Shape Wire: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for shape wire

As global industries evolve, the demand for specialized materials like shaped wire is surging, posing significant sourcing challenges for B2B buyers. Selecting the right shaped wire—whether for aerospace components, medical devices, or industrial applications—requires a deep understanding of product specifications, supplier capabilities, and market trends. This guide serves as an essential resource for international buyers, particularly those from Africa, South America, the Middle East, and Europe, helping them navigate the complexities of sourcing shaped wire products that meet their precise needs.

Within these pages, we delve into the diverse types of shaped wire available, including custom profiles and standard shapes, and explore their multifaceted applications across various industries. Additionally, we provide actionable insights on how to effectively vet suppliers, assess cost structures, and understand the implications of material properties and manufacturing processes. By equipping buyers with critical knowledge and best practices, this guide empowers them to make informed purchasing decisions that not only enhance product quality but also optimize operational efficiency. In a competitive global market, understanding the nuances of shaped wire procurement can be a decisive factor in driving business success.

Understanding shape wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Shaped Wire | Custom cross-sectional profiles tailored to specific applications | Aerospace, Medical Devices, Oil & Gas | Pros: Reduces machining costs; custom solutions. Cons: Higher initial costs; longer lead times. |

| Round Wire | Circular cross-section, available in various alloys | Electrical components, fasteners, springs | Pros: Versatile; widely available. Cons: Limited to round applications; may require additional processing. |

| Flat Wire | Rectangular cross-section, customizable thickness and width | Automotive, construction, electronic applications | Pros: High strength; excellent for tight spaces. Cons: Less common; may have limited suppliers. |

| Square Wire | Equal width and thickness, ideal for specific structural needs | Manufacturing, construction, and industrial applications | Pros: Offers rigidity; easier to handle. Cons: Limited shapes; may require additional machining. |

| Specialty Wire | Unique shapes (e.g., elliptical, triangular) for niche uses | Catheter wires, deployment mechanisms, tooling | Pros: Customizable for specific applications; innovative designs. Cons: Potentially higher costs; longer development times. |

What Are the Key Characteristics of Shaped Wire for B2B Buyers?

Shaped wire is known for its ability to be customized into various cross-sectional profiles, making it suitable for a wide range of applications. This type of wire is particularly advantageous in industries like aerospace and medical devices, where precision and specific shapes can significantly enhance product functionality. B2B buyers should consider the need for reduced machining costs and the potential for custom solutions tailored to their specific requirements.

How Does Round Wire Stand Out in the Market?

Round wire is characterized by its circular cross-section and is available in multiple alloys, making it versatile for various applications such as electrical components and fasteners. It is widely used due to its availability and adaptability. However, buyers should be aware that while round wire is versatile, it may require additional processing to meet specific design needs, which could add to production time and costs.

Why Choose Flat Wire for Your Applications?

Flat wire features a rectangular cross-section and can be customized in terms of thickness and width. This wire is particularly beneficial in automotive and electronic applications where space constraints are a concern. Its strength and adaptability make it a popular choice among B2B buyers. However, it is less commonly available compared to round wire, so sourcing may require more effort.

What Are the Advantages of Using Square Wire?

Square wire offers equal width and thickness, providing rigidity and ease of handling, making it ideal for manufacturing and construction applications. The structure of square wire can simplify assembly processes, but buyers should consider the limited range of shapes available, which may necessitate additional machining for certain applications.

How Can Specialty Wire Enhance Product Design?

Specialty wire encompasses unique shapes such as elliptical and triangular profiles, designed for niche applications like catheter wires and deployment mechanisms. This type of wire allows for innovative designs that can meet specific industry needs. While it offers significant customization benefits, buyers should be prepared for potentially higher costs and longer development times, which may impact project timelines.

Key Industrial Applications of shape wire

| Industry/Sector | Specific Application of shape wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Structural components and heat exchangers | Enhanced weight reduction and improved thermal efficiency | Compliance with aerospace standards and high precision tolerances |

| Medical | Catheter wires and surgical instruments | Increased safety and performance in critical applications | Material biocompatibility and stringent quality assurance |

| Oil & Gas | Filter screens and well screens | Improved filtration efficiency and reduced operational costs | Resistance to corrosion and high-temperature performance |

| Automotive | Wiring harnesses and structural components | Enhanced reliability and reduced weight for better fuel efficiency | Custom shapes to fit specific design requirements |

| Industrial Manufacturing | Tooling and specialized machinery components | Increased production efficiency and reduced machining costs | Availability of high-performance alloys and custom profiles |

How is Shape Wire Utilized in Aerospace Applications?

In the aerospace industry, shape wire is crucial for manufacturing lightweight structural components and heat exchangers. These components benefit from tailored geometries that reduce weight without compromising strength, which is vital for fuel efficiency and performance. Buyers in this sector must ensure that the wire meets stringent aerospace standards for safety and reliability, particularly regarding dimensional tolerances and material properties. Sourcing from reputable suppliers who understand these requirements can significantly enhance the final product’s performance.

What Role Does Shape Wire Play in Medical Devices?

Shape wire is extensively used in medical applications, particularly in the production of catheter wires and surgical instruments. The unique shapes allow for better maneuverability and adaptability within the human body, which is essential for minimally invasive procedures. Buyers need to prioritize biocompatibility and adhere to rigorous quality assurance processes to ensure patient safety. Selecting suppliers with expertise in medical-grade materials and the ability to meet stringent regulatory requirements is crucial for success in this industry.

Why is Shape Wire Important in the Oil & Gas Sector?

In the oil and gas industry, shape wire is utilized for manufacturing filter screens and well screens, which are vital for efficient filtration and resource extraction. The customized shapes enhance the filtration process, leading to lower operational costs and improved productivity. Buyers must consider the wire’s resistance to corrosion and ability to withstand high temperatures, as these factors are critical for equipment longevity. Sourcing from manufacturers with a proven track record in the oil and gas sector can mitigate risks associated with equipment failure.

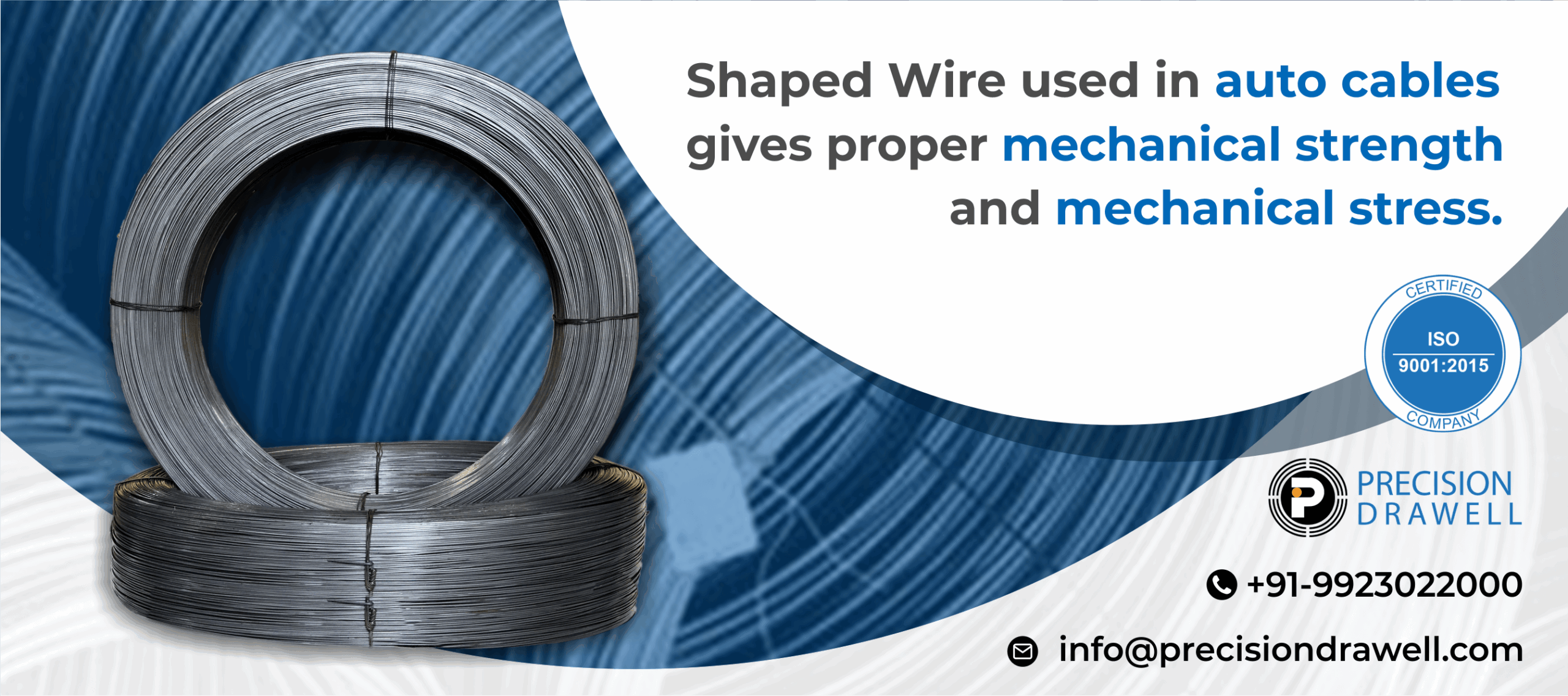

How Does Shape Wire Contribute to Automotive Manufacturing?

Shape wire is increasingly being used in the automotive industry for wiring harnesses and structural components. The ability to create custom shapes helps reduce weight, which directly contributes to better fuel efficiency and vehicle performance. Buyers should focus on sourcing wire that meets specific design requirements and industry standards to ensure reliability. Additionally, understanding the latest trends in automotive technology can provide insights into how shape wire can enhance product development.

What are the Benefits of Shape Wire in Industrial Manufacturing?

In industrial manufacturing, shape wire is employed in tooling and specialized machinery components, where it can significantly enhance production efficiency. By utilizing shaped wire, companies can reduce machining costs and streamline assembly processes. Buyers in this sector should look for suppliers who offer a variety of high-performance alloys and custom profiles tailored to their specific manufacturing needs. This ensures that the shaped wire not only meets technical specifications but also contributes to overall operational efficiency.

3 Common User Pain Points for ‘shape wire’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: A manufacturing company in Brazil experiences frequent issues with the quality of shaped wire received from various suppliers. This inconsistency leads to production delays and increased scrap rates, ultimately affecting the company’s bottom line. The buyer is frustrated by the lack of standardization and the difficulty in finding a reliable supplier who can consistently meet their specifications.

The Solution: To mitigate quality inconsistencies, B2B buyers should establish long-term partnerships with a limited number of reputable suppliers who specialize in shaped wire. Conduct thorough due diligence, including factory audits and quality certifications (such as ISO 9001), to ensure that the supplier maintains rigorous quality control processes. Request samples and perform rigorous testing to validate that the wire meets the required specifications before placing bulk orders. Additionally, buyers should communicate their expectations clearly and work closely with suppliers to develop detailed specifications for each order. This proactive approach not only enhances product quality but also fosters a collaborative relationship that can lead to better pricing and service over time.

Scenario 2: Difficulty in Specifying Custom Shapes

The Problem: An engineering firm in the Middle East is developing a new medical device that requires a unique shaped wire profile. However, the team struggles to convey their design requirements to potential suppliers, leading to misunderstandings and prototypes that do not meet their needs. This situation results in wasted time and resources, jeopardizing project timelines.

Illustrative image related to shape wire

The Solution: To effectively communicate custom shape requirements, B2B buyers should utilize advanced design tools such as CAD software to create detailed 3D models of the desired wire profile. This visual representation can be shared with potential suppliers to facilitate discussions and ensure everyone is on the same page. Additionally, buyers should engage with suppliers who have strong engineering support teams capable of providing insights on manufacturability and material properties. By collaborating early in the design process, buyers can refine their specifications and reduce the likelihood of costly revisions later on. Implementing a prototyping phase can also help verify the design before full-scale production begins, saving time and resources.

Scenario 3: Rising Costs and Supply Chain Disruptions

The Problem: A company in South America faces escalating costs associated with shaped wire, compounded by supply chain disruptions that delay deliveries. As a result, production schedules are thrown off, leading to lost sales and dissatisfied customers. The buyer is concerned about both the immediate financial impact and the long-term viability of their supply chain.

The Solution: To combat rising costs and supply chain issues, buyers should consider diversifying their supplier base to include both local and international manufacturers. This strategy not only mitigates risks associated with over-reliance on a single source but also opens up opportunities for cost negotiation and comparison. Additionally, buyers should explore the use of inventory management systems to optimize stock levels and reduce carrying costs. Establishing just-in-time delivery agreements with suppliers can also help align production schedules with material availability, minimizing downtime. Finally, engaging in strategic long-term contracts with suppliers can lock in pricing and ensure a stable supply of shaped wire, providing a buffer against market fluctuations.

Strategic Material Selection Guide for shape wire

What Are the Key Properties of Stainless Steel for Shape Wire?

Stainless steel is one of the most commonly used materials for shape wire due to its exceptional properties. It offers excellent corrosion resistance, making it suitable for applications in various environments, including those exposed to moisture and chemicals. Stainless steel can withstand high temperatures, which is critical for industries like aerospace and power generation. The material also exhibits good tensile strength, which is essential for maintaining structural integrity under stress.

Pros and Cons: The advantages of stainless steel include its durability and versatility, as it can be used in numerous applications ranging from medical devices to industrial machinery. However, its manufacturing complexity can lead to higher costs, especially for custom shapes. Additionally, while stainless steel is resistant to corrosion, it may not be suitable for highly acidic or alkaline environments without proper alloy selection.

Impact on Application: In applications like heat exchangers or medical devices, the compatibility of stainless steel with various media is crucial. Its non-reactive nature makes it an ideal choice for medical applications, where contamination must be avoided.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM and DIN when selecting stainless steel grades. Understanding local market preferences can also aid in choosing the right alloy for specific applications.

Illustrative image related to shape wire

How Does Nitinol Shape Wire Perform in Specialized Applications?

Nitinol, a nickel-titanium alloy, is renowned for its unique properties, particularly its shape memory and superelastic capabilities. This material can return to its original shape after deformation, making it ideal for applications that require flexibility and resilience, such as in medical devices like stents and guidewires.

Pros and Cons: The key advantage of Nitinol is its ability to perform in challenging conditions while maintaining its structural integrity. However, it can be more expensive than traditional metals and may require specialized manufacturing processes, which could increase lead times and costs.

Impact on Application: Nitinol’s compatibility with bodily fluids and its biocompatibility make it a preferred choice for medical applications. However, its unique properties necessitate careful consideration of design and manufacturing processes to ensure optimal performance.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of specific medical device regulations and standards, such as ISO 13485, that govern the use of Nitinol in healthcare applications.

What Advantages Does Titanium Offer for Shape Wire Applications?

Titanium is another high-performance material used in shape wire production, particularly valued for its strength-to-weight ratio and corrosion resistance. It is capable of withstanding extreme temperatures and is often used in aerospace and marine applications.

Pros and Cons: The primary advantage of titanium is its lightweight nature combined with high strength, making it ideal for applications where weight savings are critical. However, titanium is one of the more expensive materials available, and its machining can be complex, requiring specialized tools and techniques.

Impact on Application: In aerospace applications, titanium’s ability to withstand high-stress environments while remaining lightweight is invaluable. However, it may not be the best choice for applications requiring extensive bending or shaping due to its rigidity.

Considerations for International Buyers: Buyers should be cognizant of the specific standards and certifications required for titanium products in their respective industries. Compliance with ASTM and other international standards is crucial for ensuring product quality and performance.

What Role Does Alloyed Steel Play in the Shape Wire Market?

Alloyed steel, which combines carbon steel with other elements to enhance its properties, is frequently used in shape wire applications. The alloying elements can improve tensile strength, ductility, and resistance to wear and corrosion.

Pros and Cons: Alloyed steel offers a balance between performance and cost, making it a popular choice for a variety of applications. However, the specific properties can vary significantly based on the alloy composition, which may complicate material selection.

Impact on Application: Alloyed steel is suitable for applications requiring high strength and durability, such as automotive components. However, its performance in corrosive environments may not match that of stainless steel or titanium.

Considerations for International Buyers: Buyers should familiarize themselves with the specific alloy grades and their properties to ensure compliance with local standards and industry requirements.

| Material | Typical Use Case for shape wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical devices, industrial applications | Excellent corrosion resistance | Higher manufacturing complexity | Medium |

| Nitinol | Medical guidewires, stents | Shape memory properties | Expensive and complex to manufacture | High |

| Titanium | Aerospace, marine applications | High strength-to-weight ratio | High cost and machining complexity | High |

| Alloyed Steel | Automotive components | Good balance of performance and cost | Variable properties based on alloy | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for shape wire

What Are the Main Stages in the Manufacturing Process of Shaped Wire?

The manufacturing process of shaped wire involves several critical stages, each requiring specialized techniques and equipment to ensure precision and quality.

Material Preparation

The initial phase of manufacturing shaped wire begins with the selection of raw materials, which typically includes various alloys such as stainless steel, titanium, or specialty metals like Nitinol. The chosen material is sourced from reputable suppliers, and quality checks are conducted on incoming materials to ensure they meet the necessary specifications.

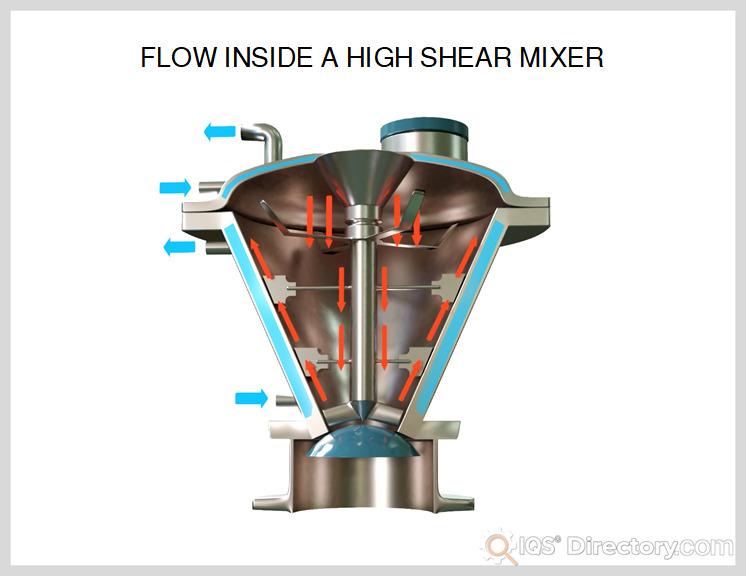

Illustrative image related to shape wire

After material selection, the wire is drawn down to the required diameter through a series of dies. This drawing process is crucial for achieving the desired mechanical properties and surface finish. The wire may undergo intermediate annealing, which involves heating and cooling to relieve stresses and enhance ductility before further processing.

Forming Techniques: How Is Shaped Wire Created?

Once the material is prepared, the actual shaping process begins. This is where advanced forming techniques come into play.

-

Rolling: Shaped wire is often produced through rolling techniques, where the wire passes through rollers that gradually form it into the desired shape. This method allows for high precision and consistency, particularly for profiles that require tight tolerances.

-

Extrusion: For certain shapes, extrusion may be used, where the material is forced through a die to create continuous lengths of shaped wire. This method is effective for complex profiles and can significantly enhance production efficiency.

-

Specialized Dies: Manufacturers may employ custom tooling to create unique shapes. This in-house capability reduces lead times and allows for rapid prototyping, enabling customers to iterate designs quickly.

What Are the Key Finishing Processes for Shaped Wire?

Finishing processes are essential for enhancing the performance characteristics of shaped wire. These processes may include:

-

Surface Treatment: Depending on the application, shaped wire may undergo surface treatments such as coating, polishing, or passivation. These treatments enhance corrosion resistance and improve aesthetic qualities.

-

Cutting and Length Adjustment: Shaped wire can be supplied in various lengths, including cut-to-length options. Precision cutting ensures that the wire meets the exact specifications required by the client.

-

Heat Treatment: For specific applications, heat treatment processes may be employed to achieve desired mechanical properties such as increased strength or improved fatigue resistance.

How Is Quality Assurance Implemented in Shaped Wire Manufacturing?

Quality assurance is a critical component of the manufacturing process, ensuring that shaped wire products meet international standards and customer specifications.

What International Standards Should B2B Buyers Consider?

B2B buyers should look for manufacturers that adhere to recognized international standards such as ISO 9001, which provides a framework for consistent quality management. Industry-specific standards, such as CE marking for products sold within the European Economic Area and API standards for oil and gas applications, are also crucial. These certifications not only signify compliance with safety and quality regulations but also enhance the credibility of the manufacturer.

What Are the Common QC Checkpoints Throughout the Manufacturing Process?

Quality control is integrated at various stages of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection focuses on verifying the quality of raw materials before they enter the production process.

-

In-Process Quality Control (IPQC): Continuous monitoring during manufacturing ensures that the wire adheres to specified tolerances and quality standards. This may involve regular measurements and tests throughout the forming and finishing stages.

-

Final Quality Control (FQC): At this stage, finished products undergo rigorous testing to confirm they meet all specifications. This may involve dimensional checks, mechanical testing, and surface inspections.

Which Testing Methods Are Commonly Used for Quality Assurance?

Several testing methods are employed to validate the quality of shaped wire:

-

Dimensional Inspection: Precision measuring tools are used to ensure that the wire dimensions conform to specifications.

-

Mechanical Testing: Tests such as tensile strength, fatigue life, and corrosion resistance are critical, particularly for applications in demanding environments like aerospace or oil and gas.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection can be utilized to detect internal flaws without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their quality management systems, manufacturing processes, and adherence to industry standards.

-

Requesting Quality Reports: Buyers should ask for documentation detailing the supplier’s quality control processes, including IQC, IPQC, and FQC results, as well as any certifications obtained.

-

Engaging Third-Party Inspectors: Employing third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance practices and product reliability.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control that can impact their procurement process. These may include:

-

Regulatory Compliance: Understanding local regulations and compliance requirements for importing shaped wire is crucial. Ensuring that the supplier’s products meet these regulations can prevent costly delays or rejections at customs.

-

Cultural and Communication Differences: Establishing clear communication channels with suppliers can mitigate misunderstandings regarding quality expectations and specifications. This is particularly important when dealing with suppliers from diverse cultural backgrounds.

-

Logistical Considerations: Quality assurance extends beyond manufacturing to include packaging, transportation, and handling. Buyers should ensure that suppliers have robust logistics practices to maintain product integrity throughout the supply chain.

In conclusion, understanding the manufacturing processes and quality assurance measures for shaped wire is vital for B2B buyers seeking reliable and high-quality products. By focusing on international standards, rigorous quality control checkpoints, and effective supplier verification methods, buyers can make informed procurement decisions that align with their specific needs and industry requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shape wire’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure shaped wire. With its diverse applications across various industries, including aerospace, medical, and industrial sectors, understanding the nuances of sourcing shaped wire is crucial for ensuring optimal performance and cost-effectiveness. Follow these steps to navigate the procurement process efficiently.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline your technical requirements. This includes dimensions, shapes (e.g., triangular, elliptical), and material properties such as corrosion resistance or tensile strength.

– Why it Matters: Precise specifications ensure that the shaped wire meets your application’s functional needs and performance criteria.

– What to Look For: Consult with your engineering team to develop a comprehensive specification sheet that includes tolerances and any special requirements.

Step 2: Research Available Alloys and Materials

Identify the alloys and materials that best suit your application. Common options include stainless steel, titanium, and specialty alloys like Nitinol for shape memory applications.

– Why it Matters: Different materials offer varied properties such as strength, corrosion resistance, and biocompatibility, which can significantly impact the performance of your end product.

– What to Look For: Investigate the specific characteristics of each alloy and consider how they align with your operational requirements.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and quality standards. Request documentation such as company profiles, certifications, and case studies.

– Why it Matters: A reliable supplier not only delivers quality products but also supports your supply chain with expertise and timely delivery.

– What to Look For: Seek references from other businesses in your industry and evaluate their performance history and customer satisfaction rates.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the shaped wire to test in your applications. This step is critical to validate their claims regarding material properties and performance.

– Why it Matters: Testing samples allows you to assess the wire’s compatibility with your production processes and end-use applications before making a larger commitment.

– What to Look For: Evaluate the samples for consistency, adherence to specifications, and any manufacturing defects.

Step 5: Assess Production Capabilities

Inquire about the supplier’s production capabilities, including their ability to produce custom shapes and handle specific volume requirements.

– Why it Matters: Understanding a supplier’s manufacturing capabilities ensures they can accommodate your current and future production needs.

– What to Look For: Ask about their technology, equipment, and lead times, as well as their flexibility in scaling production.

Illustrative image related to shape wire

Step 6: Verify Compliance and Certifications

Ensure that your chosen supplier complies with relevant industry standards and certifications, such as ISO or ASTM.

– Why it Matters: Compliance with industry standards guarantees that the products meet safety and quality benchmarks, reducing the risk of failures in your applications.

– What to Look For: Request copies of certifications and verify their validity through the certifying bodies.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Set up a point of contact for queries, updates, and negotiations.

– Why it Matters: Clear communication helps in addressing potential issues promptly and ensures that all parties are aligned on expectations and timelines.

– What to Look For: Choose suppliers who demonstrate responsiveness and transparency in their communication practices.

By following this step-by-step checklist, you can streamline your procurement process for shaped wire, ensuring that you select a supplier who meets your specific needs while minimizing risks and enhancing operational efficiency.

Comprehensive Cost and Pricing Analysis for shape wire Sourcing

What Are the Key Cost Components in Shaped Wire Manufacturing?

When sourcing shaped wire, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of alloy significantly influences the cost. High-performance materials, such as Nitinol or specialized stainless steels, typically come at a premium due to their enhanced properties, including corrosion resistance and strength.

-

Labor: Skilled labor is essential for the precision required in manufacturing shaped wire. Labor costs vary by region, with countries offering lower wages potentially providing cost advantages, but this must be balanced against quality and expertise.

-

Manufacturing Overhead: This encompasses the costs associated with operating machinery, utilities, and administrative expenses. Efficient production processes can mitigate overhead costs, which is particularly relevant for buyers looking to optimize their total spend.

-

Tooling: Custom shapes often require specialized tooling, which can be a significant upfront cost. In-house tooling capabilities can reduce lead times and costs, making suppliers with this capability more attractive.

-

Quality Control (QC): Ensuring that shaped wire meets strict tolerances necessitates robust QC processes. While this adds to the cost, it is vital for maintaining product integrity, especially in critical applications like aerospace and medical devices.

-

Logistics: Shipping costs can vary significantly based on the mode of transportation, distance, and Incoterms. Proper logistics management can help mitigate these costs and ensure timely delivery.

-

Margin: Suppliers will typically include a margin that reflects their business model, market conditions, and the perceived value of their offerings. Understanding this can help in negotiation.

How Do Volume and Specifications Influence Shaped Wire Pricing?

Pricing for shaped wire is often affected by several factors:

-

Volume/MOQ: Suppliers generally offer better pricing for larger orders. Minimum order quantities (MOQ) can lead to higher per-unit costs for smaller purchases, so buyers should assess their needs carefully.

-

Specifications and Customization: Highly customized shapes or unique specifications can lead to increased costs. Standard shapes are often more economical, so buyers should weigh the necessity of custom profiles against budget constraints.

-

Material Selection: The chosen alloy not only impacts the material cost but also affects processing and tooling requirements. Buyers should consider the performance needs of their applications when selecting materials.

-

Quality and Certifications: High-quality shaped wire often requires certifications (e.g., ISO, ASTM), which can add to costs. Buyers should evaluate whether the certification aligns with their application requirements.

-

Supplier Factors: Supplier reputation, location, and capabilities (like in-house tooling) can also influence pricing. Building relationships with reliable suppliers can lead to better terms and pricing.

-

Incoterms: The agreed terms of shipment can significantly affect the final cost. Understanding Incoterms helps buyers manage risks and costs associated with shipping and logistics.

What Negotiation Strategies Can Optimize Costs for International Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but all associated costs, including logistics, tariffs, and potential downtime due to quality issues. This holistic view can lead to more informed purchasing decisions.

-

Negotiate Terms: Building long-term relationships with suppliers can lead to more favorable terms. Consider negotiating for better pricing on larger orders or exploring flexible payment terms.

-

Be Informed: Understanding market conditions, pricing trends, and supplier capabilities can empower buyers during negotiations. Keeping abreast of industry developments ensures that buyers can negotiate from a position of strength.

-

Explore Multiple Suppliers: Engaging with multiple suppliers can help compare pricing and service levels. This competitive approach can yield better pricing and terms.

-

Consider Currency Fluctuations: For international transactions, currency exchange rates can impact costs. Buyers should be aware of these fluctuations and consider hedging strategies where applicable.

In conclusion, while the costs associated with shaped wire sourcing can vary widely based on numerous factors, buyers can optimize their procurement strategies through informed decision-making, negotiation, and a focus on total cost considerations. Always consult with suppliers for the most accurate and updated pricing, as market conditions can change rapidly.

Alternatives Analysis: Comparing shape wire With Other Solutions

When evaluating manufacturing solutions for specific applications, B2B buyers often consider various alternatives to shaped wire. Understanding these alternatives is crucial for making informed decisions that align with production needs and budget constraints. This analysis compares shaped wire against two viable alternatives: traditional round wire and molded components.

| Comparison Aspect | Shape Wire | Traditional Round Wire | Molded Components |

|---|---|---|---|

| Performance | High precision with custom shapes | Good for standard applications | Excellent for complex geometries |

| Cost | Potentially higher due to custom design | Generally lower costs | Higher initial costs, variable based on design complexity |

| Ease of Implementation | Requires specialized tooling | Widely available and easy to source | Complex manufacturing process |

| Maintenance | Low, as it minimizes machining | Moderate, depending on application | Varies greatly based on material |

| Best Use Case | Applications requiring specific shapes and tolerances | General applications in various industries | High-volume production of intricate parts |

How Does Traditional Round Wire Compare to Shape Wire?

Traditional round wire is a common alternative used in many industries due to its availability and lower cost. It is suitable for applications that do not require complex geometries or specific cross-sectional shapes. However, while round wire is cost-effective and easy to source, it often necessitates additional machining or fabrication to achieve the desired specifications. This can lead to increased production time and costs, especially in high-precision applications.

What Advantages Do Molded Components Offer Over Shape Wire?

Molded components present another alternative, particularly for high-volume production of intricate shapes. They can be designed to meet specific requirements, allowing for complex geometries that shaped wire may not accommodate. However, the initial investment in molds and the complexity of the manufacturing process can result in higher costs. Additionally, molded components may not offer the same level of customization in terms of material properties as shaped wire does. They are best suited for applications where large quantities of identical parts are needed, and the upfront costs can be justified.

How Can B2B Buyers Choose the Right Solution?

Selecting the appropriate solution depends on various factors, including the specific application, production volume, and budget constraints. For high-precision applications that require specific shapes and minimal post-processing, shaped wire is often the best choice despite a potentially higher cost. Conversely, if the application allows for standardization and cost savings, traditional round wire may suffice. For projects focused on high-volume production of complex parts, molded components could be the ideal solution, albeit with higher initial costs.

In conclusion, B2B buyers must carefully evaluate their unique needs against the strengths and weaknesses of each alternative. By doing so, they can select the most effective solution to enhance their manufacturing processes and achieve optimal results.

Essential Technical Properties and Trade Terminology for shape wire

What Are the Key Technical Properties of Shape Wire?

Understanding the technical specifications of shape wire is crucial for B2B buyers to ensure they select the right product for their applications. Here are some critical specifications to consider:

-

Material Grade

The material grade of shape wire, such as stainless steel, titanium, or Nitinol, directly influences its performance characteristics, including strength, corrosion resistance, and biocompatibility. For instance, Nitinol is favored in medical applications due to its shape memory properties, while stainless steel is commonly used in industrial settings for its durability. Selecting the appropriate material grade helps buyers meet specific application requirements while optimizing costs. -

Dimensional Tolerance

Dimensional tolerance refers to the allowable variation in the dimensions of the wire, including its diameter and cross-sectional shape. Tight tolerances are essential in applications where precision is critical, such as in aerospace or medical devices. Ensuring that the shape wire meets these tolerances can minimize machining costs and improve overall product quality, making it a key specification for buyers focused on efficiency and reliability. -

Surface Finish

The surface finish of shape wire can affect its functionality, especially in applications requiring smooth surfaces for reduced friction or improved adhesion. Common surface finishes include polished, coated, or passivated. Buyers should consider the required surface finish for their specific applications, as it can influence both performance and aesthetic qualities. -

Cross-Sectional Shape

Shape wire is available in various cross-sectional shapes, including round, flat, square, and custom profiles. Each shape serves distinct purposes; for example, flat wire is often used in electrical applications due to its surface area for contact. Understanding the specific advantages of each shape can help buyers select the most suitable wire for their needs. -

Alloy Composition

The alloy composition of shape wire can significantly affect its mechanical properties, such as tensile strength, fatigue resistance, and thermal stability. With over 160 available alloys, buyers can tailor their selection based on the specific demands of their applications. Knowledge of alloy composition allows for better predictions of performance and longevity in various environments.

What Are Common Trade Terms in the Shape Wire Industry?

Familiarity with industry jargon can enhance communication and negotiation processes for B2B buyers. Here are some key terms:

Illustrative image related to shape wire

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to source components that fit seamlessly into their systems. -

MOQ (Minimum Order Quantity)

The MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers to consider when budgeting and planning inventory, as it can affect cost efficiency and supply chain management. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price proposals from suppliers for specific quantities and specifications. Issuing an RFQ allows buyers to compare offerings from different manufacturers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in international transactions, including the transfer of risk and costs associated with shipping. Familiarity with Incoterms helps buyers navigate international logistics effectively. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is critical for buyers to align their production schedules and manage inventory levels effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing shape wire, ultimately leading to improved product performance and operational efficiencies.

Navigating Market Dynamics and Sourcing Trends in the shape wire Sector

What Are the Current Market Dynamics and Key Trends in the Shape Wire Sector?

The shape wire sector is experiencing robust growth, driven by the increasing demand for specialized components across various industries, including aerospace, medical, and automotive. International B2B buyers, particularly in emerging markets such as Africa, South America, and the Middle East, are increasingly seeking customized solutions that minimize machining costs and enhance operational efficiency. The rise of Industry 4.0 technologies, such as advanced manufacturing techniques and automation, is reshaping the landscape, enabling manufacturers to produce highly tailored wire profiles with precision and reduced lead times.

One of the significant trends is the shift towards semi-finished wire solutions that allow for net or near-net shapes, thereby reducing scrap and waste. This trend is particularly appealing to businesses looking to optimize their supply chain and lower costs. Additionally, the growing adoption of digital platforms for sourcing and procurement is facilitating easier access to suppliers and fostering competitive pricing, especially for B2B buyers in regions like Vietnam and Brazil.

Moreover, the focus on sustainability is becoming paramount. Buyers are increasingly aware of the environmental impact of their sourcing decisions, prompting them to seek suppliers that offer eco-friendly materials and practices. This shift not only aligns with global sustainability goals but also appeals to end consumers who prioritize ethical consumption.

How Is Sustainability and Ethical Sourcing Influencing the Shape Wire Sector?

Sustainability and ethical sourcing are no longer optional; they are essential components of the modern supply chain in the shape wire sector. The environmental impact of manufacturing processes, particularly in metalworking, has led to increased scrutiny from consumers and regulators alike. B2B buyers are now prioritizing suppliers who can demonstrate a commitment to reducing their carbon footprint and using sustainable materials.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for suppliers who adhere to international labor standards and promote fair trade practices. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming critical factors in supplier selection. Furthermore, the use of “green” materials, including recycled metals and eco-friendly coatings, is gaining traction, offering businesses a way to enhance their sustainability credentials while meeting customer demands.

By integrating sustainable practices into their procurement strategies, B2B buyers can not only mitigate risks associated with environmental regulations but also enhance their brand reputation. This approach can lead to long-term cost savings and a more resilient supply chain, particularly for businesses operating in regions where environmental regulations are tightening.

What Is the Brief Evolution and History of Shape Wire for B2B Buyers?

The evolution of shape wire can be traced back to the early days of metallurgy, where the need for specialized wire products emerged to meet specific application requirements. Over the decades, advancements in manufacturing techniques have significantly transformed the shape wire sector. Initially, wire was produced in standard shapes and sizes, but as industries evolved, so did the demand for customized solutions.

The introduction of advanced rolling and drawing technologies in the latter half of the 20th century enabled manufacturers to create a wider variety of shapes and profiles with enhanced precision. This innovation paved the way for the development of shape wire products tailored for critical applications in aerospace, medical devices, and industrial machinery. Today, the sector continues to evolve with the integration of digital technologies, allowing for rapid prototyping and custom design, which is essential for meeting the diverse needs of international B2B buyers.

Understanding this historical context is crucial for buyers looking to source shape wire products, as it highlights the industry’s capacity for innovation and adaptability in response to changing market demands.

Illustrative image related to shape wire

Frequently Asked Questions (FAQs) for B2B Buyers of shape wire

-

1. How do I select the right shaped wire for my application?

Choosing the appropriate shaped wire involves understanding your specific application requirements, including mechanical properties, dimensions, and environmental conditions. Start by consulting with your engineering team to define the essential characteristics, such as strength, corrosion resistance, and flexibility. Then, engage with potential suppliers to review their capabilities and past projects to ensure they can meet your specifications. Consider requesting samples or prototypes to validate the wire’s performance in your application. -

2. What are the benefits of using custom-shaped wire versus standard wire?

Custom-shaped wire offers significant advantages, including optimized designs tailored to your product needs, reduced machining costs, and improved material utilization. By achieving near-net shapes, you can minimize waste and enhance manufacturing efficiency. Additionally, custom shapes can provide unique functionalities that standard wires cannot, such as better fit in assembly applications or enhanced performance in specific environments. Collaborating with suppliers who specialize in custom solutions can further enhance your product development process. -

3. What are the minimum order quantities (MOQs) for shaped wire?

Minimum order quantities for shaped wire can vary significantly between suppliers and depend on the complexity of the design and materials used. Typically, MOQs may range from a few kilograms to several tons, depending on the supplier’s production capabilities and the specific wire profile required. It is advisable to discuss your requirements directly with suppliers to understand their MOQ policies and explore options for lower MOQs, especially if you are testing a new product or entering a new market. -

4. How can I ensure the quality of the shaped wire I purchase?

To ensure quality, choose suppliers that adhere to recognized industry standards and certifications. Request documentation that outlines their quality assurance processes, such as material testing, dimensional checks, and metallurgical analysis. Additionally, consider conducting audits or site visits to assess their production facilities and practices. Establishing a clear communication channel for ongoing quality feedback will also help maintain high standards throughout the supply chain. -

5. What payment terms are typically offered for international purchases of shaped wire?

Payment terms can vary based on supplier policies, order size, and the relationship built with the supplier. Common terms include advance payments, net 30 or 60 days, and letters of credit for larger transactions. It’s crucial to negotiate terms that work for both parties and ensure that they align with your cash flow requirements. Additionally, consider discussing potential discounts for early payment or bulk orders, which can provide financial flexibility. -

6. What logistical considerations should I be aware of when sourcing shaped wire internationally?

When sourcing shaped wire from international suppliers, consider factors such as shipping methods, lead times, and customs regulations. Choose a reliable logistics partner familiar with the shipping routes and import/export laws of your region. Ensure that your supplier provides accurate documentation to facilitate smooth customs clearance. Additionally, factor in potential delays due to geopolitical issues or transportation disruptions, and maintain clear communication with your supplier regarding delivery schedules. -

7. How can I vet suppliers for shaped wire effectively?

Vetting suppliers involves assessing their production capabilities, quality control processes, and customer service. Start by reviewing their website and product offerings, followed by seeking references from existing clients. Request samples to evaluate product quality, and inquire about their experience with similar projects. Additionally, consider their certifications, industry reputation, and responsiveness to inquiries as indicators of reliability and professionalism. -

8. What are the typical applications for shaped wire in various industries?

Shaped wire is versatile and used across multiple industries, including aerospace for structural components, medical for catheter wires, and oil & gas for filtration systems. In the automotive sector, shaped wire can be found in springs and fasteners, while in consumer products, it may be used in electronic devices. Identifying the specific needs of your industry will help in selecting the right shaped wire and collaborating effectively with your supplier to meet those demands.

Top 8 Shape Wire Manufacturers & Suppliers List

1. Ulbrich Shaped Wire – Custom Wire Solutions

Domain: ulbrichshapedwire.com

Registered: 2010 (15 years)

Introduction: Ulbrich Shaped Wire offers a variety of wire products including shaped wire, round wire, flat wire, and square wire. Their capabilities include rolling, drawing, annealing, shaping, hot-rolled wire, cut to length, and packaging. They produce custom wire profiles to exacting cross-sectional dimensions, minimizing machining costs. The company has over 50 years of experience and offers more than 160 …

2. FW Metals – Shaped Wire Solutions

Domain: fwmetals.com

Registered: 1996 (29 years)

Introduction: Shaped wire allows for versatility with nonstandard profiles including triangles, crescent shapes, and wires with continuous helical grooves. Manufactured in various alloys using specialized tooling and processing, shaped wire decreases overall cross-sectional area. Standard shapes include: D-wire (0.0381 mm x 0.1016 mm to 1.016 mm x 2.032 mm), Crescent wire (0.147 mm x 0.254 mm to 1.016 mm x 1.52…

3. AMETEK – Custom Shaped Wire Solutions

Domain: ametek-ct.com

Registered: 2011 (14 years)

Introduction: Shaped Wire Manufacturers – Custom Shapes for Shaped Wire Applications. AMETEK engineers high tolerance custom shaped wire and flat wire products in a wide range of standard shapes, including round, square, and flat wire. The range of alloys includes high purity wrought powder metallurgy alloys (nickel wire, Pfinodal® wire, Sealvar®, Nickel Irons) and materials from various metal wire manufacturer…

4. Parawire – Shaped Wire

Domain: parawire.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Shaped Wire”, “price_range”: “$8.99 – $70.85”, “customer_rating”: “4.80 out of 5 based on 5 customer ratings”, “available_shapes”: [“Half Round”, “Square”, “Twisted Square”], “available_gauges”: [“16 ga”, “18 ga”, “21 ga”], “color_options”: [“Antique Copper”, “Black”, “Bronze”, “Champagne Gold”, “Gold”, “Natural”, “Rose Gold”, “Silver”, “Solid Faux Gold”, “Titanium”, “Vintage Bro…

5. Ulbrich – Precision Shaped Wire Solutions

Domain: ulbrich.com

Registered: 1995 (30 years)

Introduction: Shaped Wire produced to exacting cross-sectional dimensions in a dedicated facility. Minimizes or eliminates costly machining by being net or near net in shape. Available alloys include Stainless Steel, Fine Wire, Nitinol, Cobalt, MP35N, L605, 304V, 304LVM, 316LV, and Tungsten. Applications include Gaskets & Seals, Header Bar, Medical Shapes, Orthodontic Wire, Wedge Wire, Jet Engines, Heat Exchang…

6. United Wire Company – Custom-Made Shaped Wire

Domain: unitedwirecompany.com

Registered: 1999 (26 years)

Introduction: United Wire Company specializes in custom-made shaped wire, including flat wire, square wire, and profile shaped wire. They offer a variety of alloys such as stainless steels, cobalt alloys, nickel alloys, carbon alloys, copper alloys, and aluminum. Their capabilities include a fast track program, custom tooling, heat treating, and packaging. They serve multiple industries, including aerospace, me…

7. Alloy Wire – Shaped Profile Wire Range

Domain: alloywire.us.com

Introduction: Shaped Profile Wire Range from 0.0157″ (0.4mm) to 0.394″ (10mm). Order quantity ranges from 10 ft (3 metres) to 10,000 lbs (3 tonnes). Available shapes include Angled Arc, Chamfered, Channel, Double D, D shaped, Flat, Half Round, Oval, Rail, Rectangle, Square, T Shaped, Trapezoidal, Wedge. Available alloys include Inconel (e.g., Inconel® 600, 601, 617, 625), Nimonic (e.g., Nimonic® 75, 80A), Incol…

8. Rings & Things – Hexagonal Wire

Domain: rings-things.com

Registered: 1996 (29 years)

Introduction: Hexagonal wire with 6 sides for maximum reflection, available in anti-tarnish brass and anti-tarnish silver. Sizes range from 16-gauge (thinner) to 12-gauge (thicker). Suitable for wire wrapping and creating bangle bracelets using the 3D Bracelet Jig. Fits Artistic Wire large crimp tubes for easy finishing. Other wire shapes available include half-round and square wire, ideal for wire banding and …

Strategic Sourcing Conclusion and Outlook for shape wire

As global industries increasingly rely on specialized materials, the strategic sourcing of shaped wire has become essential for manufacturers aiming to enhance efficiency and reduce costs. By partnering with experienced suppliers who offer custom wire profiles, businesses can achieve net or near-net shapes, minimizing waste and machining expenses. The availability of diverse alloys, tailored dimensions, and precision manufacturing capabilities allows for the development of products that meet specific application requirements across sectors such as aerospace, medical, oil and gas, and consumer goods.

International buyers from regions like Africa, South America, the Middle East, and Europe should prioritize suppliers with robust logistical support and metallurgical expertise, ensuring seamless integration into their supply chains. The future of shaped wire is promising, with ongoing advancements in technology and materials driving innovation.

Engaging with suppliers who are not only vendors but also partners in research and development will empower businesses to explore new applications and improve product performance. As you consider your next procurement decision, take action now to leverage the advantages of strategic sourcing in shaped wire and secure a competitive edge in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.