Silicon Tubes: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for silicon tubes

In an increasingly interconnected world, sourcing high-quality silicone tubes can pose significant challenges for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. As industries expand, the demand for silicone tubing—known for its versatility, durability, and temperature resistance—continues to rise. This guide offers a comprehensive overview of silicone tubes, covering various types, applications, and the nuances of supplier vetting. By addressing critical aspects such as material specifications, compliance standards, and cost considerations, this resource equips buyers with the knowledge needed to make informed purchasing decisions.

Navigating the global market for silicone tubes requires a strategic approach, particularly for buyers from regions like Vietnam and Nigeria, where local sourcing may present unique hurdles. This guide aims to empower decision-makers by providing actionable insights into best practices for procurement, including how to evaluate suppliers based on quality certifications and customer reviews. Additionally, we delve into the specific applications of silicone tubes across industries such as medical, food and beverage, automotive, and more, ensuring that buyers can find solutions tailored to their operational needs. With this comprehensive resource, B2B buyers can confidently navigate the complexities of sourcing silicone tubes, ensuring they secure reliable products that meet their business requirements.

Understanding silicon tubes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Platinum-Cured Silicone Tubing | High purity, biocompatible, suitable for medical use | Medical devices, food and beverage industries | Pros: High safety standards, excellent flexibility. Cons: Higher cost compared to other types. |

| Peroxide-Cured Silicone Tubing | Cost-effective, good for general applications | Industrial, automotive, appliances | Pros: Lower cost, versatile. Cons: Less biocompatible than platinum-cured. |

| Braid Reinforced Silicone Hose | Enhanced strength and durability due to braid reinforcement | High-pressure applications, chemical transfer | Pros: High pressure resistance, robust. Cons: Heavier and less flexible than standard tubing. |

| High-Temperature Silicone Tubing | Maintains properties in extreme temperatures | Aerospace, automotive, industrial machinery | Pros: Excellent thermal stability. Cons: Limited availability in some sizes. |

| Translucent Silicone Tubing | Semi-clear for visual flow monitoring | Beverage service, medical applications | Pros: Allows visibility of flow, inert. Cons: May be less durable in certain environments. |

What are the Characteristics of Platinum-Cured Silicone Tubing?

Platinum-cured silicone tubing is renowned for its high purity and biocompatibility, making it a preferred choice in the medical and food and beverage sectors. This type of tubing undergoes a curing process that utilizes platinum, ensuring that it meets stringent safety standards. For B2B buyers, its flexibility and resistance to extreme temperatures enhance its utility in various applications. However, its higher cost may be a consideration for budget-sensitive projects.

How Does Peroxide-Cured Silicone Tubing Compare?

Peroxide-cured silicone tubing is a more cost-effective option that finds extensive use in industrial and automotive applications. It offers good flexibility and durability but lacks the biocompatibility of its platinum-cured counterpart. Buyers should consider the intended application; while it is versatile and affordable, it may not meet the stringent requirements of medical applications.

What are the Advantages of Braid Reinforced Silicone Hose?

Braid reinforced silicone hose is designed for high-pressure applications, thanks to its internal braid reinforcement. This feature significantly enhances its strength and durability, making it ideal for chemical transfer and other demanding environments. While it provides excellent pressure resistance, buyers should note that it can be heavier and less flexible than standard tubing, which may impact installation in certain setups.

Illustrative image related to silicon tubes

Why Choose High-Temperature Silicone Tubing?

High-temperature silicone tubing is specifically engineered to withstand extreme temperature variations, making it suitable for applications in aerospace, automotive, and industrial machinery. Its ability to maintain performance under harsh conditions is a significant advantage for buyers needing reliable solutions. However, availability in specific sizes may be limited, which could affect project timelines.

What are the Benefits of Translucent Silicone Tubing?

Translucent silicone tubing allows for visual monitoring of fluid flow, making it a practical choice for beverage service and medical applications. Its inert properties ensure that it does not alter the taste or odor of the fluids it carries. While this type of tubing offers valuable visibility, potential buyers should be aware that it may have limitations in terms of durability in certain harsh environments.

Key Industrial Applications of silicon tubes

| Industry/Sector | Specific Application of Silicon Tubes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical & Healthcare | Medical tubing for infusion pumps and surgical applications | Ensures biocompatibility and maintains accuracy in dosage delivery | Compliance with health regulations, purity standards, and temperature resilience |

| Food & Beverage | Beverage dispensing and food processing | Safe and reliable transfer of liquids without contamination | NSF certification, FDA compliance, and temperature range specifications |

| Automotive | Fuel and oil transfer systems | High resistance to extreme temperatures and chemical degradation | Material certifications, pressure ratings, and compatibility with fluids |

| Chemical Processing | Chemical transfer and dispensing systems | Durable against corrosive substances and temperature fluctuations | Chemical compatibility, pressure ratings, and custom sizes |

| Electronics | Insulation for wiring and flexible connections | Excellent electrical insulation and resistance to environmental factors | Voltage ratings, thermal stability, and flexibility under varying conditions |

How Are Silicon Tubes Utilized in the Medical & Healthcare Industry?

In the medical sector, silicon tubes are critical for applications such as infusion pumps and surgical procedures. Their biocompatibility ensures that they do not react adversely with body fluids, making them ideal for precise dosage delivery. Buyers must ensure compliance with stringent health regulations, including FDA standards and purity requirements. Temperature resilience is also essential, as these tubes often operate in environments with extreme temperatures.

What Role Do Silicon Tubes Play in Food & Beverage Applications?

Silicon tubes are extensively used in the food and beverage industry for dispensing liquids and processing food. Their inert nature prevents contamination, ensuring that the products remain safe for consumption. For international buyers, it is vital to source tubes that are NSF certified and comply with FDA regulations. Additionally, understanding the temperature range specifications is crucial, as these tubes may be exposed to varying temperatures during processing.

Illustrative image related to silicon tubes

How Are Silicon Tubes Applied in Automotive Systems?

In automotive applications, silicon tubes are utilized for fuel and oil transfer systems due to their high resistance to extreme temperatures and chemical degradation. This durability ensures long-lasting performance and reliability in demanding environments. B2B buyers should prioritize sourcing tubes with appropriate material certifications and pressure ratings to ensure safety and efficiency in their applications.

Why Are Silicon Tubes Important in Chemical Processing?

Silicon tubes are invaluable in the chemical processing industry for transferring and dispensing various chemicals. Their ability to withstand corrosive substances and temperature fluctuations makes them ideal for such applications. Buyers should consider factors like chemical compatibility, pressure ratings, and the availability of custom sizes to ensure optimal performance and safety in their operations.

How Do Silicon Tubes Enhance Electronics Manufacturing?

In electronics, silicon tubes serve as insulation for wiring and flexible connections, providing excellent electrical insulation while resisting environmental factors such as moisture and UV radiation. For businesses in this sector, sourcing tubes with the right voltage ratings and thermal stability is essential to maintain operational efficiency and safety in their products.

3 Common User Pain Points for ‘silicon tubes’ & Their Solutions

Scenario 1: Sourcing Silicone Tubes for Diverse Applications

The Problem: B2B buyers often struggle with sourcing silicone tubes that meet specific application requirements. Industries like food and beverage, medical, and automotive have stringent standards for material properties such as biocompatibility, temperature resistance, and flexibility. Buyers frequently face challenges when suppliers do not provide adequate information on certifications, which can lead to compliance issues and increased costs if products need to be replaced or re-certified. This uncertainty can delay projects and affect operational efficiency.

The Solution: To overcome this sourcing challenge, buyers should first identify their specific requirements based on the intended application. It is essential to ask suppliers for detailed product specifications, including material certifications (e.g., FDA compliance for food applications, USP Class VI for medical uses) and performance data (e.g., temperature ranges and pressure ratings). Additionally, establishing a relationship with suppliers who specialize in silicone tubes can provide buyers with insights into the latest products and innovations. Utilizing a centralized procurement system with clear documentation and tracking can also help streamline the sourcing process, ensuring that all materials meet industry standards before they reach production.

Scenario 2: Ensuring Consistent Quality in Silicone Tubes

The Problem: Inconsistent quality of silicone tubes can lead to operational setbacks, such as equipment failure or product contamination. Buyers often find that variations in manufacturing processes or supplier practices result in tubing that does not meet their specifications. This inconsistency can be particularly problematic in industries like pharmaceuticals or food processing, where product integrity is critical. The repercussions of using subpar materials can include safety violations, recalls, and damage to brand reputation.

The Solution: To ensure consistent quality, buyers should conduct thorough due diligence on potential suppliers. This includes reviewing their manufacturing processes, quality control measures, and any third-party certifications that validate their claims. Establishing a robust quality assurance process is also crucial; consider implementing a system for regular testing of incoming materials against established specifications. Collaborating with suppliers on quality standards and conducting periodic audits can further enhance product reliability. If possible, buyers should also explore partnerships with suppliers that utilize advanced manufacturing techniques, such as platinum-cured silicone, which often leads to higher consistency and better performance.

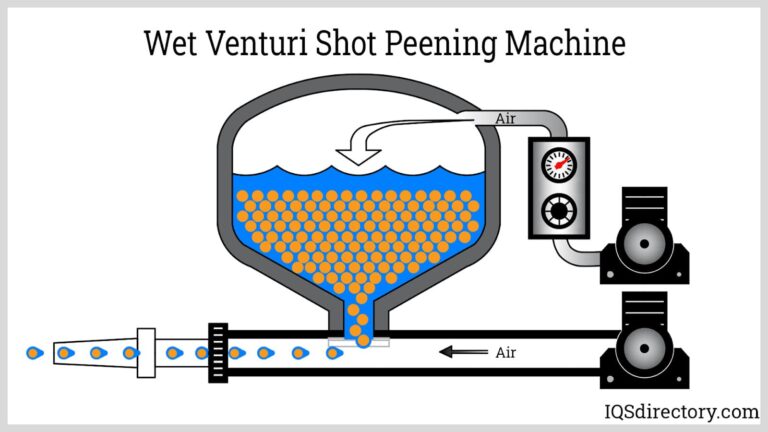

Scenario 3: Overcoming Limitations in Temperature and Chemical Resistance

The Problem: Buyers in industries such as chemical processing or food service often require silicone tubes that can withstand extreme temperatures and various chemicals. However, many standard silicone tubes may not be suitable for high-pressure or high-temperature applications, leading to premature failure and costly downtime. This limitation can hinder operational efficiency and compromise safety, particularly in environments where tube integrity is vital.

The Solution: To address these limitations, buyers should carefully assess the operating conditions of their applications before selecting silicone tubes. It is advisable to work closely with suppliers to determine the appropriate silicone formulation, such as using silicone tubes reinforced with braiding or those specifically designed for high-pressure applications. Additionally, buyers should request performance data regarding chemical compatibility and temperature resistance from suppliers. Conducting pilot tests in controlled environments can help validate the performance of the chosen silicone tubes under actual working conditions. Establishing a contingency plan for monitoring and replacing tubes as needed can also mitigate risks associated with material failure.

Strategic Material Selection Guide for silicon tubes

What Are the Key Properties of Common Materials Used in Silicon Tubes?

When selecting materials for silicon tubes, it is essential to consider the specific properties that influence performance across various applications. Below are analyses of four common materials used in silicon tubing, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

1. Platinum-Cured Silicone

Key Properties: Platinum-cured silicone exhibits excellent thermal stability, maintaining functionality in temperature ranges from -100°F to 500°F. It also possesses low compression set, which is vital for applications requiring precise dosing, such as medical devices.

Pros & Cons: This material is highly biocompatible, making it suitable for medical and food applications. However, it tends to be more expensive than other silicone types due to the complexity of the curing process, which may impact budget-sensitive projects.

Impact on Application: Platinum-cured silicone is ideal for applications involving food and beverage transfer, medical devices, and pharmaceutical manufacturing, where purity and safety are paramount.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that products meet local compliance standards, such as FDA or EU regulations. Understanding the cost implications of sourcing high-quality materials is crucial for maintaining competitive pricing.

2. Peroxide-Cured Silicone

Key Properties: Peroxide-cured silicone is known for its high tensile strength and durability, offering good resistance to heat and aging. It operates effectively in temperatures ranging from -60°F to 400°F.

Pros & Cons: While more cost-effective than platinum-cured silicone, peroxide-cured options may not be as biocompatible, limiting their use in medical applications. The manufacturing process is simpler, which can reduce lead times.

Impact on Application: This material is suitable for industrial applications such as automotive hoses, electrical insulation, and general-purpose tubing, where extreme purity is not a primary concern.

Considerations for International Buyers: Buyers should verify compliance with relevant standards such as ASTM and ISO, especially when sourcing for industries with stringent regulations. Cost-effectiveness makes this material appealing for budget-conscious projects.

3. Medical-Grade Silicone

Key Properties: Medical-grade silicone is specifically formulated to meet rigorous safety and performance standards. It is flexible, resistant to microbial growth, and can withstand sterilization processes.

Illustrative image related to silicon tubes

Pros & Cons: This type of silicone is excellent for applications in healthcare, offering high purity and safety. However, it can be more expensive due to the stringent testing and certification processes required.

Impact on Application: Medical-grade silicone is essential for applications in surgical tubing, infusion pumps, and other medical devices where patient safety is critical.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific medical device regulations that apply in their regions. Ensuring that suppliers provide necessary certifications can help mitigate compliance risks.

4. High-Temperature Silicone

Key Properties: High-temperature silicone can withstand extreme temperatures, often exceeding 500°F. It maintains flexibility and performance under thermal stress, making it suitable for demanding environments.

Pros & Cons: This material is durable and resistant to environmental factors like UV radiation and ozone. However, it may be less flexible at lower temperatures, which could limit its application range.

Impact on Application: Ideal for applications in automotive, aerospace, and industrial settings where high thermal resistance is required, such as exhaust systems and heat shielding.

Considerations for International Buyers: Buyers should consider the specific thermal requirements of their applications and ensure that the selected silicone meets international standards for performance and safety.

Summary Table of Material Selection for Silicon Tubes

| Material | Typical Use Case for silicon tubes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Platinum-Cured Silicone | Medical devices, food and beverage transfer | High biocompatibility, excellent thermal stability | Higher cost due to complex curing process | High |

| Peroxide-Cured Silicone | Automotive hoses, electrical insulation | Cost-effective, good tensile strength | Limited biocompatibility for medical use | Medium |

| Medical-Grade Silicone | Surgical tubing, infusion pumps | Meets rigorous safety standards | Higher price due to certification process | High |

| High-Temperature Silicone | Automotive, aerospace applications | Excellent thermal resistance | Less flexible at lower temperatures | Medium |

This guide provides a comprehensive overview of material selection considerations for silicon tubes, enabling international B2B buyers to make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for silicon tubes

What Are the Key Stages in the Manufacturing Process of Silicon Tubes?

The manufacturing of silicon tubes involves several critical stages, each designed to ensure the final product meets the required specifications for various applications. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is the preparation of silicone materials. High-quality silicone rubber is typically selected based on the intended application, whether for medical, food, or industrial use. The silicone can be either platinum-cured or peroxide-cured, with platinum-cured silicone offering superior biocompatibility and purity, making it ideal for medical applications. Raw materials are thoroughly tested to ensure they meet the necessary chemical and physical properties before moving on to the next stage.

Forming

Once the materials are prepared, they undergo the forming process. This can be achieved through various techniques such as extrusion, molding, or calendaring, depending on the desired tube specifications. Extrusion is a common method where the silicone is pushed through a die to create continuous tubing of specific dimensions. Advanced technology, including computer-controlled extrusion, allows for precise control over the wall thickness and diameter, ensuring consistency across production runs.

Assembly

After forming, the silicone tubes may require assembly with additional components, such as fittings or connectors. This stage may involve heat sealing or adhesive bonding to ensure a secure connection. For applications requiring more complex configurations, assembly can also include the integration of braided reinforcements to enhance the tubing’s durability and pressure resistance.

Finishing

The final stage of manufacturing involves finishing processes, which may include cutting the tubes to specified lengths, surface treatments, and packaging. Quality checks are conducted to ensure that the finished products meet the specified tolerances and are free from defects. Each batch of silicone tubes is usually labeled with production and quality control information for traceability.

How Is Quality Assurance Implemented in Silicon Tube Manufacturing?

Quality assurance (QA) is a crucial aspect of silicon tube manufacturing, ensuring that products comply with international standards and specific industry requirements. Implementing a robust QA system involves several key components.

International Standards for Quality Assurance

Manufacturers often adhere to international quality management standards, such as ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO standards demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications, such as CE marking for European markets or API specifications for the oil and gas industry, may be required depending on the application.

Quality Control Checkpoints

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify and mitigate defects. These checkpoints typically include:

- Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet predetermined specifications before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves monitoring production to catch any deviations from quality standards in real-time. This may include measuring dimensions, testing material properties, and observing production practices.

- Final Quality Control (FQC): After production, FQC checks the finished products for compliance with specifications. This may involve testing for flexibility, temperature resistance, and other critical performance metrics.

Common Testing Methods for Silicon Tubes

To ensure quality, various testing methods are employed, including:

- Tensile Testing: Measures the strength and elasticity of the silicone material.

- Burst Pressure Testing: Determines the maximum pressure the tubing can withstand before failure.

- Thermal Cycling Tests: Assesses the performance of silicone tubes under extreme temperature variations.

- Chemical Compatibility Testing: Evaluates the tube’s resistance to various chemicals it may encounter in its intended applications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with local regulations.

Supplier Audits

Conducting supplier audits is an effective way to assess the quality management systems in place. Buyers can request to visit the manufacturing facility, review QA documentation, and observe production processes firsthand. This transparency helps build trust and ensures the supplier adheres to the promised quality standards.

Quality Control Reports

B2B buyers should also request regular quality control reports from suppliers. These reports should detail the results of various testing methods and any corrective actions taken in response to identified issues. Comprehensive documentation provides insight into the supplier’s commitment to maintaining high standards.

Illustrative image related to silicon tubes

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. Third-party auditors can conduct independent evaluations of the manufacturing process, product samples, and documentation, providing additional assurance to buyers.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of the nuances in quality control that can vary by region. For instance, regulatory requirements in Europe may differ significantly from those in Africa or South America. Understanding these differences is crucial for compliance and successful market entry.

Local Compliance Requirements

Each region may have specific compliance requirements that suppliers must meet. For example, medical-grade silicone products in Europe may need to comply with stringent regulations regarding biocompatibility and sterilization, whereas in other regions, the requirements may be less rigorous. Buyers should ensure that suppliers are knowledgeable about and compliant with local regulations.

Cultural and Communication Considerations

Cultural differences can impact how quality control processes are implemented and communicated. Buyers should establish clear channels of communication with suppliers to ensure that quality expectations are understood and met. Regular meetings and updates can help bridge any gaps that may arise from geographical distance or cultural differences.

Long-Term Relationships

Building long-term relationships with suppliers can facilitate better quality control practices over time. Engaging in continuous dialogue and collaboration can lead to improvements in quality and efficiency, benefiting both parties.

In conclusion, understanding the manufacturing processes and quality assurance practices for silicon tubes is vital for B2B buyers seeking reliable suppliers. By focusing on these aspects, buyers can make informed decisions, ensuring that the products they source meet their specific needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘silicon tubes’

To effectively source silicone tubes for your business needs, following a structured approach can greatly enhance your procurement process. This guide provides a step-by-step checklist to help international B2B buyers navigate the complexities of sourcing silicone tubing.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the silicone tubes you need. Consider factors such as:

– Diameter and Length: Identify the outer and inner diameter specifications that suit your application.

– Material Type: Determine whether you require platinum-cured or peroxide-cured silicone based on your industry standards.

– Temperature Resistance: Understand the operating temperature range necessary for your application, as silicone can typically withstand extremes from -100°F to 500°F.

Having precise specifications will streamline the sourcing process and ensure that potential suppliers can meet your requirements.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers specializing in silicone tubing. Use multiple channels:

– Industry Directories: Leverage online platforms to find reputable manufacturers and distributors.

– Trade Shows and Expos: Attend industry-related events to meet suppliers face-to-face and evaluate their products firsthand.

– Peer Recommendations: Seek referrals from colleagues or industry peers who have sourced similar products.

Creating a shortlist will help you focus on suppliers that align with your technical and budgetary needs.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request:

– Company Profiles: Review their history, mission, and production capabilities.

– Certifications: Ensure they possess relevant quality certifications (e.g., ISO, NSF) that guarantee product safety and compliance.

– References: Ask for case studies or testimonials from other businesses in your industry.

This evaluation will help confirm the supplier’s reliability and capability to deliver quality products.

Step 4: Request Samples for Testing

Once you have narrowed down your list of potential suppliers, request samples of the silicone tubing. Testing samples allows you to:

– Check Quality: Assess the flexibility, durability, and overall performance of the silicone tubes in your specific applications.

– Verify Specifications: Ensure the samples meet the defined technical specifications before placing a larger order.

– Evaluate Lead Times: Understand the supplier’s ability to deliver products within your required timeframe.

This step is essential to mitigate risks associated with product performance and compatibility.

Step 5: Negotiate Pricing and Terms

Engage in discussions with your shortlisted suppliers to negotiate pricing and terms. Consider:

– Bulk Discounts: Inquire about pricing tiers based on order quantities to maximize cost savings.

– Payment Terms: Establish clear payment terms, including deposits and payment schedules.

– Shipping Costs: Discuss shipping options and costs, especially for international deliveries, to avoid unexpected expenses.

Effective negotiation can lead to favorable terms that benefit your procurement budget.

Step 6: Finalize the Purchase Agreement

Once you have selected a supplier, draft a purchase agreement that includes:

– Detailed Specifications: Clearly outline the product specifications, quantities, and delivery timelines.

– Warranties and Returns: Include warranty information and return policies for defective products.

– Confidentiality Clauses: If necessary, protect your proprietary information with confidentiality agreements.

A well-structured agreement will safeguard both parties and ensure clarity in expectations.

Step 7: Plan for Ongoing Communication

Establish a communication plan with your chosen supplier to ensure smooth collaboration. This includes:

– Regular Updates: Schedule check-ins to discuss order status and address any potential issues promptly.

– Feedback Mechanisms: Provide feedback on product performance to help the supplier improve their offerings.

Maintaining open lines of communication can foster a strong supplier relationship and enhance future procurement efforts.

Illustrative image related to silicon tubes

Comprehensive Cost and Pricing Analysis for silicon tubes Sourcing

What Are the Key Cost Components in Sourcing Silicone Tubes?

When sourcing silicone tubes, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The quality of silicone used significantly influences the price. High-grade silicone, such as platinum-cured variants, typically commands a premium due to their superior properties, including biocompatibility for medical applications.

-

Labor: Manufacturing labor costs can vary widely based on the location of the supplier. Regions with lower labor costs may offer competitive pricing, but this could be offset by potential quality concerns.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Suppliers with advanced manufacturing capabilities and clean room environments may charge higher rates, but they often ensure better product quality.

-

Tooling: Custom tooling for specific applications can add to initial costs. If your application requires specialized designs, be prepared for additional expenses during the setup phase.

-

Quality Control (QC): Rigorous QC processes, especially for products intended for medical or food applications, can increase costs. However, this investment in quality can mitigate risks associated with product failures.

-

Logistics: Shipping costs can vary based on the supplier’s location and the chosen Incoterms. International shipping often incurs additional fees, which should be factored into the total cost.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure profitability. This margin can vary based on the supplier’s market positioning and the competitiveness of their offerings.

How Do Price Influencers Affect Silicone Tube Costs?

Several factors can influence the pricing of silicone tubes:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs). Larger orders can lead to discounts, making it essential for buyers to assess their needs and negotiate effectively.

-

Specifications and Customization: Tailored specifications, such as specific dimensions or chemical resistance, can increase costs. Buyers should clearly communicate their needs to obtain accurate quotes.

-

Material Quality and Certifications: Products that meet stringent industry standards (e.g., FDA, NSF) will likely be priced higher. Buyers should consider the certifications necessary for their applications to avoid future compliance issues.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role. Established suppliers with a track record of quality may charge more, but they often provide better customer service and support.

-

Incoterms: The agreed-upon Incoterms will determine who bears the risk and cost during shipping. Understanding these terms can help buyers manage expenses effectively.

What Are the Best Practices for Negotiating Silicone Tube Prices?

To maximize value when sourcing silicone tubes, consider the following tips:

-

Negotiate Effectively: Leverage your purchasing power by discussing long-term contracts or larger orders to secure better pricing.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, maintenance, and compliance costs, which may influence the overall value.

-

Understand Pricing Nuances for International Buyers: B2B buyers from regions like Africa, South America, and the Middle East may face unique challenges, such as fluctuating exchange rates and import tariffs. It’s crucial to factor these into your budgeting.

-

Research Market Trends: Stay informed about market dynamics that may impact pricing, such as raw material shortages or shifts in demand.

-

Request Samples: Before committing to large orders, request samples to evaluate the product’s quality and suitability for your application.

Conclusion

Sourcing silicone tubes involves a complex interplay of costs and pricing factors. By understanding the key components of the cost structure and the various influencers on pricing, B2B buyers can make more informed decisions. Always negotiate and consider the total cost of ownership to ensure you’re getting the best possible value for your investment.

Alternatives Analysis: Comparing silicon tubes With Other Solutions

Exploring Alternatives to Silicon Tubes in Industrial Applications

When considering the best materials for tubing in various industrial applications, it is essential to evaluate all viable options. Silicon tubes are widely recognized for their versatility, temperature resistance, and biocompatibility. However, several alternatives also exist that may better suit specific needs based on performance, cost, and application context. This analysis provides a comparison of silicon tubes with two notable alternatives: PVC (Polyvinyl Chloride) Tubing and Rubber Tubing.

| Comparison Aspect | Silicon Tubes | PVC Tubing | Rubber Tubing |

|---|---|---|---|

| Performance | Excellent temperature range (-100°F to 500°F), good flexibility, and biocompatibility. | Good chemical resistance, but less flexibility at low temperatures. | High elasticity and durability, suitable for high-pressure applications. |

| Cost | Higher upfront costs due to material properties and manufacturing processes. | Generally lower cost, making it a budget-friendly option. | Moderate cost; depends on type and thickness. |

| Ease of Implementation | Easy to cut and manipulate; compatible with various fittings. | Simple installation; widely available and standard sizes. | Requires more effort to cut and seal; may need specific fittings. |

| Maintenance | Low maintenance; resistant to UV and oxidation. | Regular checks needed for chemical compatibility. | Requires periodic checks for wear and tear. |

| Best Use Case | Medical and food applications, high-temperature settings. | General industrial use, chemical transfer, and plumbing. | Automotive and heavy-duty applications where flexibility is crucial. |

What are the Advantages and Disadvantages of PVC Tubing Compared to Silicon Tubes?

PVC tubing offers a cost-effective solution for various industrial applications. Its affordability makes it a popular choice for projects with budget constraints. PVC is also widely available and comes in standard sizes, simplifying procurement and installation. However, it has limitations in temperature resistance and flexibility at lower temperatures, which can restrict its application in extreme environments. Moreover, PVC may not be suitable for applications involving food and medical use due to potential leaching of harmful chemicals.

How Does Rubber Tubing Compare to Silicon Tubes in Performance and Cost?

Rubber tubing presents an excellent alternative for applications requiring high elasticity and the ability to withstand high pressure. It is particularly valued in automotive and industrial contexts where flexibility is essential. Rubber tubing is durable and can handle a range of environmental conditions. However, it may not have the same high-temperature resistance as silicon tubes, limiting its use in extreme heat applications. Additionally, while rubber is generally cost-effective, it can require more frequent maintenance checks to ensure longevity, especially in high-stress environments.

Illustrative image related to silicon tubes

How Should B2B Buyers Choose Between Silicon Tubes and Their Alternatives?

In selecting the appropriate tubing solution, B2B buyers should consider several factors, including the specific application requirements, budget constraints, and environmental conditions. Silicon tubes are ideal for applications that demand high performance, such as medical devices and food processing, due to their superior flexibility and temperature resistance. Conversely, if the project is more budget-sensitive and doesn’t require extreme performance, PVC or rubber tubing may be more suitable. Understanding the pros and cons of each option allows businesses to make informed decisions that align with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for silicon tubes

What Are the Key Technical Properties of Silicone Tubes for B2B Buyers?

When selecting silicone tubes for industrial applications, understanding their technical specifications is crucial for ensuring compatibility and performance. Here are some essential properties to consider:

-

Material Grade: Silicone tubes are available in various grades, including medical, food-grade, and industrial grades. The grade determines the tube’s purity, biocompatibility, and suitability for specific applications, such as food processing or healthcare. For B2B buyers, selecting the right grade is vital to comply with industry regulations and maintain product integrity.

-

Temperature Range: Silicone tubes exhibit excellent thermal stability, with a temperature tolerance typically ranging from -100°F to +500°F. This property allows them to perform effectively in extreme environments. B2B buyers must assess the operational temperature range of their application to ensure the selected silicone tube can withstand the required conditions without degrading.

-

Durometer (Hardness): The durometer scale measures the hardness of silicone materials, usually ranging from 20 to 80 Shore A for tubing. A lower durometer indicates softer, more flexible tubing, while a higher durometer signifies greater rigidity. Understanding durometer is essential for applications requiring specific flexibility or strength, such as in pneumatic systems or medical devices.

-

Working Pressure: This specification indicates the maximum pressure the tube can safely handle during operation. Silicone tubes typically feature a working pressure ranging from 15 to 20 PSI, depending on the tube’s diameter and wall thickness. B2B buyers should match the working pressure of the silicone tube with the requirements of their systems to prevent failures and ensure safety.

-

Elongation and Tensile Strength: Elongation refers to the ability of the silicone tube to stretch without breaking, often expressed as a percentage. Tensile strength measures the maximum load the tube can withstand before failing. High elongation and tensile strength values indicate durability and resistance to wear and tear, which are critical for applications in high-stress environments.

What Are Common Trade Terms Related to Silicone Tubes in B2B Transactions?

Navigating the silicone tube market requires familiarity with specific trade terminology. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products or components that are sold under another company’s brand. In the silicone tubing sector, OEMs often require high-quality materials that meet specific performance standards. Understanding OEM relationships can help buyers secure reliable supply chains.

-

MOQ (Minimum Order Quantity): MOQ is the minimum number of units a supplier requires a buyer to purchase in a single order. This term is essential for B2B buyers, especially when managing budgets and inventory. Knowing the MOQ can help businesses negotiate better terms or find alternative suppliers who offer lower minimums.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers requesting pricing information for specific products. When sourcing silicone tubes, buyers often use RFQs to obtain competitive quotes, ensuring they get the best price and terms from multiple suppliers.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in global transactions. Incoterms clarify aspects such as shipping, insurance, and customs clearance, which are vital for B2B buyers importing silicone tubes from overseas manufacturers. Familiarity with these terms helps buyers mitigate risks and understand their obligations.

-

Lead Time: Lead time refers to the time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for planning and inventory management. Longer lead times can impact production schedules, making it essential to choose suppliers who can meet tight deadlines.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed decisions when sourcing silicone tubes. This not only facilitates smoother transactions but also enhances operational efficiency across various applications.

Navigating Market Dynamics and Sourcing Trends in the silicon tubes Sector

What Are the Current Market Trends Impacting the Silicone Tubes Sector?

The silicone tubes market is witnessing robust growth driven by several global factors. Key drivers include the increasing demand for high-performance materials in various applications such as medical devices, food and beverage processing, and automotive industries. The versatility of silicone tubing, with its temperature resistance and biocompatibility, makes it particularly appealing to manufacturers in these sectors. Emerging technologies, including advancements in 3D printing and automation, are also influencing sourcing trends by enabling customized solutions that meet specific client requirements.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers who can provide high-quality products with shorter lead times. This shift is compounded by a growing emphasis on digital platforms for procurement, which facilitates easier access to product catalogs and supplier information. Additionally, buyers are leaning towards suppliers that can demonstrate compliance with international standards, especially in industries where product safety is paramount, such as pharmaceuticals and food processing.

How Is Sustainability Shaping Sourcing Decisions in the Silicone Tubes Market?

The importance of sustainability in sourcing practices cannot be overstated in today’s market. Environmental concerns are prompting B2B buyers to seek materials and suppliers that minimize ecological footprints. For silicone tubes, this means looking for products that are manufactured using eco-friendly processes and materials.

Ethical sourcing is becoming a significant consideration, with buyers increasingly valuing suppliers who can prove their commitment to sustainable practices. Certifications such as NSF (National Sanitation Foundation) and FDA (Food and Drug Administration) compliance are essential for assuring buyers of the safety and environmental impact of silicone products. Furthermore, the adoption of ‘green’ materials and manufacturing techniques is gaining traction, with innovations in recycling silicone waste and developing bio-based silicone alternatives. These practices not only contribute to environmental sustainability but also enhance brand reputation among increasingly eco-conscious consumers.

What Is the Historical Context of Silicone Tubes in B2B Applications?

Silicone tubing has evolved significantly since its inception in the mid-20th century. Initially developed for niche applications, its unique properties—such as high thermal stability, flexibility, and resistance to environmental factors—have led to widespread adoption across various industries. The medical sector was one of the first to embrace silicone tubing due to its biocompatibility and sterilization capabilities, making it ideal for use in surgical and infusion applications.

As industries continue to innovate, the demand for silicone tubing has expanded beyond medical use to include food and beverage, automotive, and industrial applications. This evolution reflects a broader trend of increasing reliance on high-performance materials that can withstand rigorous operational conditions while ensuring safety and compliance. B2B buyers today benefit from a mature market with a diverse range of options tailored to meet specific needs, underscoring the versatility and enduring relevance of silicone tubing in global supply chains.

Frequently Asked Questions (FAQs) for B2B Buyers of silicon tubes

-

How do I choose the right silicone tubing for my application?

Choosing the right silicone tubing involves assessing several factors, including the application requirements, temperature range, chemical compatibility, and size specifications. Consider the working pressure and flexibility needed for your application. For instance, medical applications may require platinum-cured silicone tubing due to its biocompatibility, while industrial uses might prioritize durability and temperature resistance. Additionally, consulting with suppliers for samples and specifications can provide clarity on the best fit for your needs. -

What are the most common applications for silicone tubing?

Silicone tubing is versatile and commonly used in various industries, including medical, food and beverage, automotive, and chemical transfer. In medical settings, it is often utilized for infusion pumps and surgical procedures due to its purity and biocompatibility. In industrial applications, silicone tubing is favored for its resistance to extreme temperatures and flexibility, making it ideal for hydraulic lines, fuel transfer, and air conditioning systems. Understanding your industry’s requirements will help you select the appropriate type. -

What is the minimum order quantity (MOQ) for silicone tubing?

The minimum order quantity (MOQ) for silicone tubing can vary significantly based on the supplier and the specific product line. Typically, MOQs can range from 50 feet for standard sizes to several hundred feet for custom specifications. For bulk orders, many suppliers offer discounts, so it’s advisable to discuss your needs with the supplier to negotiate favorable terms. Always confirm the MOQ before placing an order to avoid unexpected costs. -

How can I ensure the quality of silicone tubing when sourcing internationally?

To ensure the quality of silicone tubing, conduct thorough due diligence on potential suppliers. Look for certifications such as ISO, FDA, or NSF, which indicate compliance with quality standards. Request samples for testing before committing to large orders. Additionally, consider third-party inspections during production and before shipping. Establishing a clear quality assurance process can help mitigate risks associated with international sourcing. -

What payment terms are typical when purchasing silicone tubing?

Payment terms for silicone tubing purchases can vary by supplier and region. Common arrangements include net 30 or net 60 days after delivery, but some suppliers may require upfront payments or deposits, especially for custom orders. Discussing payment methods, such as bank transfers or letters of credit, can also help protect both parties. Be sure to clarify payment terms in the contract to avoid misunderstandings. -

How do I vet suppliers for silicone tubing in international markets?

Vetting suppliers involves researching their reputation, production capabilities, and compliance with industry standards. Utilize platforms like Alibaba or Global Sources for reviews and ratings. Request references from previous clients and check their responsiveness during initial communications. Additionally, consider visiting the manufacturing facility if feasible, or hiring a local consultant to conduct an on-site assessment. This process helps ensure you partner with reliable suppliers. -

What logistics considerations should I keep in mind when importing silicone tubing?

When importing silicone tubing, consider shipping methods, customs regulations, and potential tariffs. Determine whether air freight or sea freight is more suitable based on urgency and cost. Be aware of import restrictions in your country regarding materials and certifications. Collaborating with a freight forwarder can streamline the logistics process, ensuring compliance and efficient delivery. Additionally, factor in lead times for production and shipping when planning your inventory. -

Can silicone tubing be customized to meet specific needs?

Yes, many suppliers offer customization options for silicone tubing, including size, color, and specific material formulations. Customization is particularly beneficial for unique applications or industries requiring specific properties, such as medical-grade tubing or tubing resistant to certain chemicals. Discuss your requirements with the supplier to understand the available options and any associated costs. Custom orders may also have longer lead times, so plan accordingly.

Top 8 Silicon Tubes Manufacturers & Suppliers List

1. WC Products – Silicone Tubing for FRC Applications

Domain: wcproducts.com

Registered: 2015 (10 years)

Introduction: This company, WC Products – Silicone Tubing for FRC Applications, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Fuel Cell Store – Silicon Tubing

Domain: fuelcellstore.com

Registered: 1999 (26 years)

Introduction: {“Product Name”: “Silicon Tubing”, “SKU”: “49100001”, “Price”: “Starting From $17.00”, “Material”: “Synthetic rubber”, “Color”: “Semi-clear (translucent) white”, “Inner Diameter Options”: [“3/32”, “1/8”, “3/16”], “Outer Diameter Options”: [“7/32”, “1/4”, “5/16”], “Max PSI”: {“3/32”: 20, “1/8”: 20, “3/16”: 15}, “Wall Thickness”: “1/16”, “Temperature Range”: “-94 to +392 F”, “Durometer”: “Shore A: 5…

3. MOCAP – Silicone Rubber Tubing

Domain: mocap.com

Registered: 1995 (30 years)

Introduction: MOCAP Silicone Rubber Tubing is designed for product masking applications. It is extruded from specially formulated silicone with a hardness rating of 60 Shore A and is heat stabilized for reuse at temperatures up to 500°F (260°C). The tubing is non-staining and is commonly used for masking studs, pins, and other round objects. It is available in lengths of 50 ft. and 100 ft. and stocked in diamet…

4. Nelco Products – Silcon® Silicone Tubing

Domain: nelcoproducts.com

Registered: 1999 (26 years)

Introduction: Silcon® Silicone Tubing features excellent flexibility and resistance to temperature extremes, good electrical properties, and the ability to self-extinguish. It is ideal for appliances and computers. The silicone rubber hose is versatile, with applications including electrical wiring covering, straws for kids’ cups, hoses for aquariums, and weatherproof covering for LED lights. Available in insid…

5. The Rubber Company – Hose & Tubing Silicone Products

Domain: therubbercompany.com

Registered: 2013 (12 years)

Introduction: Hose & Tubing Silicone Products include various types of hoses such as Agriculture Hoses, Air Hoses, Chemical Hoses, Cleaning Hoses, Dairy Hoses, Ducting Hoses, Fire Hoses, Flame Resistant Hoses, Food Grade Hoses, Fuel Hose, Gas Hoses, Hydraulic Hoses, Marine Hoses, Material Handling Hoses, Oil Hoses, Pharmaceutical Hoses, PVC Hoses, Sewer Hoses, Shotblast Hoses, Silicone Hoses, Tank Truck Hoses, …

6. Lumi-O – 300ml Silicone Tube

Domain: innovaplas.com

Registered: 2002 (23 years)

Introduction: {“name”: “300ml Silicone Tube”, “brand”: “Lumi-O”, “price”: “$42.75”, “shipping_time”: “10 to 15 business days during busy season”, “type”: “SST001”, “quantity”: “300ml”, “shipping_fees”: “included in the price”}

7. Tech-Link Silicones – Silicone Tubing Solutions

Domain: techlinksilicones.com

Registered: 2022 (3 years)

Introduction: Tech-Link Silicones Co. Ltd. specializes in manufacturing general-purpose, medical/food grade, and high-pressure silicone tubes. Key product offerings include: 1. Braid Reinforced Silicone Tubing 2. Medical Grade Silicone Tubing 3. Platinum Cured Silicone Hose 4. USP Class VI Food Safe Silicone Tubing 5. General Purpose Silicone Tubing 6. Colored Vacuum Silicone Tubing 7. High-Temperature Silicone…

8. Tubes International – Silicone Hoses & Tubings

Domain: tubes-international.com

Registered: 2007 (18 years)

Introduction: Silicone hoses and silicone tubings are widely used in various industries including pharmaceutical, biotechnological, medical, food, machine-building, construction, and power industry. Key characteristics include: resistance to low and high temperatures with minor changes in physical properties, good dielectric breakdown properties, resistance to oxidation, physiological inertness, high compressib…

Strategic Sourcing Conclusion and Outlook for silicon tubes

In the dynamic landscape of silicon tube procurement, strategic sourcing emerges as a vital practice for international buyers. The versatility of silicone tubing, with its applications across medical, industrial, and consumer sectors, underscores the importance of identifying reliable suppliers who can meet diverse quality and compliance standards. Buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships that offer not only competitive pricing but also comprehensive support in terms of product specifications, certifications, and delivery timelines.

Understanding the unique requirements of your market—be it for medical-grade tubing or industrial applications—can significantly enhance your sourcing strategy. As silicone materials continue to evolve, leveraging technological advancements and innovations from leading manufacturers will ensure you remain at the forefront of your industry.

Looking ahead, the demand for high-quality silicone tubes is set to grow, driven by increased applications in various sectors. International buyers are encouraged to engage proactively with suppliers, fostering collaborations that not only fulfill immediate needs but also anticipate future trends. By doing so, you can secure a competitive edge and ensure your operations remain robust and resilient in an ever-changing global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.