Softwall Cleanroom: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for softwall cleanroom

Navigating the complexities of the global market for softwall cleanrooms can be a daunting task for B2B buyers, especially when considering the diverse applications across industries like pharmaceuticals, biotechnology, and aerospace. Sourcing a cleanroom that meets stringent regulatory requirements while accommodating unique operational needs is critical to maintaining product integrity and compliance. This guide is designed to illuminate the multifaceted world of softwall cleanrooms, covering essential topics such as types of cleanrooms, their specific applications, supplier vetting processes, and cost considerations.

International buyers, particularly those from Africa, South America, the Middle East, and Europe, will find invaluable insights tailored to their regional challenges and market conditions. The guide empowers decision-makers to make informed purchasing choices, enabling them to select cleanroom solutions that not only align with their operational goals but also adhere to necessary ISO standards. With a focus on actionable strategies, this comprehensive resource demystifies the procurement process, helping buyers navigate supplier landscapes and evaluate product offerings effectively. By leveraging this guide, businesses can confidently invest in softwall cleanrooms that enhance operational efficiency and ensure compliance in their respective industries.

Understanding softwall cleanroom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| ValuLine™ Softwall Cleanrooms | Cost-effective, pre-fabricated, easy to assemble, available in various sizes | Pharmaceutical, electronics, medical devices | Pros: Quick installation, affordability. Cons: Limited customization options. |

| Custom Softwall Cleanrooms | Tailored designs, specific ISO ratings, and environmental controls, suitable for unique needs | Biotechnology, aerospace, defense | Pros: Highly customizable, meets unique specifications. Cons: Longer lead times. |

| Portable Softwall Cleanrooms | Lightweight, easy to transport, and set up; designed for temporary or mobile applications | Field testing, temporary labs | Pros: Flexibility and mobility. Cons: May not meet stringent permanent standards. |

| Explosion-Proof Softwall Cleanrooms | Designed with explosion-proof materials and components, ensuring safety in volatile environments | Chemical processing, manufacturing | Pros: Enhanced safety, compliance with regulations. Cons: Higher initial investment. |

| Softwall CleanBooth™ Stations | Laminar flow design for controlled airflow, available in horizontal and vertical configurations | Research labs, quality control, assembly | Pros: Effective contamination control. Cons: Requires regular maintenance for filters. |

What Are ValuLine™ Softwall Cleanrooms and Their Applications?

ValuLine™ Softwall Cleanrooms are designed for cost-sensitive projects, providing an economical solution without compromising on essential cleanroom standards. They come in various sizes and configurations, making them suitable for industries such as pharmaceuticals, electronics, and medical devices. Buyers should consider their budget and the need for rapid installation, as these cleanrooms offer quick assembly. However, the trade-off is limited customization options, which may not suit all specific operational needs.

How Do Custom Softwall Cleanrooms Meet Unique Requirements?

Custom Softwall Cleanrooms are engineered to meet specific industry standards, including various ISO ratings and environmental controls. This flexibility makes them ideal for sectors like biotechnology, aerospace, and defense, where precise conditions are critical. Buyers should assess their unique specifications, as these cleanrooms can be tailored to accommodate specialized equipment or workflows. While the customization offers significant advantages, it may lead to longer lead times, which should be factored into project planning.

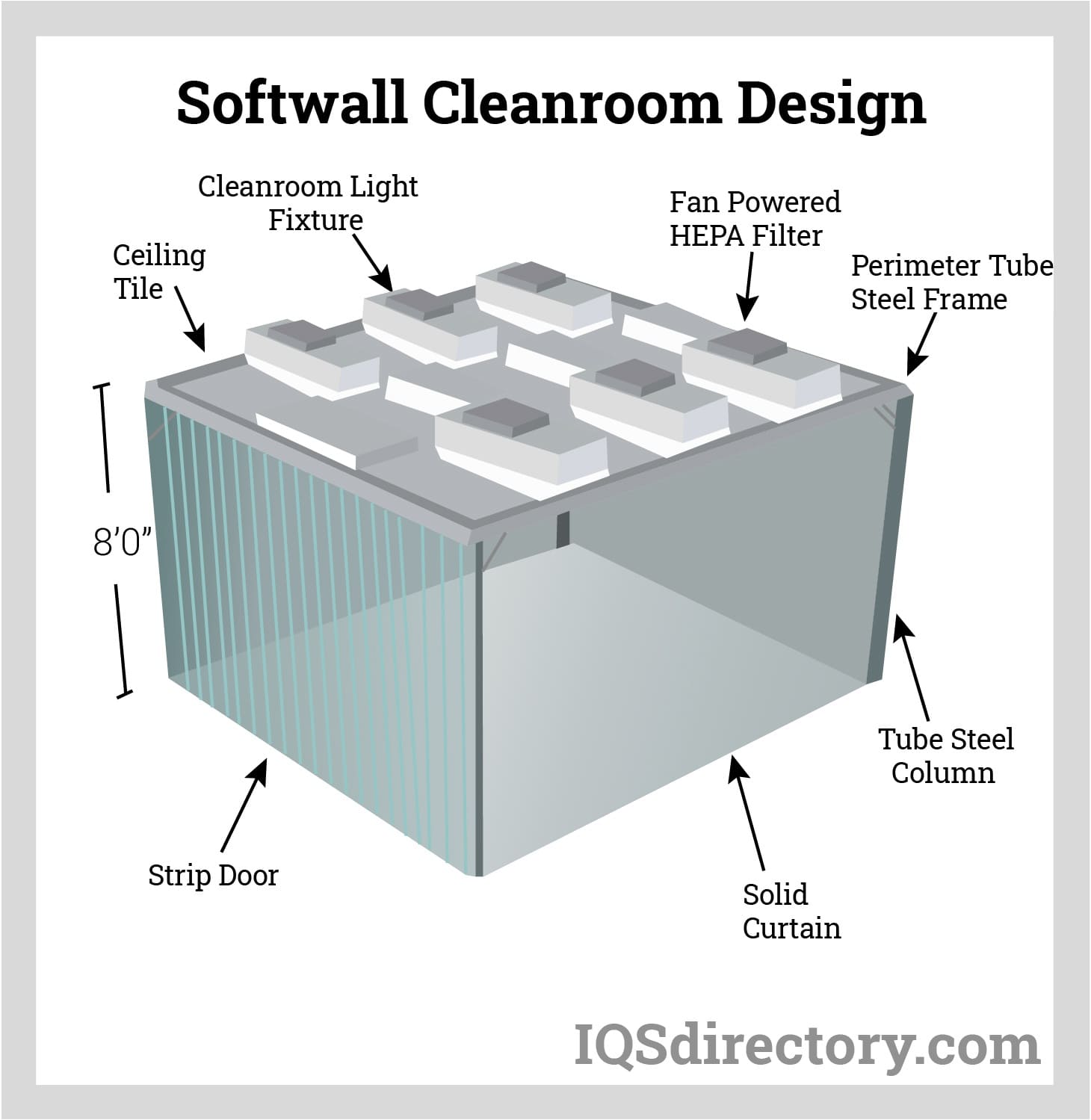

Illustrative image related to softwall cleanroom

What Makes Portable Softwall Cleanrooms a Flexible Option?

Portable Softwall Cleanrooms are lightweight and designed for easy transport and installation, making them ideal for temporary applications such as field testing or mobile laboratories. They provide the necessary controlled environment for critical processes while allowing users to relocate the cleanroom as needed. Buyers should weigh the benefits of flexibility against the potential limitations in meeting stringent permanent cleanroom standards, especially if long-term use is anticipated.

Why Choose Explosion-Proof Softwall Cleanrooms?

Explosion-Proof Softwall Cleanrooms are specifically designed to handle volatile environments, using explosion-proof materials and components to ensure safety. These cleanrooms are essential in industries like chemical processing and manufacturing, where the risk of explosion is significant. Buyers must consider the initial investment, which may be higher than standard options, but the enhanced safety features and compliance with regulations can justify the cost, particularly in high-risk environments.

How Do Softwall CleanBooth™ Stations Enhance Contamination Control?

Softwall CleanBooth™ Stations feature a laminar flow design that provides controlled airflow, effectively minimizing contamination in sensitive processes. Available in both horizontal and vertical configurations, they are suitable for research labs, quality control, and assembly operations. Buyers should consider the need for regular maintenance of the filtration system to ensure optimal performance. While these stations offer excellent contamination control, they require diligence in upkeep to maintain their effectiveness over time.

Key Industrial Applications of softwall cleanroom

| Industry/Sector | Specific Application of softwall cleanroom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Drug formulation and packaging | Ensures compliance with strict hygiene standards, reducing contamination risks. | ISO certification level, customization options, size and layout flexibility. |

| Biotechnology | Cell culture and genetic engineering | Provides a controlled environment for sensitive biological processes, enhancing yield and reliability. | Temperature control, air quality specifications, and modular design for equipment integration. |

| Semiconductor Manufacturing | Wafer fabrication and assembly | Protects sensitive components from particulate contamination, improving product quality and yield. | Cleanroom class requirements, access points, and compatibility with existing manufacturing processes. |

| Aerospace | Component assembly and testing | Reduces the risk of contamination in critical components, ensuring safety and performance standards. | Material durability, explosion-proof options, and compliance with aerospace regulations. |

| Medical Device Production | Assembly and testing of medical devices | Guarantees a sterile environment, crucial for patient safety and regulatory compliance. | ISO ratings, ease of installation, and ability to integrate with other cleanroom technologies. |

How Are Softwall Cleanrooms Used in Pharmaceuticals?

In the pharmaceutical industry, softwall cleanrooms are essential for drug formulation and packaging. These controlled environments minimize contamination risks, ensuring compliance with stringent hygiene standards mandated by health authorities. For international buyers, especially in Africa and South America, selecting a cleanroom with the appropriate ISO certification is crucial. Additionally, customization options can be pivotal to accommodate specific equipment and workflow requirements, enhancing operational efficiency.

What Role Do Softwall Cleanrooms Play in Biotechnology?

Biotechnology applications, such as cell culture and genetic engineering, require softwall cleanrooms to provide a stable, contaminant-free environment. These cleanrooms support sensitive biological processes, directly impacting yield and reliability. Buyers from regions like the Middle East and Europe should prioritize features such as temperature control and air quality specifications. Modular designs are beneficial for integrating specialized equipment, allowing for adaptable and scalable solutions in research and production settings.

Why Are Softwall Cleanrooms Critical in Semiconductor Manufacturing?

In semiconductor manufacturing, softwall cleanrooms are vital during wafer fabrication and assembly processes. They protect sensitive components from particulate contamination, which can severely impact product quality and yield. For B2B buyers in Europe and Africa, it is essential to consider cleanroom class requirements and access points that facilitate efficient workflow. Compatibility with existing manufacturing processes can also influence the choice of cleanroom design, ensuring seamless integration into production lines.

How Do Softwall Cleanrooms Enhance Aerospace Component Assembly?

The aerospace industry utilizes softwall cleanrooms for the assembly and testing of critical components. These environments mitigate contamination risks, which is crucial for maintaining safety and performance standards in aerospace applications. Buyers should focus on material durability and the availability of explosion-proof options, particularly in regions with stringent safety regulations. Compliance with aerospace industry standards is also a key consideration when sourcing cleanroom solutions.

What Benefits Do Softwall Cleanrooms Provide for Medical Device Production?

For medical device production, softwall cleanrooms are indispensable for the assembly and testing of devices. They ensure a sterile environment, which is critical for patient safety and compliance with regulatory standards. B2B buyers should emphasize the importance of ISO ratings and the ease of installation when evaluating cleanroom options. Additionally, the ability to integrate with other cleanroom technologies can enhance operational efficiency and adaptability in production environments.

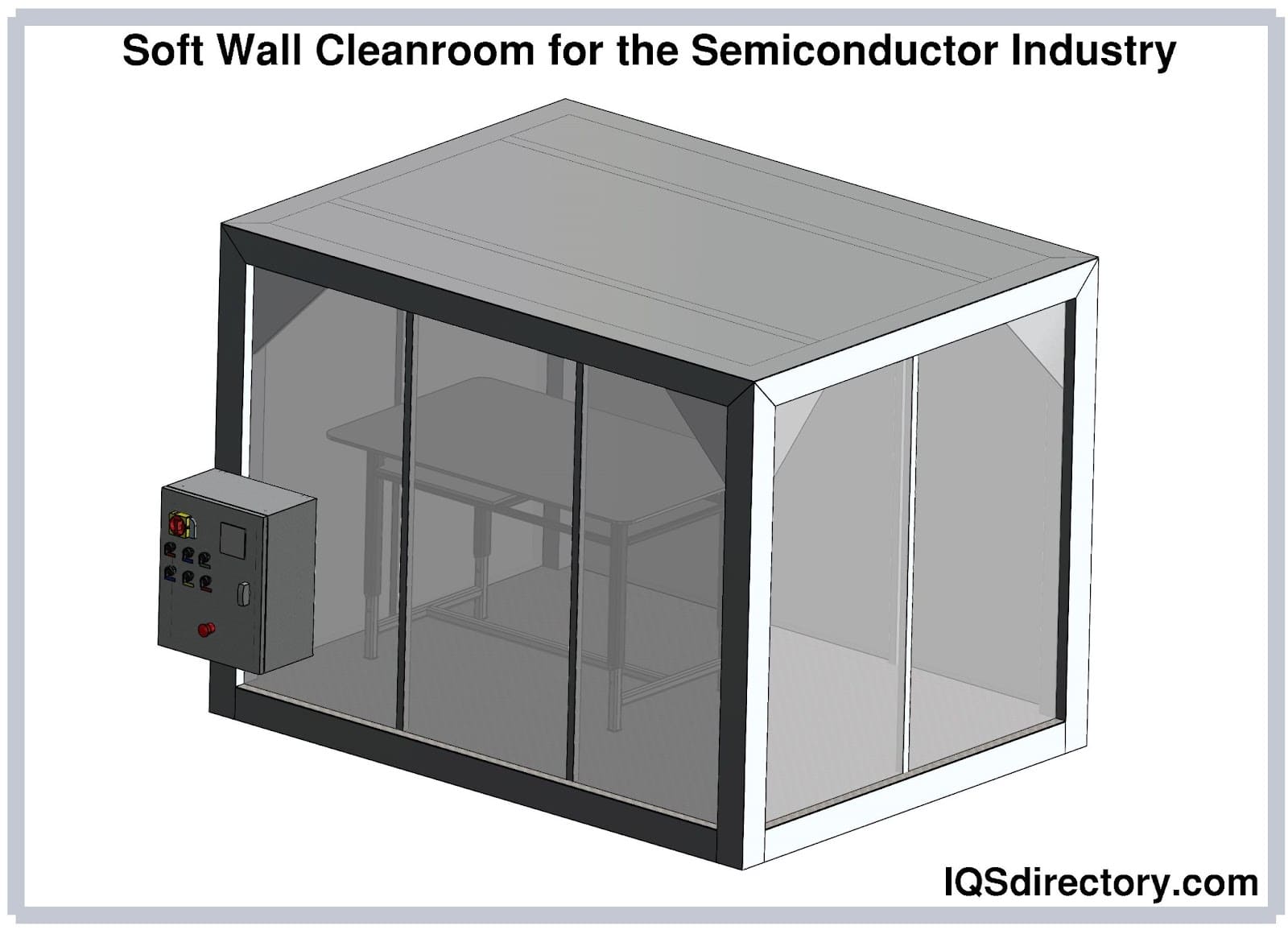

Illustrative image related to softwall cleanroom

3 Common User Pain Points for ‘softwall cleanroom’ & Their Solutions

Scenario 1: Navigating Complex Compliance Requirements in Cleanroom Design

The Problem: For businesses in regulated industries like pharmaceuticals or aerospace, meeting stringent compliance standards such as ISO ratings is non-negotiable. Buyers often struggle to navigate these complex requirements, especially when selecting a softwall cleanroom that aligns with both their operational needs and regulatory obligations. Misunderstanding the implications of ISO ratings can lead to costly redesigns or, worse, operational delays due to non-compliance.

The Solution: To effectively address compliance challenges, buyers should begin by consulting with cleanroom experts who can provide detailed insights into the specific standards applicable to their industry. Engaging with suppliers who offer customizable softwall cleanrooms can also be advantageous. These suppliers often have extensive experience and can guide buyers in selecting the right materials and configurations to meet ISO requirements. Before finalizing any purchase, it’s wise to request documentation and case studies that illustrate how similar businesses have successfully achieved compliance using the supplier’s products. Furthermore, investing in a modular cleanroom allows for future modifications as regulatory standards evolve, ensuring long-term adaptability.

Scenario 2: Cost Management and Budget Constraints

The Problem: Many B2B buyers encounter significant pressure to manage costs while still acquiring a high-quality cleanroom solution. With budgets tightly controlled, there is a constant balancing act between investing in necessary features and staying within financial constraints. Buyers may find themselves compromising on critical elements like air filtration systems or structural integrity, which can jeopardize cleanroom effectiveness.

The Solution: To navigate budget constraints, buyers should conduct a thorough cost-benefit analysis when evaluating softwall cleanroom options. Prioritizing essential features that directly impact cleanroom performance is crucial. For instance, instead of opting for high-end filtration systems from the outset, buyers can choose modular designs that allow for incremental upgrades as funds become available. Additionally, sourcing from manufacturers that offer financing options or flexible payment plans can alleviate immediate financial burdens. Buyers should also explore pre-fabricated softwall cleanroom solutions that offer lower upfront costs without sacrificing quality. By carefully evaluating the total cost of ownership—including maintenance and operational efficiencies—buyers can make informed decisions that align with their budgetary constraints.

Scenario 3: Space Limitations and Layout Challenges

The Problem: In many facilities, space is a premium commodity. Buyers often face the challenge of integrating a softwall cleanroom into existing layouts without causing disruptions to workflow. The need for a cleanroom can arise unexpectedly, leaving little time for extensive planning or construction. This can lead to frustration when the desired cleanroom size and configuration do not fit the available space, leading to inefficiencies and potential downtime.

The Solution: To optimize space utilization, buyers should consider modular softwall cleanrooms, which are designed for flexibility and can be tailored to fit specific spatial constraints. Engaging in a thorough site assessment before installation can help identify the best configuration that complements the existing workflow. Manufacturers often provide design consultations to visualize how the cleanroom will fit within the operational environment, ensuring that it doesn’t interfere with daily activities. Additionally, leveraging portable cleanroom options can provide temporary solutions while permanent installations are being finalized, minimizing operational disruptions. Buyers should also explore vertical space options, such as taller cleanrooms that utilize overhead space effectively, thereby maximizing usable floor area. By employing these strategies, businesses can successfully integrate softwall cleanrooms into their existing facilities while maintaining operational efficiency.

Strategic Material Selection Guide for softwall cleanroom

What Are the Key Materials Used in Softwall Cleanrooms?

When selecting materials for softwall cleanrooms, it is essential to consider their properties, advantages, disadvantages, and how they align with specific applications. Below, we analyze four common materials used in the construction of softwall cleanrooms: anti-static vinyl, powder-coated steel, 304 stainless steel, and Polysim.

How Does Anti-Static Vinyl Perform in Cleanroom Applications?

Anti-static vinyl is a popular choice for softwall cleanroom panels due to its excellent anti-static properties. This material can effectively dissipate static charges, which is crucial in environments sensitive to electrostatic discharge (ESD). It typically operates well within a temperature range of -20°C to 60°C, making it suitable for various cleanroom applications.

Illustrative image related to softwall cleanroom

Pros: Anti-static vinyl is lightweight, cost-effective, and easy to install, allowing for quick modifications or expansions of cleanroom space. Its transparency also enables visibility within the cleanroom.

Cons: While it is durable, it may not withstand harsh chemicals or extreme temperatures as effectively as other materials. Over time, the vinyl can become discolored or brittle, impacting its performance.

Impact on Application: This material is particularly suitable for environments where ESD is a concern, such as electronics manufacturing or pharmaceutical production.

Considerations for International Buyers: Compliance with international standards like ASTM and JIS is crucial. Buyers from regions like Africa and South America should ensure that the selected vinyl meets local regulations regarding chemical resistance and fire safety.

What Role Does Powder-Coated Steel Play in Softwall Cleanrooms?

Powder-coated steel frames are often used to support softwall cleanrooms. This material offers excellent corrosion resistance and can withstand a wide range of temperatures and pressures, making it suitable for various applications.

Pros: The powder coating provides a durable finish that is resistant to scratches and chemicals, enhancing the longevity of the cleanroom structure. Furthermore, it is available in various colors, allowing for aesthetic customization.

Illustrative image related to softwall cleanroom

Cons: While powder-coated steel is robust, it can be heavier and more expensive than other materials. Additionally, if the coating is damaged, it may expose the underlying steel to corrosion.

Impact on Application: Powder-coated steel is ideal for cleanrooms requiring structural integrity and durability, such as those in the aerospace and semiconductor industries.

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prioritize materials that comply with DIN standards for safety and quality assurance. Understanding local regulations regarding steel coatings is essential.

How Does 304 Stainless Steel Compare in Cleanroom Environments?

304 stainless steel is renowned for its corrosion resistance and durability, making it a prime choice for cleanroom applications that require stringent hygiene standards.

Illustrative image related to softwall cleanroom

Pros: This material is exceptionally resistant to rust and corrosion, making it suitable for environments exposed to moisture or chemicals. It is also easy to clean and sanitize, which is critical in maintaining cleanroom standards.

Cons: The cost of 304 stainless steel is relatively high compared to other materials. Additionally, its weight can complicate installation and transportation.

Impact on Application: Ideal for pharmaceutical and biotechnology cleanrooms, where cleanliness and sterility are paramount.

Considerations for International Buyers: Buyers from the Middle East and Africa should verify that the stainless steel meets relevant ASTM standards for corrosion resistance, especially in humid climates.

What Advantages Does Polysim Offer for Softwall Cleanrooms?

Polysim is a specialized material often used for cleanroom curtains and softwall systems. It is designed to be fire-resistant and provides excellent visibility while maintaining contamination control.

Pros: Polysim’s fire-resistant properties make it suitable for volatile environments. It is also flexible and can be easily integrated into existing cleanroom designs.

Illustrative image related to softwall cleanroom

Cons: While Polysim is durable, it may not be as resistant to mechanical wear as other materials. Its higher cost can also be a consideration for budget-conscious buyers.

Impact on Application: Particularly useful in environments where fire safety is a concern, such as laboratories and manufacturing facilities.

Considerations for International Buyers: Compliance with local fire safety regulations is crucial. Buyers should ensure that Polysim meets the necessary standards in their respective regions.

Summary Table of Material Selection for Softwall Cleanrooms

| Material | Typical Use Case for softwall cleanroom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Anti-Static Vinyl | Electronics manufacturing | Excellent ESD properties | Limited chemical resistance | Low |

| Powder-Coated Steel | Aerospace, semiconductor industries | High durability and corrosion resistance | Heavier and more expensive | Medium |

| 304 Stainless Steel | Pharmaceutical, biotechnology cleanrooms | Superior corrosion resistance | High cost and weight | High |

| Polysim | Laboratories, volatile environments | Fire-resistant and flexible | Higher cost and mechanical wear | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on their specific cleanroom requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for softwall cleanroom

What Are the Key Stages in the Manufacturing Process of Softwall Cleanrooms?

The manufacturing of softwall cleanrooms is a multi-stage process that involves careful planning and execution to ensure compliance with industry standards and customer specifications.

1. Material Preparation: Sourcing and Quality Control

The first stage involves sourcing high-quality raw materials that meet specific cleanroom standards. Common materials include anti-static vinyl for the walls and powder-coated steel or stainless steel for the frame. Suppliers typically conduct inspections to ensure materials meet the required specifications. It is crucial for B2B buyers to verify that suppliers adhere to international standards like ISO 9001, which outlines quality management systems. Buyers should request material certificates or test reports to confirm material quality and compliance.

2. Forming: Shaping Components for Cleanroom Assembly

Once materials are prepared, the next step is forming. This involves cutting and shaping the materials into components such as panels, frames, and support structures. Advanced manufacturing techniques, including CNC machining and laser cutting, are often employed to ensure precision and consistency. For cleanrooms, especially those that require specific ISO ratings, the forming process must guarantee that all components fit seamlessly to minimize contamination risks.

3. Assembly: Constructing the Cleanroom Framework

In the assembly phase, the pre-fabricated components are brought together to create the cleanroom structure. This process may involve modular assembly techniques, allowing for flexibility in design and installation. The assembly team will also integrate essential features such as HVAC systems, lighting, and filtration units. It is essential that this stage is conducted in a controlled environment to prevent contamination.

Illustrative image related to softwall cleanroom

4. Finishing: Final Touches and Quality Checks

The finishing stage includes applying protective coatings, installing seals, and ensuring that all components are securely fastened. This stage is critical for enhancing the cleanroom’s durability and functionality. Final inspections are conducted to ensure that all elements comply with specified ISO classifications and other relevant standards.

How Is Quality Assurance Integrated into the Manufacturing of Softwall Cleanrooms?

Quality assurance (QA) plays a pivotal role throughout the manufacturing process of softwall cleanrooms. Effective QA ensures that the final product meets both regulatory requirements and customer expectations.

What International Standards Are Relevant for Softwall Cleanroom Manufacturing?

International standards such as ISO 9001 are fundamental in establishing a quality management system. Additionally, specific certifications like CE marking indicate compliance with European health, safety, and environmental protection standards. For industries like pharmaceuticals and biotechnology, adherence to API (Active Pharmaceutical Ingredient) guidelines may also be necessary.

What Are the Key Quality Control Checkpoints During Production?

Quality control checkpoints are critical for maintaining the integrity of the cleanroom manufacturing process.

Illustrative image related to softwall cleanroom

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): This involves ongoing inspections throughout the manufacturing process to identify and rectify issues immediately.

- Final Quality Control (FQC): The final product undergoes rigorous testing to ensure it meets all specified standards and regulations.

These checkpoints help minimize defects and ensure that the cleanroom will perform as expected.

What Testing Methods Are Commonly Used to Ensure Cleanroom Standards?

Various testing methods are employed to validate the quality of softwall cleanrooms. Common tests include:

- Particle Count Testing: Measures the number of particles in the air to confirm compliance with ISO cleanliness standards.

- Airflow and Pressure Testing: Ensures that the cleanroom maintains the necessary airflow and pressure differentials, crucial for preventing contamination.

- Material Integrity Testing: Involves assessing the strength and durability of materials used in the cleanroom’s construction.

These tests are essential for verifying that the cleanroom will function effectively in its intended application.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must conduct due diligence when selecting suppliers for softwall cleanrooms. Here are key strategies:

- Audits: Requesting a thorough audit of the supplier’s manufacturing processes can provide insights into their quality control practices.

- Reports and Certifications: Ask for detailed QC reports, including certifications that demonstrate compliance with international standards.

- Third-Party Inspections: Engaging third-party inspectors can help validate the supplier’s claims regarding quality and compliance.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

- Regulatory Compliance: Different regions may have varying regulations regarding cleanroom standards. Buyers should ensure that suppliers are familiar with and compliant with local regulations.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate better communication and negotiation with suppliers.

- Logistics and Supply Chain: Consider the logistical challenges of sourcing materials and transporting the final product across borders. Ensuring that your supplier can manage these challenges is crucial for timely delivery and compliance.

Conclusion

The manufacturing processes and quality assurance mechanisms for softwall cleanrooms are intricate and vital for ensuring product integrity and performance. By understanding the key stages of manufacturing, relevant international standards, and effective quality control measures, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only helps mitigate risks but also ensures that the cleanroom solutions meet their specific needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘softwall cleanroom’

Introduction

When sourcing a softwall cleanroom, it’s essential to follow a structured approach to ensure that your facility meets industry standards and operational requirements. This checklist will guide international B2B buyers through the critical steps to procure a softwall cleanroom that aligns with their specific needs, ultimately enhancing productivity and compliance in sensitive environments.

Illustrative image related to softwall cleanroom

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing a softwall cleanroom. This includes determining the required ISO classification (e.g., ISO 6, ISO 7, ISO 8) based on the cleanliness levels needed for your operations. Specify dimensions, airflow patterns, and any additional features, such as built-in gowning rooms or specialized filtration systems, to ensure the cleanroom fits your facility’s layout and operational processes.

Step 2: Research Regulatory Requirements

Understanding the regulatory landscape is crucial for compliance. Different industries, such as pharmaceuticals and biotechnology, have specific regulations governing cleanroom environments. Familiarize yourself with local and international standards (e.g., ISO, ASTM) that may impact your cleanroom’s design and operation, ensuring that your choice aligns with both legal requirements and best practices.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Look for companies with proven expertise in cleanroom design and installation, and request case studies or references from similar industries. Consider their experience with international shipping and installation, particularly if you’re sourcing from regions like Europe or the Middle East, where logistics can vary.

- Key Considerations:

- Supplier’s portfolio of completed projects

- Customer testimonials and reviews

- Industry certifications and affiliations

Step 4: Request Quotes and Compare Costs

Once you’ve narrowed down your options, request detailed quotes from selected suppliers. Ensure that the quotes include all costs associated with the cleanroom, such as shipping, installation, and any additional features or accessories. Comparing these quotes will help you assess the value offered by each supplier and make an informed decision.

Step 5: Verify Supplier Certifications

Ensure that your chosen supplier holds relevant certifications and adheres to industry standards. Certifications like ISO 9001 or ISO 13485 indicate a commitment to quality management systems. Additionally, check if they comply with local regulations in your region, as this can significantly affect the cleanroom’s operational reliability.

Illustrative image related to softwall cleanroom

Step 6: Plan for Installation and Support

Installation is a critical phase that can impact the cleanroom’s performance. Confirm the installation timeline and support provided by the supplier. Inquire about post-installation services, including maintenance and troubleshooting, to ensure long-term operational success and compliance with cleanliness standards.

Step 7: Review Warranty and After-Sales Service

Finally, review the warranty terms and after-sales service offered by the supplier. A robust warranty can protect your investment and ensure that you have support for any issues that arise. Look for suppliers who offer comprehensive after-sales service, including training for your staff on proper cleanroom operation and maintenance practices.

By following these steps, B2B buyers can confidently navigate the sourcing process for softwall cleanrooms, ensuring that they invest in solutions that enhance their operational capabilities and meet regulatory demands.

Comprehensive Cost and Pricing Analysis for softwall cleanroom Sourcing

What Are the Key Cost Components in Softwall Cleanroom Sourcing?

When sourcing softwall cleanrooms, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly affects the overall cost. Common options include anti-static vinyl, powder-coated steel, and specialized filtration systems. Higher-grade materials, which may offer better durability and compliance with ISO standards, often come at a premium.

-

Labor: Labor costs encompass both the manufacturing and installation phases. Skilled labor is typically required for assembly and adherence to stringent cleanroom standards, which can increase costs in regions with higher wage rates.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment depreciation, and facility costs. Efficient manufacturing processes can help reduce these expenses.

-

Tooling: Custom designs often require specific tooling, which can be a one-time investment but adds to the initial cost. Standardized components generally lower tooling expenses.

-

Quality Control (QC): Ensuring compliance with ISO ratings necessitates rigorous QC processes, which may include testing and certification. These steps are crucial for maintaining cleanroom integrity and can add to the overall expenditure.

-

Logistics: Shipping costs vary based on distance, weight, and mode of transport. International buyers should consider potential tariffs and customs duties, especially when sourcing from suppliers in different regions.

-

Margin: Suppliers typically apply a margin to cover overhead and profit. This margin can fluctuate based on market demand, supplier reputation, and negotiation outcomes.

How Do Price Influencers Impact Softwall Cleanroom Costs?

Several factors can influence pricing, which buyers must consider when negotiating and planning their purchases:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should assess their needs carefully to maximize cost efficiency.

-

Specifications and Customization: Custom cleanroom designs tailored to specific applications may incur additional costs. Standard configurations are typically more economical.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO compliance) can elevate costs but ensure better performance and longevity, justifying the investment.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can affect pricing. Established suppliers may charge more due to perceived quality, but they often provide better support and compliance assurance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly impact total costs. Understanding these terms helps buyers anticipate additional charges related to shipping, insurance, and customs.

What Are the Best Practices for Negotiating Softwall Cleanroom Prices?

To achieve favorable pricing, buyers should consider the following tips:

-

Do Your Homework: Research various suppliers to understand market rates and available options. This knowledge empowers buyers during negotiations.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs and negotiate bulk pricing.

-

Evaluate Total Cost of Ownership (TCO): While initial costs are important, consider long-term expenses, including maintenance, energy efficiency, and potential downtime. A lower-priced cleanroom may not always equate to cost savings.

-

Be Aware of Pricing Nuances for International Purchases: Buyers from regions like Africa, South America, the Middle East, and Europe should factor in currency fluctuations, import taxes, and delivery timelines when assessing costs.

-

Negotiate Terms: Don’t hesitate to discuss payment terms, warranties, and after-sales support, as these can also impact overall costs.

Conclusion: Understanding Costs for Strategic Sourcing

While indicative prices for softwall cleanrooms can start as low as $3,463 for basic models, comprehensive sourcing involves a detailed analysis of costs and pricing influencers. By understanding these components and employing strategic negotiation tactics, international buyers can optimize their purchasing decisions and achieve better value in their cleanroom investments.

Alternatives Analysis: Comparing softwall cleanroom With Other Solutions

Exploring Alternatives to Softwall Cleanrooms for Controlled Environments

In the quest for optimal contamination control in sensitive environments, various solutions are available to businesses looking to maintain high standards of cleanliness and operational efficiency. While softwall cleanrooms are a popular choice due to their flexibility and ease of use, understanding alternative solutions can empower B2B buyers to make informed decisions tailored to their specific needs.

Comparison Table

| Comparison Aspect | Softwall Cleanroom | Hardwall Cleanroom | Laminar Flow Hood |

|---|---|---|---|

| Performance | Good air cleanliness (ISO 6-8) | Excellent air cleanliness (ISO 5) | High local air cleanliness (ISO 5) |

| Cost | Moderate initial investment | Higher upfront costs | Lower initial costs |

| Ease of Implementation | Quick setup and modular design | Longer installation time | Simple installation |

| Maintenance | Requires regular cleaning | Low maintenance after installation | Requires regular filter changes |

| Best Use Case | Versatile applications in multiple industries | Ideal for pharmaceutical and semiconductor industries | Specific tasks requiring localized control |

Detailed Breakdown of Alternatives

Hardwall Cleanrooms

Hardwall cleanrooms are constructed with solid walls and often feature a more robust design compared to softwall systems. Their primary advantage lies in their superior air cleanliness levels, often achieving ISO Class 5 or better. This makes them particularly suitable for industries such as pharmaceuticals, biotechnology, and semiconductor manufacturing where stringent cleanliness standards are mandatory. However, the trade-off includes a higher upfront investment and longer installation times, which may not be feasible for smaller operations or projects requiring rapid deployment.

Laminar Flow Hoods

Laminar flow hoods provide localized airflow control and are designed to create a sterile work environment for specific tasks. They are particularly effective in applications such as laboratory work, where the focus is on protecting sensitive samples or procedures from contamination. While they are generally more cost-effective than cleanrooms, they do not offer the same level of environmental control over larger spaces. Additionally, they require regular maintenance, particularly in the form of filter changes, to ensure optimal performance. This makes them best suited for specific tasks rather than comprehensive cleanroom environments.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate solution for controlled environments, B2B buyers should consider their specific operational requirements, budget constraints, and the level of cleanliness needed. Softwall cleanrooms offer a balance of flexibility and performance for various applications, while hardwall cleanrooms provide the highest level of cleanliness for critical processes. Laminar flow hoods can be an economical option for localized tasks. Ultimately, understanding the nuances of each option will enable businesses to align their choices with their operational goals, ensuring compliance and efficiency in their processes.

Illustrative image related to softwall cleanroom

Essential Technical Properties and Trade Terminology for softwall cleanroom

What Are the Essential Technical Properties of Softwall Cleanrooms?

Softwall cleanrooms are designed to create controlled environments that minimize contamination risks. Understanding their technical properties is crucial for businesses in regulated industries. Here are several key specifications:

-

ISO Classification

The International Organization for Standardization (ISO) grades cleanrooms based on air cleanliness levels. ISO 5 to ISO 8 classifications indicate the maximum allowable particle counts per cubic meter of air. For example, ISO 5 allows only 3,520 particles per cubic meter, while ISO 8 permits up to 3,520,000. Selecting the appropriate ISO level is vital for ensuring compliance with industry regulations and maintaining product integrity. -

Material Grade

The materials used in softwall cleanrooms, such as anti-static vinyl or powder-coated steel, significantly affect their performance. Anti-static materials help prevent electrostatic discharge, which can damage sensitive electronic components. The choice of material should align with the specific application and environmental conditions, ensuring durability and ease of maintenance. -

Airflow Design

Airflow design is crucial for maintaining cleanliness. Softwall cleanrooms typically utilize laminar flow systems, where air moves in a uniform direction, minimizing turbulence and particle dispersion. Understanding the airflow dynamics is essential for optimizing the cleanroom’s performance, particularly in industries like pharmaceuticals and biotechnology. -

Modularity

The modular nature of softwall cleanrooms allows for customizable configurations. Businesses can scale their cleanroom size and design based on changing needs. This flexibility is particularly beneficial for companies anticipating growth or those with specific equipment requirements, as it enables cost-effective adaptations without significant downtime. -

Tolerance Levels

Tolerance refers to the acceptable limits of variation in dimensions and performance of cleanroom components. Precise tolerances ensure that all parts fit correctly and function as intended, which is essential for maintaining the integrity of the controlled environment. In B2B applications, understanding tolerances helps in procurement and quality assurance processes.

What Are Common Trade Terms Related to Softwall Cleanrooms?

Familiarity with industry terminology is crucial for effective communication in the B2B landscape. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM produces components or products that are sold under another company’s brand. In the cleanroom context, an OEM might provide custom cleanroom systems designed to meet specific client requirements. Understanding OEM relationships can help businesses secure tailored solutions. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For cleanroom components, MOQs can impact purchasing strategies and inventory management. Buyers should clarify MOQ terms to avoid overcommitting resources or facing supply shortages. -

RFQ (Request for Quotation)

An RFQ is a document that invites suppliers to submit price quotes for specific products or services. In the context of cleanrooms, businesses often use RFQs to gauge pricing and availability of various cleanroom designs or components. A well-prepared RFQ can lead to better supplier negotiations. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, risk management, and delivery obligations. Understanding Incoterms is crucial for businesses sourcing cleanroom solutions from international suppliers, as it helps mitigate risks and avoid misunderstandings. -

Cleanroom Certification

Certification verifies that a cleanroom meets specific industry standards, such as ISO 14644. This documentation is essential for compliance in regulated sectors, ensuring that the cleanroom operates within the required parameters. For B2B buyers, obtaining certification is critical for maintaining trust and credibility with clients.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when investing in softwall cleanroom solutions, ultimately enhancing operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the softwall cleanroom Sector

What Are the Key Market Dynamics and Trends Influencing the Softwall Cleanroom Sector?

The softwall cleanroom sector is experiencing significant growth, driven by the increasing demand for contamination-controlled environments across various industries, including pharmaceuticals, biotechnology, and electronics. As industries expand, particularly in emerging markets in Africa, South America, and the Middle East, there is a rising need for flexible and cost-effective cleanroom solutions. Softwall cleanrooms are gaining traction due to their modular design, which allows for quick installation and reconfiguration to meet changing operational needs.

Technological advancements are also shaping the market. Innovations in materials and design are enhancing the functionality and efficiency of softwall cleanrooms. For instance, the use of anti-static and fire-resistant materials is becoming commonplace, addressing safety concerns while improving air quality and cleanliness. Furthermore, the integration of smart technology, such as IoT-enabled monitoring systems, is allowing for real-time tracking of environmental conditions, ensuring compliance with stringent regulatory standards.

International buyers, particularly from regions like Nigeria and Germany, are increasingly looking for suppliers who can offer customization options and rapid delivery times. The ability to provide tailored solutions that meet specific ISO standards is becoming a key differentiator among suppliers. As competition intensifies, understanding local market dynamics and regulatory requirements will be essential for B2B buyers to make informed sourcing decisions.

How Is Sustainability and Ethical Sourcing Shaping the Softwall Cleanroom Industry?

Sustainability and ethical sourcing are increasingly critical in the softwall cleanroom sector, reflecting a broader shift in global business practices. The environmental impact of manufacturing processes and materials used in cleanroom construction is under scrutiny, prompting companies to seek greener alternatives. For B2B buyers, this means prioritizing suppliers who utilize sustainable materials and demonstrate a commitment to reducing their carbon footprint.

The adoption of ‘green’ certifications and materials is becoming a competitive advantage. Suppliers offering cleanroom solutions with eco-friendly features, such as recyclable panel materials and energy-efficient HVAC systems, are appealing to buyers focused on sustainability. Furthermore, ethical supply chains that ensure fair labor practices and responsible sourcing are gaining importance, especially among international buyers who are increasingly aware of corporate social responsibility.

Illustrative image related to softwall cleanroom

Investing in sustainable cleanroom solutions not only helps businesses comply with environmental regulations but also enhances their brand reputation. Companies that embrace sustainability can attract environmentally conscious clients and partners, leading to increased market opportunities. As the global marketplace evolves, B2B buyers must consider the sustainability credentials of their suppliers as part of their sourcing strategy.

How Has the Softwall Cleanroom Sector Evolved Over Time?

The evolution of the softwall cleanroom sector reflects the growing complexity and demands of various industries. Initially, cleanrooms were primarily rigid structures, but the need for flexibility and adaptability led to the development of softwall designs. These modular systems, which can be easily assembled and disassembled, allow companies to quickly respond to changing production needs and comply with varying regulatory standards.

Over the decades, advancements in materials science have greatly improved the performance of softwall cleanrooms. Modern solutions now incorporate innovative materials that enhance air quality and reduce contamination risks. Additionally, the integration of technology has transformed the way cleanrooms operate, with real-time monitoring systems providing crucial data for maintaining compliance and optimizing efficiency.

As industries continue to evolve, the softwall cleanroom sector is likely to further adapt, focusing on sustainability, customization, and technological integration to meet the needs of international B2B buyers. Understanding this historical context is essential for buyers looking to make strategic sourcing decisions that align with future market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of softwall cleanroom

-

1. How do I select the right softwall cleanroom for my needs?

Choosing the right softwall cleanroom involves assessing your specific application requirements, such as the necessary ISO rating, air cleanliness level, and environmental controls. Consider factors like the size and layout of your facility, the types of processes you will conduct, and any regulatory compliance needs. Collaborating with suppliers who offer customization can help ensure that the cleanroom is tailored to your operational demands. Always request detailed specifications and, if possible, visit existing installations to gain insights into performance and suitability. -

2. What are the key benefits of softwall cleanrooms compared to hardwall cleanrooms?

Softwall cleanrooms are often more cost-effective and flexible than hardwall alternatives. They provide easier access for equipment and personnel while maintaining controlled environments. Installation and modification can be quicker and less disruptive, making them ideal for evolving production needs. Additionally, softwall cleanrooms can be disassembled and relocated, which is beneficial for businesses anticipating changes in operations or scale. -

3. What customization options are available for softwall cleanrooms?

Customization options for softwall cleanrooms include size, layout, and materials used for walls and frames. You can request specific ISO ratings and design features, such as air filtration systems and integrated lighting. Some manufacturers also offer modular designs, allowing for easy expansion or reconfiguration as your needs change. It’s advisable to discuss your specific requirements with suppliers to explore all available options. -

4. What is the typical lead time for ordering and receiving a softwall cleanroom?

Lead times can vary widely based on customization and supplier availability. Standard pre-fabricated models may ship within 1-3 days, while custom solutions can take 20-45 days or longer. When planning your purchase, factor in these timelines, along with any additional time required for installation and setup. Always confirm lead times with your supplier, especially if you have tight project deadlines. -

5. What are the minimum order quantities (MOQ) for softwall cleanrooms?

Minimum order quantities can differ by supplier and product type. Some manufacturers may allow the purchase of single units, particularly for standard models, while others may have higher MOQs for custom designs. When sourcing, clarify the MOQ with potential suppliers to ensure it aligns with your project scope and budget. This information is crucial for planning your procurement strategy effectively. -

6. How do I ensure the quality of the softwall cleanroom I am purchasing?

To ensure quality, choose suppliers with a proven track record in the cleanroom industry. Look for certifications such as ISO 9001 and compliance with relevant industry standards. Request detailed product specifications, materials used, and any quality assurance processes they implement. Additionally, consider visiting references or existing installations to evaluate the product in real-world conditions. -

7. What payment terms are typically offered for international orders of softwall cleanrooms?

Payment terms can vary significantly between suppliers. Common terms include deposits upon order confirmation, progress payments during production, and final payment upon completion or delivery. For international transactions, it’s wise to discuss payment methods such as letters of credit, wire transfers, or escrow services to mitigate risks. Always ensure clarity on payment terms before finalizing your order. -

8. What logistics considerations should I keep in mind when importing a softwall cleanroom?

When importing a softwall cleanroom, consider shipping costs, customs duties, and delivery timelines. Verify the supplier’s ability to handle logistics, including packaging and transport arrangements. Understand the regulations for importing cleanroom equipment in your country, as compliance with local standards is crucial. Collaborating with a freight forwarder experienced in handling cleanroom equipment can streamline the import process and help avoid potential delays.

Top 5 Softwall Cleanroom Manufacturers & Suppliers List

1. Clean Air Products – Modular Softwall Cleanrooms

Domain: cleanairproducts.com

Registered: 1998 (27 years)

Introduction: Modular Softwall Cleanrooms designed for functionality and reduced cost. Lightweight and easy to assemble, can be installed freestanding or hung from ceilings. Portable design ideal for temporary cleanroom needs. Two primary styles: CAP577F (lightweight, versatile, positive/negative pressure) and CAP575 (sturdier, longer/taller design). Custom modular options available. Classifications from Class …

2. Cleanroom World – Softwall Cleanrooms

Domain: cleanroomworld.com

Registered: 2007 (18 years)

Introduction: Softwall Cleanrooms are portable cleanrooms designed with curtains, providing flexibility and ease of setup. They are suitable for various applications requiring controlled environments. The cleanrooms are part of a broader range of cleanroom products and equipment offered by Cleanroom World, which includes cleanroom supplies, lab supplies, safety supplies, and ESD equipment. The company is ISO 90…

3. NGS Cleanrooms – Softwall Cleanrooms

Domain: us.ngscleanrooms.com

Registered: 2019 (6 years)

Introduction: Softwall Cleanrooms provide an economical and versatile solution for cleanroom construction, suitable for industries such as materials development, medical devices, and semiconductors. Key features include:

– Portable and easy to assemble, extend, or modify.

– Simple air management system.

– Minimal environmental change when accessing the cleanroom.

– Recommended for ISO 14644-1 class 7-8 controll…

4. NCIClean – SWCR Modular Softwall Cleanrooms

Domain: nciclean.com

Registered: 2013 (12 years)

Introduction: Product Name: SWCR Modular Softwall Cleanrooms

Part Number: SWCR

Description: Modular, vertical flow softwall cleanrooms designed for quality particulate control. Lightweight, low-cost, and easy to assemble. Available in various sizes and shapes.

Material Note: Standard vinyl curtain material replaced with Seiden Crystal 40 mil static dissipative curtain material due to shortages.

Cleanroom Class…

5. Modular Cleanrooms – Econo-Tent Solutions

Domain: modularcleanrooms.com

Registered: 1999 (26 years)

Introduction: Modular Softwall Cleanrooms, also known as Econo-Tent, offer an affordable and customizable solution for cleanroom design and implementation. Key features include:

– 100% portable and modular design

– Can be used with ceiling grids or as a stand-alone unit

– Eliminates contamination and removes particles from the air

– Easily expandable or reducible based on requirements

– Prefabricated for quick …

Strategic Sourcing Conclusion and Outlook for softwall cleanroom

In today’s competitive landscape, the strategic sourcing of softwall cleanrooms is essential for industries that require stringent contamination control. By investing in customizable solutions that cater to specific ISO ratings and operational needs, businesses can optimize their workflows and ensure compliance with international standards. The versatility of softwall cleanrooms allows for rapid deployment and easy modifications, making them an ideal choice for sectors ranging from pharmaceuticals to aerospace.

International buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize suppliers with a proven track record in delivering high-quality, tailor-made cleanroom solutions. Engaging with manufacturers that offer comprehensive support, from design to installation, can significantly enhance operational efficiency and reduce downtime.

Looking ahead, the demand for softwall cleanrooms is expected to rise as industries increasingly focus on maintaining safe and sterile environments. Now is the time for businesses to evaluate their cleanroom needs and partner with leading providers to secure the best solutions for their unique requirements. Empower your operations by embracing strategic sourcing—your pathway to enhanced productivity and compliance in a rapidly evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to softwall cleanroom