Small Enclosed Trailer: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for small enclosed trailer

In today’s fast-paced global economy, sourcing small enclosed trailers presents a unique challenge for B2B buyers navigating diverse markets. Whether you are in Africa, South America, the Middle East, or Europe, understanding the nuances of trailer specifications, pricing structures, and supplier reliability is crucial. This guide is designed to equip international buyers with the insights needed to make informed purchasing decisions.

We will explore various types of small enclosed trailers, their applications across industries, and essential factors to consider when vetting suppliers. Additionally, we’ll provide a comprehensive overview of cost considerations, financing options, and the latest trends in trailer design and functionality. By consolidating this information, our goal is to empower you with actionable knowledge that enhances your procurement strategy.

As you delve into this guide, you will gain clarity on how to identify the right trailer to meet your operational needs, ensuring that your investment aligns with your business objectives. Whether you’re seeking to transport goods securely or expand your service offerings, understanding the global market landscape for small enclosed trailers will enable you to navigate the complexities of international sourcing with confidence.

Understanding small enclosed trailer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

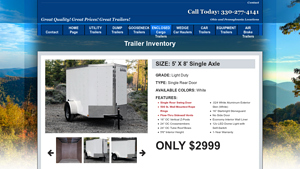

| Single Axle Enclosed Trailers | Compact size, lightweight, and typically lower cost | Small businesses, local deliveries | Pros: Affordable, easy to maneuver. Cons: Limited cargo capacity. |

| Double Axle Enclosed Trailers | Increased stability, larger payload capacity, and durability | Construction, event transport | Pros: Greater load capacity, better handling. Cons: Heavier, more expensive. |

| V-Nose Enclosed Trailers | Aerodynamic design, improved fuel efficiency | Long-distance transport, logistics | Pros: Better towing efficiency, more interior space. Cons: Higher initial cost. |

| Custom-Built Enclosed Trailers | Tailored specifications for unique business needs | Specialized industries (e.g., mobile services) | Pros: Exact fit for requirements. Cons: Longer lead times, potentially higher costs. |

| Lightweight Enclosed Trailers | Made from lighter materials, easy to tow | Small businesses, personal use | Pros: Easy to handle, fuel-efficient. Cons: May lack durability for heavy loads. |

What Are the Characteristics of Single Axle Enclosed Trailers?

Single axle enclosed trailers are designed for small-scale operations, offering a compact and lightweight solution for transporting goods. Typically featuring a single rear door, these trailers are ideal for local deliveries and small businesses that require a cost-effective transportation method. B2B buyers should consider their payload needs, as these trailers generally have a lower capacity compared to double axle models. Their affordability and ease of maneuverability make them attractive options for startups and entrepreneurs.

How Do Double Axle Enclosed Trailers Benefit Businesses?

Double axle enclosed trailers are built for stability and larger payloads, making them suitable for industries such as construction and event transport. The dual axles provide enhanced handling and weight distribution, allowing businesses to transport heavier loads safely. Buyers should evaluate their operational demands, as these trailers are typically heavier and more expensive than their single axle counterparts. The investment is often justified by the increased durability and capacity, which can lead to higher efficiency in logistics.

Why Choose V-Nose Enclosed Trailers for Transportation?

V-nose enclosed trailers feature a distinct aerodynamic design that reduces drag during towing, leading to improved fuel efficiency. They offer more interior space compared to traditional box trailers, making them a smart choice for long-distance transport and logistics operations. B2B buyers should consider the initial higher cost against potential savings in fuel and increased cargo capacity. This type of trailer is particularly advantageous for businesses that prioritize efficiency and require a reliable transport solution.

What Are the Advantages of Custom-Built Enclosed Trailers?

Custom-built enclosed trailers are designed to meet specific business needs, accommodating unique dimensions and features. These trailers are particularly beneficial for specialized industries, such as mobile services, where standard models may not suffice. While they offer the advantage of tailored specifications, buyers should be aware of the longer lead times and potentially higher costs associated with custom orders. The ability to create a trailer that perfectly fits operational requirements can significantly enhance productivity.

What Should Buyers Know About Lightweight Enclosed Trailers?

Lightweight enclosed trailers are constructed from lighter materials, making them easy to tow and ideal for small businesses or personal use. Their lightweight design contributes to better fuel efficiency, which is a crucial consideration for businesses operating on tight budgets. However, B2B buyers should assess their durability needs, as these trailers may not withstand heavy loads as well as more robust models. Lightweight trailers are perfect for those who prioritize ease of use without compromising too much on capacity.

Key Industrial Applications of small enclosed trailer

| Industry/Sector | Specific Application of small enclosed trailer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Transportation | Transporting goods securely across regions | Enhanced protection against weather and theft | Durability, weight capacity, and compliance with local regulations |

| Construction | On-site storage for tools and equipment | Reduces downtime and enhances job site efficiency | Size, security features, and ease of access |

| Event Management | Mobile storage for event equipment and supplies | Streamlined logistics and organization | Size, accessibility, and customization options |

| Automotive Services | Transporting vehicles or parts | Improved operational efficiency and safety | Weight capacity, ramp design, and ease of loading/unloading |

| Agriculture | Hauling tools and supplies for farming | Increased productivity and reduced labor costs | Robust construction, weather resistance, and interior organization features |

How are small enclosed trailers utilized in logistics and transportation?

In the logistics and transportation sector, small enclosed trailers are essential for securely transporting goods over long distances, particularly in regions where theft and weather conditions pose significant risks. These trailers offer a reliable solution for businesses needing to safeguard their cargo while on the move. Buyers should consider factors such as durability, weight capacity, and compliance with local regulations to ensure their trailers meet operational needs and legal requirements in their respective countries, especially in regions like Africa and South America where road conditions can vary.

What role do small enclosed trailers play in construction?

For construction companies, small enclosed trailers provide an effective means for on-site storage of tools and equipment. This not only minimizes the risk of theft but also reduces downtime as workers can access necessary tools without delay. Buyers in this sector should prioritize features such as size, security options, and ease of access to ensure their trailers can accommodate a variety of equipment and withstand rigorous job site conditions, which is particularly important in the Middle East where outdoor working conditions can be extreme.

How do event management companies benefit from small enclosed trailers?

Event management companies utilize small enclosed trailers for mobile storage of equipment and supplies, which is crucial for maintaining organization during events. These trailers streamline logistics by allowing easy transport of items such as tents, chairs, and sound systems. When sourcing trailers, companies should look for options that offer adequate space, accessibility, and customization features, ensuring they can meet the diverse needs of various events across Europe and beyond.

In what ways do automotive services leverage small enclosed trailers?

Small enclosed trailers are invaluable for automotive service businesses, allowing for the safe transportation of vehicles and parts. This capability enhances operational efficiency and ensures the safety of valuable assets during transit. Buyers should focus on weight capacity, ramp design, and ease of loading/unloading when selecting a trailer, as these factors significantly affect the trailer’s usability and effectiveness in diverse markets, including those in Asia and the Middle East.

How can small enclosed trailers support agricultural operations?

In agriculture, small enclosed trailers are used to haul tools and supplies, significantly increasing productivity and reducing labor costs. These trailers can be equipped to handle various types of agricultural equipment, making them versatile assets for farmers. When sourcing, buyers should emphasize robust construction, weather resistance, and features that facilitate interior organization, as these elements are crucial for efficiency in the often demanding environments found in rural areas of Africa and South America.

3 Common User Pain Points for ‘small enclosed trailer’ & Their Solutions

Scenario 1: Difficulty in Ensuring Cargo Security During Transport

The Problem: For many businesses operating in logistics or retail, ensuring the security of transported goods is paramount. Small enclosed trailers are often used to transport valuable items, yet many buyers face challenges regarding the security features of these trailers. Without adequate locking mechanisms or durable construction, trailers become vulnerable to theft, leading to potential financial losses and damaged reputations. This is especially concerning for B2B buyers in regions with high theft rates or limited law enforcement presence.

The Solution: When sourcing small enclosed trailers, prioritize models that incorporate advanced security features. Look for trailers equipped with heavy-duty locks, reinforced doors, and tamper-resistant latches. Additionally, consider trailers with built-in alarm systems or GPS tracking capabilities, which can provide real-time monitoring of cargo. For maximum security, reinforce the trailer’s structure with additional locking mechanisms or use anti-theft devices such as wheel locks or hitch locks. Training staff on best practices for securing trailers during loading and unloading can also help mitigate risks.

Scenario 2: Inadequate Space for Diverse Cargo Needs

The Problem: Many businesses encounter the issue of insufficient space when transporting various types of cargo. Small enclosed trailers can sometimes limit the volume and dimensions of items that can be transported, leading to inefficiencies and higher costs associated with multiple trips. This is particularly problematic for businesses in sectors like construction or event planning, where diverse equipment or materials must be moved regularly.

The Solution: To address space limitations, buyers should evaluate their typical cargo dimensions and choose a trailer that offers flexibility. Opt for models with adjustable shelving or removable bulkheads to maximize interior space. Additionally, consider trailers with a V-nose design, which can provide extra length while maintaining a compact exterior. For businesses with fluctuating cargo needs, investing in a modular trailer system that allows for easy reconfiguration can also be advantageous. Finally, regularly assess your cargo requirements to ensure the trailer continues to meet your needs over time, allowing for timely upgrades or adjustments.

Scenario 3: Maintenance Challenges Leading to Downtime

The Problem: Regular maintenance is crucial for the longevity and performance of small enclosed trailers, yet many businesses neglect this aspect due to time constraints or lack of knowledge. Poor maintenance can lead to issues such as tire wear, brake failure, or leaks, resulting in unexpected breakdowns and costly downtime. This scenario can be particularly detrimental for businesses that rely on tight schedules for deliveries or projects.

The Solution: To prevent maintenance-related issues, establish a proactive maintenance schedule tailored to the specific needs of your trailer. This should include regular inspections of tires, brakes, lights, and structural integrity. Utilize a checklist to ensure all components are regularly checked and replaced as necessary. Additionally, consider investing in a trailer maintenance management system that can remind you of service intervals and help track repairs. Collaborating with a reliable service provider who specializes in trailer maintenance can also ensure that any issues are addressed promptly. Training your team on basic maintenance tasks can empower them to identify potential problems early, reducing the likelihood of costly repairs and downtime.

Strategic Material Selection Guide for small enclosed trailer

What Are the Key Materials Used in Small Enclosed Trailers?

When selecting materials for small enclosed trailers, various factors such as durability, weight, cost, and environmental conditions must be considered. Here, we analyze four common materials used in the construction of small enclosed trailers: aluminum, steel, fiberglass, and wood. Each material has distinct properties and implications for international B2B buyers.

How Does Aluminum Perform in Small Enclosed Trailers?

Aluminum is a popular choice for small enclosed trailers due to its lightweight nature and corrosion resistance. Key properties include a high strength-to-weight ratio, which enhances fuel efficiency during transport. Additionally, aluminum can withstand extreme temperatures, making it suitable for diverse climates.

Pros: Aluminum is highly durable and resistant to rust, which is particularly advantageous in humid or coastal regions. Its lightweight nature reduces the overall weight of the trailer, allowing for increased payload capacity.

Cons: The primary drawback is the higher cost compared to other materials. Manufacturing complexity can also be an issue, as aluminum requires specialized welding techniques.

Impact on Application: Aluminum is compatible with various media, including water and chemicals, making it suitable for transporting sensitive goods.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards for aluminum alloys, such as ASTM or EN specifications.

What Are the Benefits of Steel in Trailer Construction?

Steel is another common material for small enclosed trailers, known for its strength and durability. Key properties include high tensile strength and resistance to deformation under heavy loads.

Pros: Steel trailers are robust and can handle significant wear and tear, making them ideal for heavy-duty applications. They are generally less expensive than aluminum, offering a more cost-effective solution for budget-conscious buyers.

Cons: Steel is prone to corrosion, especially in humid or salty environments, which can lead to increased maintenance costs. The weight of steel also limits payload capacity compared to aluminum.

Impact on Application: Steel is suitable for transporting heavy machinery or construction materials, but it may not be ideal for sensitive cargo due to potential rust issues.

Considerations for International Buyers: Buyers should consider local standards for steel grades, such as ASTM A36 or equivalent, to ensure structural integrity and compliance.

How Does Fiberglass Compare in Terms of Performance?

Fiberglass is increasingly used in small enclosed trailers due to its lightweight and corrosion-resistant properties. It offers good thermal insulation and can be molded into various shapes.

Pros: Fiberglass is resistant to rot and corrosion, making it an excellent choice for humid environments. Its lightweight nature enhances fuel efficiency.

Cons: The primary limitation of fiberglass is its brittleness, which can lead to cracks under heavy impact. Additionally, it can be more expensive than both aluminum and steel.

Impact on Application: Fiberglass is suitable for transporting delicate items, as it provides insulation and protection from external elements.

Considerations for International Buyers: Buyers should verify the fiberglass quality and ensure compliance with local regulations regarding composite materials.

What Role Does Wood Play in Small Enclosed Trailers?

Wood is often used in the construction of trailer interiors or as a structural component. It offers good insulation and aesthetic appeal.

Pros: Wood is generally less expensive and easier to work with than metal or fiberglass. It provides excellent thermal insulation and can be sourced sustainably.

Cons: Wood is susceptible to rot, pests, and warping, especially in humid climates. This can lead to higher long-term maintenance costs.

Impact on Application: Wood is suitable for interior finishes or non-structural components but may not be ideal for the exterior due to its vulnerability.

Considerations for International Buyers: Buyers should ensure that wood materials comply with local standards for treatment and sustainability, especially in regions with strict environmental regulations.

Summary Table of Material Selection for Small Enclosed Trailers

| Material | Typical Use Case for small enclosed trailer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight trailers for sensitive cargo | Corrosion-resistant and lightweight | Higher cost and manufacturing complexity | High |

| Steel | Heavy-duty trailers for construction materials | Strong and durable | Prone to corrosion and heavier weight | Medium |

| Fiberglass | Trailers for delicate items | Rot-resistant and good thermal insulation | Brittle and higher cost | High |

| Wood | Interior finishes and non-structural components | Cost-effective and easy to work with | Susceptible to rot and pests | Low |

This analysis provides actionable insights for B2B buyers in selecting the right materials for small enclosed trailers, taking into account their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for small enclosed trailer

What Are the Main Stages of Manufacturing Small Enclosed Trailers?

Manufacturing small enclosed trailers involves a systematic approach that ensures durability, functionality, and compliance with international standards. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The journey begins with selecting high-quality materials, primarily aluminum or steel, known for their strength and lightweight properties. Suppliers must ensure that raw materials meet industry standards, such as ASTM or ISO specifications. The materials are then cut to size using precision cutting tools, which minimizes waste and enhances efficiency.

-

Forming: This stage involves shaping the cut materials into the desired components of the trailer. Techniques like bending, welding, and stamping are commonly used. Advanced machinery, such as CNC (Computer Numerical Control) machines, ensures high precision in forming parts like walls, roofs, and frames. For instance, aluminum sheets may undergo a bending process to create the trailer’s body, while steel frames are welded together to provide structural integrity.

-

Assembly: The next step is assembling the formed components. This involves fitting together various parts, including the chassis, walls, and doors. Skilled labor plays a critical role here, as proper alignment and attachment are essential for the trailer’s performance and safety. During this phase, components like axles, tires, and electrical systems are also integrated. Quality checks are often performed at this stage to ensure that all parts fit correctly and function as intended.

-

Finishing: The final stage focuses on enhancing the trailer’s aesthetics and protection against environmental factors. This may include painting, powder coating, or applying protective films. Each finishing process not only improves the trailer’s appearance but also adds a layer of corrosion resistance. Final inspections are conducted to ensure that the trailer meets all quality and safety standards before it is shipped to clients.

How Is Quality Assurance Implemented in Trailer Manufacturing?

Quality assurance (QA) is crucial in the production of small enclosed trailers, ensuring that every unit meets established standards and customer expectations. This encompasses adherence to both international standards and industry-specific regulations.

-

Relevant International Standards: Compliance with international quality standards such as ISO 9001 is vital for manufacturers targeting global markets. ISO 9001 outlines the criteria for a quality management system, emphasizing consistent product quality and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) for Europe or API (American Petroleum Institute) standards for specific trailer uses can further enhance a manufacturer’s credibility.

-

Quality Control Checkpoints: Effective QA is structured around several key checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During production, continuous monitoring is performed to detect any deviations or defects in real-time. This may include inspections of weld integrity, alignment, and functionality of components.

– Final Quality Control (FQC): Before dispatch, a comprehensive inspection is conducted on the completed trailers. This includes verifying dimensions, functionality, and surface finishes. Testing for weight capacity and durability is also critical, often involving simulated load tests.

What Testing Methods Are Commonly Used in Trailer Quality Assurance?

Manufacturers employ various testing methods to validate the quality and safety of small enclosed trailers. These tests ensure compliance with both internal and external standards.

-

Load Testing: This method assesses the trailer’s structural integrity by applying weight to simulate real-world usage. Load tests help identify potential weaknesses in the frame and suspension systems.

-

Water Resistance Testing: For trailers intended for outdoor use, water resistance is critical. This testing evaluates how well the trailer can withstand rain and moisture, ensuring that cargo remains protected.

-

Road Worthiness Assessment: Trailers undergo road tests to evaluate performance metrics such as braking efficiency, stability, and handling under various conditions. This testing is essential for trailers that will be frequently used in diverse environments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, ensuring that suppliers maintain rigorous quality control practices is paramount. Here are actionable steps to verify supplier QC:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. An on-site visit allows buyers to assess compliance with international standards and evaluate equipment and technology used in production.

-

Review Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand their quality control procedures. These reports should include data on inspection results, testing outcomes, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality processes. These inspections can cover various stages of production and ensure compliance with international and industry-specific standards.

What Are the Quality Control Nuances for International Buyers?

When dealing with suppliers from different regions, international buyers must be aware of several nuances in quality control practices:

-

Cultural Differences: Variations in manufacturing cultures can influence quality standards and practices. Buyers should be prepared to navigate these differences and establish clear communication about expectations.

-

Regulatory Compliance: Each region may have distinct regulations governing trailer manufacturing. Buyers should ensure that their suppliers are familiar with and compliant with these regulations to avoid potential legal issues or product recalls.

-

Language Barriers: Language differences can complicate communication regarding quality standards. Establishing a common language or utilizing translation services can facilitate clearer discussions about specifications and expectations.

By understanding the manufacturing processes and quality assurance practices for small enclosed trailers, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their quality and safety requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘small enclosed trailer’

Introduction

This sourcing guide is designed to assist international B2B buyers in procuring small enclosed trailers, focusing on critical steps to ensure a successful purchase. By following this checklist, buyers can make informed decisions that align with their operational needs and budgetary constraints.

Step 1: Define Your Technical Specifications

Clearly outline your requirements before engaging with suppliers. Consider factors such as size, weight capacity, material quality, and intended use. For example, if you plan to transport sensitive equipment, prioritize trailers with reinforced interiors and secure locking mechanisms.

Step 2: Research Local Regulations and Compliance

Understanding local regulations regarding trailer usage is essential, especially in different regions such as Africa, South America, or the Middle East. Ensure that the trailers meet necessary safety and environmental standards. This may involve checking for certifications or inspections mandated by local authorities.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, case studies, and references from other buyers in similar industries or regions. Look for suppliers who have experience in international shipping, as this can simplify logistics and reduce potential issues.

Step 4: Assess Pricing and Payment Terms

Request detailed quotes from multiple suppliers to compare pricing structures. Pay attention to not only the base price but also additional costs such as shipping, customs duties, and taxes. Negotiate payment terms that align with your cash flow requirements, considering options such as financing or installment payments.

Step 5: Verify Warranty and After-Sales Support

A robust warranty and reliable after-sales support are crucial for ensuring long-term satisfaction with your purchase. Inquire about warranty coverage details, including what is included and the duration. Additionally, assess the supplier’s responsiveness to service inquiries and availability of spare parts.

Step 6: Conduct Quality Inspections

If possible, arrange for a quality inspection of the trailers before finalizing the purchase. This can be done through third-party inspection services or by visiting the supplier’s facility. Check for build quality, material integrity, and adherence to the specifications outlined in your order.

Step 7: Finalize Logistics and Delivery Plans

Once you have selected a supplier and confirmed your order, coordinate logistics for delivery. Discuss shipping options, estimated delivery times, and any necessary documentation required for customs clearance. Ensure that you have a contingency plan in place for potential delays.

By adhering to this checklist, B2B buyers can navigate the complexities of sourcing small enclosed trailers effectively, ensuring that their investment meets operational needs and regulatory requirements.

Comprehensive Cost and Pricing Analysis for small enclosed trailer Sourcing

What Are the Key Cost Components in Small Enclosed Trailer Manufacturing?

Understanding the cost structure is vital for B2B buyers sourcing small enclosed trailers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the price. Common materials like aluminum and steel are used for the frame, while options like fiberglass or plywood may be employed for the interior. Higher-quality materials enhance durability but raise costs.

-

Labor: Labor costs vary by region and manufacturing processes. In areas with higher labor costs, such as parts of Europe and North America, prices may be elevated. Conversely, sourcing from regions with lower labor costs can yield savings.

-

Manufacturing Overhead: This encompasses costs associated with utilities, facility maintenance, and equipment depreciation. Efficient operations can help lower these costs, which can be reflected in pricing.

-

Tooling: Initial setup costs for manufacturing, including molds and dies, can be significant. These costs are typically amortized over a larger production volume, making high-volume orders more cost-effective per unit.

-

Quality Control (QC): Investing in robust QC processes ensures product reliability and compliance with industry standards. While this may increase initial costs, it reduces the risk of costly returns and warranty claims.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and volume. Buyers should consider logistics in their total cost analysis, especially when importing trailers across borders.

-

Margin: Supplier margins can vary based on market conditions and competition. Understanding typical margins within the industry can aid in negotiating better pricing.

How Do Price Influencers Affect Small Enclosed Trailer Costs?

Several factors can influence the pricing of small enclosed trailers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for bulk purchases. Understanding the MOQ can lead to more favorable pricing structures.

-

Specifications and Customization: Custom features, such as additional height or specialized doors, can increase costs. Buyers should evaluate the necessity of custom specifications against their budget.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO or CE) can elevate costs but may provide long-term value through durability and compliance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to perceived quality and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They dictate who bears shipping costs and risks, impacting the final price.

What Buyer Tips Can Help Navigate Cost-Efficiency in Trailer Sourcing?

International B2B buyers should consider several strategies to enhance cost-efficiency:

-

Negotiation: Engage in negotiations to secure better pricing, especially for larger orders. Building a relationship with suppliers can also lead to improved terms over time.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes maintenance, insurance, and potential resale value. A lower upfront cost may lead to higher long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect overall costs. This is particularly pertinent for buyers in Africa, South America, the Middle East, and Europe.

-

Market Research: Conduct thorough market research to understand prevailing prices and supplier capabilities in different regions. This knowledge can empower buyers during negotiations.

Conclusion

The cost and pricing analysis of small enclosed trailers encompasses various components and influencers that B2B buyers must navigate. By understanding these elements and employing strategic purchasing practices, buyers can optimize their sourcing decisions and achieve better value. Keep in mind that prices are indicative and subject to change based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing small enclosed trailer With Other Solutions

Exploring Alternatives to Small Enclosed Trailers

When considering transportation and storage solutions for business needs, small enclosed trailers are a popular choice. However, various alternatives may also meet specific requirements, depending on the application. This section analyzes small enclosed trailers against other viable solutions, providing insights for B2B buyers looking to make informed decisions.

Comparison Table

| Comparison Aspect | Small Enclosed Trailer | Open Utility Trailer | Shipping Containers |

|---|---|---|---|

| Performance | High durability and security | Good for heavy loads | Extremely sturdy, weatherproof |

| Cost | Moderate ($2,500 – $5,000) | Lower ($1,000 – $3,000) | Higher ($1,500 – $5,000) |

| Ease of Implementation | Requires vehicle compatibility | Easily towed by most vehicles | Requires delivery/setup |

| Maintenance | Moderate (tires, brakes) | Low (basic upkeep) | Low (rust prevention) |

| Best Use Case | Secure transport of goods | Transporting equipment | Long-term storage solutions |

What Are the Advantages and Disadvantages of Open Utility Trailers?

Open utility trailers provide a versatile and cost-effective alternative for transporting goods and equipment. They are typically lighter than enclosed trailers, making them easier to tow with smaller vehicles. The open design allows for easy loading and unloading of oversized items. However, they lack the protection that enclosed trailers offer, making them less suitable for transporting sensitive goods that require shielding from weather elements or theft. For businesses that frequently transport bulky items, an open utility trailer may be an ideal solution, provided that the items can withstand exposure.

How Do Shipping Containers Compare to Small Enclosed Trailers?

Shipping containers are robust, weatherproof, and designed for secure storage and transport. They offer a high level of protection against environmental factors, making them suitable for long-term storage or shipping across international borders. While shipping containers can be more expensive and require more space than small enclosed trailers, they provide a solid, durable option for businesses needing extensive storage solutions. However, they are less portable than trailers, as moving them typically involves logistics and transportation services. For companies focused on secure, stationary storage or extensive transportation needs, shipping containers may be the right choice.

Conclusion: Which Solution Is Best for Your Business?

Choosing the right transportation or storage solution depends heavily on your specific operational requirements. Small enclosed trailers are well-suited for businesses needing to transport goods securely while maintaining a balance between cost and performance. In contrast, open utility trailers are ideal for transporting larger items, while shipping containers excel in providing long-term storage and protection. By carefully evaluating the performance, cost, ease of implementation, maintenance, and best use cases of each option, B2B buyers can select the solution that aligns most effectively with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for small enclosed trailer

What Are the Key Technical Properties of Small Enclosed Trailers?

When evaluating small enclosed trailers for business use, understanding their technical specifications is crucial. Here are some essential properties:

-

Material Grade: The material used in constructing the trailer significantly impacts its durability and weight capacity. Common materials include aluminum and steel. Aluminum is lightweight and resistant to corrosion, making it ideal for frequent use in diverse environments. Steel, while heavier, offers superior strength and is often used for heavier-duty applications.

-

Weight Capacity: This refers to the maximum load the trailer can safely carry. It’s typically expressed in pounds (lbs) and varies based on design and material. For B2B buyers, knowing the weight capacity helps ensure compliance with transport regulations and prevents overloading, which can lead to safety hazards and increased maintenance costs.

-

Axle Configuration: Small enclosed trailers may have single or tandem axles. A single axle is sufficient for lighter loads and offers better maneuverability, while tandem axles provide increased stability and weight distribution for heavier loads. Understanding the axle configuration is essential for selecting the right trailer based on the intended application.

-

Interior Height: The height of the trailer’s interior affects the types of cargo that can be transported. A higher interior allows for larger items and provides more flexibility in loading and unloading. For businesses that transport various goods, this specification can be a critical factor in determining usability.

-

Door Types: Different door configurations, such as rear ramp doors, side doors, or double doors, cater to specific loading and unloading needs. A rear ramp door, for example, facilitates easier loading of heavy equipment, while side doors provide quick access for smaller items. Understanding door types is vital for efficiency in operations.

What Trade Terminology Should B2B Buyers Know About Small Enclosed Trailers?

Familiarity with industry jargon can enhance communication with manufacturers and suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to the company that manufactures the trailer or its components. Understanding who the OEM is can help buyers assess quality and warranty support.

-

MOQ (Minimum Order Quantity): This is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, especially for businesses looking to make bulk purchases.

-

RFQ (Request for Quotation): An RFQ is a document used to solicit price quotes from suppliers. By issuing an RFQ, buyers can compare prices and terms from different manufacturers, ensuring they get the best deal.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help businesses navigate cross-border transactions effectively.

-

Payload: This term refers to the total weight of cargo that a trailer can carry, excluding its own weight. Knowing the payload capacity is crucial for compliance with transportation regulations and for ensuring the trailer meets business needs.

-

Tare Weight: This is the weight of the trailer when empty. It is essential for calculating the total weight when loaded, helping businesses avoid overloading and potential legal issues.

Understanding these technical properties and trade terminology can empower B2B buyers in making informed decisions, ensuring that their investment in small enclosed trailers aligns with their operational requirements and business goals.

Navigating Market Dynamics and Sourcing Trends in the small enclosed trailer Sector

What Are the Key Market Trends in the Small Enclosed Trailer Sector?

The small enclosed trailer market is experiencing significant growth driven by the increasing demand for versatile transportation solutions across various industries. Global drivers include the rise in e-commerce, which necessitates efficient logistics and delivery systems, as well as the booming construction and outdoor recreation sectors. In emerging markets, particularly in Africa and South America, there is a growing need for reliable transport options to support local businesses, including agriculture and small-scale manufacturing.

Technology is playing a pivotal role in shaping sourcing trends. B2B buyers are increasingly leveraging digital platforms for sourcing, allowing for streamlined procurement processes and greater access to a diverse range of suppliers. Innovations such as telematics, which monitor trailer performance and location, are becoming more common, enhancing operational efficiency. Additionally, the rise of mobile apps for real-time tracking and inventory management is transforming how businesses manage their trailer fleets.

Moreover, sustainability is becoming a focal point for international buyers. With growing awareness around environmental impacts, companies are seeking trailers that not only meet their functional needs but also adhere to eco-friendly standards. This shift is evident in the increasing demand for lightweight materials and energy-efficient production processes, which are now essential criteria in the purchasing decisions of B2B buyers.

How Can Sustainability and Ethical Sourcing Impact the Small Enclosed Trailer Sector?

Sustainability is no longer a niche concern; it is a fundamental expectation for B2B buyers in the small enclosed trailer market. The environmental impact of manufacturing and transporting trailers is significant, prompting companies to seek suppliers who prioritize sustainable practices. This includes using recyclable materials, reducing emissions during production, and ensuring energy-efficient operations.

Ethical sourcing is equally important, as buyers are increasingly scrutinizing the supply chains of manufacturers. They expect transparency regarding labor practices and the environmental footprint of the materials used in trailer production. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) for wood products are becoming critical indicators of a supplier’s commitment to sustainability.

Buyers should also consider suppliers who utilize green materials, such as aluminum and composites that reduce weight while maintaining strength. These innovations not only enhance fuel efficiency but also contribute to lower operational costs over time. By prioritizing sustainability and ethical sourcing, companies can align with consumer values, improve brand reputation, and ultimately drive long-term profitability.

What Is the Evolution of the Small Enclosed Trailer Market?

The small enclosed trailer has evolved significantly since its inception, transforming from a rudimentary transport solution into a sophisticated vehicle tailored for diverse applications. Initially used primarily for agricultural purposes, trailers have expanded their utility to include logistics, construction, and recreational activities.

Technological advancements have played a crucial role in this evolution. The introduction of lighter materials and improved aerodynamics has enhanced fuel efficiency, making trailers more appealing to a broader range of businesses. Furthermore, the integration of smart technology, such as GPS tracking and automated loading systems, has revolutionized trailer functionality, meeting the growing demands of modern logistics.

This evolution reflects broader market trends, including the shift toward more sustainable practices and the increasing importance of customization to meet specific customer needs. As international markets continue to grow, the small enclosed trailer sector is poised for further innovation and expansion.

Frequently Asked Questions (FAQs) for B2B Buyers of small enclosed trailer

-

1. How do I choose the right small enclosed trailer for my business needs?

Selecting the appropriate small enclosed trailer involves assessing your specific requirements, such as cargo type, weight capacity, and dimensions. Consider the trailer’s features, like ramp doors for easy loading, interior height for taller items, and material durability. Additionally, evaluate whether you need customizations, such as shelving or tie-down points. It’s beneficial to consult with suppliers about their offerings and any available modifications to ensure the trailer aligns with your operational needs. -

2. What are the key features to look for in a small enclosed trailer?

When sourcing a small enclosed trailer, focus on essential features like construction material (aluminum vs. steel), axle type, and weight rating. Ensure the trailer has adequate ventilation, a secure locking mechanism, and easy access points like rear ramps or side doors. Interior options, such as wall liners and flooring, can enhance durability and usability. Moreover, inquire about warranty terms and the availability of spare parts, as these factors contribute to long-term operational efficiency. -

3. What payment terms should I expect when purchasing a small enclosed trailer internationally?

Payment terms for international purchases typically vary by supplier and region. Common arrangements include upfront payments, partial deposits with the balance due upon delivery, or financing options. It’s crucial to clarify payment methods accepted (e.g., bank transfers, letters of credit) and any associated transaction fees. Additionally, ensure you understand the currency exchange rates and possible import duties that may affect your total costs. -

4. How can I verify the credibility of a small enclosed trailer supplier?

To vet a supplier, start by researching their business history and reputation within the industry. Look for reviews from other international buyers, check for certifications, and inquire about their experience with international shipping and customs. Establish direct communication to assess their responsiveness and willingness to provide references. Additionally, consider requesting samples or visiting their facility if possible, as this can provide insights into their operational standards. -

5. What are the typical minimum order quantities (MOQ) for small enclosed trailers?

Minimum order quantities (MOQ) for small enclosed trailers can vary significantly based on the supplier and trailer type. Some manufacturers may allow single-unit purchases, while others might require bulk orders to meet production efficiency. When negotiating, clarify whether the MOQ affects pricing and whether discounts are available for larger orders. Understanding the MOQ helps in planning your inventory and budgeting effectively. -

6. What customs regulations should I be aware of when importing small enclosed trailers?

When importing small enclosed trailers, familiarize yourself with the customs regulations of your destination country. This includes understanding import duties, taxes, and any necessary certifications or documentation required for compliance. Each country may have specific safety and environmental standards that the trailers must meet. Consulting with a customs broker can provide valuable guidance and streamline the import process. -

7. How can I ensure quality assurance during the procurement of small enclosed trailers?

To ensure quality assurance, request detailed specifications and quality certifications from the supplier. Establish quality control protocols, such as pre-shipment inspections or third-party audits, to verify that the trailers meet agreed-upon standards. Additionally, inquire about the supplier’s return policy and warranty conditions, as these will safeguard your investment against defects or unsatisfactory quality. -

8. What logistics considerations should I keep in mind when sourcing small enclosed trailers internationally?

Logistics play a crucial role in international sourcing. Assess shipping options, transit times, and costs from the supplier’s location to your destination. Consider the mode of transport—sea freight is typically more economical for large shipments, while air freight is faster but more expensive. Additionally, factor in the need for specialized handling or storage facilities upon arrival. Collaborating with a reliable logistics provider can help navigate these complexities effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Small Enclosed Trailer Manufacturers & Suppliers List

1. Carry-On – 5 x 8 Enclosed Cargo Trailer

Domain: trailersuperstore.com

Registered: 1999 (26 years)

Introduction: Enclosed Trailers for Sale at Trailer Superstore include various models and sizes from leading manufacturers such as Carry-On, Covered Wagon, Diamond Cargo, Car Mate, and Homesteader. Key products include: 1. Carry-On 5 x 8 Enclosed Cargo Trailer – Single Rear Door, Item #: 00486, Original Price: $3,499, Current Price: $2,699. 2. Carry-On 4 x 6 Enclosed Cargo Trailer – Luggage Trailer, Item #: 311…

2. Appalachian Trailers – Single Axle Cargo Trailers

Domain: appalachiantrailers.com

Registered: 2001 (24 years)

Introduction: This company, Appalachian Trailers – Single Axle Cargo Trailers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Space Trailers – Travel Utility Trailers

Domain: spacetrailers.com

Registered: 2009 (16 years)

Introduction: Travel Utility Trailers collection includes HighRider XL ($8,499.00), HighRider ($6,449.00), and LowRider ($6,449.00) models. Designed for convenience and functionality, these trailers cater to various travel needs without complicated customization. Customers can choose colors and utilize the Build & Buy Tool for adjustments. The trailers serve multiple purposes, including luggage transport, bike …

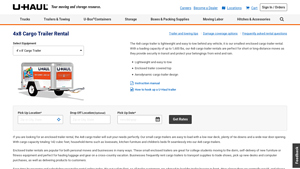

4. U-Haul – 4×8 Cargo Trailer Rental

Domain: uhaul.com

Registered: 1995 (30 years)

Introduction: Product: 4×8 Cargo Trailer Rental

Type: Enclosed cargo trailer

Dimensions: Inside – 8’1″ x 4’2″ x 4′ (LxWxH); Door opening – 3’5″ x 3’10” (WxH)

Capacity: Volume – up to 142 cu. ft.; Max load – 1,650 lbs.; Empty weight – 850 lbs.; Max combined weight (trailer + load) – 2,500 lbs.

Features: Lightweight, easy to tow, aerodynamic design, enclosed with a covered top, low rear deck, tie-downs on all thr…

5. Leonard – Enclosed Cargo Trailers

Domain: leonardusa.com

Registered: 1997 (28 years)

Introduction: Enclosed Cargo Trailers – Single & Double Axle Cargo Trailers: 1. Leonard 6×12 V-Nose Enclosed Cargo Trailer – Ramp Door, 6’3″ Interior Height, All-Tubular Frame – Price: $4,899. 2. Leonard 7×16 Tandem Axle Enclosed Cargo Trailer – V-Nose, Ramp Door, 7K GVWR, 6’3″ Interior – Price: $7,099. 3. Leonard 6×12 Cargo Trailer with 6 ft Interior Height – Price: $4,599. 4. Leonard 5×8 Single Axle Enclosed …

6. Cargo Pro – 4 x 6 Cargo Trailers

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Cargo Pro 4 x 6 Cargo Trailers, small enclosed trailer, suitable for small luggage, motorcycle camping, and cargo transport. Features aluminum wheels and options for side doors. Available for sale through Trailer Superstore. Contact for inquiries at (800) 622-7003.

Strategic Sourcing Conclusion and Outlook for small enclosed trailer

How Can Strategic Sourcing Enhance Your Small Enclosed Trailer Procurement?

In the competitive landscape of the small enclosed trailer market, strategic sourcing emerges as a pivotal strategy for international B2B buyers. By leveraging a comprehensive understanding of product specifications, market pricing, and supplier capabilities, businesses can secure optimal deals that align with their operational needs. Key takeaways include the importance of evaluating different grades of trailers, such as light, standard, and contractor grades, to match specific use cases, from light-duty transportation to more demanding applications.

Furthermore, considering factors such as financing options and nationwide shipping availability can significantly enhance the purchasing experience and streamline logistics. As the demand for durable, versatile trailers grows across regions like Africa, South America, the Middle East, and Europe, buyers are encouraged to engage with multiple suppliers, fostering competitive pricing and quality assurance.

Looking ahead, the small enclosed trailer market is poised for growth, driven by increasing logistics demands and a shift towards mobile businesses. International buyers should take proactive steps now to assess their needs and explore partnerships with reputable manufacturers. Embrace the opportunity to optimize your sourcing strategy and position your business for success in this evolving market.