Small Burn Barrel: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for small burn barrel

In the competitive landscape of waste management solutions, sourcing a small burn barrel presents unique challenges for international B2B buyers. With increasing regulatory scrutiny and a growing emphasis on sustainable practices, finding an efficient and compliant incineration option is crucial. This guide serves as a comprehensive resource, delving into various types of small burn barrels, their applications across industries, and essential considerations for supplier vetting.

Buyers will discover insights into the latest innovations in burn barrel technology, including features that enhance efficiency and safety, as well as cost-effective solutions tailored to specific regional needs. By providing detailed information on pricing structures, shipping logistics, and compliance with local regulations, this guide empowers businesses in Africa, South America, the Middle East, and Europe—such as Brazil and Saudi Arabia—to make informed purchasing decisions.

Navigating the global market for small burn barrels can be complex, but with the right knowledge and resources at hand, B2B buyers can confidently select products that meet their operational requirements while adhering to environmental standards. This guide is designed to simplify that process, ensuring you have the tools necessary to enhance your waste management strategy effectively.

Understanding small burn barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Steel Burn Barrel | Made from heavy-duty steel, removable lid | Waste management, yard debris burning | Pros: Cost-effective, widely available. Cons: Can rust over time. |

| Stainless Steel Incinerator | Patented design, warp-resistant, high burn temp | Document destruction, eco-friendly waste disposal | Pros: Durable, efficient burn. Cons: Higher initial cost. |

| Portable Burn Cage | Lightweight, easy to transport, multi-use | Camping, outdoor events, small fires | Pros: Versatile, easy setup. Cons: Limited capacity. |

| XL Burn Barrel Incinerator | Large capacity, enhanced airflow system | Large-scale waste incineration | Pros: Handles larger volumes, cleaner burn. Cons: Requires more space. |

| Pyro Cage | Multi-functional, can be used as a fire pit | Recreational use, outdoor cooking | Pros: Dual-purpose, aesthetic design. Cons: May not withstand heavy-duty use. |

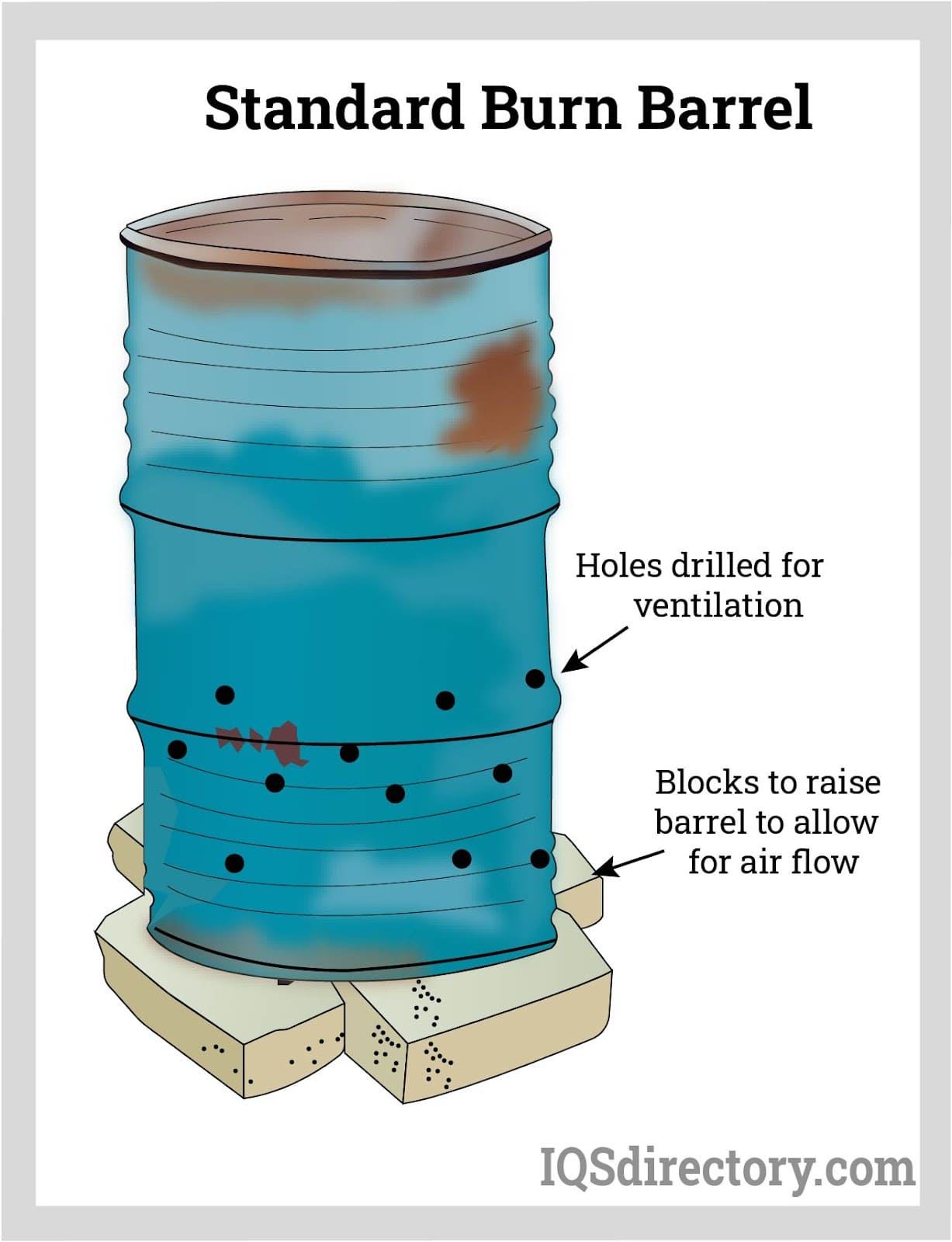

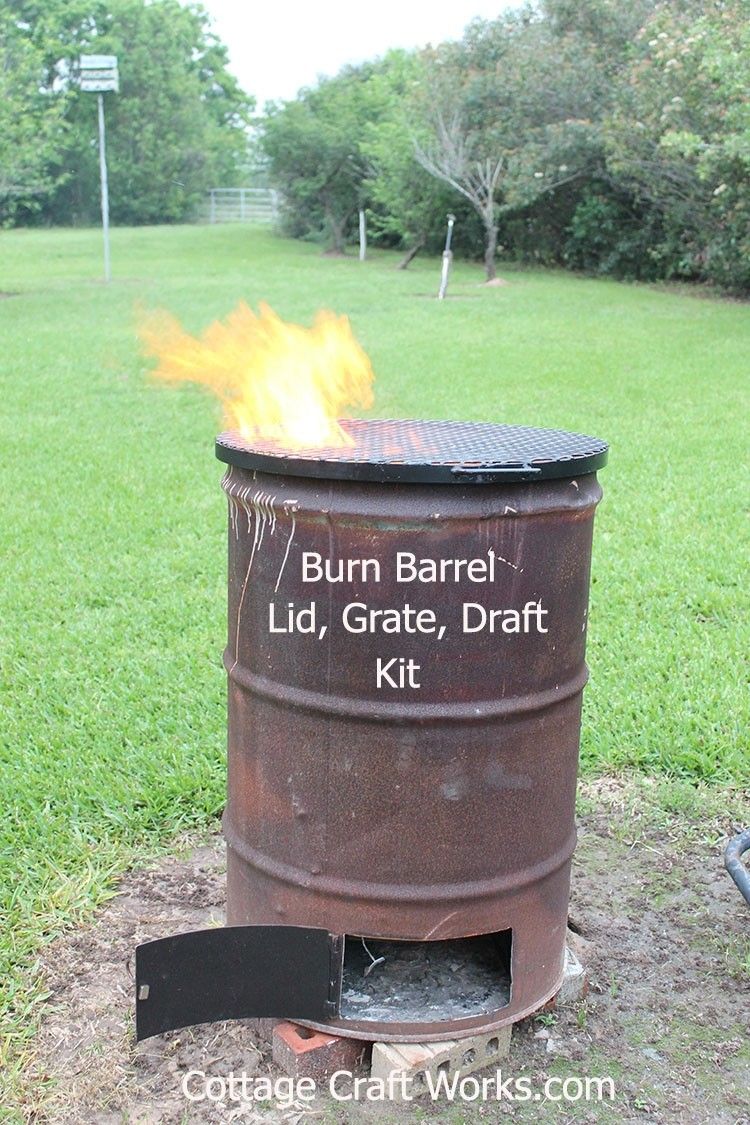

What are the Characteristics of the Standard Steel Burn Barrel?

The standard steel burn barrel is a common choice for many businesses due to its affordability and ease of use. Typically made from heavy-duty steel, these barrels feature a removable lid that helps contain smoke and ash. They are ideal for burning yard debris and managing waste in rural areas. However, buyers should consider the longevity of these barrels, as they can rust and degrade over time, particularly in damp environments.

Illustrative image related to small burn barrel

Why Choose a Stainless Steel Incinerator for B2B Needs?

Stainless steel incinerators are engineered for durability and efficiency. Their patented design allows for higher burn temperatures, ensuring complete incineration of waste materials. This type is particularly suited for businesses needing to manage sensitive documents or eco-friendly waste disposal. While they come with a higher upfront cost, their longevity and efficiency often justify the investment, especially for organizations focused on sustainability.

How Does a Portable Burn Cage Benefit B2B Operations?

Portable burn cages are lightweight and designed for versatility, making them perfect for businesses that require mobility. They can be easily transported for use in camping or outdoor events, allowing for quick setups. While they are excellent for small fires and recreational use, businesses should note their limited capacity, which may not meet the needs of larger operations.

When is the XL Burn Barrel Incinerator the Right Choice?

The XL burn barrel incinerator is designed for businesses that handle larger volumes of waste. Its enhanced airflow system allows for a more efficient burn, reducing smoke emissions and improving overall performance. This makes it suitable for large-scale waste management operations. However, potential buyers should be aware that these larger units require more space and can be more expensive to purchase and maintain.

Illustrative image related to small burn barrel

What Makes the Pyro Cage an Attractive Option for Businesses?

The Pyro cage serves multiple functions, acting as both a burn barrel and a stylish fire pit. This dual-purpose design appeals to businesses that host outdoor events or require aesthetic considerations in their waste management solutions. While it offers recreational benefits, businesses should consider its durability compared to more heavy-duty options, as it may not withstand extensive use in high-demand environments.

Key Industrial Applications of small burn barrel

| Industry/Sector | Specific Application of small burn barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Disposal of crop residues and agricultural waste | Efficient waste management reduces environmental impact | Durability, capacity, and compliance with local regulations |

| Waste Management | Incineration of non-recyclable materials | Reduces landfill use and promotes sustainability | Emissions control features and material quality |

| Construction | Burning of treated wood and debris | Quick disposal solution minimizes site clutter | Safety features and heat resistance |

| Municipal Services | Controlled burning of yard waste and public debris | Enhances community cleanliness and reduces fire hazards | Local regulations adherence and easy transportability |

| Disaster Management | Emergency waste disposal in disaster-stricken areas | Rapid response capability aids in recovery efforts | Portability and ease of setup in remote locations |

How is the small burn barrel utilized in Agriculture for waste disposal?

In the agricultural sector, small burn barrels are commonly employed for the disposal of crop residues and agricultural waste, such as dead plants and packaging materials. This method allows farmers to manage waste efficiently, reducing the environmental impact associated with open burning. By incinerating waste, farmers can also minimize pest habitats and enhance soil quality through the ash produced. For international buyers, particularly in regions like Africa and South America, sourcing burn barrels that comply with local environmental regulations and are durable enough to withstand outdoor conditions is crucial.

What role does the small burn barrel play in Waste Management?

In waste management, small burn barrels serve as an effective solution for incinerating non-recyclable materials. This application helps reduce landfill usage and promotes a more sustainable waste disposal method. By converting waste into ash, businesses can lower their carbon footprint and comply with stricter waste management regulations. For buyers in the Middle East and Europe, it is essential to consider burn barrels with advanced emissions control features to meet local environmental standards and ensure compliance with waste disposal laws.

How can Construction companies benefit from using small burn barrels?

Construction companies often face challenges with debris management, particularly when dealing with treated wood and other waste materials. Small burn barrels offer a quick and efficient disposal method, allowing contractors to maintain a clean job site and comply with safety regulations. This not only enhances operational efficiency but also mitigates the risk of fire hazards associated with accumulated debris. When sourcing burn barrels, construction firms should prioritize safety features and heat resistance to ensure reliable performance under demanding conditions.

Illustrative image related to small burn barrel

In what ways do Municipal Services utilize small burn barrels for community waste?

Municipal services can leverage small burn barrels for the controlled burning of yard waste and public debris, contributing to community cleanliness and reducing fire hazards. By implementing a systematic burning approach, municipalities can efficiently manage seasonal waste, such as fallen leaves and branches, while promoting environmental stewardship. For international buyers, particularly in Europe, it is vital to consider the barrel’s size and transportability, as well as its compliance with local waste disposal regulations to ensure effective implementation in public spaces.

How do small burn barrels support Disaster Management efforts?

In disaster-stricken areas, small burn barrels play a critical role in emergency waste disposal. They provide a rapid response capability for incinerating debris and hazardous materials, facilitating quicker recovery efforts. This application is particularly valuable in remote or hard-to-reach areas where conventional waste management services may be disrupted. Buyers in regions prone to natural disasters, such as Brazil and parts of the Middle East, should focus on sourcing portable and easy-to-set-up burn barrels to ensure they can be deployed effectively in various situations.

3 Common User Pain Points for ‘small burn barrel’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Waste Disposal

The Problem: For B2B buyers in industries such as agriculture, construction, or waste management, the challenge of adhering to local and international regulations regarding waste disposal can be daunting. In regions like Africa and South America, where regulatory frameworks may vary significantly, the use of small burn barrels can be scrutinized. Buyers often struggle to ensure that their burning practices comply with environmental laws, leading to potential fines or operational disruptions. This concern is heightened when dealing with hazardous materials, as improper disposal can have severe consequences for both public health and the environment.

The Solution: To effectively navigate these regulatory challenges, buyers should begin by thoroughly researching local regulations pertaining to waste disposal and incineration practices. Collaborating with local environmental agencies or legal advisors can provide clarity on what materials are permissible for burning and the required permits. Furthermore, sourcing burn barrels that are specifically designed to meet regulatory standards—such as those with built-in pollution control features—can help mitigate compliance risks. Buyers should also consider investing in training for their staff on proper burning techniques and safety protocols to ensure adherence to regulations, reducing the risk of penalties.

Scenario 2: Addressing Safety Concerns in Waste Incineration

The Problem: Safety is a paramount concern for B2B buyers operating in sectors where small burn barrels are utilized. Industries such as landscaping or municipal waste management often face risks associated with open burning, including fire hazards and exposure to toxic fumes. Buyers may find it challenging to ensure that their operations are safe for workers and the surrounding community, especially in densely populated areas or regions prone to wildfires. This concern can lead to hesitance in adopting burn barrels for waste management.

Illustrative image related to small burn barrel

The Solution: To alleviate safety concerns, buyers should prioritize the selection of burn barrels that incorporate advanced safety features, such as flame arrestors and sturdy construction materials that resist warping under high temperatures. Regular maintenance and inspections of the burn barrels can help identify potential hazards before they escalate. Additionally, implementing strict operational protocols—such as monitoring weather conditions and maintaining a safe distance from combustible materials—can enhance safety. Conducting safety training sessions for employees will ensure that everyone understands the risks and knows how to operate the burn barrels safely, fostering a culture of safety within the organization.

Scenario 3: Maximizing Efficiency and Minimizing Environmental Impact

The Problem: B2B buyers often grapple with the dual challenge of maximizing the efficiency of their waste disposal methods while minimizing their environmental impact. Many traditional burn barrels are inefficient, leading to incomplete combustion, excessive smoke, and harmful emissions. This inefficiency not only wastes resources but also contributes to air pollution, which can damage a company’s reputation and lead to regulatory scrutiny.

The Solution: To enhance efficiency and reduce environmental impact, buyers should consider investing in modern small burn barrels designed with advanced airflow systems that facilitate complete combustion. These systems can significantly increase burn temperatures, leading to more efficient waste incineration and reduced smoke emissions. Additionally, buyers can adopt practices such as sorting waste to separate combustible materials from non-combustibles, ensuring that only appropriate materials are burned. By documenting and reporting their waste disposal practices, companies can demonstrate their commitment to sustainability, which can improve public perception and potentially open doors to new business opportunities in eco-conscious markets.

Strategic Material Selection Guide for small burn barrel

What Are the Key Properties of Common Materials Used for Small Burn Barrels?

When selecting materials for small burn barrels, several common options stand out: carbon steel, stainless steel, galvanized steel, and cast iron. Each material has unique properties that affect performance, durability, and suitability for specific applications.

Illustrative image related to small burn barrel

How Does Carbon Steel Perform in Small Burn Barrels?

Carbon steel is a widely used material for small burn barrels due to its strength and affordability. It can withstand high temperatures, making it suitable for incineration applications. However, it is prone to corrosion, especially when exposed to moisture, which can significantly reduce its lifespan.

Pros: Carbon steel is cost-effective and easy to manufacture, making it a popular choice for budget-conscious buyers. Its high-temperature resistance allows for effective burning of waste materials.

Cons: The susceptibility to rust and corrosion necessitates regular maintenance and protective coatings, which can add to long-term costs. Additionally, its weight can complicate transportation and installation.

Impact on Application: Carbon steel burn barrels are ideal for burning yard debris and other organic waste. However, buyers in humid regions, such as parts of Africa and South America, should consider the implications of corrosion.

Illustrative image related to small burn barrel

What Advantages Does Stainless Steel Offer for Burn Barrels?

Stainless steel is increasingly favored for burn barrels due to its excellent corrosion resistance and durability. It can withstand extreme temperatures without warping, making it suitable for high-performance applications.

Pros: The longevity of stainless steel reduces replacement costs over time, and its resistance to rust makes it an ideal choice for various climates. Additionally, it requires minimal maintenance.

Cons: The primary drawback is the higher initial cost compared to carbon steel. Manufacturing processes can also be more complex, potentially leading to longer lead times.

Impact on Application: Stainless steel burn barrels are suitable for diverse waste types, including hazardous materials, due to their robust construction. International buyers should ensure compliance with local environmental regulations, especially in Europe, where stringent standards apply.

Why Choose Galvanized Steel for Small Burn Barrels?

Galvanized steel is carbon steel coated with a layer of zinc to enhance corrosion resistance. This material offers a balance between cost and performance, making it a popular choice for burn barrels.

Pros: The zinc coating provides significant protection against rust, extending the barrel’s lifespan. Galvanized steel is also relatively lightweight, facilitating easier handling and transportation.

Cons: While galvanized steel is more resistant to corrosion than carbon steel, the coating can wear off over time, especially in high-temperature applications. This can lead to rusting if not properly maintained.

Illustrative image related to small burn barrel

Impact on Application: Galvanized steel burn barrels are effective for general waste disposal. However, buyers should be aware of the potential for coating degradation in regions with extreme weather conditions, such as the Middle East.

What Are the Benefits and Limitations of Cast Iron for Burn Barrels?

Cast iron is known for its durability and ability to retain heat, making it a suitable material for burn barrels intended for prolonged use. It can withstand high temperatures and is less prone to warping.

Pros: The heat retention properties of cast iron allow for more efficient burning, reducing fuel consumption. Its robustness ensures a long lifespan with proper care.

Cons: Cast iron is significantly heavier than other materials, which can complicate transportation and installation. It is also more expensive and can be brittle, leading to potential cracking under stress.

Illustrative image related to small burn barrel

Impact on Application: Cast iron burn barrels are ideal for heavy-duty applications and can be used for burning various types of waste. However, international buyers should consider the logistics of shipping heavier materials, particularly in regions with limited infrastructure.

Summary Table of Material Selection for Small Burn Barrels

| Material | Typical Use Case for small burn barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General waste incineration | Cost-effective and strong | Prone to corrosion | Low |

| Stainless Steel | High-performance waste disposal, including hazardous | Excellent durability and corrosion resistance | Higher initial cost | High |

| Galvanized Steel | General waste disposal with moderate corrosion risks | Good corrosion resistance | Coating can wear off over time | Medium |

| Cast Iron | Heavy-duty applications and heat retention | Superior heat retention | Heavy and brittle | High |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for small burn barrel

What Are the Key Stages in the Manufacturing Process of Small Burn Barrels?

The manufacturing of small burn barrels involves several critical stages, each designed to ensure that the final product meets both performance and safety standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Small Burn Barrels?

The process begins with selecting high-quality materials, typically stainless steel, which is favored for its durability and resistance to corrosion. Manufacturers often source materials from certified suppliers to ensure compliance with international standards. The material is then cut to specified dimensions, often using laser cutting technology, which provides precision and reduces waste.

Illustrative image related to small burn barrel

Following this, the raw materials undergo a thorough inspection to verify their quality and consistency. This initial quality control (IQC) step is crucial in identifying any defects before they progress to the next stages of production.

What Techniques Are Used in the Forming Stage?

Forming is the next step, where the cut materials are shaped into the components of the burn barrel. This can involve processes such as bending, stamping, and welding. Advanced techniques, including robotic welding, are increasingly employed to enhance precision and efficiency, leading to a stronger and more reliable product.

After forming, the components are again inspected for dimensional accuracy and structural integrity, ensuring they meet the design specifications. Any deviations at this stage can lead to significant issues in assembly and functionality.

How Are Small Burn Barrels Assembled?

The assembly of small burn barrels typically involves joining the formed components together to create the final product. This may include the installation of features such as air vents, removable lids, and handles, which enhance usability and safety. Manufacturers often utilize automated assembly lines to streamline this process, ensuring consistency in product quality.

During assembly, additional quality checks are performed, including in-process quality control (IPQC), to ensure that each component is correctly positioned and securely fastened. This minimizes the risk of future failures during use.

Illustrative image related to small burn barrel

What Finishing Techniques Are Applied to Small Burn Barrels?

The final stage in manufacturing is finishing, which may include surface treatment processes like polishing, painting, or powder coating. These treatments not only enhance the aesthetic appeal of the burn barrels but also provide additional protection against the elements, ensuring longevity.

Quality assurance during the finishing stage is vital. Manufacturers conduct final quality control (FQC) checks to verify that the finish meets the required standards and that the burn barrels are free from defects before they are packaged for shipment.

What International Standards and Quality Assurance Practices Apply to Small Burn Barrels?

For B2B buyers, understanding the quality assurance practices and standards applicable to small burn barrels is essential. Compliance with international standards, such as ISO 9001, is a significant indicator of a manufacturer’s commitment to quality management systems.

How Do International Standards Enhance Product Quality?

ISO 9001 outlines the requirements for a quality management system (QMS), focusing on consistent quality and customer satisfaction. Manufacturers adhering to this standard must demonstrate their ability to provide products that meet customer and regulatory requirements, which is critical for international buyers.

Illustrative image related to small burn barrel

In addition, region-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) may be relevant, depending on the intended use of the burn barrels. These certifications indicate compliance with safety and environmental standards, which can be particularly important in regions with stringent regulations.

What Quality Control Checkpoints Should B2B Buyers Expect?

Throughout the manufacturing process, several quality control checkpoints should be established:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Regular checks during production to monitor processes and identify any deviations from standards.

- Final Quality Control (FQC): A comprehensive review of the finished product before it is shipped.

These checkpoints help to ensure that any defects are caught early, minimizing waste and ensuring the final product meets the required specifications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control measures of their suppliers.

What Are Effective Methods for Supplier Verification?

- Audits: Conducting on-site audits allows buyers to assess the manufacturing process firsthand, ensuring that quality control measures are being implemented effectively.

- Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s compliance with established standards and their internal quality control processes.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing process and product quality can provide an unbiased assessment, which is particularly valuable for international transactions.

Are There Nuances in Quality Control for International B2B Buyers?

International buyers should be aware of the nuances in quality control that may arise due to differing regulations and standards across regions. For instance, compliance with local environmental regulations in Brazil or safety standards in Saudi Arabia may require additional certifications or testing.

Furthermore, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear lines of communication and understanding the local regulations will help mitigate these challenges.

Conclusion: Why Quality Assurance Is Critical in the Burn Barrel Manufacturing Process

For B2B buyers, understanding the manufacturing processes and quality assurance practices behind small burn barrels is essential to ensure they are purchasing reliable, safe, and compliant products. By focusing on reputable suppliers who adhere to international standards and maintain rigorous quality control measures, businesses can mitigate risks and enhance their operational efficiency. Investing in high-quality burn barrels not only supports sustainability initiatives but also ensures long-term reliability and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘small burn barrel’

When sourcing small burn barrels, a structured approach can streamline the procurement process and ensure you select the best product for your needs. This guide provides a step-by-step checklist designed specifically for B2B buyers, enabling informed decisions that align with operational requirements and regional regulations.

Illustrative image related to small burn barrel

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider factors such as size, material, and burn efficiency. A robust specification helps narrow down options and ensures that the chosen burn barrel meets your operational needs, particularly in different climates and regulations across regions like Africa, South America, the Middle East, and Europe.

- Material Considerations: Opt for durable materials, such as stainless steel, which offer longevity and resistance to warping.

- Burn Efficiency: Look for designs that guarantee high burn temperatures for effective waste incineration.

Step 2: Research Regulatory Compliance

Understanding and adhering to local environmental regulations is critical when sourcing burn barrels. Regulations can vary significantly by region, affecting the type of materials used and operational guidelines.

- Local Laws: Investigate any restrictions on burning materials or emissions that may influence your choice.

- Certifications: Ensure that potential suppliers can provide documentation proving compliance with local environmental standards.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers to ensure reliability and product quality. Request detailed company profiles, case studies, and references from other businesses in your industry.

- Supplier Reputation: Look for suppliers with positive reviews and established histories in the market.

- Product Testing: Ask about the testing processes for their products to confirm quality assurance.

Step 4: Request Samples or Product Demonstrations

Before finalizing your order, request samples or arrange product demonstrations. This step allows you to assess the burn barrel’s construction, functionality, and suitability for your specific applications.

- Performance Evaluation: Observe how the barrel performs under actual burning conditions.

- User Feedback: Solicit feedback from your team about the usability and effectiveness of the product.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations to secure favorable pricing and payment terms. Understanding the market rates for burn barrels will help you negotiate effectively.

- Bulk Discounts: Inquire about discounts for large orders, which could significantly reduce your overall costs.

- Payment Options: Discuss flexible payment terms that align with your budget cycles and cash flow needs.

Step 6: Confirm Shipping and Delivery Logistics

Plan for logistics early in the procurement process to avoid delays. Confirm shipping options, delivery times, and associated costs with the supplier.

- Shipping Methods: Assess whether the supplier offers reliable shipping methods that can accommodate international deliveries.

- Delivery Timelines: Ensure that the delivery schedule aligns with your operational timelines to prevent disruptions.

Step 7: Plan for After-Sales Support

After the purchase, ensure that the supplier provides adequate after-sales support. This includes warranty details, maintenance guidelines, and customer service contact information.

- Warranty Coverage: Confirm what is covered under warranty and for how long.

- Maintenance Support: Inquire about support for maintenance or repairs to ensure long-term functionality of the burn barrel.

By following this comprehensive checklist, B2B buyers can effectively navigate the procurement process for small burn barrels, ensuring that they select a product that meets their needs while adhering to local regulations and operational standards.

Illustrative image related to small burn barrel

Comprehensive Cost and Pricing Analysis for small burn barrel Sourcing

What Are the Key Cost Components in Sourcing Small Burn Barrels?

When sourcing small burn barrels, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly influences the cost. For instance, stainless steel barrels may incur higher upfront costs but offer durability and resistance to warping, making them more cost-effective in the long run. Lower-grade materials, while cheaper, can lead to higher maintenance and replacement costs.

-

Labor: Labor costs vary based on the region of production. Countries with lower labor costs may provide more competitive pricing, but this could also affect quality. Ensure that the manufacturer adheres to fair labor practices to avoid potential ethical concerns.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, rent, and equipment maintenance. Efficient operations can reduce these costs, allowing suppliers to offer better pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. However, once established, these costs are amortized over larger production runs, making bulk orders more economical.

-

Quality Control: Rigorous QC processes ensure that products meet safety and performance standards. While this may add to the initial cost, it minimizes the risk of defects and returns, ultimately supporting a better Total Cost of Ownership (TCO).

-

Logistics: Shipping and handling costs can vary greatly depending on the origin and destination of the barrels. Consideration of Incoterms (International Commercial Terms) is crucial, as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

-

Margin: Suppliers typically build in a profit margin that reflects their business model, market conditions, and competition. Understanding this margin can aid in negotiation.

How Do Price Influencers Affect the Cost of Small Burn Barrels?

Several factors can influence the pricing of small burn barrels, particularly for international B2B buyers.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer tiered pricing based on order volume. Higher MOQs can lead to significant discounts, making it beneficial for buyers to forecast their needs accurately.

-

Specifications and Customization: Custom features or specific design requirements can increase costs. Clearly defining specifications upfront can help avoid unexpected expenses later.

-

Material Quality and Certifications: Barrels made from higher-quality materials or those that meet specific safety certifications (e.g., ISO, CE) may come at a premium. However, these certifications can enhance marketability and compliance with local regulations.

-

Supplier Factors: Supplier reliability, reputation, and location can impact pricing. Established suppliers with a proven track record may charge more but offer greater assurance in product quality and service.

-

Incoterms: Understanding Incoterms is essential for budgeting logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the final cost of the barrels, depending on who bears the shipping costs.

What Buyer Tips Can Help in Negotiating Small Burn Barrel Prices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, strategic negotiation and understanding the market can yield better pricing outcomes.

-

Conduct Market Research: Familiarize yourself with prevailing market rates and competitor offerings to strengthen your negotiating position.

-

Leverage Total Cost of Ownership (TCO): Emphasize the long-term savings associated with higher-quality barrels, which can justify a higher initial price.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority service, and access to exclusive deals.

-

Negotiate Terms: Don’t just focus on price; negotiate payment terms, delivery schedules, and warranties to create a more favorable overall agreement.

-

Be Aware of Pricing Nuances: Different regions may have unique pricing structures or cultural negotiation practices. Adapt your approach accordingly to maximize your success.

Conclusion

While sourcing small burn barrels involves various cost components and price influencers, a well-informed approach can lead to significant savings. By understanding the underlying costs, leveraging negotiation strategies, and considering the Total Cost of Ownership, international B2B buyers can make strategic purchasing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing small burn barrel With Other Solutions

Introduction to Alternative Solutions for Waste Disposal

As businesses and municipalities seek effective waste disposal solutions, the small burn barrel emerges as a popular option. However, it is crucial to explore alternatives that may offer enhanced performance, efficiency, or cost-effectiveness. This analysis compares the small burn barrel against two viable alternatives: incinerators and composting systems. Each method has its unique advantages and disadvantages, allowing buyers to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Small Burn Barrel | Incinerator | Composting System |

|---|---|---|---|

| Performance | Moderate efficiency; burns at lower temperatures | High efficiency; burns at temperatures over 1800°F | Reduces waste volume; produces compost |

| Cost | $100 – $300 | $400 – $800 | $50 – $500 |

| Ease of Implementation | Simple setup; requires minimal tools | Moderate complexity; requires installation | Easy to set up; may require space |

| Maintenance | Low; occasional cleaning | Moderate; needs regular maintenance | Low; requires periodic turning |

| Best Use Case | Small-scale yard debris | Larger waste volumes, hazardous materials | Organic waste recycling |

Detailed Breakdown of Alternatives

1. Incinerators

Incinerators represent a significant upgrade over small burn barrels in terms of performance and efficiency. They can achieve higher combustion temperatures, which ensures complete incineration of waste, leading to cleaner air emissions. However, the initial investment is higher, typically ranging from $400 to $800. The installation process can be more complex, potentially requiring professional assistance. Regular maintenance is essential to ensure optimal performance and compliance with environmental regulations. Incinerators are best suited for businesses dealing with larger volumes of waste or hazardous materials that require safe disposal.

2. Composting Systems

Composting systems offer an environmentally friendly alternative for organic waste disposal. They work by breaking down organic materials into nutrient-rich compost, which can be reused in gardening or landscaping. The cost of setting up a composting system can vary significantly, ranging from $50 for simple bins to $500 for more sophisticated setups. Implementation is generally straightforward, as most systems only require a designated space and some basic tools. Maintenance is low, involving periodic turning of the compost pile to aerate it. However, composting is limited to organic waste and may not be suitable for all types of business waste.

Illustrative image related to small burn barrel

Conclusion: How to Choose the Right Waste Disposal Solution

When selecting a waste disposal solution, B2B buyers must consider various factors such as waste volume, type, budget, and environmental impact. The small burn barrel is a cost-effective option for small-scale, non-hazardous waste but may not meet the needs of larger operations or those focused on sustainability. Incinerators provide a more efficient and comprehensive solution for significant waste management needs, while composting systems are ideal for businesses looking to minimize their environmental footprint. By assessing these criteria, buyers can choose the most appropriate solution that aligns with their operational goals and regulatory requirements.

Essential Technical Properties and Trade Terminology for small burn barrel

What Are the Key Technical Properties of a Small Burn Barrel?

When evaluating small burn barrels for procurement, several technical properties stand out as critical for ensuring durability, efficiency, and safety. Understanding these properties can help B2B buyers make informed decisions.

-

Material Grade

Small burn barrels are typically made from high-quality steel, often stainless steel or carbon steel. Stainless steel offers superior resistance to corrosion, ensuring longevity, while carbon steel is more cost-effective but may require protective coatings to prevent rusting. The choice of material impacts the barrel’s lifespan and maintenance needs, making it essential for buyers to consider their environmental conditions. -

Capacity

The capacity of a small burn barrel is measured in gallons or liters, with common sizes ranging from 30 to 55 gallons. This specification is crucial for determining how much waste can be incinerated at one time, affecting operational efficiency. Buyers should assess their volume needs based on the types and amounts of materials they plan to burn, ensuring that the selected barrel meets their operational requirements. -

Burn Temperature

The maximum burn temperature, typically exceeding 1800°F (982°C), is a vital specification. Higher burn temperatures ensure more efficient combustion, resulting in cleaner emissions and complete waste incineration. For businesses concerned about environmental regulations, selecting a barrel with a high burn temperature can facilitate compliance with local air quality standards. -

Design Features

Innovative design features such as airflow systems enhance combustion efficiency by improving oxygen flow. This can lead to hotter burns and reduced smoke emissions. Additional features like removable lids or integrated ash catchers can also enhance usability and safety, making it essential for buyers to evaluate the design based on their operational context. -

Weight and Portability

The weight of a small burn barrel affects its portability and ease of use. Heavier barrels may offer stability but can be cumbersome to relocate, while lighter models may be easier to handle but less stable in windy conditions. Businesses should consider their operational environment when selecting the appropriate weight and design. -

Safety Features

Safety is paramount in burn barrel design, with features such as flame arrestors and robust lids preventing accidental fires. Understanding the safety specifications helps businesses mitigate risks associated with outdoor burning, which is especially crucial in regions prone to wildfires.

Which Trade Terms Should B2B Buyers Know When Purchasing Small Burn Barrels?

Familiarity with industry-specific jargon can streamline procurement processes and enhance communication with suppliers. Here are some essential trade terms relevant to small burn barrels:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of burn barrels, buyers may encounter OEMs that supply components or complete products to various distributors, impacting pricing and availability. -

MOQ (Minimum Order Quantity)

MOQ signifies the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for budget planning and inventory management, allowing buyers to assess whether they can meet the supplier’s requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. B2B buyers should provide detailed specifications of the burn barrels they need, including materials and quantities, to receive accurate pricing and lead times. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to clarify responsibilities between buyers and sellers. Familiarity with Incoterms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) helps buyers understand shipping responsibilities and costs, essential for international transactions. -

Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times is crucial for planning and inventory management, ensuring that businesses can meet their operational timelines without disruption. -

Certification Standards

Certain burn barrels may require certifications to comply with local regulations, such as environmental or safety standards. Buyers should inquire about these certifications to ensure that their products meet legal requirements and industry best practices.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing small burn barrels, ultimately leading to better operational outcomes and compliance with regulations.

Illustrative image related to small burn barrel

Navigating Market Dynamics and Sourcing Trends in the small burn barrel Sector

What Are the Current Market Dynamics and Key Trends in the Small Burn Barrel Sector?

The small burn barrel market is witnessing significant growth, driven by increasing environmental regulations and a heightened awareness of waste management solutions. In regions like Africa, South America, the Middle East, and Europe, the need for efficient waste disposal methods is pressing. Many countries are facing challenges with landfills, leading to a greater emphasis on incineration as a viable alternative. This trend is further supported by technological advancements that enhance the efficiency and safety of burn barrels.

International B2B buyers are increasingly seeking products that offer durability and advanced features, such as superior airflow designs that facilitate hotter and cleaner burns. This has led to innovations in materials, with a shift towards stainless steel and other warp-resistant materials that ensure longevity and performance. Moreover, emerging technologies in monitoring and automation for burn barrels are gaining traction, allowing for more controlled and environmentally friendly operations.

Another key trend is the rise of e-commerce platforms that facilitate easier access to global suppliers. B2B buyers can now source products from various regions with just a few clicks, fostering competitive pricing and an expanded selection of burn barrel options. Buyers from regions like Brazil and Saudi Arabia are particularly focused on suppliers who can offer not only quality products but also reliable after-sales support and compliance with local regulations.

Illustrative image related to small burn barrel

How Important Is Sustainability and Ethical Sourcing in the Small Burn Barrel Industry?

As global awareness of environmental issues grows, the importance of sustainability and ethical sourcing in the small burn barrel industry cannot be overstated. B2B buyers are increasingly prioritizing suppliers who adhere to environmentally friendly practices. This includes using recyclable materials and implementing manufacturing processes that minimize carbon footprints.

Sustainability certifications, such as ISO 14001 or similar green certifications, are becoming essential for suppliers aiming to differentiate themselves in a crowded market. Buyers are looking for products that not only meet their functional needs but also align with their corporate social responsibility goals. For instance, the use of eco-friendly materials in burn barrels contributes to a reduction in harmful emissions during the burning process, thus appealing to environmentally conscious consumers.

Furthermore, ethical sourcing practices are crucial for building trust and reputation in international markets. Buyers are increasingly scrutinizing supply chains for transparency and fairness. Suppliers who can demonstrate responsible sourcing and production methods will likely gain a competitive edge, particularly in markets where ethical consumerism is on the rise.

What Is the Historical Evolution of the Small Burn Barrel?

The small burn barrel has evolved significantly over the decades, transitioning from rudimentary, open-flame designs to more sophisticated, engineered solutions. Initially, burn barrels were simple containers used for waste disposal, often resulting in incomplete combustion and air pollution. However, with growing environmental concerns and advances in materials science, modern burn barrels are designed to optimize airflow and combustion efficiency.

The introduction of stainless steel and patented designs has enhanced the durability and safety of burn barrels, making them more appealing to B2B buyers looking for long-lasting solutions. As regulations surrounding waste disposal have tightened, the demand for efficient incineration methods has spurred innovation in the sector. This evolution reflects not only technological advancements but also a broader shift towards sustainable waste management practices, aligning with the global push for greener solutions in various industries.

Illustrative image related to small burn barrel

Frequently Asked Questions (FAQs) for B2B Buyers of small burn barrel

-

How do I solve issues with burning waste efficiently?

To address inefficient burning, consider investing in a small burn barrel designed for optimal airflow and heat retention. Look for models that can reach high temperatures, as this ensures complete incineration of waste, reducing smoke and emissions. Additionally, verify that the barrel is constructed from durable materials like stainless steel to prevent warping and enhance longevity. Regular maintenance, such as cleaning out ash and ensuring proper ventilation, can also improve burning efficiency. -

What is the best small burn barrel for environmentally friendly waste disposal?

The ideal small burn barrel for eco-friendly waste disposal features a patented airflow system that facilitates a hotter burn, minimizing smoke and ensuring complete combustion. Look for products that comply with local environmental regulations and are made from sustainable materials. Additionally, models that incorporate safety features to prevent wildfires and protect air quality are preferable. Research suppliers who can provide certifications or documentation regarding the eco-friendliness of their products. -

What should I consider when vetting suppliers for small burn barrels?

When vetting suppliers, assess their reputation by checking reviews and testimonials from previous buyers. Ensure they have experience in international trade and can navigate customs regulations specific to your region. Verify the quality of their products through certifications or testing results. It’s also beneficial to inquire about their manufacturing processes and materials used to guarantee compliance with safety and environmental standards. -

What are the typical minimum order quantities (MOQs) for small burn barrels?

Minimum order quantities can vary significantly among suppliers, often ranging from 10 to 100 units for small burn barrels. Factors influencing MOQs include manufacturing capabilities, shipping logistics, and pricing structures. It’s advisable to communicate directly with potential suppliers to negotiate MOQs that align with your purchasing needs, especially if you are looking to test the market or introduce the product gradually. -

What payment terms are common in international B2B transactions for burn barrels?

Payment terms can vary by supplier, but common practices include advance payment, letters of credit, and payment upon delivery. Many suppliers may require a deposit (often 30-50%) before production, with the balance due before shipping. Always clarify payment methods accepted, currency preferences, and any additional fees that may apply. Establishing clear payment terms upfront can help mitigate risks and ensure a smoother transaction process. -

How can I ensure quality assurance (QA) for my small burn barrel orders?

To ensure quality assurance, work with suppliers who provide thorough product specifications and testing certifications. Request samples before placing bulk orders to evaluate the quality firsthand. Additionally, consider establishing a quality control agreement that outlines inspection processes during production and before shipment. Utilizing third-party inspection services can also help verify that the products meet your standards and specifications. -

What are the logistics considerations when importing small burn barrels?

Logistics considerations include shipping methods, customs regulations, and potential tariffs or duties applicable to your region. Determine whether your supplier can handle logistics or if you need to engage a freight forwarder. It’s crucial to understand the lead times for production and shipping, as well as to plan for any necessary documentation required for customs clearance. Establishing a clear communication channel with your supplier can facilitate smoother logistics management. -

How do I handle potential issues with product delivery?

If you encounter delivery issues, promptly communicate with your supplier to address the problem. Ensure you have tracking information and maintain records of all correspondence. If delays are due to shipping or customs, inquire about potential resolutions or compensation. Developing a good relationship with your supplier can help mitigate future issues, and always consider having a contingency plan for urgent needs, such as alternative suppliers or expedited shipping options.

Top 4 Small Burn Barrel Manufacturers & Suppliers List

1. Reddit – Metal Trash Can as Burn Barrel

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Using a metal trash can as a burn barrel is a practical solution for yard waste disposal. Concerns exist regarding the potential for toxic fumes from galvanized metal, but some users suggest that burning outdoors in a well-ventilated area mitigates this risk after initial uses. Alternatives like a steel drum or barrel stove are mentioned for safer burning. Local regulations may require a mesh cove…

2. Proud Pyro – The Pyro Cage

Domain: proudpyro.com

Registered: 2017 (8 years)

Introduction: The Pyro Cage is a burn cage designed as a replacement for traditional burn barrels, ideal for burning yard debris, cardboard boxes, and sensitive documents. It features excellent airflow for hotter flames and more thorough burns. The cage consists of 4 panels that easily assemble without tools, creating a strong self-supporting structure. Made from 14 gauge steel, it is over 2 times thicker than …

3. IQS Directory – Burn Barrels

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Burn barrels are repurposed metal drums, typically 55-gallon, used for incinerating combustible waste. They are designed for safety and effectiveness in waste disposal, particularly in rural areas. Types of burn barrels include traditional burn barrels, yard waste burn barrels, galvanized garden incinerators, functional burn barrels, and 20-gallon trash can burn barrels. Key features include easy …

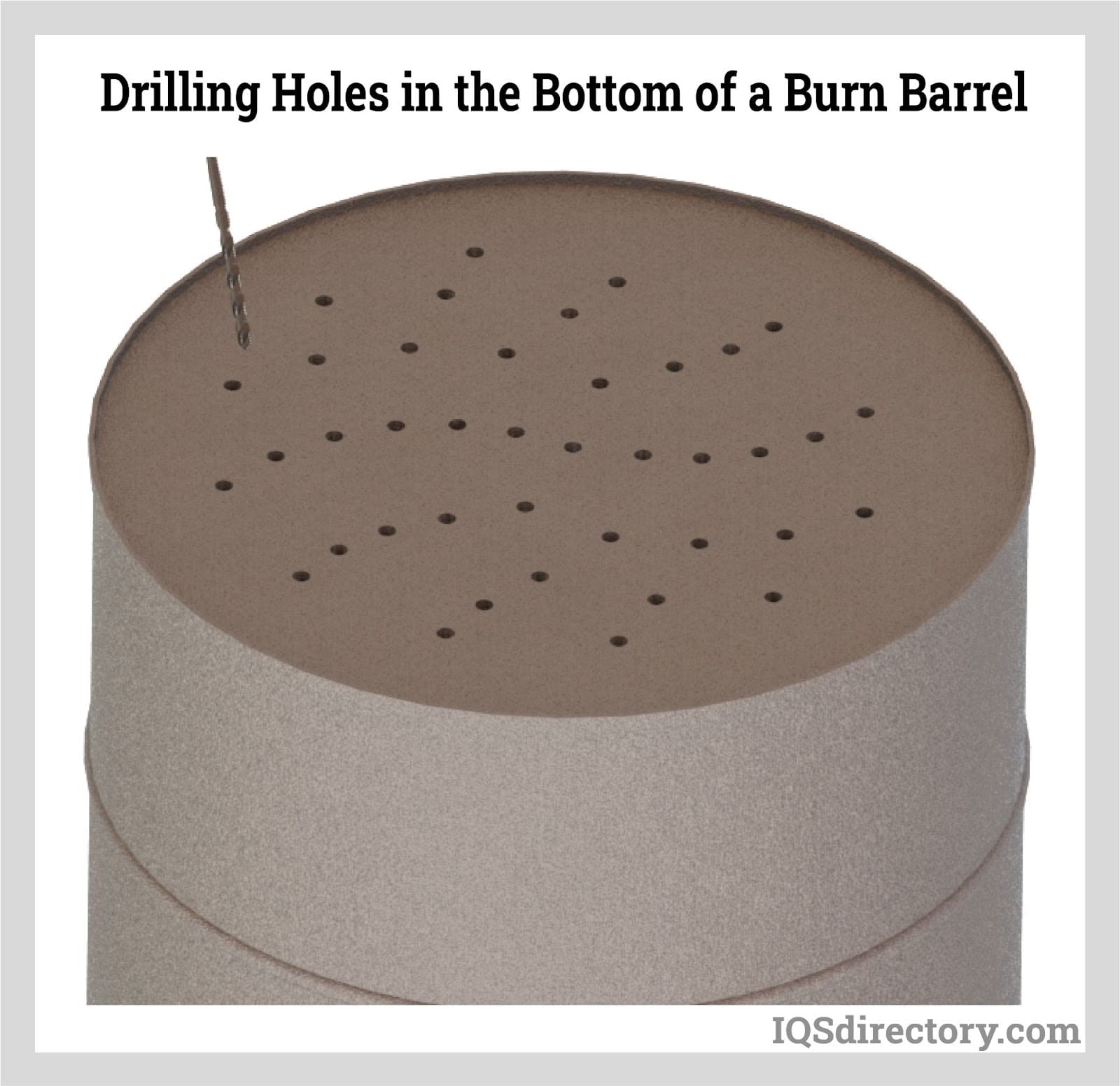

4. Hearth – 55 Gallon Steel Drum with Airflow Holes

Domain: hearth.com

Registered: 1995 (30 years)

Introduction: 55 gallon steel drum, drilled a dozen 3/8″ holes around the base (6″ from the bottom) for air flow.

Strategic Sourcing Conclusion and Outlook for small burn barrel

In conclusion, the strategic sourcing of small burn barrels presents a significant opportunity for international B2B buyers across diverse markets such as Africa, South America, the Middle East, and Europe. The unique characteristics of advanced burn barrels, including high durability, efficiency in waste management, and eco-friendly designs, make them essential for various applications—from agricultural waste disposal to backyard incineration. By prioritizing suppliers that offer innovative features, such as patented airflow systems and warp-resistant materials, businesses can enhance their operational effectiveness while ensuring compliance with environmental regulations.

Investing in quality small burn barrels not only improves waste management practices but also fosters a commitment to sustainability, appealing to increasingly eco-conscious consumers. As global markets continue to evolve, establishing reliable partnerships with manufacturers who prioritize quality and innovation will be crucial for maintaining a competitive edge.

Looking ahead, we encourage international B2B buyers to explore emerging trends in burn barrel technology and seek out suppliers that align with their operational goals. Embrace the potential of strategic sourcing to not only optimize your waste management solutions but also contribute positively to your community and environment. Take the next step today and connect with reputable manufacturers to secure the best solutions for your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to small burn barrel

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.