Snowflake Ice Maker: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for snowflake ice maker

In today’s competitive landscape, sourcing a reliable snowflake ice maker can be a daunting challenge for international B2B buyers. The need for high-quality ice production is critical across various sectors, including food service, hospitality, and specialty dessert shops. As businesses strive to meet consumer demands for innovative and visually appealing frozen treats, understanding the different types of snowflake ice makers and their applications becomes imperative.

This comprehensive guide delves into the diverse offerings of snowflake ice machines, examining their unique features, capacities, and the technology that drives them. Buyers will learn how to effectively vet suppliers, assess costs, and identify the right machines tailored to their specific operational needs. From the bustling cafes in Germany to the vibrant street vendors in South America, the insights shared here will empower stakeholders to make informed purchasing decisions that align with their business objectives.

Moreover, this guide addresses the nuances of sourcing equipment from various regions, including Africa, the Middle East, and Europe, ensuring that buyers are equipped with the knowledge to navigate the global market confidently. By arming yourself with this information, you can streamline your procurement process, enhance your product offerings, and ultimately improve customer satisfaction in an increasingly demanding marketplace.

Understanding snowflake ice maker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercial Snowflake Ice Maker | High ice production capacity (up to 440 lbs/day), air-cooled | Restaurants, cafes, food trucks | Pros: High efficiency; versatile ice shapes. Cons: Higher upfront cost; requires space. |

| Automatic Snowflake Ice Maker | Fully automated operation, low noise, compact design | Laboratories, hospitals, schools | Pros: Energy-efficient; minimal manual input. Cons: Limited ice production capacity; maintenance may be complex. |

| Bingsu Ice Maker | Specializes in producing fine, fluffy ice for desserts | Dessert shops, specialty cafes | Pros: Creates unique texture for desserts; attractive for niche markets. Cons: May not suit general ice needs; specific maintenance requirements. |

| Mini Snowflake Ice Maker | Compact size, lower ice production capacity (up to 374 lbs/day) | Small cafes, home use | Pros: Space-saving; affordable. Cons: Limited output; may not meet high-demand settings. |

| Water-Cooled Snowflake Ice Maker | Efficient cooling with water usage, suitable for high ambient temperatures | Large events, catering services | Pros: Consistent ice quality; effective in hot climates. Cons: Higher water consumption; installation complexity. |

What Are the Characteristics of Commercial Snowflake Ice Makers?

Commercial snowflake ice makers are designed for high output, capable of producing up to 440 lbs of ice per day. These machines feature robust air-cooling systems that allow for rapid heat dissipation and efficient production cycles. They are ideal for bustling environments like restaurants and cafes where large quantities of ice are needed quickly. Buyers should consider the upfront investment and the space required for installation, as these machines can be substantial in size.

How Do Automatic Snowflake Ice Makers Function?

Automatic snowflake ice makers simplify the ice production process with fully automated operations. They utilize advanced technology for reliable performance and low noise, making them suitable for sensitive environments like laboratories and hospitals. The compact design enhances their appeal in settings with limited space. However, potential buyers should note that while they are energy-efficient, their ice production capacity may be lower compared to commercial models, which could be a limitation in high-demand situations.

Why Choose a Bingsu Ice Maker?

Bingsu ice makers are specialized equipment designed to create fluffy, fine ice ideal for unique desserts. They are particularly popular in dessert shops and specialty cafes that focus on Asian-style shaved ice treats. This type of machine attracts customers looking for novel dessert experiences, thus enhancing the business’s competitive edge. However, businesses should weigh this against the fact that these machines may not fulfill broader ice production needs and could entail specific maintenance protocols.

What Are the Advantages of Mini Snowflake Ice Makers?

Mini snowflake ice makers are compact and designed for smaller operations, including small cafes or home use. They typically have a lower ice production capacity, making them suitable for establishments with modest ice needs. Their affordability and space-saving designs make them attractive for startups or smaller food service operations. However, buyers must consider that these machines may not meet the demands of larger events or high-traffic venues.

How Do Water-Cooled Snowflake Ice Makers Operate?

Water-cooled snowflake ice makers use water for cooling, making them highly effective in maintaining consistent ice quality, especially in warmer climates. They are commonly used in catering services and large events where high volumes of ice are needed quickly. While they provide efficient performance, buyers should be aware of the increased water consumption and the complexity of installation compared to air-cooled models. This could influence operational costs and logistical planning for businesses.

Key Industrial Applications of snowflake ice maker

| Industry/Sector | Specific Application of snowflake ice maker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Ice production for cafes and dessert shops | Enhances menu offerings with innovative desserts | Durability, production capacity, and ease of cleaning |

| Hospitality | Ice for beverages and food presentations in hotels | Improves guest experience with quality service | Energy efficiency and compliance with health standards |

| Healthcare | Ice for therapeutic uses in clinics and hospitals | Supports patient care through cooling solutions | Hygiene standards, compact design, and reliability |

| Retail | Snowflake ice for food displays in supermarkets | Attracts customers with visually appealing displays | Ice texture versatility and production speed |

| Events and Catering | Ice for outdoor events and catering services | Enhances event quality and guest satisfaction | Portability, ease of use, and ice production rate |

How Can Snowflake Ice Makers Benefit the Food Service Industry?

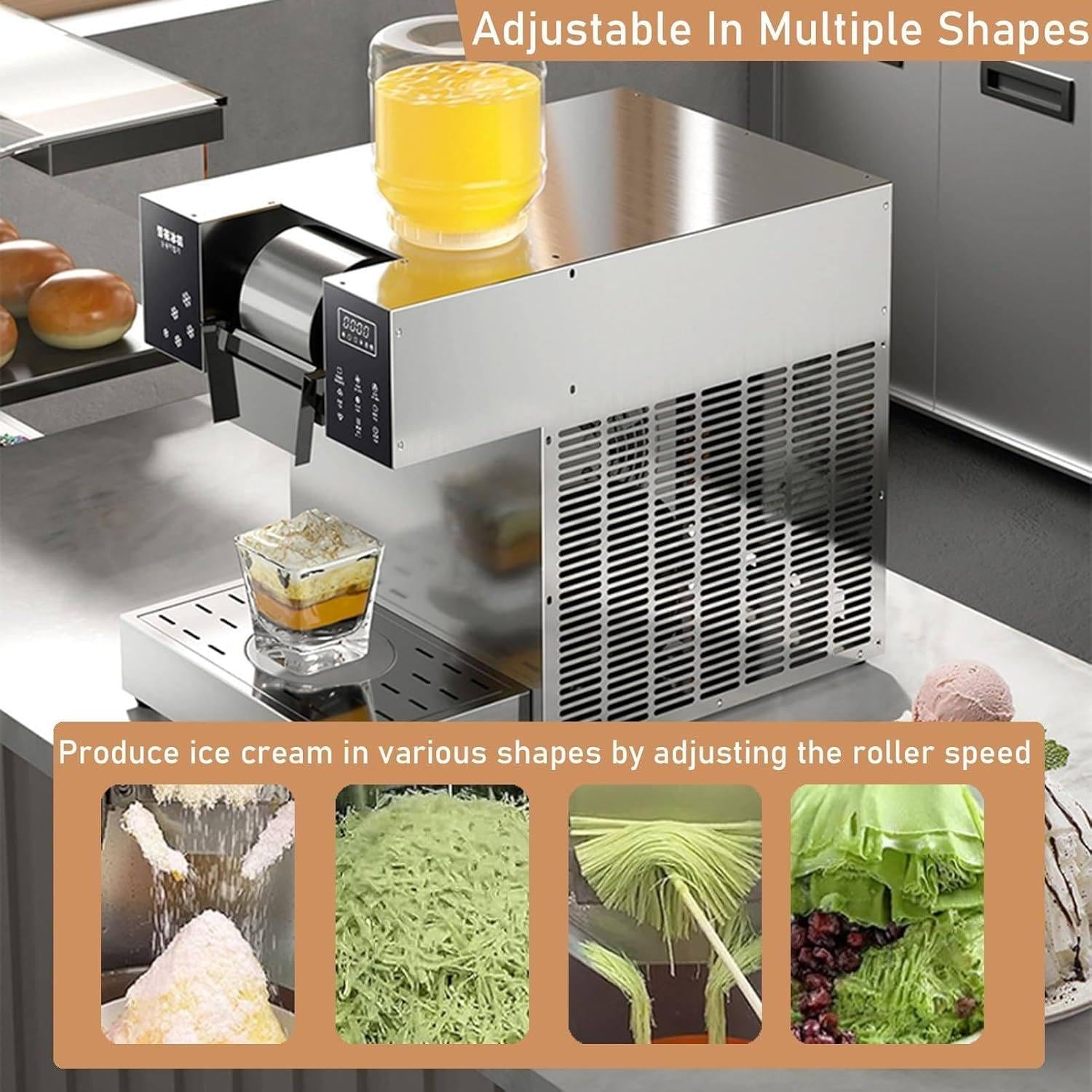

In the food service sector, snowflake ice makers are essential for cafes and dessert shops. They produce finely textured ice ideal for innovative dessert creations, such as ice creams and smoothies. By offering unique presentations, businesses can elevate their menu items, attracting more customers. Buyers should prioritize machines with high production capacity and easy cleaning features to maintain hygiene and operational efficiency.

Illustrative image related to snowflake ice maker

What Role Do Snowflake Ice Makers Play in the Hospitality Sector?

Hotels utilize snowflake ice makers primarily for beverage service and food presentations. The appeal of finely crushed ice enhances the quality of cocktails and other drinks, significantly improving guest experience. Additionally, ice sculptures or displays can be created for events, boosting the hotel’s reputation. When sourcing, buyers should consider energy-efficient models that comply with local health regulations to ensure safety and sustainability.

How Are Snowflake Ice Makers Used in Healthcare Settings?

In healthcare, snowflake ice makers serve therapeutic purposes, providing cooling solutions for patients. Ice packs made from finely crushed ice can be used to alleviate swelling or pain, making them a valuable resource in clinics and hospitals. Buyers in this sector need to focus on machines that meet stringent hygiene standards, are compact for limited spaces, and have reliable operations to ensure consistent availability.

What Advantages Do Snowflake Ice Makers Offer Retail Businesses?

Supermarkets and retail stores leverage snowflake ice makers for food displays, enhancing the visual appeal of fresh produce, seafood, and other perishable items. The use of snowflake ice keeps products looking fresh and enticing, which can lead to increased sales. Retailers should look for machines that provide versatile ice textures and quick production rates to meet high demand during peak shopping times.

How Can Snowflake Ice Makers Enhance Events and Catering Services?

For event planners and catering services, snowflake ice makers are invaluable for outdoor events, providing a consistent supply of ice for drinks and food presentations. The ability to produce large quantities of finely crushed ice quickly can significantly enhance the quality of service provided. Buyers should consider portable models that are easy to operate and maintain, ensuring they can deliver a seamless experience at various venues.

3 Common User Pain Points for ‘snowflake ice maker’ & Their Solutions

Scenario 1: Limited Ice Production Capacity for High-Demand Environments

The Problem: In commercial settings like cafes and dessert shops, the demand for snowflake ice can surge during peak hours, especially in regions with warm climates. B2B buyers often find that standard snowflake ice makers cannot meet their high-volume needs, resulting in delays and dissatisfied customers. This issue is particularly critical in places like Saudi Arabia or Brazil, where warm weather drives ice consumption, and any shortfall can lead to lost sales and customer frustration.

The Solution: To address this challenge, B2B buyers should invest in snowflake ice makers with higher production capacities, such as those that can produce upwards of 400 lbs (180 kg) of ice per day. When sourcing equipment, look for models that feature powerful compressors and efficient cooling systems to ensure rapid ice production, even during peak demand. Additionally, consider machines with adjustable settings to create different ice textures, which can enhance product offerings and customer satisfaction. Regular maintenance and proper usage guidelines should also be established to ensure maximum uptime and efficiency of the ice maker, thus preventing any disruptions in service.

Scenario 2: High Maintenance Costs and Downtime

The Problem: Snowflake ice makers, like any commercial equipment, are subject to wear and tear, leading to maintenance costs and potential downtime. B2B buyers in industries like hospitality or food service often grapple with the burden of repairs, which can disrupt operations and result in lost revenue. For instance, a malfunctioning ice maker in a bakery can halt production, leaving customers waiting and impacting the shop’s reputation.

The Solution: To mitigate maintenance costs, buyers should prioritize purchasing snowflake ice makers constructed with durable materials, such as stainless steel, which resist corrosion and extend lifespan. Additionally, selecting machines that come with comprehensive warranties and reliable customer support can provide peace of mind. Regular preventative maintenance schedules should be implemented to identify issues before they escalate. Establishing a partnership with a local service provider for timely repairs and routine check-ups can minimize downtime and keep operations running smoothly, ultimately protecting profit margins.

Scenario 3: Inefficient Energy Consumption and Environmental Impact

The Problem: As global awareness of sustainability grows, B2B buyers are increasingly concerned about the energy consumption of their equipment, including snowflake ice makers. High energy costs can significantly impact overall operational expenses, especially for businesses in regions with higher electricity rates. Furthermore, companies are under pressure to adopt more environmentally friendly practices, making inefficient machines a liability.

The Solution: Buyers should seek energy-efficient snowflake ice makers designed to minimize power usage while maintaining high performance. Look for models that utilize advanced technologies such as inverter compressors, which adjust power consumption based on the ice production demand. Additionally, machines with eco-friendly refrigerants and insulation can help reduce environmental impact. Conducting a total cost of ownership analysis can provide insights into potential long-term savings from energy-efficient models, allowing businesses to make informed decisions that align with their sustainability goals while also enhancing profitability.

Illustrative image related to snowflake ice maker

By proactively addressing these common pain points, B2B buyers can ensure their snowflake ice makers meet operational demands, reduce costs, and contribute positively to their environmental goals.

Strategic Material Selection Guide for snowflake ice maker

What Are the Key Materials Used in Snowflake Ice Makers?

When selecting materials for snowflake ice makers, it’s essential to consider their properties, advantages, and limitations. The following analysis focuses on four common materials: stainless steel, plastic, aluminum, and copper. Each material has unique characteristics that impact performance, durability, and suitability for various applications, particularly in international markets.

How Does Stainless Steel Enhance Snowflake Ice Maker Performance?

Stainless steel is a preferred choice for many components of snowflake ice makers due to its excellent corrosion resistance and high-temperature tolerance. Key properties include a temperature rating of up to 800°F (427°C) and a pressure rating that can withstand significant operational stress.

Pros: Stainless steel is incredibly durable, making it suitable for high-volume production environments. It is easy to clean and maintain, which is vital for hygiene in food-related applications.

Cons: The initial cost of stainless steel can be high compared to other materials, and its manufacturing process can be complex, requiring specialized equipment.

Illustrative image related to snowflake ice maker

Impact on Application: Stainless steel’s compatibility with food-grade standards makes it ideal for applications in cafes, restaurants, and food trucks, which are prevalent in markets across Africa, South America, the Middle East, and Europe.

What Role Does Plastic Play in Snowflake Ice Makers?

Plastic is often used in non-structural components of snowflake ice makers, such as water reservoirs and internal linings. It is lightweight and can be molded into complex shapes, enhancing design flexibility.

Pros: The cost of plastic is generally lower than metals, making it an attractive option for manufacturers looking to reduce production costs. It also offers good insulation properties.

Cons: Plastic may not withstand high temperatures and can degrade over time, especially when exposed to UV light or harsh chemicals.

Impact on Application: In regions with high humidity, such as parts of the Middle East, the choice of plastic must consider its susceptibility to warping and degradation. Compliance with food safety standards is also critical.

Why Is Aluminum Considered for Snowflake Ice Makers?

Aluminum is another commonly used material, particularly for components that require lightweight and good thermal conductivity. It can handle temperatures up to 600°F (316°C) and is resistant to corrosion when anodized.

Pros: Aluminum is lightweight and cost-effective, making it suitable for portable ice makers. Its excellent thermal conductivity allows for efficient ice production.

Illustrative image related to snowflake ice maker

Cons: While resistant to corrosion, aluminum can be less durable than stainless steel, particularly in high-stress environments.

Impact on Application: In regions like Europe, where energy efficiency is prioritized, aluminum’s thermal properties can enhance the operational efficiency of ice makers.

How Does Copper Contribute to Snowflake Ice Maker Efficiency?

Copper is primarily used in the refrigeration components of ice makers due to its superior thermal conductivity. It can handle high-pressure applications and has a temperature rating of up to 2000°F (1093°C).

Pros: Copper’s excellent heat transfer properties make it ideal for rapid cooling, enhancing ice production efficiency.

Cons: Copper is more expensive than aluminum and can corrode if not properly coated or maintained.

Impact on Application: In markets such as Germany, where quality and efficiency are paramount, the use of copper can significantly improve the performance of snowflake ice makers, although compliance with environmental regulations regarding copper usage is essential.

Summary Table of Material Selection for Snowflake Ice Makers

| Material | Typical Use Case for snowflake ice maker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, blades | High durability and corrosion resistance | Higher initial cost | High |

| Plastic | Water reservoirs, internal linings | Lightweight and cost-effective | Limited temperature resistance | Low |

| Aluminum | Housing, heat exchangers | Lightweight and good thermal conductivity | Less durable than stainless steel | Medium |

| Copper | Refrigeration components | Excellent thermal conductivity | Higher cost and corrosion risk | High |

This strategic material selection guide serves as a comprehensive overview for B2B buyers looking to invest in snowflake ice makers. By understanding the properties and implications of each material, businesses can make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for snowflake ice maker

What Are the Key Stages in the Manufacturing Process of Snowflake Ice Makers?

The manufacturing of snowflake ice makers involves several critical stages, each designed to ensure the final product meets high standards of efficiency and reliability. The typical manufacturing process includes material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Essential for Snowflake Ice Makers?

The process begins with the selection of high-quality materials. Snowflake ice makers predominantly use stainless steel due to its resistance to corrosion, durability, and ease of cleaning. Common grades include SUS201 and SUS304. Other components, such as the blades, are often made from high-grade stainless steel like 5CR15, which provides additional durability. Additionally, food-grade plastics are used for internal components to ensure safety and hygiene.

Forming: How Are Components Shaped and Prepared?

In the forming stage, the prepared materials undergo various processes such as cutting, molding, and machining. CNC (Computer Numerical Control) machines are frequently employed for precision cutting of metal sheets into required shapes for the machine’s body and internal parts. This ensures consistent quality and adherence to design specifications. For plastic components, injection molding is commonly used, allowing for complex shapes and efficient production.

Assembly: What Processes Ensure the Components Work Together?

Once the individual parts are formed, the assembly phase begins. This stage involves the integration of all components, including the compressor, cooling system, and control panel. Automated assembly lines may be used for efficiency, where components are assembled in a sequence that minimizes handling and maximizes speed. Quality control checks are often implemented during assembly to ensure that parts fit correctly and function as intended.

Finishing: How Is the Final Product Prepared for Market?

After assembly, the finishing stage involves cleaning, polishing, and applying protective coatings. This is crucial for enhancing the aesthetic appeal and durability of the ice maker. Components may undergo surface treatment processes such as electro-polishing to increase resistance to corrosion and improve hygiene standards. The final product is then thoroughly cleaned and prepared for packaging.

How Is Quality Assurance Maintained Throughout the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of snowflake ice makers, ensuring that every unit produced meets international standards and customer expectations. The QA process typically aligns with international certifications such as ISO 9001, which emphasizes a systematic approach to management and continuous improvement.

Illustrative image related to snowflake ice maker

What International Standards Are Relevant for Snowflake Ice Makers?

International standards such as ISO 9001 provide a framework for quality management systems. Compliance with these standards indicates that manufacturers have established consistent processes for production and quality control. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are relevant, particularly for machines used in environments requiring strict safety and performance guidelines.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is executed at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to verify that processes remain within specified limits. This includes checking tolerances and functionalities as components are assembled.

- Final Quality Control (FQC): After assembly, the finished ice makers undergo comprehensive testing. This includes performance tests to ensure ice production meets specified capacities, as well as safety and functionality tests.

What Common Testing Methods Are Used?

Testing methods for snowflake ice makers typically include:

- Performance Testing: Assessing the machine’s ice production capacity, cooling efficiency, and operating speed.

- Durability Testing: Subjecting the machine to extreme conditions to evaluate its resilience and longevity.

- Safety Testing: Ensuring compliance with electrical and mechanical safety standards.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality assurance practices of suppliers is essential. Here are key steps to ensure supplier reliability:

What Audit Processes Should Be Conducted?

Buyers should conduct thorough supplier audits to assess their manufacturing processes and quality control systems. This includes:

- On-Site Visits: Where feasible, visiting the manufacturing facility can provide insights into operational practices and quality management.

- Document Review: Requesting documentation of certifications, quality control processes, and previous inspection reports can offer transparency.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance practices. These services can conduct inspections at various production stages and provide comprehensive reports detailing compliance with international standards.

Illustrative image related to snowflake ice maker

What Are the Specific Quality Control Nuances for International B2B Buyers?

B2B buyers operating in diverse regions must be aware of specific nuances in quality control and certification requirements. For instance, European buyers may place greater emphasis on CE marking for product safety, while buyers in the Middle East may prioritize compliance with local regulatory standards.

How Can Buyers Ensure Compliance with Regional Standards?

Buyers should familiarize themselves with the regulatory landscape of their respective regions and ensure that suppliers can demonstrate compliance with relevant standards. This may involve requesting specific certifications and understanding the implications of non-compliance.

Conclusion: Ensuring Quality in Snowflake Ice Makers

Understanding the manufacturing processes and quality assurance measures for snowflake ice makers is crucial for B2B buyers. By focusing on materials, production stages, and rigorous quality control, buyers can make informed decisions and partner with suppliers that uphold high standards of quality and reliability. As the demand for efficient and durable ice-making solutions grows globally, prioritizing these factors will be essential for success in the competitive landscape.

Illustrative image related to snowflake ice maker

Practical Sourcing Guide: A Step-by-Step Checklist for ‘snowflake ice maker’

To assist B2B buyers in navigating the procurement of snowflake ice makers, this guide outlines key steps to ensure a successful purchasing experience. By following this checklist, businesses can make informed decisions that align with their operational needs and budgetary constraints.

Step 1: Define Your Technical Specifications

Before exploring suppliers, it’s essential to outline your specific needs for a snowflake ice maker. Consider factors such as daily ice production capacity, ice shape and texture requirements, and cooling method (air or water). Clearly defined specifications will streamline your search and help you communicate effectively with potential suppliers.

- Production Capacity: Determine how much ice you need daily—common capacities range from 80 kg to over 400 kg.

- Ice Texture: Specify the desired ice texture (e.g., snow, noodle) to ensure the machine meets your application needs.

Step 2: Research Reliable Suppliers

Identifying trustworthy suppliers is critical to ensuring quality and reliability in your purchase. Look for manufacturers with a solid reputation in the industry, focusing on those who specialize in commercial ice-making equipment.

- Check Reviews and Testimonials: Seek feedback from other businesses that have purchased similar equipment.

- Industry Experience: Prioritize suppliers with a history of serving your specific market or region.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers meet relevant industry standards and certifications. This not only ensures product quality but also compliance with safety and environmental regulations.

- Quality Certifications: Look for ISO certifications or other industry-specific quality marks.

- Safety Compliance: Ensure that the machines comply with local regulations, particularly if you are importing.

Step 4: Assess Product Features and Technology

Different models come with varying features that can significantly impact usability and efficiency. Review the specifications of potential machines to ensure they align with your operational needs.

- Cooling Speed: Machines that cool quickly (within 40 seconds) can enhance productivity.

- Ease of Operation: Features such as touch control panels and automatic cleaning functions can save time and reduce labor costs.

Step 5: Request and Compare Quotes

Once you’ve narrowed down your options, request detailed quotes from several suppliers. This will allow you to compare pricing, warranty terms, and after-sales support.

- Inclusions: Ensure that quotes detail what is included (e.g., installation, maintenance, training).

- Warranty and Support: Evaluate the length and coverage of warranties as well as the availability of customer support.

Step 6: Confirm Shipping and Delivery Terms

Understanding the logistics of shipping is crucial, especially for international buyers. Confirm delivery timelines and any associated costs before finalizing your order.

- Shipping Method: Inquire about shipping options (air vs. sea) and their impact on delivery time and cost.

- Customs and Duties: Be aware of any import duties or taxes that may apply to your purchase.

Step 7: Finalize the Purchase Agreement

Before committing to a purchase, ensure that all terms are clearly outlined in a formal agreement. This should include payment terms, delivery expectations, and what recourse is available in case of issues.

- Payment Terms: Clarify whether payment is due upfront, upon delivery, or through financing options.

- Return Policy: Understand the return policy in case the machine does not meet expectations upon arrival.

By following this structured approach, B2B buyers can make informed decisions and secure the right snowflake ice maker for their business needs.

Comprehensive Cost and Pricing Analysis for snowflake ice maker Sourcing

Understanding the cost structure and pricing of snowflake ice makers is crucial for international B2B buyers aiming to optimize procurement strategies. This analysis will delve into the essential cost components, factors influencing pricing, and provide actionable tips for buyers.

What Are the Key Cost Components in Snowflake Ice Makers?

The cost structure of snowflake ice makers can be broken down into several essential components:

-

Materials: The choice of materials significantly impacts costs. Stainless steel, for instance, is often preferred for its durability and corrosion resistance, yet it comes at a higher price point compared to other materials. Components like compressors, which are vital for performance, also contribute to the overall material costs.

-

Labor: Manufacturing labor costs vary based on geographic location. Countries with lower labor costs can provide competitive pricing, but this may affect quality. Skilled labor is essential for assembly, particularly for machines requiring precise engineering.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment depreciation. Efficient manufacturing processes can help mitigate these overheads, impacting the final price.

-

Tooling: Initial investments in tooling can be substantial, especially for customized machines. If specific configurations or sizes are required, these costs should be factored into pricing.

-

Quality Control (QC): Comprehensive quality assurance processes ensure product reliability and safety, particularly for machines intended for food production. Enhanced QC measures can increase costs but are necessary for compliance with international standards.

-

Logistics: Shipping and handling costs can vary greatly depending on the destination. International buyers should consider freight charges, insurance, and potential customs duties in their total cost calculations.

-

Margin: Supplier profit margins can differ based on market positioning and competition. Understanding the typical margin range can aid in negotiations.

How Do Price Influencers Affect Snowflake Ice Maker Costs?

Several factors can influence the pricing of snowflake ice makers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases can lead to significant discounts. Suppliers often have a MOQ, which, if met, can optimize the cost per unit.

-

Specifications and Customization: Custom features or specifications may lead to higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., CE, NSF) can increase costs but may also be necessary for compliance in certain markets, particularly in Europe.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more due to perceived quality and support, while lesser-known suppliers may offer lower prices but with risks.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is vital for determining who bears the costs and risks during transportation. Incoterms can significantly influence the total landed cost.

What Are the Best Negotiation Tips for International B2B Buyers?

When sourcing snowflake ice makers, especially in regions like Africa, South America, the Middle East, and Europe, buyers should consider the following strategies:

-

Research and Benchmarking: Before negotiations, conduct market research to understand average pricing and features. This knowledge can bolster your negotiating position.

-

Emphasize Total Cost of Ownership (TCO): Highlight the importance of TCO, which includes maintenance, energy consumption, and lifespan. A slightly higher upfront cost for a more efficient machine can lead to long-term savings.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Suppliers may offer discounts or favorable terms to loyal customers.

-

Be Open to Alternatives: If a particular model exceeds your budget, inquire about alternative machines or configurations that still meet your operational needs.

-

Negotiate Payment Terms: Favorable payment terms can improve cash flow, allowing buyers to manage their financial commitments better.

Conclusion

Navigating the cost and pricing landscape of snowflake ice makers requires a comprehensive understanding of various components and influences. By leveraging this knowledge, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that indicative prices may vary based on market conditions and supplier negotiations, so continuous market monitoring is essential.

Illustrative image related to snowflake ice maker

Alternatives Analysis: Comparing snowflake ice maker With Other Solutions

In today’s competitive food and beverage market, businesses are constantly seeking efficient solutions for ice production. While snowflake ice makers are popular for their ability to produce light and fluffy ice ideal for various culinary applications, several alternative solutions exist that can meet the same needs. This section explores these alternatives, allowing B2B buyers to make informed decisions based on their specific operational requirements.

| Comparison Aspect | Snowflake Ice Maker | Ice Cube Machine | Flake Ice Machine |

|---|---|---|---|

| Performance | Produces up to 176 lbs (80 kg) of snowflake ice per day | Produces standard ice cubes, yield varies based on model | Produces light, fluffy ice ideal for drinks, yield varies |

| Cost | Moderate ($398 – $1,490) | Lower ($300 – $1,000) | Moderate to High ($500 – $2,000) |

| Ease of Implementation | Plug-and-play; minimal setup required | Easy installation; standard plumbing | Requires more space and setup |

| Maintenance | Low; easy to clean and maintain | Moderate; regular cleaning required | Moderate; maintenance depends on model |

| Best Use Case | Ideal for dessert shops, cafes, and bakeries | Best for bars and restaurants needing standard ice | Great for seafood markets, restaurants, and bars |

What Are the Benefits and Drawbacks of Using an Ice Cube Machine?

Ice cube machines are a common alternative, particularly for establishments such as bars and restaurants that require standard ice cubes for drinks. They are generally more affordable and easier to install, making them appealing for businesses with limited budgets. However, they produce a denser ice type, which may not be suitable for all culinary applications, especially those requiring softer ice textures.

How Does a Flake Ice Machine Compare?

Flake ice machines create a different type of ice that is ideal for certain use cases, such as seafood displays or blended beverages. They can produce ice quickly and are generally efficient in cooling applications. However, they may require more space and can be more complex to install compared to snowflake ice makers. Additionally, they may have a higher initial cost, which can be a consideration for budget-conscious buyers.

Conclusion: Which Ice Production Solution Is Right for Your Business?

When deciding between a snowflake ice maker and its alternatives, B2B buyers should consider their specific operational needs, including the type of ice required, the volume of production, space constraints, and budget. Snowflake ice makers excel in producing unique ice textures for desserts and specialty drinks, while ice cube machines and flake ice machines serve different purposes. Assessing these factors will lead to an informed decision that best aligns with the business’s goals and customer preferences.

Essential Technical Properties and Trade Terminology for snowflake ice maker

What Are the Key Technical Properties of a Snowflake Ice Maker?

When evaluating snowflake ice makers for commercial use, several technical properties are crucial. Understanding these specifications can significantly impact purchasing decisions and operational efficiency.

1. Ice Production Capacity

The ice production capacity, usually measured in kilograms per 24 hours, indicates the volume of ice the machine can produce. For example, models may range from 80 kg to over 440 kg per day. This specification is vital for businesses that anticipate high customer volumes, ensuring that they can meet demand without delays.

2. Cooling Method

Snowflake ice makers typically employ either air cooling or water cooling systems. Air-cooled machines are generally more energy-efficient and easier to install, making them ideal for smaller operations. In contrast, water-cooled machines may offer faster ice production rates but require a consistent water supply. Understanding the cooling method helps buyers assess installation requirements and operational costs.

3. Material Grade

The materials used in the construction of snowflake ice makers, such as SUS201 and SUS304 stainless steel, play a crucial role in durability and corrosion resistance. Higher-grade materials ensure longevity and reduce maintenance needs, which is particularly important for businesses operating in humid or high-salinity environments. Buyers should prioritize machines made from food-grade materials to comply with health and safety regulations.

Illustrative image related to snowflake ice maker

4. Power Consumption

Power consumption, measured in watts, affects operational costs and efficiency. A typical snowflake ice maker may range from 360W to 1,890W. Understanding energy requirements allows businesses to calculate operating costs and evaluate the return on investment. Energy-efficient models can lead to significant savings over time.

5. Control Mechanism

Modern snowflake ice makers often feature advanced control mechanisms, such as intelligent touch panels. These controls allow for easy operation, speed adjustments, and cleaning functions. A user-friendly interface is essential for reducing training time for staff and ensuring consistent ice quality.

6. Bucket Capacity

The bucket capacity, typically around 3 liters, determines how much ice can be stored at one time. A larger bucket capacity allows for extended periods of operation without the need for frequent emptying, which can be beneficial in high-demand settings.

What Are the Common Trade Terms Associated with Snowflake Ice Makers?

Understanding industry jargon is essential for smooth negotiations and transactions. Here are some common terms relevant to snowflake ice makers:

Illustrative image related to snowflake ice maker

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of snowflake ice makers, businesses may seek OEM partners to create customized machines tailored to specific market needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and initial investment costs. Understanding MOQ can help businesses align their purchasing strategies with their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For buyers looking to procure snowflake ice makers, issuing an RFQ can lead to competitive pricing and better understanding of supplier capabilities.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is crucial for international buyers, as they clarify who bears costs and risks during transport, thus influencing total landed costs.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times helps businesses plan their inventory and avoid disruptions in operations, particularly during peak seasons.

6. Warranty Period

The warranty period is the duration during which the manufacturer guarantees the product against defects. Knowing the warranty terms can help businesses assess the long-term viability of their investment in snowflake ice makers and plan for potential maintenance costs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, ensuring their investment in snowflake ice makers aligns with their operational goals and market demands.

Illustrative image related to snowflake ice maker

Navigating Market Dynamics and Sourcing Trends in the snowflake ice maker Sector

What Are the Key Trends Shaping the Snowflake Ice Maker Market?

The snowflake ice maker sector is witnessing significant growth driven by increasing demand across various industries, including food service, hospitality, and healthcare. Global trends indicate a rising preference for snowflake ice due to its unique texture and versatility in applications such as beverages and desserts. The demand is particularly strong in regions like Africa and South America, where tropical climates boost the need for cooling solutions, as well as in the Middle East, where hospitality and entertainment sectors thrive.

Emerging technologies are shaping sourcing practices, with automation and energy efficiency becoming top priorities for B2B buyers. Suppliers are increasingly offering machines with advanced features like rapid cooling times, user-friendly interfaces, and customizable ice shapes. Additionally, the integration of IoT technology allows for real-time monitoring and maintenance, enhancing operational efficiency. Buyers from Europe, including Germany, are particularly focused on energy-efficient and high-performance units, reflecting stringent environmental regulations and consumer preferences for sustainable solutions.

Market dynamics are also influenced by the competitive landscape, where international manufacturers are establishing local partnerships to enhance service and support. Buyers should be proactive in evaluating supplier capabilities, including after-sales service and warranty options, to ensure long-term operational reliability.

How Is Sustainability Impacting Sourcing Decisions in the Snowflake Ice Maker Sector?

Sustainability has emerged as a critical factor in sourcing decisions for snowflake ice makers. The environmental impact of manufacturing processes and the lifecycle of equipment are increasingly scrutinized by B2B buyers. Companies are now prioritizing suppliers that utilize eco-friendly materials and practices, such as using stainless steel with high recyclability and energy-efficient compressors that reduce carbon footprints.

Ethical sourcing is also becoming paramount, as businesses recognize the importance of transparency in their supply chains. Certifications like ISO 14001 for environmental management systems and other ‘green’ labels provide assurance to buyers that suppliers are committed to sustainable practices. This trend is particularly relevant in regions with growing environmental consciousness, such as Europe and parts of the Middle East.

Incorporating sustainability into purchasing decisions not only aligns with corporate social responsibility goals but can also enhance brand reputation and customer loyalty. B2B buyers are encouraged to engage with suppliers who demonstrate a commitment to sustainability, ensuring their operations contribute positively to environmental goals.

What Is the Historical Context of Snowflake Ice Makers in the B2B Market?

The snowflake ice maker has evolved significantly since its inception, transitioning from basic manual machines to sophisticated, automated solutions that cater to a diverse array of industries. Initially popularized in the mid-20th century, these machines were primarily used in small food service establishments. As the demand for high-quality ice grew, particularly in beverage and dessert applications, manufacturers began to innovate, introducing electric models that improved efficiency and output.

By the late 20th century, advancements in refrigeration technology and materials science led to the development of more durable and efficient machines, allowing for larger production capacities and faster ice-making processes. Today, the market is characterized by a range of options that meet varying operational needs, from compact units for small cafes to high-capacity machines for large-scale food production.

The evolution of snowflake ice makers reflects broader trends in the food service industry, including the rise of gourmet desserts and specialty beverages, further solidifying their place in the B2B landscape. As technology continues to advance, the future of snowflake ice makers looks promising, with ongoing innovations likely to enhance performance and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of snowflake ice maker

-

How do I ensure the snowflake ice maker meets my production needs?

To guarantee the snowflake ice maker aligns with your production requirements, assess your daily ice volume needs. Review specifications like ice output (measured in pounds or kilograms per day) and production speed. Consider the machine’s versatility in producing various ice shapes, as this can affect your menu offerings. Finally, consult with suppliers about their machines’ performance in similar commercial environments, ensuring they can provide customer references or case studies to validate their claims. -

What is the best snowflake ice maker for high-volume production?

For high-volume production, look for models that can produce at least 400 lbs (approximately 180 kg) of ice daily. Machines with robust compressors and advanced cooling systems, such as air cooling or water cooling, are ideal for maintaining consistent output. Brands like Kolice and VEVOR offer models designed for commercial settings, ensuring durability and reliability. Always verify the machine’s energy efficiency, as this can significantly impact operational costs over time. -

What are common payment terms for purchasing snowflake ice makers internationally?

Payment terms can vary widely among suppliers. Common arrangements include a 30% deposit upfront, with the remaining balance due before shipping. Letter of Credit (LC) is also a popular option for larger transactions, providing security for both buyer and seller. Always clarify payment methods accepted (e.g., bank transfer, PayPal) and inquire about any additional fees related to international transactions, such as currency conversion costs or transaction fees. -

How can I vet suppliers of snowflake ice makers effectively?

Begin by researching potential suppliers’ reputations through reviews and ratings from previous customers. Request references and case studies to understand their reliability and product quality. Check for certifications that demonstrate adherence to international manufacturing standards, such as ISO. Additionally, consider visiting their facilities or attending trade shows to see their products in action, which can provide valuable insights into their operational practices. -

What customization options are available for snowflake ice makers?

Many manufacturers offer customization options to suit specific business needs. This may include adjustments to ice production capacity, machine size, and additional features like touch control panels or enhanced cooling systems. Discuss your requirements with suppliers to explore available options and any associated costs. Customization may also extend to branding, allowing you to incorporate your company logo or colors into the machine design. -

What are the shipping and logistics considerations for importing snowflake ice makers?

Shipping costs can vary based on the machine’s weight, dimensions, and destination. It’s crucial to understand the logistics of international shipping, including customs duties and import taxes. Work with suppliers who can provide clear shipping terms and timelines. Consider partnering with a freight forwarder to navigate complex regulations, ensuring timely delivery and compliance with local import laws, especially in regions like Africa and the Middle East. -

What quality assurance measures should I expect from snowflake ice maker suppliers?

Reputable suppliers should have stringent quality assurance processes in place. Look for manufacturers that conduct thorough testing of their machines before shipment, including performance evaluations and safety checks. Inquire about warranties and after-sales support to ensure you receive assistance in case of defects or operational issues. Certifications from recognized bodies can also indicate a commitment to quality standards. -

Are there specific maintenance requirements for snowflake ice makers?

Regular maintenance is crucial to ensure the longevity and efficient operation of snowflake ice makers. This typically includes routine cleaning of the ice-making components, regular inspection of the cooling system, and checking for any wear on blades and seals. Consult the manufacturer’s guidelines for specific maintenance schedules and procedures. Additionally, consider negotiating maintenance contracts with suppliers to ensure you have access to professional servicing as needed.

Top 4 Snowflake Ice Maker Manufacturers & Suppliers List

1. VEVOR – Commercial Snowflake Ice Machine

Domain: vevor.com

Registered: 2009 (16 years)

Introduction: {“Product Name”: “VEVOR Commercial Snowflake Ice Machine”, “Ice Production”: “176.4 lbs / 80 kg per 24 hours”, “Cooling Method”: “Air Cooling”, “Power”: “360W”, “Main Materials”: “SUS201 stainless steel, SUS304 stainless steel, 5CR15 stainless steel, PC”, “Bucket Capacity”: “3 L / 0.8 gal”, “Refrigeration Speed”: “40 seconds”, “Product Weight”: “51.4 lbs / 23.3 kg”, “Product Size”: “18.1 x 12.6 x …

2. Kolice – Bingsu Ice Machines

Domain: kolice.cc

Registered: 2014 (11 years)

Introduction: Bingsu machine – Kolice offers various models of snowflake ice machines with the following key details: 1. Kolice Auto Electric Bingsu Shaved Ice Machine – Ice Crush Machine, priced at $378.00, suitable for homemade desserts. 2. Kolice Mini Automatic LJX170F-4 – Snow flake Ice shaving Machine, capable of producing 374 lbs/day, priced at $899.00. 3. Kolice Automatically Electric Ice Crusher Shaver …

3. Facebook – Snowflake Ice Machine

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Snowflake Ice Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Infitek – Ice Makers IM-FK20 & IM-FK30

Domain: infitek.com

Registered: 2020 (5 years)

Introduction: { “model”: [“IM-FK20”, “IM-FK30”], “ice_making_capacity_kg_per_24h”: [20, 30], “ice_storage_kg”: 10, “ice_type”: “irregular fine-grained”, “cooling_mode”: “forced-air cooling”, “refrigerant”: “R290 (CFC Free)”, “electricity”: “AC110 / 220V±10%, 50 / 60Hz”, “power_consumption_W”: [280, 300], “instrument_dimensions_mm”: {“W”: 330, “D”: 480, “H”: 605}, “package_dimensions_mm”: {“W”: 640, “D”: 490, “H…

Strategic Sourcing Conclusion and Outlook for snowflake ice maker

In the dynamic landscape of commercial ice production, strategic sourcing of snowflake ice makers emerges as a critical component for businesses aiming to enhance operational efficiency and meet consumer demands. Key takeaways highlight the importance of selecting machines that not only offer high production capacity—ranging from 176 lbs to over 440 lbs per day—but also feature innovative technology for rapid cooling and versatile ice texture options. The durability and ease of maintenance of these machines, often made from stainless steel, ensure long-term reliability, making them a sound investment for various applications, from cafes to food trucks.

As international buyers from regions such as Africa, South America, the Middle East, and Europe navigate their sourcing strategies, the emphasis should be on suppliers who provide comprehensive support, including warranty options and customer service. This not only enhances the procurement process but also fosters long-term partnerships.

Looking ahead, the demand for snowflake ice makers is set to grow as consumer preferences shift towards unique frozen desserts. Now is the opportune time for businesses to leverage strategic sourcing to secure advanced ice-making technology that aligns with evolving market trends. Engage with reputable suppliers today to ensure your operations are equipped to meet future challenges and capitalize on emerging opportunities in the food service industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.