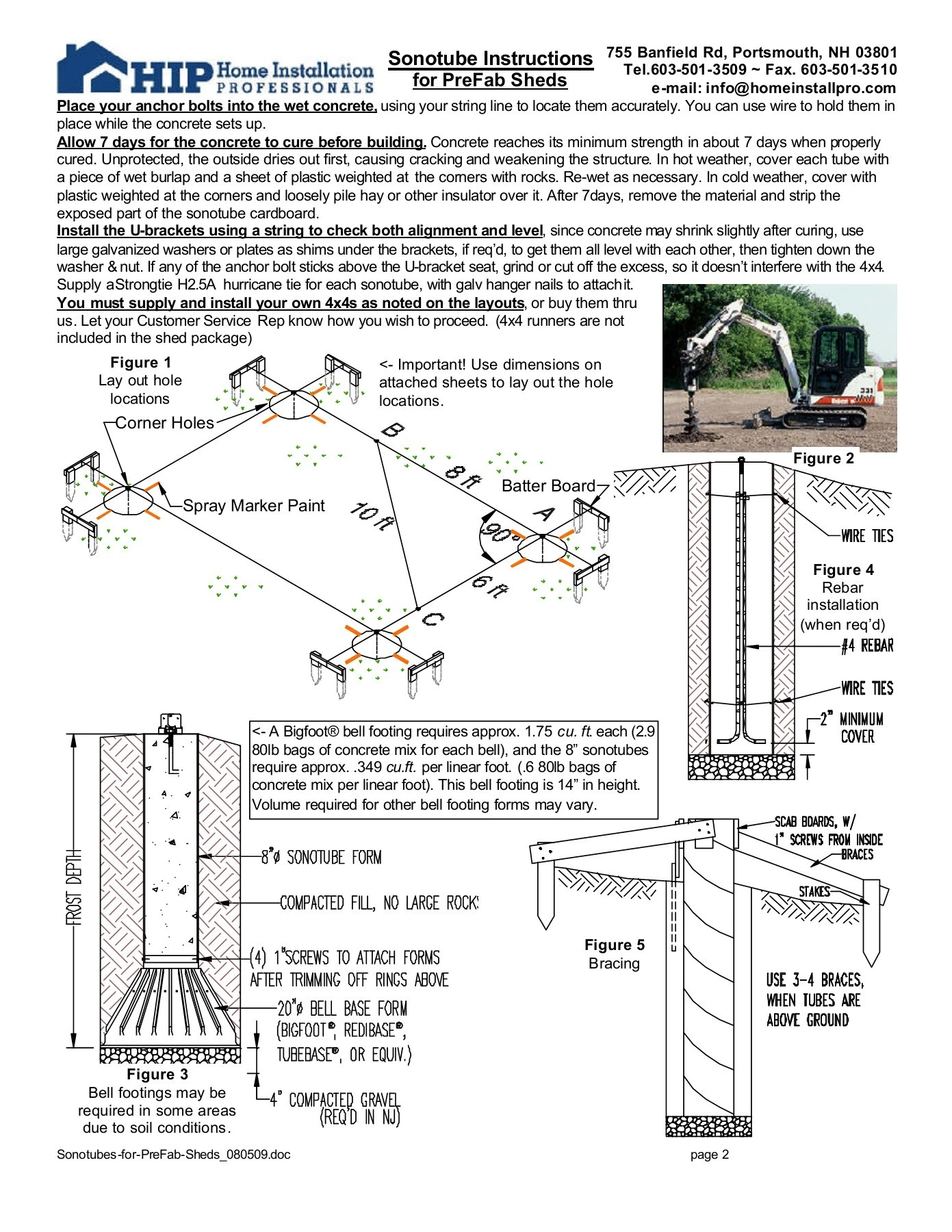

Scenario 1: Difficulty in Digging Holes for Sonotube Installation

The Problem: Many B2B buyers, especially those working in construction or landscaping in regions with rocky or compacted soil, face significant challenges when it comes to digging holes for sonotube footings. This labor-intensive task can lead to project delays and increased labor costs, particularly when traditional digging methods like post hole augers fail to penetrate tough ground conditions. Additionally, improper hole preparation can lead to uneven footings, compromising the stability of the structure being built.

The Solution: To effectively tackle the challenge of digging holes, B2B buyers should consider investing in specialized equipment, such as a mini-excavator or a hydraulic auger attachment, which can handle a variety of soil types, including rocky and clay-heavy compositions. Before commencing the project, a thorough site analysis is essential. This can involve using soil testing services to determine soil composition and density. Once the site is prepared, ensure that the excavation team is well-trained in operating heavy machinery to maximize efficiency and minimize risk. For smaller projects, a combination of hand tools and a powered auger may suffice, but having access to heavier machinery will significantly expedite the process for larger installations.

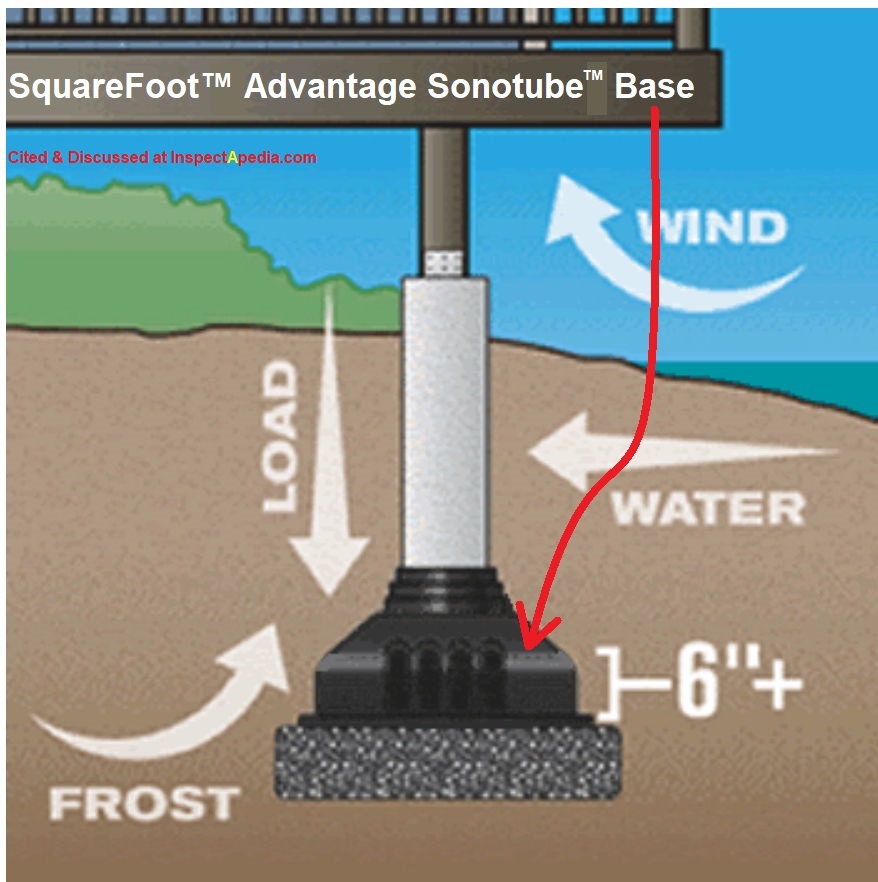

Scenario 2: Ensuring Proper Frost Depth for Footings

The Problem: In regions with severe winter climates, such as parts of Europe and North America, failing to place sonotube footings below the frost line can lead to structural instability. B2B buyers may struggle to ascertain the correct frost depth due to variations in local codes and soil conditions, which can ultimately result in costly repairs or project failures if not properly addressed.

The Solution: To prevent frost-related issues, B2B buyers must first familiarize themselves with local building codes that specify the required frost depth for footings. Engaging with local engineers or structural experts can provide valuable insights into specific site conditions. Once the frost depth is established, a reliable method for achieving the necessary depth is to use the sonotube’s length to your advantage. Ensure that the sonotubes are adequately anchored with gravel at the bottom to facilitate drainage and minimize frost heave. Additionally, employing thermal insulation around the top of the footings during the curing process can help maintain a stable temperature, further reducing the risk of frost damage.

Scenario 3: Sizing and Specifying Sonotubes for Varying Loads

The Problem: When working on diverse projects, buyers often encounter difficulties in selecting the right size and type of sonotubes to accommodate varying load requirements. Misjudging the load capacity can lead to structural failures, which not only affect safety but can also result in financial losses and reputational damage.

Illustrative image related to sonotube footings

The Solution: To accurately size sonotubes for specific loads, B2B buyers should conduct a thorough load analysis before making any purchases. This analysis should consider factors such as the weight of the structure, local environmental conditions (including wind and seismic loads), and the type of soil. Collaborating with structural engineers during this phase can yield precise calculations for the required sonotube diameter and depth. When sourcing sonotubes, buyers should consult with reputable suppliers who can provide detailed specifications and guidance on load-bearing capacities. Additionally, incorporating reinforcement options, such as rebar or steel brackets, can significantly enhance the load-bearing capabilities of the sonotubes. Properly addressing these considerations will not only ensure structural integrity but also enhance the longevity of the project.

Strategic Material Selection Guide for sonotube footings

What Are the Key Materials for Sonotube Footings?

When selecting materials for sonotube footings, various options exist, each with distinct properties, advantages, and limitations. Understanding these materials is crucial for B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe.

How Do Cardboard Sonotubes Perform in Various Conditions?

Cardboard sonotubes are commonly used for their lightweight and easy-to-handle nature. They are designed to withstand the pressure of wet concrete during the curing process, making them suitable for temporary applications. Key properties include good compressive strength and moisture resistance, which are essential for maintaining form integrity during pouring.

Pros: They are cost-effective and readily available, making them a popular choice for small to medium projects. Additionally, they are easy to cut and customize on-site, which can reduce labor costs.

Illustrative image related to sonotube footings

Cons: Cardboard sonotubes are not suitable for long-term applications due to their susceptibility to moisture damage after the concrete has cured. They may also not perform well in extreme weather conditions, such as heavy rain or high humidity.

Impact on Application: Cardboard sonotubes are best suited for residential projects or temporary structures. They are not recommended for high-load applications or areas prone to flooding.

Considerations for International Buyers: Compliance with local building codes is essential. Buyers should ensure that the materials meet relevant standards, such as ASTM or DIN, particularly in regions with strict construction regulations.

Illustrative image related to sonotube footings

What Advantages Do Plastic Sonotubes Offer?

Plastic sonotubes, such as those made from high-density polyethylene (HDPE), provide a robust alternative to cardboard. They offer superior moisture resistance and durability, making them suitable for a wider range of applications.

Pros: Plastic sonotubes are reusable and can withstand harsh environmental conditions, including UV exposure and extreme temperatures. Their smooth interior surface facilitates easy concrete pouring, reducing the risk of air pockets.

Cons: The initial cost of plastic sonotubes is higher than that of cardboard options. Additionally, they may require specialized disposal methods due to their non-biodegradable nature.

Impact on Application: Plastic sonotubes are ideal for commercial projects or areas with high moisture levels, as they maintain structural integrity over time.

Considerations for International Buyers: Buyers should verify that plastic sonotubes comply with local environmental regulations and standards. In regions with high temperatures, ensuring the material can withstand thermal expansion is crucial.

How Do Steel Sonotubes Compare in Performance?

Steel sonotubes are the most durable option available, designed to support heavy loads and withstand harsh conditions. They are often used in industrial applications where maximum strength is required.

Pros: Steel sonotubes offer exceptional load-bearing capacity and resistance to environmental factors such as corrosion. They can also be reused multiple times, providing long-term value.

Cons: The higher cost and weight of steel sonotubes can increase transportation and installation expenses. They may also require additional treatments to prevent rusting in humid environments.

Impact on Application: Steel sonotubes are suitable for high-load applications, such as large commercial buildings or infrastructure projects.

Considerations for International Buyers: Compliance with international standards, such as JIS or ASTM, is critical. Buyers must also consider the availability of steel in their region and any associated import tariffs.

What Role Do Composite Materials Play in Sonotube Footings?

Composite sonotubes combine materials like fiberglass and resin to create a lightweight yet strong option. They are increasingly popular in specialized applications.

Pros: Composite sonotubes are resistant to corrosion, lightweight, and can be manufactured to specific requirements, making them versatile for various applications.

Cons: The manufacturing complexity can lead to higher costs, and they may not be as widely available as other options.

Impact on Application: Ideal for specialized construction projects that require specific material properties, such as chemical resistance.

Considerations for International Buyers: Buyers should ensure that composite materials meet local standards and regulations, particularly in regions with stringent construction practices.

Illustrative image related to sonotube footings

Summary of Material Selection for Sonotube Footings

| Material | Typical Use Case for sonotube footings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cardboard | Temporary residential projects | Cost-effective and lightweight | Not durable for long-term use | Low |

| Plastic | Commercial projects in moist areas | Moisture resistant and reusable | Higher initial cost | Medium |

| Steel | High-load industrial applications | Exceptional strength | Heavy and higher transportation costs | High |

| Composite | Specialized construction projects | Corrosion resistant | Higher manufacturing complexity | Medium to High |

This guide provides a comprehensive overview of the materials available for sonotube footings, enabling B2B buyers to make informed decisions based on their specific project needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for sonotube footings

What Are the Key Manufacturing Processes for Sonotube Footings?

The manufacturing of sonotube footings involves several critical stages that ensure the final product meets the required standards for strength, durability, and application suitability. Understanding these processes is vital for B2B buyers seeking reliable suppliers.

How Are Raw Materials Prepared for Sonotube Production?

The process begins with the selection of high-quality raw materials. Typically, sonotubes are made from robust cardboard or plastic that can withstand the pressures of concrete pouring. The materials are sourced from reputable suppliers who adhere to international standards. Prior to production, the raw materials undergo testing to confirm their strength and flexibility.

Once the materials are procured, they are cut and shaped into the desired dimensions. This preparation stage is crucial as it sets the foundation for the subsequent manufacturing processes.

What Techniques Are Used in the Forming Process of Sonotubes?

The forming stage involves shaping the prepared materials into cylindrical tubes. For cardboard sonotubes, this is often accomplished through a spiral winding technique, where layers of material are wound around a rotating mandrel. This method ensures uniform thickness and strength throughout the tube, which is essential for supporting the weight of the concrete and the structure above.

Illustrative image related to sonotube footings

For plastic sonotubes, extrusion techniques may be employed, where molten plastic is forced through a die to create the desired tube shape. This method provides a seamless finish, enhancing the structural integrity and making it less susceptible to moisture damage.

How Is the Assembly Process Conducted for Sonotube Footings?

After forming, sonotubes may undergo an assembly process, especially when integrated with other components, such as rebar supports or footing bases. This assembly is critical in ensuring that the sonotubes are not only functional but also compatible with various construction requirements.

During this phase, manufacturers often incorporate additional features, such as grooves or notches, to facilitate easier installation and alignment on construction sites. Ensuring that these components fit seamlessly is vital for the overall performance of the footing.

What Finishing Techniques Are Applied to Sonotube Footings?

Finishing processes may include surface treatments that enhance durability and weather resistance. For cardboard sonotubes, a waterproof coating can be applied to prevent moisture absorption, which could compromise the structural integrity. Plastic sonotubes, on the other hand, may undergo UV stabilization processes to enhance their longevity, especially in regions with high sun exposure.

Illustrative image related to sonotube footings

Quality assurance checks are integral at this stage, ensuring that each sonotube meets the specified dimensions and is free from defects.

How Is Quality Assurance Implemented in Sonotube Manufacturing?

Quality assurance is a vital component of the sonotube manufacturing process, ensuring that products meet both international and industry-specific standards. B2B buyers should be aware of these standards to ensure they are purchasing reliable products.

What International Standards Should B2B Buyers Consider for Sonotubes?

Manufacturers often adhere to international quality management standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 demonstrates a commitment to quality and consistency in production processes.

Additionally, depending on the region and application, other certifications such as CE marking (for compliance with European safety standards) or API specifications (for applications in the oil and gas sector) may also be applicable.

What Are the Key Quality Control Checkpoints in Sonotube Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the required specifications.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is performed to catch any deviations from quality standards early in the process.

-

Final Quality Control (FQC): Before shipment, finished products undergo rigorous testing, including dimensional checks and structural integrity assessments.

Which Common Testing Methods Are Used to Ensure Sonotube Quality?

Testing methods for sonotubes may include:

-

Compression Testing: To evaluate the strength and load-bearing capacity of the sonotubes under various conditions.

-

Moisture Absorption Testing: Particularly for cardboard sonotubes, to ensure they can withstand environmental exposure without compromising integrity.

-

Dimensional Verification: Ensuring that all products conform to specified dimensions for compatibility with other construction elements.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control measures is crucial in mitigating risks associated with product failure. Here are some strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

B2B buyers should consider conducting on-site audits of potential suppliers. This allows them to assess the manufacturing processes, quality control measures, and adherence to standards. During the audit, buyers should request documentation of quality certifications and inspection reports.

Illustrative image related to sonotube footings

How Can Buyers Utilize Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices. These services can perform random checks on batches of sonotubes before shipment to ensure compliance with international standards.

What Documentation Should Buyers Request from Suppliers?

Buyers should request comprehensive documentation, including:

-

Quality Assurance Certificates: Proof of compliance with ISO and other relevant standards.

-

Test Reports: Detailed results from the various testing methods conducted during the FQC stage.

-

Production Records: Documentation that demonstrates adherence to specified manufacturing processes and timelines.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Variations in regional regulations and standards can impact the acceptance of products.

Understanding local building codes and requirements is essential to ensure compliance. Additionally, buyers should consider cultural differences in business practices that may affect communication and expectations regarding quality assurance.

By being informed about the manufacturing processes and quality assurance protocols for sonotube footings, B2B buyers can make educated decisions when selecting suppliers, ultimately ensuring the success of their construction projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sonotube footings’

Introduction

This guide provides a comprehensive checklist for B2B buyers looking to procure sonotube footings. As essential components in construction projects, sonotubes offer significant benefits in terms of stability and ease of installation. Following this checklist will ensure you select the right products and suppliers, streamline your procurement process, and ultimately support successful project execution.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your project is crucial. Consider factors such as load-bearing capacity, tube diameter, and depth based on soil conditions and structural needs. Clearly defined specifications will help you communicate effectively with suppliers and ensure that the sonotubes you procure meet your project demands.

Step 2: Research and Identify Reputable Suppliers

Start by compiling a list of potential suppliers with experience in manufacturing sonotubes. Look for companies that specialize in construction materials and have a solid reputation in your target regions, such as Africa, South America, the Middle East, and Europe. Utilize industry forums, trade shows, and online directories to discover suppliers that meet your criteria.

Step 3: Evaluate Supplier Certifications and Compliance

Before finalizing any agreements, verify that suppliers hold relevant certifications and adhere to international standards. This may include ISO certifications or compliance with local building codes. Ensuring that your suppliers are certified will minimize risks related to product quality and safety.

Illustrative image related to sonotube footings

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of their sonotubes. Assess the quality of materials and construction techniques used, as these factors directly impact the performance of the footings. Pay attention to aspects such as wall thickness, material consistency, and overall finish to ensure you are selecting a high-quality product.

Step 5: Compare Pricing and Delivery Options

Gather detailed quotes from multiple suppliers, taking into account not only the price per unit but also shipping costs and lead times. It’s essential to balance cost with quality and reliability. Make sure to inquire about bulk order discounts and the flexibility of delivery schedules to accommodate your project timelines.

Step 6: Review Supplier References and Case Studies

Request references and case studies from suppliers to gauge their past performance and customer satisfaction. Speaking with previous clients can provide insights into the supplier’s reliability, responsiveness, and the quality of their products. This step can help you avoid potential pitfalls and ensure you partner with a reputable supplier.

Step 7: Establish Clear Terms and Conditions

Before finalizing your order, ensure that all terms and conditions are clearly outlined in the contract. This includes payment terms, delivery schedules, warranty information, and return policies. A well-defined agreement protects both parties and sets clear expectations for the procurement process.

By following this step-by-step checklist, B2B buyers can confidently navigate the procurement of sonotube footings, ensuring that they select the right products and suppliers to support their construction projects.

Comprehensive Cost and Pricing Analysis for sonotube footings Sourcing

What Are the Key Cost Components for Sourcing Sonotube Footings?

When sourcing sonotube footings, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials, such as cardboard or plastic for sonotubes, cement, and rebar, constitutes a significant portion of the total expenditure. Prices can vary based on material quality, sustainability certifications, and supplier relationships.

-

Labor: Labor costs encompass the workforce required for both production and installation. Depending on local wage rates and the complexity of the project, labor can significantly influence the overall cost.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and administrative costs. Efficient manufacturing processes can help reduce overhead, which may lead to lower prices for buyers.

-

Tooling: The investment in specialized equipment for producing sonotubes can affect pricing. Suppliers with advanced manufacturing capabilities may offer better pricing due to economies of scale.

-

Quality Control: Ensuring that sonotubes meet industry standards and certifications is vital. QC processes can add to manufacturing costs but are essential for long-term reliability and safety.

-

Logistics: Shipping and handling costs can vary based on distance, mode of transport, and local tariffs or import duties. International buyers should consider these factors, especially when dealing with suppliers across continents.

-

Margin: Finally, the profit margin that suppliers include will vary based on their market position, competition, and demand. Understanding market dynamics can provide insights into potential negotiation points.

What Price Influencers Should Buyers Consider?

Several factors can influence the pricing of sonotube footings:

-

Volume/MOQ: Bulk purchasing often results in lower unit prices. Buyers should assess their project needs to negotiate favorable terms, especially when looking for larger quantities.

-

Specifications and Customization: Custom sonotubes tailored to specific project requirements can incur additional costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Quality and Certifications: Premium materials and certifications can justify higher prices but may also lead to greater durability and fewer long-term costs. Buyers should evaluate the total cost of ownership (TCO) rather than just upfront costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer higher prices due to their proven track record, but they might also provide better service and quality assurance.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is crucial for international shipping. These terms define the responsibilities of buyers and sellers, impacting overall costs and risk management.

How Can Buyers Optimize Costs When Sourcing Sonotube Footings?

International B2B buyers can employ several strategies to optimize their sourcing costs:

-

Negotiation: Open discussions with suppliers can lead to better pricing, especially for larger orders. Building relationships and demonstrating loyalty can also yield favorable terms over time.

-

Cost-Efficiency: Conduct a thorough analysis of the Total Cost of Ownership (TCO) by factoring in long-term durability and maintenance costs. Sometimes spending more upfront can result in savings in the long run.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and import regulations that can impact pricing. Researching local suppliers or considering regional partnerships can also be beneficial.

-

Bulk Purchasing: If feasible, consolidating orders for multiple projects can help achieve economies of scale, reducing overall costs.

-

Market Intelligence: Keeping abreast of market trends and pricing fluctuations can empower buyers to make informed decisions and time their purchases strategically.

In conclusion, understanding the cost structure and pricing influences of sonotube footings is vital for international B2B buyers. By leveraging these insights, buyers can make informed decisions that align with their project requirements and budget constraints. Always remember that prices can vary significantly based on several factors, so conducting thorough research and negotiation is essential.

Alternatives Analysis: Comparing sonotube footings With Other Solutions

Exploring Alternatives to Sonotube Footings

When considering construction solutions for foundational support, it is essential to evaluate various options available in the market. Sonotube footings, known for their efficiency and effectiveness in distributing loads, can be compared against alternative methods such as traditional concrete footings and helical piles. Each of these alternatives has its unique advantages and drawbacks, which can significantly influence decision-making in construction projects.

| Comparison Aspect | Sonotube Footings | Traditional Concrete Footings | Helical Piles |

|---|---|---|---|

| Performance | Excellent load distribution; quick curing | Strong and durable; can support heavy loads | Suitable for unstable soils; less vibration during installation |

| Cost | Moderate initial investment; low labor costs | Higher material costs and labor-intensive | Higher upfront cost, but less labor-intensive |

| Ease of Implementation | Quick setup; requires minimal excavation | Time-consuming; requires extensive excavation and forming | Quick installation; no concrete curing time required |

| Maintenance | Minimal; durable materials | Moderate; may require inspection and repair | Low; typically no maintenance needed |

| Best Use Case | Residential decks, small structures | Large buildings, commercial applications | Areas with poor soil conditions, temporary structures |

What Are the Pros and Cons of Traditional Concrete Footings?

Traditional concrete footings are a widely recognized method for providing foundational support. They consist of a concrete base that is poured into a pre-dug hole. This method offers significant strength and durability, making it suitable for heavy structures such as commercial buildings. However, the installation process can be labor-intensive and time-consuming, requiring substantial excavation and forming. Additionally, the cost of materials and labor can be higher compared to sonotubes. While they perform well in stable soil conditions, they may not be ideal for areas with poor drainage or unstable ground.

How Do Helical Piles Compare to Sonotube Footings?

Helical piles are an innovative solution for foundation support, particularly in challenging soil conditions. They are steel shafts with helical plates that are drilled into the ground, providing immediate load-bearing capacity. The primary advantage of helical piles is their ability to be installed with minimal disturbance to the surrounding soil, making them a great option for sensitive sites. However, they can be more expensive upfront and may require specialized equipment for installation. Their maintenance needs are low, as they are typically resistant to settlement issues that affect other foundation types.

Conclusion: How to Choose the Right Foundation Solution

Selecting the appropriate foundation solution depends on various factors, including the specific project requirements, soil conditions, and budget constraints. For B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the unique advantages of sonotube footings versus traditional concrete and helical piles is crucial. If speed and ease of implementation are priorities, sonotubes may be the best option. Conversely, if the project involves heavy loads or unstable soil, traditional concrete footings or helical piles could be more suitable. Ultimately, conducting a thorough analysis of site conditions and project needs will ensure the most effective and economical choice for foundational support.

Essential Technical Properties and Trade Terminology for sonotube footings

What Are the Critical Technical Properties of Sonotube Footings?

Understanding the essential technical properties of sonotube footings is crucial for international B2B buyers involved in construction and civil engineering. Here are some key specifications:

Illustrative image related to sonotube footings

-

Material Composition

Sonotubes are typically made from high-strength cardboard or fiber-reinforced composite materials. The choice of material affects durability, resistance to moisture, and overall strength. For buyers, selecting the right material can reduce long-term costs associated with structural failures or repairs. -

Diameter and Depth Specifications

Sonotubes come in various diameters, usually ranging from 6 inches to 12 inches or more, with depths that can reach up to 12 feet. The diameter and depth are critical for load-bearing capacity and must be chosen based on the specific requirements of the structure being built. This specification is vital to ensure stability and compliance with local building codes. -

Load-Bearing Capacity

This property refers to the maximum weight that a sonotube can support without failure. Load-bearing capacity is influenced by the tube’s diameter, wall thickness, and concrete mix used. For B2B buyers, understanding load limits helps in selecting appropriate sonotube sizes for various applications, from residential decks to commercial buildings. -

Frost Depth Considerations

In regions susceptible to frost heave, sonotube footings must be installed below the frost line. This depth varies by geographic location and is essential for preventing structural damage over time. Buyers must consider local environmental conditions when planning their projects to ensure long-lasting foundations. -

Curing Time and Conditions

The curing time for concrete within sonotubes typically ranges from 24 to 48 hours, depending on environmental conditions. Understanding these timelines is crucial for project planning, as delays can impact overall construction schedules and costs. -

Reinforcement Options

Incorporating rebar or other reinforcement materials enhances the structural integrity of sonotubes. Buyers should understand different reinforcement techniques to ensure compliance with safety standards and improve load-bearing capabilities.

What Are Common Trade Terms Related to Sonotube Footings?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or equipment that are used in another company’s end product. For B2B buyers, understanding OEM relationships can help in sourcing high-quality sonotubes from reputable manufacturers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ helps in budgeting and logistics, especially when sourcing materials like sonotubes from overseas. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should utilize RFQs to gather competitive pricing and terms from multiple suppliers for sonotube footings. -

Incoterms (International Commercial Terms)

These are standardized international trade terms that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms can help B2B buyers navigate shipping logistics and costs effectively. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning and ensuring that sonotube footings arrive on schedule. -

Certification Standards

These standards ensure that products meet specific safety and quality requirements. For buyers, verifying that sonotubes are certified according to local or international standards is critical for compliance and risk management.

By grasping these properties and terms, B2B buyers can make informed decisions when sourcing sonotube footings, ensuring that their construction projects are both efficient and compliant with industry standards.

Navigating Market Dynamics and Sourcing Trends in the sonotube footings Sector

What Are the Current Market Dynamics and Key Trends in the Sonotube Footings Sector?

The global sonotube footings market is experiencing significant growth, driven primarily by the increasing demand for durable and reliable foundation solutions across various construction sectors. The rise of urbanization, particularly in regions such as Africa, South America, and the Middle East, is prompting a surge in residential and commercial construction projects. In Europe, the emphasis on infrastructure development further amplifies this trend. Emerging markets are particularly keen on adopting advanced construction technologies, such as prefabricated materials and innovative mixing techniques, which enhance the efficiency and quality of sonotube footings.

B2B buyers are increasingly leveraging digital platforms to streamline their sourcing processes. Technologies such as Building Information Modeling (BIM) and cloud-based supply chain management tools are reshaping how buyers interact with suppliers. These innovations facilitate real-time data exchange, allowing for more accurate project planning and execution. Additionally, the trend towards local sourcing is gaining traction, as companies seek to mitigate supply chain disruptions and reduce lead times. International buyers are encouraged to consider regional suppliers that can offer both competitive pricing and timely delivery.

Illustrative image related to sonotube footings

How Is Sustainability Influencing the Sourcing of Sonotube Footings?

Environmental considerations are becoming paramount in the decision-making processes of B2B buyers in the sonotube footings sector. The construction industry is under increasing pressure to adopt sustainable practices, leading to a growing demand for eco-friendly materials and ethical sourcing. Many companies are now prioritizing suppliers who demonstrate a commitment to sustainability through certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 (Environmental Management Systems).

The environmental impact of sonotube footings can be mitigated through the use of recycled materials and innovative production processes that reduce waste. Buyers should seek suppliers who offer “green” sonotubes made from sustainable resources or those who implement energy-efficient manufacturing techniques. By choosing sustainable options, companies not only comply with regulatory requirements but also enhance their brand reputation among environmentally conscious consumers.

How Has the Sonotube Footings Sector Evolved Over Time?

The evolution of sonotube footings can be traced back to the need for more efficient and effective foundation solutions in construction. Initially, traditional concrete forms were prevalent; however, the introduction of cardboard sonotubes revolutionized the industry. These lightweight, easy-to-install forms offer numerous advantages, including reduced labor costs and faster project timelines. Over time, advancements in material technology have led to the development of more robust and durable sonotubes that can withstand varying soil conditions and environmental factors.

As the construction landscape continues to evolve, sonotubes are increasingly being integrated into modern building practices, reflecting a broader shift towards innovative and sustainable construction methodologies. This evolution positions sonotube footings as a vital component in contemporary construction, appealing to a diverse range of B2B buyers across global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of sonotube footings

-

How do I choose the right sonotube footing for my project?

When selecting sonotube footings, consider factors such as soil type, load-bearing requirements, and local climate conditions. For instance, in regions with frost, deeper sonotubes may be necessary to prevent heaving. Consult with structural engineers to determine the appropriate diameter and depth based on the specific application, whether it’s for residential structures or commercial projects. Additionally, ensure the sonotubes comply with local building codes and standards for durability and safety. -

What is the best way to source sonotube footings internationally?

To effectively source sonotube footings internationally, begin by identifying reputable suppliers with experience in your target markets. Utilize platforms like Alibaba or Global Sources, and participate in industry trade shows to connect directly with manufacturers. It’s crucial to review suppliers’ certifications, past project portfolios, and customer feedback. Establishing a local contact or agent can also facilitate communication and ensure that your specific requirements are met in terms of quality and compliance. -

What are the minimum order quantities (MOQs) for sonotube footings?

Minimum order quantities for sonotube footings can vary significantly between manufacturers. Some suppliers may have MOQs as low as 100 units, while others may require larger orders, especially for custom sizes or specifications. When negotiating, consider your project’s scale and future needs. Engaging in long-term partnerships can sometimes result in more favorable terms, including lower MOQs or bulk pricing discounts. -

How do I ensure the quality of sonotube footings from my supplier?

To ensure the quality of sonotube footings, request samples before placing a large order. Verify that the materials used comply with industry standards, such as ASTM specifications. Implement a quality assurance process that includes on-site inspections during production. Establishing clear communication regarding your quality expectations with the supplier will also help in maintaining standards throughout the manufacturing process. -

What payment terms are commonly accepted for international orders?

International suppliers typically accept a variety of payment terms, including letters of credit, wire transfers, or payment through secure platforms like PayPal. It’s important to negotiate favorable terms that protect both parties. Consider options like partial payments upfront with the balance upon delivery, which can help mitigate risks. Always ensure that the chosen payment method offers sufficient protection against fraud and disputes. -

How should I handle logistics and shipping for sonotube footings?

When managing logistics for sonotube footings, coordinate with your supplier to determine the best shipping method based on cost and delivery time. Consider using freight forwarders experienced in handling construction materials, as they can navigate customs and import regulations efficiently. Be aware of the packaging requirements to prevent damage during transit, and plan for potential delays by allowing extra time for shipping, especially for international deliveries. -

Can sonotube footings be customized for specific projects?

Yes, many manufacturers offer customization options for sonotube footings, including varying diameters, lengths, and wall thicknesses. If your project requires unique specifications due to environmental conditions or load requirements, communicate these needs early in the sourcing process. Customization may involve additional lead times and costs, so it’s essential to factor this into your project timeline and budget. -

What are the common applications for sonotube footings in construction?

Sonotube footings are widely used in various construction applications, including residential decks, commercial buildings, and utility poles. They are particularly effective in areas with unstable soil, as they provide a solid foundation that can withstand lateral forces and frost heave. Additionally, sonotubes are ideal for structures requiring deep footings, such as fences, light posts, and elevated decks, due to their ability to be poured in-place and cured effectively.

Top 6 Sonotube Footings Manufacturers & Suppliers List

1. Reddit – 10 Diameter Sonotube Footings

2. The Vanderveen House – Deck Supplies and Footing Solutions

Domain: thevanderveenhouse.com

Registered: 2015 (10 years)

Introduction: 1. **Deck Supplies**: Ordered from Morrisburg Building Centre, including portland cement and gravel. 2. **Digging Holes**: Options include post hole auger or mini-excavator; depth of holes should be over 4 feet to prevent frost under footings. 3. **Framing Footings**: Built 2′ x 2′ frames using 2″ x 6″ pressure treated lumber. 4. **Pouring Footings**: Mixed concrete and added rebar to connect foot…

3. Howe Lumber – Sonotubes

Domain: cust.howelumber.com

Registered: 1999 (26 years)

Introduction: Sonotubes are cylindrical concrete forms used for pouring concrete footings and piers. They are available in various sizes to accommodate different construction needs. The product is designed for easy handling and installation, providing a reliable solution for creating strong and durable foundations.

4. JLC Online – Sonotube Concrete Forms

Domain: jlconline.com

Registered: 1998 (27 years)

Introduction: 12-inch-diameter cardboard tube forms (usually Sonotubes), #4 rebar, sack concrete mix, Imer Rollbeta mixer (cost around $600), each tube and footing requires eight bags of concrete mix.

5. DIY Chatroom – Sonotubes for Playset Support

Domain: diychatroom.com

Registered: 2003 (22 years)

Introduction: Sonotubes: 8 inches wide, 3 feet deep; used for supporting posts of a large playset (15 ft x 13 ft, 16 ft high peak); installed to frost depth to avoid tree roots; 16 posts total; standoff bracket connected to 5/8″ j-bolt; no footing planned under sonotubes; soil conditions: rocky and clay-like.

6. Fine Homebuilding – Sonotube for Post Setting

Domain: finehomebuilding.com

Introduction: Sonotube is used for setting posts in construction, allowing concrete to ‘mushroom’ out and form a wider base. It is recommended to hold the tubes off the base of the footing to facilitate this. Users suggest leaving the sonotube about 6 inches above ground and pouring concrete a few inches above grade to prevent water accumulation around the post. Sonotubes are available in various sizes, such as…

Strategic Sourcing Conclusion and Outlook for sonotube footings

In navigating the complexities of sourcing sonotube footings, international buyers must prioritize strategic sourcing to ensure quality, cost-effectiveness, and timely delivery. Understanding regional soil conditions, climate impacts, and local construction regulations are essential for making informed decisions that enhance structural integrity and longevity. By collaborating with reliable suppliers who offer durable products tailored to specific environmental conditions, businesses can mitigate risks associated with construction projects.

Illustrative image related to sonotube footings

The value of sonotubes lies not only in their ability to support various structures but also in their adaptability to diverse applications across different markets. This versatility is crucial for B2B buyers in regions like Africa, South America, the Middle East, and Europe, where construction demands may vary significantly. Engaging with suppliers who provide comprehensive support and technical expertise can further streamline the procurement process and optimize project outcomes.

Looking ahead, as global construction markets continue to evolve, staying abreast of innovations in materials and construction techniques will be vital. Buyers are encouraged to leverage strategic partnerships and continually assess their sourcing strategies to remain competitive. Embrace the opportunity to invest in quality sonotube footings that will not only meet current project needs but also set the foundation for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to sonotube footings

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.