Shipment Pallet Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for shipment pallet

Navigating the complexities of sourcing shipment pallets can be a daunting challenge for international B2B buyers, particularly when considering the diverse needs across regions like Africa, South America, the Middle East, and Europe. With a myriad of pallet types available—ranging from standard wood to durable plastic—choosing the right option is essential for ensuring safe and efficient transport of goods. This guide comprehensively covers the various types of pallets, their applications in different industries, and critical factors to consider when selecting suppliers, including vetting processes and cost considerations.

Understanding the nuances of shipment pallets not only enhances your shipping strategy but also mitigates risks associated with product damage and inefficiencies in logistics. By providing actionable insights and best practices, this guide empowers B2B buyers to make informed purchasing decisions, tailored to their specific operational needs. Whether you are in Germany looking for reliable wood pallets or in Brazil assessing the benefits of reusable plastic options, our resource will help you navigate the global market effectively. Through expert analysis and practical recommendations, you can streamline your supply chain, optimize shipping costs, and enhance overall product delivery, driving your business success in today’s competitive landscape.

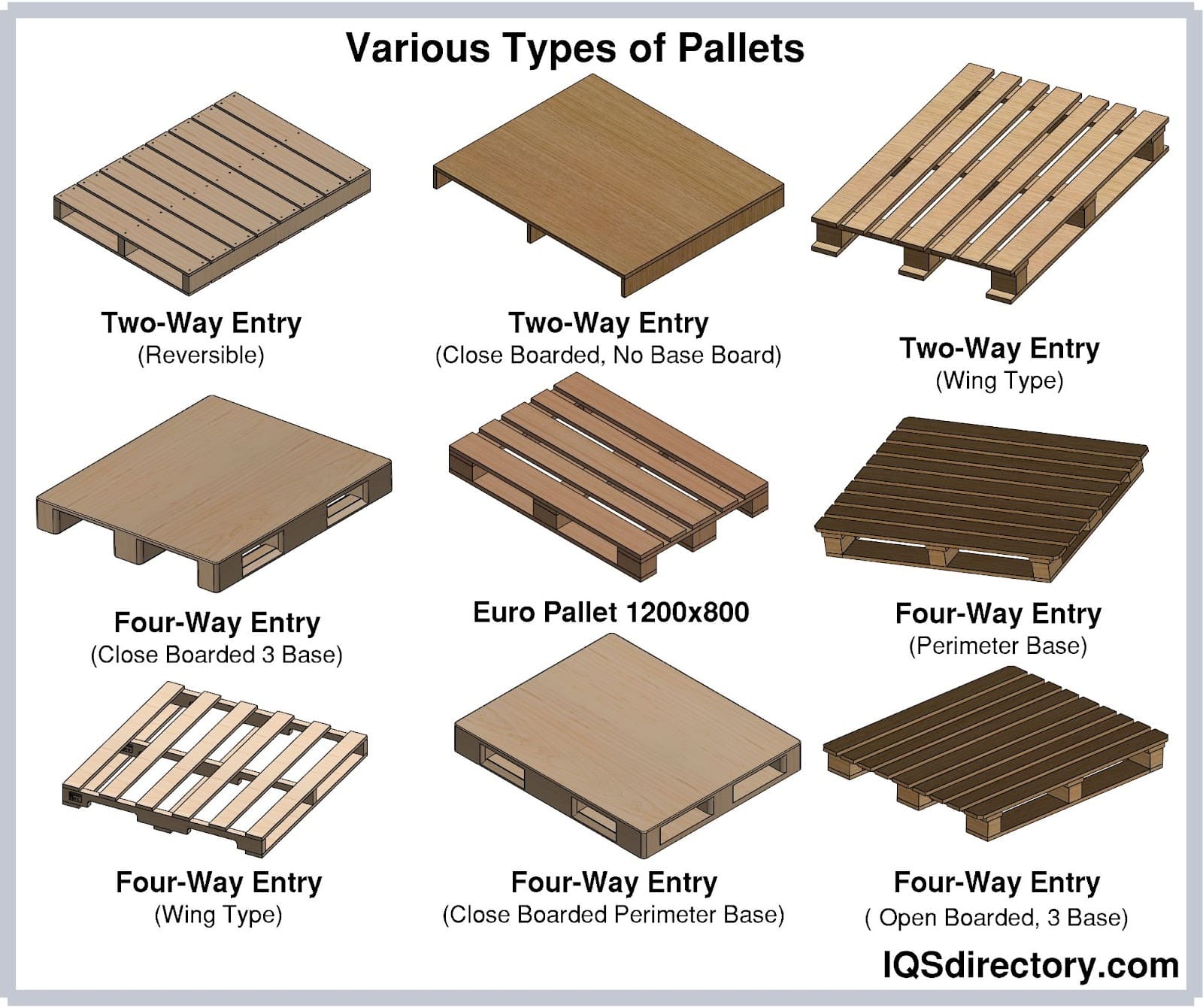

Understanding shipment pallet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Wood Pallets | Typically 40″ x 48″, four-way entry, robust construction | General freight, manufacturing | Pros: Cost-effective, strong, widely available. Cons: Susceptible to moisture and pests. |

| Plastic Pallets | Durable, reusable, often heavier, solid deck options | Pharmaceuticals, food & beverage | Pros: Moisture-resistant, hygienic, reusable. Cons: Higher upfront cost, slippery surface. |

| Corrugated Fiberboard Pallets | Lightweight, made from cardboard, often not reusable | Retail, lightweight products | Pros: Lightweight, cost-effective for low-value items. Cons: Easily damaged, not suitable for heavy loads. |

| Pressed Block Pallets | Made from compressed wood, lightweight, and less durable | Export shipments, light goods | Pros: Lightweight, eco-friendly. Cons: Limited load capacity, less sturdy than wood pallets. |

| Molded Pulp Pallets | Made from recycled paper, biodegradable | Export, agricultural products | Pros: Eco-friendly, lightweight. Cons: Not durable, limited reusability. |

What Are the Characteristics of Standard Wood Pallets?

Standard wood pallets are the most commonly used type in global shipping, typically measuring 40″ x 48″. They feature a four-way entry design, allowing forklifts to access them from any side, which enhances efficiency during loading and unloading. These pallets are suitable for a wide range of applications, including general freight and manufacturing. When purchasing, buyers should consider their strength and durability, as wood pallets can be affected by moisture and pests, making new pallets a better choice over repaired ones.

How Do Plastic Pallets Differ from Wood Pallets?

Plastic pallets are known for their durability and reusability, often designed with solid decks to protect the load from damage during transport. They are commonly used in industries such as pharmaceuticals and food & beverage, where hygiene is paramount. While they offer advantages like moisture resistance and long-term cost savings through reusability, buyers must weigh the higher initial investment against these benefits. Additionally, some plastic pallets may have slippery surfaces, complicating load securing.

What Are the Applications of Corrugated Fiberboard Pallets?

Corrugated fiberboard pallets are lightweight and made from cardboard, making them a cost-effective solution for shipping lightweight products, particularly in retail environments. However, they are not suitable for heavy loads due to their susceptibility to damage and moisture. B2B buyers should consider these factors when determining whether to use corrugated pallets, especially for products that require sturdier support during transit.

What Are the Pros and Cons of Pressed Block Pallets?

Pressed block pallets are constructed from compressed wood and are designed for lightweight applications, often used in export shipments. They are eco-friendly and offer a lighter alternative to traditional wood pallets. However, their load capacity is limited compared to standard wood pallets, which may not meet the requirements for heavier shipments. Buyers should evaluate their specific shipping needs to determine if pressed block pallets are a suitable option.

Why Consider Molded Pulp Pallets for Your Shipping Needs?

Molded pulp pallets are made from recycled paper, making them a biodegradable and eco-friendly choice for shipping agricultural products and other light goods. While they are lightweight and environmentally friendly, they lack durability and are often not reusable. B2B buyers focused on sustainability may find molded pulp pallets appealing, but they should also consider the potential downsides regarding load capacity and longevity.

Key Industrial Applications of shipment pallet

| Industry/Sector | Specific Application of Shipment Pallet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting bulk food items and beverages | Ensures safe and efficient handling, reducing spoilage and damage during transit | Compliance with food safety standards, material durability, and reusability |

| Pharmaceuticals | Shipping medical supplies and pharmaceuticals | Protects sensitive products from damage and contamination, ensuring timely delivery | Temperature control, material certifications, and load stability |

| Automotive | Moving auto parts and components | Facilitates organized logistics, reducing inventory costs and improving supply chain efficiency | Load capacity, strength, and compatibility with handling equipment |

| Retail | Distribution of consumer goods to stores | Enhances inventory management and speeds up the replenishment process | Standardization of pallet sizes, load stability, and ease of handling |

| Construction | Transporting building materials | Reduces waste and damage, improving project timelines and cost efficiency | Weight capacity, weather resistance, and stackability for storage |

How Are Shipment Pallets Used in the Food and Beverage Industry?

In the food and beverage sector, shipment pallets are essential for transporting bulk items like grains, canned goods, and beverages. They provide a stable base that minimizes product movement and spoilage during transit. Buyers in this industry must prioritize pallets that meet food safety standards, ensuring they are made from non-toxic materials and are easy to clean. Additionally, selecting reusable pallets can help reduce long-term costs and environmental impact.

Illustrative image related to shipment pallet

What Role Do Shipment Pallets Play in Pharmaceuticals?

In the pharmaceutical industry, shipment pallets are crucial for moving sensitive medical supplies and medications. These pallets help maintain the integrity of products by protecting them from contamination and physical damage during transport. Buyers should look for pallets that offer temperature control features and are certified for use with pharmaceuticals. Ensuring load stability is also vital to prevent product loss and maintain compliance with regulatory requirements.

How Are Shipment Pallets Utilized in the Automotive Sector?

Automotive manufacturers rely on shipment pallets to transport auto parts and components efficiently. These pallets facilitate organized logistics, reducing the risk of inventory shortages and streamlining the supply chain. When sourcing pallets for this application, businesses should focus on load capacity and strength to accommodate heavy parts. Compatibility with standard handling equipment is also essential to enhance operational efficiency.

What Benefits Do Shipment Pallets Provide to the Retail Industry?

In retail, shipment pallets are used to distribute consumer goods to stores, enabling effective inventory management. They help speed up the replenishment process by allowing for quick loading and unloading. Retail buyers need to consider the standardization of pallet sizes for compatibility with existing logistics systems. Ensuring load stability and ease of handling can significantly enhance supply chain operations and reduce labor costs.

Why Are Shipment Pallets Important in the Construction Industry?

For the construction sector, shipment pallets are vital for transporting building materials such as lumber, bricks, and tools. They minimize waste and damage, contributing to more efficient project timelines and overall cost savings. Buyers should prioritize pallets that can withstand heavy loads and varying weather conditions. Additionally, stackability is an important factor, as it allows for efficient storage and transport of materials on-site.

Illustrative image related to shipment pallet

3 Common User Pain Points for ‘shipment pallet’ & Their Solutions

Scenario 1: Inadequate Load Stability During Transit

The Problem: International B2B buyers often face significant challenges when shipping goods on pallets, particularly regarding load stability. When products are not securely loaded onto the pallet, they can shift during transit, leading to damage or loss. This issue is especially prevalent when shipping heavy or irregularly shaped items, as improper stacking methods can increase the risk of toppling and product damage. Buyers may also struggle with understanding the best practices for pallet loading, which can vary based on the type of goods being shipped.

The Solution: To ensure load stability, buyers should implement proven stacking methods such as column stacking or interlocking stacking. Column stacking involves placing boxes directly on top of each other in straight columns, which maximizes compression strength. For items that are rigid, interlocking cartons can enhance stability by stacking boxes corner to corner. Additionally, using load protectors between tiers can help maintain stability. Buyers should also invest in quality pallets that provide adequate support for the load’s weight and shape. Regular training sessions for warehouse staff on effective loading techniques can further mitigate risks associated with load shifting.

Scenario 2: Choosing the Right Type of Pallet for Specific Goods

The Problem: Many B2B buyers struggle with selecting the appropriate type of pallet for their shipments. With various options available—such as wood, plastic, and corrugated fiberboard—buyers may be unsure which material best suits their shipping needs. This indecision can lead to using inadequate pallets that may not withstand the rigors of shipping, potentially causing product damage or increasing shipping costs due to delays and re-shipments.

The Solution: To select the right pallet, buyers should first assess the nature of the goods being shipped. For heavy and bulky items, standard wood pallets are often the best choice due to their strength and durability. Conversely, for lighter goods or when hygiene is a concern, plastic pallets may be more appropriate, as they are reusable and resistant to moisture. Buyers should also consider the environmental conditions their pallets will face during transport, such as humidity or temperature fluctuations. Collaborating with suppliers who can provide insights into the best pallet options for specific product types and shipping conditions can significantly enhance shipping reliability and efficiency.

Scenario 3: Compliance with International Shipping Regulations

The Problem: Navigating international shipping regulations can be a daunting task for B2B buyers, particularly when it comes to pallet compliance. Different countries have specific requirements regarding the materials and treatment of pallets, especially concerning pest control and environmental standards. Failing to comply with these regulations can result in customs delays, fines, or even rejected shipments, which can severely impact business operations and customer satisfaction.

Illustrative image related to shipment pallet

The Solution: To ensure compliance with international shipping regulations, buyers should familiarize themselves with the ISPM 15 standard, which governs the treatment of wood packaging materials. This includes using heat-treated or fumigated wood pallets that are stamped with the appropriate certification mark. Working closely with logistics partners who have expertise in international shipping can provide buyers with the necessary guidance to ensure that their pallets meet regulatory requirements. Additionally, considering alternatives like plastic pallets can simplify compliance, as they are generally accepted in most countries without specific treatment requirements. Regularly reviewing and updating knowledge on international shipping standards will empower buyers to make informed decisions, minimizing the risk of compliance issues.

Strategic Material Selection Guide for shipment pallet

What are the Key Properties of Wood Pallets for Shipment?

Wood pallets are the most commonly used type of pallet in global shipping due to their robust properties. Typically made from hardwood or softwood, these pallets can support significant weight, making them suitable for a wide range of products. They are generally rated for temperature variations and can withstand pressure from stacking. However, wood pallets are susceptible to moisture, which can lead to warping or mold growth if not treated properly.

Pros and Cons of Wood Pallets

The primary advantage of wood pallets lies in their strength and durability, allowing them to carry heavy loads without significant deformation. They are also relatively inexpensive compared to other materials. However, wood pallets can be less durable over time, especially in humid environments, and may require treatment to meet international shipping standards, such as ISPM 15 for pest control. This can add to the manufacturing complexity and compliance costs.

Impact on Application

Wood pallets are compatible with a variety of products, including food and pharmaceuticals, provided they meet hygiene standards. International buyers should ensure that the wood is treated to prevent pest infestations, which is crucial for compliance with regulations in many regions.

How Do Plastic Pallets Compare for Shipment Use?

Plastic pallets are increasingly popular due to their lightweight and reusable nature. Made from high-density polyethylene (HDPE) or polypropylene, these pallets offer excellent resistance to moisture, chemicals, and temperature fluctuations, making them ideal for diverse shipping environments.

Pros and Cons of Plastic Pallets

The primary advantage of plastic pallets is their durability and longevity, as they do not splinter or absorb moisture. They are easy to clean and can be sterilized, making them suitable for industries like food and pharmaceuticals. However, plastic pallets tend to have a higher upfront cost compared to wood, which can be a limiting factor for budget-conscious companies. Additionally, they may not be as strong as wood pallets for extremely heavy loads.

Impact on Application

Plastic pallets are compatible with a wide range of media, including liquids and sensitive products. International buyers should check for compliance with local regulations regarding material safety and recycling, as some regions may have specific guidelines for plastic use.

What Advantages Do Corrugated Fiberboard Pallets Offer?

Corrugated fiberboard pallets are lightweight and made from recycled materials, making them an environmentally friendly option. They are primarily used for lightweight products and are often employed in retail and e-commerce shipping.

Illustrative image related to shipment pallet

Pros and Cons of Corrugated Fiberboard Pallets

The key advantage of corrugated fiberboard pallets is their low cost and lightweight nature, which can significantly reduce shipping costs. However, they are not as durable as wood or plastic options and are highly susceptible to moisture damage, making them unsuitable for long-distance shipping or heavy loads.

Impact on Application

These pallets are best suited for applications where weight is a concern, and products are not exposed to moisture. B2B buyers should consider the likelihood of exposure to environmental factors during transit, especially in regions with high humidity.

What Are the Considerations for Pressed Block-Style Pallets?

Pressed block-style pallets are made from compressed wood fibers, offering a lightweight alternative to traditional wood pallets. They are often used for lighter loads and in industries where cost is a primary concern.

Pros and Cons of Pressed Block-Style Pallets

The main advantage of pressed block-style pallets is their cost-effectiveness and lightweight design. However, they generally lack the strength and durability of solid wood pallets, making them less suitable for heavy or high-value products. Their manufacturing process can also lead to variability in quality.

Illustrative image related to shipment pallet

Impact on Application

These pallets are more appropriate for low-weight applications and should be used with caution in international shipping where compliance with strength standards is critical. Buyers should ensure that these pallets meet the necessary specifications for their products and shipping routes.

Summary of Material Selection for Shipment Pallets

| Material | Typical Use Case for shipment pallet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood Pallets | General freight, heavy loads | High strength and durability | Susceptible to moisture and pests | Medium |

| Plastic Pallets | Food, pharmaceuticals, chemicals | Moisture and chemical resistance | Higher initial cost | High |

| Corrugated Fiberboard Pallets | Retail, e-commerce shipping | Lightweight and cost-effective | Easily damaged by moisture | Low |

| Pressed Block-Style Pallets | Lightweight applications | Cost-effective and lightweight | Lacks strength for heavy loads | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for shipment pallet

What Are the Key Manufacturing Processes for Shipment Pallets?

The manufacturing of shipment pallets involves several critical stages that ensure the final product meets the necessary strength and durability standards required for effective logistics. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Shipment Pallet Production?

The first step in pallet manufacturing is material preparation. Common materials used include wood, plastic, and metal. For wooden pallets, raw lumber is sourced, often from sustainable forests, and then cut into specific dimensions. The wood is then dried to a controlled moisture content to prevent warping and ensure stability. For plastic pallets, resins are processed and molded into the desired shapes. Metal pallets often require cutting, bending, and welding processes to achieve the final design.

What Forming Techniques Are Utilized in Pallet Manufacturing?

Forming techniques vary depending on the material used. For wood pallets, the most common technique is assembly through nail or screw fastening, where the cut pieces are joined to form the pallet structure. In the case of plastic pallets, injection molding or thermoforming is used to create a single piece or multiple components that are later assembled. Metal pallets may use welding or rivet fastening to ensure a strong, durable construction. Each method is selected based on the desired load capacity and environmental conditions the pallet will face during shipment.

How Are Shipment Pallets Assembled?

Once the components are formed, assembly takes place. This step is crucial, as it determines the structural integrity of the pallet. For wooden pallets, components are often assembled using automated machinery that ensures precise and consistent fastening. In the case of plastic and metal pallets, assembly may involve additional steps such as reinforcing joints or adding features like corner blocks for added strength. Quality control checks are typically integrated into the assembly line to ensure each pallet meets the required specifications.

Illustrative image related to shipment pallet

What Finishing Processes Are Applied to Shipment Pallets?

The finishing process involves treatments that enhance the pallets’ durability and appearance. For wood pallets, this may include sanding, staining, or applying protective coatings to prevent moisture absorption and pest infestation. Plastic pallets may undergo surface treatment to improve grip and reduce slippage. Metal pallets often receive a coating to prevent rust and corrosion. These finishing touches not only improve the aesthetics of the pallets but also extend their operational lifespan.

What Quality Assurance Measures Are Essential for Shipment Pallets?

Quality assurance (QA) is critical in ensuring that shipment pallets meet international standards and specific customer requirements. This involves adherence to various international and industry-specific standards, such as ISO 9001, which outlines best practices for quality management systems.

How Do International Standards Impact Quality Control for Shipment Pallets?

International standards play a significant role in the manufacturing and quality assurance processes for shipment pallets. For instance, ISO 9001 ensures that manufacturers have a systematic approach to managing their processes and improving quality. Compliance with such standards is often a requirement for B2B buyers, particularly in regions like Europe, where regulations may be more stringent.

Illustrative image related to shipment pallet

In addition to ISO standards, other certifications may be relevant depending on the market. For example, CE marking is crucial for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards. Suppliers may also seek certification from bodies like the American Pallet Association (APA) or the International Plant Protection Convention (IPPC) to demonstrate adherence to industry-specific guidelines.

What Are the Key Quality Control Checkpoints in Pallet Manufacturing?

Quality control checkpoints are integral to maintaining the integrity of shipment pallets. These checkpoints typically include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): During manufacturing, various parameters such as dimensions, weight capacity, and structural integrity are monitored. This ensures that any deviations are caught early in the production process.

- Final Quality Control (FQC): After assembly and finishing, pallets undergo a final inspection to verify that they meet all specifications and standards before they are shipped to customers.

What Common Testing Methods Are Used to Ensure Pallet Quality?

Several testing methods are employed to ensure the quality of shipment pallets. These may include:

- Load Testing: Assessing the maximum weight the pallet can safely carry without deformation.

- Moisture Content Testing: Ensuring wood pallets have an appropriate moisture level to prevent warping or mold growth.

- Durability Testing: Subjecting pallets to various environmental conditions (e.g., temperature fluctuations, humidity) to assess their resilience.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are some actionable strategies:

- Supplier Audits: Conducting regular audits of suppliers can help ensure compliance with quality standards. Audits can be performed by the buyer or third-party agencies to provide an unbiased assessment of the supplier’s processes.

- Requesting Quality Reports: Suppliers should provide documentation outlining their quality control measures, including inspection reports and testing results. This transparency helps buyers understand the quality assurance practices in place.

- Third-Party Inspections: Engaging third-party inspection services can provide an additional layer of assurance. These inspections can occur at various stages of the manufacturing process and ensure that the pallets meet the required standards before shipment.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various nuances in quality control. Different regions may have specific requirements regarding certifications and standards. Understanding these local regulations is essential for ensuring compliance and avoiding costly delays or rejections at customs.

Furthermore, cultural differences may influence quality expectations and communication styles. Establishing clear channels of communication and understanding regional practices can facilitate smoother transactions and enhance the buyer-supplier relationship.

Illustrative image related to shipment pallet

In summary, the manufacturing processes and quality assurance measures for shipment pallets are multifaceted and critical to ensuring product integrity during transit. By understanding these processes and actively engaging with suppliers, B2B buyers can make informed decisions that enhance their logistics operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shipment pallet’

Introduction:

This guide serves as a practical checklist for B2B buyers looking to procure shipment pallets effectively. By following these steps, you can ensure that you select the right pallets for your shipping needs, optimizing both cost and reliability while minimizing potential damage during transport.

1. Assess Your Load Requirements

Understanding the specific weight and dimensions of the goods you plan to ship is essential. This assessment will help you determine the type of pallet that can adequately support your products. Consider both the maximum weight and the fragility of the items, as heavier or more delicate goods may require reinforced pallets.

2. Define Your Technical Specifications

Establishing clear technical specifications for the pallets you need is crucial. Consider factors such as material (wood, plastic, etc.), size (e.g., standard 40″ x 48″), and design features (e.g., four-way entry capabilities). These specifications will guide your supplier search and ensure that the pallets meet your operational needs.

3. Evaluate Potential Suppliers

Before committing, vet potential suppliers thoroughly to ensure they can meet your quality and service expectations. Request company profiles, product samples, and references from similar clients. It’s also beneficial to review their certifications to confirm compliance with industry standards and regulations.

4. Analyze Cost vs. Quality

While it may be tempting to choose the cheapest option, consider the balance between cost and quality. High-quality pallets may have a higher upfront cost but can reduce the risk of damage and the need for replacements. Analyze the long-term value, especially if you plan to reuse the pallets.

5. Inquire About Customization Options

Depending on your specific needs, you may require customized pallets. Ask suppliers if they offer customization options, such as specific sizes, branding, or additional reinforcement features. Customization can enhance the protection of your goods and improve handling efficiency.

6. Confirm Delivery and Return Logistics

Understanding the logistics of delivery and potential return processes is vital. Confirm lead times for pallet delivery and whether the supplier offers a return program for reusable pallets. Efficient logistics can save time and reduce costs, particularly in international shipping scenarios.

7. Review and Finalize Your Order

Once you have gathered all necessary information, conduct a final review of your selected supplier and pallet specifications. Ensure that all terms, including pricing, delivery schedules, and return policies, are clearly outlined in your purchase agreement. This step is crucial to avoid misunderstandings and ensure a smooth transaction.

By adhering to this checklist, B2B buyers can streamline their pallet procurement process, ensuring that they select the right products that meet their shipping requirements effectively.

Comprehensive Cost and Pricing Analysis for shipment pallet Sourcing

What Are the Key Cost Components for Sourcing Shipment Pallets?

When sourcing shipment pallets, it’s crucial to understand the various cost components that contribute to the final price. The primary elements include:

Illustrative image related to shipment pallet

-

Materials: The choice of materials significantly impacts costs. Wooden pallets are typically more cost-effective compared to plastic or metal options. However, plastic pallets offer durability and reusability, which can justify their higher initial cost over time.

-

Labor: Labor costs vary by region and the complexity of the pallet design. In areas with higher wage standards, such as Germany, labor costs may be a significant portion of the overall expenses. Additionally, skilled labor may be required for custom designs or high-quality production.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, equipment maintenance, and facility management. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Custom pallets may require specialized tooling, which can add to the upfront costs. For standard pallets, tooling costs are generally amortized over larger production runs, making them less impactful on unit pricing.

-

Quality Control (QC): Implementing a robust QC process is essential, particularly for high-value shipments. This may involve additional inspection costs, which can affect the overall price of the pallets.

-

Logistics: The cost of transporting pallets to the buyer’s location can vary widely based on distance, shipping method, and volume. International shipments may incur additional tariffs or fees, impacting total costs.

-

Margin: Supplier profit margins can vary based on market competition and the perceived value of the pallets. Understanding the margin expectations of suppliers can help in negotiations.

What Factors Influence the Pricing of Shipment Pallets?

Several factors can influence the pricing of shipment pallets, especially for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities typically reduces the per-unit cost. Suppliers may offer discounts for bulk orders, which can be a key negotiation point.

-

Specifications and Customization: Custom pallets designed to meet specific requirements often come at a premium. Understanding the necessary specifications upfront can help avoid unnecessary costs.

-

Materials: As mentioned, the choice of materials plays a crucial role. Buyers should assess the balance between cost and quality based on their shipping needs.

-

Quality and Certifications: Pallets that meet industry standards or certifications (such as ISPM 15 for wood pallets) may be priced higher. These certifications can be essential for international shipments, especially to regions with strict import regulations.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more for their experience and quality assurance.

-

Incoterms: Understanding the terms of sale (Incoterms) is vital for determining who bears the costs and risks during transit. This can significantly affect the overall price.

How Can Buyers Optimize Costs in Shipment Pallet Sourcing?

Buyers can implement several strategies to enhance cost efficiency when sourcing shipment pallets:

-

Negotiation: Don’t hesitate to negotiate prices, especially for larger orders. Leverage competitive quotes from multiple suppliers to achieve better terms.

-

Total Cost of Ownership (TCO): Consider the long-term costs associated with pallets, including durability, reusability, and maintenance. A higher upfront investment may yield savings over time.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa or South America, be aware of local market conditions, currency fluctuations, and shipping costs. Establishing relationships with suppliers familiar with international logistics can be beneficial.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Suppliers may offer favorable terms or early access to new products for loyal customers.

Conclusion

Understanding the cost structure and pricing factors related to shipment pallets is essential for international B2B buyers. By carefully evaluating materials, labor, and other cost components, as well as leveraging negotiation strategies and understanding market dynamics, businesses can optimize their sourcing decisions. Keep in mind that prices can fluctuate based on various factors, so always seek the most current quotes and be open to exploring multiple suppliers.

Alternatives Analysis: Comparing shipment pallet With Other Solutions

Exploring Alternative Solutions for Shipment Pallets

When considering the logistics of transporting goods, shipment pallets are a widely recognized option due to their versatility and efficiency. However, there are several alternatives worth exploring, each with its unique advantages and disadvantages. This analysis compares shipment pallets against two viable alternatives: freight boxes and bulk shipping methods. Understanding these options can help B2B buyers make informed decisions tailored to their specific shipping needs.

| Comparison Aspect | Shipment Pallet | Freight Boxes | Bulk Shipping |

|---|---|---|---|

| Performance | High stability and weight capacity | Moderate stability, designed for smaller loads | Excellent for large volumes |

| Cost | Moderate (dependent on material type) | Generally lower for small shipments | Lower per unit for high volumes |

| Ease of Implementation | Requires specific handling equipment | Easy to pack and handle manually | Requires specialized equipment |

| Maintenance | Durable but may require repair/replacement | Minimal maintenance needed | Minimal maintenance required |

| Best Use Case | Heavy and bulk items, long-distance shipping | Small to medium-sized items, domestic shipping | Large quantities, direct shipments |

In-Depth Analysis of Alternatives

What Are Freight Boxes and How Do They Compare?

Freight boxes are a popular alternative for shipping smaller items. They are typically made from cardboard or plastic and are designed for easy packing and handling. The primary advantage of freight boxes is their lower cost, particularly for smaller shipments, making them an economical choice for businesses looking to reduce shipping expenses. Additionally, freight boxes are lightweight, which can lower shipping costs further. However, they may not provide the same level of stability as pallets, especially for heavier or bulk items, and can be susceptible to damage if not packed carefully.

What Is Bulk Shipping and When Should It Be Used?

Bulk shipping refers to the transportation of large quantities of goods without packaging, often using containers or tankers. This method is ideal for commodities like grains, liquids, or other bulk materials. The main advantage of bulk shipping is its cost-effectiveness for high-volume shipments, as it significantly reduces per-unit transportation costs. However, it requires specialized equipment and infrastructure, such as bulk carriers, which may not be readily available for all businesses. Additionally, the handling of bulk goods can be less flexible compared to palletized shipments, which can be an important consideration for businesses with varied product sizes.

How to Choose the Right Shipping Solution for Your Business

When selecting the most suitable shipping solution, B2B buyers should carefully evaluate their specific needs, including the type and volume of goods, budget constraints, and the shipping distance. Shipment pallets may be the best option for heavy or irregularly shaped items that require stability during transport. On the other hand, freight boxes could be more advantageous for lighter, smaller shipments, while bulk shipping is ideal for businesses dealing with high volumes of homogeneous products. By considering these factors, businesses can enhance their logistics strategies and optimize their shipping processes, ensuring cost-effectiveness and reliability.

Essential Technical Properties and Trade Terminology for shipment pallet

What Are the Essential Technical Properties of Shipment Pallets?

When selecting shipment pallets, understanding their technical properties is critical for ensuring safe and efficient transportation of goods. Here are key specifications to consider:

1. Material Grade

The material of a pallet significantly influences its strength and durability. Common materials include wood, plastic, and metal. Wood pallets are typically the most cost-effective but may not withstand moisture as well as plastic pallets. For international shipments, consider the material’s compliance with regulations, especially in regions with strict import laws.

2. Load Capacity

This specification indicates the maximum weight a pallet can safely carry. It is essential to choose a pallet with a load capacity that exceeds the weight of the products being shipped. Overloading can lead to pallet failure, resulting in product damage and financial loss.

Illustrative image related to shipment pallet

3. Dimensions

Pallet dimensions are standardized, with the most common size being 40″ x 48″. However, specific industries or regions may have unique size requirements. Understanding the dimensions is vital for optimizing storage space and ensuring compatibility with handling equipment like forklifts.

4. Stiffness and Structural Integrity

Stiffness refers to the pallet’s ability to resist bending and deformation under load. Pallets with higher stiffness ratings maintain their shape, protecting the integrity of the load during transportation. This is particularly important for fragile goods or those that are stacked high.

5. Durability and Environmental Resistance

Durability encompasses how well a pallet can withstand the rigors of shipping, including moisture, temperature fluctuations, and physical stress. Selecting pallets with high durability ratings helps ensure that they can be reused multiple times, reducing overall costs.

What Are Common Trade Terms Associated with Shipment Pallets?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B space. Here are several key terms related to shipment pallets:

Illustrative image related to shipment pallet

1. OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pallets, an OEM might supply pallets to a logistics company or a manufacturer needing standardized shipping solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For pallets, this term is significant for businesses looking to manage inventory costs while ensuring they meet shipment needs without over-purchasing.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers asking for pricing and terms for a specific quantity of goods. In the context of pallets, submitting an RFQ can help businesses compare costs and specifications from different suppliers before making purchasing decisions.

Illustrative image related to shipment pallet

4. Incoterms (International Commercial Terms)

These are a set of pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms can help businesses navigate shipping logistics and responsibilities concerning palletized goods.

5. Pallet Jack

A pallet jack is a manual or powered device used to lift and move pallets. Familiarity with this term is essential for logistics operations, as the choice of equipment can impact the efficiency of loading and unloading processes.

By grasping these essential properties and trade terminologies, international B2B buyers can make informed decisions regarding shipment pallets, optimizing their shipping strategies and ensuring the safe transport of their goods.

Navigating Market Dynamics and Sourcing Trends in the shipment pallet Sector

What Are the Current Market Dynamics and Key Trends in the Shipment Pallet Sector?

The shipment pallet sector is experiencing significant transformation driven by globalization, e-commerce growth, and increasing demand for efficient logistics solutions. Key drivers include the rise of international trade, which has led to a surge in cross-border shipping activities, particularly in emerging markets such as Africa and South America. As these regions enhance their infrastructure and logistics capabilities, international B2B buyers are presented with lucrative opportunities to optimize their supply chains through improved pallet solutions.

Technological advancements are also reshaping sourcing trends. The integration of IoT (Internet of Things) in logistics is enabling better tracking and management of shipments, leading to enhanced visibility and efficiency. Moreover, automation in warehousing and pallet handling is becoming more prevalent, reducing labor costs and increasing throughput. Companies are increasingly opting for reusable and durable pallet options, such as plastic pallets, which offer long-term cost benefits and align with sustainability goals.

Additionally, shifts in consumer preferences towards faster delivery options are influencing pallet design and selection. As businesses adapt to these demands, they are prioritizing pallets that facilitate quick loading and unloading processes. This is especially critical for international buyers from regions like Europe, where efficiency in logistics can significantly impact market competitiveness.

How Is Sustainability and Ethical Sourcing Impacting the Shipment Pallet Sector?

Sustainability has emerged as a central concern in the shipment pallet sector, particularly for international B2B buyers who are increasingly aware of their environmental impact. The production and disposal of pallets can contribute to significant waste, especially with traditional wooden pallets that may not be reused or recycled effectively. This has led to a growing demand for eco-friendly alternatives, such as pallets made from recycled plastics or sustainably sourced wood.

Ethical sourcing practices are gaining traction, as businesses recognize the importance of maintaining transparent supply chains. Buyers are seeking suppliers who can provide assurance of ethical labor practices and responsible sourcing methods. Certifications such as FSC (Forest Stewardship Council) for wood pallets or recycling certifications for plastic pallets are becoming essential criteria in procurement decisions.

Furthermore, companies are encouraged to adopt life cycle assessments (LCAs) to evaluate the environmental impact of their pallet choices throughout the supply chain. By selecting pallets that minimize carbon footprints and promote circular economy principles, businesses can not only enhance their brand reputation but also meet regulatory requirements and consumer expectations for sustainability.

Illustrative image related to shipment pallet

What Is the Brief Evolution and History of the Shipment Pallet Sector?

The shipment pallet sector has evolved significantly since its inception in the early 20th century. Initially, pallets were simple wooden structures designed primarily for storage and manual handling. However, the post-World War II economic boom and the rise of the global trade network catalyzed the development of standardized pallet sizes and designs, enhancing compatibility across various transportation methods.

By the 1980s, the introduction of plastic and composite materials began to revolutionize the pallet industry, offering alternatives that were more durable and resistant to environmental factors. This diversification allowed businesses to choose pallets based on specific needs, such as hygiene standards in food and pharmaceutical industries.

Today, the shipment pallet sector continues to innovate, driven by advancements in technology and a growing emphasis on sustainability. As businesses adapt to ever-changing market demands, the evolution of pallets reflects broader trends in logistics and supply chain management, emphasizing efficiency, safety, and environmental responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of shipment pallet

-

How do I select the right pallet type for my shipment?

Choosing the right pallet type depends on several factors including the weight of your cargo, the shipping environment, and whether you require reuse. Standard wood pallets are cost-effective and suitable for most shipments, while plastic pallets offer durability and are reusable but come at a higher cost. Consider the load’s dimensions, stacking methods, and the required strength. Ensure your chosen pallet complies with international shipping standards to avoid delays or damage during transit. -

What are the key features to look for in a quality shipment pallet?

When sourcing pallets, prioritize strength, stiffness, and durability. A strong pallet can support the weight of your cargo without bending or breaking. Look for pallets that are constructed with high-quality materials, have adequate top board spacing, and are designed for four-way entry to facilitate easy handling. Additionally, consider the price in relation to the quality and whether you’ll need to reuse the pallets for future shipments. -

What is the minimum order quantity (MOQ) for shipment pallets?

MOQs for shipment pallets can vary widely depending on the supplier and the type of pallet. Generally, for standard wood pallets, MOQs might range from 50 to 200 units, while plastic pallets could require higher MOQs due to their cost. Always discuss your specific needs with potential suppliers to negotiate a suitable MOQ that aligns with your shipping volume and budget. -

How can I ensure the quality of the pallets I am purchasing?

To ensure the quality of your pallets, conduct thorough supplier vetting. Request samples before placing a large order and check for certifications like ISPM 15 for wood pallets to ensure they meet international shipping standards. Additionally, consider visiting the manufacturing facility or requesting third-party quality inspections to verify the production processes and materials used. -

What are common payment terms when sourcing pallets internationally?

Payment terms can vary based on the supplier and your negotiating power. Common options include advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60 days). It’s essential to clarify these terms in advance to avoid cash flow issues. Ensure you also understand any additional fees related to shipping, customs, and taxes, particularly for international transactions. -

How do I handle logistics for shipping pallets internationally?

Effective logistics management for international pallet shipments involves selecting the right freight forwarder who understands your destination’s regulations and requirements. Consider the mode of transport—air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Always factor in lead times for customs clearance and the potential for delays. Collaborate closely with your logistics partner to ensure compliance with import/export regulations. -

What should I consider when customizing pallets for my products?

Customizing pallets can enhance protection and efficiency but requires careful planning. Consider the dimensions and weight of your products to determine the appropriate pallet size and design. Discuss any specific needs with your supplier, such as special materials or unique features like reinforced edges for added durability. Custom pallets may involve higher costs, so weigh the benefits against your budget and shipping frequency. -

How can I secure my load on a pallet during transport?

Securing your load is crucial to prevent damage during transport. Use a combination of methods such as stretch wrap, bands, and load protectors to stabilize and protect your cargo. Ensure that the load does not overhang the pallet edges, which can compromise structural integrity. Additionally, consider using corner boards to reinforce the edges and distribute weight evenly, reducing the risk of shifting during transit.

Top 4 Shipment Pallet Manufacturers & Suppliers List

1. FedEx – Pallet Key Considerations

Domain: fedex.com

Registered: 1991 (34 years)

Introduction: Pallets are portable platforms used for handling, storing, and shipping products. Key considerations when choosing a pallet include: 1. Strength – must support the weight of the load; 2. Stiffness – should resist bending and deforming; 3. Durability – must withstand shipping conditions; 4. Functionality – should conform to industry standards; 5. Price – balance cost and quality. Recommended pallet…

2. FreightQuote – Pallet Shipping Solutions

Domain: freightquote.com

Registered: 1998 (27 years)

Introduction: Standard pallet sizes include: 48″ x 40″, 42″ x 42″, and 48″ x 48″. The most common type is the GMA pallet (48″ x 40″). Pallet shipping is defined as the transportation of goods stacked on pallets, which is cost-effective and offers advantages such as protection, movability, sustainability, standardization, and economical shipping. Common pallet types include: 1. Stringer pallets (two-way or four-…

3. Red Stag Fulfillment – Palletized Shipping Solutions

Domain: redstagfulfillment.com

Registered: 2013 (12 years)

Introduction: Palletized shipping is the practice of stacking boxes or items on a sturdy pallet, securing them with stretch wrap and straps, and moving the entire load as one unit. Key benefits include enhanced protection against damage, operational efficiency, and cost consolidation. The standard pallet size in North America is 48″ x 40″ (GMA pallet) with a typical dynamic load capacity of 2,500 lbs. Other pal…

4. InterWF – Standard Pallet Shipping Sizes

Domain: interwf.com

Registered: 2018 (7 years)

Introduction: Standard pallet shipping sizes are critical for secure and efficient transportation of goods. The most common shipping pallet size in the U.S. is 48″ x 40″ (1,219 mm x 1,016 mm), which is the industry standard for general cargo. Other international pallet sizes may vary based on region and shipping requirements. Proper palletizing involves stacking goods securely, using stretch wrap or straps, and…

Strategic Sourcing Conclusion and Outlook for shipment pallet

How Can Strategic Sourcing Enhance Your Shipment Pallet Choices?

In conclusion, the strategic sourcing of shipment pallets is crucial for optimizing logistics, reducing costs, and ensuring product safety during transit. By carefully evaluating pallet types—such as wood, plastic, or composite options—international B2B buyers can select solutions that not only meet their specific needs but also align with sustainability goals. Key factors like strength, durability, and functionality should guide your decisions, ensuring that the pallets used can withstand the rigors of transportation while protecting your products.

As you navigate the complexities of global trade, consider establishing long-term relationships with reliable suppliers who understand the regional nuances of shipping in Africa, South America, the Middle East, and Europe. Investing in quality pallets may lead to significant savings by minimizing damage and loss during shipping.

Looking ahead, the demand for sustainable and efficient shipping solutions will only grow. Engage with suppliers who prioritize innovation and sustainability, and explore new materials and technologies that can enhance your supply chain. Start optimizing your pallet sourcing strategy today to position your business for future success in an increasingly competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to shipment pallet

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.